Abstract

Fruit and vegetables are much appreciated by consumers due to their nutritional values and health-promoting compounds. However, different factors affect the postharvest life of such products, in where ethylene is a major one, even at low concentrations, besides temperature and relative humidity. Therefore, high attention has been focused on the development of effective tools to remove ethylene from the atmosphere surrounding these products during storage or in transit. Potassium permanganate scrubbers are one of the most used technologies to remove ethylene from horticultural products. To facilitate and improve the oxidation process, potassium permanganate has been supported onto inert solid materials of a small particle size. In this review, we aim to provide an outline of the most common materials used as potassium permanganate supports on postharvest treatment and their respective effects on quality aspects of various fresh produce during postharvest life. Vermiculite, activated alumina, zeolite, silica gel, activated carbon and clays are the most popular materials that have been used as a support of potassium permanganate-based ethylene scrubbers. The literature suggests that potassium permanganate supported onto silica gel or zeolite seems to be a promising tool to maintain fruit and vegetables quality attributes for long-term storage. Although vermiculite and activated alumina are the most commonly used materials to reach this goal, not promising results have been reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fresh fruit and vegetables (F&V) consumption has been associated with numerous health benefits as shown the existing related epidemiological studies which have been recently reviewed (van Berleere and Dauchet 2017). Such health benefits have been specifically linked to the F&V phytochemicals (Rodriguez-Casado 2016). Accordingly, F&V are considered as an important food group for a well-balanced diet (Sivakumar and Bautista-Baños 2014). In that scenario, F&V consumption has steadily augmented due to the increasing consumer profile interested in natural food products with high health-promoting properties. Nevertheless, the product selection by this consumer is primarily based on visual appearance attributes, such as good colour, perfect shape and size, together with taste, aroma and texture. However, F&V are perishable products and tend to lose their attractive appearance and nutritional value in a short time. It is important to remember that after harvest, F&V quality can only be maintained, not improved (Mahajan et al. 2017). It has been estimated that roughly one third of food produced for human consumption is lost or wasted globally, corresponding 50% of such food losses to F&V (Blanke 2014; FAO 2011).

Postharvest quality of F&V is affected by several factors, e.g. physical damage, transportation, etc., being storage management a key factor to provide a product with excellent quality, and subsequently long shelf life, to the consumer. Storage management should take into account respiration rate, ethylene (C2H4) production and sensitivity of the product to several critical parameters such as storage temperature and determined gas concentrations (oxygen, carbon dioxide and C2H4), while high relative humidity (RH) rates should be maintained with the aim of extending F&V shelf life (Kader 2005).

C2H4 concentration in product atmospheres is an important factor to be controlled since it often causes a faster degradation of fresh produce after harvesting, especially during their transportation and storage, leading to high product losses (Pathak et al. 2017). Warton et al. (2000) measured the C2H4 level in the atmosphere of fresh commodities storage areas, founding C2H4 levels of 0.017–0.035 μL kg−1 in supermarket stores and 0.06 μL kg−1 in wholesale markets and distribution centres. Based on the recorded levels, the latter authors indicated that the shelf life of C2H4-sensitive commodities may be reduced by 10–30% during distribution.

The main sources of C2H4 in horticultural produce environments are climacteric fruit (Pathak et al. 2017). Nevertheless, it should be considered that besides the C2H4 production of F&V tissues, there are anthropogenic and other biogenic sources of C2H4 (e.g. industrial pollution smoke, motor vehicle exhaust gases and that produced by microbial activity) that can affect the produce along the food chain (Morgott 2015). Therefore, high attention has been focused on the development of effective postharvest tools to remove C2H4 from the atmosphere surrounding fresh produce.

C2H4 can be removed from the environment through scavenging technologies by absorption, adsorption and/or oxidation mechanisms to preserve a good quality of fresh F&V for longer periods (Chopra et al. 2017). In this sense, C2H4 scavengers based on potassium permanganate (KMnO4) are the best known and the most widely used technology in F&V industry (Gaikwad and Lee 2017). KMnO4 is an eco-friendly and powerful agent that oxidises C2H4 to CO2 and H2O (Dash et al. 2009; Singh and Lee 2001). KMnO4-based scrubbers are considered as a low-cost technology with easy application (Dash et al. 2009). They can be used in packaging (as active packaging), storage facilities, transport vehicles and domestic refrigerators (Keller et al. 2013).

Since C2H4 is a gas and natural convection and diffusion are the only driving forces involved, KMnO4 is usually supported onto a porous inert material with a large surface area exposed with the aim to facilitate interaction between C2H4 and KMnO4 (Wills and Warton 2004). The materials used to support KMnO4 are diverse. Therefore, we aim to provide in this review an outline of the most common materials used as KMnO4 supports and their respective effects on various fresh produce quality during storage. Physical characteristics such as pore volume, pore size distribution and surface area of the materials are briefly described in this review.

Role of Ethylene on Postharvest Life of Fresh Fruit and Vegetables

C2H4 is an important plant hormone regulating various essential processes during plant growth and development, including ripening of F&V, like for example seed germination, cell elongation, flower development, senescence and defence against pathogens and response to external stress factors, among others (Abeles et al. 1992; Saltveit 1999). Nevertheless, C2H4 presence around F&V is undesirable since it negatively affects their postharvest life depending these undesirable effects of the product type.

Based on the respiration behaviour and C2H4 production rates during the ripening process, fruit has been classified into climacteric and non-climacteric (Cherian et al. 2014; Paul et al. 2012). The first ones are those F&V characterised by a peak in both respiration and C2H4 production during ripening (such as apple, mango, papaya, avocado, kiwifruit, banana, pear, blueberry, broccoli, among others), whereas non-climacteric fruit do not exhibit that dramatic change in respiration, remaining C2H4 production at basal levels (e.g. citrus fruits, pineapple, melon, peas, pepper, cacao, cucumber, among others) (Paul et al. 2012). C2H4 concentrations ≤ 0.1–0.2 μL kg−1 h−1 are registered in climacteric products during the pre-climacteric period, increasing at least 10-fold during ripening, while non-climacteric fruits usually do not produce more than 1 μL kg−1 h−1 at 20 °C (Kader 1980; Knee et al. 1985; Martínez-Romero et al. 2007; Saltveit 1999). In climacteric fruit, C2H4 accelerates ripening causing excessive fruit softening, colour changes, sugar content alteration, texture changes and volatile aromas synthesis. Meanwhile, in non-climacteric fruit, C2H4 stimulates senescence, often associated with yellowing of green tissues by promoting chlorophyll degradation and hastens to toughen and wilting (Barry and Giovannoni 2007; Lelievre et al. 1997; Saltveit 1999). Moreover, in both climacteric and non-climacteric fruit, C2H4 can induce chilling injuries and physiological disorders (Wills 2015).

In addition, C2H4 may increase pathogen susceptibility by inhibiting the formation of antifungal compounds, and in some cases, it can even stimulate the growth of fungi such as Botrytis cinerea on strawberries and Penicillium italicum on oranges (Abeles et al. 1992; Kader 2003). C2H4 concentrations higher than 0.1 μL L−1 strongly affect storage life of fresh produce (Wills 2015). In that sense, a C2H4 concentration between 0.1 and 0.5 μL L−1 has been proposed as the threshold level to initiate ripening of banana, avocado, honeydew melon and pear, while 0.03 μL L−1 has been assigned to kiwifruit (Blanke 2014; Knee et al. 1985). C2H4 concentrations higher than 4 μL L−1 at 20 °C has led to 30% reduction of storage life of peach, avocado and tomato, whereas 0.029, 0.035, 0.043, 0.55, 0.113, 0.65 and 0.89 μL L−1 were enough for banana, strawberry, lettuce, Chinese cabbage, kiwifruit, custard apple and mango, respectively (Warton et al. 2000; Wills et al. 2001). Therefore, it is important to remove C2H4 from fresh produce packaging and storage areas to avoid its negative effects.

