Abstract

In the present study, attempts were made to clarify the existence of a correlation between visually perceived and instrumentally measured specular gloss of a series of achromatic samples. To this end, seven achromatic physical scales of specular gloss each consisting of 10 or 11 samples were prepared using lithographically printed black, white, and five in between gray papers. The samples were visually assessed and subsequently quantified in terms of a visually uniform color constant lightness scale, by a panel of 14 observers in an especially designed unidirectional light compartment at three illumination/observation geometries, namely 20°/20°, 60°/60°, and 85°/85°. Four statistical parameters were utilized to determine the correlation between visually perceived and instrumentally measured specular gloss. The results show that the instrumental 60°/60° geometry is capable of efficiently quantifying the equivalent specular gloss as perceived by a human observer. Surprisingly, it was also possible to accurately predict the visually quantified specular gloss both at the 20° and the 85° geometries by the aid of applying special linear relationships derived from the instrumentally measured specular gloss of the 60° geometry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Specular gloss as defined by the ASTM D523 standard is the relative luminous reflectance factor of a specimen in the specular/mirror direction,1 and is one of the most important aspects of visual appearance in a multitude of industries such as automotive, surface coatings, printing, and packaging, etc.

Appearance is the result of a series of complex interactions of incident light with an object, which is influenced by the composition of the incident light, the optical characteristics of the object itself, and the human perception mechanism. These interactions modify the appearance of the object and are subdivided into two distinct categories, namely chromatic and geometric attributes.2,3 Chromatic or color attributes depend on spectral composition of the incident light, spectral reflectance or transmittance of the object, and spectral response of the observer, as well as on the illuminating and viewing geometries.4 Fortunately, color is well defined and can be quantified by recommendations made by the well-known CIE system, using conventional or specially designed spectro- and/or goniospectro-photometers.5,6

To the contrary, geometric attributes which are associated with the way in which the object reflects white light at various angles of observation, particularly reflected light at or near the specular angle, are very vaguely defined and are much more complicated to assess visually or instrumentally.

It may not be an overstatement to claim that gloss is probably the most important geometric appearance attribute. Gloss perception is associated with the way in which an object reflects white light at various angles of observation, particularly reflected light at or near the specular angle.7,8

For many years, specular gloss, defined by Hunter9 as the ratio of the light reflected from a surface at a specified angle to the incident light on the surface at that same angle but on the other side of the surface normal, was taken to be the only aspect of gloss appearance. Hunter, however, was the first to recognize the multidimensional nature of gloss perception.9,10 Since then, considerable efforts have been made by many workers to investigate gloss perception and to clarify its multidimensionality.11–17

Such works have demonstrated the complexity of gloss perception as well as a poor correlation between visual assessments and associated measurements using conventional measuring instruments, namely glossmeters, in addition to inconclusive findings regarding the multidimensional nature of gloss perception.

Using a series of achromatic paint samples, having various levels of specular gloss, distinctness of image and haze, O’Donnell10 investigated the multidimensionality of gloss perception by a multidimensional scaling technique (MDS). However, it was found that the observers were able to recognize only one attribute.

In an attempt to derive a psychophysical model for gloss, Ferwerda et al.18 employed graphically synthesized images of a sphere enclosed in a checkerboard box which were virtually illuminated by an overhead light source. Using a multidimensional scaling technique (MDS) they identified contrast gloss (CG) and distinctness of image (DOI) as possible dimensions of gloss perception. They also defined a psychophysically based model for gloss which they claimed was able to predict perceived gloss as a function of contrast gloss, distinctness of image, and the CIELAB lightness (L*).

The lack of a correlation between visually perceived gloss and the respective instrumental measurements has been investigated by some researchers.

