Abstract

Superhydrophilic stainless steel mesh membranes (SSMMs) with excellent antifouling, antimicrobial, and filtration performance, based on three-layer architecture, have been successfully prepared by a facile and environmentally friendly strategy. The superhydrophilic terpolymer poly(DMHB-SPP-HEA), denoted as PDSH, was synthesized through aqueous solution polymerization. PDSH-coated SSMMs (PDSH-SSMMs) were achieved by successive dip-coating of the commercial SSMMs into polyvinyl alcohol, divinyl sulfone (DVS), and PDSH solutions. The DVS layer and PDSH solution were crosslinked through DVS chemistry to enhance the hydrophilicity and provide a number of unique properties, such as antimicrobial activity, antifouling ability, and oil–water separation capability. Two different PDSH-SSMMs, PDSH0-SSMM and PDSH5-SSMM, were prepared and characterized using FTIR, SEM, and contact angle measurement (CAM). The antimicrobial activity, bovine serum albumin (BSA) fouling, and oil–water separation performance were evaluated simultaneously. The results indicate that PDSH0-SSMM is an excellent oil–water separation membrane for long-term separation, together with its extra antimicrobial and antifouling properties. It is promising for the industrialization of multi-functional membranes through this facile and environmentally friendly strategy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Research into antimicrobial polymers has grown over recent years. Most of them focus on experiments and understanding of the chemical structures, polymer architectures, antimicrobial performance, interactions between the polymers and microbial agents, and so on.1–7 Among the various types of antimicrobial polymers reported hitherto, quaternary ammonium compounds (QACs) are pioneers, due to their outstanding stability, and are drawing great attention with a view to their application in permanent surface coatings.5,8,9 In the 1980s, Ikeda et al. synthesized two cationic polyelectrolytes (polymethacrylate containing pendant biguanide groups and polyvinylbenzyl ammonium chloride) which showed enhanced antimicrobial activity against S. aureus and Escherichia coli (E. coli).10,11 Polycationic antimicrobial polymers are able to disrupt the outer, as well as the cytoplasmic, membrane and cause cell lysis resulting in cell death. Izumrudov et al. synthesized poly(N-alkyl-4-vinylpyridinium) bromides, poly(N,N-dimethyldiallylammonium) chloride, and ionene bromide, and revealed that all these polymers were pH and salt independent.12 Recently, poly (2-dimethylaminoethyl methacrylate) (PDMAEMA) and its derivatives have been extensively studied as their tertiary amines can be quaternized to produce antimicrobial cationic polymers through a simple and efficient post-modification process.13,14

Membrane filtration technology has been widely used to treat wastewater and drinking water in recent years because of its ease of operation, low power consumption, and high separation efficiency. However, the membranes are easily fouled by macromolecules or high molecular-weight compounds, including bacteria and viruses. In order to resolve this issue, a variety of antifouling strategies have been developed.15–18 The most attractive approach is utilizing polymeric coating based on two types of key polymers: nonionic polymers such as polyethylene glycol (PEG) and zwitterionic polymers such as poly (methacryloyloxyethyl phosphorylcholine) (PMPC), poly (sulfobetaine methacrylate) (PSBMA), and poly (carboxybetaine methacrylate) (PCBMA).19 In contrast to PEG and other nonionic materials which bind water molecules via hydrogen-bonding hydration, zwitterionic polymers are able to achieve much stronger hydration by means of electrostatic induction.20,21 The structural similarity and hydration interaction against the surface of the protein or bacteria are the main antifouling mechanism in zwitterionic polymers. It has been proved that surfaces modified with zwitterionic polymers have excellent antifouling capability against proteins, cells, and bacteria.22,23

A combination of the antimicrobial and antifouling features would make the filtration membrane more favorable for treatment of wastewater and drinking water. These membrane surfaces are based on the combination of “kill and resist” strategies within one system, which can kill attached bacteria as well as resist their negative effects.24 The antimicrobials can be (I) tethered to antifouling hydrophilic polymers, (II) alternately deposited with an antifouling layer (layer-by-layer deposition), or (III) stored in an antifouling matrix and substantially released. Inspired by tea stains, Kang et al. synthesized a brominated tannic acid (TABr) initiator primer by modification of tannic acid with alkyl bromide functionalities. The TABr with trihydroxyphenyl moieties can be easily anchored onto a stainless steel surface, and the alkyl bromide moieties serve as initiation sites for atom transfer radical polymerization (ATRP) with the cationic monomer [2-(methacryloyloxy) ethyl] trimethyl ammonium chloride (META) and zwitterionic monomers: 2-methacryloyloxyethyl phosphorylcholine (MPC) or N-(3-sulfopropyl)-N-(methacryloxyethyl)-N,N-dimethylammonium betaine (SBMA), affording a grafted antifouling and antimicrobial polymer brush surface.25 Recently, Ye et al. established a novel architecture with block copolymer brushes on commercial thin-film composite (TFC) membranes with a polydopamine (PDA) transition layer for integrated “defending” and “attacking” strategies; the polymer brushes were polymerized by grafting cationic [2-(methacryloyloxy) ethyl] trimethyl ammonium chloride (MTAC) and zwitterionic SBMA from bromoalkylated dopamine via activators regenerated by electron transfer-atom transfer radical polymerization (ARGET-ATRP). The results showed that the modified TFC membrane maintains the same water permeability and salt selectivity as the pristine TFC membrane, together with low biofouling property and excellent bacterial inactivation.26

