Abstract

Cold storage and processing increase the reducing sugar level in potato (Solanum tuberosum L.) which is responsible for browning and acrylamide formation that adversely affect sensory and nutrient quality of chips. Effect of α-amylase inhibitor from Withania somnifera (WSAI) treatment on the overall quality improvement of potato chips during processing was studied. WSAI treatment to potato slices at 200 ppm for 30 min was found to reduce browning (60%), residual amylase, and polyphenol oxidase activities (~ 40%) and reduce sugar level by 25%, respectively, over control. Color match analysis indicated an improvement in whiteness and brightness indices and a significant reduction in yellowness index of potato chips. The treatment proved to be superior over blanching and reduction in acrylamide generation during frying was which also observed in chips treated with it. Furthermore, our results were comparable to that of treatment with α-amylase inhibitor of Triticum aestivum and better than synthetic inhibitor, acarbose.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Potato (Solanum tuberosum L.) is one of the fourth essential vegetable food crops all over the world and is known as high carbohydrate-containing food after maize, rice, and wheat (Liu et al. 2013). It contains about 90% of starch (dry weight) which plays crucial role as supplement of energy in living organisms in the form of smaller oligosaccharides after hydrolysis by α-amylase. Starch degradation triggers the release of free reducing sugars which negatively impacts potato food processing and is one of the factors responsible for browning of raw potato slices and acrylamide generation during frying (Biedermann-Brem et al. 2003; Kumari et al. 2012).

Browning of potato food products (chips and fresh-cut cubes) can reduce their demand in the market, as the color of the product is one of the important selection criteria. The global market of products prepared from potatoes is ever increasing, and products like crispy chips, French fries, and snack bars are preferred by consumers over fresh-produced. To ensure the uninterrupted supply of potatoes as raw material, food processing industry stores large quantities of potatoes in cold storage at a low temperature (Liu et al. 2013). This low temperature storage prevents sprouting, water loss, and pathogen attack but at the same time leads to the initiation of cold-induced sweetening due to accumulation of reducing sugars (Zhang et al. 2014). Browning of potatoes during processing occurs mainly due to enhanced action of enzymes like polyphenol oxidases, tyrosinases, proteases, and amylases. These enzymes utilize oxidizing agents, free radicals, tyrosine, peptides, and oligosaccharides as their substrates which are generated during potato processing (Severini et al. 2003). In Maillard reaction, reducing sugars (glucose and fructose) form complex with free amino acids (asparagine and glutamine), at higher temperatures during frying, results into generation of health hazardous compound, acrylamide, and characteristic roasted flavor and brown color in the finished product (Whitfield and Mottram 1992; Amrein et al. 2003; Ayvaz and Rodriguez-Saona 2015). Acrylamide is a known potent neurotoxin and carcinogenic agent. N-Glycosides, intermediates of acrylamide formation, are made from free sugars and amino acids during the early stage of the Maillard reaction (Amrein et al. 2003). According to annual report of the World Health Organization, intake of acrylamide from processed foods ranges from 0.3 to 2.0 μg per kilogram body weight per day in adults whereas, in children, this range is even higher because of the low body weight (World Health Organization, Food Safety Programme 2002).

Generation of reducing sugars during cold storage of potatoes, browning, and formation of acrylamide during frying are the factors of concern in potato processing industry (Amrein et al. 2003). Browning of food products hampers their visual acceptance; cold-induced sweetening leads to the disturbance of sensory (flavor, smell) as well as physical properties (texture), and acrylamide generation is associated with human health concern. Therefore, food products showing these attributes are considered as nutritionally inferior and are always at the risk of consumers’ refusal. To overcome these problems during potato processing, the use of reaction inhibitory chemicals or biological compounds appears to be a wise approach. Many chemical inhibitors in various concentrations and combinations have been used and investigated for this purpose (Rocculi et al. 2007). Sulfite is a low-cost satisfactory, anti-browning compound and hence, it was popular in the nineteenth century in potato chips industry (Marshall et al. 2000). However, the use of sulfites or bisulfites is found to be associated with a number of disadvantages such as (i) reduction in nutritional value of slices; (ii) softening of cut potato tissues; (iii) addition of “off flavors” in potato chips; and (iv) detrimental health effects on consumers (Ma et al. 2010).

In the light of these facts, there is a need to find potent yet safer inhibitor of the reactions which are responsible for deteriorating the overall quality of food products derived from potatoes. Utilization of α-amylase inhibitors (α-AIs) appears to be safer and attractive option to regulate starch degradation and, in turn, reducing sugar-mediated potato browning. A number of plant species are reported to have the presence of α-AIs which play an important role in the regulation of starch hydrolysis.

