Abstract

Crosslinking characteristics and surface mechanical properties of radical and urethane dual-curable clearcoats were investigated by changing quantities of C=C bonds and OH groups in hydroxyl-functionalized urethane methacrylate oligomer (HFUMO) resins. The isocyanate blocked with a thermal radical initiator (BL-Tri-cHD) was utilized as a hybrid dual-curable thermal crosslinker to expedite the crosslinking of the main resin. The dual reactions between various HFUMO resins and BL-Tri-cHD were efficiently monitored via Fourier transform infrared spectroscopy to measure the peaks before and after curing. The influence of each functional group (C=C bond or OH group) in HFUMO on the initiation and development of crosslinking in dual-curable clearcoats was investigated by real-time measurements using rotational rheometer and rigid body pendulum tester. Temperature-dependent mechanical properties of cured films were confirmed through dynamic mechanical analysis. The surface mechanical properties of cured clearcoat films were also evaluated via the nanoindentation and nanoscratch tests, demonstrating the variation in surface resistance with respect to the C=C bond content and the OH value. Thus, the low-temperature curing and desired mechanical properties of clearcoats can be optimized by adjusting the content of the functional groups in a HFUMO and using a dual-curable crosslinker to simultaneously generate both radical and urethane crosslinking reactions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Automotive coatings play an important role in modulating the energy efficiency of the coating process. Exterior coatings of car bodies consist of multiple layers, such as the electrocoat, primer, basecoat, and clearcoat. The outermost layer is known as the clearcoat. It protects the car body and the inner coatings against surface defects, harmful chemicals, acid rains, scratches, UV rays, and bird droppings.1,2 To form a dense crosslinked network in the clearcoat layer, a rather high curing temperature greater than 150°C in an oven is required for 25–35 min. Recent studies in energy-saving, low-temperature curing technologies have focused on the development of plastic composites for car bodies to provide remarkable exteriors and good mechanical properties with tunability. For instance, new promising materials such as carbon fiber-reinforced polymers (CFRPs),3,4 nonferrous metals,5,6,–7 and lightweight plastics8,9 are currently used in the automotive industry. In response to this trend, the curing conditions in the coating processes need to be milder, since these materials are highly sensitive to temperature, unlike conventional steel-based frames. Therefore, it is important to develop clearcoats cured at low temperatures, which effectively saves energy and expense.

Development of major polymeric resins is a crucial issue in the field of automotive coatings such as clearcoats, considering that the coating properties are strongly affected by the curing reaction rate and density of the crosslinking network. In typical thermal curing systems, polyol resins with hydroxyl (OH) groups are predominantly applied to improve various coating properties such as leveling, gloss, and flow characteristics in clearcoats when the resins are cured with melamine or blocked isocyanate crosslinkers. However, these simple combinations containing resins with OH groups and crosslinkers are barely crosslinked at low temperatures.

Among recent developments in clearcoats, separately, a photoinduced coating system has emerged as an innovative, low-cost, and energy-saving technique due to its easy, rapid, and efficient curing by means of photoinitiators that easily generate radicals by stimulating the unsaturated C=C bonds in resins.1,2 However, UV curing generally possesses some disadvantages such as insufficient curing in inner dark shadow zones. Another way to facilitate radical polymerization in organic coatings is the inclusion of several thermal radical initiators (TRIs) such as benzoyl peroxide (BPO) and 2,2′-azobis(isobutyronitrile) (AIBN), which display their functionalities under certain high-temperature conditions. However, the BPO has a limitation that its reaction should be controlled under limited thermal energy due to the presence of the peroxide functional group.5,6 Additionally, the nitrogen in AIBN may degrade the optical and mechanical properties of cured films resulting in poor gloss and soft surface.7,10 To overcome these drawbacks, radical initiators derived from O-imino-isourea have gained importance for rapid and reliable radical reaction.11,12