Harrison and Poulter11 studied the correlation between visual gloss and specular reflection (S) using 10 glazed papers at various levels of lightness, visually evaluated by 164 observers. They found that there is not an explicit relation between visual gloss scales and the corresponding instrumentally measured gloss values. In an attempt to find a correction factor, the following equation (equation (1)) was derived to express the visual gloss (G) as a function of specular reflection (S) and lightness (L):

A non-linear relationship between visual and instrumental gloss has also been reported by O’Donnell and Billmeyer,10 Obein et al.,8,12–14,19 Ji et al.,15 and Leloup et al.16,17,20,21

Such discrepancies, however, may be attributed to some intrinsic practical limitations of the glossmeter itself.21

A standard glossmeter measures the magnitude of light reflected from the surface in a small solid angle around the specular direction.22 It has been demonstrated that relative dimensions of the light source and receptor apertures (i.e., illumination and detection solid angles) in a glossmeter have a great impact on the specular gloss readings.21,23

According to Seve,24 when comparing the measured specular gloss values of high gloss and low gloss surfaces, the ratio of the measured values is dependent not only on the two surfaces, but also on the solid angles used in the measuring apparatus. Discrimination between high gloss surfaces is greatly affected by the receptor solid angle, as the smallest solid angle gives a better discrimination between samples; although, for low gloss surfaces, the solid angle of the receptor has the least influence on such discrimination.

The ASTM D523 standard method specifies the receptor aperture angles and solid angles of standard glossmeters. According to this standard, glossmeters measure specular gloss of a surface relative to specular gloss of a flat black glass having a refractive index of 1.567 at the wavelength of 589.3 nm of the sodium D line,25 using three different illumination/detection geometries, namely 20°, 60°, and 85°, depending on the gloss level of the surface.1 The sample is first measured with a 60° geometry. If the measured gloss value is higher than 70 (high gloss), then it is remeasured at the 20° geometry. However, if the gloss value is less than 10 (low gloss), it is remeasured at the 85° geometry.1 The recommended receptor aperture angles and solid angles of standard glossmeters by the ASTM D523 standard method are depicted in Table 1.24

However, it must be noted that the ability of human observer to discriminate between high specular gloss values is much greater than the extent of instrumental discrimination which such solid angles provide.24

Despite the well-known fact that the currently used models describing gloss are unable to accurately evaluate gloss in the same way as the human visual system does, glossmeters are widely employed to quantify gloss appearance of objects in all related industries.

After many years of designing and developing glossmeters and measuring standards, the correlation between such instrumental measurements and the corresponding visual evaluations is still not well established.

Additionally, three different measuring geometries need to be adopted for measuring the specular gloss of fully glossy, semi-glossy, and matte surfaces, according to the ASTM D523 standard method. However, one may still ask if it is possible to measure the gloss of all kinds of surfaces at only one single measuring geometry.

In the present study, attempts were made to investigate possible existing correlations between visually perceived and instrumentally measured specular gloss. To simplify the task, a series of achromatic printed paper samples (i.e., black, white and five in-between grays) at various levels of specular gloss were prepared and employed. The specular gloss values of the samples were instrumentally determined using a glossmeter at 20°, 60°, and 85° measuring geometries. Each sample was subsequently quantified visually by a panel of observers, by the aid of a designed visually uniform color constant lightness scale. Such human-based evaluations were correlated to instrumentally measured equivalents to assess the usefulness of such instrumental measurements.

The quantification of a gloss difference in terms of a known lightness difference was made only to minimize the errors in instrumental measurements as well as the visual assessments. Since such a procedure involves the canceling out of many errors in such investigations.

The results of such correlations were also employed to investigate the possibility of estimating instrumental gloss differences at the 20° and 85° measuring geometries from a normalized derived formula, based on the 60° gloss measurement/visual assessment relationship.

Experimental

Preparation of Specular Gloss scales

The first step to carry out a comprehensive study regarding the visual and the instrumental evaluation of specular gloss was thought to be the preparation of appropriate samples. White semi-gloss papers having a 60° specular gloss value of around 30 GU were used as the base substrate throughout this investigation. Additionally, 6 other lightness levels inclusive of a black and five in-between grays were also prepared by an offset-lithography printing technique to constitute 7 lightness levels.

Color coordinates of each achromatic lightness base paper (i.e., B, W, G1–G5) for CIE D65 illuminant/1964 standard observer combination are depicted in Table 2.

A glossy UV-curable overprint varnish provided by the Farabanafsh Chemical Co. (Iran) incorporated with various amounts of a silica-based matting agent was employed to obtain different levels of specular gloss from fully glossy to matte on each of the seven lightness bases. A 12-µm-thick overprint layer was applied on each of the abovementioned papers using a K Hand Coater provided by RK PrintCoat Instruments Ltd. (United Kingdom). The applied overprints were then cured using a 365-nm wavelength UV energy source having a power flux of 24 W/cm2. In this way, 7 achromatic Specular Gloss scales each containing 10 or 11 samples ranging from fully glossy to matte, totaling 74 samples, were prepared. The instrumentally measured specular gloss values of all such samples measured at 20°, 60°, and 85° geometries are given in Table 3. The samples in Table 3 are coded based on their lightness levels and the series number. For example, MDG3 refers to the third sample in the medium dark gray Specular Gloss scale.

