Abstract

Developing a scalable and cost-effective coating process is critical to manufacturing cotton-based hydrophobic antimicrobial fabric for various commercial applications. This paper describes a scalable, cost-effective coating process that is compatible with the existing industrial finishing processes of fabrics. In this process, the fabric is continuously dipped in water-based silver salt and the reducing agent solution to impart silver particles on the fiber surface to produce different coated samples. The process is tuned to minimize process cost and material cost and maximize the antimicrobial effectiveness and durability of the fabric. This paper also introduces an easy protective coating technique with silicone binder of the antimicrobial fabric that improves the durability and hydrophobicity of the antimicrobial fabric without sacrificing the comfort properties of textile fabrics. In the presence of silicone binder, the samples show significant antibacterial effectiveness against two microorganisms, gram-positive Staphylococcus aureus and gram-negative Escherichia coli bacteria. Qualitative assessment is carried out to evaluate the antimicrobial properties of the silicone encapsulated silver particles-coated fabrics. Moreover, among the silver-coated fabrics of different cycles, silver nanoparticles (AgNPs) are deposited in the 1 cycle of silver-coated fabric and the average particle size deposited onto the fiber surface is 65.52 ± 2.71 nm. After silicone encapsulation, among all encapsulated samples, 1 cycle of silver-coated silicone encapsulated sample shows the best result in terms of antimicrobial efficacy where silicone encapsulated 1 cycle silver-coated sample shows around the zone of inhibition 0.53 and 0.25 mm and encapsulated 2 cycles silver-coated sample shows the zone of inhibition 0.14 and 0.06 mm for S. aureus and E. coli, respectively. Coated fabrics with and without silicone encapsulation are characterized by scanning electron microscopy and energy-dispersive X-ray spectroscopy.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Growing demand for comfortable, clean and hygienic textile goods has given rise to an urgent need for the production of antimicrobial textile goods. As new technologies emerge, the increasing needs of end-users in terms of health and hygiene can be fulfilled without compromising human health, safety and environmental issues.

The need for antimicrobial fabric in the healthcare industry is becoming a must day by day. It has been observed that microorganisms have long survival times in various protective disposable hygiene fabrics used for medical applications, such as splash aprons, masks, head and shoe covers, hospital surgical drapes and gowns, gloves, surgical packs, scrub suits and lab coats.1,2,3 Using disposable products with antimicrobial properties can provide good protection against transmission of diseases for both the patients and the healthcare personnel.

Additionally, there are some special medical textile applications such as ostomy bags4 and devices for urine drainage containers,5 in which the functioning and construction is dependent on antimicrobial properties. So, antimicrobial textiles can also provide a scope for being used in these special applications as bacterial barriers.

Antimicrobial textile also has the potential to be used in leather products, which will act as antimicrobial material to inhibit the growth of the microorganisms inside the product. It is known that leather, fur and leather articles can be easily contaminated with various bacterial and fungal species.6,7 These microorganisms can damage the material or be pathogenic to the wearer.

Therefore, many antibacterial agents have been applied to fabricate antibacterial textiles, such as quaternary ammonium compounds,8 chitosan,9 triclosan,10 nanoparticles of noble metals and metal oxides11,12,13,14,15,16 and bioactive plant-based products,17 in which silver nanoparticles (AgNPs) have been widely used due to their broad spectrum of antibacterial activity and low toxicity toward mammalian cells.18,19,20 Several processes have been carried out so far to produce NPs of silver, but these processes require multiple complex steps, other auxiliaries and complex reagents.21,22,23,24 But, in this work, we have introduced an in situ and scalable functional coating process where AgNPs are directly deposited on the fabric surface by dipping and drying methods in reducing agent and metallic salt solutions, respectively.25 Thus, this functional coating process of 100% cotton fabric is an inexpensive and less chemical consuming process that imparts antimicrobial properties easily. Most importantly, this method can be executed on a large-scale through continuous bath process that is available in the textile manufacturing system.

We can grow silver nanoparticles by using sodium borohydride26 and trisodium citrate,27 tricalcium phosphate28 as a reducing agent of silver salt, but these chemicals are unsafe and hazardous. Ascorbic acid works both as a reducing and protecting agent, which makes the nanoparticle-growing process economical, nontoxic and environmentally friendly.29 So, ascorbic acid has been used to grow AgNPs on the surface of the fabric.

However, fibers containing silver nanoparticles in the core-part (inside the fiber) had no consequential antibacterial activity.30 Conversely, fibers that have silver nanoparticles in the sheath-part showed excellent antibacterial effects. In our work, silver particles are deposited onto the surface of the fiber that elevates the antimicrobial activity of the fabric.