Although the results are promising, the above strategies still have some disadvantages that limit their wide application. Massive solvent consumption and harsh reaction conditions are always required during the controlled polymerization of ATRP procedure, which makes the preparation of the functionalized filtration membrane lack of efficiency, economy and environmental friendliness, and there should be significant difficulties in commercial translatability. Besides, the usage of catechol-based dopamine may be not affordable on an industrial scale. Therefore, more economical and environmentally friendly surface modification techniques without compromising membrane performance are highly desired.

Herein, we report on a three-layer architecture based superhydrophilic stainless steel mesh membrane (SSMM) with the aid of aqueous solution polymerization and successional dip-coating approach. The cationic moieties on the surface of the top layer can act as “spears,” and the zwitterionic moieties serve as “shields” meanwhile. To the best of our knowledge, this facile and environmentally friendly layered structure of superhydrophilic antimicrobial and antifouling filtration membrane has not yet been reported.

In this study, the terpolymer poly (DMHB-SPP-HEA), denoted as PDSH, was polymerized first, with hydroxyethyl acrylate (HEA), cationic monomer methacryloxyethylhexadecyl dimethylammonium bromide (DMHB) and zwitterionic monomer N-(3-methacryloylimino) propyl-N, N-dimethylammonio propanesulfonate (SPP), via aqueous solution polymerization. The DMHB monomer may serve as a polymeric emulsifier, and the emulsifier-free polymerization process barely harms the surroundings. Divinyl sulfone (DVS) chemistry was then applied to conjugate PDSH covalently onto the hydroxyl groups of the PVA pre-coated commercial SSMM through nucleophilic addition considering that DVS is a popular crosslinking reagent for its unique reactivity, stability, solubility, and affordability.27,28 The DVS chemistry has been widely used in the construction of polymer networks, especially for the crosslinking of different natural polymers, such as cellulose, dextran, and hyaluronic acid.29 The crosslinking reaction was achieved by a straightforward two-step method of dip-coating to obtain the layered structure suitable for the microfiltration membrane. The approach of successional dip-coating in aqueous solution was proved to be facile and harmless to the environment.

The intrinsic properties of the functionalized PDSH terpolymer coated stainless steel mesh membranes, denoted as PDSH-SSMMs, such as the surface chemistry, contact angle, and microstructure, were characterized. The antifouling efficiency was evaluated with bovine serum albumin (BSA) solution. The antimicrobial activity was studied using E. coli strains, that are known to be abundant in municipal wastewater and pose a big threat to drinking water security.2 The oil–water separation performance was investigated with a xylene–water mixture and the reusability of the PDSH-SSMMs was also discussed in light of results arising from 14 test cycles used to represent long-term oil–water separation. All these results prove that the superhydrophilic microfiltration membranes with layered structure have excellent antifouling, antimicrobial, and filtrating performance. Furthermore, hope can be seen for the industrialization of multi-functional membrane through this facile and environmentally friendly strategy.

Experimental

Materials

2,2′-azobis(2-methylpropionamide) dihydrochloride (AIBA), hydroxyethyl acrylate(HEA), divinyl sulfone (DVS), bovine serum albumin (BSA) standard solution (16.9 g/L), and Escherichia coli strains (K12) were purchased from Sigma-Aldrich, China. N-(3-methacryloylimino) propyl-N,N-dimethylammonio propanesulfonate (SPP), and methacryloxyethylhexadecyl dimethylammonium bromide (DMHB) were purchased from Hubei Jadechem Chemicals Co., Ltd., China. Polyvinyl alcohol (PVA 2488, polymerization degree 2400, alcoholysis degree 88%) was purchased from Taiwan Changchun Chemicals. Anhydrous ethanol, NaOH, NaCl, xylene, and CCl4 were of analytical grade and purchased from Aladdin, China. All chemicals were used as received without any treatment. Cellulose acetate microfiltration membrane (5 kDa molecular-weight cut-off) was purchased from Sartorius, China. Commercial stainless steel mesh membranes (300 mesh) were kindly provided by Nianfa Sieving Mesh Co., Ltd., Guangzhou, China, and cut into circular discs with a diameter of 6 cm. Deionized (DI) water was obtained from a Milli-Q ultrapure water purification system (Millipore, China).

Terpolymer synthesis

Two 10% (weight ratio) PDSH polymer solutions were synthesized with weight ratios of monomers (DMHB/SPP/HEA) of 0/90/10 and 5/85/10, respectively, denoted by PDSH0 and PDSH5.