As can be seen in Table 3, each scale is prepared in such a way that the samples vary significantly in specular gloss, ranging from full gloss to fully matte.

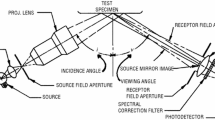

Instrumental characterization

Color coordinates (CIE L* a* b*) of the samples were determined using a GretagMacbeth ColorEye 7000A spectrophotometer (Xrite, USA). This spectrophotometer is equipped with an integrating sphere and measures color characteristics of surfaces with 8°/d geometry. All measurements were performed using the specular component-excluded (SCE) mode. The BYK-Gardner micro-Tri-gloss glossmeter (Germany) was employed to measure specular gloss values of the samples according to the ASTM D523 standard.26 This glossmeter is equipped with three gloss measuring geometries, namely 20°, 60°, and 85° for high gloss to matte surfaces. All samples were measured in triplicates at the three measuring geometries, and only the average values are reported.

Visual assessments

A designed color constant visually uniform lightness scale, proposed and utilized in our previous investigations,27,28 was employed in this work to enhance the accuracy of the visual assessment experiments. The designed lightness scale is composed of eleven 10 × 20 cm2 gray matte polyester fabrics having almost the same chromaticities and varying only in lightness values.

The 60° specular gloss value of the samples varies between 0.8 GU for the darkest sample (i.e., standard) and 2.7 GU for the lightest sample (i.e., sample 11). In other words, the differences between the darkest sample of the lightness scale as standard (i.e., sample 1) and each of the other samples (i.e., samples 2–11) were essentially only a lightness difference.

Variations of lightness differences between the standard and each of the samples in terms of ΔE CIE1976 with the corresponding visually uniform lightness scale numbers (LS) are illustrated in Fig. 1.

As illustrated in Fig. 1, the lightness scale numbers (LS) are non-linearly related to the actual lightness differences (ΔE CIE1976). The designed visually uniform lightness scale was employed to visually quantify specular gloss in terms of a color-difference equation unit (i.e., ΔE CIE1976).

A standard was selected visually having the highest value of specular gloss in each Specular Gloss scale. In order to carry out, separately the visual assessment experiments for each individual scale, the observers had the task of first performing a pairwise comparison and selecting the sample, in each pair, with the highest perceived specular gloss in the corresponding scale, in effect, performing an indirect ordinal ranking, and second of evaluating the differences between the selected standard and each sample of each scale in terms of differences in lightness of the designed visually uniform lightness scale. Wherever possible, intermediate values were also given by many observers.

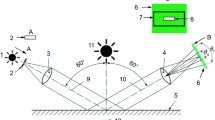

The type of illumination and viewing geometry as well as the surround has great influence on visual perception of geometric appearance attributes such as specular gloss. Therefore, a series of time-consuming and cumbersome preliminary experiments were conducted to determine the most appropriate illumination/observation combination as well as the most suitable surround. Two elaborate and sophisticated illumination conditions, one for purely unidirectional illumination with a black surround and the other for purely non-directional and completely diffuse illumination with a white surround were designed and fabricated. Additionally, a VeriVide CAC 120 light cabinet providing a combination of unidirectional and diffuse illumination with a medium gray surround was also used. The samples and the lightness scale were positioned on a gray inclined table, the angle of inclination (i.e., observation) of which could be varied between 0° and 90°. In this way, provisions were made for a series of illumination/observation conditions for visual assessment of the “differences” in any appearance attribute. Analyzing the error estimation data of such preliminary experiments statistically illustrated that for specular gloss, the minimum observation error in terms of percent standard residual sum of squares (STRESS) belongs to the unidirectional illumination.26

Therefore, all visual assessment experiments were performed under the unidirectional illumination in a dark room with a black surround, having a luminance level of around 7000 lux at a distance of 1.5 m and a correlated color temperature (CCT) of around 5600 K. A gray painted inclined table was placed in the compartment right under the light to support the samples which were viewed under 20°, 60°, and 85° illumination/observation geometries, at a distance of 50 cm subtending an angle of approximately 10° in the observer’s eye.

