Abstract

In this paper, we report the synthesis of different silica materials via the acid-catalyzed sol–gel process at room temperature (25°C), using silane precursors with various alkyl chains (dimethyl, octyl and/or hexadecyl), in order to obtain thin films with anti-reflective and hydrophobic properties. Chemical, optical and structural properties of obtained silica materials were thoroughly characterized with various techniques such as FTIR and UV–Vis spectroscopy, AFM analysis, ellipsometric measurements, ESEM and TEM microscopy. Wettability of thin films was evaluated by water contact angle measurements. FTIR spectra of silica materials revealed that the intensity of the Si–O–Si characteristic bands varies depending on the precursor type. From AFM results, we found that the obtained films present a different microstructure as a function of the silica sol formulations. The hydrophobic character of the thin films increases with increasing the length of the hydrophobic chains following the order: dimethyl < octyl < hexadecyl. UV–Vis analysis of the coatings covered with silica materials presents a low reflectance (15.5%). The proposed method in this work has the potential to be a low-cost processing path of nanostructured anti-reflection transparent substrates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Multifunctional transparent silica films/coatings are becoming very popular due to their variety of applications from anti-icing to self-cleaning, low-adhesion, anisotropic wetting, structural color, anti-reflection and anti-fogging.1,2,3,4,5,6

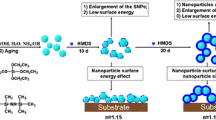

The surface properties, resulting from the multiscale structures, are due to the surface textures being on different length scales, whereas chemical properties depend less on material topography. The most common methods to prepare the nanostructured silica films are chemical vapor deposition, chemical etching and sol–gel processes.7,8,9,10 Among these techniques, sol–gel is the most commonly used because of its simplicity and large area of applications in solar panels, light sensors and high-powered laser fusion systems.11,12,13,14,15,16 The sol–gel-derived thin films can be obtained by modifying the reflectivity of the substrate surface or modifying its surface chemistry. Many factors play an important role in the final properties of sol–gel-derived coatings, such as sol–gel solution, method of application, substrate and its surface conditions. The anti-reflective coatings of sol–gel silica materials are very attractive, due to low refractive indices, low scatter and high laser damage thresholds.17 Optically transparent films that exhibit both hydrophobicity and high visible light transmittance have been potentially suitable for optical devices and thermal collectors. In order to obtain hydrophobic and transparent films, the high surface roughness required for being water repellent needs to be balanced with the low roughness needed for optical transparency. Tadanaga et al.18 reported the preparation of sol–gel transparent superhydrophobic films on glass plates by the combination of microstructural and chemical approaches. It was demonstrated that the silica sol can be modified using hexamethyldisilazane (HMDS), trimethylalkoxysilane and dimethylalkoxysilane.17,18,19,20 Ahangarania et al.21 obtained highly transparent and hydrophobic silica coatings via a simple dip-coating technique, using tetraethylorthosilicate (TEOS) as a precursor and polydimethylsiloxane (PDMS) as a hydrophobic modifying agent. Shirtcliffe et al.22 prepared porous sol–gel foams from organo-triethoxysilanes which were either completely filled with liquid or not wetted at all when exposed to different temperatures. It was shown that the surface property can be changed from hydrophilic to hydrophobic using hexadecyltrimethoxysilane (HDTMS) and silica.23 It was demonstrated that the addition of hexadecyltrimethoxysilane and triethoxytridecafluorooctylsilane to sol–gel coatings offers the most suitable chance for preparation of water repellent textiles by sol–gel coatings.24 Liu and coworkers25 developed a simple method to fabricate cotton fabrics with environmentally stable superhydrophobicity, using hybrid photoreactive silica nanoparticles and hexadecyltrimethoxysilane. It was observed that the superhydrophobic cotton fabric presents excellent washing durability. Wang et al.26 achieved two interference-type SiO2/TiO2 and SiO2/SnO2/SiO2–SnO2 multilayer anti-reflective coatings prepared via the sol–gel technique. The optical constants of the source materials were directly extracted from the sol–gel-prepared oxide thin films. Yi et al.27 reported the preparation of discrete silica nanowires with a hydrophobic surface by anisotropic sol–gel growth in a water/oil emulsion, using trimethoxy(octadecyl)silane (C18TMOS). The dip-coating method was applied to assemble substrate-supported nanowire films. It was demonstrated that the C18 alkyl groups on the silica nanowire surface can effectively maintain the superhydrophobic properties of the membrane in a wet environment. Thin films with superhydrophobic and near-infrared (NIR) reflectance properties were prepared by Sriramulu et al.28 using nanoparticles functionalized with perylene diimide and trimethoxy(octadecyl)silane (TMODS).

