Abstract

The objective of this study was to identify and kinetically study the most high-pressure (HP) resistant deteriorative factor of gilthead seabream (Sparus aurata) fillets aiming in their shelf life extension using in pack cold pasteurization technology. Fillets were HP processed (600 MPa, 25 °C, 5 min) and stored at 15 °C for 15 days, until spoilage. Lactobacilli were isolated from the spoiled fillets and were identified and classified as Pediococcus spp. The necessary HP process conditions for Pediococcus spp. cells inactivation were studied at various combinations of pressure (150–600 MPa) and temperature (20–40 °C) for appropriate time. The D values were calculated at all pressure–temperature combinations. The effect of temperature (z T) and pressure (z P) was estimated at all pressures and temperatures, respectively. According to the developed model for Pediococcus spp. inactivation, HP treatment of seabream fillets at 600 MPa and 25 °C for 5 min seemed to be capable for a 6-log10 reduction of the initial microbial load, potentially providing shelf life extension. Shelf-life experiments were conducted for validation. Untreated and HP treated at 600 MPa for 5-min samples were stored at 0, 5, 10 and 15 °C. Quality indices (colour, texture, microbial growth, sensory scoring) were monitored and kinetically modelled. Temperature dependence of quality loss rates was modelled by the Arrhenius equation. Microbial growth was well correlated with the sensory indices. HP treatment led to significant shelf life extension of fillets. Based on sensory scoring, the shelf life of the untreated samples was 11, 7, 4 and 3 days while for the HP-treated fillets 37, 27, 17 and 10 days after storage at 0, 5, 10 and 15 °C, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

New non-thermal food processing methods or combinations of them are continually being investigated by the industry in the pursuit of producing better quality foods with extended shelf life. High hydrostatic pressure (HP) is considered as a high-scored technique in the Technology Readiness Level (TRL > 7) scale, already applied world widely in various food industries producing meat products, juices, fruit preparations, etc. HP is mainly used to inactivate microorganisms in certain foods without the need of high temperatures, providing a cold pasteurization technique, while significantly increasing the shelf life of perishable products without compromising sensory quality (Hoover et al. 1989). The advantage of high-pressure treatment over traditional thermal processing rests on a better retention of nutritional and sensory properties. Generally, products are subjected to high-pressure in the range of 100–1,000 MPa (Knorr 1993).

Fresh fish is a perishable food as compared to other food commodities (Gram and Huss 1996). The short shelf life is a commercial drawback and methods of extension are being investigated. Research on the effects of HP on fish tissues has established the issues and drawbacks of this technology (Ohshima et al. 1993; Murchie et al. 2005). Several studies evaluate the potential use of HP on different fish species, such as cod (Angsupanich and Ledward 1998), tilapia (Ko and Hsu 2002), salmon (Lakshmanan et al. 2003; Gudbjornsdottir et al. 2010), sea bass (Chéret et al. 2005) and tuna (Ramirez-Suarez and Morrissey 2006). It is also applied to seafood such as abalone (Briones-Labarca et al. 2012), squid (Paarup et al. 2002), shrimp and clams (Büyükcan et al. 2009; Narwankar et al. 2011). The effect on quality parameters such as colour, lipid oxidation, textural properties, microbial growth, biogenic amines and water-holding capacity is evaluated and presented in most of these studies. Potential detrimental changes in appearance, texture and chemical parameter in HP products are dependent on the processing conditions, mainly to the applied pressure and processing time (Ohshima et al. 1993). According to Ramirez-Suarez and Morrissey (2006), HP treatment (275 and 310 MPa for 2–6 min) can prolong the shelf life of the minced albacore muscle even longer than 22 days at 4 °C. Paarup et al. (2002) reported shelf life of HP (400 MPa, 15 min) treated squid mantle of 28 days, compared to 7 days of untreated samples stored at 4 °C.

According to previous studies, the main spoilage microorganisms of seafood after HP treatment were found to be either lactic acid bacteria including Pediococcus spp. (Gram-positive bacteria) or Pseudomonas spp. (Gram-negative bacteria) (Tryfinopoulou et al. 2002; Gram and Huss 2000), depending on the type of packaging. HP treatment at 450 MPa and 25 °C for 15 min was found capable to cause 1–2 log10 reduction in the initial total microbial flora of tuna and squid samples, while 400 MPa for 5 min resulted in 5-log10 reduction in total microbial flora of oysters (Shoji and Saeki 1989; López-Caballero et al. 2000; Bremner 2002). In another study, the initial spoilage microflora of red mullet samples (psychrotropic and mesophilic bacteria) was reduced below the detection limits after HP treatment either at 300 MPa and 3 °C, or at 220 MPa and 25 °C for processing time of 5 min (Erkan et al. 2010).

Gilthead seabream (Sparus aurata) is a Mediterranean fish of high commercial value. Although usually sold as whole fish, filleted products are of high interest but suffer from significantly short shelf life. Products like chilled fillets from marine cultured Mediterranean fish have high commercial potential if their shelf life can be extended through packaging or minimal processing (Tsironi and Taoukis 2010). For fresh fishes and fillets (such as gilthead seabream), an increased shelf life may only be obtained if processed with non-thermal technologies, since conventional thermal treatment denatures fish proteins resulting in changes to the colour, flavour and texture.

