Abstract

Transformation-induced plasticity (TRIP) behavior has been observed as a mechanism by which alloys can overcome the strength-ductility tradeoff paradigm. This work focuses on the use of CALPHAD approaches to screen for TRIP behavior by examining the thermodynamic factors involved in TRIP and explores the reasons why this approach fails for some alloy systems but shows promise for identifying alloys with the potential to exhibit TRIP behavior in steels and multi-principal element alloys (MPEAs).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

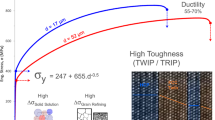

Transformation-induced plasticity (TRIP) has been used in advanced high-strength steels for several decades as a method of overcoming the strength ductility tradeoff.1,2,3 Recently, TRIP behavior has been studied in metastable \(\beta \)-Ti alloys as well as several classes of multi-principal element alloys (MPEAs), such as those rich in Co, Cr, or Ni, as well as some refractory MPEAs.4,5,6,7,8,9,10,11 This behavior is enabled by a deformation-induced martensitic transformation, where mechanical stress or strain results in transformation of a metastable parent phase to a lower energy product phase, which may or may not be the equilibrium phase. In steels, the transformation is generally from a face-centered cubic (FCC) parent phase (austenite) to a body centered cubic (BCC) or body-centered tetragonal (BCT) product phase (martensite).12,13,14 These phases have given their names to the parent and product phases of all diffusionless transformations (austenite and martensite, respectively). For other materials, the parent and product phases may have different crystal structures. For many TRIP MPEAs, the austenite is FCC and the martensite is HCP, while \(\beta \)-Ti alloys often transform from BCC to an orthorhombic phase referred to as \(\alpha {^{\prime}}{^{\prime}}\); this phase may be described as a distorted HCP unit cell, in which the distortion results in a loss of symmetry.15,16,17,18 Behaviors like TRIP are beneficial to mechanical performance of alloys, as they result in high work hardening rates, delaying plastic instability in tension, resulting in improved combinations of ultimate tensile strength and uniform elongation. Because of this, enabling TRIP has become an attractive goal in alloy design. Approaches for predicting phase stability have been designed, focusing on magnetic and electronic structure for Fe-, Co-, and Ni-bearing alloys.19,20,21 For Ti alloys, electronic factors, such as the mean d orbital energy (Md) and bond order (Bo), have been used as a method for predicting phase stability.22,23,24

Phase stability may also be predicted using CALPHAD methodologies. CALPHAD, or CALculation of PHAse Diagrams, was pioneered in the 1960 s and 1970 s by Kaufman and Bernstien as a method for determining phase stability in complex systems.25 These approaches use experimentally based data to build databases of the response of phase stability to alloying and temperature changes. CALPHAD differs from other, more fundamental, techniques as it considers only experimentally determined behavior with little or no consideration for underlying physics between changes in phase stability. Despite this, CALPHAD can use known behaviors in systems with few components to predict the behavior in more complex systems.25,26 This feature is especially beneficial for systems with a large number of components, as complex systems are experimentally challenging to fully assess for thermodynamic properties and are also difficult to explore with more fundamental models, as increased alloy complexity generally results in large computational costs for models that seek to explicitly account for electronic structure or other fundamental aspects that determine a phase’s energy.

Activating TRIP requires understanding of metastability and consideration of the thermodynamic limitations of martensitic transformations, specifically, the thermodynamic parameter, \({T}_{0},\) which describes the temperature at which two phases of a given composition have the same free energy. \({T}_{0}\) acts as the maximum temperature at which a diffusionless transformation may occur. Figure 1 explores how \({T}_{0}\) can be determined from free energy curves, as well as how phase stability affects the compositional dependence of \({T}_{0}\). \({{\varvec{T}}}_{0}\) is closely related to the free energy of transformation, \(\Delta {G}^{\alpha \to \beta }\), as \({T}_{0}\) describes the temperature at which \(\Delta {G}^{\alpha \to \beta }=0\). Above \({T}_{0}\), \(\Delta {G}^{\alpha \to \beta }>0\), so the transformation is not spontaneous and below \({T}_{0},\Delta {G}^{\alpha \to \beta }<0\), so forward progress of the transformation is favorable. The transformation may still not occur at a given temperature below \({T}_{0}\) because of the energetic cost of creating interfaces or other high energy features, such as dislocations or internal stresses, which some transformations require because of volumetric and lattice mismatches. Generally, the magnitude of \(\Delta {G}^{\alpha \to \beta }\) increases further away from \({T}_{0}\), though this may be a more complicated relationship for compositions with more than one diffusionless equilibrium temperature. As \(\Delta {G}^{\alpha \to \beta }\) increases with distance from \({T}_{0}\), it seems possible that \((T-{T}_{0})/{T}_{0}\) could be used to predict the activation of TRIP behavior in metastable materials. At low \((T-{T}_{0})/{T}_{0}\) values, large energy savings from martensitic transformations are expected, and thus TRIP behavior is favored. In this work, alloy compositions that experience TRIP behavior and those that do not were extracted from the literature and assessed for the relevant thermodynamic considerations, \({T}_{0}\) and \(\Delta {G}^{\alpha \to \beta }\).

