Abstract

This review article specifically focuses on today’s cutting-edge technology i.e., the cold gas dynamic spray coating process, which is a relatively new technique in the field of orthopedics and antibacterial coatings. Cold gas dynamic spray coating (CGDS) has many advantages over conventional high-temperature processes, such as cost-effectiveness, suitability for oxygen-sensitive materials, and sustainable environmentally-friendly properties and functionality. Powdered form feedstock material is used in this process and accelerated supersonically onto the appropriate substrate without melting. The deposition of pure ceramic deposits, such as hydroxyapatite, remains a challenge. Therefore, the authors attempt to analyze more than 100 design, experimental, numerical, and statistical-based case studies which include the challenges and future perspective of the cold gas dynamic spray coating process for biomedical applications. Further, an inclusive evaluation is carried out related to bio-implants and the development and optimization of thermal spray coatings, with a focus on the emerging CGDS coating systems for orthopedics and antibacterial purposes. By analyzing the process parameters involved in CGDS, this review intends to provide insights into the critical factors affecting the quality and properties of the coatings produced, including substrate preparation, powder characteristics, spraying conditions, and post-treatment. The results of this review could help researchers optimize the CS technique to produce more reliable and efficient bio-implants, with improved biocompatibility and mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The increasing number of elderly people in society has had a significant impact on healthcare due to the rise of chronic diseases. It is projected that by 2050, 20% of the European population will be over the age of 65, compared to 10% currently [1]. While in the past, diseased tissue was commonly removed as a way to marginally improve quality of life, advancements in biomedical science have helped to improve human survivability, which can lead to a need to replace tissues [2]. The prostheses are becoming more common to replace damaged or degenerated parts of the skeletal system. It is a critical part of the human skeletal system. However, conventional prostheses have their drawbacks, such as socket-related discomfort, difficulties in donning the prosthesis, and mobility issues. While scientific disciplines collaborate to develop new materials with better properties, modifying conventional prosthetic materials through osteointegration can still offer many opportunities to improve bone resorption and decrease allergenic responses. Additionally, since prosthesis replacement surgery is often costly and invasive, any solution that can extend the lifespan of prostheses would be highly desirable to the clinical community.

The field of biomaterials has made significant progress over the past 60–70 years [3, 4]. Biomaterials are nonliving materials employed as medical devices that work with biological processes; they were first characterized by Willam [5]. Biomaterials for medical applications have progressed across three generations. In bioimplants, there are two primary concerns: biocompatibility and structural compatibility [6]. Biocompatibility refers to a material’s capability to prompt an appropriate host response in a specific application. This concept is closely connected to biosafety and biostability, which aim to prevent chronic inflammation, infection, or dysfunction of the cellular and tissue matrix caused by the material [5, 7]. On the other hand, structural compatibility is related to mechanical properties, which is especially critical for prosthetic biomaterials.

With the ever-increasing demand for high-performance biomedical coatings, various coating techniques are being used to produce functional membranes. These techniques can be categorized into chemical and non-chemical methods. Chemical methods involve the use of chemical reactions to deposit a coating on a surface. These reactions typically involve the use of chemicals such as solvents, acids, bases, or other reactants. Chemical methods can be used to deposit coatings of various types, including organic and inorganic coatings. Non-chemical methods, on the other hand, do not involve chemical reactions during the coating deposition. These methods can include physical processes such as thermal spraying, electroplating, or physical vapour deposition (PVD), where a material is deposited onto a surface through physical means such as heating, melting, or vaporizing [8, 9]. Both chemical and non-chemical methods have their advantages and disadvantages. Chemical methods can produce coatings that are highly uniform and have excellent adhesion to the substrate, but they may also be more complex and require specialized equipment and safety measures [10]. Non-chemical methods, while simpler and more versatile, may not provide the same level of coating uniformity or adhesion. Several factors, including the substrate material, the desired coating properties, the available budget, and the technical feasibility of the potential coating processes, all play a role in determining which coating technique will be used [11, 12].

Henceforth, it shows that there is a need for a collective study that discussed the future perspective and challenges during the cold gas dynamic spray (CGDS) coating technique. Accordingly, the authors focused on reviewing the non-chemical methods of functional coatings for biomedical device applications, with a particular emphasis on thermal spray technologies, including the cold gas dynamic spray (CGDS) coating process, which involves mechanical anchoring and metallurgical bonding of accelerated solid particles on the substrate material. By identifying critical knowledge gaps and potential applications, we hope to guide further translational research in this area.

2 Thermal spray technologies

Thermal spraying is a type of coating technology that employs thick layers of metallic, plastic, composite, ceramic, cermet, alloys, and plastics onto a base material. In contrast to additional coating techniques for example CVD, PVD, electroplating, and cladding, thermal spraying is capable of rapidly producing thick coatings over large areas. These coatings typically range from 50 microns to 1 mm in thickness [13].

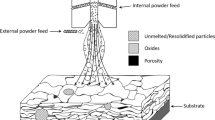

The coating material, often supplied as a granular powder or solid wire, is heated to a molten, semi-molten, or solid state during the process. Substrate-bound tiny particles are then propelled toward the substance. At the time of impact, the heated particles flatten and anchor to the substrate surface, as well as to one another [14, 15]. This results in the buildup of a laminar structure on the surface, as depicted in Fig. 1.

There are several types of thermal spray coatings, including flame, plasma, wire arc, detonation, high-velocity oxy-fuel, warm, and cold spraying [16].

2.1 Plasma spraying

Plasma spraying is a surface engineering technique that involves the use of a high-energy plasma jet to deposit a coating material onto a substrate surface. The coating material is heated and melted in a plasma arc before being blasted onto the surface of the substrate in a high-velocity gas stream. Metals, ceramics, and polymers are just some of the many possible substrates for the many different coating materials [17].

The plasma arc used in plasma spraying is generated by ionizing a gas, typically argon or nitrogen, in a plasma torch. The plasma arc produces a stream of charged particles, including ions, electrons, and neutral species, that are propelled toward the coating material. When the charged particles collide with the coating material, they transfer energy and momentum, causing the material to melt and atomize. The gas stream carries the resulting fine particles to the substrate surface, where they collide and solidify to form a thick, tenacious covering [18]. The unique characteristics of plasma spraying make it an attractive technique for a wide range of applications, including biomedical implants, wear and corrosion resistance, and thermal barrier coatings. The coatings produced by plasma spraying can exhibit high hardness, toughness, and thermal stability, making them suitable for use in harsh environments. Coatings can be made with exact control over thickness, content, and microstructure with this method, making them suitable for a wide variety of applications [19]. Despite its advantages, plasma spraying does have some limitations. The high temperatures and velocities involved in the process can lead to the formation of defects such as cracks and pores, that influence the characteristics of the coatings. Additionally, the high-energy plasma jet can cause thermal damage to some substrate materials.

2.2 Detonation spraying

Detonation spraying, also referred to as detonation gun or D-gun spraying, is a thermal spray method utilized to apply coatings on various substrates. The process employs a combustion-driven shock wave to propel particles, typically ranging from 1 to 50 micrometers, onto the surface of the substrate. Applications needing strong wear resistance, corrosion protection, and thermal insulation are good candidates for this method due to the dense coatings produced by the high velocity of these particles, which have low porosity. The distance between the nozzle and the substrate, the kind and size of the feedstock material, the fuel and oxidizer used for the combustion, the timing of the ignition, and so on are all important factors in detonation spraying. Although detonation spraying is recognized for its high-quality coatings, it poses some challenges, such as high levels of particle heating, the formation of high residual stresses in coatings, and a limited material processing range. Nevertheless, detonation spraying remains a preferred choice for numerous industrial applications, including biomedical engineering, aerospace, and automotive sectors [20].

2.3 High-velocity oxygen fuel spraying

Using a fuel gas, usually propane or hydrogen, and oxygen in a high-pressure chamber, high-velocity oxygen fuel (HVOF) spraying creates a thermal spray coating. The substrate surface to be coated is aimed towards the end of a supersonic jet of hot gases produced by the combustion. After being injected into the gas stream, the coating material—typically a powder—is heated and accelerated in the direction of the substrate. When the molten particles collide, they solidify into a dense and tenacious coating [21].

The HVOF process is characterized by its high flame temperatures, typically ranging from 2500 to 3500 degrees Celsius, and high particle velocities, ranging from 500 to 1200 m per second. These conditions result in coatings with high hardness, toughness, and wear resistance, making HVOF an attractive coating technology for a wide range of industrial applications, including aerospace, automotive, and energy production [15]. HVOF coatings have several advantages over other thermal spray coating processes. The high particle velocities and impact energies produce dense and low-porosity coatings with excellent adhesion to the substrate. Additionally, the high process temperatures allow for the deposition of a wide range of materials, including metals, ceramics, and polymers, with precise control over their microstructure and composition. However, HVOF coatings also have some limitations. The high process temperatures can cause thermal stress and distortion of the substrate material, particularly when applied to thin and delicate components. Additionally, the process can generate high levels of noise and dust, posing health and safety hazards to operators.