In the present work, we describe the potential of an isolated, purified, and characterized glycoprotein α-AI from an indigenous medicinal plant, Withania somnifera (WSAI) (Kasar et al. 2017) in lowering the release of reducing sugars and browning of potato slices during processing. The WSAI treatment also reduced the possibility of the Maillard reaction causing acrylamide generation during frying of the potato chips. The anti-browning efficiency of WSAI has been compared with standard synthetic chemical α-AI, acarbose, and commercially available proteinaceous α-AI from Triticum aestivum (TAAI). Our results suggest potential application of naturally occurring α-AIs in food processing industry especially in potato processing for improving the quality of food products.

Materials and Methods

Potato Sample

Potatoes were procured from a local market near KBC North Maharashtra University, Jalgaon, and used for experimentation. The potatoes were stored for 5 days in a dark chamber at 25 °C without addition of sprouting inhibitors then washed with sterile distilled water and wiped with clean tissue papers. Cleaned and dried potatoes were peeled; both extremes of tubers were cut into round slices (4 cm diameter, 1.0 mm thickness) having middle parenchyma tissue were prepared using a slicer. The knife, peeler, and slicer were carefully cleaned with sodium hypochlorite prior to use.

Treatment of WSAI to Potato Slices

Round slices of potato were dipped in required concentration of purified WSAI solution at 1:3 proportion (grams of potato tissue to milliliters of solution). Of the two control sets, the first one was dipped in a buffer and the other one was left in open air. Treatment with synthetic α-AIs such as acarbose and a proteinaceous TAAI (Sigma-Aldrich St. Louis, MO, USA) served as positive controls. Treatment concentrations of α-AIs and exposure time were optimized by treating the potato slices at their various concentrations (100,150, and 200 ppm) at 25 °C with gentle shaking for 10, 20, and 30 min.

Enzyme Extraction and Browning Analysis

The browning assay of treated potato slices was performed as described by Kaur and Kapoor (2000). Excess treatment solution on potato slices was removed and 5-g slices were subjected to homogenization in 15 mL phosphate buffer (20 mM, pH 7) for 2 to 4 min followed by centrifugation (Heraeus Multifuge 1 S, Osterode, Germany) at 1026×g for 10 min. An aliquot of 2 mL from supernatant obtained was used as a source of crude enzymes. The remaining supernatant was allowed to stand for 1 h in a closed container with gentle shaking at room temperature (~ 25 °C) and used for browning analysis. It was mixed with 15 mL of 95% ethanol, followed by centrifugation at 1178×g for 15 min. The resulting supernatant was then used further for measuring browning intensity at 440 nm spectrophotometrically (UV 1800, Shimadzu, Japan).

Determination of Indigenous α-Amylase Activity in Sliced Potato

The activity of exctracted α-amylase from all samples was determined by estimating reducing sugar (maltose equivalent) liberated under treatment conditions. α-Amylase activity bioassay was performed as described previously (Kasar et al. 2017). For this, the concentration of extracted enzyme was adjusted to achieve 100 μg/mL enzyme protein. Assay mixture contained 50-μL enzyme extract, 150 μL of starch solution (0.05% w/v), and 120 μL of phosphate buffer (pH 7.0, 20 mM). It was then allowed to incubate at 37 °C for 15 min. The reaction was stopped by adding DNS reagent (1% DNS, 0.05% sodium sulfite, 30% w/v NaK tartarate dissolved in 1% NaOH), and the contents were heated in a boiling water bath for 5 min. Experimental blanks were set for α-amylase enzyme and starch by replacing them with equal quantities of buffer, and absorbance was measured at 540 nm. The amount of reducing sugar released from starch hydrolysis was estimated as maltose equivalent (μM/min) from a maltose standard curve.

Determination of Polyphenol Oxidase Activity

The same extract (as in 2.4 above) was used as a source of polyphenol oxidase (PPO) enzyme. The enzyme activity assay was performed, by measuring the change in absorbance (ΔA) after 10 s and 70 s at 420 nm as described by Kaur and Kapoor (2000). The reaction mixture contained 1 mL, 0.02 M catechol as substrate, 1 mL phosphate buffer (50 mM, pH 7), and 15-μL (50 μg protein) crude enzyme extract from various treated samples. PPO enzyme activity was calculated by using the formula, enzyme units (EU) = ΔA × reaction volume/(ε + enzyme volume), where ε is the molar extinction coefficient of catechol (22,600 M−1 cm−1).

Extraction and Quantification of Sugar from Sliced Potato

Sugar extraction from potato samples was performed as per Rocculi et al. (2007) with slight modifications. Five grams of potato slices (from each set) were homogenized for 2 min with 20 mL ethanol (95%), and the homogenate was filtered through Whatman filter paper No. 1. The residue was rinsed twice with 10 mL ethanol (95%). The excess amount of ethanol from sugar extract was then evaporated using a rotary vacuum evaporator (R-124, Buchi, Switzerland) in order to reduce it to 1 mL. Distilled water was added to this evaporated sugar extract to achieve 5 mL final volume, and total reducing sugar was estimated by DNSA reagent method (Miller 1972).