A new alternative method entails reaction of unsaturated C=C bond in polyol resins with TRIs, thus enabling the curing of the coating at relatively low temperatures. Recently, Jung et al.13 have reported the role of dual-curable blocked isocyanate with a TRI (BL-Tri-cHD) to facilitate concurrent urethane and radical polymerizations between polyol resins with both OH group and C=C bond in clearcoat systems under low-temperature curing conditions. The dual-curable BL-Tri-cHD crosslinker was significantly effective in forming a crosslinked network under relatively milder curing conditions compared with the commercial blocked isocyanate (PL-350). Moreover, hydroxyl-functionalized urethane methacrylate oligomers (HFUMO) with both OH group and C=C bond, as a main binder, can play a significant role in lowering the curing temperature, when used with the hybrid BL-Tri-cHD crosslinker. By controlling the amount of the two functional groups in HFUMOs, mechanical properties and crosslinking patterns of clearcoats can be efficiently tailored.14,15,16,17,–18

In this study, thermal curing characteristics of various HFUMO resins and BL-Tri-cHD are systematically investigated based on real-time rheological and surface mechanical properties. The focus is mainly on the influence of the content of two functional units (C=C bond and OH group) in the main binder on the real-time crosslinking behavior and surface resistance properties of the clearcoat film. During thermal curing, the real-time rheological properties of HFUMO-based clearcoats were measured using a rotational rheometer equipped with a heating chamber under the small amplitude oscillatory shear (SAOS) mode. The real-time curing behavior through oscillatory pendulum periods was analyzed with a rigid body pendulum tester (RPT). RPT is particularly suited to analyze the curing dynamics of thin coating layers.19,20,21,22,–23 Dynamic mechanical analysis (DMA) of cured thin films was performed to examine the dependence of the degree of crosslinking on the temperature.24,25 The surface properties based on indentation and scratch depth profiles were qualitatively analyzed using the nanoindentation tester (nanohardness test, NHT) and nanoscratch tester (NST) at the nanometer scale.20,26,27,28,29,30,–31

Experimental methods

Synthesis of HFUMOs and blocked isocyanate using a TRI (BL-Tri-cHD)

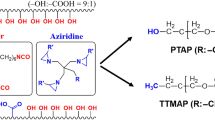

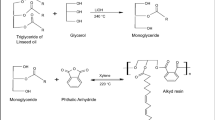

A previously reported synthetic procedure was followed to prepare blocked isocyanate with a TRI (BL-Tri-cHD) as the crosslinker and various HFUMOs with different amounts of both OH groups and C=C bonds in the backbone as the main binders (Fig. 1).13,14,–15 BL-Tri-cHD was designed to react with the two active sites in the HFUMOs, i.e., the C=C bond via free radical polymerization and the OH group via urethane reaction (Fig. 1). Above a rather mild temperature of 85°C, TRIs of BL-Tri-cHD naturally detach from the isocyanate group and generate radicals. They then react with the unsaturated C=C bond in HFUMOs, while the free isocyanates form a urethane bond with the OH group.13

To identify the influence of the amounts of C=C bonds and OH groups, HFUMO resins were synthesized in two different ways by controlling each functional group: In the first set, HFUMOs with varying C=C bond content were synthesized by manipulating the weight ratio of methacrylate to isocyanate from 0% to 60%, and the corresponding samples were designated as D0-OH125, D20-OH125, D40-OH125, and D60-OH125. The hydroxyl value in this case was 125 mg KOH/g. In the second set, the OH values of HFUMOs were altered to analyze the effect on the urethane reaction during thermal curing when the amount of C=C bond was held constant at 60%. To synthesize HFUMOs with different amounts of the OH group, the ratio of C=C acrylic prepolymer to 2-hydroxyethyl methacrylate (HEMA) was varied to 21.4%, 26.9%, 33.3%, and 39.6%, respectively, based on the solid weight. The corresponding resins obtained were designated as D60-OH40, D60-OH80, D60-OH125, and D60-OH150.

Formulation of clearcoats with various HFUMO resins

Synthesized HFUMOs were mixed with a hybrid dual-curable crosslinker (BL-Tri-cHD) for further detailed analysis of the crosslinking characteristics and physical properties of clearcoats.13 In all the clearcoat mixtures, 1,6-hexanediol diacrylate (HDDA) was added as a reactive diluent and BYK-306 was used to reduce the surface energy of the solution. Additionally, Tinuvin 400 and Tinuvin 292 were used to prevent unexpected defects induced by UV light and to stabilize the solution. The stoichiometric amounts of components required for formulating various clearcoat samples are listed in Table 1, depicting HFUMOs containing different amounts of C=C bonds and OH groups. The molar amount of the isocyanate group in the BL-Tri-cHD was adjusted to 1.1-fold that of the OH group in an HFUMO to enable a complete urethane reaction, similar to a typical clearcoat system.

