Abstract

The saltiness enhancer effect of hydrolyzed animal protein (HAP) and the quality characteristics of white pan bread were evaluated through physicochemical and sensory analyses. HAP was efficiently hydrolyzed using commercial enzymes (0.20% w/w Alcalase® 2.4 L FG and 1.00% w/w FlavourzymeTM 500 MG) under high pressurization (100 MPa) and confirmed by molecular weight distribution and amino acid composition analysis. Most HAP molecules (94.18%) comprised low molecular weight peptides < 1300 Da, or free amino acids. Amino acid composition analysis of HAP also detected highly increased glutamic acid concentration. Compared with the control, the fermentation rates of doughs and loaf volumes of breads were maintained over 89.27% and 100%, respectively, with an exception of samples containing 11.70 HAP. In sensory testing, HAP concentration increases led to concomitant saltiness increases. These results suggest promising technological options for reducing salt intake from white pan bread consumption by utilizing HAP, although further study is necessary to improve bread quality.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sodium chloride (NaCl) is an important ingredient in processed foods for the purpose of taste enhancement, inactivation of pathogenic bacteria, extension of shelf-life, and quality improvement (Doyle and Glass 2010). However, even though the physiological requirement for sodium is 10–20 mmol per day for adults, most people consume more than 100 mmol per day with Asians ingesting over 200 mmol per day (Brown et al. 2009). In European and North American countries, as much as 75% of salt intake is accounted for through sodium-seasoned restaurant-prepared or manufactured foods, with the remaining fraction of intake resulting from the sodium content of homemade foods (Brown et al. 2009). Conversely, in China, 72% of salt intake arises from home cooking with the contribution of soy sauce, miso, fermented food, and fish to dietary sodium (Brown et al. 2009). Although sodium chloride represents an essential nutrient in the body, high intake of sodium is associated with elevated blood pressure that can lead to cardiovascular disease and potential health hazards (Doyle and Glass 2010; Jimenez-Maroto et al. 2013). Accordingly, the World Health Organization recommends less than 5 g of daily salt intake for adults and requires a general reduction of salt intake level (WHO 2007). Thus, sodium reduction has been considered to be increasingly important for food products (Doyle and Glass 2010).

Multiple strategies for salt reduction have been investigated to date. First, a slight stepwise reduction (5–10%) of salt in bread has been instituted that can maintain consumer acceptance (Bolhuis et al. 2011). However, slight stepwise reductions require considerable time to significantly reduce the amount of salt and some consumers never accept cumulative salt reductions. Second, the substitution of NaCl with other inorganic salts has been attempted (Emorine et al. 2013), which can also confer a salty taste to food. The most common substitutes comprise potassium chloride (KCl), calcium chloride, magnesium sulfate, and ammonium chloride (Heidolph et al. 2011). For example, Gelabert et al. (2003) reported the replacement of NaCl with KCl, potassium-lactate, and an amino acid (i.e., glycine) in fermented sausages. They demonstrated that the mixtures of KCl-glycine and potassium-lactate-glycine exhibited multiple effects on flavor (saltiness, bitterness, and sweetness) and texture properties. Conversely, the substitution of NaCl with other inorganic salts has also been found to generate undesirable off-tastes in breads or meats (Desmond 2006; Zanardi et al. 2010). Hence, this strategy for salt intake reduction is limited. As a third strategy, Jimenez-Maroto et al. (2013) reported that natural flavor enhancer derived from soy sauce had an effect on reducing the amounts of sodium chloride required for palatability by producing umami-imparting substances in bread. The umami taste derived from ingredients of the salt enhancer increased the saltiness without a direct increase of sodium content (Brandsma 2006). One of most frequent amino acids added as a flavor enhancer is monosodium glutamate, of which only a small volume is capable of reducing the amount of required salt (Jinap and Hajeb 2010). However, the addition of monosodium glutamate to foodstuffs may not be preferable for consumers who have concerns regarding its safety (Pietrasik and Gaudette 2014). Alternatively, as a natural flavor enhancer, fish protein hydrolysates have also been demonstrated to increase salty taste (Shimono and Sugiyama 2015); in particular, arginyl dipeptides in fermented fish sauces were identified as salt taste enhancers by means of a sensomics approach (Schindler et al. 2011). In common food process, hydrolyzed vegetable protein has been usually used as a saltiness enhancer (Kaewka et al. 2009; Khetra et al. 2019). However, the studies of hydrolyzed animal protein (HAP) is insufficient to apply to the food industry.