The Importance of Support Materials in KMnO4-Based Scrubbers

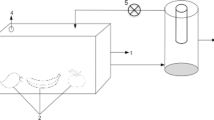

KMnO4 oxidises C2H4 to CO2 and H2O (Fig. 1), releasing manganese dioxide (MnO2) and potassium hydroxide (KOH). The general stoichiometric oxidation reaction is:

As mentioned earlier, in order to facilitate the redox process, it has been implemented adsorption of KMnO4 onto a porous inert material with a high surface area such as clays, silica (SiO2) gel, zeolites, alumina (Al2O3), vermiculite and activated carbon (Fig. 2, Table 1). Furthermore, some of these materials can adsorb C2H4 creating an adsorption–oxidation system, where the support material adsorbs C2H4 and permanganate (MnO4−) oxidises it (Pathak et al. 2017).

Currently, it is well proven that KMnO4-based C2H4 scrubbers selectivity and reactivity can be improved by using small particles which makes available a higher contact area (Shaabani et al. 2005; Spricigo et al. 2017). However, besides the role played by the surface area size, the success of a scrubber also depends on the material type and other physical characteristics such as shape and C2H4 adsorption ability. For example, it has been reported that KMnO4-based C2H4 scrubbers supported onto Al2O3 nanoparticles have higher C2H4 removal rate than scrubbers based on SiO2 nanoparticles (Spricigo et al. 2017). Bhattacharjee and Dhua (2017) reported better results in pointed gourd fruit (stored in polypropylene (PP) bags at 29–33 °C, 68–73% RH) when C2H4 scrubbers of KMnO4 supported onto celite were used instead of KMnO4-based scrubbers supported onto SiO2 gel (4–8 g scrubber kg−1 fruit). García et al. (2012) also evaluated the effect of different support materials (montmorillonite, kaolinite, vermiculite and zeolite) in KMnO4 scrubbers (17 g scrubber kg−1 fruit) on the postharvest quality of baby banana (18 °C, 70–80% RH). The best results were obtained when vermiculite was used, while the worst results were obtained with kaolinite. Attending to support material shape, a study comparing C2H4 adsorption capacity of granular, powered and fibred carbon activated was carried out by Martínez-Romero et al. (2007). The best performance was obtained with the granular shape (over 80%), followed by powered (over 70%) and finally fibred shape (over 40%).

In addition, many other parameters also play a key role in the performance of a scrubber product, e.g. temperature and RH (Gaikwad and Lee 2017; Keller et al. 2013). Spricigo et al. (2017) carried out a study about the influence of particle size (micro- versus nanoparticles), KMnO4 content (2.5, 5 and 10% KMnO4) and RH (45, 60, 75 and 90%) on the C2H4 removal rate of 0.3 g KMnO4-based C2H4 scrubbers supported onto two different materials: SiO2 and Al2O3 at 25 °C, under 1 h of exposure to 7.48 mL L−1 C2H4. The latter authors reported that as the particle size of the scrubber decreases and the KMnO4 concentration increases, C2H4 removal rate become higher, regardless of the used material. Both nano- and micrometric SiO2particle sizes showed the best performance with 10% KMnO4 under 75% RH, resulting in 100 and 73% C2H4 removal, respectively. However, there was observed a reduced C2H4 removal rate under 60 and 90% RH for both particle sizes. In the case of Al2O3, the effect of particle size reduction on C2H4 removal was more remarkable. Microparticles did not overcome 50% C2H4 removal rate, while 45% was the lower C2H4 removal rate of nanoparticles being C2H4 removal efficiency increased as the RH and KMnO4 increased.

As observed, the intrinsic characteristics of the support material highly influence the C2H4 removal efficiency. Therefore, it is crucial to review the published studies, which addressed this area.

Materials Used as KMnO4 Support on C2H4 Scrubbers

Metal Oxides

Silica Gel

The SiO2 gel is an amorphous material form of SiO2 with mesopores (pores larger than 20 Å). SiO2 is a polymer of silicic acid with a surface rich in hydroxyl groups, or silanols (Si–O–H), which participate in adsorption as well as in chemical modifications (Jal et al. 2004; Yang 2003). The SiO2 gel can be classified into two common types: low-density and regular-density SiO2 gels. The first one has a surface area of 300–350 m2 g−1 and an average pore diameter of 100–150 Å, whereas the regular density type has a surface area 750–850 m2 g−1 and a pore diameter 22–26 Å, but some materials can have higher surface areas (above 1000 m2 g−1) and high pore volume (approximately 1 cm3 g−1) (Sneddon et al. 2014; Yang 2013). Furthermore, SiO2 is a non-toxic material, and it is generally recognised as safe (GRAS) product by US Food and Drug Administration (FDA), with the GRAS Notice (GRN) No. 298 and the Codex SNI No. 551 (FDA 2009; FAO 2015). Spricigo et al. (2017) reported that 0.3 g SiO2 nanoparticles with a surface area of 549.6 m2 g−1 and an average pore size of 28.6 Å could reach a C2H4 adsorption rate of 34 ± 8% after 1 h of exposure to 7.48 mL L−1 C2H4 at 25 °C and 90% RH. SiO2 possesses the advantages of being low-cost production, great accessibility, and has an excellent thermal and chemical stability, and high specific surface area (up to 800 m2 g−1) (Jal et al. 2004; Polshettiwar et al. 2009).

In a recent study, it was reported that KMnO4 embedded onto SiO2 crystals is a good tool to slow down the ripening and senescence process of ‘Kajli’ pointed gourd fruit (Bhattacharjee and Dhua 2017). Fruit packed together with C2H4 scrubbers of KMnO4-SiO2 (8 g kg−1 of fruit) in PP bags at 29–33 °C (Table 2) showed lesser changes in sensory properties and lowered chlorophyll content decrease compared to fruit without C2H4 scrubbers. A significant reduction in weight loss and a decrease in the spoilage percent, as well as a higher disease reduction index was also observed. Singh and Giri (2014) demonstrated that KMnO4 embedded onto SiO2 crystals could prolong shelf life of guava fruit (up to 7 weeks), under active packaging using low-density polyethylene (LDPE) film at 8 °C (Table 2). With the use of KMnO4-based C2H4 scrubbers supported onto SiO2, minor changes in fruit firmness, total soluble solids content (SSC), titratable acidity (TA) and colour were obtained. Furthermore, a significant reduction in decay was reported. However, the used of SiO2 as support is not popular as observed in Tables 1 and 2 being attributed to its low C2H4 removal capacity. Eastwell et al. (1978) evaluated the C2H4 removal capacity of 20% (w/w) KMnO4 on the SiO2 gel with 5% (w/w) fuming sulphuric acid at 22 °C. After 10, 30 and 60 min of C2H4 flushing (0.02 μL L−1 C2H4 at a flow rate of 100 mL min−1), 75, 80 and 80% of residual C2H4 was obtained, respectively (percentage based on residual C2H4 of control).

Activated Alumina

Activated Al2O3 is a semi-crystalline inorganic material composed mainly of aluminium oxide (Mallakpour and Khadema 2015). The raw material used, and the preparation and activation methods determine the physicochemical and textural properties of activated Al2O3 (Mallakpour and Khadema 2015). Activated Al2O3 has a surface area from 50 to 500 m2 g−1 and pore size ranging from 60 to 150 Å (Leyva-Ramos et al. 2008; Srivastava and Eames 1998). Nevertheless, the surface composition and pore structure of activated alumina can be modified, for example, by acid treatment (Yang 2003).

Alumina is often used as a desiccant similarly to SiO2, but it is also used as a C2H4 scrubber. In fact, most commercial KMnO4-based C2H4 scrubbers are made of activated alumina as KMnO4 support (Table 1), which can be attributed to the physical and mechanical properties of the alumina particles. Alumina possesses high adsorption capacity and thermal stability, being inexpensive and non-toxic (Mallakpour and Khadema 2015). Spricigo et al. (2017) reported that 0.3 g Al2O3 nanoparticles (93.59 m2 g−1 surface area and 20.6 Å average pore size) reached a C2H4 removal rate of 21% after 1 h when they were exposed to 7.48 mL L−1 C2H4 at 25 °C and 75% RH, but when these nanoparticles were impregnated with 5 and 10% KMnO4, they showed a C2H4 removal rate of 82 and 100%, respectively. In another study, it was reported a 90% C2H4 removal after 2.5 h when 1 g Al2O3 beads containing 4% KMnO4 were exposed to 20 μL L−1 C2H4 at 20 °C (60–70% RH) (Wills and Warton 2004). The high differences between the C2H4 removal rate of the scrubbers described in the above-mentioned studies can be attributed to the particle size differences since the last work stated that the activated alumina beads are 5 mm particle diameter before the modification with KMnO4.