The PDSH5 was synthesized as follows: 0.25 g DMHB was dissolved in 5 mL DI water in a 100 mL three-necked round-bottomed flask with magnetic stirring for 10 min, 4.25 g SPP powder and 0.5 g HEA were added to the flask simultaneously under magnetic stirring for another 10 min. After that, 30 mL DI water was added to the flask over 8 min, the solution became clear after 20 min. The flask was bubbled with N2 for 1 h to purge the O2 therein and the N2 atmosphere was maintained during polymerization. Then the flask was heated to 80°C with stirring. Some 0.05 g AIBA were dissolved in 10 mL DI water and added dropwise over a 5-h period to allow polymerization. The reaction solution was heated to 90°C thereafter, and the temperature was maintained for 1 h. Finally the solution was cooled to ambient temperature, the N2 atmosphere was pumped out, and the polymerization terminated.

The prepared polymer was then purified through dialysis, the polymer solution was poured into a cellulose acetate membrane tube and dialyzed for 7 days against fresh DI water to get rid of the residual monomers, the dialysate was collected thereafter for the next dip-coating step, and some of the dialysate was taken out in the meantime and lyophilized for characterization.

The PDSH0 was synthesized by directly dissolving 4.5 g SPP and 0.5 g HEA in 35 mL DI water, and purified through dialysis (the procedure used matched that used with the PDSH5).

PDSH-SSMMs preparation

The PDSH-SSMMs with three-layered architecture were prepared by facile successive dip-coating the commercial SSMMs in PVA, DVS, and PDSH solutions. To begin with, PVA 2488 was dissolved in DI at 90°C DI water to get a 5% (weight ratio) PVA solution. The commercial SSMMs were cleaned as follows: they were immersed in 10% NaOH solution for 4 h followed by washing with DI water, the meshes were then ultrasonically cleaned three times in anhydrous ethanol for 10 min each time, rinsed with DI water, and then dried at 80°C for 8 h.

The PDSH-SSMMs were achieved by immersing the cleaned SSMMs into the 5% PVA solution for 10 min, pulled out vertically and dried at 110°C for 2 h. Then the PVA pre-coated SSMMs (PVA-SSMMs) were immersed into a pH 12 DVS-NaOH solution for 1 h, followed by dipping into PDSH solutions for 24 h to insure sufficient crosslink formation. Finally, the PDSH-SSMMs were dried in a vacuum oven at 60°C for 12 h.

The synthesis of the PDSH terpolymers and the preparation procedure of the PDSH-SSMMs are shown in Figs. 1 and 2.

Terpolymer characterization

The functional groups on the synthesized PDSH terpolymers and monomers were determined by Fourier transform infrared spectroscopy (FTIR) using Perkin Elmer 1730 spectrometer. The spectra were collected over the range 4000–400 cm−1.

Surface characterization

The functional groups of the surface layer of the PDSH-SSMM were measured by a Perkin Elmer 1730 equipped with an attenuated total reflectance (ATR) attachment. Scans, with 256 iterations, were undertaken over the range 700–4000 cm−1. An SEM instrument (Hitachi S3700) was used for the morphological investigation of the PDSH-SSMMs; all samples were sputter-coated with an approximately 70-nm-thick layer of gold before SEM imaging. Then contact angle measurements were performed using ultrapure water by the sessile drop method on a Dataphysics CAM instrument (Dataphysics OCA40 Micro). The volume of each droplet was 2.0 µL. For each sample, at least five measurements were taken and the average value was calculated.

Biological characterization

The antimicrobial activity was determined by an intimate contact method according to the AATCC 100-2004 standard, which is especially suitable for textiles coated with quaternary ammonium compounds (QACs).30–32 E. coli strains were used to evaluate the antimicrobial activity of the coated SSMMs. The strains were suspended in pH 7.0 PBS at a concentration of 105 CFU/mL. The PDSH-SSMMs were introduced into 200 mL of the bacterial suspension in an Erlenmeyer flask. The flask was shaken in a water bath at a temperature of 37°C. A control experiment was carried out using just the PVA-SSMM under the same conditions. After the membranes had been in contact with the bacterial suspension for 8 h, 0.1 mL of the bacterial suspension was pipetted out from the flask, and 0.9 mL of sterile water was added to this suspension. The suspension was diluted several times and 0.1 mL of the diluted suspension was spread onto a triplicate solid agar plate. The plates were then incubated at 37°C for 24 h, and the numbers of the viable cells were counted thereon.

Fouling experiments were investigated in a dead-end homemade testing cell as follows: 10 mL of BSA standard solution was centrifuged for 10 s at 10,000 rpm. The supernatants were then removed and diluted with PBS to a concentration of 100 mg/L. Under gravity, microfiltration was started as soon as the BSA solution was added to the 30-cm high test cell. The PVA-SSMM and the PDSH-SSMMs (PDSH0, PDSH5) were used for microfiltration, and the effective membrane area for filtration was 19.635 cm2 with a diameter of 5 cm. The steady flux (F) was recorded by the collection of the volume of the filtrates. Likewise, the pure water flux was investigated (as above) and the steady flux (F 0) was also recorded by the collection of the volume of the filtrates.

