Abstract

This work explores the functionality of oils from brewer’s spent grain by supercritical fluid extraction. The process was performed at 20 and 30 MPa, and 40 and 50 °C without and with ethanol as co-solvent in percentages equal to 4 and 8%. Supercritical fluid extraction was compared with Soxhlet using hexane as solvent. The extracts were characterized for their antioxidant capacity by 2,2-diphenyl-1-picryhydrazyl radical (DPPH) assays, total phenolic content by Folin–Ciocalteu assay, fatty acid profile by GC-FID, and oxidative stability by isothermal calorimetry. Moreover, their capacity to retard the oxidation of linseed oil was also studied. Samples from Soxhlet and supercritical carbon dioxide (30 MPa, 50 °C, and 8% of ethanol) showed the highest yields (6.1 ± 0.3% and 6.5 ± 0.1%, w/w), recovery (78.3 ± 2.1% and 81.3 ± 1.8%, w/w), total phenolic contents (28.3 ± 0.5 and 26.2 ± 0.3 mg GAE/g of sample), and antioxidant activity (16.7 ± 0.1 and 14.2 ± 0.1 mg TEA/g of sample). The fatty acid composition of brewer’s spent oil extracted by SFE was similar to that extracted by Soxhlet. The same extracts also reported the highest oxidative stability and ability to slow down linseed oil oxidation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the food industry, the processing operations are associated with the transformation of the initial raw material into a safe, nutritious, and high-quality food product. However, during the processing, most of the time, high amounts of by-products are also produced. To solve this problem, the research is focusing on finding viable alternatives able to combine food production with valorization of by-products, reduction of energy consumption, and increased environmental protection. Nowadays, many opportunities exist to valorize by-products (Galanakis 2012, 2013), i.e., through the extraction of valuable compounds and their subsequent applications in food, cosmetic, and pharmaceutical products (Galanakis et al. 2018a, b, c). Studies report that several components, recovered from food by-products, such as phenolic compounds, are stable ingredients used for food or feed products (Ferrentino et al. 2017).

Among food by-products, a focus has been placed on those produced by the brewing industry, in particular, to the brewer’s spent grain (BSG). BSG is the barley malt residue, mainly constituted by insoluble grain components, which remains after the production of wort (Lynch et al. 2016). About 39 million tons per year of BSG are produced globally; of this amount, about 3.4 million tons per year come from the beer production of the European Union. Overall, around 20 kg of wet BSG is needed to obtain 100 L of brewed beer (Moreira et al. 2013; Kitryte et al. 2015; Klimek et al. 2017). In Italy, beer production accounts for ~ 13 million hectoliters per year, thus around 0.26 million tons of BSG is produced annually. Currently, the majority of produced BSG is used as an alternative source of energy, low-value animal feed, and fertilizers, or considered a waste. However, this material is still a source of valuable components such as phenolics, lipids, cellulose, carbohydrates, proteins, or amino acids which are present in BSG after wort mashing and can be furthermore valorized (Kitryte et al. 2015; Meneses et al. 2013).

Nowadays, some techniques have been attempted for extracting the antioxidant components from BSG. They generally use processes based on acid hydrolysis, saponification, or liquid–solid extraction with organic solvents (Mussatto et al. 2006; Mccarthy et al. 2013: Hayes et al. 2011). However, some drawbacks are linked to those techniques such as the possibility of having residual toxic solvents in the final extract, long extraction time, loss of volatile compound from the extract, and thermal degradation of sensitive compounds due to the high temperature used, as well as oxidative degradation reactions of the extract during the solvent evaporation step (Fernandez et al. 2008; Fernandes et al. 2017).

Nowadays, more efficient and environmentally safe technologies have been developed to extract valuable components from solid matrices, such as supercritical fluid extraction (SFE), ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), and filtration. Published studies show that novel applications of MAE and UAE for the extraction of valuable components from BSG have been tested (Tang et al. 2010; Mallouchos et al. 2007). Among these, the application of SFE for the extraction of valuable components from BSG is still under investigation (Fernandez et al. 2008; Spinelli et al. 2016; Kitryte et al. 2015). It uses carbon dioxide (CO2) as the solvent which in the supercritical state (temperature higher than 31 °C and pressure higher than 7.3 MPa) has a diffusivity close to that of gases and a solvation power close to that of liquids. In addition, CO2 is not expensive and is environmentally friendly and generally recognized as safe by FDA and EFSA. Due to its low polarity, CO2 is often used with a co-solvent which can help improve the efficiency for the extraction of antioxidant compounds. One of the most used co-solvent is ethanol that has a good miscibility with CO2, and it is considered non-toxic for food and pharmaceutical products. Several studies demonstrate the potential of SFE to extract compounds from a variety of matrices at laboratory and industrial scale. Published results on the extraction of bioactive compounds from food by-products demonstrated that SFE has the ability to obtain carotenoids from apricot pomace (Sanal et al. 2005); polyphenols from not only apple and peach pomaces (Adil et al. 2007; Ferrentino et al. 2018) but also from grape skins (Pascual-Marti et al. 2001), orange pomace (Benelli et al. 2010), guava seeds (Castro-Vargas et al. 2010), and grape seeds (Murga et al. 2000).