There are not many reports about the effect of KMnO4-based C2H4 scrubbers with Al2O3 as KMnO4 support on postharvest life of F&V to the best of our knowledge (Table 2). However, the study carried out by Wills and Kim (1995) showed good results when packed ‘Torrey’ strawberries (250 g) in punnets overwrapped with polyethylene (PE) film and sachets containing activated Al2O3 and vermiculite impregnated with KMnO4 (10 g). They found lower C2H4 and CO2 levels in the punnets with sachets, and a longer fruit storage life. Furthermore, Shorter et al. (1992) reported lower C2H4 and CO2 levels inside packages of Granny Smith apple fruit stored in PE bags (0.5 °C, 2 weeks) with KMnO4-alumina pellets scrubbers. At the end of storage, minor physiological disorders (bitter pit and superficial scald) were observed in apples stored with the mentioned C2H4 scrubber.

Layer Silicates and Zeolites

Clays

Clay minerals are hydrous layered aluminosilicates composed of two layers: tetrahedral and octahedral layers (Bhattacharyya and Gupta 2008; Varma 2002). Tetrahedral layers consist of sheets of Si4+, but Al3+ is also common, whereas the octahedral layers usually consist of Mg2+ or Al3+, although Fe2+, Ni2+, Li+, Fe3+, Cr3+ may also be present.

Clays are characterised by high surface area, high sorption, swelling, and intercalation and cation-exchange with other ions without affecting the structure (Bhattacharyya and Gupta 2008). Moreover, they are eco-friendly, non-toxic, economical and recyclable. Therefore, it is useful to modified clays through ion exchange procedures with other positive charged atoms or organic ions (Avalos et al. 2008). In fact, clays have a key role in the environment because they act as natural scavengers of contaminants by adsorption or ion-exchange processes (Yagub et al. 2014).

Smectite group is a kind 2:1 clay with an interlayer spacing around 10 and 15 Å, where montmorillonite (MMT) is the most common member of this kind of clay (Varma 2002). MMT has an interlayer spacing of about 0.9 to 1.2 nm and great cation exchange capacity (Kaur and Kishore 2012). MMT has been used as a KMnO4 support, but its applications are mainly focused on adsorption of heavy metals, oxidation of alcohols and alkylarenes, among other organic compounds (Abollino et al. 2003; Sen et al. 2012; Shaabani et al. 2004; Shaabani et al. 2002). The KMnO4-MMT implementation for the alkenes oxidation has been only reported by Choudary et al. (1991). Nevertheless, the application of KMnO4-MMT to extend postharvest life of fresh produce has not been reported, although it should be noted that some studies do not indicate the type of clay used (Table 2). For example, Santosa and Widodo (2010) evaluated the effect of KMnO4-based C2H4 scrubber using a clay as KMnO4 support on the quality attributes of banana. They observed that 30 g of scrubber per 0.42–0.67 kg of fruit was enough to delay peel yellowing, reduced weight loss and firmness loss, and minimized the SSC and acid content increase up to 18 days at 27–30 °C. In another study carried out by Illeperuma et al. (2000), it was reported that the green life of bananas packaged under modified atmosphere with KMnO4 supported on clay bricks was extended up to 20 days at 25 °C in contrast to 4 days for fruit without C2H4 scavenger. Fruit showed little changes in firmness and SSC, lower C2H4 and carbon dioxide contents, and higher oxygen levels compared with fruit stored without C2H4 scavenger.

Vermiculite

Vermiculite is a 2:1 layered silicate composed of two tetrahedral sheets with a [T4O10]4− composition (where T can be Si4+, Al3+ or Fe3+), and an octahedral sheet formed by two planes of packed O2− and octahedral OH− anions with Mg2+ or Al3+ as central cations (Valášková and Martynkova 2012).

The interlayer space of vermiculite is between 1.49 and 1.53 Å, and the thickness of the structural unit (2:1 layer and interlayer space) is approximately 1.4 nm, depending on the interlayer cations and interlamellar water content (Valášková and Martynkova 2012). The vermiculite specific surface area varies from 1.4 to 720 m2 g−1 (Maqueda et al. 2007; Temuujin et al. 2003), but the highest specific surface area values can be achieved when the material is subjected to an acid or mechanical treatment, or both (Reinholdt et al. 2013). It has a cation exchange capacity of 12.0–15.0 mEq kg−1 (Malandrino et al. 2006).

The effect of vermiculite impregnated with KMnO4 on the quality parameters of produce has been widely studied (Table 2), although not promising results have been reported. For example, sets of three papaya fruit were wrapped in low-density PE films with sachets of KMnO4-based C2H4 scrubbers supported onto vermiculite (one sachet containing 1.5 g scrubber material) at 10 °C (90% RH). After 25 days, fruit stored together with C2H4 scrubbers showed lower CO2 production, less fresh matter loss, reduced pulp consistency loss and less SSC increase in comparison with fruit without a scrubber, but peel colour index and electrolyte leakage did not show a statistical difference between samples (Silva et al. 2009). The effect of KMnO4 supported on vermiculite (0.375 g of KMnO4 per kg of fruit) was studied on different quality parameters (firmness, appearance, colour, TA, SSC, weight, among others) of sapodilla (packaged in a tray and covered with PVC film) stored for 15 days at 25 °C (54% RH). It was only observed beneficial effects on vitamin C content and fruit firmness (throughout 5 days), but fruit showed similar softening to control fruit at the end of storage (fruit packaged without C2H4 scrubbers) (de Souza et al. 2017). Silva et al. (2015) reported higher vitamin C content and less chlorophyll loss in maxixe fruit (packed in PE trays with PVC film) with KMnO4-vermiculite sachets stored at 10 °C (90% RH) after 10 days, but final weight loss, carbohydrates content, fruit decay percent and chilling injury traits were similar to control fruit.

Zeolite

Zeolites are hydrophilic crystalline aluminosilicates with a negative framework charges that are balanced with alkali or alkali earth ions (Patdhanagul et al. 2012). Zeolites can be natural, or they can be synthesised in order to develop new materials with larger pores or channels and more catalytic sites. A total of 234 zeolite framework types have been approved by the Structure Commission of the International Zeolite Association until today (IZA-SC 2017). It was considered that zeolite Y had the highest surface area (904 m2 g−1) until 2004. After that, the surface area was enhanced with the introduction of zeolite-type metal-organic framework materials reaching surface areas up to 3000 m2 g−1 (Chae et al. 2004). The pore size of zeolites is usually ranging from 3 to 12 Å, with a manipulable size (Sneddon et al. 2014). Structural and adsorption (selectivity and sorption rates) properties of natural zeolites can be modified by fixing the type, number and location of exchangeable cations (Erdoğan 2013).

Zeolite minerals have been widely studied for their ability in adsorption of many adsorbates, including C2H4 (Erdoğan 2013; Sneddon et al. 2014). A lot of studies are focused on the C2H4 removal capacity that can be achieved using modified zeolites. In this way, Erdoğan et al. (2008) evaluated the C2H4 removal capacity of natural clinoptilolite and the modified forms with Na+, K+, and Ca+2 ions. Among all the modified zeolites, it was found that the K+ form had the highest C2H4 adsorption capacity (0.719 mmol g−1) at 20 °C, followed by the Na+ (0.069 mmol g−1) and Ca2+ forms (0.226 mmol g−1). The latter finding may be attributed to the electronegativity value and atomic diameter of potassium. However, the highest C2H4 adsorption was obtained by the unmodified form (0.956 mmol g−1). The experiment was also performed with another zeolite from a different source being observed the same behaviour. In another study, Sue-aok et al. (2010) reported that the C2H4 adsorption capacity of the K+ modified form of NaY zeolite was also higher than that shown by Rb+ and Cs+ modified forms. The C2H4 adsorption on K+ modified NaY zeolite was 102.5 cm3 g−1 at 0 °C, 98.5 cm3 g−1 on Rb+-NaY zeolite and 90.15 on Cs+-NaY zeolite. Erdoğan (2013) found that it is possible to improve the C2H4 adsorption capacity of a clinoptilolite from 0.619 to 1.219 mmol g−1 (at 20 °C) by replacing the exchangeable cations with H+ ions using 0.5 M HCl. Nevertheless, higher HCl concentration may trigger crystalline loss and Al ions reduction. Zeolites have been widely used as material support in KMnO4-based C2H4 scrubbers for active packaging for fresh F&V due to their adsorption properties, high surface area, pore structures, cation exchange capacity and molecular sieve ability, as well as to their low cost and availability (Martínez-Romero et al. 2007; Yagub et al. 2014). Some products containing zeolite are available in the market for C2H4 control since zeolites have great potential to remove C2H4. (Table 1).