In recent years, the Korean economy has grown quickly and dietary traditions have changed toward fast food and instant food, as influenced by Western culture (Lee et al. 2002). And, a high consumption of bread in Korea has been one of major reasons to cause this pattern. Sodium chloride constitutes an important ingredient in white pan bread, improving bread flavor and sensory properties, and strengthening the gluten and dough structure (Lynch et al. 2009). It also controls yeast growth and activity, resulting in an increase in bread fermentation rate (Lynch et al. 2009) and reducing spoilage to extend its shelf-life (Samapundo et al. 2010).

Therefore, the current study focused on the reduction of salt intake from bread while maintaining salty taste intensity through the use of anchovy protein hydrolysates. Specifically, the aims of this study were (1) to characterize HAP (anchovy) and (2) to evaluate its effect on the physical and sensory properties of white pan bread. To the best of our knowledge, no prior reports have demonstrated the usage of HAP as a salt enhancer for baking white pan bread.

Materials and Methods

Materials

Anchovy (Engraulis japonicus), caught in the coastal waters around Jeju Island in early March, was used in this study. Commercial enzymes used for protein hydrolysis consisted of Alcalase® 2.4 L FG (EC 3.4.21.62, endoenzyme; Novozymes, Bagsvaerd, Denmark) and FlavourzymeTM 500 MG (EC 3.4.11.1, endoenzyme and exoenzyme; Novozymes). The ingredients used for the preparation of the white pan bread samples were wheat-flour (Beksul; CJ Cheiljedang, Seoul, Korea), yeast (Saf-instant® dry yeast; Societe Industrielle Lesaffre, Marcq-en-Baroeul, France), salt (Jeung-island solar salt; Shinan, Korea), sugar (Beksul; CJ Cheiljedang, Seoul, Korea), skim milk powder (Maeil, Seoul, Korea), shortening (Ottogi; Anyang, Korea), and water (Samdasoo; Jeju, Korea).

Hydrolysis of Animal Protein

Alcalase® 2.4 L FG (endo-protease, 2.40 AU/g) and FlavourzymeTM 500 MG (endo-/exo-protease, 500 LAUP/g) have been used in the multiple industrial processes of protein hydrolysis, respectively (Nilsang et al. 2005). In particular, previous studies have suggested using both endo- and exo-proteases to avoid the bitterness associated with the incorporation of fish hydrolysate (Nilsang et al. 2005; Raksakulthai and Haard 2003; FitzGerald and O’Cuinn 2006). Kristinsson and Rasco (2000) reported that alcalase, which was three times higher than the fish proteases on gram basis, was the most efficient enzyme at cost. And, Zhang et al. (2017) also demonstrated that Flavourzyme was dominant in food protein hydrolysis and had the highest antioxidant capacity among the canola protein hydrolysates samples. Accordingly, a hydrolysis condition using the two enzymes under high pressure was optimized for anchovy by In et al. (2016); the same condition was used in the current study with minor modification.

Anchovy in distilled H2O (1:2) was mixed in an HMF-3100S blender (Hanil, Seoul, Korea) for 2 min three times consecutively and homogenized using a T25 homogenizer (IKA, Staufen, Germany) at 16,000 rpm for 5 min three times consecutively. Then, homogenized anchovy mixture was mixed with a combination of two commercial enzymes (2% (w/w), 0.20% w/w Alcalase® 2.4 L FG and 1.00% w/w FlavourzymeTM 500 MG) in polyethylene film bag. The bag was completely sealed and placed in a TFS-20 high-pressure extractor (Dima Puretech, Inchon, Korea).

The hydrolysis process was then performed at 100 MPa and 50 °C for 24 h. After the hydrolysis, the freezing tubes were placed in a chiller (Micon Control System-FC-B53 HMS; LG, Seoul, Korea) to stop the hydrolysis reaction.

Freeze Drying

HAP was immediately frozen at − 80 °C for 12 h in NF-400SF freezer (Nihon Freezer, Tokyo, Japan). Then, sample was freeze-dried for 4 days using a freeze drier (FD-8518; Ilshinbiobase, Yangju, Korea).