Filtration tests

Oil–water separation experiments using the PDSH-SSMMs were carried out in the aforementioned dead-end homemade testing cell. The oil–water mixture was prepared as follows: 496.5 g DI water were dyed with red ink droplets, then 3.5 g xylene were directly added to the red water solution under magnetic stirring to obtain a 3 g/L oil–water mixture. Then the oil–water mixture was added to the testing cell to a depth of 30 cm, and the steady flux was measured under gravity by collecting the volume of the filtrates.

The separation-rinse cycle tests were performed as follows: PDSH-SSMMs were recovered by rinsing with copious amounts of DI water after each separation procedure and used for multiple separation-rinse cycles; the steady flux of the filtrates was also recorded.

The oil content of the filtrates, after each filtration experiment, was measured by an infrared spectrophotometric oil analyzer (CY2000, Qingdao Laoshan Electric Instruments Co., Ltd). Some 50 mL filtrate was mixed with 50 mL acidified DI water at pH ≤ 2, NaCl was added to the mixture, and then the mixture was twice-extracted with CCl4. The extracted solutions were diluted with CCl4 in a volumetric flask and the diluents were added to the cuvette for subsequent oil content measurement.

Results and discussion

Terpolymer characterization

The functional groups of the synthesized PDSH5 terpolymers and the three monomers were identified by FTIR spectroscopy as shown in Fig. 3. The peak of the OH group of HEA monomer can be seen at 3400 cm−1; the peak at 1720 cm−1 is attributed to the C=O stretching vibration of the ester groups of HEA and DMHB, while the peak of the C=O stretching vibration of the amido group of SPP can be found at 1640 cm−1. In addition, there are two more characteristic peaks at 1190 and 1040 cm−1 which can be attributed to the sulfonate group of SPP, and additional two peaks representing the quaternary ammonium group were located at 960 and 1390 cm−1. These five characteristic peaks can be seen in Fig. 3e, which indicated that the PDSH5 terpolymer was successfully prepared via aqueous solution polymerization. When analyzing the PDSH0 terpolymer obtained without the use of a DMHB monomer, analogous characteristic peaks can be found in Fig. 3d, except for the quaternary ammonium group. DMHB, SPP, and HEA monomers might simultaneously participate in the emulsifier-free polymerization in aqueous medium since the DMHB is essentially a polymeric emulsifier. The emulsifier-free polymerization will be helpful in eliminating the consumption of organic solvents and proved to be environmentally friendly.

Surface characterization

The synthesized PDSH terpolymers were conjugated to PVA-SSMM through the successive dip-coating method, and the membrane surface chemistries of the PDSH5 terpolymer membrane and the PDSH5-SSMMs were then analyzed by ATR-FTIR spectroscopy (Fig. 4). The PDSH5 terpolymer membrane was prepared by blade coating and drying in a vacuum oven at 50°C to get a 10 µm thin film. When the PDSH5 terpolymer was covalently bonded to the surface of the PVA-SSMM via DVS chemistry, the difference between the PDSH5 terpolymer membrane and the crosslinked PDSH5-SSMM could be verified using the characteristic peaks for the sulfone group of the DVS.33 It can be seen in Fig. 4 that there are small, but apparent, differences between the PDSH5 terpolymer membrane and the PDSH5-SSMMs. The new peaks appearing at 1153 and 1097 cm−1, belonged to the S=O stretching vibration, and confirmed the successful conjugation between PDSH and PVA-SSMM. The electrophilic double bond of DVS involved the conjugate addition as an excellent Michael acceptor for the electron-poor state of the double bond.29

ATR-FTIR spectra of the membrane surfaces: (a) PDSH5 terpolymer membrane, (b) PDSH5-SSMMs. PDSH5 terpolymer membrane was prepared by blade coating the PDSH5 solution on a polytetrafluoroethylene sheet, then dried in vacuum at 50°C and the remaining 10 µm thin film for the characterization was peeled off

The morphology of the surfaces of the PDSH-SSMMs was characterized by SEM; SEM images of the PDSH0-SSMM and PDSH5-SSMM are shown in Fig. 5. It can be seen that there was no significant difference between the two PDSH-SSMMs, and the average pore size was found to be around 35–40 µm. The large pore size will benefit the high flux encountered during microfiltration, and therefore make contributions to improved filtration speed and reduced energy consumption. The reason for such phenomena may lie in two aspects: (I) The cationic hexadecyl quaternary ammonium moieties, together with the zwitterionic SPP moieties, may have negligible effects on the formation of membrane pores. The chain lengths of the SPP and DMHB molecules are assumed to have no distinct differences when compared to the micron-level pore sizes. (II) The crosslink reaction occurs only between the hydroxyl groups of the side chain of the PDSH and PVA, and this same crosslinking procedure may have generated no apparent differences in the thicknesses of the crosslinked interlayer.