2.4 Warm spraying

The process of warm spraying involves mixing nitrogen gas with combustion gas to reduce its temperature and is a modified version of HVOF spraying. Warm spraying provides greater coating efficiency than HVOF, despite the mixture gas containing unreacted hydrocarbons, water vapour, and oxygen [22]. This is because chemical reactions and the melting of the feed powder are slowed down by the lower temperatures. Coating materials like titanium, metallic glasses, and polymers that are easily damaged or oxidized at high temperatures benefit greatly from warm spraying [23].

2.5 Flame spraying

At the center of an oxy-acetylene gas flame, the wire is heated to melting temperature. Molten metal is atomized with nitrogen or air and then battered onto the surface of the substrate. Gear selectors, piston rings, and synchronizing rings in automobiles are coated with molybdenum via flame spraying because of the material’s exceptional resistance to wear [24]. For continuous coating over a larger area, wire spools are used, and for small-area applications, rods are used as feedstocks.

2.6 Wire arc spraying

In this process, an arc is produced by bringing two metal wires close and then passing a high current through them, generating an arc. Which can be continuously sustained by continuously feeding the metal wires. The wires are melted at the tip of the arc and propelled onto the workpiece surface using an atomizing gas like compressed air. This process is known for its high-performance coating capabilities [25], [26]. The electrically conductive wire is used as a feedstock. It is utilized in various applications, including providing anti-corrosion protection, coating vessels, applying bond coatings, and lining cylinders.

3 Cold Gas Dynamic Spray (CGDS)

The unique cold spray process is a method that involves depositing one material over another substrate. This process uses particles with high kinetic energy, and pressurized carrier gas assists in propelling particles to velocities extending between 300 and 1400 m/s. The size of the powders used for coating is usually 5–50 μm. The high-pressure cold spray process involves heating the compressed gas to a temperature of 1000 °C, while the low-pressure cold spray process heats the gas up to 550 °C [27], [28]. During the expansion of particles through the diverging section of the nozzle, their temperature decreases, resulting in their solid-state deposition. One advantage of this process over other spray deposition techniques is the generation of residual compressive stresses. Cold spray technology has various applications in the manufacturing sector, especially for advanced coatings and the repair of parts, and also in the additive manufacturing sector [29]. It helps avoid defects such as heat-affected zones, evaporation, oxidation, release of gases, residual stresses, and shrinkage porosity.

3.1 Systems of cold spraying

The cold spray technology includes two types of systems: high-pressure and low-pressure cold spray. The Cold Spray technology has two types of equipment: portable (manual) or fixed (robotic). Both types consist of several main components, including a supersonic nozzle (De-Laval nozzle), a gas compressor, a gas heater, a powder feeder mechanism, and a mechanism to monitor and control the spray parameters (as shown in Fig. 2).

Cold spray apparatus (a) Low-pressure cold spray setup, (b) High-pressure cold spray setup [30]

Despite differences in construction and gas pressure, both systems have a similar operating principle. The differences between the two processes are summarized in Table 1.

3.2 Process parameters

To ensure the success of the cold spray process, there are some crucial factors to consider. Factors such as particle velocity, nozzle shape, carrier gas type and pressure, temperature, particle size, and substrate surface roughness can influence the outcome of the process. It is important to carefully regulate and observe these factors throughout the cold spray process.

3.2.1 Particle velocity

Particle velocity (Vp) is a crucial factor in the cold spray process, and it can be affected by particle size, mass, and morphology. Particle velocity is a critical parameter that affects both the bonding strength between the particles and substrate and the extent of substrate surface erosion. The minimum particle velocity required for the adhesion of particles to a substrate in a particular medium is called the critical velocity (Vc). If the Vp is insufficient, the feedstock particles may rebound from the surface without forming a continuous coating or deposit. Conversely, when Vp is high, it can lead to surface erosion by solid particles, similar to the process of shot blasting. Once the Vp surpasses the critical value, the particles begin to deform plastically, adhere to the substrate, and form a coating layer. Metals such as aluminium, nickel, iron, and copper typically have critical velocities that range from 560 to 700 m/s [32]. Furthermore, it is commonly accepted that increased particle velocities result in reduced dwell times, which leads to decreased particle heating due to a shorter exposure time. Many firearm designs utilize a converging or diverging (De Laval) nozzle to achieve supersonic expansion, which leads to an increase in particle velocity [33]. Particle velocity and critical velocity can be calculated using equations (i) and (ii) respectively.

Vp = [(7.5 x 104) (B/ρ)] 0.5 (i)

Where, B - Brinell hardness number of substrate and ρ - Density

Vc = 667- 0.014ρ + 0.08(Tm - Tr ) + 10− 7 σ u – 0.4(Ti - Tr ) (ii)

Where, Ti - Impact temperature, Tm - Melting temperature, Tr - Reference temperature (293 K), ρ – Density, σ u - Yield stress.

3.2.2 Nozzle geometry

The geometry of the nozzle utilized can impact the velocity of the gas in a cold spray. This nozzle geometry is a critical factor in determining the velocity at which the particles impact the surface of the substrate. The De-Laval nozzle functions by directing heated gas through the nozzle to accelerate material particles to supersonic speeds. The maximum Mach number achievable is determined by the nozzle geometry, which is not dependent on parameters such as pressure and temperature [34]. Expanding the diverging portion of the nozzle is necessary to achieve a higher Mach number; however, this is restricted by the shocks that are created by the intrusion of air, which is caused by the low static pressure at the nozzle exit [35]. The shocks that occur can cause a reduction in particle velocity, leading to a decrease in Mach number and an increase in system density, entropy, static pressure, and temperature.

3.2.3 Carrier gas

Regulating the particle velocity by selecting the carrier gas in the cold spray process can impact the microstructure of coatings by controlling the impact energy of the particles. The main factors that impact particle velocity are low molecular weight and high gas constant, and therefore carrier gases such as helium, nitrogen, and air are commonly used in cold spray [36]. Due to its low molecular weight and higher gas constant, helium is considered the most suitable carrier gas for achieving high particle velocity during the cold spray process. Although helium is effective in achieving high particle velocity, its practicality in the cold spray process is restricted by its cost and availability, which can make it commercially unfeasible. To balance cost and effectiveness and achieve high particle velocity, a blend of helium and nitrogen or air is frequently employed. The use of a mixture of helium and nitrogen or air has been found to offer various advantages, including enhanced deposit densification, increased productivity, and a higher operating temperature.

3.2.4 Pressure and temperature

When it comes to the coating quality and deposition efficiency, pressure is a crucial component in the cold spray process. Low-pressure cold spraying and high-pressure cold spraying are two separate varieties of the cold spray method. Low-pressure cold spraying uses compressed air at pressures of 0.5 MPa to 1 MPa, whereas high-pressure cold spraying use helium or nitrogen at pressures exceeding 1.5 MPa [17]. Helium and nitrogen are the common carrier gases used in the cold spray process. Selecting the appropriate pressure and carrier gas are crucial factors that affect the deposition efficiency, coating morphology, and microstructure of the coatings produced using the cold spray process [37]. During high-pressure cold spraying, the carrier gas is blended with the feedstock powders in a pre-chamber zone before being introduced upstream of the nozzle. In low-pressure cold spraying, the materials are introduced perpendicularly into the diverging segment of the nozzle. The spray gun heats the gas inside. On the other hand, in high-pressure cold spraying, the carrier gas undergoes preheating in a distinct heating section prior to its introduction into the spray gun. Certain materials, such as titanium, copper, Inconel, tungsten carbide cobalt, and MCrAlY compounds, require deposition at high pressures of over 3 MPa and temperatures ranging from 500–1000° C [38]. Deposition of aluminium, tin, and oxides, on the other hand, is performed at pressure levels below 3 MPa and temperatures ranging from 20°-750° C.

3.2.5 Substrate surface roughness

The surface topology and temperature of the substrate play a crucial role in determining the adhesion of cold spray particles. An oxide-free and clean surface is preferred to achieve good bonding. For metals, grit blasting, sandblasting, grinding, or polishing are commonly used surface preparation techniques. For polymers, cleansing, and degreasing are the standard procedures [39]. An activated surface allows for better particle adhesion, while a non-activated surface promotes particle recoil. The negative effects of surface roughness on mechanical interlocking and bonding are reduced or eliminated when high-impact velocities result in particle distortion on rough substrates [40].