Sodium Analysis

Total sodium (Na) in HAP was analyzed using Dionex ICS-900 ion chromatography (Thermo Scientific, Waltham, MA, USA). Each sample was diluted 106-fold and filtered through a Millipore filter membrane of pore size 0.20 μm prior to analysis. The mobile phase was 40 mM KOH. Analysis was performed in a condition of 1 mL min−1 flow rate by isocratic elution and 1200–1400 psi of pressure.

Total Nitrogen

Total nitrogen (htot) in HAP was analyzed by micro-Kjeldahl methods (AOAC) using a TitroMatic auto Kjeldahl system (Crison, Hach Lange, Spain).

Molecular Weight Analysis

The molecular weight of HAP was analyzed using ÄKTAprime Plus gel permeation chromatography (GPC; GE Healthcare Life Sciences, Pittsburgh, PA, USA). Samples were dispersed in water with a concentration of 18 mg/mL and then 1 mL of each sample was run and separated through a GPC column (YMC Pack, Kyoto, Japan; Diol-60, 300 mm × 20 mm I.D., S-5 μm, 6 nm) at 5 mL min−1 flow rate with 1% acetic acid as a mobile phase. Samples were detected using a UV detector (Zn Optic, GE Healthcare, Uppsala, Sweden) at 246 nm. Vitamin B12 (MW 1355.37 Da; Sigma, St. Louis, MO, USA), Vitamin B1 (MW 337.27 Da; Yakuri Pure Chemicals, Osaka, Japan), and L-glutamic acid (MW 147.13 Da; Samchun Pure Chemicals, Peongtack, Korea) were used as standards.

Amino Acid Composition

The amino acid composition of HAP was analyzed using both combined and free amino acid analysis. For the combined amino acid analysis, each sample was pretreated by dispersing an aliquot of freeze-dried HAP in 30 mL of 6 N HCl, followed by hydrolysis at 130 °C for 24 h. For both amino acid analyses, the sample was diluted with distilled water, filtered using a DISMIC-13CP 0.45-μm syringe filter (Advantec, Saijo, Japan), and the filtered sample was analyzed using HPLC (Ultimate 3000, Thermo Dionex, Sunnyvale, CA, USA). Samples were separated on an Inno C18 column (4.6 mm × 150 mm, 5 μm; Young Jin Biochrom, Seongnam, Korea) and detected using a fluorescence detector. As a mobile phase, 10 mM Na2HPO4 and 10 mM Na2B4O7·10H2O (pH 8.2) were used for combined amino acid analysis, whereas 20 mM sodium phosphate buffer (pH 7.8) and 45% (v/v) acetonitrile/45% (v/v) methanol solution were used for the free amino acid analysis. Samples reacted with o-phthalaldehyde were detected using a fluorescence detector (450-nm emission and 305-nm excitation) and samples were reacted with 9-fluorenylmethyl chloroformate.

Baking of White Pan Bread

White pan bread was baked using a modified method based on AACC method 10-10b (1990); the concentrations of ingredients are shown in Table 1. Ingredients including flour, sugar, yeast, water, skim milk powder, salt, and HAP were premixed at 200 rpm (1 min) and mixed at 400 rpm (2 min) using a 5K5SS electric dough maker (KitchenAid, Benton Harbor, MI, USA). Then, after shortening added, the dough was premixed at 300 rpm (3 min) and mixed at 400 rpm (7 min).

After completion of the dough mixing, the dough was placed in an incubator at 40 °C for 60 min. After the primary fermentation, the dough was re-mixed, degassed, and left to stand for 15 min. The dough, molded to fit the bakeware, was then fermented in an incubator at 40 °C for 50 min. After the second fermentation, the dough was baked using an M4207 baker (Simfer, Istanbul, Turkey) at 180 °C for 20 min.

Measurement of the Fermentation Rate of Dough and Loaf-Specific Volume of the White Pan Bread

The dough (2 g) was transferred in the 25-mL beaker and the top was flattened. Then, the heights of doughs before and after the primary fermentation for 60 min were measured, and the fermentation rate (%) was calculated using two measurements. For measuring loaf-specific volume of the white pan bread, the volume (cm3) of the bread was calculated by multiplying the width, length, and height. Volume (cm3) of the bread divided by the weight (g) of dough was used as loaf-specific volume (cm3/g).

pH Measurement of Bread

Dough or white pan bread and distilled water (1:9) were mixed using a homogenizer (PH91; SMT, Tokyo, Japan) for 40 s to measure pH of the bread. pH changes were then measured using a pH meter (Thermo Scientific). Each sample was measured in triplicate and expressed as the mean ± standard deviation.