Variations in functional groups by FTIR analysis

Evolution of functional groups before and after thermal curing was investigated with the help of absorbance peaks measured using Fourier transform infrared spectroscopy (FTIR, Nicolet 6700/Nicolet Continuum, Thermo Fisher Scientific Inc., USA). A comparison of the FTIR spectra of the C=C bond and OH group in HFUMOs before and after curing enabled the identification of the dual curing reactions. The radical reaction was analyzed by the changes in the height of the peak at 1635 cm−1 depicting the C=C bond, while the urethane reaction was examined by the height of the peak depicting the OH bond between 3200 and 3550 cm−1.

Real-time crosslinking behaviors of HFUMO-based clearcoats

Macroscopic real-time dual curing behaviors of various clearcoat samples were examined using an MCR-301 (Anton Paar, Austria) rotational rheometer.14,15,16,17,–18 Clearcoat samples were placed inside the controlled temperature chamber (CTC) in the rheometer. The temperature in the CTC was changed from 30 to 150°C at a heating rate of 10°C/min and maintained under isothermal conditions at 150°C for 7 min. Rheological properties of the samples were measured in the parallel plate mode with an upper plate measuring 8 mm in diameter and a gap of 500 μm. Real-time elastic modulus (G′) of the clearcoat samples was monitored under the small amplitude oscillatory shear (SAOS) condition within the linear viscoelastic regime. The oscillation strain was 2% of the total gap and the angular frequency was 5 Hz.

A rigid body pendulum tester (RPT-3000W, A&D, Japan) was also used to examine the curing dynamics of clearcoat samples in the form of thin films.19,20,21,22,–23 Coating films of 80 μm thickness were deposited on steel plates placed on a heating/cooling block. The temperature was increased from 30 to 150°C at a rate of 10°C/min and maintained at 150°C for 7 min. A knife-edge RBE-160 on an FRB-300 pendulum was implemented to penetrate the thin coating film and forced to swing by an external magnetic force. The change in the oscillation pattern caused by thermal curing of clearcoat films was reflected in terms of the oscillating period.20

Dynamic mechanical analysis of cured films

Viscoelastic properties of fully cured films were analyzed using DMA (TA instruments, DMA Q 800, USA) with respect to a change in temperature. Storage modulus of films produced with various HFUMOs was measured over a temperature range of − 50 to 150°C under oscillatory conditions of 1 Hz frequency and 0.1% strain.

Surface mechanical properties of cured films

Physical properties of cured clearcoat films were evaluated using a nanoindentation tester (NHT3) (Anton Paar Tritec SA, Switzerland) at room temperature. A 2-μm-sized Berkovich-type diamond tip was brought into contact with the cured film surfaces at a loading/unloading rate of 20 mN/min. At the maximum load of 10 mN, the pause time was set to 10 s. During the entire indentation process, the normal force–indentation depth curve was recorded. The indentation depths of the clearcoat films were compared to clarify the role of the crosslinking sites in HFUMOs. The indentation hardness values were quantitatively evaluated according to the Oliver and Pharr (O&P) approach.28

A nanoscratch tester (NST, Anton Paar Tritec SA, Switzerland) was utilized to inspect the scratch and mar resistance of cured films at room temperature. During the test, sample surfaces were scratched with a diamond sphero-conical tip with a radius of 2 μm by gradually increasing the applied normal load (20 mN/min) from 0.1 to 10 mN.20,27 The scratch depths were measured within a length of 1.0 mm at a scan speed of 2.0 mm/min during the test. For a more detailed demonstration of the scratch resistance behavior of clearcoat films, the force at the first fracture position (Lc1 point), which is related to the crosslinking degree of cured clearcoat, was specified using optical microscopy. The relevant NHT and NST data from a low-temperature curable commercial 2 K clearcoat provided by KCC company, Korea (named “Reference” sample) were included for comparison.