In the present research work, the hybrid silica films/coatings have been prepared using sol–gel acid-catalyzed silica materials that contain silane precursors with different alkyl chains (dimethyl, octyl and/or hexadecyl). The purpose was to introduce a less toxic, cost-effective and easy approach to get transparent and hydrophobic silica thin films on glass surface. The mentioned silane precursors were used for surface modification, promoting a high level of adhesion at the interface. The synthesis of silica materials through sol–gel process using octyltriethoxysilane and hexadecyltrimethoxysilane or reaction between dimethoxydimethylsilane, octyltriethoxysilane and hexadecyltrimethoxysilane were not yet reported. Obtained samples were characterized both as powders (obtained after solvent evaporation) and as films (deposited onto clean glass slides), using Fourier transform infrared (FTIR) and ultraviolet–visible (UV–Vis) spectroscopy techniques, atomic force microscopy (AFM) analysis, ellipsometric measurements, ESEM and TEM microscopy and water contact angle measurements.

Materials and methods

Materials

Tetraethoxysilane (98%, TEOS, Aldrich) was used as a silica source. Silane precursors with long alkyl chains were used as hydrophobic modifying agents: dimethoxydimethylsilane (95%, DMDTES, Aldrich), octyltriethoxysilane (97%, OTES, Fluka) and hexadecyltrimethoxysilane (85%, HDTMS, Aldrich). Titanium(IV) isopropoxide (97%, TIP, Aldrich) was used as a crosslinking agent in the sol–gel process. Maleic anhydride (MA, Fluka) was added as a complexing/retardant agent. As a solvent, ethanol (99.9%, EtOH) was obtained from Chimreactiv S.R.L. As a catalyst, HCl (0.1 N) was purchased from Sigma-Aldrich. The chemicals were used as received.

Synthesis of sol–gel silica materials

Different silica materials were prepared in a similar way to that previously reported29 by the acid-catalyzed sol–gel process in two steps in order to obtain thin films with anti-reflective and hydrophobic properties.

In the first step, TEOS and silane precursors (DMDTES, OTES and/or HDTMS) were hydrolyzed in acidic conditions using ethanol (6 mL) and HCl (0.1 N; 0.23 mL). The solutions were magnetically stirred for 1 h, 300 rpm, at room temperature (25°C). As a second step, maleic anhydride (MA) (0.06 g) and crosslinking agent (TIP, 0.32 mL) were added to the solution. In order to continue the sol–gel process, the second portion of HCl (0.1 N; 0.5 mL) was added and the mixture was stirred for another hour at 25°C. The molar ratio between the silane precursors was 1:1. The amounts of silane agents used to obtain silica materials are summarized in Table 1. Obtained samples were characterized both as powders (obtained after solvent evaporation) and as film (deposited by dip-coating onto clean glass slides). Before deposition of final silica materials onto surface, the glass substrate was cleaned with soap, distilled water and finally with ethanol. All final materials were dried and kept (overnight) at room temperature (25°C) before being used for further investigations.

Characterization

Final silica materials were thoroughly characterized with various techniques such as FTIR and UV–Vis spectroscopy, ellipsometric measurements, ESEM and TEM microscopy, AFM analysis and water contact angle measurements.

FTIR spectra of materials were obtained through Jasco FTIR 6300 instrument (JASCO Int. Co., Ltd., Tokyo, Japan) with a wavenumber interval of 400–4000 cm−1 (30 scans at a resolution of 4 cm−1). All samples were dried at room temperature and characterized as powders through FTIR spectroscopy.