The effect of KMnO4-coated zeolite particles on the quality characteristics of fresh fruit was evaluated in different studies (Table 2). Emadpour et al. (2015) reported that it was possible to increase peaches’ and nectarines’ shelf lives (at 0 °C) preventing weight and firmness losses, as well as spoilage, using KMnO4-coated nano-zeolites filter in the storage chambers. It was found lower weight loss, higher texture firmness and longer (≈ 20 days) iceberg and Chinese lettuces shelf lives when using KMnO4 and zeolite-based nano-molecular filters in the storage chambers (Kalaj et al. 2008). Similar results were found when this filter system was evaluated on apricot (Emadpour et al. 2009b) and black sweet cherry (Emadpour et al. 2009a). In another study, Golden Delicious apples were wrapped in craft paper together with KMnO4-coated nano-zeolite sachets and then stored at 0 °C (90% RH) for 5 months (Sardabi et al. 2014). The latter authors observed lower pH increase/TA decrease, firmness loss and Hue angle changes when apples were stored with C2H4 scrubbers comparing to fruit without the scrubbers.

Activated Carbon

Activated carbon (AC) materials are non-crystalline porous forms of carbon obtained by pyrolysis of carbonaceous materials (Ben-Mansour et al. 2016; Sneddon et al. 2014). The activation step of carbon is carried out to create more pores and change their volume, form and size, and it can be performed by physical and chemical methods (Yang 2003). Most commercial grades of AC usually possess a pore volume between 10 to 25 Å in diameter and a surface area ranging from 300 to 4000 m2 g−1, but some of them can reach surface areas up to 5000 m2 g−1 (Martínez-Romero et al. 2007; Yang 2003).

AC can be granular, powdered or fibre, being the most preferred the granular form due to its easier regeneration and versatility. In addition, it has been reported that the best C2H4 adsorption is performed by granular form (over 80%) in comparison with powder (over 70%) and fibre forms (over 40%) (Martínez-Romero et al. 2007). Bailén et al. (2006) evaluated the effect of modified atmosphere packaging (using 20 μm thickness PP bags) with sachets containing 5 g granular AC (having a specific surface area of 226 m2 g−1) on ‘Beef’ tomato quality during postharvest storage at 8 °C (90% RH). The authors observed that granular AC delayed the changes in colour, firmness and weight in tomato, while significantly reduced the C2H4 levels inside packages up to 2 weeks (Bailén et al. 2006). AC can be combined or impregnated with other compounds such as KMnO4 to increase its effectiveness. Nevertheless, there are scarce works about the C2H4 removal capacity of AC-KMnO4 although its use as C2H4 scrubber is widely mentioned in the literature (Brody et al. 2008; Gavara et al. 2009; Sen et al. 2012). AC shows advantages such as hydrophobic behaviour, high surface area, lightweight while its production is relatively cheap (Ben-Mansour et al. 2016). Nevertheless, the KMnO4-AC combination results in active MnO2, which is an insoluble and powerful oxidising agent due to a redox reaction (Ishii et al. 1998).

Consumer Acceptance and Safety Aspects

The KMnO4-based scavengers can be used as part of a controlled or modified atmosphere system to remove the accumulated C2H4 inside a closed atmosphere (Keller et al. 2013), being then known as an active packaging. Based on Wyrwa and Barska (2017), an active packaging is a system that interacts with the packed product, actively changes the conditions of the packed food (internal atmosphere) by scavengers or emitters and prolongs its shelf life while maintaining its quality. Although active packaging can offer marketable solutions to the food industry, the market offer of such system is still poor. Accordingly, the share of advanced packaging represents about 5% of the total packaging market value, of which 35% corresponds to active packaging, and, especifically, the market share of C2H4 scavengers represents 3% of the global market value of gas removal packaging (Gaikwad and Lee 2017; Wyrwa and Barska 2017). The latter low presence of active packaging in the market may be mainly be due to consumer acceptance, since consumers have a key role on food packaging industry by their purchasing choice (Ghaani et al. 2016; Werner et al.2017).

Consumer acceptance of active packaging can be influenced by health and environmental safety concerns (risk perception) and mistrust in new technologies, which is due to a lack of information about technologies involved (Eiser et al. 2002).

Attending the concerns about possible health damage that could be caused by KMnO4, KMnO4-based scavengers are never used in direct food contact (Dainelli et al. 2008; Wyrwa and Barska 2017). KMnO4-based scrubbers are available in the form of sachets, tube filters, blankets, labels or films, with the most widely used form being sachets because they are suitable for individual packaging (Janjarasskul and Suppakul 2016) and easy to apply. Nevertheless, it is also difficult to deal with consumer perception about the presence of a non-edible artefact together with the food. According to Aday and Yener (2015), consumers do not want to see sachets or anything else apart from the desired food inside the packaging due to fear of swallowing the device and to the risk of its accidental rupture, contamination of the packaged food and ingestion of the content. Therefore, this issue is still a challenge with a constant search for solutions that allow scavengers to be incorporated into the packaging without the negative perception of the consumer.

Consumers must be correctly informed about novel technologies and the active products should be adequately labelled to change conventional consumers’ perception gaining their trust. The packaging manufacturer must provide active substances list together with chemistry, environmental and toxicological data (Werner et al.2017). In the USA, the FDA regulates food packaging and food ingredients by the Federal Food, Drug and Cosmetic Act (FFDCA), which is codified in the Title 21 of the United States Code (Chapter 9) (OLRC 2017). Meanwhile, in the European Union, conventional and active/intelligent materials or other articles intended to come into contact with food are regulated by the European Parliament Council (EC) No. 1935/2004 and the Commission Regulation (EC) No. 450/2009 (European Parliament 2004, 2009).

Toxicology and Environmental Aspects

KMnO4 has been widely used in postharvest treatment as a disinfectant and auxiliary agent in the degradation of pesticide and clinically as antiseptic and antifungal agent (Osman et al. 2014; Soriano et al. 2000; WHO 2017). The KMnO4 may be lethal for humans at high doses of approximately 142.9 mg kg−1 person. Nevertheless, KMnO4 intoxication is not common being necessary approximately 10 g of KMnO4 to produce lethal intoxication in a person of 70 kg according to the latter lethal dose (Cevik et al. 2012). For example, using KMnO4 contents of treated banana and cantaloupe melon (Table 2), and according to the KMnO4 lethal dose, a person (70 kg) would need to consume approximately 2.5 kg of treated banana or 3.4 kg of treated melon to become lethally intoxicated as described by Santosa and Widodo (2010) and Sá et al. (2008). Nevertheless, the latter product quantities may depend of course of the KMnO4 content of the used scrubbers being used commonly between 4 and 6% of KMnO4 within the commercial sachets. For example, de Souza et al. (2017) used 0.375 g of scrubber per kg of sapodilla and Brackmann et al. (2006) used 1.5 g per kg of apple, while Wills and Kim (1995) applied 20 g of scrubber per kilogram of strawberry. Furthermore, it should be noted that in case of contamination of the packed produce with KMnO4, this agent can easily be removed by washing the produce since KMnO4 is soluble in water (6.4 g per 100 mL−1 at 20 °C) (NCBI 2018).