Free energy versus composition curves may be used to define the diffusionless equilibrium temperature, \({T}_{0},\) as the temperature at which the free energy curves of two phases intersect above the composition of interest. Shown are two free energy surfaces for phases \(\alpha \) and \(\beta \) their intersection and the projection of their intersection onto the composition-temperature plane, representing \({T}_{0}\) as a function of composition.

Methods and Results

This work used Thermo-Calc 2020a and the TCHEA3, TCFE9 and TCTI2 databases to assess \(\Delta {G}^{\alpha \to \beta }\) and \({T}_{0}\) for both TRIP and non-TRIP materials (i.e., materials that do not experience a change in phase fraction during deformation) from the literature. \(\Delta {G}^{\alpha \to \beta }\) and \({T}_{0}\) were assessed for the most appropriate set of phases based on the reported behavior. Alloys that were reported to experience TRIP behavior were assessed for the known austenitic and martensitic phases, while non-TRIP alloys were assessed for FCC→BCC and/or FCC→HCP for Fe-based or MPEA compositions, and Ti-based compositions were assessed for BCC→HCP.

For steels and ferrous alloys, the martensite phase often possesses a tetragonal distortion from the cubic ferrite. These results list these transformations as FCC→BCC TRIP, as these phases are not individually modeled in the TCFE9 database, instead having a unified phase description. In iron and iron-based alloys, the BCC phase has both low and high temperature stability.21,27 These are referred to as \(\alpha \)-ferrite and \(\delta \)-ferrite, respectively. As a result of the BCC phase’s stability at both low and high temperatures in ferrous alloys, two distinct \({T}_{0}\) values might exist for a given composition. The higher \({T}_{0}\) is associated with the \(\delta \)-ferrite→\(\gamma \)-austenite transition, and the lower \({T}_{0}\) is associated with the \(\gamma \)-austenite→\(\alpha \)-ferrite transition. As TRIP in ferrous alloys is between metastable retained austenite (\(\gamma \)) and martensite modeled as ferrite (\(\alpha \)), the lower \({T}_{0}\) is the relevant parameter and was used if multiple \({T}_{0}\) values were found during the CALPHAD modelling. The results of this modeling are listed in Table I and Table II, which are summarized by Fig. 2, for both FCC→BCC TRIP and FCC→HCP TRIP.

Plot of \(\Delta {G}^{\alpha \to \beta }\) and \((T-{T}_{0})/{T}_{0}\) for both TRIP and non-TRIP MPEAs and ferrous alloys. These data are distinguished based on their martensite phase as either BCC or HCP. All alloys shown here have an FCC parent austenite phase. The regions colored in red demark combinations of (\(T-{T}_{0})/{T}_{0}\) and \(\Delta {G}^{\alpha \to \beta },\) which are not feasible for the case of α being the high temperature phase and β being the martensitic phase. The TRIP enabled alloys are marked in blue and the non-TRIP alloys in orange. For \((T-{T}_{0})/{T}_{0}>2\), data are plotted for spacing. Below \((T-{T}_{0})/{T}_{0}=0\), the data show a greater frequency of TRIP than non-TRIP behaviors, indicating that \(\Delta {G}^{\alpha \to \beta }\) and \((T-{T}_{0})/{T}_{0}\) may be used to screen for TRIP behavior. \({T}_{0}\) is a relatively strong limit to TRIP behavior. The TRIP data above \(\frac{T-{T}_{0}}{{T}_{0}}=0\) are marked with an “*”. These points are associated with TRIP behavior at cryogenic temperatures, and the predicted \({T}_{0}\) is well below room temperature. At these temperatures, accurate thermodynamic data, especially regarding the relative energies of non-equilibrium phases, are difficult to generate (Color figure online).

Steels and MPEAs are not the only materials for which TRIP results in desirable mechanical properties. Metastable \(\beta \)-titanium alloys have also exhibited this behavior and are of particular interest in applications where specific strength and light-weighting are important. These alloys transform from a metastable BCC phase (\(\beta \)-Ti) to either an HCP martensite (\(\alpha {^{\prime}}\)) or an orthorhombic martensite (\(\alpha {^{\prime}}{^{\prime}}\)). As with the martensite in ferrous materials, the \(\alpha {^{\prime}}\) and \(\alpha {^{\prime}}{^{\prime}}\) phases are not modeled independently of the low temperature HCP (\(\alpha \)) phase and have a unified description. Results from a similar analysis on Ti alloys, as was performed on the steels and MPEAs shown in Fig. 2, are listed in Table III and shown in Fig. 3.