Obtained samples were also characterized as films (deposition of silica sols onto glass surfaces) using UV–Vis spectroscopy, AFM analysis and water contact angle measurements.

AFM measurements were made with XE-100 from Park Systems. To minimize tip-sample interaction, all AFM images were recorded in true non-contact mode (patented by Park Systems) using sharp tips (NCLR from NanosensorsTM), with a radius of curvature of typically 7 nm, spring constant around 32 N/m and vibrating frequency of about 166 kHz. The AFM micrographs were processed with XEI program (v 1.8.0 - Park Systems) for displaying purposes and for subsequent statistical data analysis, including the calculation of the root mean square roughness. The AFM images are presented in the so-called “enhanced color” view mode (patented by Park Systems, which uses the change of a pixel relative to its neighbors) in order to have a better contrast of the surface topography. In the AFM images below, one arbitrary line (so-called “line scan”) is presented showing in detail the surface profile of each investigated sample.

The ellipsometric measurements were carried out on a Rotating Analyzer Ellipsometer from J.A. Woollam™, in the 300–1000 nm spectral range, with a 5 nm resolution, at an incidence angle of 60°, in air at room temperature.

Reflectance spectra of coated samples were determined by diffuse reflectance analysis, in the range of 380–780 nm, using a UV–VIS-NIR-Jasco V-570 spectrophotometer (JASCO Int. Co., Ltd., Tokyo, Japan).

Morphology and microstructure of resulted silica hybrid materials were studied by environmental scanning electron microscopy (ESEM), using a FEI-Quanta 200 microscope, and by transmission electron microscopy (TEM), employing a Tecnai ™ G2 F20 TWIN Cryo-TEM instrument (FEI Company) at 200 kV acceleration voltages.

Contact angle (CA) measurements were performed by a CAM 200 contact angle tensiometer (KSV Instruments, Finland) equipped with a high-resolution camera (Basler A602f) and an auto-dispenser. All CA measurements were carried out in a static regime at room temperature (drop volume of 6 µL). The values of contact angles were calculated from water drop images (average of ten liquid droplets placed in various regions of the film surface).

Results and discussion

FTIR spectroscopy

To evaluate the functional groups present in the materials, we recorded the FTIR spectra of the sol–gel silica materials characterized as powders (Fig. 1). In the FTIR spectra of these materials, the bands of Si–O–Si (bending vibration and asymmetric stretching) can be observed at ~ 800 and ~ 1040 cm−1.30,31 In the formation of sol–gel silica materials, Si–O–Si network was formed during the hydrolysis and condensation process, and the siloxane network could be the steric hindrance for the polymerization of alkyl group.32

It has been observed that the intensity of the Si–O–Si characteristic bands varies depending on the type of precursor used in the synthesis. This band is located at ~ 1030 cm−1, suggesting that the condensation reaction tends to form linear networks. The shift of this band toward a lower wavenumber can be due to the overall decrease in the Si–O force constant characteristic of alkylsilane group’s incorporation.33 Hydrophobicity of the Si–O–Si network by condensation of the Si–OH groups leads to an increase in the intensity of absorption corresponding to the stretching vibration of the C–H bonds.

The shift toward longer wavenumbers of the Si–O–Si band (~ 1045 cm−1, asymmetrical stretching vibrations) may be due to the presence of Si–C bonds, leading to the partial destruction of the symmetry of Si–O–Si bonds from the hybrid silica network.

In the co-hydrolysis and polycondensation reactions that occurred in the organoalkoxysilane-tetraalkoxysilane systems, the trialkoxysilyl groups are partially integrated into the siloxane networks due to the crosslinking abilities of the intermediates.

In the FTIR spectra of samples S1, S2 and S6, the characteristic bands of Si–CH3 groups were found at ~ 846 cm−1 (swinging vibration of CH2) and ~ 1260 cm−1, respectively (symmetrical deformation vibration of C–H bond). The data indicated that CH2 groups exhibit two characteristic bands: an asymmetric stretching vibration at ~ 2925 cm−1 and a symmetric stretching vibration at 2854 cm−1.34 The peak at 1465 cm−1 is attributed to the bending vibrations of −CH2–.35 All of the previously discussed data are summarized in Table 2.

