Abstract

A novel film was developed from barberry (BA) anthocyanins immobilized on cobalt-based metal–organic framework (Co-MOF) nanoparticles utilizing biodegradable polyvinyl alcohol (PVA) and chitosan nanofiber (ChNF) as intelligent and active packaging for red meat freshness. The aim of the study was evaluated in two scenarios, the first evaluation of the potential of Co-MOF for embedding in packaging films as antimicrobial properties and cobalt color change due to amine release and pH change, and the second evaluation of the application of Co-MOF in the controlled release of BA anthocyanins as antioxidant properties and color changes of food packaging films during spoilage of red meat. The findings showed that the addition of Co-MOF nanoparticles significantly increased the PVA/ChNF film’s specific surface area, and Co-MOF’s better capacity to concentrate volatile amines allowed the film to detect freshness extremely sensitively, and the antibacterial capabilities of the films for E. coli, S. aureus, and P. fluorescence bacteria were 20.3 ± 0.3 mm, 21.6 ± 0.2 mm, and 19.6 ± 0.4 mm, respectively. Moreover, the inclusion of BA and Co-MOF significantly improves the tensile strength (from 67.2 to 81.3 MPa), flexibility (18.9 to 22.3%), UV protection, water vapor resistance, and sensitivity to ammonia-induced discoloration of the PVA/ChNF film. PVA/ChNF/Co-MOF and PVA/ChNF/Co-MOF/BA films’ colors changed from pink to dark brown and from deep peach to black-greenish-brown when used to track the spoilage of red meat. In conclusion, it was possible to use the created films as intelligent and active food packaging materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is well-known that meat products with high protein contents are susceptible to spoiling as a result of bacterial infection during storage, the slow release of volatile alkaline chemicals, such as dimethylamine (DMA) and ammonia, changes in surrounding pH, and other factors (H. Jiang et al., 2024; Khezerlou et al., 2023c). Ammonia is one of these substances that poses a major hazard to human health and is frequently employed as a crucial biomarker to gauge the degree of food rotting (Khezerlou et al., 2023b). Consequently, intelligent packaging materials that are ammonia- and pH-sensitive can provide a consistent color response to indicate the degradation of meat products in warehouses. Thus, they can immediately monitor the freshness of packaged food during transit, storage, and make sales (Khezerlou et al., 2023a; Lin et al., 2022). Additionally, multifunctional packaging materials can stop bacterial activity, extending the shelf life of food by preventing germs from growing. Therefore, a recent research priority has been the creation of smart packaging materials with antimicrobial and ammonia- and pH-sensitive functionalities (Riahi et al., 2023a; Tavassoli et al., 2022; Tavassoli et al., 2024).

Most frequently, ammonia- and pH-sensitive colors were added to biopolymer matrices (such as protein, polysaccharide, lipids, and their mixtures) to create intelligent packaging materials. As pH- and ammonia-sensitive colorants, a variety of natural pigments, primarily derived from plants, are now used to create intelligent films for food safety monitoring (Feng et al., 2023; Tang et al., 2023). For instance, Alizadeh-Sani et al. (2021) created intelligent films for fish spoilage detection using pH-responsive barberry anthocyanins (BA) in a gelatin/carrageenan matrix. Additionally, saffron petal anthocyanin, rosemary extract, alizarin, red grape anthocyanins, and purple-fleshed sweet potato extract have all been used to create intelligent packaging films (Alizadeh-Sani et al., 2021a, 2021b; Ezati & Rhim, 2020; Mirmoeini et al., 2023; Mustafa et al., 2020; Yong et al., 2019). Despite offering numerous benefits, these natural pigments have limitations in food applications. These limitations include a lack of color stability, low bioavailability, limited mass production, and minimal observed health effects. The stability of plant-derived pigments against various food substances such as water, amino acids, and peptides is often low, and they exhibit insufficient resistance to light and heat conditions, which can lead to inaccurate assessment of food quality. Additionally, their migration into food alters the color of the food surface and diminishes the sensory characteristics of the product (Alizadeh Sani et al., 2024; Lin et al., 2022; Tavassoli et al., 2024b). The encapsulation method provides a solution to these challenges by protecting the pigments from degradation through encapsulation. This process enhances their stability and has the potential to enhance their health-promoting properties (Rieger et al., 2015). This study suggests using metal–organic frameworks (MOF) as brand-new delivery methods or carriers as encapsulation to get beyond the drawbacks of direct addition (Khezerlou et al., 2023c; Sultana et al., 2022). This brand-new strategy for multifunctional packaging makes it possible to conduct BA-controlled releases in MOF systems successfully and more steadily (Jiang et al., 2022b; Sani et al., 2022).

It has recently attracted considerable interest in synthesizing MOF nanoparticles from metal ions and organic ligands as a hybrid porous inorganic product that is easy to synthesize, stable for a long time, tunable in function, and used in a wide range of applications, such as gas adsorption and detection, electrochemical sensing, antibacterial, and others (Khezerlou et al., 2023d; Riahi et al., 2023a). In addition, nano MOFs’ inorganic–organic hybrid nature makes them particularly suitable for use as nanofillers in nanocomposites for their affinity with polymer matrices (Lin et al., 2022). The trace element cobalt is a crucial component of vitamin B12 and a vital part of healthy living. In contrast to MOFs based on other metals, cobalt-based MOFs (Co-MOF) have excellent application prospects due to their simple synthesis, increased chemical stability, rich color, and numerous functionalities (such as antibacterial and carrier as encapsulation) (Feng et al., 2023; Tang et al., 2023).

Polyvinyl alcohol (PVA) is a biocompatible, biodegradable, and naturally non-toxic polymer. It is used in food packaging due to its water absorption, gas and chemical resistance, and film-forming capabilities. However, its weak mechanical toughness and water vapor barrier limit its widespread use (Kim et al., 2023; Mao et al., 2023). These lacks, along with the antibacterial quality of clean PVA film, prevent its widespread application in food packaging. Biopolymer nanoparticles like chitosan nanofibers (ChNF) can be used as nanofillers to improve tensile strength and gas and water vapor barriers (Rubina et al., 2020). Previous research has demonstrated that adding ChNFs to different matrices may enhance the mechanical strength and moisture barrier of composite materials (Bakhshizadeh et al., 2023b; Wang et al., 2023). This is mostly due to the creation of strong hydrogen bonds between the biopolymers. As a result, when exposed to the high relative humidity seen in meals with high water activity, the films became more resilient to breakdown (Tavassoli et al., 2023b).

In this study, Co-MOF/BA with pH and ammonia sensitivity was developed and then applied as an antibacterial agent for PVA-based intelligent and active packaging. Moreover, Co-MOF nanofillers were investigated for their effect on antibacterial, mechanical, microstructural, water vapor barrier, color stability, UV-blocking, pH, and ammonia-responsive properties of PVA/ChNF films. Additionally, PVA/ChNF/Co-MOF/BA films have been evaluated as freshness indicators for red meat. The findings of our study provide a new strategy for the fabrication of biopolymer-based films with enormous potential for applications in active and intelligent packaging for shelf-life extension and real-time visual monitoring of the freshness of red meat.

Materials and Methods

Materials and Reagents

Barberries were bought from a local market (Qaen, Iran). Fresh meat was obtained from a local slaughterhouse and brought in an ice box to the laboratory. PVA (Mw = 89–98 kDa) from Sigma-Aldrich Co (USA), ChNF (80–85% deacetylation; viscosity 50–800 cp; Mw, 50–80 kDa) from Nano-Novin polymer Co (Iran) were purchased. cobalt nitrate hexahydrate (Co(NO3)2·6 H2O), 2-aminoterephthalic acid (NH2-BDC), and N,N-dimethylformamide (DMF) were provided by Sigma-Aldrich (USA). All other chemicals were analytical grade and of high purity.