The objective of this work was to identify and kinetically study the most HP-resistant spoilage factor of seabream fillets and to investigate the shelf life extension of fresh, chilled fillets of marine cultured gilthead seabream (Sparus aurata) treated with HP.

Materials and Methods

Colony Isolation of HP Resistant Species

Raw gilthead seabream fillets were pressurized at 600 MPa and 25 °C for 5 min and stored for 15 days at 15 °C. The process conditions selected for HP treatment of fish fillets targeting in microbial inactivation were based firstly on previous works conducted in our laboratory for various food products, in which most of the endogenous microorganisms are inactivated (at these process conditions), and secondly as the more intense process conditions in terms of pressure and temperature that could be achieved using an industrial scale equipment available in the market. The microflora in the spoiled fillets was enumerated using the appropriate growth media (De Man-Rogosa-Sharpe Agar, Merck, Darmstadt, Germany) and found to be approximately 105 cfu/g. Identification of the three colonies enumerated in the highest dilution of the microbial analysis from three different spoiled fillet samples was conducted using microscopy methods, oxidase- and catalase- tests, Gram stain and test API 50CHL (Biomerieux, France). Colonies were renewed in MRS broth with addition of 2 % glycol solution (Merck, Darmstadt, Germany) and stored at −40 °C until use. This mixture was used as the inoculum of Pediococcus spp..

Preparation of Growth Medium

Frozen gilthead seabream fillets were thawed at ambient temperature and cut into pieces. A proportion 1:5 of fish meat to ionized water was homogenized in a bag mixer (Bag Mixer ® Interscience, France) for 5 min. Sample was centrifuged at 3,000 rpm for 5 min and the supernatant was vacuum-filtrated, sterilized and stored at −30 °C until use.

Preparation of the Inoculum and the Final Sample

Bacterial cells were renewed at least three times in MRS broth (Merck, Darmstadt, Germany) before use. The inoculum was centrifuged at 3,000 rpm for 10 min, the supernatant was removed and a proportion of 10 mL of sterile growth medium was added to the precipitate. Sample was washed out one more time by centrifugation of the inoculum and addition of 100 mL of sterile growth medium with pH value of 6.16 (the initial pH value of the fillets), followed by aggregation. The initial counts of the tested microorganisms were approximately 108 cfu/mL (end of exponential phase). This final sample was used for HP inactivation kinetic experiments.

Raw Materials-Gilthead Seabream Fillets

Marine cultured gilthead seabream (Sparus aurata) fillets (weight, 90 ± 10 g; capture zone: Aegean Sea, Greece) were provided by a Greek aquaculture unit. After being ice shocked, fish was put into ice (0 °C), size sorted and transported to the filleting line in the market facilities within 10 h after catch. Fillets were vacuum packed in packages of two fillets per pack and were transported directly to the laboratory in polystyrene boxes with appropriate quantity of flaked ice (0 °C) within 2–3 h.

HP Experiments

High-pressure treatments were carried out using a laboratory pilot scale HP equipment with a maximum operating pressure of 1,000 MPa (food pressure unit FPU 1.01, Resato International BV, Roden, Holland) consisting of an operation high-pressure unit of 1.5 L in volume, which was used for the treatment of the fillets, and a multivessel system consisting of six vessels of 45-mL capacity each, which was used for the inactivation study of Pediococcus spp. All high-pressure vessels were surrounded by a circulating jacket connected to a heating-cooling system. The pressure transmitting fluid used was polyglycol ISO viscosity class VG 15 (Resato International, BV, Roden, Holland).

For inactivation kinetic experiments, the inoculums were placed into 5-mL pouches (laminate film: PP/aluminium/PE) and inactivation experiments were conducted in duplicate at various combinations of pressure (150–600 MPa) and temperature (20–40 °C) for appropriate process times.

The desired value of pressure was set and after pressure built-up (approximately 20 MPa s−1), the pressure vessel was isolated; this point defined the zero time of the process. Pressure of the vessel was released after a preset time interval by opening the pressure valve (release time <3 s). The initial temperature increase during pressure build-up (about 3 °C per 100 MPa) was taken into consideration in order to achieve the desired operating temperature. Pressure and temperature were constantly monitored (intervals of 1 s) and recorded during the process.

Shelf Life Kinetic Study

Two replicated storage experiments were carried out with untreated and HP-treated (600 MPa, 25 °C, 5 min) fish samples. Two fish fillets were placed per package. The non-processed (control) samples were stored aerobically. HP-treated samples were packed in vacuum, based on previous experiments resulting in similar shelf life of gilthead seabream fillets packaged aerobically or under vacuum and also supported in the literature for fish from temperature marine waters (Gram and Huss 1996). The aim of the study was to investigate the shelf life extension of the commercial aerobically packed raw gilthead seabream fillet by in pack cold pasteurization technology.

HP-treated fillets and Control samples were stored at controlled isothermal conditions of 0, 5, 10 and 15 °C in high-precision (±0.2 °C) low-temperature incubators (Sanyo MIR 153, Sanyo Electric, Ora-Gun, Gunma, Japan), monitored with electronic, programmable miniature data-loggers (COX TRACER ®, Belmont, NC). Samples were taken in appropriate time intervals, depending on treatment and storage temperature, to allow for efficient kinetic analysis of quality deterioration. All measurements were carried out on three different single fish fillets. Sampling frequency for microbiological analysis was based on the obtained results. For control samples, analysis was conducted every 2 days for storage at 0 °C, every day for samples stored at 5 and 10 °C and twice a day for 15 °C. For HP-treated samples, the corresponding sample days were once per week for 0 °C, twice per week for 5 and 10 °C and every 2 days for 15 °C.