3.2.6 Cold spray material

Cold spray deposition is a flexible method that offers the ability to deposit a wide range of materials, such as metals, ceramics, composites, and polymers. Additionally, it can be utilized to create biomaterial coatings with various functionalities. By meticulously adjusting the process parameters, it is possible to preserve the desirable characteristics of feedstock powder, such as chemical composition, amorphous structure, corrosion and wear-resistant properties, hardness, and bioactivity, which can help functionalize the substrate materials through as-sprayed coatings [41, 42]. The selection of materials is crucial for achieving high deposition efficiency, with lighter particles of lower density being more easily accelerated. Particle velocity is inversely proportional to particle size, and typically, particles smaller than 100 μm are used. However, using particle sizes less than 10 μm or nanoparticles can result in nozzle clogging, poor deposition, and particle self-agglomeration due to the bow shock effect. Additionally, particle morphology plays an important role, with irregularly shaped particles experiencing greater acceleration and achieving higher speeds due to greater drag forces [40, 43]. The average range of particle diameters utilized in CGDS tests for various materials is presented in Table 2.

3.2.7 Metallic materials

Metallic coatings are widely utilized in biomedical devices owing to their exceptional biological, mechanical, and chemical characteristics. Among thermal spray methods, the cold spray has emerged as an efficient technique to deposit metallic coatings with exceptional quality, particularly for heat-sensitive materials. Titanium is a popular choice for medical implants due to its outstanding biocompatibility, non-toxic properties, and mechanical strength [44]. Various types of titanium powders with different shapes have been cold sprayed to achieve different types of coatings [42]. For example, angular titanium powder has been used to create porous coatings, while coral-shaped titanium particles have been utilized to produce highly dense coatings [45]. Spherical, medium-sized titanium powders have been found to be the best for cold spraying, resulting in high deposition efficiency and low-porosity coatings near the substrate. Copper coatings have gained significant attention due to the increase in antimicrobial resistance (AMR) and the effectiveness of copper in killing various viruses, including SARS-CoV-2 [46]. Cold spray is a suitable method for copper coating applications, producing dense coatings with minimal oxides or inclusions required for antibacterial, anticorrosion, and conductive copper coatings. Both the size distribution and oxygen content of particles can have an impact on the formation of copper coatings as well as their deformation behaviour. Cold spraying of smaller particles onto a rigid ceramic surface can result in limited deformation of copper. Tantalum is a valuable material for implants due to its corrosion resistance and biocompatibility, but it is expensive to use in large amounts [47,48,49]. Instead, researchers have explored the use of tantalum coatings produced through cold spray technology. Studies have found that different shapes of tantalum particles can be used to create coatings, with narrow size distributions and angular particles producing dense coatings without pores. Preheating the gas in the process softens the tantalum, leading to plastic deformation and tight bonds between splats. However, highly dense coatings with high deposition efficiency and microhardness can also be achieved using porous tantalum produced by the HDH process [50]. Angular tantalum particles did not work well for deposition, despite having a larger drag coefficient, because of their lower hardness and greater compressibility and compaction behaviour compared to quasi-spherical and angular morphology feedstocks.

The production of biocompatible coatings with strong resistance to corrosion is a critical requirement for implant materials composed of metal alloys such as Ti, Co-Cr, and SS. Cold spray technology holds great promise for achieving this goal. Among implant materials, Ti alloys are highly regarded for their exceptional biocompatibility and corrosion resistance, while Co-Cr alloys are recognized for their remarkable stiffness and wear resistance. Stainless steel (SS) typically demonstrates the highest level of ductility and cyclic twist strength. The combination of these materials is frequently employed to produce coatings with enhanced mechanical and chemical characteristics. However, it can be challenging to deposit more than two materials due to differences in their density and particle shape, which affect particle velocities. A recent study found that adding 33.3% Co-Cr alloy to a composite coating improved its strength and density, but adding more led to a drop in deposition efficiency and coating thickness. The non-spherical shape of SS particles caused them to experience varying acceleration compared to the spherical Co-Cr alloy particles during their travel in the nozzle, owing to the larger drag force acting upon them [51].

3.2.8 Ceramic and composite materials

Ceramic coatings are becoming popular in biomedical applications due to their ability to resist corrosion and fight against bacteria. However, making ceramic coatings through cold spray is challenging because ceramics lack ductility [52], [53]. Scientists have found a way to overcome this challenge by using a ceramic/metal composite feedstock, where metals serve as a flexible component to help attach non-flexible materials. Several studies have explored different composite mixtures to create thick and dense ceramic coatings. Various researchers have researched HA/Ta and HA/Ti mixtures, respectively, to create coatings with pure ceramics [54], [55]. Another researcher [56] improved the brittleness of HA by adding a PVA binder and sintering the coating. Additionally, researchers have studied TiO2 coatings with different particle sizes, and they found that nanocrystal TiO2 coatings are not as effective as agglomerated TiO2 coatings, which can be made thicker by adding a PVA binder to ultra-fine particles. The substrate’s ductility also affects the coating deposition, with ductile substrates showing higher deposition efficiency than hard substrates [57].

4 Application of cold spray in bio-coatings

Cold spray coatings have a variety of applications in the biomedical industry, including surface provision, protection, and performance enhancement. The coatings function as shields that protect against corrosive surroundings as well as prevent wear and friction. In order to attain the desired level of performance, a number of factors associated with the cold spray technique can be fine-tuned, such as porosity, coating thickness, adhesion strength, hardness, degree of oxidation, and surface roughness. Furthermore, the cold spray technique can produce coatings with biocompatibility, antimicrobial properties, and self-cleaning characteristics [58, 59]. When creating coatings for prosthetic implants, for instance, it is essential to have a porous structure with pores of the appropriate size to promote the growth of bone cells. When it comes to anticorrosion coatings, however, excessive porosity is undesirable.

Cold spray coatings currently use versatile biomaterials for orthopaedic and antibacterial coatings. Advanced surface alterations utilizing both physical and chemical techniques have been created to enhance the overall coating functionality, combining several features. Implant failure risk factors, such as insufficient implant stability and antimicrobial activity, have prompted research into multifunctional implant coatings [29]. Table 3 represents the coating material, composition, particle size, and application area.

Scientists have created a new surface for titanium alloy by attaching a substance that fights bacteria and another substance that helps cells stick to the surface. The goal of these modifications is to reduce bacterial infections while still promoting the growth and development of bone cells. When using polymeric implants, there is a need for better infection control and lower infection rates, so research is being carried out on dual-function systems that can both prevent fouling (the accumulation of unwanted material) and fight bacteria [66].

4.1 Medical implant coatings

Mechanical and biocompatibility properties are both necessary for implants. Mechanical compatibility with hard tissues can be difficult to achieve due to the high Young’s moduli of metallic and ceramic implants relative to the bone. To address the issue of mechanical compatibility between hard tissues and implants, a possible solution is to employ biomaterials and coatings that are tailored to closely mimic Young’s modulus of bone [6]. This strategy can help prevent an uneven distribution of stress between the host bone and the implant. Introducing porous networks into load-bearing implants can be a viable approach to improving mechanical compatibility and creating a favourable environment for tissue growth and implant integration by facilitating blood supply. With the cold spray technique, it is possible to generate coatings that exhibit different levels of porosity and hardness [49], [61], [67,68,69,70].

The term biocompatibility refers to an implant material’s capability to operate effectively in a particular biological environment without eliciting adverse responses from the host [71]. Insufficient biocompatibility of an implant material can cause adverse host reactions and inflammation and compromise the implant’s mechanical and physical properties. Inadequate biocompatibility of bone implants can lead to the formation of fibrotic tissue at the interface between the device and tissue, which can result in inadequate anchorage to the surrounding bone and, ultimately, device loosening [72]. To promote favorable cell-surface interactions and reduce negative side effects, biocompatible surface coatings have been developed. Biocompatibility can be optimized by manipulating surface properties like wettability, topography, roughness, and chemistry. The modification of surface roughness and topography by means of techniques such as sandblasting, acid/alkaline etching, or plasma etching has been shown to influence cell behaviour, cell viability, and protein adsorption. Therefore, this approach can be helpful in optimizing biocompatibility. Encouraging outcomes have been observed using conventional thermal spray methods to create biocompatible implant coatings [73,74,75].

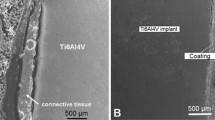

Yoon et al. [76] demonstrated that surface morphology optimization using plasma spray can improve biological responses. In a study by researchers, three coatings with different roughness values were evaluated, and it was observed that the coating with a roughness of Ra 14.89 μm had the highest cell attachment rate. Moreover, an animal study conducted by a group of researchers [77] found that the use of a plasma-sprayed titanium coating on PEEK led to enhanced bone attachment and osteointegration compared to uncoated PEEK. The titanium-coated samples showed an increase in stiffness and shear strength over time, leading to the formation of new bone around the implant. In contrast, the uncoated PEEK samples developed a layer of fibrous tissue. According to another study [78], when applying a titanium coating to PEEK, it is important to consider specific surface properties such as thickness, porosity, roughness, adhesive strength, and shear strength. In their study, they controlled the temperature by modifying the plasma torch’s power during the process to maintain the chemical and physical properties of PEEK.