On the other hand, as AgNPs cannot be chemically bonded with natural fibers without complex surface modification processes, that can cause unsatisfied laundering durability of AgNPs treated antibacterial textiles. In addition, the release of AgNPs in great numbers into the natural environment that can affect the health of various organisms.31,32 Hence, some binders can be applied to fix AgNPs on the fibers to provide the durability of antibacterial properties.33 Thereafter, we have chosen silicone as a binder to bring durability of AgNPs on the fabric and hydrophobicity in the fabric.34

As commonly obtained in literature, the high affinity of silver toward sulfur or phosphorus is the major integrand of this phenomenon. The bacterial cell membrane has an abundance of sulfur-containing proteins. The AgNPs can react with these proteins inside or outside the cell membrane, which successively deteriorates the workability of the bacterial cell.35 The silver ions (particularly Ag+) released from AgNPs react with phosphorus moieties in DNA which results in the inactivation of DNA replication. Otherwise, the ions can also interact with sulfur-containing proteins, leading to the inhibition of enzyme functions.36 Because of these properties, the incorporation of AgNPs into various matrices such as textiles and wound dressing materials is possible.37,38,39,40,41,42,43,44,45,46,47,48

Hence, compared to different complicated surface modification and synthetic procedures, this paper has introduced an eco-friendly, low cost and simple application strategy for antibacterial property improvement of fabric from AgNPs by functional coating which brings the key novelty of this research. Hydrophobicity with and without silicone encapsulated silver-coated fabrics are analyzed using the sessile drop method.49 Further, the morphology of the treated fabrics is analyzed by scanning electron microscopy (SEM). Finally, this article will investigate the effectiveness of the antimicrobial activity of the only silver-coated fabrics (control samples) and silicone encapsulated silver-coated fabrics. To evaluate antimicrobial activities qualitative assessment (AATCC 147) will be followed. The test results will evaluate the performance standard of silver on the various products such as 100% cotton fabric, which will add value to the substrate as well as to silver itself as a reliable antimicrobial agent that can be used for various antimicrobial applications.

Experimental process

Materials

To conduct this experiment, 100% cotton knitted fabric (basis weight in gram per sq. meter is 194) with (1 × 1) interlock structure is used. All the materials used in this experiment are cleaned with acetone first and finally with distilled water. The usable chemicals in this experiment like L-ascorbic acid, AgNO3, and acetone were purchased from Merck KGaA, Germany, and used without further purification. L-ascorbic acid (99%, Mw = 176.12) and AgNO3 (≥ 99%, Mw = 169.87) are used for the synthesis of silver nanoparticles. Orgasil 103-OCI 80% acetic cure silicone sealant (density 0.98 ± 0.02 g/cm3) is used to protect the deposited metallic particles onto the fabric surface. Only distilled water is used as the solvent to prepare the L-ascorbic acid and AgNO3 solutions. Two different types of bacteria are used in the study: the gram-positive bacteria Staphylococcus aureus (ATCC 6538) and gram-negative bacteria Escherichia coli (ATCC 10229). Other materials used are pipette, camera, dryer, hand gloves and tray.

Functional coating procedure

In this experiment, 2 w/v % (2 g solute in 100 mL water) of L-ascorbic acid, and silver nitrate (AgNO3) solutions are prepared in individual beakers. Then, a (6 × 6 inch) pre-cleaned and mercerized cotton fabric is immersed into a solution of L-ascorbic acid for about 5 min as shown in Fig. 1. Following that, the sample is dried for 5 min at 80°C. Then, it is immersed into the AgNO3 solution for 5 min. After completing immersion, it is again dried for 5 min at 80°C. One cycle includes one-time sample immersion in the ascorbic acid solution and one-time sample immersion in the silver nitrate solution following the drying process. This process can be repeated several times to produce multiple-cycle samples.

The following reaction explains how the ascorbic acid reduces the silver salts and forms elemental silver.

After that the dried sample is then encapsulated in a silicone (Si) binder solution for 5 min and just for one-time. The solution is prepared by thoroughly mixing silicone (Si) gel in acetone solvent in a ratio of 1:7. The encapsulated samples are dried for 10 min at 80°C.

Table 1 indicates the number of samples will be taken under consideration for further investigation.

Weight-gain%

The weight of the cotton fabric before and after coating (for a single cycle or, for multiple cycles) is measured, and the weight-gain% of the samples is calculated. The weight-gain% of the fabric samples is measured by using the following formula:

Hydrophobicity test

To determine the hydrophobicity of the only silver coated fabric and the silicone encapsulated silver-coated fabric, the sessile drop method is used. It is a widely employed method for analyzing the contact angle which is the direct measurement of the tangent angle at a three-phase equilibrium interfacial point.

Figure 2 represents the experimental setup for contact angle measurement and the representative image of the measured contact angle. The setup includes pipette, camera, light source, base plate, computer and the sample.

Scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) analysis

The surface morphology of the coated fabrics is studied using HR SEM (high-resolution scanning electron microscopy). The surface morphology of only silver-coated (1 and 3 cycle) fabric and silver-coated (1 and 3 cycle) silicone encapsulated fabric is studied by means of HR SEM to overview the surface morphology and the state of the particles depositions on the fabric surface and how the silicone binder protects the deposited silver particles on the surface of the fabric. Platinum is sputtered onto the fabric samples, as a conducting material to analyze the samples. The developed silver nanoparticles (AgNPs) size is also analyzed in only the silver-coated (1 and 3 cycle) fabric samples. Furthermore, EDS (energy-dispersive X-ray spectroscopy) is also taken for the elemental analysis and chemical characterization of the experimented samples.

Antimicrobial effectiveness assessment

The AATCC 147 is a qualitative antimicrobial assessment method for textiles. To testify the antimicrobial efficacy of the control sample (only silver-coated fabrics) and silver-coated (1, 2 and 3 cycles) silicone encapsulated fabric samples, this method is used. In order to perform the AATCC 147 method, an inoculum is prepared as follows: 1.0 ± 0.1 ml of a 24 h culture in nutrient broth (NB) is transferred into 9.0 ± 0.1 ml of sterile distilled water. With an inoculating loop, parallel streaks of the diluted inoculum are made over a standard Petri dish with nutrient agar (NA), without refilling the loop. Each sample under experiment (6 mm × 2 mm) is placed transversely across inoculum streaks. The textile samples are placed over the streaks, ensuring intimate contact with the agar surface. The Petri dishes are incubated for 24 h at 37 ± 2°C (AATCC 147 2004). After that, the interruption of bacterial growth is observed and streaks of interrupted growth underneath and along the side of the test material indicate the antibacterial effectiveness of the fabric.

For this, the inoculated plates are examined for the interruption of growth along the streaks of inoculum beneath the fabric and for a clear zone of inhibition beyond the fabric edge. The average width of the zone of inhibition around the test specimen was calculated in mm using the formula:

where T is the width of the zone of inhibition and I is the width of the specimen.

Result and discussion

Figure 3 shows the weight-gain% of the silver dip-coated (1 cycle, 2 cycles and 3 cycles) developed samples both before and after silicone encapsulation. Before treating the sample in the reducing agent and the silver nitrate solutions, the sample (6 × 6 in.) weight is calculated and after 1 cycle percolation of the sample into the reducing agent and silver nitrate bath, respectively, the sample weight is again measured. Therefore, after 1 cycle of dip-coating, the weight-gain% of the sample is 11.72%. After completing 1 cycle of silver particles coating, 0.6 gm weight is increased for the 36 in.2 fabric area. So, the concentration of NPs deposited onto the fabric surface is approximately 0.02 g/in.2. Repeating the same process 2 times, the weight-gain% of the silver-coated (2 cycles) fabric is raised at 19.56%. Similarly, the same process is performed 3 times, where the weight-gain% of the silver-coated (3 cycles) fabric is increased 28.30%. The reason behind the increasing percentage of the weight-gain of 1 cycle, 2 cycles and 3 cycles silver coated fabric from its original weight is that as the number of cycles increases, more AgNPs are deposited onto the surface of the fabrics.

Moreover, after the encapsulation of the samples with the silicone binder, the weight-gain% of the 1 cycle, 2 cycles and 3 cycles silver-coated samples becomes 22.07%, 29.26% and 37.51%, respectively, from its original weight. An extra-thin silicone film is formed onto the surface of the samples after silicone encapsulation that raises the weight percentage of the samples.

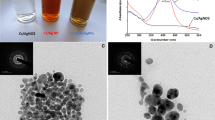

Surface topography of the samples and morphology of the silver particles

To observe the distribution of the silver particles on the fiber surface and to analyze the composition of the coated samples is exigent. The following figures describe the SEM images and EDS of the coated fabrics developed in this work.

Figures 4a and 4b shows the SEM micrographs of the only silver-coated (1 cycle) fabric. It is seen from the figure that there is a uniform distribution of AgNPs throughout the fibers in the silver-coated (1 cycle) fabric. Figure 4c indicates the size and diameter range of the silver particles that are coated into the fibers. Ten particles are marked in the figure, where the average diameter of the particles is 65.53 ± 2.71 nm. From the result, it is evident that the coated silver particles (1 cycle) onto the fiber surface are in the nanometer range. Moreover, EDS is used to determine which chemical elements are present in the sample and to estimate their relative abundance. Figure 4d represents the EDS of the silver-coated (1 cycle) fabric. From the EDS analysis, it is seen that there are 52.88% AgNPs present in the sample in terms of mass and in terms of the number of atoms present, the percentage is 16.55%. As platinum is sputtered onto the fabric sample as a conducting material to analyze the sample, 14.23% platinum is present in the fabric in terms of mass (atomic percentage 2.46%).

