Abstract

This study aimed to assess workers’ exposure to benzene, toluene, ethylbenzene, and xylene (BTEX) compounds in refueling stations of Ardabil city (Iran). Twenty-four refueling stations including 15 petrol and 9 compressed natural gas (CNG) stations from different regions were selected and monitored for ambient BTEX concentrations. Air samples were taken based on NIOSH Manual of Analytical Method no 1501. Target compounds were extracted using CS2 and analyzed by GC equipped with FID. Average concentrations of benzene, toluene, ethylbenzene, and xylene were obtained 2.01, 1.80, 2.72, and 1.65 mg/m3, respectively. Benzene concentrations exceeded the occupational exposure limit set by the Iran Ministry of Health and Medical Education. Its concentrations were significantly higher in commercial areas (2.72 mg/m3) compared to suburban areas (1.89 mg/m3). BTEX concentrations in gasoline stations were slightly, but not significantly, higher than those in CNG stations. Long-term exposure cancer risk of 1884 × 10−6 ± 390 × 10−6 and hazard index of 22.83 ± 3.66 were estimated for benzene and BTEX compounds, respectively. The results declare the necessity for controlling BTEX emission (mainly benzene) and monitoring employee’s exposure in refueling stations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Development of industries in recent decades has led to serious environmental problems including emission of volatile organic compounds (VOCs) into the urban atmosphere. Benzene, toluene, ethylbenzene, and xylene, known as BTEX, are environmentally important VOCs and emitted into the atmosphere from both artificial and natural sources (Caselli et al. 2010; Davil et al. 2013; Fazlzadeh Davil et al. 2012; Liu et al. 2009; Sturaro et al. 2010; Tiwari et al. 2010). These compounds are used as raw materials or solvents in various industries and released into the environment through evaporation, leaking from underground fuel tanks as a result of poor maintenance, vehicle exhaust emissions, combustion of fossil fuels, and evaporative emissions from refueling vehicles, and therefore, traffic-related sources are considered as the most important sources for indoor and outdoor ambient air pollution (Bailey and Eggleston 1993; Bauri et al. 2015; Caselli et al. 2010; Esteve-Turrillas et al. 2007; Rad et al. 2014; Singh et al. 1992; Truc and Kim Oanh 2007). Sources for BTEX in indoor environments include infiltration of outdoor air pollution, smoking, paints, adhesives, and other VOC-emitting materials utilized in building interiors (Hazrati et al. 2015; Singh et al. 1992; WHO 2000). BTEX compounds are known as a significant cause of cancer in humans and may develop neurological disorders and symptoms such as weakness, loss of appetite, fatigue, confusion, and the nausea (Hoskins 2011).

Benzene is the most toxic compound within the BTEX, and long-term exposure to its low concentrations may increase the incidence of leukemia and aplastic anemia in humans (Baker et al. 1985; Mehlman 1990; Niri et al. 2009; Wong 1995). The World Health Organization has reported that prolonged exposure to 1.7 μg/m3of benzene causes leukemia in 10 people per million (WHO 2000). The International Agency for Research on Cancer (IARC) has classified benzene as an intense carcinogenic compound and ethylbenzene as a suspected carcinogenic compound (IARC 1999). On the other hand, the presence of VOCs, such as BTEX, increases levels of photochemical oxidants especially ozone in the atmosphere that is potentially dangerous to human health and the environment (Atkinson 2000; Khoder 2007).

Several studies have monitored air quality of petrol stations in terms of BTEX concentration (Backer et al. 1997; Cheng et al. 1990; Egeghy et al. 2000; Esteve-Turrillas et al. 2007; Lagorio et al. 1998; Tironi et al. 1986; Vainiotalo et al. 1999). Most of these studies considered the petrol-fueled vehicles as the emission sources for these compounds. Gasoline is a mixture of over 200 petroleum-derived chemicals, mainly low-molecular-mass compounds (e.g., paraffinic, naphtenic, olefinic, and aromatic) with a range of boiling points from 38 to 150–205 °C and a carbon number distribution of C4–C12. Its composition varies depending on the crude oil origin and the refining process. Among other chemical hazards, the group of aromatic components of gasoline constituted by benzene, toluene, ethylbenzene, and xylenes (BTEXs) are considered to be the most hazardous components of most gasoline fuels (El-Naggar and Majthoub 2013; Periago and Prado 2005).