Surface engineering has been explored as a means of enhancing the biocompatibility of PEEK. This approach is promising for bone implants, as PEEK has Young’s modulus comparable to that of bone, making it a potential alternative to metallic materials [79]. However, PEEK’s interaction with surrounding bone tissue needs further optimization. To improve osseointegration, PEEK substrates are often coated with titanium or bio-ceramic. The cold spray process offers an advantage over traditional coating methods that require higher temperatures than PEEK’s melting point or glass transition point, which can cause heat-induced degradation [44], [77, 78]. This method can avoid such degradation while still effectively coating PEEK. Research has found that using cold spray hydroxyapatite coatings on PEEK implants can improve their anchoring strength and osteointegration. The increased area of contact at the bio interface resulting from surface engineering can provide a favorable environment for bone growth and improve long-term implant stability. Achieving ideal cell adhesion requires precise adjustment of surface topography to a particular roughness. In one study, researchers compared the viability and proliferation of osteoblastic cells on a sand-blasted rough Ti surface with a roughness value of Ra 4 μm to those on a high-roughness coating with a roughness value of approximately Ra 40 μm created by using a coarse titanium feedstock with a micro-roughness of Ra 12 μm. The roughness characteristics of the feedstock were maintained by the cold spray process, which resulted in an uneven surface that promoted cell attachment and proliferation [60].

4.2 Antimicrobial coatings

Medical devices and implants are prone to infection, which can lead to chronic wounds or implant failure. Staphylococci, specifically S. aureus and S. epidermidis, are common culprits in implant-related infections [80]. The process of infection starts when bacteria attach to different biomaterials and generate biofilms on the surface of the implant. The biofilm formation process commences with microorganisms sticking to the substrate, which is then followed by the creation of an extracellular matrix. Once the biofilm is formed, it protects the microorganisms against phagocytes and provides nutrients for them to spread over the surface, leading to colony formation [81]. Bacteria within biofilms are highly resistant to antibiotics, making them difficult to treat and often resulting in systemic chronic infections. Cold spray processes are efficient in producing antimicrobial surfaces due to their strong bonding, microstructure, and high deposition efficiency. These surfaces are suitable for a variety of applications, including implants, frequently touched surfaces, the food industry, and the marine environment [71, 82,83,84,85]. To develop antimicrobial surfaces that release inorganic antimicrobial agents like copper, silver, magnesium oxide, titanium oxide, and zinc oxide, the incorporation of these agents into cold spray coatings has been explored. Additionally, organic antibiotics have been explored as a means of creating such surfaces.

Due to the increasing number of healthcare-associated infections (HAIs), there has been an interest in exploring non-implant surface antimicrobial coatings as a means of preventing and controlling infections. Healthcare facilities are susceptible to bacterial contamination, especially on high-touch surfaces, ventilators, central lines, patient rooms, and urinary catheters, which can result in infections [86]. To prevent healthcare-associated infections, researchers have investigated non-implantable surface antimicrobial coatings. Studies have found that Cu-containing cold spray coatings are effective in dealing with HAIs. The deposition mechanism influences bacterial killing efficiency, with cold spray deposition of Cu coatings being more effective than other methods [87]. Zn ions in cold spray coatings have also shown promise in combating S. aureus and P. aeruginosa. The use of nanomaterials in coatings can enhance their antimicrobial and self-sterilizing functions, which are crucial for preventing virus transmission via hand-to-surface contact. Examples of suitable cold spray implant coatings with coating conditions and surface characteristics are included in Table 4.

Cold-spray copper surfaces have been found to be effective against the influenza A virus. Recent studies have demonstrated the efficacy of cold spray methods in applying copper coatings to stainless-steel push plates to prevent viral transmission and in metalizing antimicrobial metals using cold spray technology onto carbon fiber-reinforced polymers for use in medical implants and objects with frequently touched surfaces [88]. Recent research on cold spray coatings that aims to create antimicrobial materials is summarized in Table 5.

4.3 Antifouling coatings

Antifouling coatings can prevent the attachment and growth of proteins, bacteria, and marine organisms on materials, and various strategies can be employed to design them, including controlling surface wettability, incorporating surface topography, and utilizing biocidal agents. Cold spray techniques have been developed for marine antifouling technologies, offering better adhesion strength and efficacy against microbial attachment compared to conventional coatings. Cold spray techniques show promise in preventing infections in medical devices and high-pressure marine environments. These techniques have been developed to prevent virus transmission on stainless-steel push plates and create antimicrobial coatings on carbon fiber-reinforced polymers while also being environmentally friendly [93]. Antifouling coatings can be made from various materials, such as copper, silver, hydrophilic, or superhydrophobic materials. Cold spray embedding of active metal particles under polymer surfaces has shown potential for antifouling applications. Research has shown that the particle loading density and embedment depth affect the antifouling efficiency of these coatings, with a successful application to various polymer substrates of differing hardness and elastic moduli [62], [94].

Superhydrophobic coatings have emerged as a promising strategy for preventing the adhesion of various biological components and microbial contamination on medical devices [95]. Gibes et al. [96] used low-pressure cold spray deposition to fabricate superhydrophobic coatings using silica particles with immobilized hydrophobic agents. Wang et al. [69] utilized vacuum cold spray deposition to produce a superhydrophobic TiO2-oleic acid nanocomposite coating that maintained its water repellency with a contact angle of 151.2 degrees even after abrasion testing. This technique is another example of the use of cold spray deposition in creating functional coatings. The potential applications of these coatings are diverse, ranging from biosensors and vascular stents to prosthetic valves and hemodialysis filtration systems, among others.

4.4 Bioactive coatings

In the field of bone formation, bioactive materials are those that encourage the growth of bone cells along the implant surface, promoting tissue regeneration. Despite its biocompatibility and mechanical strength, titanium presents a significant challenge due to its lack of bioactivity after being implanted. Strategies have been developed to enhance the bioactivity of titanium by modifying its surface with bioactive materials. To enhance the bioactivity of titanium substrates, bioactive materials like bio-ceramics, surface-treated metals, polymers, and composite materials have been studied. The goal is to make these substrates more biocompatible with host tissues. These materials also hold potential for tissue engineering and wound healing applications. Once more, cold spray offers a variety of options for customizing coatings due to the difference in process variables and the intrinsic characteristics of feedstock particles [97, 98]. Table 6 highlights some of the examples.

4.5 Anticorrosive coatings

Biomaterial corrosion is a significant issue that involves reduction and oxidation reactions, consequently, the body may be exposed to toxic ions through their release. The corrosion process primarily affects the exposed surface of various biomaterials, including stainless steel, bio-ceramics, titanium, composites, cobalt chromium, and polymers. Rust is a common product of corrosion. While the formation of a protective layer on the surface can help reduce the rate of corrosion, there are instances when it may not be sufficient to fully prevent corrosion from occurring throughout the material [101]. Various factors may initiate the corrosion of metallic materials, including oxygen, electrical stimulation, and microorganisms. In comparison to metallic materials, polymers are relatively unreactive and thus less susceptible to corrosion. Therefore, they can be employed as protective coatings for metallic materials in environments that promote corrosion. Although certain environments, such as acidic media or exposure to specific chemicals, may lead to polymer corrosion, the corrosion process can weaken the protective properties of the polymer coating [102, 103].

The corrosion behaviour of cold spray coatings has been extensively investigated, with researchers often evaluating the coatings’ corrosion resistance by immersing them in simulated body fluids or conducting electrochemical tests under controlled conditions. Post-treatments, such as heat annealing, have been employed to improve the protective properties of these coatings. Annealing at high temperatures has been demonstrated to improve splat bonding and increase coating density, thus minimizing corrosion at the gaps between splats [104]. Studies have also revealed that cold spray coatings containing mixtures of materials exhibit lower corrosion rates than pure coatings and that annealing treatment can further enhance their corrosion resistance. For example, annealing cold-spray stainless steel coatings at high temperatures reduces their porosity and increase their hardness, resulting in greater resistance to corrosion. Additionally, heat-annealing cold-sprayed pure titanium improves its microhardness and corrosion resistance, making it a suitable material for implant applications [105]. Table 7 contains a list of the anticorrosive cold spray coatings addressed in this section.

