Abstract

Toughening is the most important postharvest factor that negatively affects quality of fresh white asparagus (Asparagus officinalis L.) spears. It is assumed to result from wounding-induced or developmentally regulated cell wall thickening and increased lignification of sclerenchyma sheath cells and of vascular bundle elements. Postharvest application of ethanol has been shown to be an effective disinfectant of white asparagus spears; it is also known to delay or inhibit plant development. The latter was tested for its potential efficacy to reduce undesired spear toughening. In this context, effects of ethanol treatment on changes in cell wall properties were investigated. Practically relevant short-term washing of spears in 50 % ethanol solution (v/v) at 10 °C for 30 and 90 s reduced toughening of fresh white asparagus spears during 4 days of storage at approx. 20 °C. The treatment inhibited the biosynthesis of secondary cell wall structural carbohydrates (hemicellulose and cellulose) and of lignins, although to a lesser extent. Cell wall contents of pectic substances were also less affected, while the content of cell wall proteins was pronouncedly reduced by ethanol exposure. As a conclusion, practically relevant short-term washing with ethanol solution seems to be a promising approach to improve quality maintenance and safety of fresh white asparagus spears.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In Germany, white asparagus (Asparagus officinalis L.) is a very important and popular crop (Statistisches Bundesamt 2011). Mostly purchased fresh or, to a lesser degree, as minimally processed convenience products, white asparagus spears are highly susceptible to microbial spoilage as well as undesired physiological and textural changes. Hence, it is essential to optimize postharvest handling and processing to ensure high product quality (Huyskens-Keil et al. 2011) and safety (Hassenberg et al. 2012) for both fresh and processed asparagus.

To guarantee produce safety, new and non-hazardous techniques to improve postharvest hygienic status must be developed. Recently, various physical (Lescano et al. 1993; Poubol et al. 2010; Hassenberg et al. 2012) or chemical treatments (Simón et al. 2004; Jamieson et al. 2009; Sothornvit and Kiatchanapaibul 2009) have been tested as sanitizers.

In this context, ethanol may be a sustainable option. Ethanol has antimicrobial activity (Larson and Morton 1991; Gabler et al. 2004) and is naturally found in plants (Davies 1980). Ethanol is considered to be generally recognized as safe (“GRAS”) compound (Dao and Dantigny 2011). Applied in solution or as vapour, ethanol effectively reduced microbial loads on fruits (Yuen et al. 1995; Lichter et al. 2002; Karabulut et al. 2004; Zhang et al. 2007; Gutiérrez-Martínez et al. 2012) and vegetables (Corcuff et al. 1996; Tzortzakis and Economakis 2007; Hu et al. 2010; Herppich et al. 2014). On the other hand, it has long been known that ethanol potentially retards tissue ripening (Kelly and Saltveit 1988) and delays senescence in cut flowers (Heins 1980) and broccoli inflorescences (Corcuff et al. 1996). Thus, ethanol treatment can actively prolong produce shelf life or vase life. Furthermore, ethanol may also induce compact growth in ornamentals (Miller and Finan 2006; Mibus et al. 2014). It may (Hu et al. 2010; Herppich et al. 2014) or may not (Corcuff et al. 1996) affect respiration, total soluble solid contents (Tzortzakis and Economakis 2007) or texture of the produce (Liu and Jiang 2006). In many kinds of fruit, ethanol treatments inhibit rapid softening during storage (Kelly and Saltveit 1988; Margosan et al. 1997; Plotto et al. 2006; Wang et al. 2011). For example, ethanol vapour may reduce lignin deposition in green asparagus spears (Liu and Jiang 2006). This finding indicates that short-term ethanol treatments affect cell wall properties, resulting in more tender asparagus spears.

Spear toughening is probably the most important parameter negatively affecting quality and shelf life of fresh and processed white asparagus (Lipton 1990; Everson et al. 1992; Rodríguez et al. 1999; Herppich and Huyskens-Keil 2008). Postharvest spear toughening is a multifactorial process (Huyskens-Keil and Herppich 2013), resulting from thickening of the cell walls (Chang 1983; Zurera et al. 2000), an increase in the degree of lignification of sclerenchyma sheath cells and vascular bundle elements (Billau 1986; Lipton 1990; Waldron and Selvendran 1990; Rodríguez et al. 1999) and/or from enhanced cross-linking of cell wall polymers by ferulic acid (Rodríguez-Arcos et al. 2004; Jaramillo et al. 2007). These reactions can simply reflect unaltered shoot differentiation (O’Donoghue and Somerfield 1998; Herppich et al. 2005) or may be due to increased ethylene formation induced by wounding at harvest (Hsiao et al. 1981; Jaramillo et al. 2007; Bhowmik and Matsui 2004; Liu et al. 2010).

The potential effects of ethanol on biophysical and biochemical cell wall properties of white asparagus spears have apparently never been investigated in detail. Hence, this study evaluates (1) to what extent application of ethanol under simulated practical conditions, i.e. washing of spears with a 50 % ethanol solution at 10 °C for 30 and 90 s, can reduce toughening in white asparagus spears and (2) to analyze the potential underlying mechanisms, i.e. which of the functional cell wall components (cellulose, hemicellulose, pectic substance, lignin, proteins) is the primary target of the ethanol treatment.