It is believed that approximately 60–85 % of atmospheric benzene is derived from mobile sources, and therefore, higher concentrations are often found inside motor vehicles, inside petrol stations, and adjacent to major roadways (Carey 1987; Winebrake and Deaton 1999; Winebrake et al. 2001). Petroleum derivatives and consequently petrol stations, as the important sources, may contribute to BTEX compounds in urban atmosphere. Therefore, it is important to monitor BTEX levels in petrol stations’ ambient air to pursue proper planning and management policies. Since there are no data published on VOC concentrations in Ardabil city, concentrations of BTEX compounds were monitored in ambient air of refueling stations.

Methods

In a cross-sectional study, 15 petrol stations and 9 compressed natural gas (CNG) stations from different regions of Ardabil city were selected and their ambient air was monitored for BTEX compounds. Among these, 7 stations were located in residential areas, 3 in commercial, and 14 in the suburban areas (Fig. 1). Air samples were taken from standing breathing zone of employees, ∼150 cm above the ground level.

Air sampling process

Air samples were taken based on NIOSH Manual of Analytical Method no 1501. SKC personal sampling pumps equipped with adjustable low-flow holders were used for air sampling. Flow rates were calibrated using a soap bubble flow meter. Air sampling was performed at the flow rate of 0.2 L/min and continued for 50 min to collect a total air volume of 10 L. Coconut charcoal sorbent tubes (SKC, Anasorb CSC, 6 × 70-mm size, 2 sections, 50/100-mg sorbent, and 20/40 mesh) were used for this purpose. The tubes were attached to collar of workers, and after completion of the sampling period, the tubes were detached and transported to laboratory according to the manufacturer guideline. They were stored at −20 °C and analyzed within 72 h.

Sample preparation and analysis

BTEX compounds were extracted from charcoal tubes by 2 mL of GC-grade carbon disulfide (CS2). The vials containing CS2 and charcoal were gently shaken for 20 min. The solvent was transferred into GC vials and BTEX compounds were quantified by a GC (Agilent 7890A) equipped with an FID detector using a capillary column (TRB-1 ms, 30 m × 0.32 mm, 0.25 μm in film thickness). The injector was maintained at the split mode with the ratio of 1:5 and temperature of 300 °C. Nitrogen (99.999 %) was used as the carrier gas at a flow rate of 2.6 mL/min. Aliquots of 1 μL were taken from the vial and injected into a capillary column. Injector temperature was set at 250 °C. Oven temperature was programmed at 40 °C for 10 min and then 10 °C/min to 230 °C (Hazrati et al. 2015; NIOSH 2003; Rezazadeh Azari et al. 2011).

QC and QA measures

In order to control breakthrough of the sorbent tubes, front and back sections of the tubes were analyzed separately, and none of the target compounds was detected in the back section for all samples. Recovery of analytical method was tested by injecting 10 μg of standard solution, and average recovery of 92 % (87–102 %) was found. Method and field blanks were taken (one for each batch of five) and subjected to the same preparation and analytical procedures. Concentration of target compounds were found to be less than 5 % of the values quantified for the samples, and therefore, no correction was made for blank values.

The GC detector was calibrated by running a five-point calibration standard solution of BTEX ranging from 0.01 to 50 ppm, and R 2 values of 0.992, 0.981, 0.980, and 0.983 were obtained for benzene, ethylbenzene, toluene, and xylene, respectively.

Statistical analysis and the risk assessment

Other variables including the region that stations were located (i.e., residential, commercial, and suburban areas), type of the fuel served (i.e., gasoline or CNG), and station information were collected using a self-designed questionnaire. Levels of BTEX in indoor air were compared with national occupational limit levels. Data obtained were analyzed by t test and nonparametric tests using SPSS version 16, and the confidence level was set at 95 %.

The risk assessment analysis was comprised based on the recommended reference doses and work condition of the refueling stations’ employees (Table 1), and the calculations were carried out as reported by Majumdar et al. (2011) for the BTEX compounds.