Fourteen observers including five males and nine females with normal color vision (pre-tested by the Ishihara test) participated in the visual assessment experiments. The observers were not allowed to move their heads freely throughout the experiments in order to maintain the observation distance and geometry. Such configurations rendered a rather unrealistic condition for visual assessment of specular gloss. Each visual assessment session was completed without any time restrictions. Figure 2 illustrates the setup of unidirectional illumination compartment for visual assessment of specular gloss at the 20°, 60°, and 85° illumination/observation geometries.

In order to evaluate the correlation between differences in various instrumental parameters and the corresponding visually assessed differences, four statistical parameters namely, coefficient of determination (R 2), Gamma (γ), coefficient of variation (CV), and STRESS were used. These four statistical parameters can be calculated with the aid of equations (2a)–(2d)29–31 for two seemingly equivalent data sets, namely ∆E v (i.e., visually quantified differences) and ∆I (i.e., instrumentally measured differences):

In these equations, n is the number of samples and F is an adjusting factor ensuring that on average ∆E v and ∆I are equal. Near to 1 values of R 2 and γ and near to zero values of CV and STRESS indicate close to best agreement between two sets of data (i.e., close to best agreement between visually perceived differences and instrumentally measured differences).

Results and discussion

In order to study the visual perception of specular gloss, and correlate visual differences in terms of a visually uniform lightness scale to their corresponding instrumental measurements, the reported lightness scale values (LS) were converted to the corresponding lightness difference (ΔE) values, which are directly proportional to the perceived differences in specular gloss.

The inter-observer variability of each observer was first determined by calculating the STRESS parameter. An average STRESS value of 23% which is surprisingly low compared to the STRESS values published by other workers,32,33 indicated that there is a good general agreement between the observers. This good inter-observer agreement must be attributed to the innovative visual assessment technique based on the quantification of geometrical attributes in terms of a visually uniform lightness scale, which was proposed and utilized in our previous investigations.27,28

The results of visual assessment in terms of visual differences (i.e., ΔE v) separately for 20°, 60°, and 85° illumination/observation geometries are depicted in Table 4. For each sample, the average value of ΔE vs obtained by all observers is reported.

Visual perception of specular gloss

Specular gloss is considered to occur as a result of directionally selective reflection of the incident light from the surface with a preference in the specular direction.17

Therefore, the type and intensity of illumination and geometry of illumination and observation are expected to have a great effect on the perceived gloss.

In order to put this premise to test, the variations of visual gloss differences (i.e., ΔE v) of the samples against their corresponding gloss rank numbers, separately for seven achromatic Specular Gloss scales, namely black (B) to white (W) and for 20°, 60°, and 85° geometries, were investigated. Figure 3 illustrates such scatter plots.

As illustrated in Fig. 3, for the three visual assessment geometries, the visual specular gloss differences reported by the observers for light achromatic scales (i.e., MLG, LG, and W) are higher than the respective visual differences for dark ones (i.e., B, DG, and MDG). In other words, it seems that the loss of gloss perceived by the observers for light achromatic levels is greater than the corresponding perceived gloss loss of dark achromatic levels irrespective of the illumination/observation geometry.

This disagreement in visual perception of specular gloss differences of dark and light samples could have arisen from the remarkable diffuse reflection of light achromatic levels which interferes with the specular reflection and adversely affects the specular gloss perception. Such contradiction is even more obvious for semi-glossy and matte samples (i.e., higher perceived loss of gloss of light samples as compared to dark ones). For light samples with high levels of specular gloss, the contribution of the specular reflection is high enough to be least influenced by the diffuse reflection.

A brief look at Fig. 3 also indicates that the perceived specular gloss is affected by the visual assessment geometry and, in other words, the angle of illumination and observation. In order to investigate this effect, the variations of 20°, 60°, and 85° visual gloss differences (i.e., ΔE v) of only black (B) and white (W) achromatic Specular Gloss scale samples against their corresponding gloss rank numbers are depicted in Fig. 4. Since the results obtained from the other five achromatic scales (i.e., DG–LG) are similar to the results of black (B) and white (W) Specular Gloss scales, the respective scatter plots are only presented in Fig. A1.