Preparation of Co-MOF/BA Films

Synthesis of CO-MOFs and Encapsulation of BA in Co-MOF

Before production of the colorimetric film, BA was extracted from barberry fruits based on (Khezerlou et al., 2023c). For the synthesis of Co-MOF, 0.1 g NH2-BDC, and 0.3 g Co (NO3)2.6H2O were mixed in 4 mL DMF with 6 mL deionized water in the Teflon reactor, followed by reacting for 16 h under 145 °C. Then, the product was gathered by centrifugation (7000 rpm, 10 min), washed with ethanol and deionized water (three times), and dried for 24 h at 60 °C to obtain pink Co-MOF powders (Feng et al., 2023). Synthesis of Co-MOF loaded anthocyanins, by dissolving 10 mL of BA at different concentrations (1%, 2%, 3%, and 4% w/v) with 20 mg of Co-MOF powder in water and ethanol (ratio 7:3) was stirred slowly for 24 h at room temperature. The Co-MOF-loaded anthocyanins were then centrifuged at 8000 rpm for 20 min and washed with ethanol to remove any unencapsulated anthocyanins. Finally, Co-MOF-loaded anthocyanin powders were obtained at 40 °C. The concentration of the obtained powders was measured at a wavelength of 275 nm by a UV–vis spectrophotometer, and the encapsulation efficiency and loading capacity were measured with the following formulas:

where A1 is the encapsulated BA, A2 is the total amount of BA, and A3 is the amount of recovery Co-MOF.

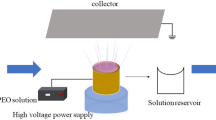

Fabrication of PVA-Based Films

The composition of PVA-based films is shown in Table 1, after examining the produced films, concentration no. 3 was chosen as the ideal film. Finally, colorimetric films were formulated as follows: The PVA aqueous solution (5% w/v) was prepared by stirring for 2 h at 100 °C. Additionally, 1 g of ChNF was dissolved in acetic acid (1% w/v) and stirred for 1 h at 80 °C. Then, the PVA/ChNF were mixed in 80:20 ratios by stirring for 1 h at 60 °C. The PVA/ChNF solution was combined with 30% w/v (based on PVA) of glycerol as a plasticizer and 3% w/v of BAs@Co-MOFs and mixed continuously for 1 h at room temperature. After that, 20 mL of the solution was added to a polystyrene culture dish with a 90 mm diameter. The film solution was then dried for 24–48 h at 25 °C and 50% relative humidity (RH). The labeled PVA/ChNF/BAs@Co-MOFs were then peeled off and kept for eventual use at 4 °C and 75% RH.

Ammonia Test

In the ammonia-sensing test, the freshness indicator sample (diameter, 1.5 cm) was located in the headspace of a container containing 10 mL of 8 mmol/L ammonia at room temperature for 20 min. The photos of the freshness indicators were taken every 4 min, and the sensitivity (SRGB) was obtained with the help of the equation:

Monitoring the Freshness and Increasing the Shelf Life of Red Meat

Two different freshness indicators were used, including PVA/ChNF/Co-MOF, and PVA/ChNF/Co-MOF/BA. One piece of meat (50 g) was put into a clean container, and the freshness indicators (2 cm in diameter) were sealed tightly to the inside of the container door without direct contact with the sample and then placed in the freezer at 4 °C for 10 days.

The label’s visible color changes were observed and documented using digital photography. In addition, the color measurements (L*, a*, b*) were captured using a Hunter lab colorimeter (CR-400, Minolta, Japan) (Tavassoli et al., 2023a). Furthermore, the microbial quality of the packaged fillets was assessed using total viable count (TVC; plate count agar incubated at 37 ± 1 °C for 2 days) and psychrotrophic bacterial count (PTC; plate count agar incubated at 7 ± 1 °C for 10 days). Each stage involved three sets of experiments, and the results were expressed as log CFU/mL (Mohebi et al., 2023).

Chemical quality analysis included testing for total volatile base nitrogen levels (TVB-N; mg N/100 g, using the steam distillation method with a Kjeldahl distillation apparatus), as well as pH measurement using a digital pH meter from Thermo Scientific in Indonesia (Khezerlou et al., 2023a). Additionally, oxidative degradation was assessed in terms of peroxide value (PV; meq peroxide/1000 g lipid) and thiobarbituric acid reactive substances (TBA; mg malondialdehyde (MDA)/kg lipid) based on the method detailed by Turgut et al. (2016) (Turgut et al., 2016). All chemicals and culture media used in this study were obtained from Merck, Germany.

Results and Discussion

Characterization of Films

Scanning Electron Microscopy (SEM)

The effect of Co-MOF and BA extract individually and together on the morphology of PVA film was investigated through SEM. As can be seen, the Co-MOF exhibits a sphere-organized rod or nanosheet morphology with an average particle size of approximately 110 nm (Fig. 1Aa). The pure PVA film showed a relatively smooth and uniform cross-sectional morphology, which could be attributed to the fact that it did not contain any special components (Fig. 1Ab). The addition of ChNF to the PVA film had rougher surface morphologies, which can be attributed to the protrusion of some nanofibers from their surface (Fig. 1Ac). However, the incorporation of BA anthocyanins into the film leads to a slightly smoother surface morphology, which may be due to their ability to interact with other structural components (Fig. 1Ae) (Khezerlou et al., 2023a). On the other hand, the introduction of Co-MOF resulted in a slightly rough surface of the film due to the presence of Co-MOF nanofillers, causing it to crack. This change led to an increase in the moisture content of the films and disrupted their cohesion and integrity (Fig. 1Ad). It is interesting that the addition of BA extract and Co-MOF together made the surface of the film smooth and uniform (Fig. 1Af), and also made the distribution of Co-MOF better and without obvious accumulation in the whole film, which improved the performance of the film. Moreover, by crack pinning, fracture deflection, crack bridging, and/or nanosheet pulling out, the well-dispersed Co-MOF and BA extraction may effectively delay and inhibit the propagation of microcracks, which is useful for dissipating sizable amounts of energy (Feng et al., 2023; Tang et al., 2023). Lin et al. (2022) showed that the addition of grape skin anthocyanins to PVA/starch-based film makes the surface and cross-section even, which is caused by the formation of intermolecular hydrogen bonds between the phenolic hydroxyl groups in grape skin anthocyanins and the hydroxyl groups of starch and PVA (Lin et al., 2022).

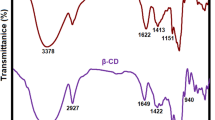

A SEM images: a Co-MOF, b Pure PVA, c PVA/ChNF, d PVA/ChNF/Co-MOF, e PVA/ChNF/BA, and f PVA/ChNF/Co-MOF/BA; B FTIR spectrum of the PVA-based films; C XRD diffraction pattern of the PVA-based films; D The properties of the physical, mechanical, and optical of the PVA-based films; a MC and SI; b WS and WVP; c transparency and thickness; d tensile strength and elongation at break

Fourier-Transform Infrared (FTIR)

In order to detect the interaction between the compounds used in the PVA-based film, FTIR spectra of the PVA/ChNF/Co-MOF/BA films were measured (Fig. 1B). The distinctive peaks for the pure PVA film at 3441, 2924, 1624, and 1044 cm−1 corresponded to the vibrations of the OH stretching, CH2 stretching, COO stretching, and C–O–C stretching, respectively. The peaks did not significantly shift when ChNF was added to the PVA film, proving that there were no substantial chemical alterations made to the PVA-based films. However, the addition of Co-MOF gradually reduced the peak OH tension of PVA-based films to a lower wave number (3434 cm−1 and 3441 cm−1). This could be due to the formation of hydrogen bonds in the carboxyl groups of Co-MOF with the hydroxyl and carboxyl (oxygen-containing) groups in the PVA matrix (Feng et al., 2023). A slight change in the intensity of the COO stretching peak can also be explained by the presence of cobalt ions in Co-MOF, as well as the presence of a large amount of carboxyl groups in PVA (Tang et al., 2023). Additionally, the FTIR spectrum indicated that the addition of BA was highly compatible with a matrix of PVA/ChNF, which formed a homogeneous molecular structure through the intermolecular interactions of BA’s phenolic groups and PVA-based OH stretching. Upon interaction between BA and Co-MOF, there were slight shifts in the positions of specific peaks, potentially as a result of hydrogen bonding. The peaks exhibited broad absorption bands spanning from 3434 to 3439 cm−1, consistent with the stretching vibration of − OH, indicating the presence of a substantial quantity of hydroxyl groups. Furthermore, some small peaks are observed in the PVA/ChNF/Co-MOF/BA film due to the physical interactions between the Co-MOF as a filler and BA with the PVA/ChNF polymer combination via hydrogen bonds and van der Waals forces (R. Yang et al., 2023). A study by Khan and co-workers (2023) on gelatin/carrageenan-based films incorporating a copper metal–organic framework (Cu-MOF) and red cabbage anthocyanins (RCA) showed that the addition of RCA had a high compatibility with the film matrix and it did not change the FTIR spectrum (Khan et al., 2023).