Texture Properties

The texture properties measured included the hardness, cohesiveness, springiness, gumminess, and chewiness of dough, as well as the hardness and adhesiveness of white pan bread. Dough after a second fermentation was formed in the shape of a sphere with 1-cm radius. To evaluate the effects of various proportions of HAP and salt on the texture properties, texture profile analysis of the dough after a second fermentation was carried out using a CT3-1000 texture analyzer (Brookfield Engineering Laboratories, Stoughton, MA, USA) with a TA18 probe and TA-RT-KI fixture. The selected settings were as follows: 50 g trigger load; 2.5 mm/s test speed; and 50% deformation. In addition, white pan bread was molded to 4 × 1 × 1 cm (width × length × height) using the texture analyzer, TA3/100 probe, and TA-SBA fixture. The selected settings were 70 g trigger load and 2.5-mm/s test speed at compression type. All samples were measured in triplicate.

Sensory Test

Sensory testing was conducted to confirm the effect of salty taste enhancement and the quality of white pan bread supplemented with various amounts of HAP (Kramer et al. 1974; Lee et al. 2016a). A total of 30 students excluding smokers and heavy drinkers were selected and trained for the sensory test. Of these, 10 students were designated as alternates in the case that some panelists were unavailable for testing. A panel of twenty students was used to provide the descriptive analysis of white pan bread. For testing, samples were evenly prepared to 3 × 3 × 1 cm (width × length × height) and included crust and crumb. All the samples were presented to the panelists at once, and the panelists were instructed to taste the samples from left to right. Warm water was served for the panelists to rinse out their mouths in between tasting. A 5-point scale (score test) was used for all the attributes in this study, with the lowest scoring level expressed as 1 and the highest level as 5 (Lee et al. 2016a). Sensory attributes such as saltiness, sweetness, sourness, preference of saltiness, and overall taste were assessed, and the quality attributes of white pan bread such as crust color, crumb color, flavor, uniformity of pores, and moisture were determined. All attributes were scored in terms of intensity and high score meant high intensity.

Statistical Analysis

All the data were analyzed by ANOVA using the SPSS 22.0 statistical program (SPCC Inc., Chicago, IL, USA). Differences among the means were compared using Duncan’s multiple range test (p < 0.05). All measurements were performed on at least three sample preparations and expressed as the means ± standard deviations. Principal component analysis (PCA) was performed using XLSTAT ver. 2016. 02. 28540. (Addinsoft, New York, NY, USA).

Results and Discussion

Chemical properties and GPC Molecular Weight of HAP

HAP was completely dissolved in deionized H2O. The mass of Na, nitrogen, and protein per 100 g of HAP powder were 17.86 ± 0.69, 11.97 ± 0.60, and 74.80 ± 2.16 g, respectively. The GPC molecular weight distribution of HAP was classified as within three major regions as shown in Table 2. Peak region I ranged from 1300 Da to 10 kDa, in which high molecular weight peptides and proteins were detected. Only 5.82% of HAP molecules were distributed in this range. Peak region II ranged from 250 Da to 1300 Da, within which low molecular weight peptides (di, tri, and oligo peptides) were detected. One major group of HAP molecules (47.79%) was detected in this range. Peak region III comprised molecules under 250 Da consisting mostly of amino acids or di-/tri-peptides. Another major group of HAP molecules (46.39%) was detected in this range. The molecules in this range are known to affect the taste of products and salt from raw materials. The GPC results indicated that the majority of HAP molecules (94.18%) were composed of low molecular peptides (under 1300 Da) or free amino acids. In et al. (2016) reported that anchovy HAP hydrolyzed by both Alcalase® 2.4 L FG and FlavourzymeTM 500 MG under high pressure showed a similar pattern of GPC peak distributions as identified in the current study, which showed that 75.10% of peaks were distributed below 1300 Da molecular weight. The GPC peak distributions of salted and fermented anchovy sauce have also been reported, with 99.83% of molecular weight fractions being distributed under 1100 Da. (Yun et al. 2015). These two previous studies indicated that our method under pressurization efficiently hydrolyzed anchovy in the current study to a degree comparable with those in the studies.