Results

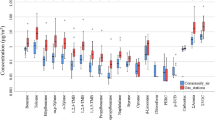

The ambient BTEX concentrations in petrol and CNG stations are presented in Fig. 1 and Table 2. The average concentration of benzene (2.01 ± 0.41 mg/m3) was higher than (1.6 mg/m3) the occupational exposure limit (OEL) recommended by Iran Ministry of Health and Medical Education (Table 2). The average concentrations of 2.01 ± 0.41, 1.80 ± 0.11, 2.72 ± 0.82, and 1.65 ± 0.07 mg/m3were determined for benzene, toluene, ethylbenzene, and xylene for all the monitored refueling stations, respectively. Within the BTEX compounds, only benzene concentrations significantly differed between the areas monitored (i.e., residential, commercial, and suburban) (p value = 0.02) with the commercial area having the highest average benzene concentration of 2.72 mg/m3 (Table 3). BTEX concentrations were higher in petrol serving stations compared to the CNG refueling stations (Table 3). However, only toluene concentrations were statistically different between the stations serving different fuel types (p value = 0.049).

The risk assessment for long-term exposure of employees to BTEX compounds showed notably high cancer risk values for benzene exposure in the refueling stations (Table 4). The average cancer risk of 1884 × 10−6 ± 390 × 10−6 was significantly higher than the unit cancer risk value (i.e., 1 × 10−6). Moreover, the average non-cancer risk values, expressed as hazard quotient (HQ), for exposure to benzene (17.73 ± 3.67) and xylene (4.29 ± 0.19) were higher than the unit value of 1. The average value of hazard index (HI) for long-term exposure to BTEX compounds was 22.83 ± 3.66, which is appreciably higher than the unit value of 1.

Discussion

BTEX concentrations in the ambient air of refueling stations

The fuelling process was done by the car owners, and the petrol pumps were not equipped with a vapor recovery system to collect the vapor coming from the car tank during the filling process in our study. According to the results, workers of the refueling stations are exposed to high concentrations of benzene in such public environments. Although ethylbenzene, toluene, and xylene average concentrations were higher than the typical outdoor air levels, they did not exceed national OEL time-weighted average (TWA) values.

Benzene concentrations in ambient air of petrol stations have been monitored in some countries. The levels reported for Sudan, Saudi Arabia, Thailand, Brazil, and Italy (Caselli et al. 2010; Correa et al. 2012; El-Naggar and Majthoub 2013; Salih and Younis 2013; Tunsaringkarn et al. 2012) are well lower than the concentrations found in the present study. This might be due to differences in VOC contents of the petrol, fuel vapor control systems applied in refueling stations, and the volume of petrol sold per day.

However, other studies conducted in Tehran (Iran) and the USA (Egeghy et al. 2000; Fazlzadeh Davil et al. 2012; Mosaddegh et al. 2014) found the concentrations much higher than the values reported in our work. The exact reason for these differences are not clear; however, the high concentration might reflect less safe refueling methods, high number of cars served, and consequently high volume of petrol sold by Tehran stations. In the USA case, exposure to benzene was measured during self-service refueling process and that petrol vapor releasing from the car tank while refueling might be responsible for the quantified high concentrations. The average benzene levels before and after refueling were about 8.6 and 160 μg/m3, respectively.

Unlike benzene, the toluene, ethylbenzene, and xylene concentrations found in the present study are well below the OEL-TWA values and lower than the results reported for ambient air of most petrol stations studied worldwide (Table 5). However, air pollution due to toluene and ethylbenzene and xylene (TEX) in Tehran refueling stations was appreciably higher than those of found in our work (Rezazadeh Azari et al. 2011).

The average concentrations of BTEX compounds in this study are much higher than the average values reported for urban atmospheric ambient air (Buczynska et al. 2009; Caselli et al. 2010; Kerchich and Kerbachi 2012; Sturaro et al. 2010). This may imply the presence of pollutant sources and a lower rate of photochemical reactions responsible for atmospheric degradation of BTEX due to covered roof and lack of intense solar radiation in refueling stations (Sturaro et al. 2010).

Gasoline is a complex mixture of mainly low-molecular-mass paraffinic, naphtenic, olefinic, and aromatic compounds. Its composition varies depending on the crude oil origin and the refining process applied as well as the national regulations limiting specific constituents of the petrol. Based on regulations adopted by European Parliament, the aromatic content of the gasoline must be <35 % v/v. This figure for benzene is <1 % v/v (Commission 2009). The concentrations of aromatic compounds especially BTEX detected in ambient air of different gasoline stations should normally vary based on the standards applied for manufacturing of the fuel served. Since different refineries in the Islamic Republic of Iran produce petrol with different quality in terms of aromatic content, therefore, air pollution to BTEX compound may vary in gasoline stations based on the fuel-providing refinery.