X-ray Diffraction (XRD)

The amount of crystallinity in a film tends to increase its density and hardness (Tavassoli et al., 2021). Therefore, X-ray diffraction was used to measure the crystallinity of different PVA-based films (Fig. 1C). All films had relatively similar spectral patterns, for example, the XRD diffraction of PVA showed a strong characteristic of the crystalline peak at 19.4°. With the addition of ChNF to the film matrix, there were no significant changes in the peak location, indicating that ChNF was well-compatible with the PVA film. The addition of Co-MOF to the film produced a series of peaks similar to the PVA matrix, the characteristic diffraction peaks of Co-MOF at 2θ = 10.5, 13.2, 14.6, 17.3, 19.6, and 20.3° are visible, which is consistent with the results of other authors’ studies (Feng et al., 2023; Tang et al., 2023). Also, the diffraction pattern of PVA/ChNF/Co-MOF/BA film showed that the presence of Co-MOF and BA extract did not cause a major change in the X-ray diffraction pattern, which indicates that they do not change the structure of the molecules.

Physical Properties

Moisture Content (MC) and Swelling Index (SI)

The findings shown in Fig. 1Da show that the addition of ChNF significantly (p < 0.05) reduced the MC of pure PVA film from 14.3 to 12.6%. This drop may have been caused by the inclusion of more solid material and the replacement of certain molecules. Contrarily, the quantity of MC increased (15%) as a result of the addition of Co-MOF to the PVA/ChNF matrix. This increase in MC can be ascribed to the formation of pores in the film, which allows moisture from the environment to permeate. The amount of MC was reduced as a result of the incorporation of BA extract in PVA/ChNF films. The hydroxyl groups of the PVA/ChNF polymer chain and the BA extract may form hydrogen bonds, which reduce intermolecular interactions and in turn cause the drop in MC (Sani et al., 2021). As a result, just a small amount of water molecules from the surrounding environment are absorbed. In PVA/ChNF/Co-MOF/BA films, where the BA extract was combined with Co-MOF in the film matrix, the lowest value of MC was found (10.5%). This finding suggests that the integration of BA and Co-MOF was well-formed, resulting in the creation of a coherent structure in the film. According to our results, Lin et al. (2022) showed that the addition of grape skin anthocyanins together with MIL-101 to PVA and starch (PS) matrix can significantly reduce the amount of MC.

One of the factors that determine how well a material will withstand water is its SI. In comparison to pure PVA films (102%), ChNF-containing PVA films had a lower SI (98%) (Fig. 1Da). This behavior may be brought on by the saturation of the PVA polymer network brought on by the addition of ChNF, which causes the water molecules to diffuse quickly through the PVA polymer network, decreasing SI. After the addition of BA and Co-MOF, SI decreases. Notably, the decrease is more pronounced with the addition of BA (83.3%). This phenomenon could be due to the presence of hydroxyl groups in the structure of anthocyanins and their interaction with the biopolymer matrices. The PVA/ChNF/Co-MOF/BA film also had the lowest SI (75.6%), which can be attributed to the molecular interactions between the anthocyanins in the BA extract and the polymer chain as well as the potent interaction between the Co-MOF (as filler) and polymer chains, which decreases swelling of the polymer chains near the interface (Jiang et al., 2022a, 2022b).

Water Vapor Permeability (WVP) and Water Solubility (WS)

One of the most crucial aspects of packing materials is the WVP of the films since it directly affects food deterioration and the preservation of the sensory qualities of food products (Tavassoli et al., 2022). Low WVP was found in the PVA/ChNF film (3.8 10−11 g.m/m2.s.Pa) compared to the pure WPI film (3.4 10−11 g.m/m2.s.Pa), which may have been caused by ChNF’s complete dissolution in the film matrix and filling of any available spaces, which decreased the mobility of the polymer chains and the rate of water vapor diffusion. The addition of Co-MOF caused the WVP of the PVA/ChNF film to decline to 3.2 10−11 g.m/m2.s.Pa. The results show that the PVA/ChNF/Co-MOF films have greater water vapor barrier performance than pure PVA film, which may be attributed to the Co-MOF’s presence inside the PVA matrix, which greatly reduces porosity and creates a tortuous path for moisture diffusion in the film material. Additionally, the level of WVP was reduced in the film by adding anthocyanins from the BA extract. This effect may be brought on by the creation of hydrogen bonds between the film matrix and BA anthocyanins, which have decreased the number of accessible hydroxyl groups and, thus, reduced the ability of the films to absorb water vapor (Tavassoli et al., 2023a). The lowest WVP was found in the PVA/ChNF/Co-MOF/BA film, which may be attributed to the Co-MOF nanofillers’ tortuous Co-MOF moisture diffusion channel in the PVA matrix (Riahi et al., 2023a; Tang et al., 2023). The transparent PVA/ChNF/Co-MOF/BA films that have been created have good water vapor barrier capabilities, hence they may find use in food packaging. Similar to the results of this study, Tang et al. (2023) showed that the addition of Co-MOF to the carboxymethyl cellulose (CMC) matrix caused a rapid reduction of WVP.

The WS of PVA-based films is shown in Fig. 1Db. The maximum WS was found in the pure PVA film (65.4%), and when ChNF was added to the PVA matrix, the WS of the film dropped to 55.2%. The development of intramolecular contacts between ChNF and the film-forming solution may be the reason for the reduction in the WS of films brought on by the presence of ChNF. In general, the WS of the films decreased with the addition of BA and Co-MOF extract, and the PVA/ChNF/Co-MOF/BA film had the lowest WS (36.5%). The hydrophilic properties of the anthocyanins in BA extract, which induce a strong network to develop with Co-MOF in the film matrix, may be the origin of this phenomenon (Kathuria et al., 2023).

Transparency

In Fig. 1Dc, the findings for the films’ transparency are displayed. Pure PVA-based films exhibited remarkable transparency (90.73%). The inclusion of ChNF reduced the transparency of the film as compared to the pure PVA film. The ChNF’s ability to scatter light selectively may be the origin of this phenomenon. Additionally, the transparency of the film was reduced by the inclusion of Co-MOF in the PVA/ChNF matrix. This study demonstrates that the UV blocking ability of the PVA film may be significantly improved by the Co-MOF nanofillers and is only somewhat decreased by the optical transparency of the PVA film. Moreover, film transparency was reduced when BA extract was present, which may have been caused by the anthocyanins’ ability to scatter light (Bakhshizadeh et al., 2023b). These findings were consistent with the authors’ earlier research, which demonstrated that adding BA extract to chitin nanofiber (CNF) and methylcellulose (MC) films reduced transparency (12.04%) (Sani et al., 2021); however, in this study, the level of transparency was reduced more (4.34%) as a result of the presence of Co-MOF. As a result, the developed PVA/ChNF/Co-MOF/BA films have good UV-blocking and water barrier properties, which may have applications in the packaging of food.

Thickness and Mechanical Properties

In Figs. 1Dc and 1Dd, the results of the thickness and mechanical characteristics of PVA-based films are shown. As can be seen, adding ChNF caused the thickness of PVA-based films to rise from 69.1 to 72.3 µm. The thickness of the films significantly increased (81.6 µm) as a result of the addition of Co-MOF. This is because Co-MOF was inserted into the PVA matrix’s network and filled its pores. Although the PVA/ChNF film’s thickness increased due to the presence of BA extract, this thickness increase was less than that of Co-MOF. On the other hand, the thickness of the film reached its highest value (88.6 µm) when both components (BA extract and Co-MOF) were present. This increase in thickness brought on by the addition of Co-MOF and BA extract anthocyanins may be attributable to the fact that these compounds increased the solid content of the films (Sani et al., 2023; Tavassoli et al., 2023b).

