Abstract

Particle number (PN) and mass (PM) concentrations were measured in four offices in a HVAC building, one of them corresponding to a printer room. On-line monitoring of the indoor PM concentrations was accompanied with monitoring of the outdoor concentration. In addition, black carbon was measured in two of the selected offices. PN concentrations were measured with a variety of instruments (SMPS,NanoScan, P-Trak) covering a range between 10 nm and 9 μm, whereas PM10 mass concentrations were measured with several DustTraks. Cleaning activities and printing were identified as the most significant indoor sources for ultrafine particles with the latter resulting in a substantial increase of indoor PN<1 concentrations in the printer room during workdays. Moreover, indoor transport of fine particles from the printer room was found to have an important contribution to both indoor PN<1 and PM10 concentrations in two of the rest three offices. The physical presence of the occupants had an impact on particles >2.5 μm during workdays due to particle resuspension. However, when the offices were not occupied (night, weekend) the outdoor environment was a strong contribution to indoor concentrations. Lastly, black carbon preserved low concentrations in both under study offices and was not associated with printer emissions suggesting that black carbon is not an appropriate measure for assessing printer emissions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Indoor contaminants involve a variety of chemical compounds and gaseous pollutants. As the main component of particulate matter, indoor pollutants essentially influence indoor air quality (IAQ) with human occupational health being on the focus for improving environmental conditions. Accordingly, several studies have investigated the effect of ventilation and air-conditioning system (HVAC) to indoor concentration of particles (Fisk et al. 2000; Liddament 2000; Quang et al. 2013; Park et al. 2014; Chatoutsidou et al. 2015). These studies indicate the effective removal of outdoor particles through the ventilation system, thus reduce human exposure to ambient pollutants. Nonetheless, human occupation itself can cause particle generation and release of numerous chemical compounds by indoor activities (Nazaroff and Weschler 2004; Wu et al. 2012; Sangiorgi et al. 2013; Hussein et al. 2015).

In general terms, pollutants may be considered as outdoor or indoor origin. Outdoor-originated pollutants include all compounds that are transported indoors mainly by natural convection. In this case, technical characteristics of the buildings play important roles such as mechanical ventilation, filters, and insulation from doors and windows (Taylor et al. 1999; Liu and Nazaroff 2001; Tian et al. 2009; Lai et al. 2012). Indoor concentrations are then closely associated with outdoor ones. Alternatively, pollutants may originate from indoor sources as the product of human occupation, where chemical composition and characteristics of indoor pollutants are directly linked with primary sources. IAQ in office environments is highly affected by photocopier equipment as shown by numerous studies (Lee and Hsu 2007; Kagi et al. 2007; Koivisto et al. 2010; McGarry et al. 2011), whilst the physical presence of the occupants can contribute as well (Fisk et al. 2000; Chatoutsidou et al. 2015). In particular, hardcopy devices are responsible for enrichment of indoor environment with ultrafine particles, ozone and volatile organic compounds (VOCs) (Destaillats et al. 2008, Vicente et al. 2016). On the contrary, human presence that is not associated with particle generation (cleaning, smoking) mainly influences bigger particles with resuspension activities playing the most dominant role (Qian et al. 2008; Serfozo et al. 2014; Chatoutsidou et al. 2015).

The last years, printer emissions has been on the focus as a major contaminant in the indoor working environment. Many researchers aimed to identify the characteristics of the emitted particles, their impact to IAQ, estimate the emission rates, investigate formation mechanisms and provide an exposure index (He et al. 2007; Lee and Hsu 2007; Kagi et al. 2007; Schripp et al. 2008; Morawska et al. 2009; Hanninen et al. 2010; Koivisto et al. 2010; Betha et al. 2011; McGarry et al. 2011; Byeon and Kim 2012; Salthammer et al. 2012; Kowalska et al. 2015; Vicente et al. 2016). These studies employed different experimental methods and techniques. Hence, a variety of measurements is available consisted of measurements in office workplaces, chambers and copy centres. The experimental set up usually involved online monitoring of particle number size distributions, mass concentrations, ozone, carbon dioxide (CO2), volatile organic compounds (VOC) sampling, air temperature and relative humidity. All studies verify the impact of printer emissions to airborne ultrafine particles and VOC compounds. Whilst emission characteristics were examined thoroughly (He et al. 2007; Wensing et al. 2008; Schripp et al. 2008; Betha et al. 2011; Salthammer et al. 2012), exposure studies are limited with Hanninen et al. 2010 and McGarry et al. 2011 proposed that the associated health risk is low due to the use of the printers. As such, occupational exposure was attributed predominantly to particles originating from sources other than printers. However, these results need to be linked with toxicology studies. Pirela et al. 2015 suggest that the emitted particles may be deleterious to lung cells and that epigenetic modifications might translate to pulmonary disorders. Furthermore, multi-zone environments have been investigated the last years in order to examine the impact between particle transport and indoor airflows (Miller and Nazaroff 2001; Kao et al. 2009; Ng et al. 2013; Rim et al. 2013; McGrath et al. 2014). It was found that multi-zone environments and the relevant concentrations are affected by several factors, those belonging to building design and those to the primary emissions. Accordingly, primary emissions and the related source characteristics (concentration, size distribution, duration of emission) affect IAQ with enrichment of the indoor air with pollutants, with the location of the source playing a significant role. On the other hand, building design and operation of the ventilation system has major impact to the airtightness of the building and inter-zone distribution through exhaust or supply flows (Ng et al. 2013). Higher exchange rates are recommended in cases of higher pollutant concentrations, where inhalation exposure can be considerably reduced. Internal layout, airflows or door configuration determine particle transport to indoor areas and dilution of the indoor concentrations (McGrath et al. 2014). Moreover, IAQ control in buildings with HVAC operating system is challenging due to recirculation of the indoor air through the heating and air-conditioning operation. As such, filters can behave as a source of contamination due to particle deposition (Hinds 1999). A common assessment of all relevant parameters must be undertaken in order to promote high-quality conditions for the occupants.

Herein, particle concentrations were measured in a multi-zone HVAC building equipped with a printer room. Although, emission characteristics from laser printers are widely investigated, experimental studies in real working environments are scarce; hence, occupational exposure to these contaminants is still limited. The present study aimed to investigate the influence of printer emissions to the indoor environment in a rural/suburban location. The objective was to evaluate the impact from the use of printers to indoor particle number (PN), mass (PM) concentrations and black carbon (BC) in different locations of the building. Printer emissions were evaluated in a real office environment characterized by a large number of printed pages during the day. The influence of human occupation to indoor PN and PM concentrations was also investigated.