Color Match Spectrophotometer Analysis for Quantitative Determination of Yellowness, Whiteness, and Brightness Indices of Potato Slices

Color analysis of the treated and untreated potato slices was done by measuring the reading from three surfaces at different locations of the same slice. For this, color-match CIELAB Spectro: 5100H spectrophotometer (Premier Colorscan Instruments, Mumbai, India) on reflectance mode was used to read the coordinates (L*, a*, b*). According to L*, a*, b*, color space system L* is the browning intensity, b* is the position on the green (−) to red (+) axis and a* is the position on the blue (−) to yellow (+) axis (Granato and Masson 2010). This analysis provided yellowness index (YI), whiteness index (WI), and brightness index (BI) of the potato slices.

Effect of Blanching on Dry Weight and Nutrient Values of Potato Slices

Blanching is the traditional method used in potato processing industry to reduce browning by incubating potato slices at 80 °C for 15 min. For measuring the effect on dry weight and nutrient value of potato slices, blanched- and α-AIs (WSAI, TAAI, and acarbose)-treated potato slices (1 g each) were homogenized separately in 10-mL distilled water. The extracted samples were centrifuged at 885×g to pellet the tissues, which were then dried at 75 °C overnight in an oven for removal of the total moisture. Dried samples were ground to fine powder and weighed separately to record dry weight. To quantify the total carbohydrate content, 50 mg of powdered samples were individually refluxed in 15 mL 1 N HCl on hot plate magnetic stirrer (Q18A, Remi, India) for 30 min. Individual samples were then filtered through Whatman filter paper No. 1, and the filtrate was utilized for the total carbohydrate determination by phenol sulfuric acid method (DuBois et al. 1956). Protein content of treated and untreated samples was also analyzed by the method of by Bradford (1976). All the measurements were recorded in triplicates.

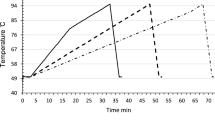

Determination of Acrylamide Content in Fried Potato Chips

Treated potato slices, as in previous experiments, were used for frying. These slices after incubation and treatment at optimized conditions were dried with the help of blotting papers to remove the treatment solutions. Potato slices (5 g from each treatment set) were fried in fresh soybean oil (Fortune, India) at a starting temperature of 130 °C for 3 min on heating a plate (Prestige PIC 201200 Watt Induction Cooktop, India). At the end of 3 min, the chips were removed from the hot oil and packaged separately in sealed and labeled filter paper bags for further study.

Extraction of acrylamide from processed potato chips was done as reported by Khoshnam et al. (2010) with some modifications. In this, powdered potato chip samples were weighed (5 g from each set) in screw capped bottle, defatted by adding 10 mL hexane with gentle agitation for 10 min at 25 °C, and finally the mixture was dried under vacuum. Acrylamide from each defatted potato chip sample was extracted in a mixture of acetone and water (20 mL acetone and 100-μL water) in an ultrasonic bath at 40 °C for about 20 min. The mixture was filtered through a filter paper, and the filtrate was evaporated under vacuum to dry. To this, 2 mL HPLC grade water (HiMedia, Mumbai, India) was added and shaken thoroughly at 170 rpm and 30 °C temperature overnight to dissolve the entire residue. These aqueous solutions were then used for qualitative and quantitative analyses of acrylamide.

The extracted acrylamide from fried potato chips of all treatment sets was individually added in 100 mg dried-fine potassium bromide (KBr) powder, and round fine discs were prepared using a hydraulic press (Carver Inc., Wabash, USA) and resulting discs were used for FTIR analysis. The MIR source spectra were collected using a Spectrum Two 88522 Fourier-Transform IR Spectrometer (PerkinElmer, Waltham, MA, USA) equipped with optional KBr beam splitter and lithium tantalate (LiTaO3) detector. Spectra were collected over a range of 4000–400 cm−1 at 4 cm−1 resolution. The percent transmittance spectrum was obtained by peak-to-peak and signal-to-noise (S/N) ratio of 10,000:1 with a single scan against the KBr disc (reference spectrum).

The aqueous solutions of individually extracted acrylamide samples were filtered through 0.22 μm syringe filter and 20 μL each separately was injected through the sample port using auto-sampler of HPLC (LCMS-2020 with prominence front-end system, Shimadzu, Japan) with C18-AQ, (2 × 250 mm) column. HPLC grade (Himedia, Mumbai, India) water was used as mobile phase at 1 mL/min flow rate and the column temperature was 30 °C. The acrylamide detection was done at 206 nm with a UV detector and quantified by establishing linearity with various concentrations of standard acrylamide (Sigma-Aldrich, St. Louis, MO, USA). Quantification of acrylamide in various samples was performed on the basis of peak area measurements of standards run under the same conditions.