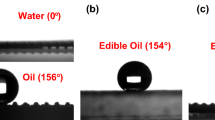

The surface hydrophilicity is one of the most important factors in determining the antifouling and the water permeability properties of MF membranes. The hydrophilicity of the PDSH-SSMMs synthesized in this study was evaluated by sessile drop contact angle measurement, which is commonly used to explore the wettability of surfaces. Photographs of the contact angle of the PVA-SSMM and the PDSH-SSMMs are shown in Fig. 6. It is clear that the contact angle decreased significantly after modification by PDSH. The PVA-SSMM had an average contact angle of 48° ± 2°. Nevertheless, the value decreased dramatically to 8° ± 2° and 3° ± 1° when the PVA-SSMM was crosslinked with PDSH5 and PDSH0 terpolymers, giving reductions of approximately 83% and 94% in the contact angle values, respectively. The decrease in the contact angle indicated the creation of a superhydrophilic surface. After the crosslinking between PVA-SSMM and PDSH terpolymers was terminated, the surface became superhydrophilic due to the high affinity of the zwitterionic polymer to water.17 Although the morphology of the two PDSH-SSMMs had no significant differences, the contact angle of the PDSH5-SSMM increased slightly, indicating a reduced coverage of SPP moieties as they were replaced by DMHB moieties: the long hexadecyl chain of the DMHB has a lower affinity to water and thus enlarged the contact angle therewith. Due to the superhydrophilicity, the PDSH-SSMMs were more resistant, and less prone to fouling, allowing them to operate at a constant permeability for longer period (as proved by oil–water separation experiments).

Biological tests

Antimicrobial activity tests were carried out on the PDSH-SSMMs and the PVA-SSMM using E. coli strains, and the results are shown in Fig. 7. No obvious differences in antimicrobial activity were found between the PDSH0-SSMM and PDSH5-SSMM; both of the PDSH-SSMMs showed high antimicrobial activity, while the PVA-SSMM had poor antimicrobial activity. The average number of CFUs surviving on the surface of the PVA-SSMM was approximately 197, while there were only six CFUs observed on the surface of both PDSH-SSMMs. The bacterial removal efficiency of both PDSH-SSMMs was as high as 97%. These results can be explained in two ways: (I) The antimicrobial activity was mainly due to the interaction of the quaternary ammonium group of DMHB with the cell membrane of microbes and was more pronounced when the alkyl chain length was between 4 and 18, otherwise, the antimicrobial effect may be completely diminished, (II) The zwitterionic SPP moieties have a high affinity to water in essence and could not adsorb hydrophobic substances including microbes and fungi.8,9 The low affinity to E. coli cell membranes can lead to the small average number of CFUs observed on the surface of the both PDSH-SSMMs, although the zwitterionic groups had barely any effect on the bactericidal process.

The antifouling propensity of the PDSH-SSMMs was evaluated by the filtration of a 100-mg/L BSA solution in a homemade testing cell. When pure water was used in the microfiltration process, the PVA-SSMM, PDSH0-SSMM, and PDSH5-SSMM all had relatively high fluxes (1560, 1510, and 1505 mL/m2s, respectively). However, a decrease in the flux was seen when 100 mg/L BSA had permeated, and the fluxes were 1250, 1430, and 1395 mL/m2s, respectively. In the case of the PVA-SSMM, there was a decrease in flux when fouled with BSA that can be explained by the large number of hydroxyl groups on a surface for which the hydrophilicity can be relatively easily enhanced. As for the PDSH0-SSMM and PDSH5-SSMM, there was less impact on the flux upon BSA microfiltration. The PDSH0-SSMM and PDSH5-SSMM had a flux decrement of 5.3% and 7.3%, and one of 19.9% for the PVA-SSMM. The PDSH0-SSMM and PDSH5-SSMM both showed a high permeate flux and excellent antifouling ability compared to the PVA-SSMM because of the superhydrophilic surface and their ionic nature. Both the charge repulsion and superhydrophilicity of the PDSH-SSMMs reduced the degree of BSA adsorption to the membrane surface. The PDSH5-SSMM was less effective with regards to its antifouling ability than PDSH0-SSMM only because of its long alkyl chain, which is innately hydrophobic. Therefore, the SSMMs could be most efficiently modified by coating with PDSH0 to enhance their surface superhydrophilicity and fouling resistance (Fig. 8).