Analyzing the FTIR spectra, it can be concluded that the hydrolysis and polycondensation reactions between the silane precursors successfully occurred.

Atomic force microscopy and diffuse reflectance analysis

The obtained samples sols were deposited (by drop) onto microscopic glass slides, dried at room temperature (25°C) and characterized as films topographically and optically through AFM (Fig. 2) and diffuse reflectance analysis (Fig. 3).

AFM was used to follow the topographical and textural changes of the sol–gel silica coatings as a function of their preparation. One reason is that the surface morphology of the prepared films has a clear/strong effect on water repellence properties.

Figure 2 shows the surface morphology of the films obtained by silane material deposition onto glass slides. Two-dimensional AFM images, with a surface area of 1 × 1 μm2, are presented in Fig. 2, together with arbitrary line scans registered along the red lines indicated in each AFM micrograph. From Fig. 2, textural changes can be observed due to the modification of the sols with organic radicals.

Among the investigated samples, samples S5 and S6 exhibit a more uniform aspect, as also suggested by their plotted line scans. Overall, all samples are very smooth, with root mean square (RMS) roughness values that do not exceed 0.35 (sample S1), having surface profile with a z-corrugation in a domain of ~ 1 nm (Δz of their line scans from − 0.5 to 0.5 nm). Therefore, beside RMS roughness and line scans, a more complete picture of samples topography could be offered by the peak-to-valley (Rpv) parameter, which gives the difference between the deepest and highest points in each scanned area. Therefore, in Fig. 3, the RMS roughness values are plotted together with the Rpv parameters for all silica-based samples, as obtained from the AFM images presented in Fig. 2. The RMS roughness values of the obtained films stand in the range of 0.24–0.33 nm, with the lowest one (0.24 nm) being recorded for both samples S2 and S4. However, for samples S2 and S4, different Rpv parameters are estimated, namely of 2.22 nm (sample S5) and 1.77 nm (sample S4), which appear to be the smoothest surface among the samples under discussion.

Therefore, it can be stated that the hydrophobic character of the silica-based films (as will be shown in “Contact angle measurements” section) is due to the chemical properties of the films and not linked to their morphology.

We found that thin films present anti-reflective properties in the wide visible light wavelength region on glass substrates. Figure 4 shows the diffuse reflectance analysis as a function of a wavelength of the visible light and indicates the anti-reflective character of the thin films (obtained by dip-coating deposition of sol–gel silica materials onto glass slides). UV–Vis analysis of the uncoated glass substrate revealed a reflectance value of 16.2% at 550 nm, whereas the coatings covered with silica materials presented a low reflectance (15.5%). The anti-reflective effects based on the small roughness in this study showed small incident angle dependence.36

Optical constants variation of the anti-reflective films deposited on glass substrate is shown in Fig. 5. The recorded spectra as Psi and Delta were fitted by WVASE® software37 in order to evaluate the layer thickness and the optical constants. Ellipsometric fit parameters of the anti-reflective films deposited on glass substrate are presented in Table 3. A three-layer model (air/anti-reflective film/intermix/glass substrate) was used to model the experimental data. For the substrate, we built our own optical constants by measuring a clean glass slide and fitting the experimental data with a Cauchy model.38 Intermix is a thickness adjusting layer based on Bruggeman Effective Medium Approximation (B-EMA) theory,39 consisting of a mixture of 50–50% volume fraction of materials underneath and above it. The anti-reflective film was also fitted by a Cauchy model. Another active fit parameter was the angular spread, which is a non-ideality for slightly curved surfaces. The quality of the fits was evaluated by Mean Squared Error (MSE) regression analysis.40

From the best fits with the lowest MSE values, the layer thickness and optical constants were obtained. The film thickness varies roughly from 1 up to 4 µm as a function of composition and deposition conditions. Regarding the optical constants, all the films have refractive index values smaller than the glass substrate, and the smallest values were determined for sample S1. All the films are optically transparent on large spectral range, having the adsorption edge below 380 nm (3.3 eV).