The magnified images in Figs. 5a–5c, represent the silicone encapsulated 1 cycle silver-coated fabric. It is clear from the figures that there is a uniform additional layer of encapsulated silicone onto silver particles throughout the fibers in the fabric. This protective layer of silicone binder reduces the porosity of the fabric surface and makes the sample hydrophobic. Figure 5d shows the EDS of the silicone encapsulated 1 cycle silver-coated sample. The EDS analysis shows that silver and silicone are present in the sample in mass percentages of 88.40% and 0.08%, respectively, whereas the percentages in terms of atomic composition are 50.05% and 0.17%, respectively. From Figs. 5a–5c, it is evident that a thin layer of silicone binder encapsulates the silver nanoparticles in the fabric. But, Fig. 5d indicates that the nanoparticles are still exposed to some extent after silicone encapsulation.

Figures 6a and 6b represent the SEM views of the only silver-coated (3 cycles) fabric. It is evident from the figures that silver particles are clustering around the fibers in the fabric compared with the SEM image of the only silver-coated (1 cycle) fabric (Figs. 4a, 4b). This magnified image also shows that silver particles developed in the reduction process agglomerates on the fiber surface in the fabric. Figure 6c indicates the size and diameter range of the silver particles that are deposited into the fibers. Here, ten marked particle sizes are measured, where the average diameter of the particles is 1.43 ± 0.32 µm. It is clear from the result: the coated silver particles (3 cycles) onto the fiber surface are in the micrometer range. Further, the EDS of the silver-coated (3 cycle) sample is shown in Fig. 6d. The EDS analysis represents that there are 57.97% silver (Ag) particles present in the sample in terms of mass and the atomic percentage is 17.32%. However, it is noticeable that the silver particle size differs with the number of cycles of dip-coating. When the sample is coated for 1 cycle, the silver is deposited onto the fiber surface in the form of nanoparticles, whereas if the number of dip-coating increases the size of the silver particles deposited onto the fabric surface also increases as more NPs get aggregated. For this reason, the size of the silver particles deposited onto the fabric shows in the micrometer scale when the fabric is treated with 3 cycles of dip-coating.

Surface wetting behavior

Hydrophobicity is the aversion of water molecules to the surface. It occurs due to the unbalanced secondary force of interaction when the drop comes in contact with the material. This force or interaction can be analyzed by measuring the contact angle as the obtained value is associated with the surface energy of the materials. The contact angle is defined as the angle made by the intersection of the liquid/solid interface and the liquid/air interface. It can be alternately described as the angle between the solid sample’s surface and the tangent of the droplet’s ovate shape at the edge of the droplet. To conduct this experiment, silver particles coated fabrics (with and without silicone encapsulation) are used. Figures 7a and 7b shows the contact angle of the without silicone encapsulated and with encapsulated fabrics. The contact angle values for without silicone encapsulated and with encapsulated fabrics are 106° and 126°, respectively.

If water molecules are dropped onto the raw cotton fabric, they get absorbed by the fabric surface. Whenever the AgNPs are coated onto the raw cotton fabric surface, they tend to avert the water molecules from getting absorbed into the fabric surface as silver particles are deposited onto the surface. For that reason, the only silver-coated fabric shows the aversion of the water droplet with its surface and shows the contact angle value of 106° (Fig. 7a). On the other hand, while this NPs-coated specimen is encapsulated with the silicone binder, a thin layer is formed onto the surface of the fabric which can repulse the water droplets as silicone, being a rubbery material, creates flexible networks among the AgNPs, coating the cotton fibers. As a result, the silicone encapsulated silver-coated fabric sample shows much repulsion of the water droplet from its surface and, from Fig. 7b, it is seen that the contact angle value is 126°.

It is generally accepted that if the value of the contact angle is less than 90°, the surface is considered hydrophilic and if the water contact angle is larger than 90°, the surface is to be hydrophobic.50 So, it can be stated that both the silver-coated fabrics (with and without silicone encapsulation) are hydrophobic in nature as both of the samples show contact angle values higher than 90°.

Antimicrobial effectiveness

The antibacterial effects of control samples (only silver-coated (1, 2 and 3 cycle)) and silver-coated (1, 2 and 3 cycle) silicone encapsulated fabrics are assessed qualitatively against both of our test microorganisms, as mentioned earlier. After incubation, a streak of interrupted growth underneath and along the side of the test material indicates the antibacterial effectiveness of the fabric. The inoculated plates were examined for the interruption of growth along the streaks of inoculum beneath the fabric and for a clear zone of inhibition beyond the fabric edge. The bacterial inhibition was measured as per the formula mentioned previously in equation (2).