Results and discussion

FTIR analysis of clearcoats with varying quantities of functional groups in HFUMOs

The reactivity of HFUMO-based resins containing both C=C bonds and OH groups was analyzed by FTIR (Fig. 2). The changes in C=C and OH stretching vibrations before and after thermal curing were analyzed according to the absorbance peaks at 1635 cm−1 and the broad band in the range of 3200–3550 cm−1, respectively. The influence of the variation in the amounts of C=C bonds and OH groups in HFUMOs was determined based on their respective peaks before the thermal curing. Obviously, the C=C bond peak disappeared after the radical reaction with TRIs in BL-Tri-cHD, whereas the absorbance signal from the OH group vanished because of the urethane reaction of the OH group with the deblocked isocyanate from BL-Tri-cHD.

First, as shown in Figs. 2a and 2b, the absorbance peaks of HFUMOs with different C=C bond contents were compared. The C=C bond peak intensity increased with the increasing double bond content before curing. The OH stretching peak showed a similar absorbance pattern. Notably, the peaks of both functional groups disappeared after curing, regardless of differences in their C=C bond amounts. In the case of HFUMO resins with different OH values (Figs. 2c and 2d), the C=C peaks showed almost the same absorbance level, while the OH peaks increased significantly in intensity with the increasing OH value in the HFUMO before curing. When the curing was completed, the peaks of both functional groups evidently vanished in all cases, similar to those in Figs. 2a and 2b.

Rheological analysis of crosslinking behavior

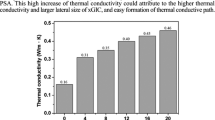

In clearcoat samples with the same content of BL-Tri-cHD, the influence of the amount of C=C bonds in HFUMOs on the progress of the radical reaction was macroscopically examined using the rotational rheometer (Fig. 3a). The real-time elastic modulus (G′) of clearcoat samples with different amounts of C=C bonds was monitored under heating conditions described in “Real-time crosslinking behaviors of HFUMO-based clearcoats” section. G′ increased rapidly with respect to the amount of C=C bonds as the temperature exceeded 70°C because the higher C=C bond content in HFUMOs increased the number of opportunities for the TRIs detached from BL-Tri-cHD crosslinker to initiate radical polymerization, thereby resulting in a rapid onset of curing. Further, the final G′ was larger with the increasing content of C=C bonds due to the enhanced crosslinking inside the network induced by the radical reaction.

Crosslinking behaviors of clearcoat mixtures containing HFUMOs with different amounts of OH groups, measured during thermal curing, are compared in Fig. 3b. In these samples, the amount of BL-Tri-cHD was altered since the ratio of the hydroxyl group in the binder to the isocyanate group in the crosslinker was maintained at 1:1.1. The onset of thermal curing was around 70°C, thus confirming the initiation of thermal curing at relatively low temperatures. The final values of G′ were inversely proportional to the amount of BL-Tri-cHD. According to the clearcoat formulation based on the fixed molar ratio (1:1.1) between the OH and NCO groups, the clearcoat system with a higher portion of binder, i.e., D60-OH40, exhibited a higher elastic modulus.12

Analysis of curing behaviors using RPT

Curing behaviors of thin clearcoat films with various HFUMOs were characterized using an RPT. The crosslinking degree of clearcoat films containing different amounts of C=C bonds was estimated using the oscillatory pendulum period (Fig. 4a). Similar to the real-time rheological properties of bulk clearcoat samples, thin coating films with more C=C bonds showed a faster curing rate and a more vigorous reaction, based on the change in the oscillating pattern. As shown in Fig. 4a, the network formation in D60-OH125 occurred immediately after 5 min following a gradual elevation in the temperature. Network formation in D40-OH125, D20-OH125, and D0-OH125 occurred sequentially, depending on their C=C bond content. The effect of the amount of C=C bond on the crosslinked network underscored the significance of dual curing as a potential method not only in low-temperature curing, but also to synergistically enhance the network properties.

Figure 4b shows the influence of OH value in HFUMOs on curing onset time and dynamics of thin clearcoat films. The curing of clearcoat samples occurred initially at a relatively low temperature. However, the extent of curing was inversely related to that of the OH value, similar to the rheological results. The portion of the HFUMO resin in the mixture primarily determines the inverse relationship between the oscillating period and the OH value during the curing reaction.