Inhibition of Human Salivary Amylase by TAAI, WSAI, and Acarbose

Inhibitory potential of WSAI, TAAI, and acarbose against human salivary amylase was studied at varying concentrations (25 to 400 ppm). Human salivary amylase activity was assayed as per by Kasar et al. (2017). One unit of 훼-amylase was defined as the amount of enzyme required to release 1 μM of reducing sugar (calculated as maltose) from substrate starch per minute at 37 °C under given assay conditions. Inhibitory activity was expressed as the percent inhibition of human salivary amylase activity.

Statistical Analysis

Data from sugar analysis and browning, residual 훼-amylase, polyphenol oxidase enzyme, and acrylamide detection assays, were subjected to statistical analysis by one-way ANOVA followed by Tukey’s post hoc test. For acceptable results, the P value was considered to be greater than the 훼-value (level of significance 0.05, i.e., P < 0.05).

Results and Discussion

Exposure with α-Amylase Inhibitors Reduces Browning of Potato Slices

The α-amylase inhibitor (WSAI) was isolated and purified from an indigenous medicinal plant W. somnifera and partially characterized (Kasar et al. 2017). Browning of potato is due to generation of colored compounds such as melanoidins (Namiki 1988). Among the three different concentrations of WSAI, TAAI, and acarbose used for treating potato slices, 200 ppm was found to be the best in anti-browning action (Fig. 1). Treatment for 30 min showed substantial reduction in the formation of brown pigments as compared to control samples. The treatment resulted in 62.02, 63.11, and 61.2% reduction in browning with WSAI, TAAI, and acarbose, respectively, at 200-ppm concentration (Fig. 1). Increased higher generation of browning pigments, i.e., melanoidins, was observed with the increased levels of glucose resulting from degradation of starch during storage and the processing of potato chips (Yu et al. 2017). Indigenous α-amylase activity in potatoes may be responsible for increased concentration of glucose in them.

Residual amylase activity of treated potato samples was found to be reduced by 51, 44, and 62% by WSAI, TAAI, and acarbose, respectively, over untreated samples (192.59 μmol of maltose released/min taken as 100%) (Fig. 2a). Earlier, overexpression of amylase inhibitor protein from Solanum berthaultii (SbAI) successfully inhibited α and β amylases in potato which resulted in the reduction in cold-induced sweetening. A dose-dependent inhibition of α and β amylases extracted from potato by SbAI was also noted in vitro (Zhang et al. 2014).

Determination of α-amylase and polyphenol oxidase activities in potato slices treated with WSAI, TAAI, and acarbose at 200-ppm concentration for 30 min. a Residual α-amylase activity. b Residual polyphenol oxidase activity. One-way ANOVA was performed followed by Tukey’s post hoc test. Statistical data is significant at P value < 0.005

Treatment with Amylase Inhibitors Alters Polyphenol Oxidase Activity

PPO activity in potato slices was reduced by 40, 55, and 35% when treated with 200 ppm WSAI, TAAI, and acarbose, respectively (Fig. 2b). Citric acid—a known inhibitor of PPO—is used as anti-browning chemical during potato processing as it has chelating and acidulant properties which block functioning of the active site (Lee et al. 1991). Gunes and Lee (1997) observed that a solution mix of 0.5% l-cysteine and 2% citric acid causes significant inhibition of PPO-induced browning of packaged potato food products. Similarly, utilization of 4-hexylresorcinol with iso-ascorbic acid has been described previously for anti-browning of apple and banana slices (Moline et al. 1999; İyidoǧan and Bayındırlı 2004).

Alterations in Sugar Levels in Potato Slices after Treatment with Amylase Inhibitors

The level of reducing sugars in potato slices was found to be lowered as a function of treatment with AIs which explains the correlation between browning intensity and reducing sugars. Untreated potato slices showed the highest content of reducing sugars (709.33 μg/g) while the levels in potato slices treated with WSAI, TAAI, and acarbose were 583.67 μg/g, 536.33 μg/g, and 646.33 μg/g, respectively (Fig. 3). These findings indicate interaction of AIs with indigenous potato amylase(s) and modulation/regulation of reducing sugar generation. Such trait is desirable as far as potato processing is concerned. Amount of reducing sugars (glucose and fructose) decides suitability of raw potatoes in food product processing as it is a determinant factor in browning reactions (Rodriguez-saona et al. 1997, Yu et al. 2017). As per Biedermann et al. (2002), fructose is more responsible than glucose for acrylamide generation, whereas Yu et al. (2017) suggested that glucose has main role in browning, due to the Maillard reaction, as compared to fructose. Potato cultivars ATX 854 and NDTX 4930 with low reducing sugar contents were observed to produce low amount of acrylamide during the preparation of potato chips (Granda et al. 2004). Zhang et al. (2014) demonstrated less generation of reducing sugars in potato lines which are transformed with AI gene from S. berthaultii (SbAI) indicating the potential role of proteinaceous amylase inhibitors in in situ reduction of sugar generation. Similarly, a glycoprotein α-AI from Colocasia sp. could inhibit the activity of human salivary and potato α-amylases. Potato slices treated with this α-AI showed a decrease in free reducing sugars and browning during processing (Kumari et al. 2012). This study supports our findings related to the role of amylase inhibitors in decreasing the generation of reducing sugars.