Amino Acid Composition of HAP

The amino acid composition of HAP was analyzed using both combined and free amino acids methods (Table 3). Previous studies reported that protein hydrolysates were composed of amino acids and various-sized peptides with umami and inherent flavors and aromas (Kaewka et al. 2009). The total amounts of combined and free amino acids were 267.40 ± 5.81 and 406.20 ± 7.72 g/kg, respectively. As the targets of the combined amino acids method are oligopeptides and proteins and the total amounts of free amino acids were much higher than those obtained using the combined method, our hydrolysis method under pressurization was seemed to be efficient.

In the combined amino acids method, alanine (16.57%), which yields a sweet taste, leucine (12.31%), lysine (13.55%), glycine (6.84%), proline (7.49%), and valine (8.26), were detected as relatively high quantities. However, the free amino acid method showed a different composition. The most marked difference was that glutamic acid had the highest quantity (13.48%) among all amino acids. Glutamic acid is known to affect the umami and salty taste of HAP (Youn et al. 2015). Previous study reported that main hydrolysates were consisted of free amino acids such as glutamic acid and glutamic acid-rich oligo peptides, and theses influenced umami taste in Red Hake fish (Imm and Lee 1999). Alanine (10.84%), isoleucine (7.92%), leucine (12.78%), phenylalanine (6.20%), threonine (7.07%), and valine (13.24%) were also detected at a relatively high quantity compared with other free amino acids.

Fermentation Rate of Dough

The effects of varying HAP levels on the dough fermentation rate and white pan bread volume are shown in Table 4A and B. The fermentation rate of the control dough sample was significantly higher than the rates of treated doughs with the exception of that of HAP 1.46 (Table 4A). The addition of HAP decreased the fermentation rate in a manner dependent on the amount of HAP added. As sodium chloride is known to suppress yeast activity thereby decreasing the fermentation rate of dough (Jimenez-Maroto et al. 2013), its replacement by HAP appeared to affect the regulation of dough fermentation rate.

Loaf-Specific Volume of White Pan Bread

In the loaf-specific volume test, all bread samples with added HAP maintained comparable loaf-specific volume with controls, with the exception of bread with 11.70 g of added HAP (Table 4B), even though bread with added HAP showed decreased fermentation rates compared with controls. The H 11.70 sample showed a significantly lowered loaf-specific volume value of 1.64 ± 0.14 with dramatically low fermentation rate compared with controls. However, a trend toward decrease was shown among bread samples with added HAP. In the bakery, the decreased yeast activity obtained with sodium chloride results in slowing down gas production (Jimenez-Maroto et al. 2013) and sodium chloride also enhances the strength and stability of dough and loaf volume of bread (McCann and Day 2013); conversely, HAP was revealed not to be related with gas production and loaf-specific volume.

pH Measurement of Dough and White Pan Bread

The effects of varying HAP levels on the pH values of dough and white pan bread are shown in Table 4A and B. The pH of dough was somewhat higher than that of bread in each sample. pH values had a tendency to increase as the amount of HAP content increased, which supported the trend of decreasing fermentation rates of doughs. The pH of the control was significantly lower than those in the treated group.

Texture Analysis of Dough and White Pan Bread

The dough texture measurements are shown in Table 4A. The hardness values of the dough samples with added HAP were higher compared with that of the control, and the value increased with increasing amount of HAP content. Cohesiveness of the dough with added HAP was lower than those of the control, although the values also decreased with increasing amount of HAP content. Doughs with high contents of added HAP (H 5.85 and H 11.70) showed significantly lower values than those of the control. Springiness values of the dough with added HAP did not differ significantly from those of the control. Among the results of gumminess and chewiness, the H 2.93 dough sample showed the highest values among all samples.

The texture measurements of white pan bread are shown in Table 4B. Hardness values of both crumb and crust samples revealed a similar increasing trend as that of dough, and the values of all crumb and crust samples with added HAP significantly differed from that of the control with the exception of the H 1.46 crust sample. Lynch et al. (2009) described that the changed hardness values were detected by wheat breads produced with various levels of salt addition. Compared with the bread with 1.2% sodium chloride, bread without sodium chloride showed significantly higher harness on day 5 (p < 0.05). This result is considered that reduced salt content reduces the strength of gluten network which results in increased hardness of the bread (Lynch et al. 2009). Lee et al. (2016b) reported that the changed hardness values were detected by dried noodle doughs produced with various contents of HAP. The hardness of the dough increased as the HAP contents increased.