Filtration tests

To test the oil–water separation ability of the PDSH-SSMMs, the aforementioned homemade testing cell was used for multiple separations of an oil–water mixture (Fig. 9). By using this test cell, 14 separation cycles of a xylene–water mixture were undertaken and the steady flux over each cycle was recorded. The steady fluxes over the first cycle, with the PDSH0-SSMM and PDSH5-SSMM, were 930 and 918 mL/m2s, respectively. The high flux values, driven solely by gravity, stemmed from the surface superhydrophilicity and relatively large pore sizes of the PDSH-SSMMs, which were attractive from the viewpoint of energy conservation. The slight decrease in flux with the PDSH5-SSMM was because of the hydrophobic long alkyl chain group of the DMHB monomer in this PDSH5 terpolymer. The variation in flux during subsequent separation cycles was also measured and is shown in Fig. 10. It can be seen that the flux decreased gradually, but there was no significant decrease because the rate of change was less than 11%. The steady fluxes in these xylene–water mixture separation processes were 880 and 820 mL/m2s after 14 cycles (5.4% and 10.7% decreases compared with the values at the end of the first cycle). The relatively flat slope of the line in Fig. 10 implies that the PDSH0-SSMM was more superhydrophilic than the PDSH5-SSMM.

The oil content of the filtrates with PDSH0-SSMM and PDSH5-SSMM was 38 and 42 mg/L, which meant that the rejection rates were 98.73% and 98.6%, respectively. The favorable separation efficiency may also stem from the superhydrophilic surface and ionic functional group of the PDSH terpolymers. These results indicated excellent oil–water separation ability for the PDSH-SSMMs over long-term separation operations.

Necessity of the zwitterion

To establish the role of the zwitterion, a copolymer containing quaternary ammonium groups but no zwitterionic moieties was synthesized and purified following the procedures described in the experimental section. The DMHB-HEA copolymer, denoted as PDH, was synthesized with monomers weight ratios of 5/95(DMHB/HEA). The composition of PDH copolymer was confirmed by FTIR spectroscopy. As shown in Fig. 11, the spectrogram of PDH displays the featured peaks from both of the two monomers (HEA and DMHB). Then, the commercial SSMMs were successively dip-coated in PVA, DVS, and PDH solutions to achieve the PDH-coated SSMMs, denoted as PDH-SSMMs. The PDH-SSMMs were characterized and compared with the PDSH5-SSMMs, the results are listed in Table 1.

As shown in Fig. 11a and b, both HEA and DMHB have the characteristic peaks at 1720 and 1630 cm−1, which belong to the C=O vibration of the ester groups and C=C vibration of the acrylate moieties, respectively. In addition, the peak of the OH group of HEA can be seen at 3400 cm−1, and two characteristic peaks representing the quaternary ammonium group were located at 960 and 1390 cm−1. As to Fig. 11c, all of the above-mentioned peaks can be seen except that the peaks at 1630 cm−1 became negligible, which means that the C–C double bond of the monomers had taken part in the polymerization completely. Therefore, the PDH copolymer was successfully polymerized and confirmed.

It can be seen in Table 1 that there were obvious differences between the PDH and PDSH5 polymers. The water contact angle of PDH increased to 58°, and that can be attributed to the lack of the hydrophilic SPP moieties and the existence of the hydrophobic dodecyl moieties of the DMHB monomer. This large value would severely affect the membrane properties when compared PDH-SSMMs with PDSH5-SSMMs except that the bacterial removal efficiency has not been weakened for the reasons discussed previously in the antimicrobial activity tests. The pure water flux and BSA flux of PDH were 1530 and 1175 mL/m2s, respectively. The 23.3% decrement of flux means much worse antifouling property. As to the oil–water separation tests, the first steady flux of PDH was 830 mL/m2s and gradually decreased to 620 mL/m2s after 14 cycles, resulting in 25.3% flux decrement in spite of the rinse process at the end of each filtration cycle. Meanwhile, the oil content of the filtrate increased to 123 mg/L, and oil rejection rate decreased to 87.7%. In contrast to the PDSH5-SSMMs, the deterioration in the membrane performance of the PDH-SSMMs may be due to the lack of the superhydrophilicity which stemmed from the ionic nature of the zwitterionic SPP moieties. The comparison results concluded that the SPP zwitterion is indispensable in constructing multi-functional filtration membrane.