Amylase Inhibitors Modulate Whiteness, Brightness, and Yellowness Indices of Potato Slices

Browning of potato slices is not desirable as it affects their sensory properties. It is also associated with consumers’ perception of quality and acceptability (Pedreschi et al. 2006). Color match spectrophotometer measured the color effect in the form of L*, a*, and b* values which correspond to whiteness, brightness, and yellowness indices. Potato slices treated with WSAI, TAAI, and acarbose for 30 min showed significant reduction in brown color (Fig. 4). Of the three AIs tested, WSAI treatment showed increase in whiteness and brightness indices (− 7.68 to 21.70 and 21.49 to 26.02, respectively) and maximum reduction in yellowness index, from 47.06 to 12.55, in potato slices. TAAI, on the other hand, was observed to have better effect on whiteness (− 7.68 to 20.08) and brightness indices (21.49 to 26.47) compared to control, while yellowness index decreased from 47.06 to 17.10. A similar trend with acarbose treatment was recorded. Increase in L* value is an indicator of reduction in darker shade of the slices. It was found to be increased after treatment with WSAI (59.88 to 61.01) and TAAI (59.88 to 62.58) as compared to untreated samples. According to Granda et al. (2004), L* value explains lightness, which is zero for dark shade and 100 for lighter shade. Whiteness index (WI) indicates whiteness of food products during food processing (Hsu et al. 2003) and superior WI was found to improve consumer acceptability towards slices of cabbage treated with 0.1% sodium metabisulphite (Ibrahim et al. 2004). The color of SbAI-transformed potato chip was perceived to be lighter as compared to the respective control (Zhang et al. 2014).

Amylase Inhibitors Protect the Quality and Nutritive Value of Potato Chips as Compared to Blanching

Presently, blanching treatment (Heating at 80 °C for 15 min in water) to fresh potato slices is routinely employed to minimize browning in commercial processes. However, it causes adverse effects on the quality and nutritional value of the chips. The treatment with AIs was found to be relatively better in preserving both quality and nutritive value of the chips as compared to blanching. The nutritive value of treated slices was determined by estimating the total carbohydrates, proteins, and dry weight (Table 1). The total carbohydrate content in slices treated with WSAI was 10% higher than in blanching-treated samples. It was found to be still higher in TAAI- and acarbose-treated samples. Similarly, the protein content of slices treated with AIs was higher than that of blanched slices (1.88 mg/g). The dry weight of the chips was observed to be 115, 114.0, 106, and 64 mg/g of fresh weight for the slices treated with WSAI, TAAI, acarbose, and blanching, respectively. According to the national nutrient database of USDA, boiling (blanching) treatment to the potatoes leads to 5% loss of minerals and 35% loss of proteins (Montville et al. 2013). Other researchers also observed that cooking processes such as boiling affect nutritional value of potatoes (Tian et al. 2016). McGill et al. (2013) reported a decrease in potassium (from 550 to 379 mg), phosphorous (from 71 to 44 mg), and magnesium (from 30 to 22 mg) in potatoes upon boiling. Our results suggest that treating potato slices with α-AIs and particularly, WSAI, is beneficial over blanching treatment as far as overall quality and nutritional value of the chips are concerned.

Effect of Amylase Inhibitors Treatment on Acrylamide Generation in Fried Potato Chips

Qualitative detection of acrylamide in treated potato chips was done by FTIR analysis. It revealed the presence of functional groups specific to acrylamides (Table 2) in the range of 1201–1699 cm−1 for MIR (Ayvaz and Rodriguez-Saona 2015). Acrylamide-specific functional group stretching/bending observed in the present study was matching to those of earlier report on IR analysis of acrylamide (Dejong 1993). Quantitative determination of generated acrylamide during frying in treated and untreated potato chips was done by HPLC analysis (Table 1). Of the AIs studied, acrylamide content was found to be the least in WSAI-treated samples followed by TAAI, blanching, and acarbose treatments. Its level in WSAI-treated samples was almost 50% less than in air (2.61 ± 0.4 μg/mL) and buffer controls (2.31 ± 0.25 μg/mL). This data corroborates well with the level of reducing sugars recorded in respective samples (Fig. 3). A decrease in acrylamide concentration by 35 to 40% in the model system, 89% in cookies, 51% in fried, and 62% in baked tortilla chips was observed when treated with proteins isolated from seeds of Amaranthus hypochondriacus (Salazar et al. 2012). Acrylamide generation was also found to be reduced when potato slices were treated with asparaginase and vanadyl sulfate before frying (Pedreschi et al. 2011; Kalita and Jayanty 2013). Granda et al. (2004) reported that vacuum frying reduces the acrylamide generation (85 to 99%) as compared to traditionally fried potato chips. Similarly, lowering the frying oil temperature from 190 to 150 °C was also found to be responsible for significant reduction in acrylamide content (Pedreschi et al. 2004).