Tensile tests were used to assess the flexibility of biodegradable films and tensile stress (TS) (Fig. 1Dd). The integrity of food packaging films is often maintained better when TS and elongation at break (EAB) levels rise (Tang et al., 2023; Y. Yang et al., 2007). As can be seen, the ChNF addition enhanced the TS and EAB of the pure PVA film from 67.2 MPa and 18.9% to 69.4 MPa and 19.1%. These outcomes may be a result of the interaction between ChNF and PVA as well as the addition of CNF, which causes the empty spaces in the polymer matrix to be filled. The addition of Co-MOF and BA anthocyanins to the PVA/ChNF film resulted in additional substantial increases in the TS and EAB (p < 0.05) (81.3 MPa and 22.3%, respectively). This effect may be caused by strong interactions caused by the development of hydrogen bonds between the OH groups of the anthocyanins and the polymer chains, which result in the establishment of physical crosswise connections in the structure of the films (Weng et al., 2014). Additionally, the dispersion of Co-MOF and their interactions with the polymer matrix largely control their reinforcing effect. Given the SEM findings (Fig. 1A), the significant increase in tensile strength should be attributed to the strong hydrogen bond interactions between the well-dispersed Co-MOF and PVA matrix. These interactions are beneficial for preventing phase separation and enabling efficient stress transmission at the interface (Hu et al., 2022). The tensile fracture surfaces of film samples are examined by SEM in order to better understand the PVA/ChNF/Co-MOF films’ reinforcing process. As can be observed from Fig. 1Ad, the PVA/ChNF/Co-MOF film displays a rough fracture surface with evident ridged textures (Fig. 1Ad), suggesting the production of strong interfacial adhesion between the well-dispersed Co-MOF and PVA matrix. The pure PVA film, on the other hand, has a comparatively smooth morphology (Fig. 1Aa). Therefore, BA extraction and Co-MOF can thus be added to the PVA film to give it improved TS and EAB.

Color Properties

pH-Dependence of Solutions and Film Colors

pH changes in food items are frequently caused by alterations in their safety, freshness, and quality. These pH variations can be a useful tool for determining key quality attributes (Guo et al., 2023). So, it was investigated how pH affected the color response of BA extract and Co-MOF/BA solutions. The color changes of solutions containing BA extract and Co-MOF/BA throughout a pH range of 2 to 12 are depicted in Fig. 2. The anthocyanin-rich BA extract displayed a range of colors according to the pH, from red/pink at pH 2 to peach at pH 3–5, brick red at pH 6, dark red at pH 7, dark green at pH 8, greenish-yellow at pH 9–10, and lastly light green at pH 11 (Fig. 2a). In contrast, the color changes in Co-MOF/BA solutions were a little darker, resulting in color shifts from pink to dark green at different pH ranges (2–12) (Fig. 2b). This demonstrates that adding Co-MOF to the BA extract causes the amount of color to rise and the colors to be more clearly seen. The changes in anthocyanins’ molecular structure, which are brought on by pH level variations and affect their UV-absorption capabilities, are what cause the color shifts. In fact, the hyperchromic and bathochromic properties of anthocyanin cause its color to change from red (pH 3–4, when the flavylium cation form predominates) to pink/purple/colorless (pH = 4–8, when the carbinol pseudobase form predominates), and finally to brown/green/yellow (pH > 8–9, when the chalcone form predominates). Anthocyanins are perfect for the creation of pH-sensitive films or indicators due to their ability to react to pH changes (Bakhshizadeh et al., 2023a). Regarding the usage of various types of anthocyanins as color indicators in biopolymer-based packaging films, several research have produced results that are similar (Bakhshizadeh et al., 2023a; Huang et al., 2023; Kong et al., 2023; Tavassoli et al., 2023b).

According to Fig. 2c, the pH-responsive PVA/ChNF/Co-MOF/BA films showed a sufficient color response that matched the outcomes seen when anthocyanin-rich BA extract and Co-MOF were dissolved in buffer solutions. In acidic settings with a pH range of 2–6, the PVA/ChNF/Co-MOF/BA films maintained their reddish-pink coloring, ensuring that all of the color features of the films were stable and matched the films’ reddish look. But when the pH leveled out at 7, they transformed to a pale peach color, the samples’ b-values (blueness/yellowness) turned negative, and the surface of the films took on a reddish hue (Fig. 2d). As the pH value increased the b value of the films, which represents the yellow hue in the films, continuously decreased and reached a minimum at pH 12. Additionally, when the pH rose from 10 to 12, the value (greenness/redness) of the films rapidly dropped. The anthocyanins’ structural breakdown in reaction to altering their charge at various pHs was thought to be the cause of the pH-responsive films’ noticeable color shifts when exposed to alkaline buffers. The red/pink to greenish-brown color shift of the PVA/ChNF/Co-MOF/BA films matched the variation in the Co-MOF/BA solution. The color difference (ΔE) index is useful in evaluating the performance of a colorimetric indicator objectively, as mentioned in our previous work. As a result, a key consideration in the creation of freshness indicators has been the variance in the ΔE value (Fig. 2e). With this as a backdrop, it can be seen that a considerable change in ΔE was seen as the pH increased from 2 to 12, showing that the indicator films showed a discernible visual color modification that could be seen with the naked eye. According to Bakhshizadeh and co-workers (2023a), the films containing anthocyanins-rich common poppy extract displayed a color transition from reddish to green when the pH changed from acidic to alkaline conditions. Lin et al. (2022) also observed that the color of PVA-based intelligent films containing MOF-loaded grape skin anthocyanin changed from red to yellow-green as the pH level increased from 2 to 12.

UV–Vis Properties

The optical images of pure PVA-based films are shown in Fig. 3Aa. Pure PVA film has no color and notable transparency. Also, the addition of ChNF did not significantly change the film’s ability to transmit light. The PVA/ChNF/Co-MOF films that develop after the addition of Co-MOF can still be clear and uniform in appearance, but with pink due to the hue of Co-MOF. The transmittance spectra of the PVA/ChNF/Co-MOF films were obtained and are shown in Fig. 3Ab in order to better understand the impact of Co-MOF on the optical properties of the PVA film. As can be observed, pure PVA film has a comparatively high light transmittance at 250 nm (T250) and 650 nm (T650), which are 46.14% and 87.08%, respectively, for both UV and visible lights. The addition of Co-MOF and BA decreased the light transmission so that the PVA/ChNF/Co-MOF/BA film was 0.014% and 46.11% at 250 nm and 650 nm, respectively. According to the aforementioned findings, the addition of Co-MOF and BA can provide PVA film with an obviously increased UV-shielding ability, with just a little reduction in visual transparency. Due to the strong UV-light absorption rate by the Co-MOF nanofillers and the BA anthocyanins, the UV-shielding effectiveness of PVA/ChNF/Co-MOF/BA films has clearly enhanced (Alizadeh Sani et al., 2024). Tang et al. (2023) showed that the addition of Co-MOF to carboxymethyl cellulose matrix reduces light transmission and has high anti-UV properties.

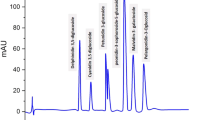

A—a Appearance of films and b UV–vis light transmittance spectra of the PVA-based films; B—a color sensitivity of intelligent films containing the PVA/ChNF/Co-MOF/BA to ammonia vapor, b ΔE, and c data of L*, a*, b*; C the release of BA from PVA/ChNF/BA and PVA/ChNF/Co-MOF/BA intelligent films in ethanol solutions (10% and 95%) at different times; D dose-responsive DPPH radical scavenging activity of the PVA-based films; E antibacterial properties of the PVA-based films

Ammonia Test

When meat and meat products are spoiled by bacteria, volatile ammonia is produced, and intelligent films can identify this ammonia (Tavassoli et al., 2023a). For this reason, a sensitivity test (SRGB) was used to assess the intelligent film’s sensitivity to the ammonia atmosphere. PVA/ChNF/Co-MOF/BA film’s volatile ammonia sensitivity was assessed for 20 min at 4-min intervals. Figure 3B displays the intelligent film’s color change and SRGB. The intelligent film’s hue transitioned from peach to light peach-brown in the first 4 min, and its SRGB value grew to 24.7%. This color shift may be the result of NH3 reacting with the H2O in the intelligent films, which creates NH4+ and OH − . The NH4+ generated changes in the anthocyanins’ structure and the color of the intelligent film. Additionally, after 8 min of exposure to an ammonia environment, the color of the intelligent film changed from a light peach-brown to a dark brown, and its SRGB rose to 42.6%. Furthermore, the SRGB of the intelligent film reached 39.7 and 38.8% at 12 and 16 min, respectively. Lastly, the development of the green color caused the SRGB value to drop to 37.8% in the 20th min. The findings demonstrated that the intelligent film containing BA anthocyanins strongly responded to volatile ammonia in the first 4–8 min, demonstrating the film’s quick responsiveness and great potential for application as a gas sensor. One of the important reasons for the color changes of the PVA/ChNF/Co-MOF/BA film exposed to ammonia gas (which was mostly brown in the early stages) could be the presence of Co-MOF in the intelligent films. The Co-MOF is thought to be capable of capturing ammonia molecules through the creation of hydrogen bond interactions. This adsorption activity can change the coordination environment of cobalt ions, resulting in a unique change in the color of the Co-MOF. In a study conducted by Tang et al. (2023), they showed that exposure of Co-MOF to ammonia gas for 2 min caused a color change from light purple to brown. According to this discovery, ammonia molecules may be taken up by Co-MOF by forming hydrogen bonding connections. This adsorption behavior alters the cobalt ions’ coordination environment, which can result in the distinctive color shift of Co-MOF (Feng et al., 2023).