From Figs. 8a–8d, it has been observed that the 1 cycle Ag coated Si encapsulated fabric sample shows interrupted growth underneath and alongside the fabric for both microorganisms. It is also seen from the figures that the bacterial inhibition of S. aureus is slightly more than E. coli in the single cycle silver-coated fabric and the silicone encapsulated fabric, where the achievement for attaining maximum bacterial growth inhibition is (0.531) mm and (0.25) mm, respectively.

The silicone encapsulated 2 cycles silver-coated fabric does not show a higher zone of inhibition value like the 1 cycle silver-coated silicone encapsulated fabric. But the encapsulated 2 cycle silver-coated fabric shows clear interruption of the growth of bacteria underneath the fabric and attaining a small growth of inhibition for both S. aureus and E. coli is 0.137 mm and 0.061 mm, respectively (Figs. 9a–9d).

On the other side, from Figs. 10a–10d, it is seen that silicone encapsulated 3 cycles silver-coated fabric does not show any zone of inhibition for both pathogens. But it is clearly evident from the figures that the fabric interrupts the growth of bacteria along the streaks of inoculum beneath the fabric. This fabric shows comparatively lower antibacterial efficacy for both pathogens than both the silver-coated (1 cycle and 2 cycles) silicone encapsulated fabrics.

Moreover, Figs. 11a and 11b represent bacteria growth of inhibition (mm) against both microorganisms with respect to the number of silver-coating cycles for both the control samples and the silicone encapsulated silver-coated samples. Figures 11a and 11b show the antimicrobial performance of both the coated samples and the raw cotton sample against the microorganisms S. aureus and E. coli, respectively. In the case of both the figures, it is evident that the raw cotton fabric sample and the 3 cycles silver coated (both with and without silicone encapsulation) sample do not show any zone of inhibition (0 mm) for both pathogens. Additionally, for both the pathogens S. aureus and E. coli, the values of the zone of inhibition have reduced from 1 cycle sample to 2 cycles sample (both with silicone and without silicone encapsulated samples).

From Fig. 11a, it is seen that in the case of S.aureus, the inhibition zone value reduced from 0.509 to 0.098 mm for only silver-coated samples and from 0.531 to 0.137 mm for silicone encapsulated silver-coated fabric samples. Similarly, from Fig. 11b for E.coli, the inhibition zone value reduced from 0.24 to 0.057 mm for only silver-coated samples and from 0.25 mm to 0.061 mm for silicone encapsulated silver-coated fabric samples.

It also has been observed from Fig. 11 that the bacterial inhibition of S. aureus shows more growth of inhibition than E. coli in the case of all different cycles of silver coating to the cotton fabric. Therefore, it can be demonstrated that before silicone encapsulation (control samples) and after silicone encapsulation, all the silver-coated fabrics show antimicrobial efficacy and silicone encapsulated samples show quite similar bacteria resistivity to the control samples.

From EDS analysis, it is observed that the silver particles are still exposed to the surface of the fabric after silicone encapsulation, which can directly come in contact with bacteria organisms. But an interesting fact is noticeable from the antibacterial efficacy results that the 1 cycle silver-coated fabric shows higher antibacterial activity, whereas the 3 cycles silver-coated fabric shows the least antibacterial effectivity among the samples. Moreover, from Figs. 4c and 6c, it is evident that the average size of deposited silver particles in the 1 cycle dip-coated sample is in the nano range (65.53 ± 2.71 nm), whereas, in the 3 cycles dip-coated sample, the size reaches the micro range (1.43 ± 0.32 µm) as a result of the aggregation of NPs. These results indicate that silver particles of lower size have higher antibacterial effectiveness than that of aggregated NPs. The smaller-sized nanoparticles liberate more silver ions because of the high surface to volume ratio and thus, proved the smaller particles show more effectiveness for killing the bacteria as compared to larger ones.51,52 Therefore, the smaller AgNPs showed better inhibitory action as a significantly large surface area is in contact with the bacterial effluent owing to the larger surface to volume ratio as compared to larger AgNPs. Thus, smaller particles released more silver ions than those of the larger particles to kill more bacteria.53,54 A single cycle of silver coating consumes less chemicals and deposits particles of the lowest size (nm) on the fabric surface, showing the highest antimicrobial effectiveness among all developed samples.

Conclusion

This study is concerned with the development of a low cost, less chemical consuming and scalable coating process to produce cotton-based antimicrobial knit fabrics by means of dip-coating with the reducing agent and silver salt, respectively, for the application of leather products and disposable antimicrobial textiles.