SFE has been also applied for the extraction of valuable components from BSG (Moreira et al. 2013; Kitryte et al. 2015; Spinelli et al. 2016; Vieira et al. 2014). In all the studies, an optimization of the processing parameters (pressures of 15, 25, and 35 MPa; temperatures of 40, 50, and 60 °C) was performed using only CO2 and CO2 + 20, 40, and 60% ethanol to obtain an extract characterized in terms of total phenols and flavonoids. It is well known that using these amounts of ethanol CO2 turns its properties from supercritical to subcritical, changing completely its extraction behavior. To the best of our knowledge, no papers have been published investigating SFE efficiency with an amount of co-solvent lower than 10%, thus keeping the solvent in a supercritical state. Moreover, no studies have been done investigating the oxidative stability and the ability of BSG extract to retard oil oxidation.

Based on this background, the aim of the present work was to recover oils with antioxidant activity from BSG applying SFE using only CO2 and adding ethanol (4 and 8%) as co-solvent. The efficiency of the process was determined in terms of yield, while the extracts were characterized in terms of antioxidant activity by the DPPH assay, total phenolic content by Folin–Ciocalteu assay, and fatty acid profile by gas chromatography. The oxidative stability of BSG extracts and their capacity to retard the oxidation of linseed oil was also studied by isothermal calorimetry. Moreover, the quality of the oils extracted by SFE was compared to that obtained using hexane with Soxhlet.

Materials and Methods

Materials

Carbon dioxide (99.99%) for extraction was obtained from Rivoira (Milano, Italy). Linseed oil, 1, 1 diphenyl-2-picryl-hydrazyl (DPPH), gallic acid, and 6-hydroxy-2, 5, 7, 8-tetramethylchroman-2 carboxylic acid (Trolox) were purchased from Sigma-Aldrich (Milan, Italy). Methanol, ethanol, and Folin–Ciocalteu’s reagent were bought from Merck (Darmstadt, Germany). All chemicals and reagents were of HPLC or analytical grade.

Sample Preparation

The malt was purchased from a local market. BSG was obtained from a laboratory-scale brewery plant (Free University of Bolzano, Bolzano, Italy) directly after the mashing process. As soon as obtained, the material (approx. 74.6 ± 2% moisture content) was dried at 50 °C for 48 h in a ventilated oven. BSG reached a final moisture content of 7.1 ± 1% (Sartorious MA160, Torino, Italy). The product presented a polysaccharide content of 61 ± 2.3%, a protein content of 20 ± 1.2%, and a total oils content of 8 ± 1.4% (the remaining fraction was ash).

To perform the extraction, it was ground to obtain a fine powder with the following particle size distribution: 9 ± 4% of the sample presented a diameter higher than 1 mm, 25 ± 2% a diameter comprised between 1 mm and 500 μm (Retsch GmbH, Verder Scientific, Germany), 44 ± 4% a diameter comprised between 500 and 250 μm, and 21 ± 1% a diameter comprised between 250 and 100 μm.

Supercritical Fluid Extraction Apparatus and Procedure

Extractions with supercritical carbon dioxide were carried out using a high-pressure pilot plant (Superfluidi s.r.l., Padova, Italy). The system was equipped with 1-L volume extractor vessel and two gravimetric separators (Fig. 1). The high-pressure vessel contained an extraction basket of 800 mL, closed on both ends with porous stainless steel filter mesh to avoid any possible carryover of samples. The temperature of the extraction and separation vessels was automatically controlled by recirculating the water from two independent thermostated water baths. CO2 was pressurized by a high-pressure diaphragm pump (Lewa LDC e M e 9XXV1, Milano, Italy) pre-cooled at 4.0 °C in order to deliver liquid CO2 from a storage cylinder to the extraction vessel efficiently. The system was equipped with a high-pressure tank for CO2 storage to be compressed and reused. The extraction was carried out by passing the CO2 through the sample, receiving the extract in the separator, and finally releasing CO2 for storage tank for further reuse.

Layout of the supercritical carbon dioxide pilot-scale system: 1, CO2 tank; 2, pressure gauge; 3, on-off valve; 4, needle valve; 5,CO2 storage tank; 6, cooling bath; 7, high pressure pump; 8, heat exchanger; 9, high pressure extraction vessel; 10, digital thermometer; 11, separator 1; 12, separator 2; 13, collecting vessel 1; 14, collecting vessel 2; 15 co-solvent resevoir; 16, co-solvent pump

The extraction was performed with either CO2 or CO2 with ethanol (4 and 8%) as a co-solvent. The extraction was performed by placing approximately 80 ± 2 g of sample inside the extraction vessel and the CO2 was flushing through the sample with a flow rate equal to 3.6 L/h. The extraction time was set to 1 h based on the kinetics of the yield which show no increases of the collected extract increasing the time. The experiments were performed at temperatures of 40 °C and 50 °C and pressures of 20 MPa and 30 MPa. A temperature higher than 50 °C was not taken into account to avoid its deleterious effect on the extracts. Pressures higher than 30 MPa were not considered as preliminary results performed at 35 MPa showed no significant differences in the antioxidant activity and yield of the extracts.

After the experiments, the sample was collected in a vial, weighted, and stored for further characterization. Each experiment under certain conditions was repeated two times. Therefore, the results were expressed as mean values and standard deviations.