Release Test

The results of encapsulation efficiency and loading capacity of BA in Co-MOFs show that the amount of BA is sufficiently loaded in Co-MOF so that these results for encapsulation efficiency and loading capacity are 88.3 ± 0.19% and 20.62 ± 0.23% were calculated. The reason for this can be pointed to the effective confinement of BA in Co-MOFs in porous structures. Oktay et al. (2023) showed that the loading of red grape anthocyanins was done well due to the porous structure of zeolitic imidazolate framework-8. A CO-MOF has a high porosity, which allows it to encapsulate BA to some degree, and the plentiful hydroxyl groups in its ligands provide BA with numerous adsorption sites through hydrogen bonding (Feng et al., 2023; Tang et al., 2023). The antioxidant and antibacterial properties of packaging materials are directly impacted by BA release behavior. In this work, 10% (v/v) and 95% (v/v) ethanol solutions were used as alcoholic and fatty food substitutes, respectively, to assess the release behavior of BA from Co-MOF. In both the food simulants (10% and 95% ethanol), as shown in Fig. 3C, the release trend of BA was greater when applied alone to the film (PVA/ChNF/BA) than when added to was encapsulated by Co-MOF. Equilibrium was not seen in the 10% ethanol simulator for the PVA/ChNF/BA film sample, indicating that the addition of BA extracts alone had a significant release. In contrast, BA extract film encapsulated in Co-MOF reached equilibrium in 10% ethanol simulating solution in 60 min, while this behavior in 95% ethanol simulating solution was almost the same from the beginning and the release rate was in equilibrium. It is also important to note that the polarity of the simulants is connected to the fact that the release rate of BA in 10% ethanol is larger than that in 95% ethanol. By encouraging damage to the hydrogen bonds between Co-MOF and BA, the high polar solvent (10% ethanol) aids BA’s release from the films. These findings show that BA is encapsulated inside the porous structure of Co-MOF, giving the film packaging materials a prolonged and controlled release effect. In a study conducted by Yang et al. (2023), they showed that the release rate of carvacrol (CV) from ZnMOF-74 in 10% ethanol simulant solutions was higher due to the polarity of the simulant (R. Yang et al., 2023).

Antioxidant Activity

Materials used for packaging are crucial in protecting food from oxidizing and spoiling. To prevent chemical deterioration, it is essential to evaluate the antioxidant capabilities of these materials. The 2, 2-diphenyl-1-picrylhydrazyl (DPPH) test is a rapid and practical way to assess the film’s antioxidant strength (Kurek et al., 2018; Tavassoli et al., 2023b). Figure 3D shows that when compared to the other films, the PVA and PVA/ChNF films exhibited the lowest DPPH radical scavenging activity (4.8% and 6.8%, respectively). PVA/ChNF films have a limited antioxidant capacity due to the presence of hydroxyl groups at C-3 and amino groups at C-2. DPPH free radicals and hydrogen ions combine with these functional groups to form stable molecules (Bakhshizadeh et al., 2023b). Anthocyanins in BA, which have a high capacity to donate hydrogen atoms, contributed significantly (72.6%) to the PVA/ChNF/BA films’ DPPH radical scavenging ability. It is crucial to note that the DPPH scavenging activity of all films under study was significantly impacted by the increase in film amount (µL/mL) during the test. A possible explanation might be the anthocyanin content of the matrix made of PVA/ChNF because the ability of the active components to be released and their capacity to interact with the active sites of the polymer influence the antioxidant capability of films that include antioxidant chemicals. The PVA/ChNF/Co-MOF/BA film was shown to have strong antioxidant activity at all concentrations, as well. Because Co-MOF encapsulation may successfully protect BA anthocyanins and lessen the degradation brought on by unfavorable factors in the environment, this is the reason (Jiang et al., 2022b). The statement can be inferred from the release test as BA contained within the structure of Co-MOFs exhibited a controlled release, while BAs not encapsulated within Co-MOFs displayed a high rate of release. Also, the distinct structure of Co-MOFs, composed of metal nodes bound together by organic linkers, may contribute to their antioxidative properties. This arrangement leads to large surface areas and high porosity, which enable the inclusion or encapsulation of antioxidative substances and support their regulated release (Safarkhani et al., 2024). The antioxidant stability of the film is best demonstrated by the total antioxidant activity and DPPH radical activity that were preserved after storage. These findings demonstrated that Co-MOF-encapsulated films containing BA extract exhibited superior antioxidant stability than other films. Previous studies have also shown that encapsulating active ingredients in MOF nanosystems can improve the antioxidant stability of films. For instance, Jiang and co-workers (2023) showed that encapsulating catechin (CA) in CD-MOF can stabilize CA and increase the antioxidant power in zein films.

Antibacterial Activity

Improving the safety and lifespan of packaged food items requires evaluating the packaging materials’ capacity to stop the development and spread of spoilage organisms and dangerous diseases (Wang et al., 2023). As a result, the disk technique was used to evaluate the antibacterial properties of PVA/ChNF-based films against Gram-positive (S. aureus) and Gram-negative (E. coli and P. fluorescence) bacteria. The results are shown in Fig. 3E. Due to the fact that PVA is not known for having antibacterial qualities, the films manufactured wholly from it did not demonstrate any capacity to kill any microorganisms. The ChNF and BA anthocyanins, on the other hand, were successful in killing bacteria since all of the remaining films showed some amount of antimicrobial action against them. ChNFs interact with membranes and cell components, increasing their permeability (Alizadeh-Sani et al., 2021a, 2021b). By including antimicrobial phenolic groups in their structural design, BA anthocyanins improve the films’ ability to prevent bacterial growth. In fact, phenolic substances like anthocyanins are thought to have antimicrobial properties through a number of mechanisms, including increasing the permeability of cell membranes, preventing the absorption of crucial substances required for cell growth and proliferation, as well as disrupting crucial metabolic pathways (Alizadeh-Sani et al., 2021a, 2021b). Additionally, it was discovered that the PVA/ChNF/Co-MOF film has strong antibacterial action, as evidenced by the inhibition zones of 16.8 mm, 15.9 mm, and 15.3 mm for S. aureus, E. coli, and P. fluorescence, respectively. Cobalt ions that are discharged from the surface of films containing Co-MOF frequently have an antibacterial effect because they have the power to harm bacterial cell membranes in addition to killing them (Feng et al., 2023). In comparison to other films, PVA/ChNF/Co-MOF/BA films had the strongest antibacterial activity (S. aureus 21.6 mm, E. coli 20.3 mm, and P. fluorescence 19.6 mm). It was also shown that S. aureus bacteria are more susceptible to and disintegrate more quickly in these films. This could be probable because the structure, physiology, and metabolism of Gram-positive and Gram-negative bacteria differ (Jiang et al., 2022a, 2022b).