Methodology

Sampling site

Indoor/outdoor 1-week sampling campaign was conducted at the Technical University of Crete, Greece during May (18–25) 2015. Indoor sampling was performed in a building located in the university campus that belongs to the School of Environmental Engineering. Outdoor sampling was sited 50 m away from the under study building in approximately 1.5 m above the ground. The area surrounding the university campus corresponds to an urban/semi-rural area with insignificant contribution from vehicular emissions (Kopanakis et al. 2013) and is located 5 km north-west of the city of Chania. Detailed description of the area can be found in Lazaridis et al. 2008 and in Kopanakis et al. 2013.

The under study building is a two-floor building that consists of offices and computer rooms on the ground floor and offices and a few laboratories on the first floor. All offices or laboratories in each floor are connected to a main corridor, which uses two, exits one at each end. The two floors are connected through an elevator, internal stairs and square-shaped openings areas of 4 m2 on the ceiling of the ground floor, thus give a feeling of internal balcony. The building is occupied daily on weekdays during open hours, i.e. 08:00 to 21:00.

The building is equipped with mechanical ventilation and separate air-conditioning (AC) system, both of them operated manually by the occupants. Mechanical ventilation uses district ventilation ducts for entrance and exhaust of the airflows. Therefore, the offices are connected with each other through ventilation ducts, depending on their location in the building.

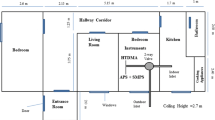

Four offices were selected to conduct the measurements (PR, A1, B1, B2). Offices A1, B1 and B2 correspond to typical working offices whereas PR corresponds to a printer room. Two of them are located on the ground floor (PR, A1), and two of them are located on the first floor (B1, B2). Figure 1 shows the internal layout of each floor and the location of each office. The offices are of rectangular shape and are connected to the outdoors with one window and to the indoors with one door. All selected offices face the north side of the building. Mechanical ventilation was turned off during the campaign but the air-conditioning system was selectively used by the occupants.

Office A1 was occupied permanently by 2–3 people, but other people entered the office occasionally for a short period. No hardcopy device was present inside A1 but common office equipment (personal computers, telephones) whilst furniture (desks, chairs, shelves, closet) covers the internal area. On the contrary, PR is a printer room where four professional printers (Xerox 4110 PS, HP LaserJet 550 and two HP LaserJet 9050) were operated by the users of the building during open hours. PR is not permanently occupied but instead several people enter the room briefly. Office B1 was permanently used by two people, whereas office B2 was very rarely occupied. Both offices are covered with common office equipment and furniture like A1.

Prior to the measurement, the possible major indoor sources were identified in order to minimize the impact from multiple sources. Hence, smoking and combustion in general was not allowed as well as the use of electrical appliances besides office equipment. Furthermore, a diary was given to the occupants to report all indoor activities or any kind of deviation from the measurement protocol. Windows in all the offices were permanently closed during the campaign. The doors in PR and A1 were constantly open during open hours of the building, whereas the doors of B1 and B2 were opened only to enter or exit the office. Table 1 summarizes the location and use profile for each office.

Instrumentation

Particle number size distribution was measured with a NanoScan SMPS (TSI) 3910 and an SMPS+C (CPC Model 5.403 and L-DMA-Vienna type, GRIMM). NanoScan was logging the data every 1 min in 13 channels from 0.01 to 0.42 μm. The measuring principle of NanoScan is based on a unipolar charging where the positively charged particles sent to a radial DMA for size classification which is followed by counting in a CPC. SMPS+C was taking a sample every 6 min and 46 s at flow rate 0.3 l/min in the size range from 0.011 to 1 μm in 44 channels. The operational principle of SMPS is based on a bipolar charging of the sample air in the DMA with a following counting in a CPC. Additionally, particle number concentration was measured with two P-Traks 8525 (TSI) with a 5-min log interval at flow rate 0.1 l/min. P-Trak uses high-purity isopropyl alcohol to grow microscopic particles for easier detection and is able to measure the total particle number concentration in the size range 0.02–1 μm.

Indoor particle mass concentration was measured with a DustTrak II 8532 (TSI) at flow rate 3 l/min, DustTrak 8520 (TSI) at flow rate 1.7 l/min and DustTrak DRX 8534 (TSI). Outdoor particle mass concentration was measured with DustTrak II 8530 (TSI) at flow rate 3 l/min. The log interval was chosen 5 min for all instruments. All DustTrak used a PM10 head to sample, whereas DustTrak DRX measured size-segregated mass fractions for PM1, PM2.5, PM10 and respirable particles.

In addition to the online monitoring of particle number and mass concentrations, black carbon was measured using a MicroAeth AE51 with time resolution of 1 min and flow rate at 100 ml/min. Indoor temperature and relative humidity was recorded with Tinytag data loggers. Table 2 lists the sampling instrument that was placed at each location.

All instruments were synchronized prior to the beginning of the measurements, thus log times of all data were the same (except SMPS).

Side-by-side tests

Side-by-side tests were conducted for all DustTraks. The PM10 concentration was measured in a chamber of 7.6 m3 volume equipped with a HEPA filter (EN 1822). Background measurements were performed whilst incense burning was used as a source for indoor particles. Hence, the following least square linear relationships were obtained between the instruments:

As such, all measured data from the DustTrak II 8532, DustTrak I 8520 and DustTrak DRX 8534 were converted to the equivalent DustTrak II 8532 reading. Subsequently, all DustTrak II 8532 readings (measured and equivalent) were corrected through the gravimetric instrument Sequential Sampler FH 95 SEQ, THERMO, by operating side-by-side for 10 days. The following least square equation was obtained:

For comparative analysis of the particle number concentrations P-Trak values were corrected to the corresponding SMPS values. P-Trak uses higher minimum size limit (20 nm) and is generally accepted to underestimate ambient concentrations especially when a source of ultrafine particles is present (Matson et al. 2004, Zhu et al. 2006). Therefore, a factor was used to interpret the P-Trak values to the equivalent SMPS values. The factor was obtained as \( {F}_c={PN}_{\mathrm{Ptrak}}/{PN}_{\mathrm{SMPS}} \) where \( {PN}_{\mathrm{Ptrak}} \) corresponds to the particle number concentration measured by the P-Trak and \( {PN}_{\mathrm{SMPS}} \) corresponds to the particle number concentration measured by the SMPS. Laboratory measurements were performed using the P-Trak placed in B2. \( {F}_c \) was found equal to 0.78 in agreement with Morawska et al. 2011. P-Trak values were then corrected to the equivalent SMPS values by the equation:

Moreover, side-by-side measurements were performed between the two P-Traks and the following least square linear relationship was obtained:

Thus, number concentration in A1 was corrected twice in order to convert P-Trak readings into the equivalent SMPS values. Laboratory measurements between NanoScan and SMPS showed that the data were in reasonable agreement.