For the extract obtained by CO2 and ethanol as co-solvent, the samples were flushed off by nitrogen at 25 °C to remove the residual ethanol until they reached a final constant weight.

The extraction yield was defined according to the weight of the extracted oil divided by the weight of the sample loaded (w/w, %) in the high-pressure vessel while the recovery was calculated dividing the weight of the extracted oil by the total oil of BSG (w/w, %) (Sökmen et al. 2018).

Soxhlet Extraction

Hexane was used for Soxhlet extraction of oil from BSG. The method consisted of 150 mL of solvent recycling over 5 g of sample in a Soxhlet apparatus for 6 h at the boiling temperature of hexane. After the extraction was completed, the solvent was removed at 40 °C at a reduced pressure using a rotary evaporator (LABOROTA 4000, Heidolph, Schwabach, Germany). After the evaporation of the solvent, the oil yield was determined as percent of the mass of extracted oil to the mass of BSG loaded in the thimble.

Isothermal Calorimetry

A micro-calorimeter (Thermal Activity Monitor, Model 421 TAM III, TA Instruments, USA) was used to perform all calorimetric analyses. The system was equipped with 24 micro-calorimetric channels submerged in oil bath, each of them positioned above each other as a twin calorimeter. The micro-calorimeters were equipped with built-in metal reference specimens having a heat capacity approximately equal to that of a glass vial. Before every experiment, each channel was calibrated by a gain calibration procedure with electric impulses (as recommended by manufacturer guidelines). To study the oxidative stability of the extracts, approximately 100 ± 5 mg was transferred in a 4-mL glass ampoule and closed hermetically with silicone septa. The ampoules were first heated for 2 min at the temperature of the experiment, then were lowered into the thermal equilibration position and left there for 15 min for equilibration. The heat flow rates were recorded at the interval of 30 s in isothermal conditions as the auto-oxidation reaction proceeded. For BSG extracts, isothermal temperatures of 60 °C and 90 °C with an absolute accuracy of ± 0.0005 °C were used. These temperatures were chosen based on our preliminary experiments (data not shown) by taking into account the antioxidant capacity behavior of the extracts. For evaluating the capacity of the extract to inhibit the exothermic oxidation of linseed oil, about 3 mg of extract was added to 100 mg of oil. Tocopherol was used as a comparison standard antioxidant (0.22 mg of tocopherol/100 mg of oil). The experiments were performed in an isothermal mode at 30 °C using the same procedure described above. Isothermal calorimetry experiments were performed in triplicate and the results expressed as mean values and standard deviations.

Free Radical Scavenging Activity

The antioxidant activity of extracts was determined using DPPH assay as described by Brand-Williams et al. (1995) with some slight modifications. Aliquots of 1.9 mL of DPPH solution (20 mg of DPPH dissolved in 500 mL of ethanol and sonicated for 2 min) were put into the cuvettes and 100 μL of the diluted extract (1 g of extract/10 mL of ethanol) was added. The mixture was maintained in the dark for 1 h at 25 °C. The absorbance was measured at 517 nm with a spectrophotometer (Cary 100 Series UV-Vis Spectrophotometer, Agilent Technologies, Italy). The antioxidant activity of the extracts (mean value of the triplicate assays) was determined as their capacity to scavenge the DPPH free radicals. The results were expressed as Trolox equivalent antioxidant (TEA) value per gram of extract (mg TEA/g of extract) based on Trolox standard calibration curve prepared before.

Total Phenolic Content

The total phenolic content was determined using the Folin–Ciocalteu method (Singleton and Rossi 1965). A defined amount of extract was diluted in ethanol (0.1 g of extract/1 mL of ethanol). The cuvettes were prepared mixing 1.2 mL of distilled water, 40 μL of extract, 300 μL of 20% sodium carbonate solution, and 100 μL of Folin–Ciocalteu reagent. The mixture was kept in darkness for 2 h for the reaction and then the absorbance was recorded at 765 nm using a spectrophotometer (Cary 100 Series UV-Vis Spectrophotometer, Agilent Technologies, Italy). The total phenolic content (mean value of the triplicate assays) was expressed as milligrams of gallic acid equivalent (GAE) per gram of extract (mg GAE/g of extract) following the previously prepared gallic acid standard calibration curve.

Fatty Acid Profile

The fatty acid composition of the extracts was analyzed by gas chromatography (GC) using a chromatograph (Thermo Scientific TRACE 1300, Milano, Italy) equipped with a flame ionization detector and a TG-POLAR column (60 m, 0.25 cm, and 0.2 μm) after derivatization to fatty acid methyl esters according to Metcalfe et al. (1966). About 8 mL of hexane and 100 μL of extract were put in a conical graduated tube. The mixture was shaken and 300 μL of KOH (0.5 M) in methanol was added to the mixture and reshaken. The mixture was allowed to stand for 3 min and the upper layer was taken for GC analysis. The column temperature was held at 50 °C for 1 min, then heated to 220 °C at 10 °C/min then to 260 °C at 5 °C/min. Both detector and injector were held at 260 °C. The oven temperature was held at 130 °C during separation. The nitrogen was used as a carrier gas with a flow rate of 1 mL/min. The analysis was performed injecting 1.0 μL of the prepared sample using an auto-sampler (Thermo Scientific AI/AS 1310, Milan, Italy). Fatty acid methyl esters (FAMEs) were identified by comparison of retention times with FAME standard mixture (SUPELCO FAMEs Mix GLC-30; Sigma Aldrich, Milano, Italy) and quantified using area normalization. A duplicate measurement was performed for each sample and the results expressed as mean values and standard deviations.