Material and Methods

Plant Material and Experimental Design

In a series of experiments (2009–2011; Herppich et al. 2014), white asparagus spears of the cultivar “Gijnlim” were harvested from a commercial field (Spargelhof Nottebohm GbR, Kartzow, Germany) and transported to the laboratory, in which the spears were rapidly hand washed, sorted according to EC quality standard class I, cut to a length of 22 cm (mean spear diameter: 1.8 ± 0.2 cm) and randomly separated into nine batches. Thereafter, lots of up to 11 spears were either washed in 2 L of 50 % (v/v) ethanol (Carl Roth GmbH & Co, Karlsruhe, Germany) or tap water at 10 °C for 30 and 90 s (90 s only ethanol-treated spears) or not treated (controls). Finally, the spears were stored at 20 °C in a water vapour-saturated atmosphere for up to 4 days (Herppich and Huyskens-Keil 2008). On days 0, 2 and 4 of the experiments, spears of each treatment were randomly taken out of storage and analyzed further.

Ethanol treatments are considered optimal for practical application in fresh asparagus spear processing and do not cause any adverse off-taste or odour of spears (see Herppich et al. 2014).

Determination of Mechanical Properties

On the initial day of the experiments (day 0), 18 spears were evaluated for variability in the data. On days 2 and 4 of the experiments, six spears per treatment were randomly removed from storage for analysis. At the positions 2.5, 7.5, 12.5 and 18 cm from the base, spears were sliced with a stainless steel microtome blade (S35, 0.26 mm total thickness, Feather Safety Razor Co., Ltd., Osaka, Japan) adapted to a Zwicki 1120 material testing machine (Zwick, Ulm, Germany; crosshead speed 600 mm min−1) to determine tissue toughness (Atkins and Vincent 1984; Herppich et al. 2004). Mean cutting force over the entire spear diameter (F cut) and the actual cutting length (L cut) were used to calculate the cutting energy (E cut = F cut / (L cut × π / 4)).

Analysis of Chemical Cell Wall Properties

For each treatment, three batches of asparagus spears (approx. 300 g) were freeze-dried, and an aliquot (100 mg, three replicates) was washed with hot (70 °C) ethanol (80 %). The alcohol insoluble fraction (AIF) was analyzed for cell wall content of proteins, pectic substances, cellulose, hemicellulose and lignin.

The cell wall protein content was determined according to a modified method of Bradford (1976). Aliquots of the dried, ground material (50 mg) were dispersed in 1 mL 0.1 M phosphate buffer pH 6.0 (0.1 M sodium hydrogen phosphate, 0.1 M disodium hydrogen phosphate) with a vortex mixer (3 × 10 s) and centrifuged (11,400 rpm, 15 min; Multifuge X1, Heraeus, Hanau, Germany) at 4 °C. In a reaction tube, 100 μL of the supernatant was diluted with 900 μL phosphate buffer, 1 mL Coomassie blue added, and the solution was measured photometrically (595 nm) after 20 min (PU 8730, Philips, Kassel, Germany). A calibration series (10 to 50 μg) was obtained from phosphate buffer and bovine serum albumin.

Cell wall extraction and cell wall fractionation (water-soluble pectin, EDTA-soluble pectin and water-insoluble pectin) were conducted according to McComb and McCready (1952) and Ben Arie and Lavee (1971) as modified by Huyskens (1991). The colorimetric determination of the pectic substances followed the method described by Blumenkrantz and Asboe-Hansen (1973) using meta-hydroxybiphenyl (MHDP, Sigma H 6527, Sigma-Aldrich, München, Germany) as a colour reagent. In each fraction, the amount of galacturonic acid was measured photometrically (PU 8730, Philips, Kassel, Germany) at 520 nm. Analyses were performed with three replications for each treatment. The content of pectic substances was expressed as milligram galacturonic acid per gram dry mass.

Cellulose and lignin were analyzed according to Goering and van Soest (1972) and AOAC (1999). One gram freeze-dried sample was extracted with 100 mL acid detergent fibre (ADF) reagent (N-cetyl-N,N,N-trimethyl-ammoniumbromid dissolved with 96 % H2SO4) using a Fibertec System (M 1020, Tecator, Sweden). Thereafter, the solution was vacuum-filtered, washed with boiled, double-distilled water until removal of the acidity and again washed with 90 % acetone. The residue was dried at 105 °C for 24 h, weighed, ash-dried at 500 °C for 24 h and weighed again to calculate ADF. The dried ADF residue was used for acid detergent lignin (ADL) determination. Cellulose content was calculated as the difference between ADF and ADL. The content of lignin and cellulose, respectively, were expressed as milligram per gram dry mass.

Using the neutral detergent fiber (NDL) approach (van Soest and Goering 1963), one gram of freeze-dried material was cooked in 100 mL of NDL mixture (Titriplex III, di-sodium borate, dodecylhydrogensulfate-Na, ethylene-glycol-monoethylester) to determine the hemicellulosic cell wall fraction. The solution was subsequently vacuum-filtered and washed with demineralized water and with 90 % acetone. The insoluble residue was dried at 105 °C for 24 h, weighed, ash-dried at 500 °C for 24 h and weighed again to calculate NDF. The hemicellulose content was obtained by subtracting ADF from NDF and given as milligram per gram dry mass.

Statistical Analysis

All data were statistically analyzed (one-way ANOVA) with WinSTAT (R. Fitch Software, Bad Krozingen, Germany). Treatment means were compared using the Duncan’s multiple range test (p < 0.05). In the figures, the mean variability of data was indicated by the standard deviation.