Comparing the visual specular gloss differences of the three visual assessment geometries illustrates that for both achromatic levels, the visually perceived gloss difference decreases with increased angle of observation. In this way for a given sample, the largest and the smallest visual gloss differences always belong to the 20° and the 85° geometries, respectively. In other words, at larger angles of illumination and observation, the higher the levels of specular gloss, the lower the loss of gloss is perceived by the observers. However, such result seems to be predictable as according to the Fresnel’s equations of reflection, specular reflection increases with increased angles of illumination.34

Besides the angle of illumination and observation, the gloss level of the sample (fully glossy, semi-glossy or matte) is another factor affecting the perceived specular gloss. Variation of visual gloss differences at 60° geometry for the medium gray (MG) Specular Gloss scale samples against the corresponding gloss rank numbers is exclusively depicted in Fig. 5.

As can be seen in Fig. 5, the gloss loss of fully glossy (i.e., gloss rank numbers of 1–3) and matte (i.e., gloss rank numbers of 8–11) samples is more obvious to the observers. In other words, it seems that the observers are more sensitive to gloss changes of fully glossy and matte samples as compared to semi-glossy ones. Similar results can be obtained for the other two visual assessment geometries, namely 20° and 85°. However, for 85° geometry, the extent of observer’s sensitivity seems to be less than those for 20° and 60° geometries (i.e., lower slopes of the fitted lines).

Correlation between visual results and instrumental measurements

Figure 6 illustrates the scatter plots of instrumentally measured specular gloss values (G i) of the samples of black (B) and white (W) Specular Gloss scales at 20°, 60°, and 85° geometries against their corresponding gloss rank numbers (See Fig. A2 for the DG to LG Specular Gloss scales).

As expected, for each sample, the highest and lowest values of instrumental specular gloss always belong to the 85° and the 20° measuring geometries, respectively.

By dividing the entire specular gloss range into three distinct ranges of fully glossy (70–100 GU at 60°), semi-glossy (20–70 GU at 60°), and matte (0–20 GU at 60°) subdivisions, it is quite obvious that for both achromatic gloss scales, the largest instrumental gloss differences of fully glossy samples (i.e., samples 1–4) are related to the 20° measuring geometry, while for semi-glossy and matte samples, this geometry results in smaller specular gloss values with fewer differences. On the other hand, the largest differences in specular gloss for matte samples (i.e., the three last samples) have been obtained by the 85° measuring geometry.

However, as can be seen in Fig. 6, the 60° geometry is capable of providing instrumental specular gloss data having proper relevant variations in the entire range of gloss (i.e., fully glossy to matte).

Since the observers were asked to report visual differences (i.e., ΔE v) between each sample and a standard in each individual specular gloss scale, the corresponding instrumental differences (i.e., ∆G i) were also calculated.

In an attempt to find a linear relation between visual and instrumental differences of specular gloss, it was found that for all achromatic levels, linear correlations exist between quantified visual differences and the corresponding calculated instrumental differences at 60° and 85° geometries, while for 20° geometry such linear correlations only exist for fully and semi-glossy samples. Figure 7 depicts such linear relations, as well as the corresponding error estimation data in terms of four statistical parameters, namely R 2, γ, CV, and STRESS values given on the right hand side of each plot (See Fig. A3 for DG to LG Specular Gloss scales).

Although there are high linear correlations between visual and the corresponding instrumental differences for both 60° and 85° measuring geometries, the instrumental specular gloss differences at the 85° geometry are rather small as compared to visual assessments (small slopes of the fitted lines). In other words, while the observers are able to perceive specular gloss differences, the 85° geometry cannot provide gloss differences in the same way as the visual system does. On the other hand, the 60° measuring geometry gives distinguishable instrumental specular gloss values more correlated to the visual equivalents in the entire range of gloss (i.e., fully glossy to matte). However, the 20° geometry only gives linear correlations with the visual assessments for fully and semi-glossy subdivisions.