Microbiological Analysis

Total aerobic viable count was enumerated on Plate Count Agar (PCA, Merck, Darmstadt, Germany) after incubation at 25 °C for 72 h. Pseudomonas spp. were enumerated on Cetrimide Agar (CFC, Merck, Darmstadt, Germany) after incubation at 25 °C for 48 h. For Lactobacillus enumeration the pour-plate method on De Man-Rogosa-Sharpe Agar (MRS, Merck, Darmstadt, Germany) was used, followed by incubation at 25 °C for 120 h. Two replicates of at least three appropriate dilutions were enumerated for three fillet specimens (Koutsoumanis et al. 2002).

Colour Measurement

Quantification of the colour change was based on measurement of CIELab values (L value: lightness, a value: redness and greenness, b value: yellowness and blueness), using a CR-Minolta Chromameter® (Minolta Co., Chuo-Ku, Osaka, Japan) with an 8-mm diameter measuring area. The instrument was standardized under “C” illuminant condition according to the CIE (Commission International de l’ Eclairage) using a standard white reference tile (calibration plate CR-200, L = 97.50, a = −0.31, b = −3.83). Measurements were conducted for fish flesh at three different points of the fillet.

Texture Analysis

Texture parameters were defined using a texture analyser with a load cell of 5 kg (TA-XT2i, Stable Micro Systems, Godalming, Surrey, United Kingdom). A compression aluminium plate of 75-mm diameter was selected. Double compression was applied to construct the texture profile analysis (TPA) parameters of three different specimens. The aluminium plate approached the sample at the speed of 0.5 mm/s and distance of 2 mm into the fish flesh. Then the force was reduced and the sample was allowed to rebound 5 s before the second compression. Force-time curves were obtained and texture parameters (hardness, cohesiveness and adhesiveness) were determined using Texture Expert Exceed Application (Version 2.64, Stable Micro Systems Ltd) (Sigurgisladottir et al. 1999; Jin et al. 2014). Hardness was calculated as the peak force (N) of the first compression cycle. Cohesiveness was calculated as the positive area during the second compression divided by the area during the first compression. Adhesiveness was defined as the negative area (N · sec) for the first compression.

Sensory Analysis

The sensory characteristics of raw and cooked fish fillets were evaluated by a trained sensory panel of eight, selected according to ISO 8586–1 (1993) standard. Discriminative tests, such as triangle test, were used to determine differences between fish fillets of different spoilage levels (Botta 1995). Gilthead seabream fillets were cooked individually, wrapped in aluminium foil, at 180 °C for 20 min, in preheated oven (dry-heat cooking). Panellists developed a list of profiling attributes concerning appearance and odour of raw fillets and appearance, odour and taste of cooked samples. The sensory parameters were evaluated using descriptive terms and recorded in appropriate forms, reflecting the organoleptic evolution of quality deterioration. A preference/acceptance test was also conducted. Scoring was assigned separately for each parameter on a 1 to 9 descriptive hedonic scale (9 being the highest quality score and 1 the lowest). A score of 5 was considered as the acceptability/non-acceptability threshold.

Data Analysis

The kinetic parameters (k and D values) were calculated using the Baranyi Growth Model (Baranyi and Roberts 1995). For curve fitting the in-house program DMfit of IFR (Institute of Food Research, Reading, UK) was used. Kinetic parameters such as, the rate constant (k) of the microbial inactivation or growth and the decimal reduction time (D) were estimated.

Temperature dependence of the rate constants, k, was modelled by the modified Arrhenius Eq. (1)

where; k ref is the quality loss or growth rate constant at a reference temperature, T ref is a reference temperature (e.g. 4 °C for refrigerated foods), T is the temperature in kelvin, R is the universal gas constant and, E a is the activation energy, which was estimated from the slope of Arrhenius plots of lnk vs. (1/T ref − 1/T) by linear regression (Taoukis et al. 1997).

Statistical Analysis

The parameters of the mathematical model, which described the inactivation of HP-resistant species as a function of pressure–temperature combinations, were calculated using non-linear regression (SYSTAT 8.0 Statistics 1998, SPCC Inc., USA). The experimental D values were correlated to the predicted from the model ones using the statistical software package SigmaPlot (v 8.0, SPCC Inc., USA).

Analysis of variance (ANOVA) at a significance level of 95 % was used for the analysis of quality degradation rates of untreated and HP-treated gilthead seabream fillets (STATISTICA® 7.0, StatSoft Inc., Tulsa, USA). Significant differences were calculated according to Duncan’s multiple range test (α = 0.05).

Results

Identification and Inactivation of HP Resistant-Species as a Function of Pressure and Temperature

According to the API 50CHL test, the HP-resistant isolates were classified as Pediococcus spp. The effect of processing at various combinations of pressure (150–600 MPa) and temperature (20-40 °C) on the inactivation of Pediococcus spp. was studied as a function of time. In Fig. 1, the effect of process temperature at 600 MPa on the reduction of Pediococcus spp. counts and, in Fig. 2 the effect of pressure processing at 30 °C on the reduction of Pediococcus spp. counts are illustrated. HP inactivation of Pediococcus spp. was described by the Baranyi model (R 2 ranged from 0.91 to 0.99). The D values were estimated at all pressure and temperature combinations studied (Table 1). The D values decreased with increasing processing pressure and temperature at all temperature and pressure levels tested, respectively, indicating the synergistic effect of temperature and pressure on the inactivation. Moreover, this microorganism seemed to be more resistant when studied in the fish model system than in phosphate buffer where the needed time for a 4-log10 reduction at 600 MPa and 23 °C was found equal to 1.7 min (Panagou et al. 2007) compared to 2.4 min in this study (value estimated using the data received in 600 MPa and all the studied temperatures).