Attending to environmental concerns, KMnO4 is an eco-friendly powerful oxidising agent in many organic and inorganic redox reactions that has also gained importance in green chemistry (Dash et al. 2009; Singh and Lee 2001). KMnO4 is preferred to be used as a ‘green’ oxidation reagent since it was noted that manganese dioxide (MnO2), a co-product formed by MnO4− reduction, can be recycled to regenerate MnO4− (Singh and Lee 2001) and both MnO2 and KOH, another co-product, can be used as fertilisers (Keller et al. 2013). In addition, it is worth mentioning that KMnO4 has been largely used in environmental applications to neutralise organic and nuclear pollutants such as trichloroethylene, pesticides, alkaloid toxins and ethylenediaminetetraacetic acid, among others (Dash et al. 2009).

Conclusions

C2H4 can induce negative changes on postharvest quality of F&V sensitive to this gas, mainly undesirable sensory quality due to yellowing of green vegetables, overly soft and mealy fruit, browning and bitter taste including shelf life reduction. Scrubbers with C2H4 removal capacity allow reducing weight loss of F&V while firmness and appearance can be preserved for a longer time. Then, postharvest losses due to rapid produce deterioration may be highly reduced depending on the selected support material in KMnO4 scrubbers providing then a product with excellent quality to consumers. Vermiculite and activated alumina are the most commonly used materials to reach this goal, being activated alumina the most used in commercial KMnO4-based C2H4 scrubbers. However, based on the information described above, scrubbers using SiO2 gel or zeolite as KMnO4 supports seem to be a promising tool to slow down the ripening process and prolong shelf life of F&V. Although vermiculite impregnated with KMnO4 has been widely studied, not promising results have been founded. More studies using activated Al2O3 and activated carbon are needed. In general, the combination of nano-sized materials with C2H4 oxidant agents can be considered as an ideal approach for C2H4 removal and preservation of quality characteristics of F&V under controlled or modified atmospheres.

References

Abeles, F., Morgan, P., & Saltveit Jr., M. (1992). Ethylene in plant biology (2nd ed.). New York: Academic Press.

Abollino, O., Aceto, M., Mal`andrino, M., Sarzanini, C., & Mentasti, E. (2003). Adsorption of heavy metals on Na-montmorillonite. Effect of pH and organic substances. Water Research, 37(7), 1619–1627. https://doi.org/10.1016/S0043-1354(02)00524-9.

Aday, M. S., & Yener, U. (2015). Assessing consumers’ adoption of active and intelligent packaging. British Food Journal, 117(1), 157–177. https://doi.org/10.1108/BFJ-07-2013-0191.

AgraCo Technologies International, LLC. (2014). Case studies and resources for produce saver sachets. Agraconew. http://www.agraconew.com/products/produce-saver/case-studies-resources/. Accessed 12 September 2017.

Avalos, F., Ortiz, J. C., Zitzumbo, R., López-Manchado, M. A., Verdejo, R., & Arroyo, M. (2008). Effect of montmorillonite intercalant structure on the cure parameters of natural rubber. European Polymer Journal, 44(10), 3108–3115. https://doi.org/10.1016/j.eurpolymj.2008.07.020.

Bailén, G., Guillén, F., Castillo, S., Serrano, M., Valero, D., & Martínez-Romero, D. (2006). Use of activated carbon inside modified atmosphere packages to maintain tomato fruit quality during cold storage. Journal of Agricultural and Food Chemistry, 54(6), 2229–2235. https://doi.org/10.1021/jf0528761.

Barry, C., & Giovannoni, J. (2007). Ethylene and fruit ripening. Journal of Plant Growth Regulation, 26(2), 143–159. https://doi.org/10.1007/s00344-007-9002-y.

Ben-Mansour, R., Habib, M. A., Bamidele, O. E., Basha, M., Qasem, N. A. A., Peedikakkal, A., Laoui, T., & Ali, M. (2016). Carbon capture by physical adsorption: materials, experimental investigations and numerical modeling and simulations—a review. Applied Energy, 161, 225–255. https://doi.org/10.1016/j.apenergy.2015.10.011.

Bhattacharjee, D., & Dhua, R. (2017). Ethylene absorbents improve the shelf life of pointed gourd (Trichosanthes dioica Roxb.) fruits. International Journal of Pure & Applied Bioscience, 5(1), 64–71. https://doi.org/10.18782/2320-7051.2450.

Bhattacharyya, K. G., & Gupta, S. S. (2008). Adsorption of a few heavy metals on natural and modified kaolinite and montmorillonite: a review. Advances in Colloid and Interface Science, 140(2), 114–131. https://doi.org/10.1016/j.cis.2007.12.008.

Bioconservación. (2015). Bi-On® R12. Subsoleservicios. http://www.subsoleservicios.cl/index.php/es/filtracion-via-seca-de-gases-toxicos-corrosivos-olores-y-biogas/familia-peroxidos-con-r-12/item/download/120_504dec9f0ad0795e4be8073757f3fb86. Accessed 12 September 2017.

Blanke, M. M. (2014). Reducing ethylene levels along the food supply chain: a key to reducing food waste? Journal of the Science of Food and Agriculture, 94(12), 2357–2361. https://doi.org/10.1002/jsfa.6660.

Brackmann, A., Giehl, R., Freitas, S., Eisermann, A., & Mello, A. (2006). Uso de filmes de polietileno e absorção de etileno para o transporte refrigerado de maçã “Gala”. Semina: Ciências Agrárias, 27(3), 423–428.

Brody, A. L., Bugusu, B., Han, J. H., Sand, C. K., & McHugh, T. H. (2008). Scientific status summary. Innovative food packaging solutions. Journal of Food Science, 73(8), R107–R116. https://doi.org/10.1111/j.1750-3841.2008.00933.x.

Bry-Air (Asia), Pvt. Ltd. (2011). Technical specification of BRYSORBTM chemical media. BryAir. https://www.bryair.com/wp-content/uploads/2017/07/Technical-specification-of-GPF-media-1.pdf. Accessed 13 September 2017.

Cevik, S. E., Yesil, O., Ozturk, T. C., & Guneysel, O. (2012). Potassium permanganate ingestion as a suicide attempt. Clinics and Practice, 2(2), 76–77. https://doi.org/10.4081/cp.2012.e32.

Chae, H. K., Siberio-Perez, D. Y., Kim, J., Go, Y., Eddaoudi, M., Matzger, A. J., et al. (2004). A route to high surface area, porosity and inclusion of large molecules in crystals. Nature, 427(6974), 523–527. https://doi.org/10.1038/nature02311.

Cherian, S., Figueroa, C., & Nair, H. (2014). ‘Movers and shakers’ in the regulation of fruit ripening: a cross-dissection of climacteric versus non-climacteric fruit. Journal of Experimental Botany, 65(17), 4705–4722. https://doi.org/10.1093/jxb/eru280.

Chopra, S., Dhumal, S., Abeli, P., Beaudry, R., & Almenar, E. (2017). Metal-organic frameworks have utility in adsorption and release of ethylene and 1-methylcyclopropene in fresh produce packaging. Postharvest Biology and Technology, 130, 48–55. https://doi.org/10.1016/j.postharvbio.2017.04.001.

Choudary, B., Valli, V., & Prasad, A. (1991). A novel montmorillonite-KMnO4 system for the oxidation of alkenes under triphase conditions. Synthetic Communications, 21(20), 2007–2013. https://doi.org/10.1080/00397919108019806.

Circul-Aire Inc. (2006). MULTI-MIX® media type: MM-1000. Chemical media specification. Circul-Aire. http://circul-aire.com/download/12.MSpecMM1000.pdf. Accessed 12 September 2017.

Dainelli, D., Gontard, N., Spyropoulos, D., Zondervan-van den Beuken, E., & Tobback, P. (2008). Active and intelligent food packaging: legal aspects and safety concerns. Trends in Food Science & Technology, 19(1), S103–S112. https://doi.org/10.1016/j.tifs.2008.09.011.