Results and Discussion

Effects of Ethanol on Spear Toughness

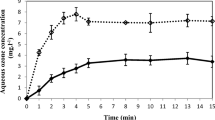

The toughness of untreated control spears, as indicated by their mean cutting energy, continuously increased during storage (Fig. 1). Toughening was only minor in the spear tips (Fig. 1d–f; cut at position 18 cm) and much more pronounced in the developmentally older (e.g. Huyskens-Keil and Herppich 2013) bases (cut at position 2.5 cm). Spears treated with tap water closely reflected the controls. Hence, results were not explicitly presented. In contrast, spears washed in 50 % ethanol solution for 30 s retained, at least partially, their tenderness. Although variability in the toughness data was high, thus preventing significant differences between treated spears and controls, the same pronounced tendency was found in all experiments. The effect of ethanol did not increase with a longer duration of washing treatment (Fig. 1, 2010, 2011).

Means of tissue toughness as indicated by mean cutting energy of (a–c) entire spears and of the respective tips and bases (d–f) of white asparagus stored either untreated (circles) and after washing with ethanol solution for 30 s (squares) or 90 s (triangle) in water vapour-saturated atmosphere at 20 °C for 4 days. Given are means (n = 6) ± standard deviation of three independent experiments during different years (2009, 2010, 2011). The same letters indicate that means are not statistically different (p < 0.05)

It is well established that ethanol dipping or its application as vapour not only reduces the microbial load of fresh produce (Gutiérrez-Martínez et al. 2012; Herppich et al. 2014) but it may also retard tissue development (Podd and van Staden 1998). This may be manifested by either delayed ripening in fruit (Kelly and Saltveit 1988) or delayed senescence in cut flowers (Heins 1980) and broccoli inflorescences (Corcuff et al. 1996). Thus, ethanol treatment may actively prolong produce shelf life or vase life.

In many fruit, retardation of development by ethanol treatments is indicated by the inhibition of rapid tissue softening (Margosan et al. 1997; Plotto et al. 2006; Ayala-Zavala et al. 2005; Bai et al. 2011; Wang et al. 2011). In contrast, in asparagus spears, which are actively growing young stems (O’Donoghue and Somerfield 1998), development inevitably increases tissue toughening (Herppich and Huyskens-Keil 2008). Consequently, it seems reasonable to expect that washing in ethanol solution may help to impede this undesirable effect of shoot development on postharvest quality of asparagus spears.

Effects of Ethanol Treatment on Components of Secondary Cell Walls

To evaluate the possible direct effects of ethanol on shoot cell wall metabolism, the relevant cell wall components were extracted and analyzed. In control spears, total cell wall content significantly increased with storage duration (Fig. 2). This increase in total cell wall matter was either reduced or fully inhibited by ethanol washing for 30 s. Longer duration of washing did not increase this effect.

Total cell wall content (i.e. the sum of cellulose, hemicellulose, lignin, pectic substances and protein contents) of white asparagus spears stored either untreated (circles) and after washing with ethanol solution for 30 s (squares) or 90 s (triangle) in water vapour-saturated atmosphere at 20 °C for 4 days. Given are means (n = 6) ± standard deviation. The same letters indicate that means are not statistically different (p < 0.05)

To further evaluate whether ethanol potentially impacts spear toughness by differentially affecting cell wall biochemistry, variation of the major cell wall components was investigated in spears of each treatment (Fig. 3). Cellulose and hemicellulose were the main components of spears’ cell walls, cell wall proteins contributed to approx. 23 %, while the initial lignin content was normally far less than 10 % (Table 1). The increase in total cell wall content of untreated control spears during storage was mainly due to the incorporation of cellulose and hemicelluloses (Fig. 3). Independent of its duration, ethanol treatment pronouncedly and significantly inhibited the accumulation of these structural carbohydrates (Fig. 3). The relative contribution of cellulose and hemicelluloses to the total cell wall material, however, remained relatively constant during storage. In addition, it was unaffected by the ethanol treatment (Table 1). Compared to controls, incorporation of lignin into cell walls was obviously only slightly retarded or even enhanced by the ethanol treatments during 4 days of storage (Fig. 3). Its relative contribution may increase above 9 % by the end of the storage period (Table 1). On the other hand, ethanol dipping significantly reduced the absolute (Fig. 3) and the relative protein content of cell walls (Table 1). This reaction clearly depended on the duration of the treatment. Nevertheless, the content of cell wall proteins also declined in untreated control spears.

Contents of white asparagus spears’ cell walls main components. Spears, either untreated (circles) or washed with ethanol solution for 30 s (squares) or 90 s (triangle), were stored in water vapour-saturated atmosphere at 20 °C for 4 days. Given are means (n = 6) ± standard deviation. The same letters indicate that means are not statistically different (p < 0.05)

In the present experiments, short-term (30 s) dipping in 50 % ethanol solution reduced toughening of white asparagus spears, although to a minor degree. In general, toughening is a complex and multifactorial process (Huyskens-Keil and Herppich 2013). Nevertheless, it is primarily related to increased fibre content and/or lignification of spears (Hsiao et al. 1981; Lipton 1990; Siomos et al. 2000). Both responses reflect thickening and development of secondary cell walls, mainly of sclerenchyma sheath cells and vascular bundle elements (Waldron and Selvendran 1990) as well as variations in cell wall structure (Zurera et al. 2000). Secondary cell walls are enriched in both cellulose and lignin (Mellerowicz et al. 2001; Anderson-Gunneras et al. 2005); consequently, both major cell wall components (Saltveit 1988; Lipton 1990; Everson et al. 1992; Bhowmik and Matsui 2004; Villanueva et al. 2005; Herppich and Huyskens-Keil 2008) may be the aim of ethanol-related modifications.