Unlike benzene concentrations that were significantly higher in commercial (2.72 mg/m3) comparing to suburban areas (1.89 mg/m3), TEX concentrations were not significantly differed between the stations located in different areas, namely, residential, commercial, and suburbs (p > 0.05). Since industrial settlements, commercial centers, and urban traffic vary in different areas, relatively similar levels of TEX found for the stations located at different areas imply that air quality at petrol stations are not influenced by surrounding atmospheric air quality.

Average BTEX concentrations in ambient air of gasoline pump stations (Table 3) were higher than those of CNG stations, though the differences were not statistically significant. The maximum benzene concentrations were observed in the gasoline station No. 1, 8, and 12 and the minimum concentrations were recorded for CNG station No.9, 15, and 24. This might be due to more strict safety regulations applied for CNG refueling stations as well as the fact that BTEX compounds were present at very low concentrations (v/v) in CNG fuel (Bakar 2008).

Exposure risks of BTEX in the refueling stations

The hazard index of 22.83 ± 3.66 shows a great concern in terms of workers’ exposure to BTEX compounds at refueling stations. The main causes of the concern are benzene and xylene, which have HQs considerably higher than the unit value. Many non-cancer effects were reported for exposure to the BTEX compound such as disturbances of memory, mood, equilibrium, and sleep that occurred simultaneously with headache and indigestion (Kilburn et al. 1985). Chronic human inhalation exposure to xylenes can cause kidney, liver, and nerve damage. It can also affect the central nervous system with symptoms such as headache, fatigue, dizziness, and memory loss (Gunathilaka 2003). A significant relationship has been reported between benzene and toluene exposure with fatigue among the refueling station workers (Tunsaringkarn et al. 2012). They also reported a high cancer risk value of 175 × 10−6 for long-term exposure of workers in refueling stations. This high cancer risk agrees well with the results of the present study.

Conclusions

BTEX concentrations present in refueling stations are generally higher than typical outdoor air levels suggesting petrol and CNG stations as sources for atmospheric air pollution. In terms of BTEX levels, air quality of gasoline fuel stations is poorer than that of the CNG stations. This highlights the necessity for improvement in quality of gasoline supplied (i.e., meeting standards of VOC and benzene content v/v of the fuel) as well as the enhancement of safety measures applied while refueling at petrol stations. Among the BTEX compounds, ethylbenzene has the highest average concentration followed by benzene. However, only benzene levels were higher than the occupational exposure limits set by the Iran Ministry of Health. Also, there is a big concern about non-cancer effects for xylene and especially cancer risk for benzene exposure for the workers of refueling stations. Therefore, assessment of worker exposure through monitoring benzene and its derivatives in biological samples and comparing with biological exposure indices are highly recommended.

References

Atkinson R (2000) Atmospheric chemistry of VOCs and NOx. Atmos Environ 34:2063–2101

Backer LC, Egeland GM, Ashley DL, Lawryk NJ, Weisel CP, White MC, Bundy T, Shortt E, Middaugh JP (1997) Exposure to regular gasoline and ethanol oxyfuel during refueling in Alaska. Environ Health Perspect 105:850

Bailey J, Eggleston S (1993) The contribution of gasoline fuelled vehicle exhaust to the UK speciated hydrocarbon inventory. Sci Total Environ 134:263–271

Bakar RA (2008) A technical review of compressed natural gas as an alternative fuel for internal combustion engines. Am J Eng Appl Sci 1:302

Baker EL, Smith TJ, Landrigan PJ (1985) The neurotoxicity of industrial solvents: a review of the literature. Am J Ind Med 8:207–217

Bahrami A, Jonidi-Jafari A, Mahjub H (2008) Environmental exposure to xylenes in drivers and petrol station workers by urinary methylhippuric acid. J Res Health Sci 8:61–68

Bauri N, Bauri P, Kumar K, Jain V (2015) Evaluation of seasonal variations in abundance of BTXE hydrocarbons and their ozone forming potential in ambient urban atmosphere of Dehradun (India). Air Qual Atmos Health 1–12

Buczynska AJ, Krata A, Stranger M, Locateli Godoi AF, Kontozova-Deutsch V, Bencs L, Naveau I, Roekens E, Van Grieken R (2009) Atmospheric BTEX-concentrations in an area with intensive street traffic. Atmos Environ 43:311–318