Differential Interactions of Amylase Inhibitors with Human Salivary Amylase

A dose-dependent decrease in human salivary amylase activity was noted when treated with TAAI and acarbose, and almost 50 and 60% inhibition was recorded at their 400-ppm concentration, respectively. On the other hand, WSAI did not inhibit human salivary amylase activity (Fig. 5). Amylase inhibitor isolated from white bean was found to inhibit almost 95% human salivary amylase activity (Layer et al. 1985). One of the desirable features in AIs used in food processing industry for quality improvement is their indifference towards human salivary amylase. In the present study, only WSAI showed no inhibition of human salivary amylase even at substantially high concentration.

Conclusion

Browning of potato food products due to polyphenol oxidase activity and reducing sugar content is a common problem in food processing industry. In the present study, treatment of potato slices with a laboratory isolated, purified, and characterized α-AI from an indigenous medicinal plant, W. somnifera (WSAI), for 30 min showed significant reduction in browning, residual amylase and polyphenol oxidase activities, level of reducing sugars, and improvement in whiteness and brightness indices over untreated samples. The treatment was also found to be superior to the traditional blanching treatment in preserving overall quality and nutritional indices of potato slices. The acrylamide content, post frying, was found to be marginally less and dry weight was almost 100% more in WSAI-treated over blanched-treated potato chips. All the results of WSAI treatment were comparable with that of commercially obtained TAAI and better than synthetic α-AI and acarbose. Thus, WSAI treatment to potato slices before processing offers a heathier (better nutritional value), greener (less energy consuming), and economical (significant improvement in dry weight post frying) alternative method without compromising the overall sensory quality of the finished product. In our opinion, this is the first report on utilization of plant-derived proteinaceous AIs for the improvement of nutritional and sensory qualities of potato chips during processing.

References

Amrein, T. M., Bachmann, S., Noti, A., Biedermann, M., Barbosa, M. F., Biedermann-Brem, S., & Amadó, R. (2003). Potential of acrylamide formation, sugars, and free asparagine in potatoes: a comparison of cultivars and farming systems. Journal of Agricultural and Food Chemistry, 51(18), 5556–5560. https://doi.org/10.1021/jf034344v.

Ayvaz, H., & Rodriguez-Saona, L. E. (2015). Application of handheld and portable spectrometers for screening acrylamide content in commercial potato chips. Food Chemistry, 174, 154–162. https://doi.org/10.1016/j.foodchem.2014.11.001.

Biedermann, M., Biedermann-Brem, S., Noti, A., Grob, K., Egli, P., & Mändli, H. (2002). Two GC-MS methods for the analysis of acrylamide in foodstuffs. Mitteilungen aus Lebensmitteluntersuchung und Hygiene, 93(6), 638–652.

Biedermann-Brem, S., Noti, A., Grob, K., Imhof, D., Bazzocco, D., & Pfefferle, A. (2003). How much reducing sugar may potatoes contain to avoid excessive acrylamide formation during roasting and baking? European Food Research and Technology, 217(5), 369–373. https://doi.org/10.1007/s00217-003-0779-z.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72(1–2), 248–254. https://doi.org/10.1016/0003-2697(76)90527-3.

Dejong, S. (1993). PLS fits closer than PCR. Journal of Chemometrics, 7(6), 551–557. https://doi.org/10.1002/cem.1180070608.

DuBois, M., Gilles, K. A., Hamilton, J. K., Rebers, P. T., & Smith, F. (1956). Colorimetric method for determination of sugars and related substances. Analytical Chemistry, 28(3), 350–356. https://doi.org/10.1021/ac60111a017.

Granato, D., & Masson, M. L. (2010). Instrumental color and sensory acceptance of soy-based emulsions: a response surface approach. Food Science and Technology (Campinas), 30(4), 1090–1096. https://doi.org/10.1590/S0101-20612010000400039.

Granda, C., Moreira, R. G., & Tichy, S. E. (2004). Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. Journal of Food Science, 69(8), E405–E411. https://doi.org/10.1111/j.1365-2621.2004.tb09903.x.

Gunes, G., & Lee, C. Y. (1997). Color of minimally processed potatoes as affected by modified atmosphere packaging and anti-browning agents. Journal of Food Science, 62(3), 572–575. https://doi.org/10.1111/j.1365-2621.1997.tb04433.x.

Hsu, C. L., Chen, W., Weng, Y. M., & Tseng, C. Y. (2003). Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chemistry, 83(1), 85–92. https://doi.org/10.1016/S0308-8146(03)00053-0.