Conclusions

In this study, a superhydrophilic terpolymer PDSH was successfully synthesized and applied to PVA-SSMMs to prepare superhydrophilic PDSH-SSMMs with three-layer architecture, through a facile and environmentally friendly approach. The resulting PDSH-SSMMs showed good antimicrobial, antifouling, and oil–water separation properties. The following conclusions could be drawn from the testing results: (I) Superhydrophilicity was achieved by conjugating the PVA-SSMM with PDSH terpolymers through DVS chemistry; this superhydrophilicity rendered the PDSH-SSMMs more effective than the PVA-SSMM in all the tests. (II) The PDSH-SSMMs show no obvious differences in surface morphology and in antimicrobial tests: the average pore size of the PDSH-SSMM was 35–40 µm, and the bacterial removal efficiency of both PDSH-SSMMs was as high as 97%. The structural difference had no effect on the pore-forming and antimicrobial abilities, despite the presence of the strong bactericidal quaternary ammonium group. (III) Subtle distinctions can be seen between the PDSH-SSMMs in contact angle, antifouling, and oil–water separation tests. The PDSH0-SSMM was superior to the PDSH5-SSMM with regard to its contact angle (3° ± 1°), BSA solution flux decrement (5.3%), xylene content after separation (38 mg/L), and rejection rate (98.73%). The steady flux of the xylene–water mixture separation remained at 880 mL/m2s after 14 separation-rinse cycles, which represented a mere 5.4% flux decrement. The superiority of the PDSH0-SSMM may lie in the superhydrophilicity, and ionic nature of its zwitterionic groups. (IV) PDSH0-SSMM could be a good candidate for antimicrobial, antifouling, and long-term oil–water separation membrane. And this facile and environmentally friendly manufacturing strategy will hopefully pave the way for the industrialization of multi-functional filtration membrane. (V) The SPP zwitterion is indispensable in constructing a multi-functional filtration membrane, because the membrane performance, such as surface wettability, antimicrobial activity, antifouling ability, and filtration performance, will be dramatically deteriorated without the hydrophilic zwitterionic SPP moieties.

References

Kenawy, ER, Worley, SD, Broughton, R, “The Chemistry and Applications of Antimicrobial Polymers: A State-of-the-Art Review.” Biomacromolecules, 8 (5) 1360–1384 (2007)

Timofeeva, L, Kleshcheva, N, “Antimicrobial Polymers: Mechanism of Action, Factors of Activity, and Applications.” Appl. Microbiol. Biotechnol., 89 475–492 (2011)

Siedenbiedel, F, Tiller, JC, “Antimicrobial Polymers in Solution and on Surfaces: Overview and Functional Principles.” Polymers, 4 46–71 (2012)

Munoz-Bonilla, A, Fernandez-García, M, “Polymeric Materials with Antimicrobial Activity.” Prog. Polym. Sci., 37 281–339 (2012)

Ribeiro, AMC, Carrasco, LDM, “Cationic Antimicrobial Polymers and Their Assemblies.” Int. J. Mol. Sci., 14 9906–9946 (2013)

Jain, A, Duvvuri, LS, Farah, S, Beyth, N, Domb, AJ, Khan, W, “Antimicrobial Polymers.” Adv. Healthc. Mater., 12 (3) 1969–1985 (2014)

Swartjes, JJTM, Sharma, PK, van Kooten, TG, van der Mei, HC, Mahmoudi, M, Busscher, HJ, Rochford, ETJ, “Current Developments in Antimicrobial Surface Coatings for Biomedical Applications.” Curr. Med. Chem., 22 2116–2129 (2015)

Buffet-Bataillon, S, Tattevin, P, Bonnaure-Mallet, M, Jolivet-Gougeon, A, “Emergence of Resistance to Antibacterial Agents: The Role of Quaternary Ammonium Compounds-A Critical Review.” Int. J. Antimicrob. Ag., 39 381–389 (2012)

Tischer, M, Pradel, G, Ohlsen, K, Holzgrabe, U, “Quaternary Ammonium Salts and Their Antimicrobial Potential: Targets or Nonspecific Interactions?” Chem. MedChem., 7 22–31 (2012)

Ikeda, T, Tazuke, S, Suzuki, Y, “Biologically Active Polycations: Synthesis and Antimicrobial Activity of Poly (Trialkylvinylbenzyl Ammonium Chloride)s.” Makromol. Chem., 185 869–876 (1984)

Ikeda, T, Yamaguchi, H, Tazuke, S, “New Polymeric Biocides: Synthesis and Antibacterial Activities of Polycations with Pendant Biguanide Groups.” Antimicrob. Agents Chemother., 26 (2) 139–144 (1984)

Izumrudov, VA, Zhiryakova, MV, Kudaibergenov, SE, “Controllable Stability of DNA-Containing Polyelectrolyte Complexes in Water-Salt Solutions.” Biopolymers, 52 94–108 (1999)

Layman, JM, Ramirez, SM, Green, MD, Long, TE, “Influence of Polycation Molecular Weight on Poly (2-Dimethylaminoethyl Methacrylate)-Mediated DNA Delivery In Vitro.” Biomacromolecules, 10 1244–1252 (2009)

Ji, W, Panus, D, Palumbo, RN, Tang, R, Wang, C, “Poly (2-Aminoethyl Methacrylate) with Well-Defined Chain Length for DNA Vaccine Delivery to Dendritic Cells.” Biomacromolecules, 12 4373–4385 (2011)

Xuan, FQ, Liu, JS, “Preparation, Characterization and Application of Zwitterionic Polymers and Membranes: Current Developments and Perspective.” Polym. Int., 58 1350–1361 (2009)

Schlenoff, JB, “Zwitteration: Coating Surfaces with Zwitterionic Functionality to Reduce Nonspecific Adsorption.” Langmuir, 30 9625–9636 (2014)