Our developed samples are encapsulated with a silicone binder, where the silicone encapsulation acts as a protective thin layer, making the fabric hydrophobic, which is ensured by measuring the contact angle of the samples. The antibacterial effectiveness of the silicone encapsulated samples are examined using AATCC 147 testing method which performs the qualitative antibacterial assessment on textile fabrics that signifies the silicone encapsulated silver-coated (1 cycle) sample as an effective antimicrobial fabric. SEM analysis of the fabric samples provides us with information about the topography of their surfaces.

To date, a great deal of effort has been made to develop antimicrobial fabrics, but most of them are quite complicated and costly. This study offers an easier, simpler and less costly method which aims to contribute toward developing commercially viable cotton-based antimicrobial fabrics. This study can further be extended to general apparel applications after verifying the washing durability of the developed antimicrobial fabric.

References

Neely, AN, Maley, MP, “Survival of Enterococci and Staphylococci on Hospital Fabrics and Plastic.” J. Clin. Microbiol., 38 (2) 724–726 (2000)

Slaughter, S, et al., “A Comparison of the Effect of Universal Use of Gloves and Gowns with That of Glove Use Alone on Acquisition of Vancomycin-Resistant Enterococci in a Medical Intensive Care Unit.” Annu. Int. Med., 125 448–456 (1996)

Montazer, M, Rangchi, F, Siavoshi, F, “Preparation of Protective Disposable Hygiene Fabrics for Medical Applications,” Medical and Healthcare Textiles, 164–170 (2010).

Fernandez, L, Deaton, JE, Gordon, CR, “Ostomy bag.”. United States Patent US10238529B2, 2014.

Watanabe, T, Yum, SI, Lee, ES, Chin, IW, “Antimicrobial Device for Urine Drainage Container.” United States Patent US5176665A, 1992.

Chirila, C, Deselnicu, V, Crudu, M, “Comparative Study Regarding Resistance of Wet-White and Wet-Blue Leather to the Growth of Fungi.” Leather and Footwear Journal, 14 (2) 107–120 (2014)

Chirila, C, Crudu, M, Deselnicu, V, “Study Regarding the Resistance of Wet-White Leather Tanned with Titanium – Aluminum to the Growth of Fungi.” Proc. 5th ICAMS 2014, 31–35 October 2014, Bucharest, 2014.

Sun, J, Li, J, Qiu, X, Qing, F, “Synthesis and Structure-Activity Relationship (SAR) of Novel Perfluoroalkyl-Containing Quaternary Ammonium Salts.” J. Fluor. Chem., 126 (9–10) 1425–1431 (2005)

Ali, S, Joshi, S, Rajendran, M, “Novel Self-Assembled Antimicrobial Textile Coating Containing Chitosan Nanoparticles.” AATCC Rev., 11 (5) 49–55 (2011)

Kalyon, BD, Olgun, U, “Antibacterial Efficacy of Triclosan-Incorporated Polymers.” Am. J. Infect. Control, 29 (2) 124–125 (2001)

Jiang, T, Liu, L, Yao, J, “Synthesis of Ag Nanoparticles on the Cotton Characterization of Ag Deposited Fabrics.” Fibers Polym., 12 (5) 620–625 (2011)

Joshi, M, Ali, SW, Rajendran, S, “Antibacterial Finishing of Polyester/Cotton Blend Fabrics Using Neem (Azadirachta indica): A Natural Bioactive Agent.” J. Appl. Polym. Sci., 106 (2) 793–800 (2007)

Yang, Z, Peng, H, Wang, W, Liu, T, “Crystallization Behavior of Poly(ε-Caprolactone)/Layered Double Hydroxide Nanocomposites.” J. Appl. Polym. Sci., 116 (5) 2658–2667 (2010)

Montazer, M, Seifollahzadeh, S, “Enhanced Self-Cleaning, Antibacterial and UV Protection Properties of Nano TiO2 Treated Textile Through Enzymatic Pretreatment.” Photochem. Photobiol., 87 (4) 877–883 (2011)

Vasilev, K, Sah, VR, Goreham, RV, Ndi, C, Short, RD, Griesser, HJ, “Antibacterial Surfaces by Adsorptive Binding of Polyvinyl-Sulphonate- Stabilized Silver Nanoparticles.” Nanotechnology, 21 (21) 215102 (2010)

Xia, N, Cai, Y, Jiang, T, Yao, J, “Green Synthesis of Silver Nanoparticles by Chemical Reduction with Hyaluronan.” Carbohydr. Polym., 86 (2) 956–961 (2011)

Alemdar, S, Agaoglu, S, “Investigation of In Vitro Antimicrobial Activity of Aloe Vera Juice.” J. Anim. Vet. Adv., 8 (1) 99–102 (2009)