Two-compartment indoor mass balance model

Consider a two-compartment indoor volume i and j with an AC operating system where particles are emitted only at compartment i. Assuming a well-mixed air volume, indoor particle concentration in compartment i can be described by a mass balance model:

where \( {C}_{\mathrm{in}, i} \) is the indoor particle number concentration (cm−3) at i compartment, \( {C}_{\mathrm{in}, j} \) is the indoor particle number concentration (cm−3) at j compartment, \( {C}_{\mathrm{out}} \) is the outdoor particle number concentration (cm−3), \( P \) is the penetration efficiency from outdoors, a is the air exchange rate (h−1) with the outdoor environment, λ is the recirculation rate of the indoor air in the AC system (h−1), η is the single-pass removal efficiency of the AC system, \( {b}_1 \) (h−1) is the airflow rate from compartment j to i, \( {b}_2 \) (h−1) is airflow rate from compartment i to j, k is the deposition rate (h−1) in compartment i, S is the emission rate of particles (h-1,), V is volume of the area under study (cm−3) and t is the time (h). Hussein et al. 2009 has reported that coagulation for ultrafine particles becomes significant when the indoor concentration is higher than 104 cm−3. For numerical calculations, particle coagulation using the present mass balance model was considered negligible since indoor PN concentration was rarely higher than 104 cm−3.

Equation (1) can be used to determine the total removal of particles in compartment i when no source is present (\( S=0 \)). Thus, Eq. (1) is rewritten:

where the total removal rate is expressed by the quantity \( a+ k+\lambda \eta +{b}_2 \) which corresponds to losses due to airflow from the under study volume to outdoors (a) or to compartment j (\( {b}_2 \)), losses due to filtration of the indoor air by the AC system (\( \lambda \eta \)) and losses due to particle deposition on indoor surfaces (k). On the contrary, the first two terms on the right hand side of Eq. (2) express the airflow into the under study volume from the outdoors and indoors respectively, thus, have a positive contribution to indoor particle concentration at compartment i.

Equation (2) can be solved analytically; therefore, indoor PN concentration at any time t is given as:

Equation (3) suggests that the indoor PN concentration is exponentially decreasing with a rate equal to \( a+ k+\lambda \eta +{b}_2 \). Subsequently, the first term in the right hand side of Eq. (3) represents the PN concentration that remains suspended indoors but originates by penetration from the outdoors or is transported from the indoors.

Equation (1) was used as a mass balance model in order to evaluate the contribution from printer emissions inside PR. Therefore, the contribution from other internal areas into PR was incorporated as a common term in Eq. (1)—compartment j—considering that the major source of ultrafine particles was located in PR (printers).

Results and discussion

PN concentrations in the printer room

The measured PN<0.4 concentration inside PR during the campaign is plotted in Fig. 2 along with the total number of printed pages. It is seen that PN<0.4 concentration preserved lower concentrations on weekends and on workdays during closed hours (21:00–08:00). These periods were considered as background concentrations mostly affected by the outdoor concentration. Median concentration during these hours was 3,080 cm−3. Moreover, Fig. 2 indicates a substantial increase of the indoor particle number concentration early in the morning (08:00–09:00) for workdays, which is not associated with any printing activity. Peak concentration reached 28,320, 39,672, 30,217, 33,378 and 46,506 cm−3 for 19/05, 20/05, 21/05, 22/05 and 25/05, respectively. This sharp increase usually lasted for 5 min and was caused by cleaning of the corridor just outside PR. Emissions from cleaning agents usually involve particle generation in the ultrafine region (Huang et al. 2011; Nørgaard et al. 2014) as the product of secondary organic aerosol formation by primary VOC emissions (Nazaroff and Weschler 2004; Coleman et al. 2008). Figure 1S demonstrates that cleaning-generated particles lie in the ultrafine region with the dominant particle size being always at 50 nm for all five cases.

However, the most important contribution to submicron particles indoors in terms of long exposure is attributed to emissions from printers. Although, outdoor measurement of PN concentrations during the campaign is missing, parallel measurements of both indoor and outdoor PN concentrations were performed for 48 h at a different period (Figure 2S). The measurement period corresponded to a weekend thus PR was constantly unoccupied and no activity took place. Figure 2S demonstrates that outdoor PN concentration is characterized by great variability as a result of outdoor atmospheric conditions (mainly meteorological conditions), whereas indoor PN concentration presents a smoother curve which suggests the absence of significant sources. Therefore, the intensive temporal fluctuations of indoor PN concentration observed on working hours (Fig. 2) is attributed to human activities, i.e. the use of printers inside PR.

Printing periods, which correspond to periods with printing activity, were identified usually between 09:00 and 21:00 on workdays. A t test was performed to investigate if PN concentrations in PR are statistically higher on printing periods compared to the background levels. Assuming a null hypothesis that the two concentration means (\( {\mu}_{\mathrm{em}},{\mu}_{\mathrm{bc}} \)) are equal and the alternative hypothesis being \( {\mu}_{\mathrm{em}}-{\mu}_{\mathrm{bc}}>0 \), p value was found <0.001. Thus, at confidence level >99% PN concentrations during printing periods are statistically significantly greater than that during background periods, a conclusion that is associated with printer emissions. Figure 2 indicates that during these periods, PN<0.4 concentration was considerably higher compared to no printing periods (night hours, weekend). Median concentration during printing periods was 4933 cm−3.

In addition, Fig. 3 compares the histograms of the frequency of observation of PN concentrations obtained for background and printing periods. It suggests that there is a shift towards higher concentrations during printing periods with the most frequent PN concentrations being at 5000 cm−3, in contrast with background concentrations where the most frequent concentrations were measured between 2500 and 3000 cm−3.