Statistical Analysis

The results were reported as mean values ± standard deviation. The statistical analysis was performed by a one-way analysis of variance using SPSS for Windows (version 20.0.0, SPSS Inc., USA). Also, a two-way analysis of variance was carried out to evaluate the effect of independent variables on the response (Design-Expert® Software version 7). Tukey HSD test was used to evaluate the significant differences (p < 0.05) between mean values.

Results and Discussion

Effect of Extraction Conditions on Yield, Recovery, Total Phenolic Content, and Antioxidant Activity

The effect of SFE processing was evaluated by means of a factorial design with three factors (pressure, temperature, and co-solvent) each at two levels. Table 1 shows the effect of the processing variables on the oil yield, recovery, total phenolic content, and antioxidant activity. In general, the extraction conditions (pressure, temperature, and addition of co-solvent) affect significantly (p < 0.05) the yield, the recovery, the total phenol content, and the antioxidant activity. The results of the statistical analysis are reported in Table 2. Among the three factors, the addition of ethanol as co-solvent has the main effect (p < 0.05). The positive effect of ethanol as co-solvent on the extraction capacity of SFE is explained by considering the polarity of ethanol. CO2 is a non-polar solvent and, even at high density, its ability to dissolve polar compounds is limited. The addition of a modifier ameliorates the extraction efficiency of polar compounds by increasing their solubility (Lim et al. 2002; Pereira and Meireles 2010). Since phenolic compounds are polar in nature, the addition of ethanol has a great impact on their extraction (Sanal et al. 2005; Lee et al. 2010). These compounds play a big role in the antioxidant capacity of plant extracts. They substantially contribute to the antioxidant activity owing to the redox properties of their hydroxyl groups (Materska and Perucka 2005), which are responsible in scavenging free radicals by donating hydrogen atoms or electrons (Amarowicz et al. 2004). The significant increase (p < 0.05) of the antioxidant activity can be associated to the presence of such polar phenolic compounds, which might contribute a lot to improve the overall antioxidant activity of the extract.

The second factor significantly affecting the process is the temperature. The results indicate that higher temperatures increase the yield, total phenolic content, and antioxidant activity. In the literature, the effect of temperature is reported to be negative on SFE of phenolic compounds at low pressures between 10 and 15 MPa (Chafer et al. 2004; Özkal et al. 2005; Roy et al. 1996). However, beyond such pressure threshold, the temperature positively affects the extraction capacity of SFE. Such behavior can be easily explained considering that the solubility of CO2 is controlled by a balance between the solvent density and the change in the solute vapor pressure (Lim et al. 2002; Choi et al. 1998; Adil et al. 2008). According to our results, at the extraction conditions used, the vapor pressure effect (diffusion effect) improves significantly the extraction yield.

Finally, the statistical analysis reveals that pressure, although in minor proportion, contributes significantly to the process performance. SFE performed at high pressures led to higher yields, total phenols, and antioxidant activity. The results indicate that an increase of pressure (at constant temperature) enhances CO2 density, which thereby affects positively the solubility of analytes in CO2 improving the yield and consequently the total phenolic content and antioxidant activity (Salgin et al. 2006). For example, the density of CO2 increases from 19.1 mol/L at 20 MPa to 20.7 mol/L at 30 MPa at a constant temperature of 40 °C and from 17.8 mol/L at 20 MPa to 19.8 mol/L at 30 MPa at a constant temperature of 50 °C (Özkal et al. 2005). The statistical analysis also reveals the existence of an interaction between pressure, temperature, and co-solvent (p < 0.05). However, although these interaction factors are statistically significant, they are quite small in comparison with the main effects.

In Table 1, the results of the extracts obtained with Soxhlet are also reported. The yield of the process is not significantly different from that obtained by SFE at 30 MPa and 50 °C, and using 8% of ethanol as co-solvent. However, the oil extracted with Soxhlet has a higher content of total phenolic compounds and antioxidant activity compared to those obtained by SFE. Other authors have attempted to compare the Soxhlet or the hydrodistillation method with SFE (Aghel et al. 2004; Cao et al. 2007). They found that there were less compounds extracted by SFE than Soxhlet and they attributed these differences to the different techniques used to obtain the extracts.

They reported that during SFE a part of the extracted components escaped along with CO2, while in Soxhlet trapping the oil was simultaneously performed along with the condensing solvent in the tube avoiding the loss of volatile components from the oil.

Effect of Extraction Conditions on Fatty Acid Profile

Table 3 shows the fatty acid profiles of beer spent grain extracted by SFE at different conditions of pressure and temperature in the absence and presence of ethanol (4 and 8%) as co-solvent. Regardless of the pressure and temperature used for the extraction, the samples report similar amounts of polyunsaturated and monounsaturated fatty acids. More than 50% of the fatty acid profiles of all the samples is constituted of linoleic acid (C18:2). Overall, pressure and temperature do not significantly influence the fatty acid profiles of the extracts.