Ibrahim, R., Osman, A., Saari, N., & Rahman, R. A. (2004). Effects of anti-browning treatments on the storage quality of minimally processed shredded cabbage. Journal of Food Agriculture and Environment, 2, 54–58.

İyidoǧan, N. F., & Bayındırlı, A. (2004). Effect of L-cysteine, kojic acid and 4-hexylresorcinol combination on inhibition of enzymatic browning in Amasya apple juice. Journal of Food Engineering, 62(3), 299–304. https://doi.org/10.1016/S0260-8774(03)00243.

Kalita, D., & Jayanty, S. S. (2013). Reduction of acrylamide formation by vanadium salt in potato French fries and chips. Food Chemistry, 138(1), 644–649. https://doi.org/10.1016/j.foodchem.2012.09.123.

Kasar, S. S., Marathe, K. R., Bhide, A. J., Herwade, A. P., Giri, A. P., Maheshwari, V. L., & Pawar, P. K. (2017). A glycoprotein α-amylase inhibitor from Withania somnifera differentially inhibits various α-amylases and affects the growth and development of Tribolium castaneum. Pest Management Science, 73(7), 1382–1390. https://doi.org/10.1002/ps.4467.

Kaur, C., & Kapoor, H. C. (2000). Inhibition of enzymatic browning in apples, potatoes and mushrooms. Journal of Scientific and Industrial Research, 59(5), 389–394.

Khoshnam, F., Zargar, B., Pourreza, N., & Parham, H. (2010). Acetone extraction and HPLC determination of acrylamide in potato chips. Journal of the Iranian Chemical Society, 7(4), 853–858. 2011330182042265.

Kumari, B., Sharma, P., & Nath, A. K. (2012). α-Amylase inhibitor in local Himalyan collections of Colocasia: isolation, purification, characterization and selectivity towards α-amylases from various sources. Pesticide Biochemistry and Physiology, 103(1), 49–55. https://doi.org/10.1016/j.pestbp.2012.03.003.

Layer, P., Carlson, G. L., & Dimagno, E. P. (1985). Partially purified white bean amylase inhibitor reduces starch digestion in vitro and inactivates intraduodenal amylase in humans. Gastroenterology, 88(6), 1895–1902. https://doi.org/10.1016/0016-5085(85)90016-2.

Lee, P. M., Lee, K. H., Ismail, M., & Karim, A. (1991). Biochemical studies of cocoa bean polyphenol oxidase. Journal of the Science of Food and Agriculture, 55(2), 251–260. https://doi.org/10.1002/jsfa.2740550210.

Liu, X., Cheng, S., Liu, J., Ou, Y., Song, B., Zhang, C., & Xie, C. (2013). The potato protease inhibitor gene, St-Inh, plays roles in the cold-induced sweetening of potato tubers by modulating invertase activity. Postharvest Biology and Technology, 86, 265–271. https://doi.org/10.1016/j.postharvbio.2013.07.001.

Ma, Y., Wang, Q., Hong, G., & Cantwell, M. (2010). Reassessment of treatments to retard browning of fresh-cut russet potato with emphasis on controlled atmospheres and low concentrations of bisulphite. International Journal of Food Science & Technology, 45(7), 1486–1494. https://doi.org/10.1111/j.1365-2621.2010.02294.x.

Marshall, M. R., Kim, J., & Wei, C. (2000). Enzymatic browning in fruits, vegetables and sea foods. Food and Agricultural Organization, 41, 259–312.

McGill, C. R., Kurilich, A. C., & Davignon, J. (2013). The role of potatoes and potato components in cardiometabolic health: a review. Annals of Medicine, 45(7), 467–473. https://doi.org/10.3109/07853890.2013.813633.

Miller, G. L. (1972). Use of DNSA reagent for determination of reducing and non-reducing sugar. Analytical Chemistry, 31, 426–428.

Moline, H. E., Buta, J. G., & Newman, I. M. (1999). Prevention of browning of banana slices using natural products and their derivatives. Journal of Food Quality, 22(5), 499–511. https://doi.org/10.1111/j.1745-4557.1999.tb00181.x.

Montville, J. B., Ahuja, J. K., Martin, C. L., Heendeniya, K. Y., Omolewa-Tomobi, G., Steinfeldt, L. C., & Moshfegh, A. (2013). USDA food and nutrient database for dietary studies (FNDDS), 5.0. Procedia Food Science, 2, 99–112. https://doi.org/10.1016/j.profoo.2013.04.016.

Namiki, M. (1988). Chemistry of Maillard reactions: recent studies on the browning reaction mechanism and the development of antioxidants and mutagens. Advances in Food Research, 32, 115–184. https://doi.org/10.1016/S0065-2628(08)60287-6.

Pedreschi, F., Kaack, K., & Granby, K. (2004). Reduction of acrylamide formation in potato slices during frying. LWT-Food Science and Technology, 37(6), 679–685. https://doi.org/10.1016/j.lwt.2004.03.001.