The impact from printer emissions in particle size is highlighted in Fig. 4. Figure 4a demonstrates that ultrafine PN concentration varied temporarily with sharp increases leading to substantially higher indoor concentration during daytime (printing period), compared to that during night-time (no printing period) where no activity took place (Fig. 4c). On average, PN<0.1 concentration between 09:00 and 21:00 was 1.2 times higher compared to that at night-time during the campaign. In addition, particles in the size range 0.1–0.4 μm presented higher concentration during daytime (Fig. 4b), although the corresponding concentrations were significantly lower than that of PN<0.1. Hardcopy devices and printers are known for their effect on indoor PN concentration and especially in particle sizes <0.1 μm (Schripp et al. 2008; Wensing et al. 2008; McGarry et al. 2011). Recent investigation on emission characteristics from laser printers suggests that particles are of secondary nature and are formed in the air from VOCs, emitted by the printers. This effect leads to indoor ultrafine particle generation, either by homogenous nucleation or secondary particle formation (Morawska et al. 2009). On the other hand, the higher (compared to night hours) PN concentrations measured during day hours for particles in the size range 0.1–0.4 μm are attributed to coagulation of ultrafine particles. Thus, PN0.1–0.4 concentration maintained lower levels than PN<0.1 concentration but still higher compared to the concentration during the no printing period (Fig. 4d). However, indoor PN concentration for submicron particles during night-time is likely influenced by outdoors. Therefore, submicron particle concentrations in PR are substantially affected by printer emissions.

PM concentrations in the printer room

PM10 concentration in PR presented a behaviour similar to the one observed for PN concentration (Fig. 2), i.e. intensive temporal fluctuations during open hours characterized by higher ambient concentrations compared to closed hours. This behaviour is likely due to printer emissions and associated particles <1 μm (PM1). Median concentration during printing periods was 15 μg/m3, whereas during no printing periods, it was 12 μg/m3 suggesting an increase of 25%. Vicente et al. 2016 reported that approximately 60% of the measured PM10 concentration in copy centres was composed of particles <2.5 μm. Figure 5 suggests that PM2.5 concentration contributed to PM10 concentration in PR by 72–95% during open hours.

Moreover, Fig. 5 demonstrates that PM1/PM10 and PM2.5/PM10 ratios preserved ratios higher than >0.9 during periods where the building was not occupied (workdays 21:00–08:00, weekend). In practice, a diurnal variation for both ratios was observed during working days, whereas during the weekend, no diurnal variation was present. PM2.5/PM10 reached a ratio almost equal to 1 during closed hours (21:00–08:00) on weekdays suggesting that indoor PM concentration during the night inside PR is dominated by smaller micron-sized particles and that coarse particle concentration (> PM2.5) is negligible, i.e. not suspended in the air. The same behaviour applies for PM1/PM10 but with lower ratios since PM1 is included in PM2.5. Similar results were obtained for the weekend where the office was constantly unoccupied. Therefore, during closed hours submicron particles most probably originate from the outdoors due to infiltration, although a major part corresponds to the suspended particulate matter emitted from daily activities due to low terminal settling velocity and long residence time.

Nevertheless, during open hours the contribution from coarse particles becomes important. In more detail, ratios <0.9 for both PM1/PM10 and PM2.5/PM10 were obtained only during open hours (08:00–21:00), implying that coarse particles (>2.5 μm) are significantly suspended during daytime most notably due to particle resuspension. Particle size and resuspension are associated in many studies (Qian et al. 2008; Serfozo et al. 2014; Hussein et al. 2015). Note also that the PM1/PM10 ratio reached its lowest value on 21/05 which coincides with a substantial increase of PM10 concentration in the same day (Fig. 2), caused by cleaning activities inside PR. Sarwar et al. 2004 and Nørgaard et al. 2014 have shown that the use of cleaning products (general purpose cleaner, floor cleaner) causes an immediate increase in particle mass concentration along with particle number concentration due to fine particle formation/growth. Moreover, cleaning activities (dusting, vacuuming) can cause increased concentration of coarse particles due to resuspension (Ferro et al. 2004). However, in the rest of the workdays (no cleaning) resuspension of coarse particles is attributed to human walking or the physical presence of the occupants.

I/O ratio

Figure 6 presents the I/O ratios obtained from all measured PM10 data. Ratios higher than 0.90 (10th percentile) found for all three offices (PR, A1, B2). This finding strongly suggests that the indoor PM10 concentrations preserved values considerably higher than the outdoor levels, therefore, implies the presence of indoor sources. PM I/O ratios higher than 1 in commercial buildings are also reported in Challoner et al. 2014.

B2 preserved the higher I/O ratios among the three offices due to the substantially higher indoor PM10 concentrations measured in that office (Table 3). I/O ratios for B2 varied between 1.42 and 2.10 with a mean value at 1.71. No indoor source was recorded in B2 (it was very rarely occupied) besides cleaning the office on 21/05 (higher daily median PM10 concentration, 23 μg/m3). The cleaning of B2 resulted in a sharp short-term increase of PM10 as seen in PR due to the use of cleaning agents. Similar observation is reported in Alves et al. 2014a and Pagel et al. 2016. Nevertheless, it is believed that the higher I/O ratios obtained for B2 are due to particle transport from another internal area through gaps of the door or from the ventilation ducts. It is likely that indoor PM10 concentration in the office was influenced by that of other offices through ventilation ducts when mechanical ventilation was off. Accordingly, forced airflows inside the ventilation ducts prevent air mixing between the offices when mechanical ventilation is operating, whereas the opposite behaviour is not ensured when mechanical ventilation is not operating. Thus, it is likely that the high concentrations are associated with an indoor source originating from another office which is connected with B2 with the same ventilation duct.