Dynamic mechanical analysis

The storage moduli (E′) of fully cured clearcoat films were compared along the measuring temperature (− 50 to 150°C) via DMA to investigate the influence of variation in C=C bond (Fig. 5a) and OH groups (Fig. 5b) in HFUMOs on their final mechanical properties. In Fig. 5a, the E′ curves for samples with different amounts of C=C bonds showed similar values at low temperature. However, under high-temperature conditions, the changes in E′ corresponded to the rheological and RPT test results, showing a higher degree of crosslinking in samples with higher C=C bond amount. Notably, the continuous decrease in E′ for D0-OH125 at high temperature might be associated with a relatively low degree of crosslinking without C=C bonds.

Figure 5b represents the E′ of clearcoat films with different OH values. Unlike Fig. 5a, HFUMO resins with different OH values showed a crossover of E′ curves as the temperature increased. From − 50 to 20°C, the E′ data strongly correlated with the data obtained from the NHT and NST tests for fully cured films, where the surface hardness was higher for D60-OH150 and lower for D60-OH40, as described in the next sections. This effect is attributed to the urethane bond, which contributes to a rigid structure with low chain mobility at such a temperature range. Meanwhile, the DMA results showed an inverse relationship between E′ and C=C bond content when the temperature increased above 20°C in real-time rheology and RPT tests.24,25

Indentation depth profiles

The indentation patterns and hardness of thermally cured clearcoat films produced from RPT were measured via NHT. Figure 6a shows the indentation depth profiles of clearcoat films with different amounts of C=C bonds in HFUMOs, suggesting that increasing the content of C=C bonds results in a shorter indentation depth and a harder surface, but the difference was not significant. The calculated indentation hardness (HIT) values indicated in the figure increased slightly with the increasing C=C bond content in HFUMOs.

The indentation properties of cured films with different OH values are depicted in Fig. 6b. Compared with Fig. 6a, the surface mechanical properties were dependent more on the proportion of OH groups than on the C=C bond content. The gap between the indentation depths in the cured films was larger. Subsequently, their surface resistance (or indentation hardness) was reduced with a decrease in the amount of OH groups, which was consistent with that of E′ at low temperature, as shown in Fig. 5b. It is worth mentioning that HFUMO-based clearcoat films used in this study exhibited better indentation profile compared to a typical 2 K film.

Scratch depth profiles

The mechanical resistance to the dynamic load on the cured film surfaces was analyzed using the NST. In Fig. 7a, clearcoat samples carrying different amounts of C=C bonds showed similar levels of mechanical resistance from scratch depths along the scan position, but revealed a clear increase in the first Lc1 point with increasing amounts of C=C bonds, as confirmed in the panoramic views (Fig. 7b). The larger Lc1 connotes the formation of a denser crosslinked network.

When cured films containing HFUMOs with different OH values were scratched (Fig. 7c), the change in the scratch depth is apparently greater in Fig. 7a. It was qualitatively consistent with the results of E′ at low temperature (Fig. 5b) and indentation profiles (Fig. 6b). Additionally, the Lc1 point in the panoramic images indicates that the network was strengthened with the increased OH value (Fig. 7d). The scratch depths and Lc1 point indicate that the cured film with the largest OH content (i.e., D60-OH150) had the highest scratch resistance.20 The large difference between scratch depth profiles is directly linked to the indentation results in the NHT analysis. The D60-OH40 film showed a severe fluctuation in scratch depth, reflecting that the reduced amount of urethane bonds in the clearcoat film result in low surface hardness.15 These results suggest that the main reaction of OH-NCO urethane bonding forms a physically stable structure between the isocyanate crosslinker and the HFUMO resin under low-temperature curing conditions.

Conclusions

The radical and urethane reactions of various clearcoats with different amounts of two functional groups, C=C bonds and OH groups, in HFUMO during the thermal curing process were investigated, focusing on real-time curing dynamics and surface mechanical properties. FTIR spectroscopy revealed the dual curing reactions of clearcoat mixtures with various HFUMO binders and a hybrid dual-curable crosslinker. The real-time curing analyses by rheological and rigid body pendulum tests showed the possibility of low-temperature curing via dynamic evolution under thermal curing. The DMA results showed the behavior of E′ under different temperatures, identifying the role of the two functional groups in the chain mobility of the crosslinked network. Surface resistance was strongly influenced by the urethane reaction in the clearcoat mixture, resulting in a strong linkage between the isocyanate crosslinker and the resin. In conclusion, the C=C bond in HFUMO resins lowers the initiation temperature by reacting with the TRI in BL-Tri-cHD, whereas the OH group contributes to the formation of a physically stable structure with a low chain mobility. Thus, an automotive clearcoat containing HFUMO resins with C=C bonds and OH groups can be applied to develop low-temperature curing systems with tunable coating properties.