The adhesiveness values of all crumb samples with added HAP did not significantly differ from that of the control; however, those of crust samples with high contents of added HAP were significantly decreased compared with that of the control. A decreasing trend of crust adhesiveness was shown with increasing amount of HAP.

Sensory Testing of White Pan Bread

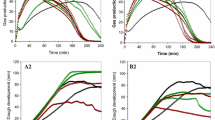

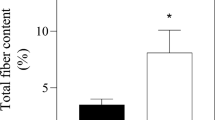

The white pan breads with higher HAP concentrations showed greater saltiness and sourness, albeit lower levels of sweetness, crust color, crumb color, and moisture (Fig. 1a, b). The increased saltiness may be caused by a high concentration of glutamic acid produced by the hydrolysis process. Glutamic acid is known to contribute to saltiness and can be produced through the hydrolysis process of anchovy (Youn et al. 2015). Consistent with this observation, Jimenez-Maroto et al. (2013) reported that replacing sodium chloride with salt enhancer may cause an increase of saltiness because of the umami compounds contained therein. Sourness was increased as the HAP contents increased. And, this result was assumed to be caused by the HAP addition and increased sour-tasting amino acids including aspartic acid, glutamic acid, and histidine through the HAP hydrolysis process. Park et al. (2002) reported that increased amounts of aspartic acid and histidine induced the increase of sourness. Other studies also reported that the perceived taste of glutamic acid was related to sourness (Chen and Zhang 2007; Gabriel and Uneyama 2013; Gunlu and Gunlu 2013). In the case of sweetness, it was reduced as HAP contents increased. This result was assumed to be caused by the HAP addition and the reduced contents of sweet-tasting amino acids including alanine, glycine, hydroxyproline, and proline through the hydrolysis process (Gabriel and Uneyama 2013).

Sensory attributes of all bread samples were investigated along with different concentrations of HAP by PCA analysis (Fig. 2). Close relationships were observed between the majority of sensory parameters, whereas saltiness and sourness were located on the opposite side on the x-axis. Bread samples supplemented with only salt (control) and 1.46 g of HAP (H1.46) had the closest relationships with overall acceptability. The H 1.46 bread sample was most closely related to flavor, sweetness, crust color, and preference of saltiness. Higher concentrations of HAP in bread samples were less relevant to these sensory attributes. This result was seemed to be related to the HAP addition and the increased contents of bitter-tasting amino acids including histidine, leucine, methionine, phenylalanine, tyrosine, and valine (Gabriel and Uneyama 2013). Through PCA analysis, the bread sample supplemented with 1.46 g HAP was concluded to be the most preferable for use in bread products according to the sensory panels, as it was high in most preferred parameters as well as overall acceptability.

Principal component analysis (PCA) result in white pan bread supplemented with different amounts of HAP. PCA result indicates the relationship between sensory attributes and bread samples. Triangles stand for samples described in Table 1 and circles stand for sensory attributes

Conclusion

This study was performed to verify the saltiness enhancer effect of HAP in white pan bread. HAP was hydrolyzed using two food grade enzymes at 100 MPa of pressure. As expected, the GPC results showed that the majority of HAP molecules (94.18%) were composed of low molecular peptides (under 1300 Da) or free amino acids. In combined and free amino acid analysis, alanine (16.57%) which yields a sweet taste and glutamic acid (13.48%) which is known to affect the umami and salty taste were detected with the highest quantities, respectively. In general, fermentation rate and loaf-specific volume are primary determinants of bread quality. In this study, over 89.27% of fermentation rates and over 100% of loaf-specific volumes were maintained at doughs and breads until amount of HAP 5.85, compared with control.

Even though HAP showed the above promising results, there were still possibly negative aspects. The hardness of dough and bread samples also increased compared to control with increased HAP addition, whereas the adhesiveness of bread sample decreased. Sensory results showed that increased HAP additions decreased many favorable attributes. However, sensory results clearly showed that increased HAP additions led a trend of increasing saltiness taste even compared with control. And this result matched with the radical purpose of this study which was to investigate the saltiness enhancer effect of HAP in white pan bread.

Multiple favorable results of HAP support the potential of HAP as an NaCl replacer when added to white pan bread, even though further study is still necessary to improve bread quality. Unpleasant flavor masking of HAP may be necessary to apply to bakery products; however, HAP is seemed to be possibly applied to fish products. In addition, these data will be useful toward the application of HAP in the bread industry.

References

AACC. (1990). Approved methods, Method 10-10b. In Optimized-straight bread-making method.