A comparison between offices PR and A1 (occupied offices) suggests that PR was characterized by slightly higher I/O ratios. Mean values were 1.24 and 1.18 for PR and A1, respectively. I/O ratios higher than 1 for PM10 are also reported in a study inside copy centres (Vicente et al. 2016). The difference between the two offices is associated with printer emissions and especially the fine particle fraction. To further investigate the statistical significance of printer emission to PM10 concentrations and the resulting I/O ratios in PR and A1, three t tests were performed. The t test #1 examined the statistical significance of printer emission to I/O ratios in PR and A1. The test was conducted using the overall I/O ratios obtained for PR and A1. The t test #2 examined the statistical significance of printer emission to I/O background and emission period ratios in PR, whilst t test #3 examined the statistical significance of printer emission to I/O background and emission period ratios in A1. The results of the tests are presented in Table 4. In all cases p value was <0.05; thus, the null hypothesis was rejected. The statistically significant higher I/O ratios in PR and significantly greater ratios during emission periods in both offices are attributed to printer emissions. Enrichment with particles <1 μm in PR, caused by the use of printers during open hours, leads to higher PM10 concentrations compared to the PM10 concentrations measured in A1. It is well-established that the physical presence of people in indoor environments has impact on coarse particles (Fisk et al. 2000; Qian et al. 2008; Shaughnessy and Vu 2012; Chatoutsidou et al. 2015; Hussein et al. 2015) due to particle resuspension. However, the present results demonstrate that printing emissions in PR had bigger impact on PM10 concentration than particle resuspension due to human occupation. Figure 5 shows that the PM1 concentration, submicron particles, dominated the indoor air in PR with PM1/PM10 being usually above 0.7, whilst the median PM>2.5 concentration during the campaign was 0.44 μg/m3.

Lastly, no operation of the mechanical ventilation in the under study offices is believed to contribute to the high I/O ratios reported in the present study. Studies that have investigated the impact of mechanical ventilation confirm that the operation of the HVAC system results in reduced I/O ratios indoors for both fine and coarse particles (Goyal and Kumar 2013; Quang et al. 2013; Park et al. 2014; Othman et al. 2016).

Contribution of printer emissions in the printer room

Figure 7 presents the daily median PN<1 concentrations obtained only during open hours in each office. In general, higher PN<1 concentrations of submicron particles were measured inside PR, whilst the other three offices preserved nearly similar levels of PN concentrations (with an exception on 18/05 for B1-increased median concentration is due to a local indoor source). Median PN concentration in PR was higher by an average factor of 1.58, 1.50 and 1.61 from the median PN concentration in A1, B1 and B2, respectively. Higher concentrations in PR are attributed to emissions from printers; although, cleaning of the office contributed temporarily to particle generation in the ultrafine region.

Time-resolved PN concentrations in PR showed an exponential decrease of the indoor concentration after reaching a peak concentration on workdays during open hours (Fig. 4a). The data after these peaks were used to determine the total removal rate (\( a+ k+\lambda \eta +{b}_2 \)) for ultrafine particles, the particle size that was mostly affected by printer emissions.

The total removal rate of ultrafine particles was estimated for each calendar day separately using Eq. (3). Table 1S lists the averaged total removal rate for each workday along with the averaged suspended PN<0.1 concentration originating from areas other than PR. High removal rates were obtained for all days. Although, it was not possible to estimate each variable separately, it is believed that the main contribution to the total removal rate in PR originates from \( {b}_2 \), the exchange rate of PR with internal areas of the building. The door connecting PR with the main corridor was always open during daytime, thus air and particulate matter transport is easier and more effective. McGrath et al. 2014 conducted measurements in a room with different sources and found that the open door scenario results in lower indoor concentrations which is associated with easier escape of particles. Moreover, daily variations of the total removal rate are likely influenced by diurnal variations of the air currents inside the building. A higher estimate (12.84 h−1) was obtained on 20/05, which corresponds to the day with the lower measured indoor PN<1 concentration between the working days (Fig. 7).

Subsequently, emissions from printers were estimated for PN<0.1 concentration using Eq. (1) for each time interval. The emission rates were determined from the term \( S/ V \). Only, positive numbers were accepted when evaluating \( d{C}_{\mathrm{in}, i}/ d t \) in order to represent the physical situation: emissions increase indoor particle concentration. Moreover, linear regression was used to correlate the estimated emission rates with the corresponding indoor PN<0.1 concentrations. Accordingly, a least square line was obtained for each day with \( {C}_{\mathrm{in}}= a S+ b \). Table 5 presents the statistical indicators of the estimated emission rates in PR. The parameters of linear regression are given in Table 2S. It suggests that the two variables (\( {C}_{\mathrm{in}} \) and S) are in good agreement, with R 2 being higher than 0.8. Hence, emission rates were well estimated from number concentration data.

Ultrafine particle emission rates were significantly scattered. The number of printed pages as well as indoor conditions such as internal air flows can influence daily variations. Higher values were obtained for 21/05 and 22/05 with 90th percentile at 669 · 108 min−1 and 758 · 108 min−1, respectively. Figure 7 suggests that both days correspond to the higher averaged PN<1 concentrations measured in PR with 5363 cm−3 and 6360 cm−3 for 21/05 and 22/05, respectively. Median emission rates obtained in the present study varied between 109 and 1010 min−1, which is in agreement with other studies that evaluated emission rates from printers (He et al. 2007; Koivisto et al. 2010). The main particle removal process is believed to come from the ventilation of the room which influences substantially the ambient PN<1 concentrations. Consequently, indoor PN<1 concentrations were increased only by a few thousands (4000–5000 cm−3) during printing periods. Emissions from printers and the relevant indoor PN concentrations depend substantially on the printer, room characteristics and indoor conditions (Wensing et al. 2008; Koivisto et al. 2010). Figure 8 shows that there is no specific trend between indoor PN concentrations and the number of printed pages, which is associated with daily variations in removal rates inside PR. The same observation is reported in Betha et al. 2011 in a study in a commercial printing center. Variations in time are also associated with the use of the printers during the day. Multiple prints were performed during open hours of the office with the printed pages varying considerably in number. Figure 8 demonstrates the complexity of a real working environment in residential buildings and the difficulty to obtain a mathematically based correlation, unlike experimental studies conducted in controlled conditions.

Impact of printer emissions in other offices

The use of printers influenced substantially both the PN and PM concentrations in PR. In turn, printer emission had significant impact in other offices due to particle transport. PM10 concentrations in A1 and B2 were found to correlate significantly with PM10 concentrations in PR. Figures 9 and 10 present the correlation of PM10 concentration in each office with the PM10 concentration in PR and with the outdoor concentration. All data correspond to printing hours, i.e. 09:00–21:00. It is observed that higher correlation was found between the PM10 concentrations in the under study offices and PR. Specifically, R 2 was 0.74 between the PM10 concentration in A1 and PR, whereas R 2 was 0.47 between the PM10 concentration in A1 and the outdoor concentration. For B2 the same observation was found but with lower correlation for both cases. Thus, R2 was 0.69 between the PM10 concentration in B2 and PR and 0.36 between B2 and outdoors. These findings demonstrate that PM10 concentrations in A1 and B2 are primarily affected by the PM10 concentration in PR due to particle transport through the internal areas of the building. Nevertheless, the outdoor environment is an important but weaker contribution to indoors during occupied hours.