Dash, S., Patel, S., & Mishra, B. (2009). Oxidation by permanganate: synthetic and mechanistic aspects. Tetrahedron, 65(4), 707–739. https://doi.org/10.1016/j.tet.2008.10.038.

de Souza, W., Bezerra, M., Dantas, P., da Curnha, A., & Sales, R. (2017). Potassium permanganate effects on the quality and post-harvest conservation of sapodilla (Manilkara zapota (L.) P.Royen) fruits under modified atmosphere. Acta Agronómica, 66(3), 331–337. https://doi.org/10.15446/acag.v66n3.54579.

Deltatrak. (n.d.). AirRepair. Ethylene absorbers. Deltatrak. http://www.deltatrak.com/images/SpecSheets/SS0108_19005_19009_13L1.pdf. Accessed 12 September 2017.

Eastwell, K., Bassi, P., & Spencer, M. (1978). Comparison and evaluation methods for the removal of ethylene and other hydrocarbons from air for biological studies. Plant Physiology, 62(5), 723–726. https://doi.org/10.1104/pp.62.5.723.

Eiser, J. R., Miles, S., & Frewer, L. J. (2002). Trust, perceived risk, and attitudes toward food technologies. Journal of Applied Social Psychology, 32(11), 2423–2433. https://doi.org/10.1111/j.1559-1816.2002.tb01871.x.

Emadpour, M., Ghareyazie, B., Kalaj, J., Omrani, A., & Mohammadi, D. (2009a). Effect of potassium permanganate-coated nano-zeolites on cherry quality and shelf life. Journal of Agricultural Engineering Research, 10(1), 11–26.

Emadpour, M., Ghareyazie, B., Kalaj, Y., Entesari, M., & Bouzari, N. (2015). Effect of the potassium permanganate coated zeolite nanoparticles on the quality characteristic and shelf life of peach and nectarine. International Journal of Agricultural Technology, 11(5), 1263–1273.

Emadpour, M., Kalaj, Y., Omrani, A., Ghareyazie, B., & Mohammadi, G. (2009b). Effect of ethylene absorption using nano-particles on the storage and quality characteristics of apricot. Pajouhesh-Va-Sazandegi, 21, 82–89.

Erdoğan, B. (2013). A comparative adsorption study of C2H4 and SO2 on clinoptilolite-rich tuff: effect of acid treatment. Journal of Hazardous Materials, 262, 627–633. https://doi.org/10.1016/j.jhazmat.2013.09.014.

Erdoğan, B., Sakızcı, M., & Yörükoğulları, E. (2008). Characterization and ethylene adsorption of natural and modified clinoptilolites. Applied Surface Science, 254(8), 2450–2457. https://doi.org/10.1016/j.apsusc.2007.09.058.

Ethylene Control Inc. (2015). Safety data sheet. Data supplied by the provider.

Euopean Parliament, Council of the European Union. (2004). Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. http://data.europa.eu/eli/reg/2004/1935/oj. Accessed 11 January 2018.

European Parliament, Council of the European Union. (2009). Commission Regulation (EC) No 450/2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. http://data.europa.eu/eli/reg/2009/450/oj. Accessed 11 January 2018.

FAO. (2011). Global food losses and food waste-extent, causes and prevention. Düsseldorf, Germany.

FAO. (2015). List of codex specifications for food additives. CAC/MISC 6–2015. Food and Agriculture Organization of the United Nations. www.fao.org/input/download/standards/9/CXA_006efs_2015.pdf. Accessed 17 October 2017.

FDA. (2009). GRAS Notice 000298: Silicon dioxide. Food Drug Administration. https://www.fda.gov/downloads/Food/.../GRAS/NoticeInventory/ucm269341. Accessed 17 October 2017.

Gaikwad, K., & Lee, Y. (2017). Current scenario of gas scavenging systems used in active packaging—a review. Korean Journal of Packaging Science & Technology, 23(2), 109–117. https://doi.org/10.20909/kopast.2017.23.2.109.

García, J., Balaguera-López, H., & Herrera, A. (2012). Conservación del fruto de banano bocadillo (Musa AA Simmonds) con la aplicación de permanganato de potasio (KMnO4). Revista Colombiana de Ciencias Hortícolas, 6(2), 161–171. https://doi.org/10.17584/rcch.2012v6i2.1974.

Gavara, R., Catalá, R., & Hernández-Muñoz, P. (2009). Extending the shelf-life of fresh-cut produce through active packaging. Stewart Postharvest Review, 5(4), 1–5.

Ghaani, M., Cozzolino, C. A., Castelli, G., & Farris, S. (2016). An overview of the intelligent packaging technologies in the food sector. Trends in Food Science & Technology, 51, 1–11. https://doi.org/10.1016/j.tifs.2016.02.008.

Illeperuma, K., Chamara, D., & Galappatty, P. (2000). Effect of modified atmosphere and ethylene absorbers on extension of storage life of “Kolikuttu” banana at ambient temperature. Fruits, 55(6), 381–388.

Ishii, T., Takizawa, S., Shimamura, T., Hashimoto, M., Ichimura, S., & Karibe, F. (1998). Air cleaning filter. USA Patent US5830414 A. USA: Kondoh Industries Limited.

Jal, P. K., Patel, S., & Mishra, B. K. (2004). Chemical modification of silica surface by immobilization of functional groups for extractive concentration of metal ions. Talanta, 62(5), 1005–1028. https://doi.org/10.1016/j.talanta.2003.10.028.

Janjarasskul, T., & Suppakul, P. (2016). Active and intelligent packaging: the indication of quality and safety. Critical Reviews in Food Science and Nutrition, (just-accepted), 00-00, 1080/10408398.2016.1225278.

Jeronimo, E. M., Brunini, M. A., de Arruda, M. C., Cruz, J. C. S., Gava, G. J. C., & Silva, M. A. (2007). Qualidade de mangas “Tommy Atkins” armazenadas sob atmosfera modificada. Ciência E Agrotecnologia, 31(4), 1122–1130. https://doi.org/10.1590/S1413-70542007000400027.

Kader, A. (1980). Prevention of ripening in fruits by use of controlled atmospheres. Food Technology, 34(3), 51–54.

Kader, A. (2003). A perspective on postharvest horticulture (1978–2003). Hortscience, 38(5), 1004–1008.

Kader, A. (2005). Increasing food availability by reducing postharvest losses of fresh produce. In V International Postharvest Symposium, (682), 2169–2176. https://doi.org/10.17660/ActaHortic.2005.682.296.

Kalaj, Y., Ghareyazie, B., Emadpour, M., & Omrani, A. (2008). Effect of the removal of ethylene hormone by potassium permanganate coated zeolite nanoparticles on the increased quality and quantity of storage of iceberg lettuce (Lactuca sativa L.) and Chinese cabbage (Brassica pekinensis). Journal of Agricultural Sciences and Natural Resources, 15(6), 188–197.

Kaur, N., & Kishore, D. (2012). Montmorillonite: an efficient, heterogeneous and green catalyst for organic synthesis. Journal of Chemical and Pharmaceutical Research, 4(2), 991–1015.

Keller, N., Ducamp, M. N., Robert, D., & Keller, V. (2013). Ethylene removal and fresh product storage: a challenge at the frontiers of chemistry. Toward an approach by photocatalytic oxidation. Chemical Reviews, 113(7), 5029–5070. https://doi.org/10.1021/cr900398v.

Knee, M., Proctor, F. J., & Dover, C. J. (1985). The technology of ethylene control: use and removal in post-harvest handling of horticultural commodities. Annals of Applied Biology, 107(3), 581–595. https://doi.org/10.1111/j.1744-7348.1985.tb03174.x.

Köstekli, M., Özdzikicierlev, O., Cortés, C., Zulueta, A., Esteve, M. J., & Frígola, A. (2016). Role of potassium permanganate ethylene on physicochemical properties, during storage of five different tomato cultivars. MOJ Food Processing & Technology, 3(2), 00069. https://doi.org/10.15406/mojfpt.206.03.00069.

Lelievre, J.-M., Latche, A., Jones, B., Bouzayen, M., & Pech, J.-C. (1997). Ethylene and fruit ripening. Physiologia Plantarum, 101(4), 727–739. https://doi.org/10.1111/j.1399-3054.1997.tb01057.x.