Freshness Monitoring Trials

The storage of foods that contain protein, such as meat and meat products, in ambient conditions or under refrigeration is likely to cause bacterial spoilage, oxidation of fats and proteins, and biochemical changes. Over time, ammonia and amine compounds produced by the degradation of proteins accumulate in sealed packages, causing pH levels to rise. In order to demonstrate the effectiveness of the films in detecting volatile nitrogen compounds, both PVA/ChNF/Co-MOF and PVA/ChNF/Co-MOF/BA films were affixed to a container filled with fresh meat and used to monitor the freshness of the meat (Fig. 4Aa–f). Figure 4B–E presents the microbiological analysis (i.e., TVC and PTC) and chemical properties (i.e., pH, PV, TBA, and TVB-N) in red meat packaged with the treated group films (PVA/ChNF/Co-MOF and PVA/ChNF/Co-MOF/BA). Raw red meat is generally a favorable medium for microbial growth. The initial TVC and PTC of red meat samples were determined to be 3.1 ± 0.03 and 2.1 ± 0.09 log CFU/g, respectively (Fig. 4C), suggesting a standard quality and safety for the samples. Red meat is considered unsuitable for human consumption when the TVC and PTC exceed 7 Log CFU/g. Also, the initial pH, PV, TBA, and TVB-N of red meat at 4 °C were 6.2 ± 0.24, 0.45 ± 0.02 meq peroxide/kg fat, 0.2 ± 0.01 MDA/kg lipid and 6.32 ± 0.62 mg N/100 g, respectively, affirming the appropriate quality of the red meat. Accordingly, with the passage of storage time at 4 °C, the meat samples were slightly spoiled after 4 days of storage and reached the dangerous limit for consumption. The color changes in PVA/ChNF/Co-MOF and PVA/ChNF/Co-MOF/BA films were observed on day 4, which in this period changed from pink to light brown and from dark peach to light orange as indicators of freshness. At the end of storage time, TVC, PTC, pH, PV, TBA, and TVB-N finally reached 6.7 ± 0.18 log CFU/g, 3.78 ± 0.11 log CFU/g, 8.41 ± 0.24 and 1.59 ± 0.02 meq peroxide/kg fat, 0.71 ± 0.06 MDA/kg lipid, and 38.6 ± 1.2 mg N/100 g, respectively. The PVA/ChNF/Co-MOF and PVA/ChNF/Co-MOF/BA films changed to dark brown and black-greenish-brown colors and the films were able to visually identify the changes in the quality of meat samples (Fig. 4f). Feng et al. (2023) developed a Co-MOF packaging film loaded in sodium alginate matrix. Films showed a noticeable color change from pale pink to black-brown after 24 h of storage in shrimp samples, and ΔE values increased dramatically to more than 45, which was closely correlated with TVBN accumulation (Feng et al., 2023). Riahi and co-workers (2023) developed dual-functional packaging films with gelatin (Gel) and PVA matrix combined with MOF and red cabbage anthocyanins (RCA). They showed that Gel/PVA/RCA/MOF films show color changes from reddish/pink to light and dark green in the application of shrimp freshness monitoring (Riahi et al., 2023b).

In Fig. 4A, the initial redness values (L⁎; 60.84, a⁎; 9.11, and b⁎; 5.74) of the films indicate the favorable quality of red meat during the early storage period at 4 °C. As the storage time progressed, the L⁎, a⁎, and b⁎ values decreased to 13.73, 5.9, and 3.74, respectively, indicative of chemical and microbial spoilage in the red meat samples after 10 days. The observed ΔE values exceeding 5 during storage suggest detectable color alterations and changes in meat quality status, even by untrained panelists. A similar transition in color, from red and orange-pink to light green, was observed over a 10-day storage period in a sodium alginate/gelatin-based film loaded with plum peel extract by Chen et al. (2023). This transition was accompanied by an increase in pH from 5.82 to 6.84 and a rise in TVB-N level in fresh chicken from 7.73 mg/100 g to 34.58 mg/100 g (Chen et al., 2023). Goudarzi et al. (2023) also highlighted a decline in L⁎ (96.87) and a⁎ (− 2.25) parameters of Prunus domestica extract + PVA/κ-carrageena nanofiber mats, reaching 51.19 and − 12.44, respectively, along with visible color changes from white to purplish-red in minced lamb meat after 15 days (Goudarzi et al., 2023).

Conclusion

Novel intelligent active films were successfully developed for the purpose of monitoring the freshness of red meat by combining BA and Co-MOF using a casting approach with a PVA/ChNF matrix. The results showed that the addition of Co-MOF and BA anthocyanins increases the compatibility and specific surface of films made of PVA. With its clear pH-dependent color-changing characteristics, BA acted as a volatile ammonia indicator throughout the meat freshness monitoring process, and Co-MOF’s excellent capacity to enrich volatile organic amines significantly increased the monitoring sensitivity. Furthermore, S. aureus, E. coli, and P. fluorescence were all effectively inhibited by the loading of Co-MOF and BA anthocyanins onto the film. The Co-MOF nanofillers are uniformly distributed inside the PVA matrix to generate suitable nanocomposite films, according to SEM and FTIR measurements. The intelligent film also shows outstanding mechanical characteristics and color stability. This change can be easily observed with the naked eye and was compatible during the storage of red meat samples, accompanied by levels of pH, TVB-N, TVC, PV, PTC, and TBA. With the help of the red meat’s TVB-N values, the as-prepared PVA/ChNF/Co-MOF/BA film was effectively used as a low-cost, quick-response trademark for real-time monitoring of red meat freshness. This is the first attempt to create an intelligent active film for monitoring the freshness of red meat using Co-MOF material and BA anthocyanins, which is a crucial way to ensure food safety and increase food shelf life. The developed PVA/ChNF/Co-MOF/BA films, which are robust and resistant and exhibit ammonia-responsive, antibacterial, and UV-blocking properties, offer enormous potential for use in active food packaging. However, there can be challenges and limitations when using MOFs in food packaging. Some of these limitations include low capacity, challenges with recycling, ineffective gas molecule separation, and high production expenses, which hinder the widespread use of MOFs in food packaging. Resolving these obstacles would enable the creation of effective packaging materials embedded with MOFs to uphold food safety and quality and prolong shelf life. Also, given their widespread use in intelligent food packaging, additional research on the safety assessment of films has to be done in the future. Lastly, it is essential to conduct a thorough assessment of the complete metabolic pathway to ensure that there are no long-term effects on human health from any unintentional introduction of MOFs into the human body, even though studies on immediate toxic effects evaluation are available.

Data Availability

No datasets were generated or analysed during the current study.

References

Alizadeh Sani, M., Khezerlou, A., Tavassoli, M., Abedini, A. H., & McClements, D. J. (2024). Development of sustainable UV-screening food packaging materials: A review of recent advances. Trends in Food Science & Technology, 145, 104366. https://doi.org/10.1016/j.tifs.2024.104366

Alizadeh-Sani, M., Tavassoli, M., McClements, D. J., & Hamishehkar, H. (2021a). Multifunctional halochromic packaging materials: Saffron petal anthocyanin loaded-chitosan nanofiber/methyl cellulose matrices. Food Hydrocolloids, 111, 106237. https://doi.org/10.1016/j.foodhyd.2020.106237

Alizadeh-Sani, M., Tavassoli, M., Mohammadian, E., Ehsani, A., Khaniki, G. J., Priyadarshi, R., & Rhim, J.-W. (2021b). pH-responsive color indicator films based on methylcellulose/chitosan nanofiber and barberry anthocyanins for real-time monitoring of meat freshness. International Journal of Biological Macromolecules, 166, 741–750. https://doi.org/10.1016/j.ijbiomac.2020.10.231

Bakhshizadeh, M., Ayaseh, A., Hamishehkar, H., Samadi Kafil, H., Niknazar Moghaddam, T., Baghban Haghi, P., ... Lorenzo, J. M. (2023a). Multifunctional performance of packaging system based on gelatin/alove vera gel film containing of rosemary essential oil and common poppy anthocyanins. Food Control, 154, 110017. https://doi.org/10.1016/j.foodcont.2023.110017

Bakhshizadeh, M., Moghaddam, T. N., Tavassoli, M., Ayaseh, A., & Bangar, S. P. (2023b). Gelatin/chitosan nanofibres containing β-cyclodextrin complex and corn poppy (Papaver rhoeas L.) for intelligent packaging. International Journal of Food Science & Technology, 58(5), 2360–2368. https://doi.org/10.1111/ijfs.16369

Chen, K., Li, J., Li, L., Wang, Y., Qin, Y., & Chen, H. (2023). A pH indicator film based on sodium alginate/gelatin and plum peel extract for monitoring the freshness of chicken. Food Bioscience, 53, 102584. https://doi.org/10.1016/j.fbio.2023.102584

Ezati, P., & Rhim, J.-W. (2020). pH-responsive chitosan-based film incorporated with alizarin for intelligent packaging applications. Food Hydrocolloids, 102, 105629.