The obtained results show that measuring the specular gloss of achromatic fully glossy, semi-glossy, and matte surfaces using the 60° geometry results in gloss values having high correlations with visual assessments of specular gloss. Therefore, this automatically gives rise to the presumption that despite the recommendations of the ASTM standard for measuring the specular gloss using three different geometries, namely 20°, 60°, and 85°, the 60° geometry is appropriately capable of quantifying the specular gloss of not only semi-glossy but also fully glossy and matte surfaces in the same way as the human visual system perceives. In order to put such a presumption to the test, the possibility of predicting 20° and 85° instrumentally measured specular gloss using the 60° geometry was investigated in this work.

The linear relationships between the 60° measured specular gloss differences (ΔG 60) and the corresponding visual differences (ΔE 60) were employed, separately for each achromatic level, to predict the 20° and the 85° instrumental specular gloss values using the respective quantified visual differences (i.e., ΔE v,20 and ΔE v,85, respectively). The predicted differences (i.e., ΔG predicted,20 and ΔG predicted,85) and the corresponding actual differences (i.e., ΔG i,20 and ΔG i,85) for black (B) and white (W) achromatic Specular Gloss scales are depicted in Table 5 (See Table A1 for DG to LG Specular Gloss scales).

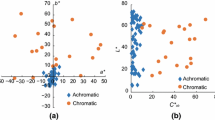

Correlation between the predicted specular gloss differences (ΔGpredicted) against the corresponding actual measured values (ΔG i) for the 20° and the 85° geometries for all achromatic levels are presented in Fig. 8. In order to determine the correlation between the predicted and the actual values, the R 2 parameters are also given on the right hand side of each plot, separately for each Specular Gloss scale.

High linear correlations between the predicted and the actual specular gloss differences for both geometries (i.e., R 2 > 0.9) indicate that at all achromatic levels, the 60° measuring geometry is appropriately capable of giving valid estimations for both 20° and 85° specular gloss measurements. Although such an estimation for the 20° specular gloss is only valid for fully and semi-glossy samples, the specular gloss of matte surfaces known as sheen, not specular gloss, is technically measured using the 85°, not the 20° geometry. Furthermore, as discussed previously, there is not a correlation between the visually quantified specular gloss of the matte samples at the 20° illumination/observation geometry and the corresponding instrumentally measured differences.

These results reveal that the 60° specular gloss is an appropriate measure for quantifying the specular gloss over the entire range of gloss, namely fully glossy, semi-glossy, and matte, at various achromatic levels in the same way that human visual system perceives gloss. Moreover, this measure can suitably be used to predict the specular gloss at the two other measuring geometries, namely 20° and 85°, which have been technically recommended for fully glossy and matte surfaces, respectively.

In order to obtain a total linear relationship to estimate specular gloss for a combination of all achromatic levels, the correlation between the 60° measured specular gloss differences and the corresponding visual differences were determined for the combination of all achromatic levels.

Such linear correlations together with the corresponding linear fitted model and the R 2 parameter are depicted in Fig. 9.

Correlation analysis in Fig. 9 indicates that the instrumentally measured specular gloss differences at the 60° geometry are linearly correlated to the corresponding visual differences for a combination of all achromatic levels (R 2 = 0.89).

Such linear relationship was employed as the foundation for deriving prediction equations, separately for fully glossy subdivision at the 20° and matte subdivision at the 85° measuring geometry, based on the corresponding visually quantified differences (i.e., ΔE v,20 and ΔE v,85, respectively).

Equation (3) was used as a general model to derive prediction equations for specular gloss of fully glossy samples at the 20° measuring geometry and matte samples at the 85° geometry, using the respective visual differences (ΔE v):

where G predicted is the predicted specular gloss value and G st is the specular gloss value of a standard sample having the highest instrumental specular gloss. G st values for the 20° geometry and the 85° geometry were 86.4 and 108.3 GU, respectively.

Analyzing the correlations between the predicted specular gloss differences (G predicted) and the corresponding actual measured differences (G i) for the 20° and the 85° geometries, for a combination of all achromatic levels, resulted in the best linear fit when the coefficient k is 5.5 for the 20° geometry and 1.5 for the 85° geometry.

Figure 10 illustrates the scatter diagram of the predicted specular gloss values (G predicted) against the corresponding actual measured values (G i) for the 20° and the 85° geometries for a combination of all achromatic levels.