Contact angle measurements

Figure 6 depicts the drops of water deposited on the surfaces coated with the sol–gel silica materials. Analyzing the data, we can see that these coatings have hydrophobic properties (water contact angle > 90°). Improving the hydrophobic character of the coatings is a result of the decrease in surface energy caused by the presence of a large number of hydrophobic groups at the surface. It can be observed that the water contact angle onto glass surfaces increases from 96° to 110°. In hydrolysis and polycondensation reactions, the –H’s of the surface OH’s of silica films are replaced by –Si–CH3 groups, resulting in dehydroxylation of the film surface. These groups form a layer on the surface that is nonhydrolyzable and hence hydrophobic.41 When the surface is covered by the –Si–CH3 groups, the silica surface can result in more C–H bonds giving rise to more hydrophobicity. The hydrophobic character of the films increases with increasing the length of the hydrophobic chains following the order: dimethyl < octyl < hexadecyl. Film obtained by sol–gel silica material that contains TEOS + HDTMS (sample S4) presents a high contact angle (109 ± 2°) compared with other films and proves that (at least on the exposed surface) the less polar (organic) component dominates. The trimethylsilyl functionalization of silica materials greatly modified the water adsorption isotherms, making them significantly more resistant to water absorption.42 The experimental data are similar with other results already reported.43 The hydrolyzed TEOS bonds produced during the hydrolyzing stage reacted with HDTMS, producing more hydrophobic bonds. The resulting hierarchal surfaces are not sufficiently rough to provide superhydrophobicity in the form of microscopic air pockets.

ESEM and TEM microscopy

The microstructure of silica hybrid materials is presented in Fig. 7. It was demonstrated that the adhesion to glass depends on the nature of the organic radical of the alkoxysilane.33

The scanning electron microscopy analysis shows that the silica hybrid materials present less self-assembled structure which can be attributed to the lower hydrophobicity. The ESEM images indicate that there were no significant morphological and structural changes in the silica hybrid materials. No additional cracks or other defects were identified. Nimittrakoolchai et al.44 demonstrated that the surface that contains more hydroxyl-terminated polydimethylsiloxane component tended to yield better hydrophobic property than the surface that contains more inorganic component, regardless of the degree of surface roughness.

TEM microscopy was used to investigate the compatibility between the organic and the inorganic phases. From TEM images, the silica hybrid materials exhibit good distribution and miscibility between organic and inorganic phases. All samples show silica nano-clusters (dark spots). It was shown that the free silanol groups in the silica domains condensed with each other by forming Si–O–Si linkages. These linkages brought the molecules closer together determinate the growing of the silica domains or clusters (Fig. 8).45

Conclusions

Thin films with anti-reflective and hydrophobic properties were prepared by deposition onto glass surface of silica hybrid materials obtained via acid-catalyzed sol–gel process. The sol–gel silica materials were obtained using different silane precursors (dimethoxydimethylsilane, octyltriethoxysilane and hexadecyltrimethoxysilane). Optical, morphological and structural properties of obtained coatings were presented. FTIR spectra showed that the Si–O–Si networks are formed in the silica hybrid systems. The thickness of prepared hybrid coatings varied roughly from 1 up to 4 µm. UV–Vis analysis of substrates covered with silica hybrid materials revealed a reflectance value of about 15.6% at 550 nm. TEM and ESEM analyses showed that silica hybrid materials exhibited a smooth film surface and a good homogeneous distribution of silica domains in the hybrid systems. The film with HDTMS (S4) had a good water contact angle compared with other films (109 ± 2°). The obtained silica coatings via acid-catalyzed sol–gel process could be used for the coating of optical elements sensitive to humidity.