Pedreschi, F., Leon, J., Mery, D., & Moyano, P. (2006). Development of a computer vision system to measure the color of potato chips. Food Research International, 39(10), 1092–1098. https://doi.org/10.1016/j.foodres.2006.03.009.

Pedreschi, F., Mariotti, S., Granby, K., & Risum, J. (2011). Acrylamide reduction in potato chips by using commercial asparaginase in combination with conventional blanching. LWT-food Science and Technology, 44(6), 1473–1476. https://doi.org/10.1016/j.lwt.2011.02.004.

Rocculi, P., Galindo, F. G., Mendoza, F., Wadsö, L., Romani, S., Dalla Rosa, M., & Sjöholm, I. (2007). Effects of the application of anti-browning substances on the metabolic activity and sugar composition of fresh-cut potatoes. Postharvest Biology and Technology, 43(1), 151–157. https://doi.org/10.1016/j.postharvbio.2006.08.002.

Rodriguez-saona, L. E., Wrolstad, R. E., & Pereira, C. (1997). Modelling the contribution of sugars, ascorbic acid, chlorogenic acid and amino acids to non-enzymatic Browning of potato chips. Journal of Food Science, 62(5), 1001–1010. https://doi.org/10.1111/j.1365-2621.1997.tb15024.x.

Salazar, R., Arámbula-Villa, G., Vázquez-Landaverde, P. A., Hidalgo, F. J., & Zamora, R. (2012). Mitigating effect of amaranth (Amarantus hypochondriacus) protein on acrylamide formation in foods. Food Chemistry, 135(4), 2293–2298. https://doi.org/10.1016/j.foodchem.2012.06.089.

Severini, C., Baiano, A., De Pilli, T., Romaniello, R., & Derossi, A. (2003). Prevention of enzymatic browning in sliced potatoes by blanching in boiling saline solutions. LWT-Food Science and Technology, 36(7), 657–665. https://doi.org/10.1016/S0023-6438(03)00085-9.

Tian, Y., Zhao, Y., Huang, J., Zeng, H., & Zheng, B. (2016). Effects of different drying methods on the product quality and volatile compounds of whole shiitake mushrooms. Food Chemistry, 197(Pt A), 714–722. https://doi.org/10.1016/j.foodchem.2015.11.029.

Whitfield, F. B., & Mottram, D. S. (1992). Volatiles from interactions of Maillard reactions and lipids. Critical Reviews in Food Science & Nutrition, 31(1–2), 1–58. https://doi.org/10.1080/10408399209527560.

World Health Organisation Staff, World Health Organization. Food Safety Programme, FAO., World Health Organization, WHO, & Food Safety Programme. (2002). Health implications of acrylamide in food: report of a joint FAO/WHO consultation, WHO headquarters, Geneva, Switzerland, 25–27 June 2002. World Health Organization.

Yu, H., Seow, Y. X., Ong, P. K., & Zhou, W. (2017). Effects of high-intensity ultrasound on Maillard reaction in a model system of d-xylose and l-lysine. Ultrasonics Sonochemistry, 34, 154–163. https://doi.org/10.1016/j.ultsonch.2016.05.034.

Zhang, H., Liu, J., Hou, J., Yao, Y., Lin, Y., Ou, Y., & Xie, C. (2014). The potato amylase inhibitor gene SbAI regulates cold-induced sweetening in potato tubers by modulating amylase activity. Plant Biotechnology Journal, 12(7), 984–993. https://doi.org/10.1111/pbi.12221.

Funding

One of the authors (SSK) acknowledges the fellowship awarded by the Department of Science and Technology, New Delhi, under its DST-INSPIRE (Innovation in Science Pursuit for Inspired Research) Fellowship program. Financial support from the RGSTC, Mumbai ((RGSTC/File 2018/DPP-184/CR-23) to VLM,APG and PKP and UGC-BSR Mid-Career Grant (F.1 9-205/201 7(BSR)) to VLM are gratefully acknowledged. Financial support from the UGC and Department of Sciences and Technology, New Delhi, for strengthening the research facilities in the School of Life Sciences, KBCNMU, Jalgaon, under SAP–DRS (F.4-23/2015/DRS-II [SAPII]) and FIST (SR/FST/LSI-433/2010) programs, respectively, are also gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Conceived and designed the experiments: VLM, PKP, and APG

Experimental work: SSK

Data analysis and preparation of the manuscript: SSK, VLM, PKP, and APG

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kasar, S.S., Giri, A.P., Pawar, P.K. et al. A Protein α-Amylase Inhibitor from Withania Somnifera and its Role in Overall Quality and Nutritional Value Improvement of Potato Chips during Processing. Food Bioprocess Technol 12, 636–644 (2019). https://doi.org/10.1007/s11947-019-2233-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-2233-7