References

Maier, A, Schmidt, R, Oswald-Tranta, B, Schledjewski, R, “Non-destructive Thermography Analysis of Impact Damage on Large-Scale CFRP Automotive Parts.” Materials, 7 (1) 413–429 (2014)

Oldring, PKT (ed.) Chemistry and Technology of UV and EB Formulation for Coatings, Inks and Paints, Vol. 1–5. Wiley SITA Technology, London (1991)

Pappas, SP (ed.) Radiation Curing: Science and Technology (Topics in Applied Chemistry). Springer, New York (1992)

Stewart, R, “Rebounding Automotive Industry Welcome News for FRP.” Reinf. Plast., 55 (1) 38–44 (2011)

Studer, K, Nesvadba, P, Jung, T, Benkhoff, J, Powell, K, Lordelot, C, “Novel Curing Agents: Thermal Radical Initiators as Viable Alternatives to Peroxides.” Prog. Org. Coat., 61 (2–4) 119–125 (2008)

Studer, K, Decker, C, Beck, E, Schwalm, R, Gruber, N, “Redox and Photoinitiated Crosslinking Polymerization: I. Dual-cure Isocyanate-Acrylate System.” Prog. Org. Coat., 53 (2) 126–133 (2005)

Kotoyori, T, “Critical Ignition Temperatures of Chemical Substances.” J. Loss Prev. Process Ind., 2 (1) 16–21 (1989)

Seubert, C, Nietering, K, Nichols, M, Wykoff, R, Bollin, S, “An Overview of the Scratch Resistance of Automotive Coatings: Exterior Clearcoats and Polycarbonate Hardcoats.” Coatings, 2 (4) 221–234 (2012)

Holbery, J, Houston, D, “Natural-Fiber-Reinforced Polymer Composites in Automotive Applications.” JOM, 58 (11) 80–86 (2006)

Kotoyori, T, “The Self-accelerating Decomposition Temperature (SADT) of Solids of the Quasi-autocatalytic Decomposition Type.” J. Hazard. Mater., 64 (1) 1–19 (1999)

Kim, B, Lee, DG, Kim, DY, Kim, HJ, Kong, NS, Kim, JC, Noh, SM, Jung, HW, Park, YI, “Thermal Radical Initiator Derivatives based on O-imino-isourea: Synthesis, Polymerization, and Characterization.” J. Polym. Sci. Pol. Chem., 54 (22) 3593–3600 (2016)

Hwang, JW, Kim, KN, Noh, SM, Jung, HW, “The Effect of Thermal Radical Initiator derived from O-imino-isourea on Thermal Curing Characteristics and Properties of Automotive Clearcoats.” J. Coat. Technol. Res., 12 (1) 177–186 (2015)

Jung, KI, Kim, B, Lee, DG, Lee, TH, Choi, SY, Kim, JC, Noh, SM, Park, YI, Jung, HW, “Characteristics of Dual-Curable Blocked Isocyanate with Thermal Radical Initiator for Low-Temperature Curing of Automotive Coatings.” Prog. Org. Coat., 125 160–166 (2018)

Park, S, Hwang, JW, Kim, KN, Lee, GS, Nam, JH, Noh, SM, Jung, HW, “Rheology and Curing Characteristics of Dual-Curable Clearcoats with Hydroxyl Functionalized Urethane Methacrylate Oligomer: Effect of Blocked Isocyanate Thermal Crosslinkers.” Korea-Aust. Rheol. J., 26 (2) 159–167 (2014)

Noh, SM, Lee, JW, Nam, JH, Byun, KH, Park, JM, Jung, HW, “Dual-curing Behavior and Scratch Characteristics of Hydroxyl Functionalized Urethane Methacrylate Oligomer for Automotive Clearcoats.” Prog. Org. Coat., 74 (1) 257–269 (2012)

Raghavan, SR, Chen, LA, McDowell, C, Khan, SA, Hwang, R, White, S, “Rheological Study of Crosslinking and Gelation in Chlorobutyl Elastomer Systems.” Polymer, 37 (26) 5869–5875 (1996)