References

Mihoreanu, C, Banciu, A, Enesca, A, Anca, D, “Silica-Based Thin Films for Self-Cleaning Applications in Solar Energy Converters.” J. Energy Eng., 143 04017029 (2017)

Joshi, DN, Atchuta, SR, Lokeswara, RY, Naveen, KA, Sakthivel, S, “Super-Hydrophilic Broadband Anti-reflective Coating with High Weatherstability for Solar and Optical Applications.” Sol. Energy Mater. Sol. Cells, 200 110023–110028 (2019)

Tasleem, S, Sabah, A, Cheema, UA, Sabir, A, “Transparent Hydrophobic Hybrid Silica Films by Green and Chemical Surfactants.” ACS Omega, 4 13543–13552 (2019)

Prasad, G, Chakradhar, RPS, Parthasarathi, B, Anand Prabub, A, Anandana, C, “Transparent Hydrophobic and Superhydrophobic Coatings Fabricated Using Polyamide 12–SiO2 Nanocomposite.” Surf. Interface Anal., 49 427–433 (2017)

Farhadi, S, Farzaneh, M, Kulinich, SA, “Anti-icing Performance of Superhydrophobic Surfaces.” Appl. Surf. Sci., 257 6264–6269 (2011)

Garlisi, C, Trepci, E, Li, X, Sakkaf, RA, Al-Ali, K, Nogueira, RP, Zheng, L, Azar, E, Palmisano, G, “Multilayer Thin Film Structures for Multifunctional Glass: Self-Cleaning, Antireflective and Energy-Saving Properties.” Appl. Energy, 264 114697–114728 (2020)

Spataru, CI, Purcar, V, Ghiurea, M, Radovici, C, Stanga, G, Donescu, D, “Effects of the Nanoassociation of Hexadecyltrimethoxysilane Precursors on the Sol–Gel Process.” J. Sol–Gel Sci. Technol., 65 (3) 344–352 (2012)

Nostell, P, Roos, A, Karlson, B, “Optical and Mechanical Properties of Sol–Gel Antireflective Films for Solar Energy Applications.” Thin Solid Film, 434 170–175 (1999)

Biswas, PK, Sujatha Devi, P, Chakraborty, PK, Chatterjee, A, Ganguli, D, Kamath, MP, Joshi, AS, “Porous Anti-reflective Coatings with a High Spectral Coverage by Sol–Gel Spin Coating Technique.” J. Mater. Sci. Lett., 22 181–183 (1999)

Brevnov, DA, Barela, M, Piyasena, ME, López, GP, Atanassov, PB, “Patterning of Nanoporous Anodic Aluminum Oxide Arrays by Using Sol–Gel Processing, Photolithography, and Plasma Etching.” Chem. Mater., 16 682–687 (2004)

Hsu, CC, Lan, WL, Chen, NP, Wu, CC, “The Hydrophobic and Omnidirectional Antireflection Coating of SiO2 Nanospheres with C18-TEOS.” Opt. Laser Technol., 58 202–206 (2014)

Sim, DM, Choi, MJ, Hur, YH, Nam, B, Chae, G, Park, JH, Jung, YS, “Ultra-High Optical Transparency of Robust, Graded-Index, and Anti-fogging Silica Coating Derived from Si-Containing Block Copolymers.” Adv. Opt. Mater., 1 428–433 (2013)

Guo, ZL, Zhao, HX, Zhao, W, Wang, T, Kong, DP, Chen, TJ, Zhang, XY, “High-Quality Hollow Closed-Pore Silica Antireflection Coatings Based on Styrene–Acrylate Emulsion @ Organic–Inorganic Silica Precursor.” ACS Appl. Mater. Interfaces, 8 11796–11805 (2016)

Moghal, J, Kobler, J, Sauer, J, Best, J, Gardener, M, Watt, AA, Wakefield, G, “High-Performance, Single-Layer Antireflective Optical Coatings Comprising Mesoporous Silica Nanoparticles.” ACS Appl. Mater. Interfaces, 4 854–859 (2012)

Wang, WT, Lu, N, Hao, JY, Xu, HB, Qi, DP, Chi, LF, “Self-Assembled Monolayer Islands Masked Chemical Etching for Broad-Band Antireflective Silicon Surfaces.” J. Phys. Chem. C, 114 1989–1995 (2010)

Poirié, T, Schmitt, T, Bousser, E, Vernhes, R, Martinu, L, Klemberg-Sapieha, JE, “Hybrid Organic/Inorganic Nanolaminate Structures with Enhanced Tribo-mechanical Properties for Optical Applications.” Surf. Coat. Technol., 315 399–407 (2017)