Laschewsky, A, “Structures and Synthesis of Zwitterionic Polymers.” Polymers, 6 1544–1601 (2014)

Li, Q, Imbrogno, J, Belfort, G, Wang, XL, “Making Polymeric Membranes Antifouling Via “Grafting from” Polymerization of Zwitterions.” J. Appl. Polym. Sci., 132 41781–41792 (2015)

Cao, ZQ, Jiang, SY, “Super-Hydrophilic Zwitterionic Poly(carboxybetaine) and Amphiphilic Non-ionic Poly(ethylene glycol) for Stealth Nanoparticles.” Nano Today, 7 404–413 (2012)

Chen, SF, Zheng, J, Li, LY, Jiang, SY, “Strong Resistance of Phosphorylcholine Self-Assembled Monolayers to Protein Adsorption: Insights into Nonfouling Properties of Zwitterionic Materials.” J. Am. Chem. Soc., 127 14473–14478 (2005)

He, Y, Hower, J, Chen, SF, Bernards, MT, Chang, Y, Jiang, SY, “Molecular Simulation Studies of Protein Interactions with Zwitterionic Phosphorylcholine Self-Assembled Monolayers in the Presence of Water.” Langmuir, 24 10358–10364 (2008)

Callow, JA, Callow, ME, “Trends in the Development of Environmentally Friendly Fouling-Resistant Marine Coatings.” Nat. Commun., 2 244 (2011)

Cao, ZQ, Brault, N, Xue, H, Keefe, A, Jiang, SY, “Manipulating Sticky and Non-Sticky Properties in a Single Material.” Angew. Chem. Int. Ed., 50 6102–6104 (2011)

Yu, Q, Wu, ZQ, Chen, H, “Dual-Function Antibacterial Surfaces for Biomedical Applications.” Acta Biomater., 16 1–13 (2015)

Pranantyo, D, Xu, LQ, NeohK, G, Kang, ET, “Tea Stains-Inspired Initiator Primer for Surface Grafting of Antifouling and Antimicrobial Polymer Brush Coatings.” Biomacromolecules, 16 723–732 (2015)

Ye, G, Lee, JH, Perreault, F, Elimelech, M, “Controlled Architecture of Dual-Functional Block Copolymer Brushes on Thin-Film Composite Membranes for Integrated “Defending” and “Attacking” Strategies Against Biofouling.” ACS Appl. Mater. Interfaces, 7 23069–23079 (2015)

Bordawekar, M, Lipscomb, GG, Escobar, I, “Use of a Temperature Sensitive Surface Gel to Reduce Fouling.” Sep. Sci. Technol., 44 3369–3391 (2009)

Gorey, C, Escobar, IC, Gruden, C, Coleman, M, Mileyeva-Biebesheimer, O, “Development of Smart Membrane Filters for Microbial Sensing.” Sep. Sci. Technol., 43 4056–4074 (2008)

Sanfrutos, JM, Lopez-Jaramillo, FJ, Elremaily, MAA, Hernández-Mateo, F, Santoyo-Gonzalez, F, “Divinyl Sulfone Cross-Linked Cyclodextrin-Based Polymeric Materials-Synthesis and Applications as Sorbents and Encapsulating agents.” Molecules, 20 3565–3581 (2015)

Unnithan, AR, Barakat, NAM, Pichiah, PBT, Gnanasekaran, G, Nirmala, R, Cha, YS, Jung, CH, El-Newehy, M, Kim, HY, “Wound-Dressing Materials with Antibacterial Activity from Electrospun Polyurethane-Dextran Nanofiber Mats Containing Ciprofloxacin HCL.” Carbohydr. Polym., 90 1786–1793 (2012)

Gao, Y, Kyratzis, IL, “Antimicrobial Finishing of Wool Using an Oxidative Pretreatment to Enhance the Exhaustion of Quaternary Ammonium Compounds.” J. Appl. Polym. Sci., 125 (S2) E71–E78 (2012)

Cai, ZS, Sun, G, “Antimicrobial Finishing of Acrilan Fabrics with Cetylpyridinium Chloride.” J. Appl. Polym. Sci., 94 243–247 (2004)

Birkner, M, Ulbricht, M, “Ultrafiltration Membranes with Markedly Different pH- and Ion-Responsivity by Photografted Zwitterionic Polysulfobetain or Polycarbobetain.” J. Membr. Sci., 494 57–67 (2015)

Acknowledgments

This work was financially supported by the Public Interest Research and Capacity Building Program of Guangdong (Grant No. 2015A010105004) and the Natural Science Foundation of Guangdong (Grant No. 2015A030313207).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, M., Zhao, J., Tu, W. et al. Combined ‘spear and shield’: superhydrophilic antimicrobial and antifouling mesh membrane for efficient oil–water separation through facile and environmentally friendly strategy. J Coat Technol Res 14, 243–253 (2017). https://doi.org/10.1007/s11998-016-9834-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9834-0