Feng, S., Tang, Q., Xu, Z., Huang, K., Li, H., & Zou, Z. (2023). Development of novel Co-MOF loaded sodium alginate based packaging films with antimicrobial and ammonia-sensitive functions for shrimp freshness monitoring. Food Hydrocolloids, 135, 108193.

Goudarzi, J., Moshtaghi, H., & Shahbazi, Y. (2023). Kappa-carrageenan-poly(vinyl alcohol) electrospun fiber mats encapsulated with Prunus domestica anthocyanins and epigallocatechin gallate to monitor the freshness and enhance the shelf-life quality of minced beef meat. Food Packaging and Shelf Life, 35, 101017. https://doi.org/10.1016/j.fpsl.2022.101017

Guo, H., Shao, C., Ma, Y., Zhang, Y., & Lu, P. (2023). Development of active and intelligent pH food packaging composite films incorporated with litchi shell extract as an indicator. International Journal of Biological Macromolecules, 226, 77–89. https://doi.org/10.1016/j.ijbiomac.2022.11.325

Hu, W., Zou, Z., Li, H., Zhang, Z., Yu, J., & Tang, Q. (2022). Fabrication of highly transparent and multifunctional polyvinyl alcohol/starch based nanocomposite films using zinc oxide nanoparticles as compatibilizers. International Journal of Biological Macromolecules, 204, 284–292.

Huang, H.-L., Tsai, I. L., Lin, C., Hang, Y.-H., Ho, Y.-C., Tsai, M.-L., & Mi, F.-L. (2023). Intelligent films of marine polysaccharides and purple cauliflower extract for food packaging and spoilage monitoring. Carbohydrate Polymers, 299, 120133. https://doi.org/10.1016/j.carbpol.2022.120133

Jiang, L., Liu, F., Wang, F., Zhang, H., & Kang, M. (2022a). Development and characterization of zein-based active packaging films containing catechin loaded β-cyclodextrin metal-organic frameworks. Food Packaging and Shelf Life, 31, 100810. https://doi.org/10.1016/j.fpsl.2022.100810

Jiang, L., Wang, F., Du, M., Xie, C., Xie, X., Zhang, H., ... Deng, T. (2022b). Encapsulation of catechin into nano-cyclodextrin-metal-organic frameworks: Preparation, characterization, and evaluation of storage stability and bioavailability. Food Chemistry, 394, 133553.

Jiang, H., Zhao, S., Li, Z., Chen, L., Mo, H., & Liu, X. (2024). Swan-feathers inspired smart-responsive sustainable carboxymethyl cellulose/polyvinyl alcohol based food packaging film for robustly integrated intelligent and active packaging. Nano Today, 56, 102272. https://doi.org/10.1016/j.nantod.2024.102272

Jiang, L., Ye, R., Xie, C., Wang, F., Zhang, R., Tang, H., ... Liu, Y. (2023). Development of zein edible films containing different catechin/cyclodextrin metal-organic frameworks: Physicochemical characterization, antioxidant stability and release behavior. LWT, 173, 114306. https://doi.org/10.1016/j.lwt.2022.114306

Kathuria, A., El Badawy, A., Al-Ghamdi, S., Hamachi, L. S., & Kivy, M. B. (2023). Environmentally benign bioderived, biocompatible, thermally stable MOFs suitable for food contact applications. Trends in Food Science & Technology, 138, 323–338. https://doi.org/10.1016/j.tifs.2023.06.024

Khan, A., Riahi, Z., Kim, J. T., & Rhim, J.-W. (2023). Gelatin/carrageenan-based smart packaging film integrated with Cu-metal organic framework for freshness monitoring and shelf-life extension of shrimp. Food Hydrocolloids, 145, 109180. https://doi.org/10.1016/j.foodhyd.2023.109180

Khezerlou, A., Tavassoli, M., Khalilzadeh, B., Ehsani, A., & Kazemian, H. (2023d). Metal-organic framework-based advanced sensing platforms for the detection of tetracycline in food and water samples. Food Control, 153, 109965. https://doi.org/10.1016/j.foodcont.2023.109965

Khezerlou, A., Alizadeh Sani, M., Tavassoli, M., Abedi-Firoozjah, R., Ehsani, A., & McClements, D. J. (2023a). Halochromic (pH-Responsive) Indicators based on natural anthocyanins for monitoring fish freshness/spoilage. Journal of Composites Science, 7(4). https://doi.org/10.3390/jcs7040143

Khezerlou, A., Tavassoli, M., Alizadeh-Sani, M., Hashemi, M., Ehsani, A., & Bangar, S. P. (2023b). Multifunctional food packaging materials: Lactoferrin loaded Cr-MOF in films-based gelatin/κ-carrageenan for food packaging applications. International Journal of Biological Macromolecules, 126334. https://doi.org/10.1016/j.ijbiomac.2023.126334

Khezerlou, A., Tavassoli, M., Alizadeh Sani, M., Ehsani, A., & McClements, D. J. (2023c). Smart packaging for food spoilage assessment based on Hibiscus sabdariffa L. anthocyanin-loaded chitosan films. Journal of Composites Science, 7(10). https://doi.org/10.3390/jcs7100404

Kim, H., Panda, P. K., Sadeghi, K., & Seo, J. (2023). Poly (vinyl alcohol)/hydrothermally treated tannic acid composite films as sustainable antioxidant and barrier packaging materials. Progress in Organic Coatings, 174, 107305.

Kong, J., Ge, X., Sun, Y., Mao, M., Yu, H., Chu, R., & Wang, Y. (2023). Multi-functional pH-sensitive active and intelligent packaging based on highly cross-linked zein for the monitoring of pork freshness. Food Chemistry, 404, 134754. https://doi.org/10.1016/j.foodchem.2022.134754

Kurek, M., Garofulić, I. E., Bakić, M. T., Ščetar, M., & Uzelac, V. D. (2018). Development and evaluation of a novel antioxidant and pH indicator film based on chitosan and food waste sources of antioxidants. Food Hydrocolloids, 84, 238–246.

Lin, X., Li, N., Xiao, Q., Guo, Y., Wei, J., Jiao, T., ... Chen, X. J. F. C. (2022). Polyvinyl alcohol/starch-based film incorporated with grape skin anthocyanins and metal-organic framework crystals for colorimetric monitoring of pork freshness. Food Chemistry, 395, 133613.

Mao, L., Wang, C., Yao, J., Lin, Y., Liao, X., & Lu, J. (2023). Design and fabrication of anthocyanin functionalized layered clay/poly (vinyl alcohol) coatings on poly (lactic acid) film for active food packaging. Food Packaging and Shelf Life, 35, 101007.

Mirmoeini, S. S., Moradi, M., Tajik, H., Almasi, H., & Gama, F. M. (2023). Cellulose/salep-based intelligent aerogel with red grape anthocyanins: Preparation, characterization and application in beef packaging. Food Chemistry, 425, 136493.

Mohebi, E., Abbasvali, M., & Shahbazi, Y. (2023). Development of biomaterials based on chitosan-gelatin nanofibers encapsulated with Ziziphora clinopodioides essential oil and Heracleum persicum extract for extending the shelf-life of vacuum-cooked beef sausages. International Journal of Biological Macromolecules, 253, 127258. https://doi.org/10.1016/j.ijbiomac.2023.127258

Mustafa, P., Niazi, M. B., Jahan, Z., Samin, G., Hussain, A., Ahmed, T., & Naqvi, S. R. (2020). PVA/starch/propolis/anthocyanins rosemary extract composite films as active and intelligent food packaging materials. Journal of Food Safety, 40(1), e12725.

Oktay, C., Kahyaoglu, L. N., & Moradi, M. (2023). Food freshness monitoring using poly(vinyl alcohol) and anthocyanins doped zeolitic imidazolate framework-8 multilayer films with bacterial nanocellulose beneath as support. Carbohydrate Polymers, 319, 121184. https://doi.org/10.1016/j.carbpol.2023.121184

Riahi, Z., Hong, S. J., Rhim, J.-W., Shin, G. H., & Kim, J. T. (2023a). High-performance multifunctional gelatin-based films engineered with metal-organic frameworks for active food packaging applications. Food Hydrocolloids, 144, 108984.