In this context, it is interesting that immersing the bases of green asparagus spears in 2 % (v/v) ethanol solution for 15 min led to a reduced lignin deposition as did other growth regulators such as GA3 and 1-MCP (Liu and Jiang 2006). In many investigations, lignin has been assumed to be the cell wall component primarily responsible for spear toughening (Billau 1986; Lipton 1990; Waldron and Selvendran 1990; Bhowmik and Matsui 2004). On the other hand, results of the present and also earlier investigations (Rodríguez et al. 1999; Herppich et al. 2005; Huyskens-Keil and Herppich 2013) do not necessarily indicate a prominent role of lignin in this context. Here, lignin formation was not reduced by ethanol dipping, while the relative contribution of this structural component to total cell wall materials was either not affected or eventually increased in investigated spears after a short-term ethanol treatment. Despite the clear evidence that lignin is an important determinant of cell wall strength, this finding may indicate that the potential contribution of changes in cell wall lignin contents to the reduction in spear toughening is nonetheless somewhat exaggerated and even more so when compared to cellulose (Huyskens-Keil and Herppich 2013). Unfortunately, no information about texture or other cell wall components was provided by Liu and Jiang (2006) in their investigation on the ethanol effect on lignification in green asparagus.

There is evidence that lignification may be affected by wounding that inevitably occurs when cutting the stems at harvest (Bhowmik and Matsui 2004; Jaramillo et al. 2007). In such situation, reinforcement of cell walls in close vicinity of the wounded site with lignin may be a characteristic response of plants (Vance et al. 1980; Nicholson and Hammerschmidt 1992). Wounding stress may, furthermore, mediate the stimulation of ethylene production (Yang and Hoffman 1984; Ecker 1995; Bhowmik and Matsui 2004). This, in turn, has been shown to enhance lignification in asparagus spears (Haard et al. 1974). Indeed, exposure to ethylene increased the lignin content of certain asparagus shoot tissues (Haard et al. 1974; Liu and Jiang 2006). The fact that the major mode of ethanol action is its ability to inhibit biosynthesis (Kelly and Saltveit 1988; Podd and van Staden 1998; Jin et al. 2013) and/or function of ethylene in fruit and cut flowers (Pun et al. 2013) fits into this catena of metabolic responses in terms of lignification.

However, stress stimulation of ethylene production occurs with a lag time of only few minutes (Voesenek and van der Veen 1994) and subsides again after reaching a peak within few hours (Yang and Hoffman 1984). In white asparagus, ethylene production only increased after prolonged storage (Hennion and Hartmann 1990). Furthermore, lignification is assumed to be a highly complex interaction of enzyme-catalyzed (phenylalanine ammonia-lyase (PAL, EC 4.3.1.1), cinnamyl alcohol dehydrogenase (CAD, EC 1.1.1.195), peroxidases (POD, EC 1.11.1.7)) and non-enzyme-catalyzed lignin biosynthesis caused by oxidative polymerization of lignin precursors (Stephane et al. 1992; Liu and Jiang 2006). The complex dynamics in lignin synthesis might explain the delayed shift of lignification-associated changes in cell wall structure attributed to toughening. This may lead to the present findings that toughening could be inhibited by the short-term ethanol treatment while at the same time lignin formation has not been clearly reduced by ethanol. Indeed, Saltveit (1989) showed that exogenously applied ethanol affected associated physiological responses in tomato slices and fruit only in a time-delayed and concentration-dependent fashion (Beaulieu and Saltveit 1997). In contrast, Jin et al. (2013) found that increasing the ethanol vapour concentration from 0.5 to 3 mL kg−1 renders the treatment less effective in maintaining the postharvest quality of oriental sweet melons. This coincides with the present finding that increasing washing time reduces the partial inhibition of toughness and the effects on cell wall components. In fact, higher concentrations or, in the present case, longer duration of ethanol treatment may lead to adverse effects or even to tissue damage due to the inherent toxicity of ethanol (Miller and Finan 2006; Mibus et al. 2014).

Effects of Ethanol Treatment on Primary Cell Wall Components

To give a comprehensive picture of the effect of ethanol on entire cell wall metabolism, analyses of the major component of primary cell wall were essential. Hence, specific fractions of the pectic substances were investigated and shown in detail for spears ethanol treated for 30 s.

Total pectin content of cell walls increased significantly and continuously by nearly 80 % during 4 days of storage at 20 °C and water vapour-saturated atmosphere (Fig. 4). It contributed to total cell wall material by approx. ten percent irrespective of treatment and storage time. Ethanol dipping for 30 s reduced (18 %) the accumulation of this cell wall component at a later stage of storage. Water soluble (38 %) and insoluble (48 %) pectins were the major pectin fractions, but only the former pectins increased with further shoot development. In addition, only water-soluble pectins responded to ethanol treatment. After 4 days of storage, the content of this pectin fraction was 18 % lower in treated spears than in controls. EDTA-soluble pectins comprised the smallest fraction (approx. 14 % of total pectins), and the content increased by 3.7 mg gDM −1 in controls and by 2.5 mg gDM −1 in ethanol-treated spears (day 4).