At each temperature, the effect of pressure on the inactivation was expressed through the z P value. These values ranged from 171 to 198 MPa (R 2 from 0.89 to 0.93).

At each pressure, the effect of temperature on the D values of Pediococcus spp. was expressed by the z T value. These values ranged from 23.5 to 33.7 °C for the tested range of processing pressures (R 2 from 0.92 to 0.96), with no definite trend when the applied pressure is increased, which is in agreement with previous studies for a wide range of tested microorganisms, growth media or processing conditions (Reyns et al. 2000; Mallidis et al. 2003; Katsaros et al. 2010). In all the obtained curves, a tailing was observed with further processing significantly increasing the inactivation of microorganisms. For pressures up to 450 MPa, the tailing was observed at 2.8–3.1 log10 cfu/mL, while for higher pressures (600 MPa) the inactivation reached 1.0 ± 0.4 log10 cfu/mL (Fig. 2).

Modelling Inactivation of Pediococcus spp. as a Function of Temperature and Pressure and Selection of HP Cold Pasteurization Conditions

A single multi-parameter equation was applied to describe the effect of pressure and temperature process conditions on the D value of the tested microorganism, combining the aforementioned effect of pressure on the z T values and considering that the effect of process temperature on the z P values was small (Table 1) and followed no clear trend (Eq. 2):

where, D o the decimal reduction time at reference conditions of pressure and temperature at 300 MPa and 30 °C, respectively.

The parameters of Eq. (2) were determined by non-linear regression (Table 2), with a satisfactory statistical fit (R 2 = 0.99). The model gave satisfactory results with the predictions. The R 2 = 0.98 for the regression line y = x indicated that there was a good agreement between predicted and observed Pediococcus spp. decimal reduction times (D).

According to the developed model in order to achieve a 6D reduction of the initial load of Pediococcus spp., process time of almost 3 min, at 600 MPa and 25 °C, is sufficient. This treatment will lead to a maximum inactivation of lactic acid bacteria down to approximately 1 log10 cfu/g due to the tailing effect which was observed in all tested conditions. Taking into account the time needed to build up and stabilize the process conditions (pressure–temperature), the practically recommended process time for the 6D reduction of initial microbial load is approximately 5 min.

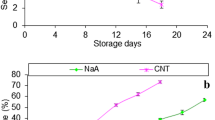

Effect of HP on Microbial Growth of Gilthead Seabream Fillets

The exponential growth rates of total viable count, Pseudomonas spp. and lactic acid bacteria in untreated and HP-treated gilthead seabream fillets stored at 0, 5, 10 and 15 °C are presented in Fig. 3a–c. Microbial growth was significantly inhibited in treated samples at all storage temperatures (P < 0.05). Initial microorganism load of fillets was also significantly decreased after HP treatment (P < 0.05). Pseudomonas spp. count was initially 3.7 log10 cfu/g while after HP treatment they were below detection limit (less than 2 log10 cfu/g). HP led to more than 2.9 log10 cfu/g reduction to the initial count of lactic acid bacteria (final load was below the detection limit, i.e. lower than 1 log10 cfu/g). This is in agreement with previous results reported for HP-treated tuna (Ramirez-Suarez and Morrissey 2006), rainbow trout and mahi mahi (Yagiz et al. 2007), squid (Paarup et al. 2002), and shrimp and clams (Büyükcan et al. 2009). Gómez-Estaca et al. (2007) observed that treatment with 300 MPa for 15 min led to significant inhibition of total plate count and lactic acid bacteria growth in cold-smoked dolphin–fish fillets.

Pseudomonas spp. dominated spoilage in control samples and this was in agreement with previous studies on aerobically stored gilthead seabream (Koutsoumanis and Nychas 2000; Tsironi et al. 2009; Tsironi and Taoukis 2010). Pseudomonas spp. counts in HP-treated fillets were below detection limits (<100 cfu/g) for the whole storage period, i.e. 60 days at 0 and 5 °C, 35 days at 10 °C and 25 days at 15 °C. Lactobacilli counts showed a slow increase in treated samples but remained below the spoilage level of 6 log10 cfu/g, that has been reported for vacuum or modified atmosphere packed fish (González-Rodrigez et al. 2002; Stamatis and Arkoudelos 2007; Pantazi et al. 2008; Tsironi and Taoukis 2010). Total viable counts in HP-treated samples reached maximum counts of 6.5–7.0 logcfu/g after 35 and 22 days of isothermal storage at 5 and 10 °C, respectively. The maximum TVC loads for untreated fillets were 8.0–8.5 logcfu/g and were achieved after 7 and 4 days at 5 and 10 °C, respectively. Under this context, HP treatment may result in more than threefold shelf life extension of gilthead seabream fillets, cold pasteurizing the products, by reducing the initial load and delaying microorganisms’ growth.