In addition, Fig. 11a, b present the correlation between A1 and B2 with PR using the number concentration data. Again, good agreement was found between PN<1 concentrations for both cases with R 2 0.63 and 0.61 for A1 and B2, respectively. Although, parallel correlation with the outdoor data is missing in this case, the present results confirm the impact of submicron particles that originated from PR but transported to other offices. Recall that A1 was occupied during open hours; hence, human presence in A1 had a negligible impact to indoor PN concentration for submicron particles. Fine particles are not effectively escaped as coarse particles due to their smaller inertia that allows them to be influenced by airflow patterns of the building, momentum jets and eddies indoors (Kao et al. 2009). Internal airflows, location and magnitude of the emissions influence substantially particle transport indoors (McGrath et al. 2014), thus variations may be observed from day to day. Therefore, smaller particles are easily transported to internal areas of the building compared to bigger particles.

The relative higher correlation obtained for A1 compared to B2 (both for PN and PM concentrations) is associated with the location of each office. It is likely that A1 is more effectively influenced by printer emissions because the office is located closer to PR and at the same floor (ground floor).

Figure 12 presents the correlation of PN<1 concentration between PR and B1 using the data between 09:00–21:00 for workdays. Due to different log intervals of the instruments, average values were used for PR data. The poor correlation (R 2 = 0.19) found between these offices does not allow to end at a safe conclusion for office B2. A possible reason is the discrepancies between the data due to the different log intervals. Linear regression parameters for mass and number concentration data are given in Table 3S and Table 4S respectively.

Overall, the present results imply that the impact from printer emissions is significant and that submicron particle transport indoors is important to other locations of the building. Daily variations of internal airflows and environmental conditions are believed to influence indoor particle transport.

Black carbon

Table 6a summarizes statistical indicators for black carbon in PR and B1, where open hours (08:00–21:00) values are compared with the corresponding closed hours (21:00–08:00) values. In general, BC levels in both offices maintained low concentrations with no significant difference between open hours and closed hours. Both indoor averaged and mean BC concentration was considerably lower compared to other studies where mean indoor BC concentration was usually above 1 μg/m3 (Viana et al. 2011; Wang et al. 2013; Reche et al. 2015; Tunno et al. 2015). Averaged BC during open hours and closed hours in PR was almost equal (0.24 and 0.25 μg/m3, respectively), whereas in B1, BC was slightly higher during open hours (0.38 μg/m3) compared to that during closed hours (0.32 μg/m3). The values also indicate higher BC concentrations in B1 compared to that in PR during the sampling period.

The low indoor BC concentrations for both open and closed hours strongly suggest the absence of a direct impact from indoor sources. Accordingly, the results demonstrate that black carbon was not directly influenced by emission from printers. Similar observation is reported in Betha et al. 2011, in measurements in a printing centre. Instead, BC concentration in both offices is likely influenced by outdoor levels. Indoor/outdoor relation of black carbon is well noted in other studies (LaRosa et al. 2002; Diapouli et al. 2011; Viana et al. 2011; Reche et al. 2015). In the present case, daily variations in the two offices are believed to originate from outdoor fluctuations. The carbonaceous content of particles is closely related with PM concentrations (Alves et al. 2014b). Table 6b verifies that BC is a major component of fine particles with better correlation for PM1 (R 2 = 0.52). Higher correlation for fine particles (PM2.5) is also reported in Wang et al. 2013.

Conclusions

The impact from human occupation and printing activity was studied in four modern offices (three typical working offices and one printer room) in a HVAC building. Indoor particle number (PN) and mass (PM) concentrations were measured in all four offices whilst black carbon was measured in two selected offices. Different occupation schemes characterized each office; however, common sources were identified in all offices as the product of human occupation.

The primary contribution to indoor PN and PM concentrations in PR originated from printer emissions in terms of long exposure; although, cleaning activities substantially influenced indoor PN concentration in terms of short exposure. Both sources affected ultrafine particle concentration (<0.1 μm) with PM1 corresponding to >75% of the PM10 concentration. In addition, the results showed that fine particle concentration in two of the three offices was influenced by printer emissions indirectly due to indoor particle transport. Regression analysis provided high correlations (R 2) between the indoor (PN and PM) concentrations in PR and the corresponding concentrations in A1 and B2. The same behaviour was not identified for B1. On the contrary, in periods were the offices were closed and no printing activity took place (night, weekend), indoor concentrations were influenced by the outdoor concentration.

Human occupation during workdays had secondary impact in the occupied offices. Human presence without particle generation was associated with resuspension activities that caused increased concentration indoors for particles higher than 2.5 μm. I/O ratios higher than 1 that were obtained for two of the selected offices (A1, PR) were attributed to printer emissions, whereas the relative substantial higher ratios obtained for B2 were associated with particle transport through the ventilation ducts. Lastly, indoor black carbon was not associated with printer emissions rather than was influenced by outdoor levels as a significant component of particulate matter. The results presented herein indicate that evaluation of printer emissions with black carbon measurements is ineffective.

Overall, particle number and mass concentrations in the under study building are influenced primarily by indoor sources (printers) during working days. Human occupation has significant impact to fine particle concentration; thus, use of the ventilation system on a daily basis and continuously during open hours is necessary.