Leyva-Ramos, R., Medellin-Castillo, N., Jacobo-Azuara, A., Mendoza-Barron, J., Landin-Rodriguez, L., Martinez-Rosaes, J., et al. (2008). Fluoride removal from water solution by adsorption on activated alumina prepared from pseudo-boehmite. Journal of Environmental Engineering and Management, 18(5), 301–309.

Mahajan, P., Caleb, O., Gil, M., Izumi, H., Colelli, G., Watkins, C., et al. (2017). Quality and safety of fresh horticultural commodities: recent advances and future perspectives. Food Packaging and Shelf Life, 14, 2–11. https://doi.org/10.1016/j.fpsl.2017.08.001.

Malandrino, M., Abollino, O., Giacomino, A., Aceto, M., & Mentasti, E. (2006). Adsorption of heavy metals on vermiculite: influence of pH and organic ligands. Journal of Colloid Interface Science, 299(2), 537–546. https://doi.org/10.1016/j.jcis.2006.03.011.

Mallakpour, S., & Khadema, E. (2015). Recent development in the synthesis of polymer nanocomposites based on nano-alumina. Progress in Polymer Science, 51, 74–93. https://doi.org/10.1016/j.progpolymsci.2015.07.004.

Maqueda, C., Romero, A. S., Morillo, E., & Pérez-Rodríguez, J. L. (2007). Effect of grinding on the preparation of porous materials by acid-leached vermiculite. Journal of Physics and Chemistry of Solids, 68(5–6), 1220–1224. https://doi.org/10.1016/j.jpcs.2007.01.037.

Martínez-Romero, D., Bailén, G., Serrano, M., Guillén, F., Valverde, J. M., Zapata, P., Castillo, S., & Valero, D. (2007). Tools to maintain postharvest fruit and vegetable quality through the inhibition of ethylene action: a review. Critical Reviews in Food Science Nutrition, 47(6), 543–560. https://doi.org/10.1080/10408390600846390.

Molecular Products Limited. (2009a). Ethylene removal for fruit, vegetable and flower conservation. Molecular Products. http://www.molecularproducts.com/wp-content/uploads/2017/01/Ethysorb-3mm-UK-TDS-V4.pdf. Accessed 12 September 2017.

Molecular Products Limited. (2009b). SofnofilTM. Molecular products. http://www.molecularproducts.com/wp-content/uploads/2017/01/Sofnofil-TDS-v-4.pdf. Accessed 12 September 2017.

Morgott, D. A. (2015). Anthropogenic and biogenic sources of ethylene and the potential for human exposure: a literature review. Chemico-Biological Interactions, 241, 10–22. https://doi.org/10.1016/j.cbi.2015.08.012.

NCBI (2018). PubChem Compound Database; CID=516875. National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/516875 Accessed 10 January 2018.

OLRC (2017). Title 21-Food and Drugs, Chapter 9-Federal food, drug, and cosmetic act. Office of the Law Revision Counsel United States Code. http://uscode.house.gov/browse/prelim@title21/chapter9&edition=prelim. Accessed 11 January 2018.

Osman, K. A., Al-Humaid, A. I., Al-Redhaiman, K. N., & El-Mergawi, R. A. (2014). Safety methods for chlorpyrifos removal from date fruits and its relation with sugars, phenolics and antioxidant capacity of fruits. Journal of Food Science and Technology, 51(9), 1762–1772. https://doi.org/10.1007/s13197-012-0693-0.

Ozeano Urdina S.L. (2013a) Ficha técnica de producto Filtro Ozeano “L”. Ozeano. http://www.ozeano.net/wp-content/uploads/2015/01/FICHA-TECNICA-OZEANO-L.pdf. Accessed 13 September 2017.

Ozeano Urdina S.L. (2013b) Ficha técnica de producto Ozeano 'SACHET S5'. Ozeano. http://www.ozeano.net/wp-content/uploads/2015/01/Ficha-Sachet.pdf. Accessed 13 September 2017.

Patdhanagul, N., Rangsriwatananon, K., Siriwong, K., & Hengrasmee, S. (2012). Combined modification of zeolite NaY by phenyl trimethyl ammonium bromide and potassium for ethylene gas adsorption. Microporous and Mesoporous Materials, 153, 30–34. https://doi.org/10.1016/j.micromeso.2011.12.007.

Pathak, N., Caleb, O., Geyer, M., Herppich, W., Rauh, C., & Mahajan, P. (2017). Photocatalytic and photochemical oxidation of ethylene: potential fot storage of fresh produce—a review. Food and Bioprocess Technology, 10(6), 982–1001. https://doi.org/10.1007/s11947-017-1889-0.

Paul, V., Pandey, R., & Srivastava, G. (2012). The fading distinctions between classical patterns of ripening in climacteric and non-climacteric fruit and the ubiquity of ethylene—an overview. Journal of Food Science and Technology, 49(1), 1–21. https://doi.org/10.1007/s13197-011-0293-4.

Polshettiwar, V., Len, C., & Fihri, A. (2009). Silica-supported palladium: sustainable catalysts for cross-coupling reactions. Coordination Chemistry Reviews, 253(21–22), 2599–2626. https://doi.org/10.1016/j.ccr.2009.06.001.

Purafil Inc. (2015a). Product bulletin for Purafil Select Media. Purafil. https://www.purafil.com/wp-content/uploads/2014/12/Purafil-Select-Media-Bulletin.pdf. Accessed 12 September 2017.

Purafil Inc. (2015b). Product Bulletin for Purafil Chemisorbant Media. Purafil. https://www.purafil.com/wp-content/uploads/2014/12/Purafil-Chemisorbant-Media-Bulletin.pdf. Accessed 12 September 2017.

Reinholdt, M. X., Hubert, F., Faurel, M., Tertre, E., Razafitianamaharavo, A., Francius, G., Prêt, D., Petit, S., Béré, E., Pelletier, M., & Ferrage, E. (2013). Morphological properties of vermiculite particles in size-selected fractions obtained by sonication. Applied Clay Science, 77-78, 18–32. https://doi.org/10.1016/j.clay.2013.03.013.

Rodriguez-Casado, A. (2016). The health potential of fruits and vegetables phytochemicals: notable examples. Critical Reviews in Food Science Nutrition, 56(7), 1097–1107. https://doi.org/10.1080/10408398.2012.755149.

Sá, C. R. L., Oliveira, E., Terao, D., & Hansen, A. (2008). Efeito do KMnO4 e 1–MCP com atmosfera modificada na conservação pós-colheita de melão Cantaloupe. Revista Ciência Agronômica, 39(1), 60–69.

Salamanca, F. A., Balaguera-López, H. E., & Herrera, A. O. (2014). Efecto del permanganato de potasio sobre algunas características poscosecha de frutos de tomate “Chonto” (Solanum lycopersicum L.) II International Conference on Postharvest and Quality Management of Horticultural Products of Interest for Tropical Regions, 1016(1016), 171–176. https://doi.org/10.17660/ActaHortic.2014.1016.24.

Saltveit, M. (1999). Effect of ethylene on quality of fresh fruits and vegetables. Postharvest Biology and Technology, 15(3), 279–292. https://doi.org/10.1016/S0925-5214(98)00091-X.

Santosa, E., & Widodo, W. (2010). The use of clay as potassium permanganate carrier to delay the ripening of Raja Bulu banana. Jurnal Hortikultura Indonesia, 1(2), 88–95.

Sardabi, F., Mohtadinia, J., Shavakhi, F., & Jafari, A. A. (2014). The effects of 1-methylcyclopropen (1-MCP) and potassium permanganate coated zeolite nanoparticles on shelf life extension and quality loss of Golden Delicious apples. Journal of Food Processing and Preservation, 38(6), 2176–2182. https://doi.org/10.1111/jfpp.12197.

Sen, C., Mishra, H., & Srivastav, P. (2012). Modified atmosphere packaging and active packaging of banana (Musa spp.): a review on control of ripening and extension of shelf life. Jounal of Stored Products and Postharvest Research, 3(9), 122–132. https://doi.org/10.5897/JSPPR11.057.