The addition of ethanol significantly changes the abundance of some fatty acids, in particular palmitic acid (C16:0) and linolenic acid (C18:3). Moreover, the samples extracted with 8% of ethanol show significant high values of linoleic acid (C18:2) with the exception of the extract obtained at 20 MPa and 40 °C. As shown before, this sample also reports low values of antioxidant activity and phenolic content indicating the low extracting capacity of CO2 at these processing conditions. No significant differences are found when the beer spent grain is extracted by hexane in Soxhlet or by SFE with the addition of co-solvent. Similar results have been also published by Da Porto et al. (2012) where SFE carried out on hempseeds was compared with Soxhlet extraction with hexane.

Oxidative Stability of Brewer’s Spent Grain Extracts

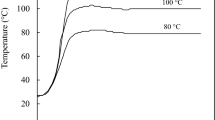

The oxidative stability of beer spent grain extracts was next investigated by isothermal calorimetry. Figure 2 shows the resulting heat flow signal generated by the brewer’s spent grain extracts obtained by SFE. Regardless of the extraction conditions, all the samples result in a heat flow signal with a similar pattern. Initially, the rate of heat generated is negligible. Then, the signal suddenly increases, reaching a maximum value (exothermic peak). After that, the signal decays, returning to a value close to 0. Overall, the recorded signal reflects the changes in the rate of autoxidation occurring to the samples in the presence of oxygen (Labuza and Dugan Jr. 1971; Angelo et al. 1996; Ghnimi et al. 2017). This process is generally described in three steps. The “initiation phase” lasts until the calorimetric trace remains negligible. The “propagation phase” starts when the exothermic signal rises reaching the maximum value. When the rate of the reaction decreases, the “termination phase” occurs with the drop of the calorimetric trace due to the excessive presence of free radicals.

The possibility of describing the different steps of the radical chain reaction provides a suitable way to compare the effect of the extraction process on the resulting oxidative stability of the sample. Providing that the oxidative stability of an oil is proportional to the duration of the “initiation phase,” the highest stability is observed for the samples extracted at the highest temperature (50 °C) with pressure of 20 MPa (curve c) and 30 MPa (curve d).

Concerning the samples extracted by SFE with the addition of ethanol and by Soxhlet, the results are stable at 60 °C. They were loaded in the micro-calorimetry thermostat for more than 366 h. In this period of time, no oxidation reactions occurred.

Since the extracts obtained by SFE with the addition of ethanol report high oxidative stabilities at 60 °C, their behavior was studied at a temperature of 90 °C.

Figure 3 shows the resulting heat flow signals for the oil samples obtained at the different SFE processing conditions with 8% of ethanol as co-solvent and the one obtained with Soxhlet. As shown at 60 °C, the samples with the highest oxidative stability are those extracted with the highest temperature (50 °C) at 30 MPa. In such condition of temperature and with 8% of ethanol as co-solvent, the samples are oxidized late in time compared to those extracted without ethanol. The oils extracted at 30 MPa and 50 °C (curve d), and those at 20 MPa and 50 °C (curve c) with 8% ethanol show the highest oxidative stability. The same figure also shows the thermogram of the oil extracted with Soxhlet, which reported the highest oxidative stability (curve e) compared to that obtained with SFE at 30 MPa, 50 °C, and 8% of ethanol (curve d).

Calorimetric thermograms of BSG extracts by SFE + ethanol (8%) as a co-solvent and Soxhlet. SFE extraction were carried out at 20 MPa, 40 °C (curve a); 30 MPa, 40 °C (curve b); 20 MPa, 50 °C (curve c); 30 MPa, 50 °C (curve d). Soxhlet extraction was carried out with hexane (curve e). Experiments were performed in isothermal mode at 90 °C

Overall, the trend of the oxidative stability of the samples correlates with the results of the antioxidant activity and total phenolic content. No correlation was found with the results of the fatty acid profile. BSG extracts obtained at 30 MPa and 50 °C with 8% ethanol report the highest values of bioactive compounds and here also show the highest oxidative stability. The correlation between the stability of oil and its total phenolic content is in agreement with previously published works (Taghvaei et al. 2014). Similar results have been recently published by Haman et al. (2017, 2018) who applied isothermal calorimetry to study the oxidative stability of linoleic acid (Haman et al. 2017) and spent coffee extracts (Haman et al. 2018). Both studies reported the existence of a direct correlation between the antioxidant activity and the oxidative stability of the samples.