Total pectic substances’ content and their main fractions of white asparagus spears’ cell walls. Spears, either untreated (circles) and after dipping in ethanol solution for 30 s (squares), were stored in water vapour-saturated atmosphere at 20 °C for 4 days. Given are means (n = 6) ± standard deviation. The same letters indicate that means are not statistically different (p < 0.05)

Retardation effects of ethanol washing on the incorporation of cellulose, hemicellulose, pectic substances and, in particular, cell wall protein into cell walls of asparagus spears was pronounced. Consistently, Liu et al. (2010) reported a strong inhibitory effect of several sanitizers on changes of cellulose in Zizania latifolia Turcz., which was also accompanied by the retardation of toughening. In this context, Lucas et al. (1995) found that for any plant tissue, the intrinsic (fracture) toughness of cell walls linearly increases with the wall volume fraction. Hence, ethanol treatment may reduce the increase in spear toughness by impeding development of secondary cell walls, which includes both the accumulation of structural carbohydrates and lignification. It is probable that this effect of ethanol on carbohydrate accumulation may contribute to the growth repression observed in intact potted ornamentals (Miller and Finan 2006; Mibus et al. 2014).

Ethanol treatment clearly also results in an unspecified reduction of protein contents in carnation (Podd et al. 2002) and cucumber (Saltveit 1994; Saltveit et al. 2004). According to Saltveit et al. (2004), this effect mainly results from the inhibition of de novo protein synthesis. In the present experiment, cell wall protein content remained constant in stored controls, while it declined in ethanol-treated spears. Podd et al. (2002) concluded that the inhibition of protein synthesis may “prevent enzyme-mediated reactions as well as growth and development”. This, of course, should also include overall accumulation of all major cell wall components.

On the other hand, cell wall proteins are generally important components of both primary and secondary cell walls (Reiter 2002), constituting approx. ten percent of the wall in growing cells (Wolf et al. 2012). Besides their involvement in cell wall biosynthesis and in signalling, structural proteins are important for cell wall biomechanical properties (Wu and Cosgrove 2000). It is long known that these proteins are involved in cell wall strengthening responses to, for example, osmotic (Marshall et al. 1999), drought (Neumann 1995) or cold (Gómez Galindo et al. 2004) stress. Hence, ethanol-induced reduction of cell wall protein content may directly contribute to the observed retardation of spear toughening.

Short-term washing in 50 % ethanol solution can be easily incorporated into asparagus processing. It has been shown that this treatment is long enough to reduce pathogen contamination (Herppich et al. 2014). Thus, additional ethanol washing of spears may be economically advantageous and effectively introduced in practice.

Conclusion

Short-term (30 or 90 s) washing with 50 % ethanol solution at 10 °C partially reduced toughening of fresh white asparagus spears. Hence, ethanol washing, which can be easily incorporated into practical processing, seems to be a promising approach to optimize quality maintenance of spears.

In asparagus spears, ethanol primarily inhibited the synthesis of components of secondary cell walls (cellulose and hemicellulose). Compared to the structural carbohydrates, inhibitory effects of ethanol on lignin formation were less pronounced. Main elements of primary cell walls were also less affected (pectins) and the cell wall protein content reduced by ethanol exposure. Hence, the underlying metabolism, especially enzyme-mediated spear toughening processes, requires further investigation.

References

Anderson-Gunneras, S., Mellerowicz, E. J., Love, J., Segerman, B., Ohmiya, Y., Coutinho, P. M., Nilsson, P., Henrissat, B., Moritz, T., & Sundberg, B. (2005). Biosynthesis of cellulose-enriched tension wood in Populus: global analysis of transcripts and metabolites identifies biochemical and developmental regulators in secondary wall biosynthesis. Plant Journal, 45, 144–165.

AOAC. (1999). Official methods of analysis (14th ed.). Washington: Association of Official Analytical Chemists.

Atkins, A. G., & Vincent, J. F. V. (1984). An instrumented microtome for improved histological section and the measurement of fracture toughness. Journal of Materials Science Letters, 3, 310–312.

Ayala-Zavala, J. F., Wang, S. Y., Wang, C. Y., & Gonález-Aguilar, G. A. (2005). Methyl jasmonate in conjunction with ethanol treatment increases antioxidant capacity, volatile compounds and postharvest life of strawberry fruit. European Food Research and Technology, 221, 731–738.

Bai, J., Plotto, A., Spotts, R., & Rattanapanone, N. (2011). Ethanol vapor and saprophytic yeast treatments reduce decay and maintain quality of intact and fresh-cut sweet cherries. Postharvest Biology and Technology, 62, 204–212.

Beaulieu, J. C., & Saltveit, M. (1997). Inhibition of tomato fruit ripening by acetaldehyde and ethanol is concentration dependent and varies with initial fruit maturity. Journal of the American Society for Horticultural Science, 122, 392–398.

Ben-Arie, R., & Lavee, S. (1971). Pectic changes occurring in “Elberta” peaches suffering from woolly break down. Phytochemistry, 10, 531–538.

Bhowmik, P., & Matsui, T. (2004). Changes in the activity and expression of 1-aminocyclopropane-1-carboxylate (ACC) synthase, ACC oxidase, and phenylalanine ammonia-lyase in asparagus spears in response to wound-induced ethylene synthesis. HortScience, 39, 1074–1078.

Billau, W. (1986). Untersuchungen über Lokalisation und Ausmaß der Lignifizierung in Pflanzen von Asparagus officinals L. Dissertation. Universität Hohenheim, Germany.

Blumenkrantz, N., & Asboe-Hansen, G. (1973). New method for quantitative determination of uronic acids. Analytical Biochemistry, 54, 484–489.

Bradford, M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72, 248–254.

Chang, D. C. N. (1983). Fine structural changes of asparagus spear during storage. Acta Horticulturae, 138, 305–312.

Corcuff, R., Ad, J., Hamza, E., Castaigne, E., & Makhlouf, J. (1996). Storage of broccoli florets in ethanol vapor enriched atmospheres. Postharvest Biology and Technology, 7, 219–229.