References

Alves C, Calvo AI, Marques L, Castro A, Nunes T, Coz E, Fraile R (2014a) Particulate matter in the indoor and outdoor air of a gymnasium and a fronton. Environ Sci Pollut R 21:12390–12402

Alves CA, Urban RC, Pegas PN, Nunes T (2014b) Indoor/outdoor relationships for PM10 and associated organic compounds in a primary school. Aerosol Air Qual Res 14:86–98

Betha R, Selvam V, Blake DR, Balasubramanian R (2011) Emission characteristics of ultrafine particles and volatile organic compounds in a commercial printing center. J Air Waste Manage 61:1093–1101

Byeon JH, Kim J-W (2012) Particle emission from laser printers with different printing speeds. Atmos Environ 54:272–276

Chatoutsidou SE, Ondráček J, Tesar O, Tørseth K, Zdimal V, Lazaridis M (2015) Indoor/outdoor particulate matter number and mass concentration in modern offices. Build Environ 92:462–474

Coleman BK, Lunden MM, Destaillats H, Nazaroff WW (2008) Secondary organic aerosol from ozone-intiated reactions with terpene-rich household products. Atmos Environ 42:8234–8245

Destaillats H, Maddalena RL, Singer BC, Hodgson AT, McKone TE (2008) Indoor pollutants emitted by office equipment: a review of reported data and information needs. Atmos Environ 42:1371–1388

Diapouli E, Eleftheriadis K, Karanasiou AA, Vratolis S, Hermansen O, Colbeck I, Lazaridis M (2011) Indoor and outdoor particle number and mass concentrations in Athens. Sources, sinks and variability of aerosol parameters. Aerosol Air Qual Res 11:632–642

Ferro AR, Kopperud RJ, Hildemann LM (2004) Source strengths for indoor human activities that resuspend particulate matter. Environ Sci Technol 38:1759–1764

Fisk WJ, Faulkner D, Sullivan D, Mendell MJ (2000) Particle concentrations and sizes with normal and high efficiency air filtration in a sealed air-conditioned office building. Aerosol Sci Technol 32:527–544

Goyal R, Kumar P (2013) Indoor outdoor concentrations of particulate matter in nine microenvironments of a mix-use commercial building in megacity Delhi. Air Qual Atmos Health 6:747–757

Hanninen O, Bruske-Hohlfeld I, Loh M, Stoeger T, Kreyling W, Schmid O, Peters A (2010) Occupational and consumer risk estimates for nanoparticles emitted by laser printers. J Nanopart Res 12:91–99

He C, Morawska L, Taplin L (2007) Particle emission characteristics of office printers. Environ Sci Technol 41:6039–6045

Hinds WC (1999) Aerosol Technology. John Wiley & Sons, New York

Huang Y, Ho KF, Ho SSH, Lee SC, Yau PS, Cheng Y (2011) Physical parameters effect on ozone-initiated formation of indoor secondary organic aerosols with emissions from cleaning products. J Hazard Mater 192:1787–1794

Hussein T, Dada L, Juwhari H, Faouri D (2015) Characterization, fate and re-suspension of aerosol particles (0.3-10 μm): the effects of occupancy and carpet use. Aerosol Air Qual Res 15:2367–2377

Hussein T, Hruška A, Dohányosová P, Džumbová L, Hemerka J, Kulmala M, Smolík J (2009) Deposition rates on smooth surfaces and coagulation of aerosol particles inside a test chamber. Atmos Environ 43:905–914

Kagi N, Fujii S, Horiba Y, Namiki N, Ohtani Y, Emi H, Tamura H, Kim YS (2007) Indoor air quality for chemical and ultrafine particle contaminants from printers. Build Environ 42:1949–1954

Kao HM, Chang TJ, Hsieg YF, Wang CH, Hsieg CI (2009) Comparison of airflow and particulate matter transport in multi-room buildings for different natural ventilation patterns. Energ Buildings 41:966–974

Koivisto AJ, Hussein T, Niemelä R, Tuomi T, Hämeri K (2010) Impact of particle emissions of new laser printers on modeled office room. Atmos Environ 44:2140–2146

Kopanakis I, Chatoutsidou SE, Torseth K, Glytsos T, Lazaridis M (2013) Particle number size distribution in the Eastern Mediterranean: formation and growth rates of ultrafine airborne atmospheric particles. Atmos Environ 77:790–802

Kowalska J, Szewczyńska M, Pośniak M (2015) Measurements of chlorinated volatile organic compounds emitted from office printers and photocopiers. Environ Sci Pollt Res Int 22:5241–5252

Lai CKA, Fung JLS, Leung KY (2012) Penetration of fine particles through rough cracks. Atmos Environ 60:436–443

LaRosa LE, Buckley TJ, Wallace LA (2002) Real-time indoor and outdoor measurements of black carbon in an occupied house: an examination of sources. J Air Waste Manage 52:41–49

Lazaridis M, Dzumbova L, Kopanakis I, Ondracek J, Glytsos T, Alexandropoulou V, Voulgarakis A, Katsivela E, Michalopoulos N, Eleftheriadis K (2008) PM10 and PM2.5 levels in the Eastern Mediterranean (Akrotiri research station, Crete, Greece). Water Air Soil Poll 189:85–101

Lee CW, Hsu DJ (2007) Measurements of fine and ultrafine particles formation in photocopy centers in Taiwan. Atmos Environ 41:6598–6609

Liddament MW (2000) A review of ventilation and the quality of ventilation air. Indoor Air 10:193–199

Liu DL, Nazaroff WW (2001) Modeling pollutant penetration across building envelopes. Atmos Environ 35:4451–4462

Matson LE, Ekberg LE, Afshari A (2004) Measurement of ultrafine particles: a comparison of two handheld condensation particle counters. Aerosol Sci Tech 38:487–495

McGarry P, Morawska L, He C, Jayaratne R, Falk M, Tran Q, Wang H (2011) Exposure to particles from laser printers operating within office workplaces. Environ Sci Technol 45:6444–6452

McGrath JA, Byrne MA, Ashmore MR, Terry AC, Dimitropoulou C (2014) Development of a probabilistic multi-zone multi-source computational model and demonstration of its applications in predicting PM concentrations indoors. Sci Total Environ 490:798–806

Miller SL, Nazaroff WW (2001) Environmental tobacco smoke particles in multizone indoor environments. Atmos Environ 35:2053–2067

Morawska L, He C, Johnson G, Jayaratne R, Salthammer T, Wang H, Uhde E, Bostrom T, Modini R, Ayoko G, McGarry P, Wensing M (2009) An investigation into the characteristics and formation mechanisms of particles originating from the operation of laser printers. Environ Sci Technol 43:1015–1022

Morawska L, Mc Garry P, He C, Jayaratne R, Falk M, Wang L (2011) Nanoparticles from printer emissions in workplace environments. Report, International Laboratory for Air Quality and Health (ILAQH). Queensland University of Technology, Brisbane

Nazaroff WW, Weschler CJ (2004) Cleaning products and air fresheners: exposure to primary and secondary air pollutants. Atmos Environ 38:2841–2865