The temperature dependence of the growth rates was modelled by Arrhenius equation (R 2 > 0.96, for control and HP-treated samples). The activation energies and the estimated growth rates at reference temperature 4 °C are shown on Table 3.

Effect of HP on Appearance and Colour of Gilthead Seabream Fillets

The HP process increased (P < 0.05) the lightness of the fillets, measured by the L value (Table 4). The fillets were slightly translucent with a gray tinge, and when treated at 600 MPa for 5 min, there was loss of translucency. The gray tinge was also lost and the fillets became more white and opaque. The a value, an index of visual redness, decreased after HP treatment (P < 0.05), as shown on Table 4. The b value increased (P < 0.05) after HP treatment. Similar results have been reported for other species, such as rainbow trout, mahi mahi (Yagiz et al. 2007), cod, mackerel (Ohshima et al. 1993) and tuna (Ramirez-Suarez and Morrissey 2006). Ohshima et al. (1993) reported significant increase in a value and no significant changes of b value of mackerel after HP treatment. These changes may be attributed to globin denaturation and/or to heme displacement or release (Cheftel and Culioli 1997). According to Chéret et al. (2005) these changes of fish colour by HP processing may be attributed to modifications of protein matrix.

L value of Control and HP-treated fillets decreased during storage and was found to be adequately modelled by an apparent zero-order reaction (Eq. 3), as shown in Fig. 4a–b:

where k L is the colour change rate constant at temperature T and L, L o the values at storage times t and zero, respectively. The k L values increased with storage temperature and were higher for the control fillets (k L,contol = 0.407 ± 0.026, 0.902 ± 0.056, 1.404 ± 0.178 and 2.174 ± 0.459 days−1 for isothermal storage at 0, 5, 10 and 15 °C, respectively), indicating that flesh colour in untreated samples deteriorated faster than in the HP-treated fillets (k L,HP = 0.076 ± 0.008, 0.122 ± 0.009, 0.176 ± 0.010 and 0.332 ± 0.030 day−1 for isothermal storage at 0, 5, 10 and 15 °C, respectively). Temperature dependence of the kL values was adequately described by Arrhenius kinetics (R 2 > 0.97, for control and HP-treated samples). The estimated E a values were 71.7 (±7.3) and 62.5 (±5.3) kJ/mol for untreated and HP-treated samples, respectively, indicating similar temperature dependence of the colour change rates (P > 0.05).

Effect of HP on Texture of Gilthead Seabream Fillets

Texture parameters were also affected by HP treatment. Hardness increased significantly (P < 0.05) after HP processing (Table 5). Yagiz et al. (2007) reported higher hardness values on HP-treated rainbow trout and mahi mahi when compared to untreated fish muscle and attributed this to myofibrillar protein denaturation and gel formation (Ohshima et al. 1993; Cheftel and Culioli 1997). Increased hardness has been also reported for HP (500 MPa, 5 min) treated sea bass (Chéret et al. 2005; Angsupanich and Ledward 1998) reported significant increase in hardness of cod treated with 400 and 600 MPa for 20 min and attributed this to the formation of hydrogen-bonded networks in the fish muscle. Cohesiveness increased after HP treatment (Table 5), being in agreement with Yagiz et al. (2007), who reported significantly higher cohesiveness for rainbow trout and mahi mahi treated at 600 MPa, compared to untreated samples. Adhesiveness was lower in HP-treated fillets (Table 5), compared to the control samples, as also reported by Yagiz et al. (2009) for HP-treated salmon, but these changes showed no dependence on storage time and temperature.

Texture parameters in treated samples remained almost stable during preservation at all storage temperatures. Hardness of untreated samples increased significantly (P < 0.05) during storage, reaching values of 40 ± 3.2 N after 1-week storage at 5 °C. Cohesiveness showed a progressive decrease during storage of Control fillets, reaching values of 0.21 ± 0.03 at the end of storage period (Fig. 5a–c). Ramirez-Suarez and Morrissey (2006) also reported that texture of HP-treated (275 and 310 MPa for 6 min) minced albacore tuna was not affected during refrigerated storage at 4 °C.

Sensory Evaluation of Gilthead Seabream Fillets and Shelf Life Determination

The characteristics of freshness (appearance, odour and taste) for the untreated samples were strong for only 3–4 days when stored at 5 °C. Fresh fish had a sweet seaweed-like odour, which developed into a strong fishy odour. The sensory spoilage characteristics were sour, fish and putrid off flavours and discoloration of fish flesh. HP-treated samples showed significantly lower rates of organoleptic degradation compared to untreated fillets (P < 0.05). Off-flavours were evident to HP-treated samples after approximately 3 weeks at 5 °C. A score of 5 for overall impression was considered as the limit of acceptability equivalent to slight off odour and off taste development.

Overall acceptability scores were modelled by apparent zero order lines (R 2 > 0.94), as shown in Fig. 6a–b, and the rates of sensory deterioration were described by the Arrhenius equation (R 2 > 0.98). The activation energy values were similar to the respective ones for microbial growth (61.6 ± 6.7 and 57.4 ± 5.6 kJ/mol for the untreated and the HP-treated samples, respectively).