4.6 Wear resistant coatings

Wear refers to the wearing down of materials as a result of friction, abrasion, or frequent use. The rate of corrosion in load-bearing implants such as artificial joints and hips may increase due to wear and cracking of the material surface. Furthermore, wear debris can cause the body’s immune system to trigger inflammation, leading to aseptic loosening [108]. Titanium and its alloys are favoured in dental and orthopaedic applications due to their advantageous properties, yet its limited tribological properties make it unsuitable for longer use. To improve the wear and corrosion resistance of materials such as 316 L stainless steel and magnesium alloys, which are commonly used in bone repair, researchers are exploring surface coatings [109, 110]. This is because wear resistance is crucial to extending the lifespan of implants within the human body [111,112,113]. Cold spray is a technique that has gained attention in recent years for producing wear-resistant coatings by incorporating nitrides, ceramic-based materials, and carbides into the coating with better deposition efficiency [114,115,116]. For example, improved wear resistance and biocompatibility can be achieved by deploying titanium or TiC-based coatings, which have been deposited on Ti alloys, making them suitable for knee implants Cold sprayed metal-ceramic coatings using satellited powders [65], [115]. The process of low-pressure cold spray deposition was utilized to coat a medical-grade Co-Cr alloy with a protective layer. Subsequently, a TiO2 layer was created by thermal oxidation [117]. This process resulted in a coating with outstanding wear performance, minimal wear loss, enhanced biocompatibility, and antibacterial properties.

5 Conclusions

This article presents recent advancements in cold spray coatings, which allow for precise control over microstructure and composition. When designing a biomedical device, it is essential to maintain fine-grained control over a wide variety of properties. Despite being a relatively new technology, the cold spray has demonstrated its potential for modifying surface properties such as roughness, density, porosity, and antimicrobial effectiveness. Furthermore, composite coatings can be achieved through a single cold spray process or by utilizing hybrid surface treatments.

-

While the cold spray process is characterized by its high particle kinetic velocity and low process temperature, there are several additional elements that influence the resulting coating. When seeking to replicate or extend the findings of a particular study, it is essential to consider the specific conditions and spray parameters employed in that investigation. Variables such as substrate properties, feedstock powders, spray configurations, equipment performance, substrate pretreatment, coating post-treatments, and the level of morphological and chemical characterization should all be carefully taken into consideration.

-

Combining cold spray additive manufacturing’s benefits with those of individualized medical technologies are attracting a lot of attention. Cold spray technology’s ability to deposit thick, high-quality coatings at low cost makes it a promising technique for producing patient-specific implants using 3D printing. Moreover, there is an increasing interest in using cold spray technology to embed particles into soft materials like polymers, which could lead to multifunctional materials with unique properties. This field presents ample opportunities for scientific advancement and intellectual property generation, particularly in the realm of biomedical applications and devices.

-

The existing research on cold-spray biocompatible coatings has predominantly concentrated on evaluating their mechanical properties and functionalities, with limited attention paid to comprehending and regulating the bio-interfacial interactions between these coatings Nonetheless, this void is anticipated to be filled quickly and facilitating the creation of new and improved biomedical devices.

-

With the progression of this technology, it will become apparent that precise management of various parameters is essential to producing coatings that meet regulatory standards. Thus, the attainment of uniform coatings with established quality control measures will be a critical aspect of their application in biomedical devices.

References

Liao, T.Y., Biesiekierski, A., Berndt, C.C., et al.: Multifunctional cold spray coatings for biological and biomedical applications: A review. Prog. Surf. Sci. 97, 100654 (2022). https://doi.org/10.1016/J.PROGSURF.2022.100654

Kumar, S.: Influence of processing conditions on the mechanical, tribological and fatigue performance of cold spray coating: A review. 38:324–365. (2022). https://doi.org/10.1080/02670844.2022.2073424

Hench, L.L.: Biomaterials: A forecast for the future. Biomaterials. 19, 1419–1423 (1998). https://doi.org/10.1016/S0142-9612(98)00133-1

Ratner, B.D., Hoffman, A.S., Schoen, F.J., et al.: Introduction to Biomaterials Science: An Evolving, Multidisciplinary Endeavor. Academic Press Cambridge, MA, USA (2020)

Ramakrishna, S., Mayer, J., Wintermantel, E., Leong, K.W.: Biomedical applications of polymer-composite materials: A review. Compos. Sci. Technol. 61, 1189–1224 (2001). https://doi.org/10.1016/S0266-3538(00)00241-4

Katti, K.S.: Biomaterials in total joint replacement. Colloids Surf., B. 39, 133–142 (2004). https://doi.org/10.1016/J.COLSURFB.2003.12.002

Bauer, S., Schmuki, P., von der Mark, K., Park, J.: Engineering biocompatible implant surfaces: Part I: Materials and surfaces. Prog. Mater. Sci. 58, 261–326 (2013). https://doi.org/10.1016/J.PMATSCI.2012.09.001

Liao, Z., Li, J., Su, Y., et al.: Antibacterial hydroxyapatite coatings on titanium dental implants. Frontiers of Materials Science 2023 17:1 17:1–17. (2023). https://doi.org/10.1007/S11706-023-0628-X

Lv, Y., Chen, Y., Zheng, Y., et al.: Evaluation of the antibacterial properties and in-vitro cell compatibilities of doped copper oxide/hydroxyapatite composites. Colloids Surf., B. 209, 112194 (2022). https://doi.org/10.1016/J.COLSURFB.2021.112194

Shanmugam, K., Doosthosseini, H., Varanasi, S., et al.: Flexible spray coating process for smooth nanocellulose film production. Cellulose. 25, 1725–1741 (2018). https://doi.org/10.1007/S10570-018-1677-7/FIGURES/17

Singh, N., Batra, U., Kumar, K., et al.: Progress in bioactive surface coatings on biodegradable mg alloys: A critical review towards clinical translation. Bioactive Mater. 19, 717–757 (2023). https://doi.org/10.1016/J.BIOACTMAT.2022.05.009

Atiq Ur Rehman, M., Bastan, F.E., Haider, B., Boccaccini, A.R.: Electrophoretic deposition of PEEK/bioactive glass composite coatings for orthopedic implants: A design of experiments (DoE) study. Mater. Design. 130, 223–230 (2017). https://doi.org/10.1016/J.MATDES.2017.05.045

Cizek, J., Matejicek, J.: Medicine meets Thermal Spray Technology: A review of patents. J. Therm. Spray Technol. 27, 1251–1279 (2018). https://doi.org/10.1007/S11666-018-0798-8/FIGURES/20

Vardelle, A., Moreau, C., Akedo, J., et al.: The 2016 Thermal Spray Roadmap. J. Therm. Spray Technol. 2016. 25, 8 (2016). https://doi.org/10.1007/S11666-016-0473-X

Tejero-Martin, D., Rezvani Rad, M., McDonald, A., Hussain, T.: Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019. 28(4), 598–644 (2019). https://doi.org/10.1007/S11666-019-00857-1

Vilardell, A.M., Cinca, N., Concustell, A., et al.: Cold spray as an emerging technology for biocompatible and antibacterial coatings: State of art. J. Mater. Sci. 50, 4441–4462 (2015). https://doi.org/10.1007/S10853-015-9013-1/TABLES/7

Rokni, M.R., Nutt, S.R., Widener, C.A., et al.: Review of Relationship between particle deformation, Coating Microstructure, and Properties in high-pressure Cold Spray. J. Therm. Spray Technol. 2017. 26(6), 1308–1355 (2017). https://doi.org/10.1007/S11666-017-0575-0

Sun, W., Chu, X., Lan, H., et al.: Current implementation status of Cold Spray Technology: A short review. J. Therm. Spray Technol. 31, 848–865 (2022). https://doi.org/10.1007/S11666-022-01382-4/FIGURES/17

Govande, A.R., Chandak, A., Sunil, B.R., Dumpala, R.: Carbide-based thermal spray coatings: A review on performance characteristics and post-treatment. Int. J. Refract. Met. Hard Mater. 103, 105772 (2022). https://doi.org/10.1016/J.IJRMHM.2021.105772

Sharma, V., Kazi, S.: An investigation on D-gun sprayed Al2O3-SiC coatings. Surf. Coat. Technol. 375, 303–314 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.07.021

Sharma, R.K., Das, R.K., Kumar, S.R.: Microstructure, mechanical and tribological properties of high velocity oxy fuel thermal spray coating: A review. Materialwiss. Werkstofftech. 54, 90–97 (2023). https://doi.org/10.1002/MAWE.202200101

Kuroda, S., Kawakita, J., Watanabe, M., Katanoda, H.: Warm spraying—a novel coating process based on high-velocity impact of solid particles. http://www.tandfonline.com/action/journalInformation?show=aimsScope&journalCode=tsta20#VmBmuzZFCUk 9:17. (2008). https://doi.org/10.1088/1468-6996/9/3/033002

Kawakita, J., Katanoda, H., Watanabe, M., et al.: Warm spraying: An improved spray process to deposit novel coatings. Surf. Coat. Technol. 202, 4369–4373 (2008). https://doi.org/10.1016/J.SURFCOAT.2008.04.011