Ng LC, Musser A, Persily AK, Emmerich SJ (2013) Multizone airflow models for calculating infiltration rates in commercial reference buildings. Energ Buildings 58:11–18

Nørgaard AW, Kudal AW, Kofoed-Sørensen V, Koponen IK, Wolkoff P (2014) Ozone-initiated VOC and particle emissions from a cleaning agent and an air freshener: risk assessment of acute airway effects. Environ Int 68:209–218

Othman M, Latif MT, Mohamed AF (2016) The PM10 compositions, sources and health risks assessment in mechanically ventilated office buildings in an urban environment. Air Qual Atmos Health 9:597–612

Pagel EC, Reis NC Jr, de Alvarez CE, Santos JM, Conti MM, Boldrini RS, Kerr AS (2016) Characterization of the indoor particles and their sources in an Antarctic research station. Environ Monit Assess 188:167

Park JS, Jee N-Y, Jeong J-W (2014) Effects of types of ventilation system on indoor particle concentrations in residential buildings. Indoor Air. doi:10.1111/ina.12117

Pirela SV, Miousse IR, Lu X, Castranova V, Thomas T, Qian Y, Bello D, Kobzik L, Koturbash I, Demokritou P (2015) Effects of laser printer-emitted engineered nanoparticles on cytotoxicity, chemokine expression, reactive oxygen species, DNA methylation and DNA damage: a comprehensive in vitro analysis in human small airway epithelial cells, macrophages, and lymphoblasts. Environ Health Persp. doi:10.1289/ehp.1409582

Qian J, Ferro AR, Fowler KR (2008) Estimating the resuspension rate and residence time of indoor particles. J Air Waste Manage 58:502–516

Quang TN, He C, Morawska L, Knibbs LD (2013) Influence of ventilation and filtration on indoor particle concentrations in urban office buildings. Atmos Environ 79:41–52

Reche C, Rivas I, Pandolfi M, Viana M, Bouso L, Àlvarez-Pedrerol M, Alastuey A, Sunyer J, Querol X (2015) Real-time indoor and outdoor measurements of black carbon at primary schools. Atmos Environ 120:417–426

Rim D, Persily A, Emmerich S, Dols WS, Wallace L (2013) Multi-zone modeling of size-resolved outdoor ultrafine particle entry into a test house. Atmos Environ 69:219–230

Salthammer T, Schripp T, Uhde E, Wensing M (2012) Aerosols generated by hardcopy devices and other electrical aplliances. Environ Pollut 169:167–174

Sangiorgi G, Ferrero L, Ferrini BS, Lo Porto C, Perrone MG, Zangrando R, Gambaro A, Lazatti Z, Bolzacchini E (2013) Indoor airborne particle sources and semi-volatile partitioning effect of outdoor fine PM in offices. Atmos Environ 65:205–214

Sarwar G, Olson DA, Corsi RL, Weschler CJ (2004) Indoor fine particles: the role of terpene emissions from consumer products. J Air Waste Manage 54:367–377

Schripp T, Wensing EU, Salthammer T, He C, Morawska L (2008) Evaluation of ultrafine particle emissions from laser printers using emission test chambers. Environ Sci Technol 42:4338–4343

Serfozo N, Chatoutsidou SE, Lazaridis M (2014) The effect of particle resuspension during walking activity to PM10 mass and number concentrations in an indoor microenvironment. Build Environ 82:180–189

Shaughnessy R, Vu H (2012) Particle loadings and resuspension related to floor coverings in chamber and in occupied school environments. Atmos Environ 55:515–524

Taylor BJ, Webster R, Imbabi MS (1999) The building envelope as an air filter. Build Environ 34:353–361

Tian L, Zhang G, Jinghua T, Zhou J, Zhang Q (2009) Mathematical model of particle penetration through smooth/rough building envelop leakages. Build Environ 44:1144–1149

Tunno BJ, Shields KN, Cambal L, Tripathy S, Holguin F, Lioy P, Clougherty JE (2015) Indoor air sampling for fine particulate matter and black carbon in industrial communities in Pittsburg. Sci Total Environ 536:108–115

Viana M, Díez S, Reche C (2011) Indoor and outdoor sources and infiltration processes of PM1 and black carbon in an urban environment. Atmos Environ 45:6359–6367

Vicente ED, Ribeiro JP, Custódio D, Alves CA (2016) Assessment of the indoor air quality in copy centres at Aveiro, Portugal. Air Qual Atmos Health. DOI: 10.1007/s11869-016-0401-8

Wang X, Chen R, Meng X, Geng F, Wang C, Kan H (2013) Associations between fine particle, coarse particle, black carbon and hospital visits in a Chinese city. Sci Total Environ 458–460:1–6

Wensing M, Schripp T, Uhde E, Salthammer T (2008) Ultra-fine particles release from hardcopy devices: sources, real-room measurements and efficiency of filter accessories. Sci Total Environ 407:418–427

Wu XM, Apte GM, Bennett DH (2012) Indoor particle levels in small- and medium-sized commercial buildings in California. Environ Sci Technol 46:12355–12363

Zhu Y, Yu N, Kuhn T, Hinds WC (2006) Field comparison of P-trak and condensation particle counters. Aerosol Sci Tech 40:422–430

Acknowledgments

The present work was supported by the European Union 7th framework program HEXACOMM FP7/2007-2013 under grant agreement N° 315760.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

Fig. 1S: Particle number size distribution (dN/dlogDp) of peak concentration in PR during cleaning of the corridor. Fig. 2S: Indoor particle number concentration in PR and outdoor particle number concentration as measured for 48 h on 10-11/10/2015. The office was closed and no activity took place during the measurement. Table 1S: Averaged total removal rate and suspended PN<0.1 concentration originating from other areas estimated for each workday. Table 2S: Parameters of linear regression between emission rates (S) and indoor PN<0.1 concentration for PR. Table 3S: Parameters of linear regression for mass concentration data for offices A1 and B2. Table 4S: Parameters of linear regression for number concentration between PR and A1, B1 and B2. (DOCX 16 kb)

Rights and permissions

About this article

Cite this article

Chatoutsidou, S.E., Serfozo, N., Glytsos, T. et al. Multi-zone measurement of particle concentrations in a HVAC building with massive printer emissions: influence of human occupation and particle transport indoors. Air Qual Atmos Health 10, 679–693 (2017). https://doi.org/10.1007/s11869-017-0461-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11869-017-0461-4