HP processing of gilthead seabream fillets led to significant shelf life extension (P < 0.05) as compared to untreated fillets. The shelf life of the untreated samples calculated by the Arrhenius model (limit = 5 score for overall acceptability) was 11, 7, 4 and 3 days while for the HP-treated fillets shelf life was estimated at 37, 27, 17 and 10 days at 0, 5, 10 and 15 °C, respectively. Paarup et al. (2002) reported shelf life 7 and 28 days for untreated and HP-treated (400 MPa for 15 min) vacuum-packed squid mantles, respectively, during storage at 4 °C. HP improved also the shelf life of minced albacore tuna muscle for more than 22 days (Ramirez-Suarez and Morrissey 2006) and for 12–14 days for shrimp and clams, during refrigerated storage at 4 °C (Büyükcan et al. 2009). Lower pressures (220–330 MPa) for 5–10 min resulted in limited shelf life extension at 4 °C for gilthead seabream fillets (18 for HP-treated vs. 15 days for control fillets) and the process conditions were selected based on chemical indices (TMA-N, TBARs) and colour changes (Erkan and Üretener 2010). In the present study, the processing conditions (600 MPa, 5 min) were selected based on the inactivation of the most resistant microorganisms found in the microflora of fish resulting in significant inhibition of microbial growth at refrigerated conditions.

Pseudomonas spp. growth was a good index for quality deterioration of aerobically packed untreated fillets, as also reported for Mediterranean fish species (Taoukis et al. 1999; Koutsoumanis and Nychas 2000; Koutsoumanis et al. 2002; Pantazi et al. 2008). Limit of sensory shelf life, coincided with a Pseudomonas spp. level of 106 cfu/g. Based on microbial growth, shelf life of control samples was estimated at 12, 7, 4 and 3 days at 0, 5, 10 and 15 °C, respectively, similar to the values estimated by sensory evaluation. In HP-treated samples lactobacilli, usually used as spoilage index of vacuum-packed fish (González-Rodrigez et al. 2002; Stamatis and Arkoudelos 2007; Pantazi et al. 2008; Tsironi and Taoukis 2010), did not reach the spoilage level of 6 log10 cfu/g during the whole study. Textural changes together with rancid taste were the dominant reasons for sensory rejection of treated samples.

Conclusions

Pressure and temperature appeared to act synergistically in Pediococcus spp. inactivation. HP inactivation of Pediococcus spp. was described by the Baranyi model. To serve as a tool for calculation of adequate process conditions, a composite mathematical model was developed. The model describes the decimal reduction times of Pediococcus spp. as a function of pressure and temperature process conditions, taking into account the effect of pressure on the z T values and considering that there was not observed an effect of process temperature on the z Pvalues. The developed model was validated by shelf life experiments of seabream fillets. Results indicated that the application of HP led to improved quality stability during subsequent refrigerated storage and significant shelf life extension, in terms of microbial growth and organoleptic degradation. Based on sensory scoring, the shelf life of the untreated samples was 11, 7, 4 and 3 days and for the HP-treated fillets 37, 27, 17 and 10 days at 0, 5, 10 and 15 °C, respectively (limit equal to 5 /9 for overall acceptability scoring).

Several technologies, including packaging, have been investigated for their potential to extend the shelf life of gilthead seabream, such as osmotic dehydration (Tsironi et al. 2009; Tsironi and Taoukis 2010), vacuum impregnation (Andrés-Bello et al. 2014), light salting (Goulas and Kontominas 2007) and modified atmosphere packaging (Tsironi et al. 2011). Limited shelf life is obtained or the sensory characteristics of the fish (mainly taste and odour) are influenced, as reported by Goulas and Kontominas (2007) for the addition of oregano essential oil to the surface of fish fillet. The results of the study show the potential of using HP for marine cultured gilthead seabream fillet cold pasteurization, by inactivating the dominant microbial factor that causes quality deterioration. The proposed process conditions for gilthead seabream fillets are 600-MPa pressure, at ambient temperature (25 °C) for 5 min, leading to more than threefold shelf life extension during storage at 5 °C.

References

Andrés-Bello, A., De Jesús, C., García-Segovia, P., Pagán-Moreno, M. J., & Martínez-Monzó, J. (2014). Vacuum impregnation as a tool to introduce biopreservatives in gilthead sea bream fillets (Sparus aurata). LWT - Food Science and Technology. doi:10.1016/j.lwt.2014.09.063.

Angsupanich, K., & Ledward, D. A. (1998). High pressure treatment effect on cod (Gadus morhua) muscle. Food Chemistry, 63(1), 39–50.

Baranyi, J., & Roberts, T. A. (1995). Mathematics of predictive food microbiology. International Journal of Food Microbiology, 26, 199–218.

Botta, J. R. (1995). Evaluation of seafood freshness quality (pp. 65–143). New York: VCH Publishers.

Bremner, H. A. (2002). Safety and quality issues in fish processing. Cambridge, England: Woodhead Publishing Limited.

Briones-Labarca, V., Perez-Won, M., Zamarca, M., Aguilera-Radic, J. M., & Tabilo-Munizaga, G. (2012). Effects of high hydrostatic pressure on microstructure, texture, colour and biochemical changes of red abalone (Haliotis rufecens) during cold storage time. Innovative Food Science and Emerging Technologies, 13, 42–50.

Büyükcan, M., Bozoglou, F., & Alpas, H. (2009). Preservation and shelf-life extension of shrimps and clams by high hydrostatic pressure. International Journal of Food Science and Technology, 44(8), 1495–1502.

Cheftel, J. C., & Culioli, J. (1997). Effects if high pressure on meat: a review. Meat Science, 46(3), 211–236.