Carey P (1987) Air toxics emissions from motor vehicles. EPA, Ann Arbor

Caselli M, de Gennaro G, Marzocca A, Trizio L, Tutino M (2010) Assessment of the impact of the vehicular traffic on BTEX concentration in ring roads in urban areas of Bari (Italy). Chemosphere 81:306–311

Cheng WKBG, Groats JFK, Rezcek (1990) A study of exposure to motor gasoline hydrocarbon vapors at service stations. CPPI Report No. 90–8. Canadian Petroleum Products Institute, Ottawa

Commission EE (2009) Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 amending Directive 98/70/EC as regards the specification of petrol, diesel and gas-oil and introducing a mechanism to monitor and reduce greenhouse gas emissions and amending Council Directive 1999/32/EC as regards the specification of fuel used by inland waterway vessels and repealing Directive 93/12. EEC. EEA, Denmark

Correa SM, Arbilla G, Marques MRC, Oliveira KMPG (2012) The impact of BTEX emissions from gas stations into the atmosphere. Atmos Pollut Res 3:163–169

Davil MF, Naddafi K, Rostami R, Zarei A, Feizizadeh M (2013) A mathematical model for predicting 24-h variations of BTEX concentrations in ambient air of Tehran. Int J Environ Health Eng 2:4

Egeghy PP, Tornero-Velez R, Rappaport SM (2000) Environmental and biological monitoring of benzene during self-service automobile refueling. Environ Health Perspect 108:1195

El-Naggar A, Majthoub M (2013) Study the toxic effects of aromatic compounds in gasoline in Saudi Arabia petrol stations. Int J Chem Sci 11:106–120

Esteve-Turrillas FA, Pastor A, de la Guardia M (2007) Assessing air quality inside vehicles and at filling stations by monitoring benzene, toluene, ethylbenzene and xylenes with the use of semipermeable devices. Anal Chim Acta 593:108–116

Fazlzadeh Davil M, Rostami R, Zarei A, Feizizadeh M, Mahdavi M, Mohammadi A, Eskandari D (2012) A survey of 24 hour variations of BTEX concentration in the ambient air of Tehran. J Babol Univ Med Sci (JBUMS) 14:50–55

Gunathilaka M (2003) Hazardous air pollutants: concentrations of benzene, toluene, ethylbenzene and xylene (BTEX) in Christchurch, 2001/2002. Environment Canterbury, Christchurch

Guo H, Lee SC, Chan LY, Li WM (2004) Risk assessment of exposure to volatile organic compounds in different indoor environments. Environ Res 94:57–66

Hazrati S, Rostami R, Fazlzadeh M (2015) BTEX in indoor air of water pipe cafes: levels and factors influencing their concentrations. Sci Total Environ 2015:347–353

Hoskins JA (2011) Health effects due to indoor air pollution. Survival and Sustainability. Springer, Berlin Heidelberg, pp 665–676

IARC (1999) Monographs on the evaluation of carcinogenic risks to humans. II edn. IARC, Lyon, pp 401–432

Kerchich Y, Kerbachi R (2012) Measurement of BTEX (benzene, toluene, ethylbenzene, and xylene) levels at urban and semirural areas of Algiers City using passive air samplers. J Air Waste Manage Assoc 62:1370–1379

Khoder M (2007) Ambient levels of volatile organic compounds in the atmosphere of Greater Cairo. Atmos Environ 41:554–566

Kilburn KH, Seidman BC, Warshaw R (1985) Neurobehavioral and respiratory symptoms of formaldehyde and xylene exposure in histology technicians. Arch Environ Health 40:229–233

Lagorio S, Crebelli R, Ricciarello R, Conti L, Iavarone I, Zona A, Ghittori S, Carere A (1998) Methodological issues in biomonitoring of low level exposure to benzene. Occup Med 48:497–504

Liu J, Mu Y, Zhang Y, Zhang Z, Wang X, Liu Y, Sun Z (2009) Atmospheric levels of BTEX compounds during the 2008 Olympic Games in the urban area of Beijing. Sci Total Environ 408:109–116

Majumdar D, Mukherjeea A, Sen S (2011) BTEX in ambient air of a Metropolitan City. J Environ Prot 2:11