Inhibition of Linseed Oil Oxidation by Brewer’s Spent Grain Extracts

In this section, the antioxidant activity of the brewer’s spent grain extracts was tested. Briefly, the extracts were added to linseed oil and the antioxidant activity of the oil sample was measured as the time delay of the initiation phase of linseed oil. Figure 4 shows the thermogram of linseed oil. Before the addition of BSG extracts, linseed oil (curve a) shows a characteristic exothermic peak occurring at 3.5 ± 0.1 h. At the same temperature (30 °C), BSG extracts are highly stable and do not exhibit any exothermic peaks for more than 1 month of continuous recording. When linseed oil is mixed with BSG extracts by SFE (curve b), SFE with 8% ethanol (curve d), and Soxhlet (curve e), its exothermic peak is delayed significantly. The longest delay of the linseed oil peak was observed with the Soxhlet extract followed by SFE extract obtained at the highest temperature (50 °C) and pressure (30 MPa) and 8% ethanol as co-solvent. Such delay can be attributed to the highest activity of the antioxidant compounds of the BSG oils. The extent of such shift reflects the capacity of BSG extracts to inhibit the oxidation, delaying or preventing the oxidative stress of linseed oil. Moreover, the extracts obtained by Soxhlet and SFE with ethanol as co-solvent show a higher capacity to stabilize the oil than the extract obtained by SFE. This can be attributed to the higher total phenolic compounds and antioxidant activity of the extracts, which contribute greatly to the stabilization of linseed oil. For comparison, Fig. 4 shows also the calorimetric trace obtained when linseed oil is mixed with α-tocopherol (curve c). Similar to the observed behavior of BSG extracts, α-tocopherol also delays the appearance of the initiation phase of linseed oil oxidation reaction. In detail, when 0.22 mg of α-tocopherol was added to linseed oil, the exothermic peak was delayed at 8.00 ± 0.1 h. Accordingly, the antioxidant capacity of SFE and Soxhlet extracts can be also expressed as equivalent concentration of α-tocopherol. This equals to 0.16 ± 0.1 mg of tocopherol for the extract obtained with SFE (curve b), 0.30 ± 0.2 mg of tocopherol for the one obtained with SFE and 8% ethanol as co-solvent (curve d), and 0.66 ± 0.1 mg of tocopherol for the one obtained using hexane with Soxhlet (curve e).

Calorimetric thermograms of linseed oil (100 mg, curve a) and linseed oil with the addition of BSG extracts (3 mg) obtained by SFE (curve b) at 30 MPa, 50 °C; SFE + 8% ethanol (curve d) at 30 MPa, 50 °C; and Soxhlet (curve e). Experiments were performed in isothermal mode at 30 °C. For comparison, the signal of linseed oil with the addition of α-tocopherol (0.22 mg in 100 mg of oil) was also reported (curve c)

Conclusion

In this work, the bioactivity of the extracts obtained from BSG using the SFE technique has been investigated and compared with a Soxhlet extraction using hexane. For SFE, the results show that the extraction conditions (pressure, temperature, and addition of a co-solvent) affect the yield, total phenolic content, antioxidant activity, and oxidative stability of the extracts. The samples with the highest total phenolic content and antioxidant activity report the highest oxidative stability. In particular, BSG extracts obtained at 30 MPa and 50 °C with 8% of ethanol as co-solvent show the highest oxidative stability. The same sample added to linseed oil is able to inhibit the autoxidation reaction of the oil showing an effect similar to that of α-tocopherol. The comparison with Soxhlet shows that hexane gives an extract with a higher total phenolic content, and antioxidant activity and oxidative stability compared to that obtained by SFE with ethanol. However, hexane should be considered with care as traces still could be present in the final product. This in turn would pose a serious concern on human health. Moreover, the SFE offers the advantage of shorter extraction times, being 1 h rather than 6 h for the Soxhlet extraction, and lower temperatures. Therefore, it could be possible to manipulate the composition of the oil extracted by changing the operating parameters of the SFE extraction. On a more general perspective, the study confirms the possibility of using SFE as environmentally friendly technology for the recovery of high valuable compounds from BSG.

References

Adil, I. H., Cetin, H. I., Yener, M. E., & Bayindirli, A. (2007). Subcritical (carbon dioxide plus ethanol) extraction of polyphenols from apple and peach pomaces, and determination of the antioxidant activities of the extracts. Journal of Supercritical Fluids, 43(1), 55–63.

Adil, I. H., Yener, M. E., & Bayindirli, A. (2008). Extraction of total phenolics of sour cherry pomace by high pressure solvent and subcritical fluid and determination of the antioxidant activities of the extracts. Separation Science and Technology, 43(5), 1091–1110.

Aghel, N., Yamini, Y., Hadjiakhoondi, A., & Pourmortazavi, S. M. (2004). Supercritical carbon dioxide extraction of Mentha pulegium L. essential oil. Talanta, 62(2), 407–411.

Amarowicz, R., Pegg, R. B., Rahimi-Moghaddam, P., Barl, B., & Weil, J. A. (2004). Free-radical scavenging capacity and antioxidant activity of selected plant species from the Canadian prairies. Food Chemistry, 84(4), 551–562.

Angelo, S., Vercellotti, A. J., Jacks, J. T., & Legendre, M. (1996). Lipid oxidation in foods. Critical Reviews in Food Science and Nutrition, 36, 175–224.

Benelli, P., Riehl, C. A. S., Smania, A., Smaniac, E. F. A., & Ferreira, S. R. S. (2010). Bioactive extracts of orange (Citrus sinensis L. Osbeck) pomace obtained by SCFE and low pressure techniques: mathematical modeling and extract composition. Journal of Supercritical Fluids, 55(1), 132–141.

Brand-Williams, W., Cuvelier, M., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. LWT- Food Science and Technology, 28(1), 25–30.

Cao, H., Xiao, J. B., & Xu, M. (2007). Comparison of volatile components of Marchantia convoluta obtained by supercritical carbon dioxide extraction and petrol ether extraction. Journal of Food Composition and Analysis, 20(1), 45–51.

Castro-Vargas, H. I., Varela, L. I. R., Ferreira, S. R. S., & Parada, F. (2010). Extraction of phenolic fraction from guava seeds (Psidium guajava L.) using supercritical carbon dioxide and co-solvents. The Journal of Supercritical Fluids, 51(3), 319–324.