Riahi, Z., Khan, A., Rhim, J.-W., Shin, G. H., & Kim, J. T. (2023b). Gelatin/poly(vinyl alcohol)-based dual functional composite films integrated with metal-organic frameworks and anthocyanin for active and intelligent food packaging. International Journal of Biological Macromolecules, 126040. https://doi.org/10.1016/j.ijbiomac.2023.126040

Rieger, K. A., Eagan, N. M., & Schiffman, J. D. (2015). Encapsulation of cinnamaldehyde into nanostructured chitosan films. Journal of Applied Polymer Science, 132(13). https://doi.org/10.1002/app.41739

Rubina, M., Elmanovich, I., & Vasil’kov, A. (2020). AFM studies of chitosan, gold-chitosan, and silver-chitosan films morphology. Macromolecular Symposia, 389(1), 1900068. https://doi.org/10.1002/masy.201900068

Safarkhani, M., Farasati Far, B., Lima, E. C., Jafarzadeh, S., Makvandi, P., Varma, R. S., ... Rabiee, N. (2024). Integration of MXene and microfluidics: A perspective. ACS Biomaterials Science & Engineering, 10(2), 657–676. https://doi.org/10.1021/acsbiomaterials.3c01361

Sani, M. A., Tavassoli, M., Hamishehkar, H., & McClements, D. J. (2021). Carbohydrate-based films containing pH-sensitive red barberry anthocyanins: Application as biodegradable smart food packaging materials. Carbohydrate Polymers, 255, 117488. https://doi.org/10.1016/j.carbpol.2020.117488

Sani, M. A., Tavassoli, M., Azizi-Lalabadi, M., Mohammadi, K., & McClements, D. J. (2022). Nano-enabled plant-based colloidal delivery systems for bioactive agents in foods: Design, formulation, and application. Advances in Colloid and Interface Science, 305, 102709. https://doi.org/10.1016/j.cis.2022.102709

Sani, M. A., Dabbagh-Moghaddam, A., Jahed-Khaniki, G., Ehsani, A., Sharifan, A., Khezerlou, A., ... Maleki, M. (2023). Biopolymers-based multifunctional nanocomposite active packaging material loaded with zinc oxide nanoparticles, quercetin and natamycin; development and characterization. Journal of Food Measurement and Characterization, 17(3), 2488–2504. https://doi.org/10.1007/s11694-022-01791-7

Sultana, A., Kathuria, A., & Gaikwad, K. K. (2022). Metal–organic frameworks for active food packaging. A Review. Environmental Chemistry Letters, 20(2), 1479–1495. https://doi.org/10.1007/s10311-022-01387-z

Tang, Q., Zou, Z., Huang, Y., Liang, S., Li, H., & Xu, L. (2023). Novel ammonia-responsive carboxymethyl cellulose/Co-MOF multifunctional films for real-time visual monitoring of seafood freshness. International Journal of Biological Macromolecules, 230, 123129.

Tavassoli, M., Sani, M. A., Khezerlou, A., Ehsani, A., & McClements, D. J. (2021). Multifunctional nanocomposite active packaging materials: Immobilization of quercetin, lactoferrin, and chitosan nanofiber particles in gelatin films. Food Hydrocolloids, 118, 106747. https://doi.org/10.1016/j.foodhyd.2021.106747

Tavassoli, M., Alizadeh Sani, M., Khezerlou, A., Ehsani, A., Jahed-Khaniki, G., & McClements, D. J. (2022). Smart biopolymer-based nanocomposite materials containing ph-sensing colorimetric indicators for food freshness monitoring. Molecules, 27(10). https://doi.org/10.3390/molecules27103168

Tavassoli, M., Khezerlou, A., Firoozy, S., Ehsani, A., & PuniaBangar, S. (2023a). Chitosan-based film incorporated with anthocyanins of red poppy (Papaver rhoeas L.) as a colorimetric sensor for the detection of shrimp freshness. International Journal of Food Science & Technology, 58(6), 3050–3057. https://doi.org/10.1111/ijfs.16432

Tavassoli, M., Khezerlou, A., Moghaddam, T. N., Firoozy, S., Bakhshizadeh, M., Sani, M. A., ... Lorenzo, J. M. (2023b). Sumac (Rhus coriaria L.) anthocyanin loaded-pectin and chitosan nanofiber matrices for real-time monitoring of shrimp freshness. International Journal of Biological Macromolecules, 242, 125044. https://doi.org/10.1016/j.ijbiomac.2023.125044

Tavassoli, M., Khezerlou, A., Bakhshizadeh, M., Ebrahimi, A., Abedi-Firoozjah, R., Alizadeh-Sani, M., ... Hashemi, M. (2024). Smart packaging containing red poppy anthocyanins for fish freshness monitoring. Journal of Food Measurement and Characterization. https://doi.org/10.1007/s11694-024-02386-0

Tavassoli, M., Khezerlou, A., Sani, M. A., Hashemi, M., Firoozy, S., Ehsani, A., ... McClements, D. J. (2024b). Methylcellulose/chitosan nanofiber-based composites doped with lactoferrin-loaded Ag-MOF nanoparticles for the preservation of fresh apple. International Journal of Biological Macromolecules, 259, 129182. https://doi.org/10.1016/j.ijbiomac.2023.129182

Turgut, S. S., Soyer, A., & Işıkçı, F. (2016). Effect of pomegranate peel extract on lipid and protein oxidation in beef meatballs during refrigerated storage. Meat Science, 116, 126–132. https://doi.org/10.1016/j.meatsci.2016.02.011

Wang, F., Xie, C., Tang, H., Hao, W., Wu, J., Sun, Y., ... Jiang, L. (2023). Development, characterization and application of intelligent/active packaging of chitosan/chitin nanofibers films containing eggplant anthocyanins. Food Hydrocolloids, 139, 108496.

Weng, W.-Y., Tao, Z., Liu, G.-M., Su, W.-J., Osako, K., Tanaka, M., & Cao, M.-J. (2014). Mechanical, barrier, optical properties and antimicrobial activity of edible films prepared from silver carp surimi incorporated with ε-polylysine. Packaging Technology and Science, 27(1), 37–47. https://doi.org/10.1002/pts.2001

Yang, Y., Zhou, Y., Chuo, H., Wang, S., & Yu, J. (2007). Blood compatibility and mechanical properties of oxidized-chitosan films. Journal of Applied Polymer Science, 106(1), 372–377. https://doi.org/10.1002/app.25399

Yang, R., Liu, B., Yu, F., Li, H., & Zhuang, Y. (2023). Superhydrophobic cellulose paper with sustained antibacterial activity prepared by in-situ growth of carvacrol-loaded zinc-based metal organic framework nanorods for food packaging application. International Journal of Biological Macromolecules, 234, 123712. https://doi.org/10.1016/j.ijbiomac.2023.123712

Yong, H., Wang, X., Bai, R., Miao, Z., Zhang, X., & Liu, J. J. F. H. (2019). Development of antioxidant and intelligent pH-sensing packaging films by incorporating purple-fleshed sweet potato extract into chitosan matrix. Food Hydrocolloids, 90, 216–224.

Acknowledgements

The study was approved & supported by the Vice-Chancellor for research, ABADAN UNIVERSITY OF MEDICAL SCIENCES, ABADAN, IRAN (Project No. 1506).

Author information

Authors and Affiliations

Contributions

Seyyed Mohammad Ali Noori: Conceptualization, Investigation, Original draft preparation, Writing—review & editing. Arezou Khezerlou: Conceptualization, Investigation, Data curation, Writing—review & editing. Mohammad Hashemi: Investigation, Writing—review & editing. Mahmood Alizadeh-Sani, Solmaz Firoozy, Faramarz Khodaian and Shiva Adibi: Investigation, Analyzing data and Drawing figures and graphs. Mahshid Naghashpour: Conceptualization, Methodology, Supervision, Writing—review & editing. Milad Tavassoli: Investigation, Conceptualization, Methodology, valorization, Data curation, Original draft preparation, Writing—review & editing.

Corresponding authors

Ethics declarations

Ethics Approval and Consent to Participate

The study was in strict accordance with the protocol approved by the registered ethical committee (Ethic code: IR.ABADANUMS.REC.1401.094) dated 2022-12-06.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Seyyed Mohammad Ali Noori and Arezou Khezerlou contributed equally to this work and are co-first authors.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Noori, S.M.A., Khezerlou, A., Hashemi, M. et al. Polyvinyl Alcohol/Chitosan Nanofiber-Based Films Incorporated with Barberry Anthocyanin-Loaded CO-MOF as Multifunctional Performance for Red Meat Sample Packaging. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03548-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03548-0