Mehlman MA (1990) Dangerous properties of petroleum-refining products: carcinogenicity of motor fuels (gasoline). Teratog Carcinog Mutagen 10:399–408

Mosaddegh MM, Tahmasebi N, Barkhordari FA, Fallahzadeh H, Esmaielian S, Soltanizadeh K (2014) The investigation of exposure to benzene, toluene, ethylbenzene and xylene (BTEX) with solid phase microextraction method in gas station in Yazd province. ISMJ 16:419–427

NIOSH (2003) NIOSH manual of analytical methods (NMAM), fourth edition. Hydrocarbons, aromatic. Centers for Disease Control and Prevention, 1600 Clifton Rd. Atlanta, GA, USA 30329–4027

Niri V, Mathers J, Musteata M, Lem S, Pawliszyn J (2009) Monitoring BTEX and aldehydes in car exhaust from a gasoline engine during the use of different chemical cleaners by solid phase microextraction-gas chromatography. Water Air Soil Pollut 204:205–213

Periago J, Prado C (2005) Evolution of occupational exposure to environmental levels of aromatic hydrocarbons in service stations. Ann Occup Hyg 49:233–240

Rad HD, Babaei AA, Goudarzi G, Angali KA, Ramezani Z, Mohammadi MM (2014) Levels and sources of BTEX in ambient air of Ahvaz metropolitan city. Air Qual Atmos Health 7:515–524

Rezazadeh Azari M, Naghavi Konjin Z, Zayeri F, Salehpour S, Seyedi M (2011) Occupational exposure of petroleum depot workers to BTEX compounds. Int J Occup Environ Med 3:39–44

Salih DA, Younis M (2013) GC-MS-estimation and exposure levels of environmental benzene in the BTEX-mixture of air-pollutants in gasoline stations and urban road sides. Int J Res Pharm Chem 3(1):88-94

Singh HB, Salas L, Viezee W, Sitton B, Ferek R (1992) Measurement of volatile organic chemicals at selected sites in California. Atmos Environ A Gen Top 26:2929–2946

Sturaro A, Rella R, Parvoli G, Ferrara D (2010) Long-term phenol, cresols and BTEX monitoring in urban air. Environ Monit Assess 164:93–100

Tironi G, Nebel GJ, Williams RL (1986) Measurement of vapor exposure during gasoline refueling. SAE technical paper series no. 860087.Society of Automotive Engineers, Warrendale, PA

Tiwari V, Hanai Y, Masunaga S (2010) Ambient levels of volatile organic compounds in the vicinity of petrochemical industrial area of Yokohama, Japan. Air Qual Atmos Health 3:65–75

Truc VTQ, Kim Oanh NT (2007) Roadside BTEX and other gaseous air pollutants in relation to emission sources. Atmos Environ 41:7685–7697

Tunsaringkarn T, Siriwong W, Rungsiyothin A, Nopparatbundit S (2012) Occupational exposure of gasoline station workers to BTEX compounds in Bangkok, Thailand. Int J Occup Environ Med 3:117–125

Vainiotalo S, Peltonen Y, Ruonakangas A, Pfäffli P (1999) Customer exposure to MTBE, TAME, C6 alkyl methyl ethers, and benzene during gasoline refueling. Environ Health Perspect 107:133

WHO (2000) Air quality guidelines for Europe. In: WHO regional publications, European Series, second ed., No. 91. WHO, Copenhagen

Winebrake JJ, Deaton ML (1999) Hazardous air pollution from mobile sources: a comparison of alternative fuel and reformulated gasoline vehicles. J Air Waste Manage Assoc 49:576–581

Winebrake JJ, Wang MQ, He D (2001) Toxic emissions from mobile sources: a total fuel-cycle analysis for conventional and alternative fuel vehicles. J Air Waste Manage Assoc 51:1073–1086

Wong O (1995) Risk of acute myeloid leukaemia and multiple myeloma in workers exposed to benzene. Occup Environ Med 52:380–384

Acknowledgments

The authors acknowledge financial support of Ardabil University of Medical Sciences for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hazrati, S., Rostami, R., Fazlzadeh, M. et al. Benzene, toluene, ethylbenzene and xylene concentrations in atmospheric ambient air of gasoline and CNG refueling stations. Air Qual Atmos Health 9, 403–409 (2016). https://doi.org/10.1007/s11869-015-0349-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11869-015-0349-0