Xu, Y, Zhang, B, Fan, WH, Sun, HY, “Antireflective Silica Thin Films with Super Water Repellence via Sol–Gel Process.” Appl. Opt., 42 108–112 (2003)

Tadanaga, K, Katata, N, Minami, T, “Super-Water-Repellent Al2O3 Coating Films with High Transparency.” J. Am. Ceram. Soc., 80 (4) 1040–1042 (1997)

Suratwala, I, Hanna, L, Miller, EL, Whitman, PK, Thomas, IM, Ehrmann, PR, “Surface Chemistry and Trimethylsilyl Functionalization of Stober Silica Sols.” J. Non-Cryst. Solids, 316 349–363 (2003)

Xu, Y, Zhang, B, Fan, WH, Sun, HY, “Comparative Study on Hydrophobic Antireflective Films from the Three Kinds of Methyl-Modified Silica Sols.” J. Non-Cryst. Solids, 351 258–266 (2005)

Ahangarani, S, Lari, N, Shanaghi, A, “A Novel Route to Prepare Hydrophobic and Durable Antireflective Hybrid Silica Coating by Sol–Gel Method.” Prot. Met. Phys. Chem., 52 475–480 (2016)

Shirtcliffe, NJ, McHale, G, Newton, MI, Perry, CC, Roach, P, “Porous Materials Show Superhydrophobic to Superhydrophilic Switching.” Chem. Commun., 25 3135–3137 (2005)

Pipatchanchai, T, Srikulkit, KJ, “Hydrophobicity Modification of Woven Cotton Fabric by Hydrophobic Fumed Silica Coating.” J. Sol–Gel Sci. Technol., 44 119–123 (2007)

Mahltig, B, Bottcher, H, “Modified Silica Sol Coatings for Water-Repellent Textiles.” J. Sol–Gel Sci. Technol., 27 43–52 (2003)

Liu, B, Wang, L, Gao, Y, Tian, T, Min, J, Yao, J, Xiang, Z, Huang, C, Hu, C, “Synthesis and Characterization of Photoreactive Silica Nanoparticles for Super-Hydrophobic Cotton Fabrics Application.” Text. Res. J., 85 795–803 (2014)

Wang, J, Ge, J, Hou, H, Wang, M, Liu, G, Qiao, G, Wang, Y, “Design and Sol–Gel Preparation of SiO2/TiO2 and SiO2/SnO2/SiO2–SnO2 Multilayer Antireflective Coatings.” Appl. Surf. Sci., 422 970–974 (2017)

Yi, D, Xu, C, Tang, R, Zhang, X, Caruso, F, Wang, Y, “Synthesis of Discrete Alkyl-Silica Hybrid Nanowires and Their Assembly into Nanostructured Superhydrophobic Membranes.” Angew. Chem. Int. Ed., 55 8375–8380 (2016)

Sriramulu, D, Reed, LE, Annamalai, M, Venkatesan, VT, Valiyaveettil, S, “Synthesis and Characterization of Superhydrophobic, Self-Cleaning NIR-Reflective Silica Nanoparticles.” Sci. Rep., 6 35993–36002 (2016)

Purcar, V, Rădiţoiu, V, Dumitru, A, Nicolae, CA, Frone, AN, Anastasescu, M, Rădiţoiu, A, Raduly, MF, Gabor, RA, Căprărescu, S, “Antireflective Coating Based on TiO2 Nanoparticles Modified with Coupling Agents via Acid-Catalyzed Sol–Gel Method.” Appl. Surf. Sci., 487 819–824 (2019)

Zhang, Y, Zhang, X, Ye, H, Xiao, B, Yan, L, Jiang, B, “A Simple Route to Prepare Crack-Free Thick Antireflective Silica Coatings with Improved Antireflective Stability.” Mater. Lett., 69 86–88 (2012)

Uysal, B, Tepehan, FZ, “Controlling the Growth of Particle Size and Size Distribution of Silica Nanoparticles by the Thin Film Structure.” J. Sol–Gel Sci. Technol., 63 177–186 (2012)