Chafer, A., Fornari, T., Berna, A., & Stateva, R. P. (2004). Solubility of quercetin in supercritical CO2 + ethanol as a modifier: measurements and thermodynamic modeling. The Journal of Supercritical Fluids, 32(1-3), 89–96.

Choi, E. S., Noh, M. J., & Yoo, K. P. (1998). Solubilities of o-, m- and p-coumaric acid isomers in carbon dioxide at 308.15-323.15 K and 8.5-25 MPa. Journal of Chemical and Engineering Data, 43(1), 6–8.

Da Porto, C., Decorti, D., & Tubaro, F. (2012). Fatty acids composition and oxidative stability of hemp (Cannabis sativa L.) seed oil extracted by supercritical carbon dioxide. Industrial Crops and Products, 36(1), 401–404.

Fernandes, R. P. P., Trindade, M. A., Tonin, F. G., Pugine, S. M. P., Lima, C. G., Lorenzo, J. M., & de Melo, M. P. (2017). Evaluation of oxidative stability of lamb burger with Origanum vulgare extract. Food Chemistry, 233, 101–109.

Fernandez, M. P., Rodriguez, J. F., Garcia, M. T., De Lucas, A., & Gracia, I. (2008). Application of supercritical fluid extraction to brewer’s spent grain management. Industrial & Engineering Chemistry Research, 47(5), 1614–1619.

Ferrentino, G., Asaduzzaman, M., & Scampicchio, M. M. (2017). Current technologies and new insights for the recovery of high valuable compounds from fruits by-products. Critical Reviews in Food Science and Nutrition, 58, 386–404.

Ferrentino, G., Morozova, K., Mosibo, O. K., Ramezani, M., & Scampicchio, M. (2018). Biorecovery of antioxidants from apple pomace by supercritical fluid extraction. Journal of Cleaner Production, 186, 253–261.

Galanakis, C. M. (2012). Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends in Food Science & Technology, 26(2), 68–87.

Galanakis, C. M. (2013). Emerging technologies for the production of nutraceuticals from agricultural by-products: a viewpoint of opportunities and challenges. Food and Bioproducts Processing, 91(4), 575–579.

Galanakis, C. M., Tsatalasa, P., Charalambous, Z., & Galanakis, I. M. (2018a). Control of microbial growth in bakery products fortified with polyphenols recovered from olive mill wastewater. Environmental Technology & Innovation, 10, 1–15.

Galanakis, C. M., Tsatalasa, P., Charalambous, Z., & Galanakis, I. M. (2018b). Polyphenols recovered from olive mill wastewater as natural preservatives in extra virgin olive oils and refined olive kernel oils. Environmental Technology & Innovation, 10, 62–70.

Galanakis, C. M., Tsatalasa, P., & Galanakis, I. M. (2018c). Phenols from olive mill wastewater and other natural antioxidants as UV filters in sunscreens. Environmental Technology & Innovation, 9, 160–168.

Ghnimi, S., Budilarto, E., & Kamal-Eldin, A. (2017). The new paradigm for lipid oxidation and insights to microencapsulation of omega-3 fatty acids. Comprehensive Reviews in Food Science and Food Safety, 16(6), 1206–1218.

Haman, N., Romano, A., Asaduzzaman, A., Ferrentino, G., Biasioli, F., & Scampicchio, M. (2017). A microcalorimetry study on the oxidation of linoleic acid and the control of rancidity. Talanta, 164, 407–412.

Haman, N., Ferrentino, G., Imperiale, S., & Scampicchio, M. (2018). Antioxidant and prooxidant activity of spent coffee extracts by isothermal calorimetry. Journal of Thermal Analysis and Calorimetry, 232, 1065–1075.

Hayes, J. E., Allen, P., Brunton, N., O'grady, M. N., & Kerry, J. P. (2011). Phenolic composition and in vitro antioxidant capacity of four commercial phytochemical products: olive leaf extract (Olea europaea L.), lutein, sesamol and ellagic acid. Food Chemistry, 126(3), 948–955.

Kitryte, V., Saduikis, A., & Venskutonis, P. R. (2015). Assessment of antioxidant capacity of brewer’s spent grain and its supercritical carbon dioxide extract as sources of valuable dietary ingredients. Journal of Food Engineering, 167, 18–24.

Klimek, P., Wimmer, R., Mishra, P. K., & Kudela, J. (2017). Utilizing brewer’s-spent-grain in wood-based particleboard manufacturing. Journal of Cleaner Production, 141, 812–817.

Labuza, T. P., & Dugan, L., Jr. (1971). Kinetics of lipid oxidation in foods. Critical Reviews in Food Science and Nutrition, 2, 355–405.

Lee, Y. H., Charles, A. L., Kung, H. F., Ho, C. T., & Huang, T. C. (2010). Extraction of nobiletin and tangeretin from Citrus depressa Hayata by supercritical carbon dioxide with ethanol as modifier. Industrial Crops and Products, 31(1), 59–64.

Lim, G. B., Lee, S. Y., Lee, E. K., Haam, S. J., & Kim, W. S. (2002). Separation of astaxanthin from red yeast Phaffia rhodozyma by supercritical carbon dioxide extraction. Biochemical Engineering Journal, 11(2-3), 181–187.