Dao, T., & Dantigny, P. (2011). Control of food spoilage fungi by ethanol. Food Control, 22, 360–368.

Davies, D. D. (1980). Anaerobic metabolism and the production of organic acids. In D. D. Davies (Ed.), The biochemistry of plants (Vol. 2, pp. 581–611). New York: Academic Press.

Ecker, J. (1995). The ethylene signal transduction pathway in plants. Science, 268, 667–675.

Everson, H. P., Waldron, K. W., Geeson, J. D., & Browne, K. M. (1992). Effects of modified atmospheres on textural and cell wall changes of asparagus during shelf-life. International Journal of Food Science and Technology, 27, 187–199.

Gabler, F. M., Mansour, M. F., Smilanick, J. L., & Mackey, B. E. (2004). Survival of spores of Rhizopus stolonifer, Aspergillus niger, Botrytis cinerea and Alternaria alternata after exposure to ethanol solution at various temperatures. Journal of Applied Microbiology, 96, 1354–1360.

Goering, H. K., & van Soest, P. J. (1972). Forage fibre analyses. Agriculture Handbook 379 (20 pp). Washington: USDA.

Gómez Galindo, F., Bråthen, E., Knutsen, S. H., Sommarin, M., Gekas, V., & Sjöholm, I. (2004). Changes in the carrot (Daucus carota L. cv. Nerac) cell wall during storage. Food Research International, 37, 225–232.

Gutiérrez-Martínez, P., Osuna-López, S. G., Calderón-Santoyo, M., Cruz-Hernández, A., & Bautista-Baños, S. (2012). Influence of ethanol and heat on disease control and quality in stored mango fruits. LWT - Food Science and Technology, 45, 20–27.

Haard, N. F., Sharma, S. C., Wolfe, R., & Frenkel, C. (1974). Ethylene induced isoperoxidase changes during fiber formation in postharvest asparagus. Journal of Food Science, 39, 452–456.

Hassenberg, K., Huyskens-Keil, S., & Herppich, W. B. (2012). Impact of postharvest UV-C and ozone treatments on microbiological properties of white asparagus (Asparagus officinalis L.). Journal of Applied Botany and Food Quality, 85, 174–181.

Heins, R. D. (1980). Inhibition of ethylene synthesis and senescence in carnation by ethanol. Journal of the American Society for Horticultural Science, 105(1), 141–144.

Hennion, S., & Hartmann, C. (1990). Respiration and ethylene in harvested asparagus spears during aging at 20 °C. Scientia Horticulturae, 43, 189–195.

Herppich, W. B., & Huyskens-Keil, S. (2008). Cell wall biochemistry and biomechanics of harvested white asparagus shoots as affected by temperature. Annals of Applied Biology, 152, 377–388.

Herppich, W. B., Herold, B., Geyer, M., & Gomez, F. (2004). Effects of temperature and water relations on carrots and radish tuber texture. Journal of Applied Botany, 78, 11–17.

Herppich, W. B., Huyskens-Keil, S., & Kadau, R. (2005). Effects of short-term low-temperature storage on mechanical and chemical properties of white asparagus cell walls. Journal of Applied Botany and Food Quality, 79, 63–71.

Herppich, W. B., Huyskens-Keil, S., & Hassenberg, K. (2014). Impact of ethanol treatment on physiological and microbiological properties of fresh white asparagus (Asparagus officinalis L.) spears. LWT - Food Science and Technology, 57, 156–164. doi:10.1016/j.lwt.2014.01.022.

Hsiao, P.-H., Su, J.-C., & Sung, H.-Y. (1981). Changes of some enzyme activities and level of metabolites of asparagus spears after harvest. Journal of the Chinese Agricultural Chemical Society, 19, 1–11.

Hu, W., Jiang, A., Tian, M., Liu, C., & Wang, Y. (2010). Effect of ethanol treatment on physiological and quality attributes of fresh-cut eggplant. Journal of the Science of Food and Agriculture, 90, 1323–1326.

Huyskens, S. (1991). Morphological, physiological and biochemical aspects in the cultivation of two curcubits: Luffa acutangula L. Roxb. and Momordica charantia L. Dissertation, Universität Bonn, Germany.

Huyskens-Keil, S., & Herppich, W. B. (2013). High CO2 effects on biochemical and textural properties of white asparagus (Asparagus officinalis L.) spears in postharvest. Postharvest Biology and Technology, 75, 45–53.

Huyskens-Keil, S., Hassenberg, K., & Herppich, W. B. (2011). Impact of postharvest UV-C and ozone treatment on textural properties of white asparagus (Asparagus officinalis L.). Journal of Applied Botany and Food Quality, 84, 229–234.

Jamieson, L. E., Meier, X., Page, B., Zulhendri, F., Page-Weir, N., Brash, D., McDonald, R. M., Stanley, J., & Woolf, A. B. (2009). A review of postharvest disinfestation technologies for selected fruits and vegetables. Report of the New Zealand Institute for Plant and Food Research Ltd., pp. 36. Available at: http://maxa.maf.govt.nz/sff/about-projects/search/L09-133/review-postharvest-disinfestation-fruit-veges.pdf.

Jaramillo, S., Rodriguez, R., Jiménez, A., Guillén, R., Fernández-Bolanos, J., & Heredia, A. (2007). Effects of storage conditions on the accumulation of ferulic acid derivates in white asparagus cell walls. Journal of the Science of Food and Agriculture, 87, 286–296.