Tadanaga, K, Ueyama, K, Sueki, T, Matsuda, A, Minami, T, “Micropatterning of Inorganic–Organic Hybrid Coating Films from Various Tri-Functional Silicon Alkoxides with a Double Bond in Their Organic Components.” J. Sol–Gel Sci. Technol., 26 431–434 (2003)

Purcar, V, Stamatin, I, Cinteza, O, Petcu, C, Raditoiu, V, Ghiurea, M, Miclaus, T, Andronie, A, “Fabrication of Hydrophobic and Antireflective Coatings Based on Hybrid Silica Films By Sol–Gel Process.” Surf. Coat. Technol., 206 4449–4454 (2012)

Gao, W, Reven, L, “Solid-State NMR Studies of Self-Assembled Monolayers.” Langmuir, 11 1860–1863 (1995)

Pereiraa, MM, Nevesa, ÂCB, Calvete, MJF, Dias, LD, Fernandes, A, “Binol Derivative Ligand Immobilized onto Silica: Alkyl-Cyanohydrinsynthesis via Sequential Hydroformylation/Heterogeneous Cyanosilylation Reactions.” Catal. Today, 99 218–219 (2013)

Tadanaga, K, “Surface Morphology Control of Thin Films Prepared by Solution Processes and Its Application.” J. Ceram. Soc. Jpn., 121 819–824 (2013)

Tompkins, HG, WVASE32® Software Training Manual. J.A. Woollam Co., Inc., Lincoln (2006)

Tompkins, HG, McGahan, WA, Spectroscopic Ellipsometry and Reflectometry. Wiley, New York (1999)

Bruggeman, DAG, “Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen.” Ann. Phys., 24 636–679 (1935)

Tompkins, HG, Irene, EA, Handbook of Ellipsometry. William Andrew Publishing, Norwich (2005)

Rao, V, Latthe, SS, Nadargi, DY, Hirashima, H, Ganesan, V, “Preparation of MTMS Based Transparent Superhydrophobic Silica Films by Sol–Gel Method.” J. Colloid Interface Sci., 332 484–490 (2009)

Philipavičius, J, Kazadojev, I, Beganskienė, A, Melninkaitis, A, Sirutkaitis, V, Kareiva, A, “Hydrophobic Antireflective Silica Coatings via Sol–Gel Process.” Mater. Sci. Medzg., 14 283–287 (2008)

Wang, SD, Luo, SS, “Fabrication of Transparent Superhydrophobic Silica-Based Film on a Glass Substrate.” Appl. Surf. Sci., 258 5443–5450 (2012)

Nimittrakoolchai, O, Supothina, S, “Deposition of Transparent, Hydrophobic Polydimethylsiloxane—Nanocrystalline TiO2 Hybrid Films on Glass Substrate.” Songklanakarin J. Sci. Technol., 32 157–162 (2010)

Jena, KK, Alhassan, SM, Tiwari, A, Hihara, LH, “Functional Nano-coating Materials by Michael Addition and Ring-Opening Polymerization: Reactivity, Molecular Architecture and Refractive Index.” Sci. Rep., 8 11912–11921 (2018)

Acknowledgments

The work has been supported by a grant of the Romanian Ministery of Research and Innovation, PCCDI—UEFISCDI, project number PN-III-P1-1.2-PCCDI-2017-0428, within PNCDI III (Nos. 40PCCDI, PC4-FOTOMAH) and supported by Romanian Ministry of Research and Innovation -MCI through INCDCP ICECHIM Bucharest 2019-2022 Core Program PN. 19.23 - Chem-Ergent, Project No. 19.23.03.04.

Author information

Authors and Affiliations

Contributions

VP conceived and designed the experiments; VR established the methodology; AR reflectance analysis; FMR FTIR analysis; ANF water contact angle measurements; MA AFM analysis; MS ellipsometric measurements; EA ESEM analysis; RŞ TEM analysis; LEW and SC supervised the experiments; RM and GCI designed the manuscript. Each contributor was essential to the production of this work.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rădiţoiu, V., Purcar, V., Rădiţoiu, A. et al. Sol–gel hybrid films based on organosilanes with long alkyl chains. J Coat Technol Res 17, 1389–1399 (2020). https://doi.org/10.1007/s11998-020-00359-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00359-8