Bolhuis, D. P., Temme, E. H. M., Koeman, F. T., Noort, M. W. J., Kremer, S., & Janssen, A. M. (2011). A salt reduction of 50% in bread does not decrease bread consumption or increase sodium intake by the choice of sandwich fillings. Journal of Nutrition, 141(12), 2249–2255.

Brandsma, I. (2006). Reducing sodium - a European perspective. Food Technology, 60(3), 24–29.

Brown, I. J., Tzoulaki, I., Candeias, V., & Elliott, P. (2009). Salt intakes around the world: implications for public health. International Journal of Epidemiology, 38(3), 791–813.

Chen, D. W., & Zhang, M. (2007). Non-volatile taste active compounds in the meat of Chinese mitten crab (Eriocheir sinensis). Food Chemistry, 104(3), 1200–1205.

Desmond, E. (2006). Reducing salt: a challenge for the meat industry. Meat Science, 74(1), 188–196.

Doyle, M. E., & Glass, K. A. (2010). Sodium reduction and its effect on food safety, food quality, and human health. Comprehensive Reviews in Food Science and Food Safety, 9(1), 44–56.

Emorine, M., Septier, C., Thomas-Danguin, T., & Salles, C. (2013). Heterogeneous salt distribution in hot snacks enhances saltiness without loss of acceptability. Food Research International, 51(2), 641–647.

FitzGerald, R. J., & O’Cuinn, G. (2006). Enzymatic debittering of food protein hydrolysates. Biotechnology Advances, 24(2), 234–237.

Gabriel, A. S., & Uneyama, H. (2013). Amino acid sensing in the gastrointestinal tract. Amino acids, 45(3), 451–461.

Gelabert, J., Gou, P., Guerrero, L., & Arnau, J. (2003). Effect of sodium chloride replacement on some characteristics of fermented sausages. Meat Science, 65(2), 833–839.

Gunlu, A., & Gunlu, N. (2013). Taste activity value, free amino acid content and proximate composition of Mountain trout (Salmo trutta macrostigma Dumeril, 1858) muscles. Iranian Journal of Fisheries Sciences, 13(1), 58–72.

Heidolph, B. B., Ray, D. K., Roller, S., Koehler, P., Weber, J., Slocum, S., & Noort, M. W. J. (2011). Looking for my lost shaker of salt. Replacer: flavor, function, future. Cereal Foods World, 56(1), 5–19.

Imm, J. Y., & Lee, C. M. (1999). Production of seafood flavor from Red Hake (Urophycis chuss) by enzymatic hydrolysis. Journal of Agricultural and Food Chemistry, 47(6), 2360–2366.

In, Y. W., Yun, H. S., Bang, E., Lee, H. J., Lee, M. Y., & Cho, H. Y. (2016). Selection of commercial proteolytic enzymes for the preparation of anchovy protein hydrolysates under pressurization. Food Engineering Progress, 20(2), 89–97.

Jimenez-Maroto, L. A., Sato, T., & Rankin, S. A. (2013). Saltiness potentiation in white bread by substituting sodium chloride with a fermented soy ingredient. Journal of Cereal Science, 58(2), 313–317.

Jinap, S., & Hajeb, P. (2010). Glutamate. Its applications in food and contribution to health. Appetite, 55(1), 1–10.

Kaewka, K., Therakulkait, C., & Cadwallader, K. R. (2009). Effect of preparation conditions on composition and sensory aroma characteristics of acid hydrolyzed rice bran protein concentrate. Journal of Cereal Science, 50(1), 56–60.

Khetra, Y., Kanawjia, S. K., Puri, R., Kumar, R., & Meena, G. S. (2019). Using taste-induced saltiness enhancement for reducing sodium in Cheddar cheese: effect on physico-chemical and sensorial attributes. International Dairy Journal, 91, 165–171.

Kramer, A., Kahan, G., Cooper, D., & Papavasiliou, A. (1974). A non-parametric ranking method for the statistical evaluation of sensory data. Chemical Senses, 1(1), 121–133.

Kristinsson, H. G., & Rasco, B. (2000). Kinetics of the hydrolysis of Atlantic salmon (Salmon salar) muscle proteins by alkaline proteases and a visceral serine protease mixture. Process Biochemistry, 36(1-2), 131–139.