Jin, Y. Z., Lin, D. Q., Liu, W. W., Qi, H. Y., & Bai, X. H. (2013). Ethanol vapour treatment maintains postharvest storage quality and inhibits ethylene biosynthesis during storage of oriental sweet melons. Postharvest Biology and Technology, 86, 372–380.

Karabulut, O. A., Arslan, U., Kuruoglu, G., & Ozgenc, T. (2004). Control of postharvest diseases of sweet cherry with ethanol and hot water. Journal of Phytopathology, 5, 298–303.

Kelly, M. O., & Saltveit, M. E., Jr. (1988). Effect of endogenously synthesized and exogenously applied ethanol on tomato fruit ripening. Plant Physiology, 88, 143–147.

Larson, E. L., & Morton, H. E. (1991). Alcohols. In S. S. Block (Ed.), Disinfection, sterilization, and preservation (pp. 191–203). London: Lea and Febiger.

Lescano, G., Narvaiz, P., & Kairiyama, E., (1993). Gamma irradiation of asparagus (Asparagus officinalis, var. Argenteuil). LWT - Food Science and Technology, 26, 411–416.

Lichter, A., Zutkhy, Y., Sonega, L., Dvir, O., Kaplunov, T., Sarig, P., & Ben-Arie, R. (2002). Ethanol controls postharvest decay of table grapes. Postharvest Biology and Technology, 24, 301–308.

Lipton, W. J. (1990). Postharvest biology of fresh asparagus. Horticultural Reviews, 12, 69–115.

Liu, Z.-Y., & Jiang, W.-B. (2006). Lignin deposition and effect of postharvest treatment on lignification of green asparagus (Asparagus officinalis L.). Plant Growth Regulation, 48, 187–193.

Liu, M., Qian, B., Zhang, H., Deng, Y., Shen, Y., Ping, J., & Cao, L. (2010). Sanitizer treatments alleviate lignification of sliced few-flower wildrice (Zizania latifolia Turcz.). Food Research International, 43, 2363–2368.

Lucas, P. W., Darvell, B. W., Lee, P. K. D., Yuen, T. D. B., & Choong, M. F. (1995). The toughness of plant cell walls. Philosophical Transactions of the Royal Society, B: Biological Sciences, 348, 363–372.

Margosan, D. A., Smilanick, J. L., Simmons, G. F., & Henson, D. J. (1997). Combination of hot water and ethanol to control postharvest decay of peaches and nectarines. Plant Disease, 81, 1405–1409.

Marshall, J. G., Dumbroff, E. B., Thatcher, B. J., Martin, B., Rutledge, R. G., & Blumwald, E. (1999). Synthesis and oxidative insolubility of cell-wall proteins during osmotic stress. Planta, 208, 401–408.

McComb, E., & McCready, R. (1952). Colorimetric determination of pectic substances. Analytical Biochemistry, 24, 1630–1632.

Mellerowicz, E. J., Baucher, M., Sundberg, B., & Boerjan, W. (2001). Unravelling cell-wall formation in the woody dicot stem. Plant Molecular Biology, 47, 239–274.

Mibus, H., Hoff, K., & Serek, M. (2014). Ethanol treatment induces compact growth in Kalanchoë. Scientia Horticulturae, 168, 234–239.

Miller, W. B., & Finan, E. (2006). Root-zone alcohol is an effective growth retardant for paperwhite narcissus. HortTechnology, 16, 294–296.

Neumann, P. M. (1995). The role of cell wall adjustment in plant resistance to water deficits. Crop Science, 35, 1258–1266.

Nicholson, R. L., & Hammerschmidt, R. (1992). Phenolic compounds and their role in disease resistance. Annual Review of Phytopathology, 30, 369–389.

O’Donoghue, E. M., & Somerfield, S. D. (1998). Cell walls of asparagus after harvest. Acta Horticulturae, 464, 447–450.

Plotto, A., Bai, J., Narciso, J. A., Brecht, J. K., & Baldwin, E. A. (2006). Ethanol vapor prior to processing extends fresh-cut mango storage by decreasing spoilage, but does not always delay ripening. Postharvest Biology and Technology, 39, 134–145.

Podd, L. A., & van Staden, J. (1998). The role of ethanol and acetaldehyde in flower senescence and fruit ripening—a review. Plant Growth Regulation, 26, 183–189.

Podd, L. A., Hills, P. N., & van Staden, J. (2002). Physiological responses and extension of vase life of cut carnation flowers treated with ethanol and acetaldehyde. II. Protein content and enzyme activity. Plant Growth Regulation, 38, 107–117.

Poubol, J., Lichanporn, I., Puthmee, T., & Kanlayanarat, S. (2010). Effect of ultraviolet-C irradiation on quality and natural microflora of asparagus spears. Acta Horticulturae, 875, 257–262.

Pun, U. K., Niki, T., & Ichimura, K. (2013). Ethanol reduces sensitivity and delays petal senescence in cut Tweedia caerulea flowers. Plant Growth Regulation, 69, 125–130.

Reiter, W.-D. (2002). Biosynthesis and properties of the plant cell wall. Current Opinion in Plant Biology, 5, 536–542.

Rodríguez, R., Jiménez, A., Guillén, R., Heredia, A., & Fernández-Bolanos, J. (1999). Postharvest changes in white asparagus cell wall during refrigerated storage. Journal of Agricultural and Food Chemistry, 47, 3551–3557.

Rodríguez-Arcos, R. C., Smith, A. C., & Waldron, K. W. (2004). Effects of storage on wall-bound phenolics in green asparagus. Journal of Agricultural and Food Chemistry, 52, 4740–4750.