Sensitech Inc. (2013). Ryan® ethylene absorption products from Sensitech. Sensitech. http://files.sensitech.com/sensitech/en/contentimages/RyanEthyleneControlDSWeb.pdf. Accessed 12 September 2017.

Shaabani, A., Bazgir, A., & Lee, D. (2004). Oxidation of organic compounds by potassium permanganate supported on montmorillonite K10. Synthetic Communications, 34(19), 3595–3607. https://doi.org/10.1081/SCC-200031039.

Shaabani, A., Bazgir, A., Teimouri, F., & Lee, D. G. (2002). Selective oxidation of alkylarenes in dry media with potassium permanganate supported on montmorillonite K10. Tetrahedron Letters, 43(29), 5165–5167. https://doi.org/10.1016/s0040-4039(02)00976-0.

Shaabani, A., Tavasoli-Rad, F., & Lee, D. (2005). Potassium permanganate oxidation of organic compounds. Synthetic Communications, 35(4), 571–580. https://doi.org/10.1081/SCC-200049792.

Shorter, A. J., Scott, K. J., Ward, G., & Best, D. J. (1992). Effect of ethylene absorption on the storage of Granny Smith apples held in polyethylene bags. Postharvest Biology and Technology, 1(3), 189–194. https://doi.org/10.1016/0925-5214(92)90001-6.

Silva, D., Salomão, L., de Siqueira, D., Cecon, P., & Rocha, A. (2009). Potassium permanganate effects in postharvest conservation of the papaya cultivar Sunrise Golden. Pesquisa Agropecuária Brasileira, 44(7), 669–675. https://doi.org/10.1590/S0100-204X2009000700003.

Silva, F., Ribeiro, W., França, C., Araújo, F., & Finger, F. (2015). Action of potassium permanganate on the shelf-life of Cucumis anguria fruit. XI International Controlled and Modified Atmosphere Research Conference, (1071, 1071), 105–111. https://doi.org/10.17660/ActaHortic.2015.1071.9.

Singh, N., & Lee, D. (2001). Permanganate: a green and versatile industrial oxidant. Organic Process Research & Development, 5(6), 599–603. https://doi.org/10.1021/op010015x.

Singh, R., & Giri, S. (2014). Shelf-life study of guava (Psidium guajava L.) under active packaging: an experiment with potassium permanganate salt as ethylene absorbent. Journal of Food Safety and Food Quality-Archiv Fur Lebensmittelhygiene, 65(2), 32–39. https://doi.org/10.2376/0003-925X-65-32.

Sivakumar, D., & Bautista-Baños, S. (2014). A review on the use of essential oils for postharvest decay control and maintenance of fruit quality during storage. Crop Protection, 64, 27–37. https://doi.org/10.1016/j.cropro.2014.05.012.

Sneddon, G., Greenaway, A., & Yiu, H. (2014). The potential applications of nanoporous materials for the adsorption, separation, and catalytic conversion of carbon dioxide. Advance Energy Materials, 4(10), 1301873. https://doi.org/10.1002/aenm.201301873.

Soriano, J. M., Rico, H., Moltó, J. C., & Manes, J. (2000). Assessment of the microbiological quality and wash treatments of lettuce served in university restaurants. International Journal of Food Microbiology, 58(1–2), 123–128. https://doi.org/10.1016/S0168-1605(00)00288-9.

Spricigo, P., Foschini, M., Ribeiro, C., Corrêa, D., & Ferreira, M. (2017). Nanoscaled platforms based on SiO2 and Al2O3 impregnated with potassium permanganate use color changes to indicate ethylene removal. Food and Bioprocess Technology, 10(9), 1622–1630. https://doi.org/10.1007/s11947-017-1929-9.

Srivastava, N., & Eames, I. (1998). A review of adsorbents and adsorbates in solid-vapour adsorption heat pump systems. Applied Thermal Engineering, 18(9–10), 707–714. https://doi.org/10.1016/S1359-4311(97)00106-3.

Sue-aok, N., Srithanratana, T., Rangsriwatananon, K., & Hengrasmee, S. (2010). Study of ethylene adsorption on zeolite NaY modified with group I metal ions. Applied Surface Science, 256(12), 3997–4002. https://doi.org/10.1016/j.apsusc.2010.01.065.

Temuujin, J., Okada, K., & MacKenzie, K. (2003). Preparation of porous silica from vermiculite by selective leaching. Applied Clay Science, 22(4), 187–195. https://doi.org/10.1016/S0169-1317(02)00158-8.

Valášková, M., & Martynkova, G. (2012). Vermiculite: structural properties and examples of the use. In M. Valášková & G. Martynkova (Eds.), Clay minerals in nature-their characterization, modification and application (Vol. 9, pp. 209–238). Rijeka: InTech Janeza Trdine.

van Berleere, M., & Dauchet, L. (2017). Fruits, vegetables, and health: evidence from meta-analyses of prospective epidemiological studies. In F. Mariott (Ed.), Vegetarian and plant-based diets in health and disease prevention (pp. 215–248). London: Elsevier Science. https://doi.org/10.1016/B978-0-12-803968-7.00013-7.

Varma, R. (2002). Clay and clay-supported reagents in organic synthesis. Tetrahedron, 58(7), 1235–1255. https://doi.org/10.1016/S0040-4020(01)01216-9.

Warton, M., Wills, R., & Ku, V. (2000). Ethylene levels associated with fruit and vegetables during marketing. Australian Journal of Experimental Agriculture, 40(3), 465–470. https://doi.org/10.1071/EA99125.

Werner, B. G., Koontz, J. L., & Goddard, J. M. (2017). Hurdles to commercial translation of next generation active food packaging technologies. Current Opinion in Food Science, 16, 40–48. https://doi.org/10.1016/j.cofs.2017.07.007.

WHO (2017). 20th WHO model list of essential medicines (EML). Essential medicines and health products. http://www.who.int/medicines/publications/essentialmedicines/en/. Accessed 15 January 2018.

Wills, R. (2015). Low ethylene technology in non-optimal storage temperatures. In R. Wills & J. Golding (Eds.), Advances in postharvest fruit and vegetable technology (pp. 167–190). Boca Raton: CRC Press. https://doi.org/10.1201/b18489-9.

Wills, R., & Kim, G. (1995). Effect of ethylene on postharvest life of strawberries. Postharvest Biology and Technology, 6(3–4), 249–255. https://doi.org/10.1016/0925-5214(95)00005-Q.

Wills, R., & Warton, M. (2004). Efficacy of potassium permanganate impregnated into alumina beads to reduce atmospheric ethylene. Journal of the American Society Horticultural Science, 129(3), 433–438.

Wills, R., Warton, M., Mussa, D., & Chew, L. (2001). Ripening of climacteric fruits initiated at low ethylene levels. Australian Journal of Experimental Agriculture, 41(1), 89–92. https://doi.org/10.1071/EA00206.

Wyrwa, J., & Barska, A. (2017). Innovations in the food packaging market: active packaging. European Food Research and Technology, 243(10), 1681–1692. https://doi.org/10.1007/s00217-017-2878-2.

Yagub, M., Sen, T., Afroze, S., & Ang, H. (2014). Dye and its removal from aqueous solution by adsorption: a review. Advances in Colloid and Interface Science, 209, 172–184. https://doi.org/10.1016/j.cis.2014.04.002.

Yang, R. (2003). Adsorbents: fundamentals and applications. New Jersey: John Wiley & Sons. https://doi.org/10.1002/047144409X.

Yang, R. (2013). Adsorbents and absorption isotherms. In R. Yang (Ed.), Gas separation by adsorption processes (pp. 9–48). Massachusetts: Butterworth-Heinemann.

Funding

The authors express their gratitude to CONACYT (National Council of Science and Technology, Mexico) for a doctoral grant (No. 291212) to Marianela Hazel Álvarez-Hernández.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Álvarez-Hernández, M.H., Artés-Hernández, F., Ávalos-Belmontes, F. et al. Current Scenario of Adsorbent Materials Used in Ethylene Scavenging Systems to Extend Fruit and Vegetable Postharvest Life. Food Bioprocess Technol 11, 511–525 (2018). https://doi.org/10.1007/s11947-018-2076-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2076-7