Chéret, R., Chapleau, N., Delbarre-Ladrat, C., Verrez-Bagnis, V., & Lamballerie, M. (2005). Effects of high pressure on texture and microstructure of sea bass (Dicentrarchus labrax L.) fillets. Journal of Food Science, 70(8), 477–483.

Erkan, N., & Üretener, G. (2010). The effect of high hydrostatic pressure on the microbiological, chemical and sensory quality of fresh gilthead sea bream (Sparus aurata). European Food Research and Technology, 230, 533–542.

Erkan, N., Üretener, G., & Alpas, H. (2010). Effect of high pressure (HP) on the quality and shelf life of red mullet (Mullus surmelutus). Innovative Food Science and Emerging Technologies, 11, 259–264.

Gómez-Estaca, J., Gómez-Guillén, M. C., & Montero, P. (2007). High pressure effects on the quality and preservation of cold-smoked dolphinfish (Coryphaena hippurus) fillets. Food Chemistry, 102(4), 1250–1259.

González-Rodrigez, M. N., Sanz, J. J., Santos, J. Á., Otero, A., & Garćia-López, M. L. (2002). Numbers and types of microorganisms in vacuum-packed cold-smoked freshwater fish at the retail level. International Journal of Food Microbiology, 77, 161–168.

Goulas, A. E., & Kontominas, M. G. (2007). Combined effect of light salting, modified atmosphere packaging and oregano essential oil on the shelf-life of sea bream (Sparus aurata): biochemical and sensory attributes. Food Chemistry, 100(1), 287–296.

Gram, L., & Huss, H. H. (1996). Microbiological spoilage of fish and fish products. International Journal of Food Microbiology, 33, 121–137.

Gram, L., & Huss, H. H. (2000). Flesh and processed fish and shellfish. In B. M. Lund, T. C. Baird-Parker, & G. W. Gould (Eds.), The microbial safety and quality of food, vol. 1 (pp. 245–266). Maryland: Aspen Publishers Inc.

Gudbjornsdottir, B., Jonsson, A., Hafsteinsson, H., & Heinz, V. (2010). Effect of high-pressure processing on Listeria spp. and on the textural and microstructural properties of cold smoked salmon. LWT--Food Science and Technology, 43, 366–374.

Hoover, D. C., Metrick, C., Papineau, A. M., Farkas, D. F., & Knorr, D. (1989). Biological effects of high hydrostatic pressure on microorganisms. Food Technology, 43, 99–107.

ISO 8586–1. (1993). Sensory analysis—general guidance for the selection, training and monitoring of assessors, part 1: selected assessors. International Organization for Standardization, Geneva (http://iso.org).

Jin, W. G., Wu, H. T., Li, X. S., Zhu, B. W., Dong, X. P., Li, Y., & Fu, Y. H. (2014). icrostructure and inter-molecular forces involved in gelation-like protein hydrolysate from neutrase-treated male gonad of scallop (Patinopecten yessoensis). Food Hydrocolloids, 40, 245–253.

Katsaros, G. I., Tsevdou, M., Panagiotou, T., & Taoukis, P. S. (2010). Kinetic study of high pressure microbial and enzyme inactivation and selection of pasteurisation conditions for Valencia Orange Juice. International Journal of Food Science and Technology, 45(6), 1119–1129.

Knorr, D. (1993). Effects of high hydrostatic pressure processes on food safety and quality. Food Technology, 47, 156–161.

Ko, W. C., & Hsu, K. C. (2002). Effect of high-pressure storage on the processing quality of tilapia meat. Process in Biotechnology, 19, 411–416.

Koutsoumanis, K., & Nychas, G. J. E. (2000). Application of a systematic experimental procedure to develop a microbial model for rapid fish shelf life predictions. International Journal of Food Microbiology, 60, 171–184.

Koutsoumanis, K., Giannakourou, M. C., Taoukis, P. S., & Nychas, G. J. E. (2002). Application of shelf life decision system (SLDS) to marine cultured fish quality. International Journal of Food Microbiology, 73, 375–382.

Lakshmanan, R., Piggot, R. J., & Paterson, A. (2003). Potential applications of high pressure for improvement in salmon quality. Trends in Food Science and Technology, 14, 354–363.

López-Caballero, M. E., Pérez-Mateos, M., Montero, P., & Borderís, J. A. (2000). Oyster preservation by high-pressure treatment. Journal of Food Protection, 63(2), 196–201.

Mallidis, C., Galiatsatou, P., Taoukis, P. S., & Tassou, C. (2003). The kinetic evaluation of the use of high hydrostatic pressure to destroy Lactobacillus plantarum and Lactobacillus brevis. International Journal of Food Science and Technology, 38, 579–585.

Murchie, L. W., Cruz-Romero, M., Kerry, J. P., Linton, M., Patterson, Smiddy, M., & Kelly, A. L. (2005). High pressure processing of shellfish: a review of microbiological and other quality aspects. Innovative Food Science and Emerging Technologies, 6, 257–270.

Narwankar, S. P., Flimlin, G. E., Schaffner, D. W., Tepper, B. J., & Karwe, M. V. (2011). Microbial safety and consumer acceptability of high-pressure processed hard clams (Mercenaria mercenaria). Journal of Food Science, 76(6), 375–380.