Saltveit, M. E. (1988). Effect of endogenously synthesized and exogenously applied ethanol on tomato fruit ripening. Plant Physiology, 88, 143–147.

Saltveit, M. E. (1989). Effect of alcohols and their interaction with ethylene on the ripening of epidermal pericarp discs of tomato fruit. Plant Physiology, 90, 167–174.

Saltveit, M. E. (1994). Exposure to alcohol vapours reduces chilling-induced injury of excised cucumber cotyledons, but not of seedlings or excised hypocotyl segments. Journal of Experimental Botany, 45, 813–821.

Saltveit, M. E., Peiser, G., & Rab, A. (2004). Effect of acetaldehyde, arsenite, ethanol, and heat shock on protein synthesis and chilling sensitivity of cucumber radicles. Physiologia Plantarum, 120, 556–562.

Simón, A., González-Fandos, E., & Tobar, V. (2004). Influence of washing and packaging on the sensory and microbiological quality of fresh peeled white asparagus. Journal of Food Science, 69, FMS6–FMS12.

Siomos, A., Sfakiotakis, E. M., & Dogras, C. C. (2000). Modified atmosphere packaging of white asparagus spears: composition, color and textural quality responses to temperature and light. Scientia Horticulturae, 84, 1–13.

Sothornvit, R., & Kiatchanapaibul, P. (2009). Quality and shelf-life of washed fresh-cut asparagus in modified atmosphere packaging. LWT - Food Science and Technology, 42, 1484–1490.

Statistisches Bundesamt, Pressemitteilung Nr. 275, 22.07.2011. Available at: https://www.destatis.de/DE/PresseService/Presse/Pressemitteilungen/2011/07/PD11_275_412.html.

Stephane, H. C. H., Anthony, L., & Claude, H. (1992). Activities of enzymes involved in lignification during the postharvest storage of etiolated asparagus spears. Physiologia Plantarum, 86, 474–478.

Tzortzakis, N. G., & Economakis, C. D. (2007). Maintaining postharvest quality of the tomato fruit by employing methyl jasmonate and ethanol vapour treatment. Journal of Food Quality, 30, 567–580.

Van Soest, P. J., & Goering, H. K. (1963). Use of detergents in the analysis of fibrous feeds. II. A rapid method for determination of fibre and lignin. Journal of the Association of Official Agricultural Chemists, 46, 829–835.

Vance, C., Kirk, T., & Sherwood, R. (1980). Lignification as a mechanism of disease resistance. Annual Review of Phytopathology, 18, 259–288.

Villanueva, M. J., Tenorio, M. D., Sagardoy, M., Redondo, A., & Saco, M. D. (2005). Physical, chemical, histological and microbiological changes in fresh green asparagus (Asparagus officinalis, L.) stored in modified atmosphere packaging. Food Chemistry, 91, 609–619.

Voesenek, L. A. C. J., & van der Veen, R. (1994). The role of phytohormones in plant stress: too much or too little water. Acta Botanica Neerlandica, 43, 91–127.

Waldron, K. W., & Selvendran, R. R. (1990). Effect of maturation and storage on asparagus (Asparagus officinalis) cell wall composition. Physiologia Plantarum, 80, 576–583.

Wang, K., Jin, P., Tang, S., Shang, H., Rui, H., Di, H., Cai, Y., & Zheng, Y. (2011). Improved control of postharvest decay in Chinese bayberries by a combination treatment of ethanol vapor with hot air. Food Control, 22, 82–87.

Wolf, S., Hématy, K., & Höfte, H. (2012). Growth control and cell wall signaling in plants. Annual Review of Plant Biology, 63, 381–407.

Wu, Y., & Cosgrove, D. J. (2000). Adaptation of roots to low water potentials by changes in cell wall extensibility and cell wall proteins. Journal of Experimental Botany, 51, 1543–1553.

Yang, S., & Hoffman, N. (1984). Ethylene biosynthesis and its regulation in higher plants. Annual Review of Plant Physiology, 35, 155–189.

Yuen, C. M. C., Paton, J. E., Hanawati, R., & Shen, L. Q. (1995). Effects of ethanol, acetaldehyde and ethyl formate vapour on the growth of Penicillium italicum and P. digitatum on oranges. The Journal of Horticultural Science and Biotechnology, 70, 81–84.

Zhang, W. S., Li, X., Wang, X. X., Wang, G. Y., Zheng, J. T., Abeysinghe, D. C., Ferguson, I. B., & Chen, K. S. (2007). Ethanol vapour treatment alleviates postharvest decay and maintains fruit quality in Chinese bayberry. Postharvest Biology and Technology, 46, 195–198.

Zurera, G., Muńoz, M., Moreno, R., Gonzalez, J. A., Amaro, M. A., & Ros, G. (2000). Cytological and compositional evaluation of white asparagus spears as a function of variety, thickness, portion and storage conditions. Journal of the Science of Food and Agriculture, 80, 335–340.

Acknowledgments

The authors thank Veronika Egert, Susanne Meier, Corinna Rolleczek, Janett Schiffmann and Gabriele Wegner for doing an excellent job in the laboratories and Prof. Craig E. Martin, KU Lawrence, for checking the language of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Herppich, W.B., Huyskens-Keil, S. & Hassenberg, K. Impact of Ethanol Treatment on the Chemical Properties of Cell Walls and Their Influence on Toughness of White Asparagus (Asparagus officinalis L.) Spears. Food Bioprocess Technol 8, 1476–1484 (2015). https://doi.org/10.1007/s11947-015-1507-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1507-y