Such high linear correlations indicate that the 60° specular gloss measure is capable of giving highly accurate predictions of the other two gloss measures, irrespective of the achromatic level. Moreover, the instrumentally measured specular gloss values at the 60° geometry have high correlations with the corresponding visually quantified gloss for the entire range of gloss (i.e., fully glossy, semi-glossy and matte). In other words, the 60° measuring geometry seems to be adequate in order to measure the specular gloss value of surfaces having various levels of gloss and lightness.

Conclusions

Seven achromatic specular gloss scales as well as a color constant visually uniform lightness scale were prepared.

Each individual specular gloss scale was quantified visually by a panel of observers, with the aid of the common lightness scale under a unidirectional illumination at 20°, 60°, and 85° illumination/observation geometries. Each sample was also measured by a glossmeter, according to the ASTM standard, at the three mentioned measuring geometries.

Differences in quantified visual specular gloss were correlated to the corresponding differences in instrumentally measured parameters. The results show very good general agreements between observers in quantifying specular gloss which can be attributed to the visual assessment technique utilizing a common lightness scale. Furthermore, it was found that the visual perception of specular gloss is influenced by the lightness level and the gloss level of the sample, as well as the assessment geometry. Linear correlations were found between visual differences in specular gloss and the corresponding instrumental differences for the 60° and 85° geometries. Additionally, the results reveal that the 60° measuring geometry is efficiently capable of quantifying specular gloss at various gloss levels in the same manner as the human observer perceives. The unequivocal predictability of the 20° and 85° instrumental specular gloss measured by the derived linear relationship based on the 60° instrumentally measured specular gloss was also revealed.

References

ASTM Standard D 523-89, “Standard Test Method for Specular Gloss.” In: Annual Book of ASTM Standards, Vol. 06.01. ASTM International, West Conshohocken, PA, 1999

CIE 175:2006 Report, “A Framework for the Measurement of Visual Appearance.” Central Bureau of the International Commission on Illumination, CIE, Paris, 2006

Nadal, ME, Thompson, EA, “NIST Reference Goniophotometer for Specular Gloss Measurements.” J. Coat. Technol., 73 73–80 (2001)

ASTM Standard E284-05a, “Standard Terminology of Appearance.” In: Annual Book of ASTM Standards, Vol. 06.01. ASTM International, West Conshohocken, PA, 2006

Eugene, C, “Measurement of Total Visual Appearance: A CIE Challenge of Soft Metrology.” Presented at the 12th IMEKO TC1 & TC7 Joint Symposium on Man, Science and Measurement, Annecy, France, September 2008

Simonot, L, Hebert, M, Dupraz, D, “Goniocolorimetry: From Measurement to Representation in the CIELAB Color Space.” Color Res. Appl., 36 169–178 (2011)

Pointer, M, “Measuring Visual Appearance—A Framework for the Future.” NPL Report COAM 19, National Physical Laboratory, Middlesex, 2003

Ged, G, Obein, G, Silvestri, Z, Rohellec, JL, Viénot, F, “Recognizing Real Materials from Their Glossy Appearance.” J. Vision, 10 1–17 (2010)

Hunter, RS, Harold, RW, The Measurement of Appearance. Wiley, New York, 1987

Billmeyer, FW, O’Donnell, FXD, “Visual Gloss Scaling and Multidimensional Scaling Analysis of Painted Specimens.” Color Res. Appl., 12 315–326 (1987)

Harrison, VGW, Poulter, SRC, “Gloss Measurement of Papers—The Effect of Luminance Factor.” Br. J. Appl. Phys., 2 92–97 (1951)

Obein, G, Knoblauch, K, Chrisment, A, Viénot, F, “Perceptual Scaling of the Gloss of a One-Dimensional Series of Painted Black Samples.” Perception ECVP Abstract, 31 63 (2002)

Obein, G, Knoblauch, K, Viénot, F, “Difference Scaling of Gloss: Nonlinearity, Binocularity, and Constancy.” J. Vision, 4 711–720 (2004)

Obein, G, Pichereau, T, Harrar, M, Monot, A, Knoblauch, K, Viénot, F, “Does Binocular Vision Contribute to Gloss Perception.” J. Vision, 4 (11) 73 (2004)

Ji, W, Pointer, MR, Luo, MR, Dakin, J, “Gloss as an Aspect of the Measurement of Appearance.” J. Opt. Soc. Am. A, 23 22–33 (2006)