Ohshima, T., Ushio, H., & Koizumi, C. (1993). High-pressure processing of fish and fish products. Trends in Food Science & Technology, 4, 370–375.

Paarup, T., Sanchez, J. A., Peláez, C., & Moral, A. (2002). Sensory, chemical and bacteriological changes in vacuum-packed pressurized squid mantle (Todaropsis eblanae) stored at 4°C. International Journal of Food Microbiology, 74, 1–12.

Panagou, E. Z., Tassou, C. C., Manitsa, C., & Mallidis, C. (2007). Modelling the effect of high pressure on the inactivation kinetics of a pressure-resistant strain of Pediococcus damnosus in phosphate buffer and gilt-head sea bream (Sparus aurata). Journal of Applied Microbiology, 102(6), 1499–1507.

Pantazi, D., Papavergou, A., Pournis, N., Kontominas, M. G., & Savvaidis, I. N. (2008). Shelf-life of chilled fresh Mediterranean swordfish (Xiphias gladius) stored under various packaging conditions: microbiological, biochemical and sensory attributes. Food Microbiology, 25, 136–143.

Ramirez-Suarez, J. C., & Morrissey, M. T. (2006). Effect of high pressure processing (HP) on shelf life of albacore tuna (Thunnus alalunga) minced muscle. Innovative Food Science and Emerging Technologies, 7, 19–27.

Reyns, K. M. F. A., Sootjens, C. C. F., Cornelis, K., Weemars, C. A., Hendrickx, M. E., & Michiels, C. W. (2000). Kinetics analysis and modeling of combined high–pressure–temperature inactivation of the yeast Zygosaccharomyces bailii. International Journal of Food Microbiology, 56, 199–210.

Shoji, T., & Saeki, H. (1989). Processing and preservation of fish meat by pressurization. In R. Hayashi (Ed.), Use of high pressure in food. Kyoto: San-Ei Publications.

Sigurgisladottir, S., Hafsteinsson, H., Jonsson, A., Lie, O., Nortvedt, R., Thomassen, M., & Torrissen, O. (1999). Textural properties of raw salmon fillets as related to sampling method. Journal of Food Science, 64(1), 99–104.

Stamatis, N., & Arkoudelos, J. (2007). Quality assessment of Scomber colias japonicus under modified atmosphere and vacuum packaging. Food Control, 18, 292–300.

Taoukis, P. S., Labuza, T. P., & Saguy, I. S. (1997). Kinetics of food deterioration and shelf-life prediction. In K. J. Valentas, E. Rotstein, & R. P. Singh (Eds.), Handbook of food engineering practice. Boca Raton, Florida: RC Press.

Taoukis, P. S., Koutsoumanis, K., & Nychas, G. J. E. (1999). Use of time-temperature integrators and predictive modelling for shelf life control of chilled fish under dynamic storage conditions. International Journal of Food Microbiology, 53, 21–31.

Tryfinopoulou, P., Tsakalidou, E., & Nychas, G.-J. E. (2002). Characterization of Pseudomonas spp. associated with spoilage of gilt-head sea bream stored under various conditions. Applied and Environmental Microbiology, 68(1), 65–72.

Tsironi, T., & Taoukis, P. S. (2010). Modeling microbial spoilage and quality of gilthead seabream fillets: combined effect of osmotic pre-treatment, modified atmosphere packaging and nisin on shelf life. Journal of Food Science, 75(4), 243–251.

Tsironi, T., Salapa, I., & Taoukis, P. (2009). Shelf life modelling of osmotically treated chilled gilthead seabream fillets. Innovative Food Science and Emerging Technologies, 10, 23–31.

Tsironi, T., Stamatiou, A., Giannoglou, M., Velliou, E., & Taoukis, P. S. (2011). Predictive modelling and selection of time temperature integrators for monitoring the shelf life of modified atmosphere packed gilthead seabream fillets. LWT - Food Science and Technology, 44(4), 1156–1163.

Yagiz, Y., Kristinsson, H. G., Balaban, M. O., & Marshall, M. R. (2007). Effect of high pressure treatment on the quality of rainbow trout (Oncorhynchus mykiss) and Mahi Mahi (Colyphaena hippurus). Journal of Food Science, 72(9), 509–515.

Yagiz, Y., Kristinsson, H. G., Balaban, M. O., Welt, B. A., Ralat, M., & Marshall, M. R. (2009). Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon. Food Chemistry, 116, 828–835.

Acknowledgement

This research has been co-financed by the European Union (European Social Fund - ESF) and Greek national funds through the Operational Program “Education and Lifelong Learning” of the National Strategic Reference Framework (NSRF) - Research Funding Program: THALES: Reinforcement of the interdisciplinary and/or inter-institutional research and innovation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsironi, T., Maltezou, I., Tsevdou, M. et al. High-Pressure Cold Pasteurization of Gilthead Seabream Fillets: Selection of Process Conditions and Validation of Shelf Life Extension. Food Bioprocess Technol 8, 681–690 (2015). https://doi.org/10.1007/s11947-014-1441-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1441-4

0,

0,  5,

5,  10 and

10 and  15 °C (mean values of two independent experiments ± standard deviation)

15 °C (mean values of two independent experiments ± standard deviation)

5 °C and

5 °C and  10 °C and HP-treated (600 MPa, 5 min) samples stored at

10 °C and HP-treated (600 MPa, 5 min) samples stored at  5 °C and

5 °C and  10 °C

10 °C