Hebeish, A, El-Naggar, ME, Fouda, MMG, Ramadan, MA, Al-Deyab, SS, El-Rafie, MH, “Highly Effective Antibacterial Textiles Containing Green Synthesized Silver Nanoparticles.” Carbohydr. Polym., 86 (2) 936–940 (2011)

Rai, M, Yadav, A, Gade, A, “Silver Nanoparticles as a New Generation of Antimicrobials.” Biotechnol. Adv., 27 (1) 76–83 (2009)

Sharma, VK, Yngard, RA, Lin, Y, “Silver Nanoparticles: Green Synthesis and Their Antimicrobial Activities.” Adv. Colloid Interface Sci., 145 (1–2) 83–96 (2009)

Ilić, V, Šaponjić, Z, Vodnik, V, Potkonjak, B, Jovančić, P, Nedeljković, J, Radetić, M, “The Influence of Silver Content on Antimicrobial Activity and Color of Cotton Fabrics Functionalized with Ag Nanoparticles.” Carbohydr. Polym., 78 (3) 564–569 (2009)

El-Rafie, MH, Ahmed, HB, Zahran, MK, “Characterization of Nanosilver Coated Cotton Fabrics and Evaluation of Its Antibacterial Efficacy.” Carbohydr. Polym., 107 174–181 (2014)

Perelshtein, I, Applerot, G, Perkas, N, Guibert, G, Mikhailov, S, Gedanken, A, “Sonochemical Coating of Silver Nanoparticles on Textile Fabrics (Nylon, Polyester and Cotton) and Their Antibacterial Activity.” Nanotechnology, 19 (24) 12 (2008)

Shahid-ul-Islam, Butola, BS, Kumar, A, “Green Chemistry Based In-Situ Synthesis of Silver Nanoparticles for Multifunctional Finishing of Chitosan Polysaccharide Modified Cellulosic Textile Substrate.” Int. J. Biol. Macromol., 152 1135–1145 (2020)

Mamun, MAA, Islam, MT, Islam, MM, Sowrov, K, Hossain, MA, Ahmed, DM, Shahariar, H, “Scalable Process to Develop Durable Conductive Cotton Fabric,” Adv. Fiber Mater. (2020).

Umer, A, Naveed, S, Ramzan, N, Rafique, MS, “Selection of a Suitable Method for the Synthesis of Copper Nanoparticles.” Nano, 7 (5) 1230005 (2012)

Shahariar, H, Jur, JS, “Correlation of Printing Faults with the RF Characteristics of Coplanar Waveguides (CPWs) Printed on Nonwoven Textiles.” Sensors Actuators, A Phys., 273 240–248 (2018)

Hamedi, M, Forchheimer, R, Inganäs, O, “Towards Woven Logic from Organic Electronic Fibres.” Nat. Mater., 6 (5) 357–362 (2007)

Polte, J, et al., “Mechanism of Gold Nanoparticle Formation in the Classical Citrate Synthesis Method Derived from Coupled In Situ XANES and SAXS Evaluation.” J. Am. Chem. Soc., 132 (4) 1296–1301 (2010)

Yeo, SY, Jeong, SH, “Preparation and Characterization of Polypropylene/Silver Nanocomposite Fibers.” Polym. Int., 52 (7) 1053–1057 (2003)

Bradford, A, Handy, RD, Readman, JW, Atfield, A, Mühling, M, “Impact of Silver Nanoparticle Contamination on the Genetic Diversity of Natural Bacterial Assemblages in Estuarine Sediments.” Environ. Sci. Technol., 43 (12) 4530–4536 (2009)

Miao, AJ, Luo, Z, Chen, CS, Chin, WC, Santschi, PH, Quigg, A, “Intracellular Uptake: A Possible Mechanism for Silver Engineered Nanoparticle Toxicity to a Freshwater Alga Ochromonas Danica.” PLoS One, 5 (12) 6–13 (2010)

El-Rafie, MH, Mohamed, AA, Shaheen, TI, Hebeish, A, “Antimicrobial Effect of Silver Nanoparticles Produced by Fungal Process on Cotton Fabrics.” Carbohydr. Polym., 80 (3) 779–782 (2010)

Wimalasiri, VK, Weerathunga, HU, Kottegoda, N, Karunaratne, V, “Silica Based Superhydrophobic Nanocoatings for Natural Rubber Surfaces,” J. Nanomater., 2017 (2017).