Khan, SA, Plitz, IM, Frantz, RA, “In Situ Technique for Monitoring the Gelation of UV Curable Polymers.” Rheol. Acta, 31 (2) 151–160 (1992)

Chiou, BS, Raghavan, SR, Khan, SA, “Effect of Colloidal Fillers on the Cross-Linking of a UV-Curable Polymer: Gel Point Rheology and the Winter-Chambon Criterion.” Macromolecules, 34 (13) 4526–4533 (2001)

Zhang, Y, Yang, X, Zhao, X, Huang, W, “Synthesis and Properties of Optically Clear Silicone Resin/Epoxy Resin Hybrids.” Polym. Int., 61 (2) 294–300 (2012)

Noh, SM, Lee, JW, Nam, JH, Park, JM, Jung, HW, “Analysis of Scratch Characteristics of Automotive Clearcoats Containing Silane Modified Blocked Isocyanates via Carwash and Nano-scratch Tests.” Prog. Org. Coat., 74 (1) 192–203 (2012)

Chiu, HT, Wu, JH, “A Study on the Curing Behavior of Silicone/Polyurethane/Epoxy Blends by Rigid-Body Pendulum Rheometer.” Polym.-Plast. Technol. Eng., 45 (9) 1081–1085 (2006)

Chiu, HT, Wu, JH, “Silicone/Polypropylene Oxide-Polyethylene Oxide Copolymer/Clay Composites (i) - Curing Behavior, Intermolecular Interaction and Thermomechanical Properties.” J. Polym. Res., 11 (4) 247–255 (2005)

Chiu, HT, Cheng, JO, “Thermal Imidization Behavior of Aromatic Polyimides by Rigid-Body Pendulum Rheometer.” J. Appl. Polym. Sci., 108 (6) 3973–3981 (2008)

Rath, SK, Bahadur, J, Panda, HS, Sen, D, Patro, TU, Praveen, S, Patri, M, Khakhar, DV, “Anomalous Toluene Transport in Model Segmented Polyurethane–Urea/Clay Nanocomposites.” Soft Matter, 14 (19) 3870–3881 (2018)

Das, A, Mahaling, RN, Stöckelhuber, KW, Heinrich, G, “Reinforcement and Migration of Nanoclay in Polychloroprene/Ethylene–Propylene–Diene-Monomer Rubber Blends.” Compos. Sci. Technol., 71 (3) 276–281 (2011)

Briscoe, BJ, Fiori, L, Pelillo, E, “Nano-indentation of Polymeric Surfaces.” J. Phys. D- Appl. Phys., 31 (19) 2395 (1998)

Tahmassebi, N, Moradian, S, Ramezanzadeh, B, Khosravi, A, Behdad, S, “Effect of Addition of Hydrophobic Nano Silica on Viscoelastic Properties and Scratch Resistance of an Acrylic/Melamine Automotive Clearcoat.” Tribol. Int., 43 (3) 685–693 (2010)

Pharr, GM, Oliver, WC, Brotzen, FR, “On the Generality of the Relationship Among Contact Stiffness, Contact Area, and Elastic Modulus During Indentation.” J. Mater. Res., 7 (3) 613–617 (1992)

Oliver, WC, Pharr, GM, “An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments.” J. Mater. Res., 7 (6) 1564–1583 (1992)

Ngan, AHW, Wang, HT, Tang, B, Sze, KY, “Correcting Power-law Viscoelastic Effects in Elastic Modulus Measurement Using Depth-sensing Indentation.” Int. J. Solids Struct., 42 (5–6) 1831–1846 (2005)

Decker, C, Lorinczova, I, “UV-radiation Curing of Waterborne Acrylate Coatings.” JCT Res., 1 (4) 247–256 (2004)

Acknowledgments

This study was supported by research grants from the Ministry of Trade, Industry & Energy (MOTIE, Korea) under the Industrial Technology Innovation Program (Nos. 10067706, 20010256).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

June, YG., Jung, K.I., Lee, D.G. et al. Influence of functional group content in hydroxyl-functionalized urethane methacrylate oligomers on the crosslinking features of clearcoats. J Coat Technol Res 18, 229–237 (2021). https://doi.org/10.1007/s11998-020-00398-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00398-1