Tikkanen, J., Gross, K.A., Berndt, C.C., et al.: Characteristics of the liquid flame spray process. Surf. Coat. Technol. 90, 210–216 (1997). https://doi.org/10.1016/S0257-8972(96)03153-2

Wagner, N.: Effect of process parameters on Twin Wire Arc Sprayed Steel Coatings. J. Mater. Eng. Perform. 30, 6650–6655 (2021). https://doi.org/10.1007/S11665-021-05941-8/FIGURES/9

Gedzevicius, I., Valiulis, A.V.: Analysis of wire arc spraying process variables on coatings properties. J. Mater. Process. Technol. 175, 206–211 (2006). https://doi.org/10.1016/J.JMATPROTEC.2005.04.019

Viscusi, A., Astarita, A., Gatta, R., Della, Rubino, F.: A perspective review on the bonding mechanisms in cold gas dynamic spray. 35:743–771. (2018). https://doi.org/10.1080/02670844.2018.1551768

Lupoi, R., O’Neill, W.: Powder stream characteristics in cold spray nozzles. Surf. Coat. Technol. 206, 1069–1076 (2011). https://doi.org/10.1016/J.SURFCOAT.2011.07.061

Irissou, E., Legoux, J.G., Ryabinin, A.N., et al.: Review on cold spray process and technology: Part I - intellectual property. J. Therm. Spray Technol. 17, 495–516 (2008). https://doi.org/10.1007/S11666-008-9203-3/FIGURES/23

Singh, H., Sidhu, T.S., Kalsi, S.B.S., Karthikeyan, J.: Development of cold spray from innovation to emerging future coating technology. J. Brazilian Soc. Mech. Sci. Eng. 35, 231–245 (2013). https://doi.org/10.1007/S40430-013-0030-1/FIGURES/15

Singh, S., Raman, R.K.S., Berndt, C.C., Singh, H.: Influence of Cold Spray Parameters on Bonding Mechanisms. Rev. Met. 2021. 11 (2021). Page 2016 11:2016 https://doi.org/10.3390/MET11122016

Jodoin, B.: Cold spray nozzle mach number limitation. J. Therm. Spray Technol. 11, 496–507 (2002). https://doi.org/10.1361/105996302770348628/METRICS

Góral, A., Żórawski, W., Makrenek, M.: The effect of the standoff distance on the microstructure and mechanical properties of cold sprayed Cr3C2-25(Ni20Cr) coatings. Surf. Coat. Technol. 361, 9–18 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.01.006

Gabor, T., Akin, S., Tsai, J.T., et al.: Numerical Studies on Cold Spray Particle Deposition Using a Rectangular Nozzle. Proceedings of ASME 2022 17th International Manufacturing Science and Engineering Conference, MSEC 2022 1:. (2022). https://doi.org/10.1115/MSEC2022-85673

Li, S., Muddle, B., Jahedi, M., Soria, J.: A numerical investigation of the cold spray process using underexpanded and overexpanded jets. J. Therm. Spray Technol. 21, 108–120 (2012). https://doi.org/10.1007/S11666-011-9691-4/FIGURES/15

Yin, S., Suo, X., Liao, H., et al.: Significant influence of carrier gas temperature during the cold spray process. https://doi.org/101179/1743294414Y0000000276 30:443–450. (2014). https://doi.org/10.1179/1743294414Y.0000000276

Kamaraj, M., Radhakrishnan, V.M.: Cold Spray Coating Diagram: Bonding Properties and Construction Methodology. J. Therm. Spray Technol. 28, 756–768 (2019). https://doi.org/10.1007/S11666-019-00853-5/FIGURES/8

Raoelison, R.N., Xie, Y., Sapanathan, T., et al.: Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Additive Manuf. 19, 134–159 (2018). https://doi.org/10.1016/J.ADDMA.2017.07.001

Singh, S., Singh, H., Chaudhary, S., Buddu, R.K.: Effect of substrate surface roughness on properties of cold-sprayed copper coatings on SS316L steel. Surf. Coat. Technol. 389, 125619 (2020). https://doi.org/10.1016/J.SURFCOAT.2020.125619

Jodoin, B., Ajdelsztajn, L., Sansoucy, E., et al.: Effect of particle size, morphology, and hardness on cold gas dynamic sprayed aluminum alloy coatings. Surf. Coat. Technol. 201, 3422–3429 (2006). https://doi.org/10.1016/J.SURFCOAT.2006.07.232

Ziemian, C.W., Wright, W.J., Cipoletti, D.E.: Influence of Impact Conditions on Feedstock Deposition Behavior of Cold-Sprayed Fe-Based metallic glass. J. Therm. Spray Technol. 27, 843–856 (2018). https://doi.org/10.1007/S11666-018-0720-4/FIGURES/18

Bhattiprolu, V.S., Johnson, K.W., Ozdemir, O.C., Crawford, G.A.: Influence of feedstock powder and cold spray processing parameters on microstructure and mechanical properties of Ti-6Al-4V cold spray depositions. Surf. Coat. Technol. 335, 1–12 (2018). https://doi.org/10.1016/J.SURFCOAT.2017.12.014

Sandhu, H.S., Phull, G.S., Saini, M.S., et al.: A Review: Bio-compatible thermal spray coating on bio-implant. Lecture Notes in Mechanical Engineering. 71–77 (2021). https://doi.org/10.1007/978-981-16-1079-0_8/COVER

Adebiyi, D.I., Popoola, A.P.I., Botef, I.: Low pressure cold spray coating of Ti-6Al-4V with SiC-based cermet. Mater. Lett. 175, 63–67 (2016). https://doi.org/10.1016/J.MATLET.2016.03.142

MacDonald, D., Fernández, R., Delloro, F., Jodoin, B.: Cold Spraying of Armstrong process Titanium Powder for Additive Manufacturing. J. Therm. Spray Technol. 26, 598–609 (2017). https://doi.org/10.1007/S11666-016-0489-2/FIGURES/11

Raha, S., Mallick, R., Basak, S., Duttaroy, A.K.: Is copper beneficial for COVID-19 patients? Med. Hypotheses. 142, 109814 (2020). https://doi.org/10.1016/J.MEHY.2020.109814

Tang, J.R., Zhao, Z.P., Cui, X.Y., et al.: Microstructure and bioactivity of a cold sprayed rough/porous Ta coating on Ti6Al4V substrate. Sci. China Technological Sci. 63, 731–739 (2020). https://doi.org/10.1007/S11431-019-1446-0/METRICS

Zeng, G., Zahiri, S.H., Gulizia, S., et al.: A comparative study of cell growth on a cold sprayed Ti–Ta composite. J. Alloys Compd. 826, 154014 (2020). https://doi.org/10.1016/J.JALLCOM.2020.154014

Soro, N., Attar, H., Brodie, E., et al.: Evaluation of the mechanical compatibility of additively manufactured porous Ti–25Ta alloy for load-bearing implant applications. J. Mech. Behav. Biomed. Mater. 97, 149–158 (2019). https://doi.org/10.1016/J.JMBBM.2019.05.019

Tang, J., Zhao, Z., Li, N., et al.: Influence of feedstock powder on microstructure and mechanical properties of Ta cold spray depositions. Surf. Coat. Technol. 377, 124903 (2019). https://doi.org/10.1016/J.SURFCOAT.2019.124903

Al-Mangour, B., Mongrain, R., Irissou, E., Yue, S.: Improving the strength and corrosion resistance of 316L stainless steel for biomedical applications using cold spray. Surf. Coat. Technol. 216, 297–307 (2013). https://doi.org/10.1016/J.SURFCOAT.2012.11.061

Goyal, K., Goyal, R.: Improving hot corrosion resistance of Cr3C2–20NiCr coatings with CNT reinforcements. (2019). 36:1200–1209. https://doi.org/10.1080/02670844.2019.1662645

Sova, A., Papyrin, A., Smurov, I.: Influence of ceramic powder size on process of cermet coating formation by cold spray. J. Therm. Spray Technol. 18, 633–641 (2009). https://doi.org/10.1007/S11666-009-9359-5/TABLES/3

Guillem-Marti, J., Cinca, N., Punset, M., et al.: Porous titanium-hydroxyapatite composite coating obtained on titanium by cold gas spray with high bond strength for biomedical applications. Colloids Surf., B. 180, 245–253 (2019). https://doi.org/10.1016/J.COLSURFB.2019.04.048

Tang, J., Zhao, Z., Liu, H., et al.: A novel bioactive Ta/hydroxyapatite composite coating fabricated by cold spraying. Mater. Lett. 250, 197–201 (2019). https://doi.org/10.1016/J.MATLET.2019.04.123