Morones, JR, et al., “The Bactericidal Effect of Silver Nanoparticles.” Nanotechnology, 16 (10) 2346–2353 (2005)

Matsumura, Y, Yoshikata, K, Ichi Kunisaki, S, Tsuchido, T, “Mode of Bactericidal Action of Silver Zeolite and its Comparison with that of Silver Nitrate.” Appl. Environ. Microbiol., 69 (7) 4278–4281 (2003)

El-Rafie, MH, Shaheen, TI, Mohamed, AA, Hebeish, A, “Bio-Synthesis and Applications of Silver Nanoparticles Onto Cotton Fabrics.” Carbohydr. Polym., 90 (2) 915–920 (2012)

Gupta, P, Bajpai, M, Bajpai, SK, “Textile Technology: Investigation of Antibacterial Properties of Silver Nanoparticle-Loaded Poly (Acrylamide-Co-Itaconic Acid)-Grafted Cotton Fabric.” J. Cotton Sci., 12 (3) 280–286 (2008)

Ki, HY, Kim, JH, Kwon, SC, Jeong, SH, “A Study on Multifunctional Wool Textiles Treated with Nano-Sized Silver.” J. Mater. Sci., 42 (19) 8020–8024 (2007)

Hermans, MH, “Silver-Containing Dressings and the Need for Evidence.” Am. J. Nurs., 106 (12) 60–68 (2006)

Lee, HY, Park, HK, Lee, YM, Kim, K, Park, SB, “A Practical Procedure for Producing Silver Nanocoated Fabric and Its Antibacterial Evaluation for Biomedical Applications.” Chem. Commun., 28 2959–2961 (2007)

Kim, HW, Kim, BR, Rhee, YH, “Imparting Durable Antimicrobial Properties to Cotton Fabrics Using Alginate-Quaternary Ammonium Complex Nanoparticles.” Carbohydr. Polym., 79 (4) 1057–1062 (2010)

Lee, HJ, Yeo, SY, Jeong, SH, “Antibacterial Effect of Nanosized Silver Colloidal Solution on Textile Fabrics.” J. Mater. Sci., 38 (10) 2199–2204 (2003)

Gorenšek, M, Recelj, P, “Reactive Dyes and Nano-Silver on PA6 Micro Knitted Goods.” Text. Res. J., 79 (2) 138–146 (2009)

Shateri Khalil-Abad, M, Yazdanshenas, ME, Nateghi, MR, “Effect of Cationization on Adsorption of Silver Nanoparticles on Cotton Surfaces and Its Antibacterial Activity.” Cellulose, 16 (6) 1147–1157 (2009)

Pollini, M, Russo, M, Licciulli, A, Sannino, A, Maffezzoli, A, “Characterization of Antibacterial Silver Coated Yarns.” J. Mater. Sci. Mater. Med., 20 (11) 2361–2366 (2009)

Purwar, R, Joshi, M, “Recent Developments in Antimicrobial Finishing of Textiles. A Review.” AATCC Rev., 4 (3) 22–26 (2004)

Williams, U, Halo Source, J, Cho, V, “Antimicrobial Functions for Synthetic Fibers: Recent Developments.” AATCC Rev., 5 17–21 (2005)

Hebbar, RS, Isloor, AM, Ismail, AF, Contact Angle Measurements. Elsevier B.V. (2017).

Gourley, L, Britten, M, Gauthier, SF, Pouliot, Y, “Characterization of Adsorptive Fouling on Ultrafiltration Membranes by Peptides Mixtures Using Contact Angle Measurements.” J. Memb. Sci., 97 (C) 283–289 (1994)

Agnihotri, S, Mukherji, S, Mukherji, S, “Size-Controlled Silver Nanoparticles Synthesized Over the Range 5–100 nm Using the Same Protocol and Their Antibacterial Efficacy.” RSC Advances, 4 (8) 3974–3983 (2014)

Raza, M, Kanwal, Z, Rauf, A, Sabri, A, Riaz, S, Naseem, S, “Size- and Shape-Dependent Antibacterial Studies of Silver Nanoparticles Synthesized by Wet Chemical Routes.” Nanomaterials, 6 (4) 74 (2016)

Pal, S, Tak, YK, Song, JM, “Does the Antibacterial Activity of Silver Nanoparticles Depend on the Shape of the Nanoparticle? A Study of the Gram-Negative Bacterium Escherichia coli.” Appl. Environm. Microbiol., 73 (6) 1712–1720 (2007)

Xiu, Z, Zhang, Q, Puppala, HL, Colvin, VL, Alvarez, PJJ, “Negligible Particle-Specific Antibacterial Activity of Silver Nanoparticles.” Nano Letters, 12 (8) 4271–4275 (2012)

Funding

This work is supported by the research grant from Bangladesh University of Textiles, Dhaka, Bangladesh. Code: 3631108, FY-2020-21, SN- 13.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Islam, M.T., Mamun, M.A.A., Hasan, M.T. et al. Scalable coating process of AgNPs-silicone on cotton fabric for developing hydrophobic and antimicrobial properties. J Coat Technol Res 18, 887–898 (2021). https://doi.org/10.1007/s11998-020-00451-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00451-z