Lee, M. J., Popkin, B. M., & Kim, S. (2002). The unique aspects of the nutrition transition in South Korea: the retention of healthful elements in their traditional diet. Public Health Nutrition, 5(1A), 197–203.

Lee, J., Cho, H. Y., & Choi, M. J. (2016a). Effect of hydrolyzed anchovy oligopeptide under 5kDa on dried noodle as salty taste enhancer. Food Engineering Progress, 20(3), 183–189.

Lee, J., Lee, M. Y., Cho, H. Y., & Choi, M. J. (2016b). Effect of liposome-coated salt on salty taste intensity of noodle. Food Engineering Progress, 20(2), 98–104.

Lynch, E. J., Dal Bello, F., Sheehan, E. M., Cashman, K. D., & Arendt, E. K. (2009). Fundamental studies on the reduction of salt on dough and bread characteristics. Food Research International, 42(7), 885–891.

McCann, T. H., & Day, L. (2013). Effect of sodium chloride on gluten network formation, dough microstructure and rheology in relation to breadmaking. Journal of Cereal Science, 57(3), 444–452.

Nilsang, S., Lertsiri, S., Suphantharika, M., & Assavanig, A. (2005). Optimization of enzymatic hydrolysis of fish soluble concentrate by commercial proteases. Journal of Food Engineering, 70(4), 571–578.

Park, J. N., Watanabe, T., Endoh, K. I., Watanabe, K., & Abe, H. (2002). Taste-active components in a Vietnamese fish sauce. Fisheries Science, 68(4), 913–920.

Pietrasik, Z., & Gaudette, N. J. (2014). The impact of salt replacers and flavor enhancer on the processing characteristics and consumer acceptance of restructured cooked hams. Meat Science, 96(3), 1165–1170.

Raksakulthai, R., & Haard, N. F. (2003). Exopeptidases and their application to reduce bitterness in food: a review. Critical Reviews in Food Science and Nutrition, 43(4), 401–445.

Samapundo, S., Deschuyffeleer, N., Van Laere, D., De Leyn, I., & Devlieghere, F. (2010). Effect of NaCl reduction and replacement on the growth of fungi important to the spoilage of bread. Food Microbiology, 27(6), 749–756.

Schindler, A., Dunkel, A., Stähler, F., Backes, M., Ley, J., Meyerhof, W., & Hofmann, T. (2011). Discovery of salt taste enhancing arginyl dipeptides in protein digests and fermented fish sauces by means of a sensomics approach. Journal of Agricultural and Food Chemistry, 59(23), 12578–12588.

Shimono, M., & Sugiyama, K. (2015). Salty taste enhancer and food or drink containing same. US Patent No. US8,932,661 B2.

World Health Organization. (2007). Reducing Salt Intake in Populations: report of a WHO Forum and Technical Meeting, 5–7 October 2006, Paris, France. URL (www.who.int/dietphysicalactivity/Salt_Report_VC_april07.pdf) (2018.06.12).

Youn, S. J., Cha, G. H., & Shin, J. K. (2015). Salty taste enhancing effect of enzymatically hydrolyzed anchovy protein. Korean Journal of Food Science and Technology, 47(6), 751–756.

Yun, H.-S., Park, H.-S., Lee, M.-Y., Shin, J.-K., & Cho, H.-Y. (2015). A feasibility study on producing salt taste enhancer in the commercial fermented fish and soy sauces. Food Engineering Progress, 19(2), 139–147.

Zanardi, E., Ghidini, S., Conter, M., & Ianieri, A. (2010). Mineral composition of Italian salami and effect NaCl partial replacement on compositional, physico-chemical and sensory parameters. Meat Science, 86(3), 742–747.

Zhang, S., Zhang, C., Qiao, Y., Xing, L., Kang, D., Khan, I. A., Huang, M., & Zhou, G. (2017). Effect of Flavourzyme on proteolysis, antioxidant activity and sensory qualities of Cantonese bacon. Food Chemistry, 237, 779–785.

Funding

This research was supported by a high value-added food technology development program [312010043HD030], Ministry of Agriculture, Food and Rural Affairs, Korea. This paper was also supported by the KU Research Professor Program of Konkuk University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cho, Y., Lee, J., Lee, MY. et al. Effects of Hydrolyzed Animal Protein on the Enhancement of Saltiness and Quality Characteristics of White Pan Bread. Food Bioprocess Technol 12, 1832–1841 (2019). https://doi.org/10.1007/s11947-019-02332-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02332-9