Lee, J.H., Jang, H.L., Lee, K.M., et al.: Cold-spray coating of hydroxyapatite on a three-dimensional polyetheretherketone implant and its biocompatibility evaluated by in vitro and in vivo minipig model. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 105, 647–657 (2017). https://doi.org/10.1002/JBM.B.33589

Hajipour, H., Abdollah-zadeh, A., Assadi, H., et al.: Effect of feedstock powder morphology on Cold-Sprayed Titanium Dioxide Coatings. J. Therm. Spray Technol. 27, 1542–1550 (2018). https://doi.org/10.1007/S11666-018-0782-3/FIGURES/10

Khalik, M.A., Zahiri, S.H., Palanisamy, S., et al.: Rapid elimination of porosity and brittleness in cold spray additive manufactured grade 2 titanium via in situ electro-plastic treatment. Int. J. Adv. Manuf. Technol. 119, 773–788 (2022). https://doi.org/10.1007/S00170-021-08309-3/FIGURES/17

Singh, G., Saini, A., Pabla, B.S.: Preparation and characterization of sr-doped hap biomedical coatings on polydopamine-treated ti6al4v substrates. 30:. (2022). https://doi.org/10.1142/S0218625X21410092

Vilardell, A.M., Cinca, N., Garcia-Giralt, N., et al.: Osteoblastic cell response on high-rough titanium coatings by cold spray. J. Mater. Science: Mater. Med. 29, 1–10 (2018). https://doi.org/10.1007/S10856-018-6026-8/FIGURES/9

Sun, J., Han, Y., Cui, K.: Innovative fabrication of porous titanium coating on titanium by cold spraying and vacuum sintering. Mater. Lett. 62, 3623–3625 (2008). https://doi.org/10.1016/J.MATLET.2008.04.011

Stenson, C., McDonnell, K.A., Yin, S., et al.: Cold spray deposition to prevent fouling of polymer surfaces. 34:193–204. (2016). https://doi.org/10.1080/02670844.2016.1229833

Koivuluoto, H., Näkki, J., Vuoristo, P.: Corrosion properties of cold-sprayed tantalum coatings. J. Therm. Spray Technol. 18, 75–82 (2009). https://doi.org/10.1007/S11666-008-9281-2/TABLES/3

Gardon, M., Melero, H., Garcia-Giralt, N., et al.: Enhancing the bioactivity of polymeric implants by means of cold gas spray coatings. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 102, 1537–1543 (2014). https://doi.org/10.1002/JBM.B.33134

Kusiński, J., Kac, S., Kowalski, K., et al.: Microstructure and Properties of TiC/Ti Coatings deposited by the Supersonic Cold gas spray technique. Archives of Metallurgy and Materials Vol. 63, 867–873 (2018). https://doi.org/10.24425/122416

Zander, Z.K., Becker, M.L.: Antimicrobial and antifouling strategies for Polymeric Medical Devices. ACS Macro Lett. 7, 16–25 (2018). https://doi.org/10.1021/ACSMACROLETT.7B00879/ASSET/IMAGES/LARGE/MZ-2017-008792_0005.JPEG

Aydin, H., Alomair, M., Wong, W., et al.: Cold sprayability of mixed commercial purity Ti Plus Ti6Al4V Metal powders. J. Therm. Spray Technol. 26, 360–370 (2017). https://doi.org/10.1007/S11666-017-0528-7/FIGURES/14

Gkomoza, P., Lampropoulos, G.S., Vardavoulias, M., et al.: Microstructural investigation of porous titanium coatings, produced by thermal spraying techniques, using plasma atomization and hydride-dehydride powders, for orthopedic implants. Surf. Coat. Technol. 357, 947–956 (2019). https://doi.org/10.1016/J.SURFCOAT.2018.10.072

Wang, Z., Chen, X., Gong, Y., et al.: Superhydrophobic nanocoatings prepared by a novel vacuum cold spray process. Surf. Coat. Technol. 325, 52–57 (2017). https://doi.org/10.1016/J.SURFCOAT.2017.06.044

Niinomi, M.: Recent progress in Research and Development of Metallic Structural Biomaterials with mainly focusing on mechanical biocompatibility. Mater. Trans. 59, 1–13 (2018). https://doi.org/10.2320/MATERTRANS.M2017180

Rui, D., Li, X., Jia, W., et al.: Releasing kinetics of dissolved copper and antifouling mechanism of cold sprayed copper composite coatings for submarine screen doors of ships. J. Alloys Compd. 763, 525–537 (2018). https://doi.org/10.1016/J.JALLCOM.2018.05.355

Apostu, D., Lucaciu, O., Berce, C., et al.: Current methods of preventing aseptic loosening and improving osseointegration of titanium implants in cementless total hip arthroplasty: A review. J. Int. Med. Res. 46, 2104–2119 (2018). https://doi.org/10.1177/0300060517732697

Li, S., Ni, J., Liu, X., et al.: Surface characteristics and biocompatibility of sandblasted and acid-etched titanium surface modified by ultraviolet irradiation: An in vitro study. J. Biomedical Mater. Res. Part B: Appl. Biomaterials. 100B, 1587–1598 (2012). https://doi.org/10.1002/JBM.B.32727

Hatamleh, M.M., Wu, X., Alnazzawi, A., et al.: Surface characteristics and biocompatibility of cranioplasty titanium implants following different surface treatments. Dent. Mater. 34, 676–683 (2018). https://doi.org/10.1016/J.DENTAL.2018.01.016

Diba, F.S., Reynolds, N., Thissen, H., et al.: Tunable chemical and topographic patterns based on Binary Colloidal crystals (BCCs) to modulate MG63 cell growth. Adv. Funct. Mater. 29, 1904262 (2019). https://doi.org/10.1002/ADFM.201904262

Yoon, B.J.V., Xavier, F., Walker, B.R., et al.: Optimizing surface characteristics for cell adhesion and proliferation on titanium plasma spray coatings on polyetheretherketone. Spine J. 16, 1238–1243 (2016). https://doi.org/10.1016/J.SPINEE.2016.05.017

Walsh, W.R., Bertollo, N., Christou, C., et al.: Plasma-sprayed titanium coating to polyetheretherketone improves the bone-implant interface. Spine J. 15, 1041–1049 (2015). https://doi.org/10.1016/J.SPINEE.2014.12.018

Vogel, D., Dempwolf, H., Baumann, A., Bader, R.: Characterization of thick titanium plasma spray coatings on PEEK materials used for medical implants and the influence on the mechanical properties. J. Mech. Behav. Biomed. Mater. 77, 600–608 (2018). https://doi.org/10.1016/J.JMBBM.2017.09.027

Ma, R., Tang, T.: Current Strategies to Improve the Bioactivity of PEEK. International Journal of Molecular Sciences 2014, 15, 5426–5445 15:5426–5445. (2014). https://doi.org/10.3390/IJMS15045426

Oliveira, W.F., Silva, P.M.S., Silva, R.C.S., et al.: Staphylococcus aureus and Staphylococcus epidermidis infections on implants. J. Hosp. Infect. 98, 111–117 (2018)

Arciola, C.R., Campoccia, D., Speziale, P., et al.: Biofilm formation in Staphylococcus implant infections. A review of molecular mechanisms and implications for biofilm-resistant materials. Biomaterials. 33, 5967–5982 (2012). https://doi.org/10.1016/J.BIOMATERIALS.2012.05.031

El-Eskandrany, M.S., Al-Azmi, A.: Potential applications of cold sprayed Cu50Ti20Ni30 metallic glassy alloy powders for antibacterial protective coating in medical and food sectors. J. Mech. Behav. Biomed. Mater. 56, 183–194 (2016). https://doi.org/10.1016/J.JMBBM.2015.11.030

Suo, X., Abdoli, L., Liu, Y., et al.: Colonization of Bacteria on the Surfaces of Cold-Sprayed copper Coatings alters their Electrochemical Behaviors. J. Therm. Spray Technol. 26, 687–694 (2017). https://doi.org/10.1007/S11666-017-0535-8/FIGURES/7

Zhao, Z., Meng, F., Tang, J., et al.: A novel method of fabricating an antibacterial aluminum-matrix composite coating doped graphene/silver-nanoparticles. Mater. Lett. 245, 211–214 (2019). https://doi.org/10.1016/J.MATLET.2019.02.121

Wang, K., Wang, S., Xiong, T., et al.: Properties of Zn-Al-Mg-TiO2 coating prepared by cold spraying. Surf. Coat. Technol. 387, 125549 (2020). https://doi.org/10.1016/J.SURFCOAT.2020.125549

Costa, P., Polícia, R., Perinka, N., et al.: Multifunctional Touch Sensing and Antibacterial polymer-based Core-Shell Metallic Nanowire Composites for High Traffic Surfaces. Adv. Mater. Technol. 7, 2101575 (2022). https://doi.org/10.1002/ADMT.202101575