Leloup, FB, Pointer, MR, Dutré, P, Hanselaer, P, “Geometry of Illumination, Luminance Contrast, and Gloss Perception.” J. Opt. Soc. Am. A, 27 2046–2054 (2010)

Leloup, FB, Pointer, MR, Dutré, P, Hanselaer, P, “Luminance-Based Specular Gloss Characterization.” J. Opt. Soc. Am. A, 28 1322–1330 (2011)

Ferwerda, JA, Pellacini, F, Greenberg, DP, “A Psychophysically-Based Model of Surface Gloss Perception.” Proc. SPIE, 4299 291–301 (2001)

Obein, G, Vienot, F, Leroux, TR, “Bidirectional Reflectance Distribution Factor and Gloss Scales.” Proc. SPIE, 4299 279–290 (2001)

Leloup, FB, Pointer, MR, Dutré, P, Hanselaer, P, “Overall Gloss Evaluation in the Presence of Multiple Cues to Surface Glossiness.” J. Opt. Soc. Am. A, 29 1105–1114 (2012)

Leloup, FB, Obein, G, Pointer, MR, Hanselaer, P, “Toward the Soft Metrology of Surface Gloss: A Review.” Color Res. Appl., 39 559–570 (2014)

Westlund, HB, Meyer, GW, Hunt, FY, “The Role of Rendering in the Competence Project in Measurement Science for Optical Reflection and Scattering.” J. Res. Natl. Inst. Stand. Technol., 107 247–259 (2002)

Arney, JS, Ye, L, Banach, S, “Interpretation of Gloss Meter Measurements.” J. Imaging Sci. Technol., 50 567–571 (2006)

Seve, R, “Problems Connected with the Concept of Gloss.” Color Res. Appl., 18 241–252 (1993)

Nadal, ME, Thompson, EA, “New Primary Standard for Specular Gloss Measurements.” J. Coat. Technol., 72 61–66 (2000)

Ameri, F, Khalili, N, “Effect of Illumination/Observation Geometries on Visual Assessment of Certain Geometric Attributes of Automotive Paints.” J. Color Sci. Technol., 7 323–330 (2014), In Persian

Mirjalili, F, Moradian, S, Ameri, F, “A New Approach to Investigate Relationships Between Certain Instrumentally Measured Appearance Parameters and Their Visually Perceived Equivalents in the Automotive Industry.” J. Coat. Technol. Res., 11 (3) 341–350 (2014)

Mirjalili, F, Moradian, S, Ameri, F, “Derivation of an Instrumentally Based Geometric Appearance Index for the Automotive Industry.” J. Coat. Technol. Res., 11 (6) 853–864 (2014)

Kirchner, E, Dekker, N, “Performance Measures of Color-Difference Equations: Correlation Coefficient Versus Standardized Residual Sum of Squares.” J. Opt. Soc. Am. A, 28 841–1848 (2011)

García, PA, Huertas, R, Melgosa, M, Cui, G, “Measurement of the Relationship Between Perceived and Computed Color Differences.” J. Opt. Soc. Am. A, 24 1823–1829 (2007)

Huang, M, Cui, G, Melgosa, M, Sánchez-Marañón, M, Li, C, Luo, MR, Liu, H, “Power Functions Improving the Performance of Color-Difference Formulas.” Opt. Express, 23 597–610 (2015)

Huang, Z, Xu, H, Luo, MR, “Camera-Based Model to Predict the Total Difference Between Effect Coatings Under Directional Illumination.” Chin. Opt. Lett., 9 093301 (2011)

Huang, Z, Xu, H, Luo, MR, Cui, G, Feng, H, “Assessing Total Differences for Effective Samples Having Variations in Color, Coarseness, and Glint.” Chin. Opt. Lett., 8 717–720 (2010)

Torrance, KE, Sparrow, EM, “Theory for Off-Specular Reflection from Roughened Surfaces.” J. Opt. Soc. Am. A, 57 1105–1112 (1967)

Acknowledgment

The authors wish to thank Mr. Khosro Moradi at the Farabanafsh Chemical Co. and the Center of Excellence for Color Science and Technology for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirjalili, F., Moradian, S., Ameri, F. et al. Quantification and prediction of visually perceived specular gloss at three illumination/viewing geometries. J Coat Technol Res 13, 239–256 (2016). https://doi.org/10.1007/s11998-015-9756-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9756-2