Lynch, K. M., Steffen, E. J., & Arendt, E. K. (2016). Brewers’ spent grain: a review with an emphasis on food and health. Journal of the Institute of Brewing, 122(4), 553–568.

Mallouchos, A., Lagos, G., & Komaitis, M. (2007). A rapid microwave-assisted derivatization process for the determination of phenolic acids in brewer’s spent grains. Food Chemistry, 102, 606–611.

Materska, M., & Perucka, I. (2005). Antioxidant activity of the main phenolic compounds isolated from hot pepper fruit (Capsicum annuum L.). Journal of Agricultural and Food Chemistry, 53(5), 1750–1756.

Mccarthy, A. L., O'callaghan, Y. C., Piggott, C. O., Fitzgerald, R. J., & O'brien, N. M. (2013). Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: a review. Proceedings of the Nutrition Society, 72(01), 117–125.

Meneses, N. G. T., Martins, S., Teixeira, J. A., & Mussatto, S. I. (2013). Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Separation and Purification Technology, 108, 152–158.

Metcalfe, L. D., Schmitz, A. A., & Pelka, J. R. (1966). Rapid preparation of fatty acid esters from lipids for gas chromatographic analysis. Analytical Chemistry, 38(3), 514–515.

Moreira, M. M., Morais, S., Carvalho, D. O., Barros, A. A., Delerue-Matos, C., & Guido, L. F. (2013). Brewer’s spent grain from different types of malt: evaluation of the antioxidant activity and identification of the major phenolic compounds. Food Research International, 54(1), 382–388.

Murga, R., Ruiz, R., Beltran, S., & Cabezas, J. L. (2000). Extraction of natural complex phenols and tannins from grape seeds by using supercritical mixtures of carbon dioxide and alcohol. Journal of Agricultural and Food Chemistry, 48(8), 3408–3412.

Mussatto, S. I., Dragone, G., & Roberto, I. C. (2006). Brewers’ spent grain: generation, characteristics and potential applications. Journal of Cereal Science, 43(1), 1–14.

Özkal, S. G., Yener, M. E., & Bayındırlı, L. (2005). Mass transfer modeling of apricot kernel oil extraction with supercritical carbon dioxide. The Journal of Supercritical Fluids, 35(2), 119–127.

Pascual-Marti, M. C., Salvador, A., Chafer, A., & Berna, A. (2001). Supercritical fluid extraction of resveratrol from grape skin of Vitis vinifera and determination by HPLC. Talanta, 54(4), 735–740.

Pereira, C. G., & Meireles, M. A. (2010). Supercritical fluid extraction of bioactive compounds: fundamentals, applications and economic perspectives. Food and Bioprocess Technology, 3(3), 340–372.

Roy, B. C., Goto, M., & Hirose, T. (1996). Extraction of ginger oil with supercritical carbon dioxide: experiments and modeling. Industrial and Engineering Chemistry Research, 35(2), 607–612.

Salgin, U., Doker, O., & Calimli, A. (2006). Extraction of sunflower oil with supercritical CO2: experiments and modeling. Journal of Supercritical Fluids, 38(3), 326–331.

Sanal, I. S., Bayraktar, E., Mehmetoglu, U. U., & Calimli, A. (2005). Determination of optimum conditions for SC-(CO2 plus ethanol) extraction of beta-carotene from apricot pomace using response surface methodology. Journal of Supercritical Fluids, 34(3), 331–338.

Singleton, V., & Rossi, J. A. (1965). Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. American Journal of Enology and Viticulture, 16, 144–158.

Sökmen, M., Demir, E., & Alomar, S. Y. (2018). Optimization of sequential supercritical fluid extraction (SFE) of caffeine and catechins from green tea. The Journal of Supercritical Fluids, 133, 171–176.

Spinelli, S., Conte, A., Lecce, L., Padalino, L., & Del Nobile, M. A. (2016). Supercritical carbon dioxide extraction of brewer’s spent grain. Journal of Supercritical Fluids, 107, 69–74.

Taghvaei, M., Jafari, S. M., Assadpoor, E., Nowrouzieh, S., & Alishah, O. (2014). Optimization of microwave-assisted extraction of cottonseed oil and evaluation of its oxidative stability and physicochemical properties. Food Chemistry, 160, 90–97.

Tang, D.-S., Tian, Y.-J., He, Y.-Z., Li, L., Hu, S.-Q., & Li, B. (2010). Optimisation of ultrasonic-assisted protein extraction from brewer’s spent grain. Czech Journal of Food Sciences, 28, 9–17.

Vieira, E., Rocha, M. M., Coelho, E., Pinho, O., Saraiva, J. A., Ferreira, I., et al. (2014). Valuation of brewer’s spent grain using a fully recyclable integrated process for extraction of proteins and arabinoxylans. Industrial Crops and Products, 52, 136–143.

Funding

The authors received financial support from the Province of Bolzano (Landesregierung mittels Beschluss Nr. 1472, 07.10.2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferrentino, G., Ndayishimiye, J., Haman, N. et al. Functional Activity of Oils from Brewer’s Spent Grain Extracted by Supercritical Carbon Dioxide. Food Bioprocess Technol 12, 789–798 (2019). https://doi.org/10.1007/s11947-019-02249-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-019-02249-3