Mishchenko, O., Filatova, V., Vasylyev, M., et al.: Kinetically Deposited Copper Antimicrobial Surfaces. Coatings 2019, 9, 257 9:257. (2019). https://doi.org/10.3390/COATINGS9040257

Sundberg, K., Champagne, V., McNally, B., et al.: Effectiveness of nanomaterial copper cold spray surfaces on inactivation of influenza a virus. J. Biotechnol. Biomater. 5, 205 (2015)

Liu, Y., Dang, Z., Wang, Y., et al.: Hydroxyapatite/graphene-nanosheet composite coatings deposited by vacuum cold spraying for biomedical applications: Inherited nanostructures and enhanced properties. Carbon. 67, 250–259 (2014). https://doi.org/10.1016/J.CARBON.2013.09.088

Tamai, K., Kawate, K., Kawahara, I., et al.: Inorganic antimicrobial coating for titanium alloy and its effect on bacteria. J. Orthop. Sci. 14, 204–209 (2009). https://doi.org/10.1007/S00776-008-1306-7/METRICS

Sanpo, N., Tharajak, J.: Antimicrobial Property of Cold-Sprayed transition Metals-Substituted Hydroxyapatite/PEEK coating. Appl. Mech. Mater. 866, 77–80 (2017). https://doi.org/10.4028/WWW.SCIENTIFIC.NET/AMM.866.77

Hutasoit, N., Kennedy, B., Hamilton, S., et al.: Sars-CoV-2 (COVID-19) inactivation capability of copper-coated touch surface fabricated by cold-spray technology. Manuf. Lett. 25, 93–97 (2020). https://doi.org/10.1016/J.MFGLET.2020.08.007

Maan, A.M.C., Hofman, A.H., de Vos, W.M., Kamperman, M.: Recent developments and practical feasibility of polymer-based Antifouling Coatings. Adv. Funct. Mater. 30, 2000936 (2020). https://doi.org/10.1002/ADFM.202000936

Dumée, L.F., He, L., King, P.C., et al.: Towards integrated anti-microbial capabilities: Novel bio-fouling resistant membranes by high velocity embedment of silver particles. J. Membr. Sci. 475, 552–561 (2015). https://doi.org/10.1016/J.MEMSCI.2014.10.051

Khanmohammadi Chenab, K., Sohrabi, B., Rahmanzadeh, A.: Superhydrophobicity: Advanced biological and biomedical applications. Biomaterials Sci. 7, 3110–3137 (2019). https://doi.org/10.1039/C9BM00558G

Gibas, A., Baszczuk, A., Jasiorski, M., Winnicki, M.: Prospects of low-pressure Cold Spray for Superhydrophobic Coatings. Coat. 2019. 9, 829 (2019). https://doi.org/10.3390/COATINGS9120829

Moura, D., Souza, M.T., Liverani, L., et al.: Development of a bioactive glass-polymer composite for wound healing applications. Mater. Sci. Engineering: C. 76, 224–232 (2017). https://doi.org/10.1016/J.MSEC.2017.03.037

Civantos, A., Martínez-Campos, E., Ramos, V., et al.: Titanium Coatings and Surface modifications: Toward clinically useful bioactive implants. ACS Biomaterials Science and Engineering. 3, 1245–1261 (2017). https://doi.org/10.1021/ACSBIOMATERIALS.6B00604/ASSET/IMAGES/MEDIUM/AB-2016-00604X_0006.GIF

Moreau, D., Borit, F., Corté, L., Guipont, V.: Cold Spray Coating of Submicronic ceramic particles on poly(vinyl alcohol) in dry and Hydrogel States. J. Therm. Spray Technol. 26, 958–969 (2017). https://doi.org/10.1007/S11666-017-0551-8/FIGURES/12

Vilardell, A.M., Cinca, N., Garcia-Giralt, N., et al.: In-vitro study of hierarchical structures: Anodic oxidation and alkaline treatments onto highly rough titanium cold gas spray coatings for biomedical applications. Mater. Sci. Engineering: C. 91, 589–596 (2018). https://doi.org/10.1016/J.MSEC.2018.05.071

Manivasagam, G., Dhinasekaran, D., Rajamanickam, A.: Biomedical Implants: Corrosion and its Prevention - A Review. Recent Pat. Corros. Sci. 2, 40–54 (2010). https://doi.org/10.2174/1877610801002010040

Deshpande, P.P., Jadhav, N.G., Gelling, V.J., Sazou, D.: Conducting polymers for corrosion protection: A review. J. Coat. Technol. Res. 11, 473–494 (2014). https://doi.org/10.1007/S11998-014-9586-7/FIGURES/4

Arthur, D.E., Jonathan, A., Ameh, P.O., Anya, C.: A review on the assessment of polymeric materials used as corrosion inhibitor of metals and alloys. Int. J. Industrial Chem. 2013. 4(1 4), 1–9 (2013). https://doi.org/10.1186/2228-5547-4-2

Kumar, S., Vidyasagar, V., Jyothirmayi, A., Joshi, S.V.: Effect of Heat Treatment on Mechanical Properties and Corrosion Performance of Cold-Sprayed Tantalum Coatings. J. Therm. Spray Technol. 25, 745–756 (2016). https://doi.org/10.1007/S11666-016-0388-6/TABLES/2

Zhou, X., Mohanty, P.: Corrosion behaviour of cold sprayed titanium coatings in simulated body fluid. 47:145–154. (2013). https://doi.org/10.1179/1743278211Y.0000000037

Dikici, B., Topuz, M.: Production of Annealed Cold-Sprayed 316L Stainless Steel Coatings for Biomedical Applications and their in-vitro corrosion response. Prot. Met. Phys. Chem. Surf. 54, 333–339 (2018). https://doi.org/10.1134/S2070205118020168/METRICS

Cetiner, D., Paksoy, A.H., Tazegul, O., et al.: Thermal oxidation of Cold Sprayed Titanium-Based Coating deposited on Co-Cr Alloy. J. Therm. Spray Technol. 27, 1414–1427 (2018). https://doi.org/10.1007/S11666-018-0772-5/TABLES/2

Bitar, D., Parvizi, J.: Biological response to prosthetic debris. World J. Orthop. 6, 172 (2015). https://doi.org/10.5312/WJO.V6.I2.172

Radha, R., Sreekanth, D.: Insight of magnesium alloys and composites for orthopedic implant applications – a review. J. Magnesium Alloys. 5, 286–312 (2017). https://doi.org/10.1016/J.JMA.2017.08.003

Yildiz, F., Yetim, A.F., Alsaran, A., Efeoglu, I.: Wear and corrosion behaviour of various surface treated medical grade titanium alloy in bio-simulated environment. Wear. 267, 695–701 (2009). https://doi.org/10.1016/J.WEAR.2009.01.056

Ching, H.A., Choudhury, D., Nine, M.J., Abu Osman, N.A.: Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 15, 014402 (2014). https://doi.org/10.1088/1468-6996/15/1/014402

Penkov, O.V., Khadem, M., Lee, J.S., et al.: Highly durable and biocompatible periodical Si/DLC nanocomposite coatings. Nanoscale. 10, 4852–4860 (2018). https://doi.org/10.1039/C7NR06762C

Kheradmandfard, M., Kashani-Bozorg, S.F., Lee, J.S., et al.: Significant improvement in cell adhesion and wear resistance of biomedical β-type titanium alloy through ultrasonic nanocrystal surface modification. J. Alloys Compd. 762, 941–949 (2018). https://doi.org/10.1016/J.JALLCOM.2018.05.088

Yin, S., Chen, C., Suo, X., Lupoi, R.: Cold-Sprayed Metal Coatings with nanostructure. Adv. Mater. Sci. Eng. 2018 (2018). https://doi.org/10.1155/2018/2804576

Spencer, K., Fabijanic, D.M., Zhang, M.X.: The influence of Al2O3 reinforcement on the properties of stainless steel cold spray coatings. Surf. Coat. Technol. 206, 3275–3282 (2012). https://doi.org/10.1016/J.SURFCOAT.2012.01.031

Melendez, N.M., McDonald, A.G.: Development of WC-based metal matrix composite coatings using low-pressure cold gas dynamic spraying. Surf. Coat. Technol. 214, 101–109 (2013). https://doi.org/10.1016/J.SURFCOAT.2012.11.010

Al-Hamdani, K.S., Murray, J.W., Hussain, T., et al.: Cold sprayed metal-ceramic coatings using satellited powders. Mater. Lett. 198, 184–187 (2017). https://doi.org/10.1016/J.MATLET.2017.03.175

Funding

The author(s) have received no funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethical concerns

Not Required.

Conflict of Interest

The author declares that no conflict of interest exists among all authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sandhu, H.S., Goyal, D., Sharma, A. et al. Sustainable development in cold gas dynamic spray coating process for biomedical applications: challenges and future perspective review. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01474-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01474-7