Plot of \(\Delta {G}^{\alpha \to \beta }\) and \((T-{T}_{0})/{T}_{0}\) for both TRIP and non-TRIP Ti-alloys. The HCP phase listed as the martensite represents both the HCP martensite (α') and the orthorhombic martensite (α'') as these share a unified phase description in the TCTI2 Thermo-Calc database. There are no easily demarked regions of TRIP and TWIP behavior; instead, the non-TRIP behavior continues to follow the TRIP behavior to well below \((T-{T}_{0})/{T}_{0}=0\). The regions colored in red demark combinations of \((T-{T}_{0})/{T}_{0}\) and \(\Delta {G}^{\alpha \to \beta }\) which are not feasible. The TRIP enabled alloys are marked in blue and the non-TRIP alloys in orange. For \((T-{T}_{0})/{T}_{0}>2\), \((T-{T}_{0})/{T}_{0}\) is plotted as 2 for spacing (Color figure online).

Discussion

The results for FCC→BCC and FCC→HCP alloys are promising. While some data points associated with non-TRIP behavior exist below \((T-{T}_{0})/{T}_{0}=0\),which would not be expected when considering only the volumetric energy savings from the transformation, the majority of plotted data are consistent with TRIP occurring below \((T-{T}_{0})/{T}_{0}=0\), with increasing chance of TRIP behavior occurring with progressively lower \((T-{T}_{0})/{T}_{0}\) and non-TRIP behavior occurring primarily above \((T-{T}_{0})/{T}_{0}=0\). These data, where \((T-{T}_{0})/{T}_{0}>0\), are plotted not because TRIP behavior is expected but rather to illustrate whether thermodynamic or other concerns are primarily responsible for the lack of TRIP behavior in an alloy system and to allow for evaluation of the accuracy of the \({T}_{0}\) predictions, as TRIP points reported in this region are thermodynamically disfavored and thus there is likely an error in the determined \({T}_{0}\) from CALPHAD. Although strain plays a role in phase stability, and therefore changes to \({T}_{0}\) from the unstress condition occur during mechanical loading, the data which show TRIP at temperatures above \({T}_{0}\) are for the same composition, Fe−30Ni-0.23C, predicted to have \({T}_{0}=130.3K\), tested at 173 K and 233 K, where slow kinetics means that equilibrium thermodynamic behavior—used to build CALPHAD models—may be difficult to measure experimentally. In the case of the FCC→BCC and FCC→HCP alloys, most non-TRIP alloys were plotted above \((T-{T}_{0})/{T}_{0}=0\), indicating that thermodynamic concerns are dominant in determining if TRIP behavior occurs.

The relative frequency of TRIP behavior as compared to non-TRIP behavior below \((T-{T}_{0})/{T}_{0} =0\) suggests a thermodynamic assessment of \({T}_{0}\) and \(\Delta {G}^{\alpha \to \beta }\) may be a viable method for rapid assessment of TRIP potential. Assessing an alloy’s ability to experience TRIP using only readily accessed thermodynamic parameters could be especially useful for some MPEAs, such as those based upon the third transition metals, which have a vast and relatively unexplored design space, but which may be modeled by CALPHAD techniques that extend knowledge of phase stability in few component systems to higher component systems. As a comparison between \(\Delta {G}^{\alpha \to \beta }\) and \((T-{T}_{0})/{T}_{0}\) for effectiveness, they perform similarly; however, from a design point of view, \({T}_{0}\) has the advantage of being universal to an alloy, regardless of temperature, while \(\Delta {G}^{\alpha \to \beta }\) must be calculated for each temperature. It must be acknowledged that this approach, which essentially condenses \(\Delta {G}^{\alpha \to \beta }(T)\) to a single value, does lose information when comparing between different alloy systems. This is well illustrated by comparison between Fig. 2, where multiple alloy systems are considered, resulting in a wide spread of \(\Delta {G}^{\alpha \to \beta }\) at the same \((T-{T}_{0})/{T}_{0}\), and Fig. 3, where only Ti-based alloys are considered and the majority of points fall along a relatively narrow band of \(\Delta {G}^{\alpha \to \beta }\) v. \((T-{T}_{0})/{T}_{0}\) space. Nevertheless, evaluating only \({T}_{0}\) and comparison to the anticipated testing temperature appears to be effective for the FCC→BCC and FCC→HCP alloys. When selecting a value of \((T-{T}_{0})/{T}_{0}\) as a cutoff for screening TRIP potential, several values of \((T-{T}_{0})/{T}_{0}\) seem to stand out. Below \(\frac{T-{T}_{0}}{{T}_{0}}=-0.55\), only TRIP behavior was observed. However, the exact location of this cutoff may be an effect of sampling, as few points exist below this \(T/{T}_{0}\) level. Below \((T-{T}_{0})/{T}_{0}=-0.2\), TRIP is observed in 89% of tested alloys and temperatures, which is an improvement over considering all \((T-{T}_{0})/{T}_{0}<0\), where only 83% of tested alloys and compositions exhibit TRIP behavior. The selection of these numbers is arbitrary but necessary because the actual factors controlling TRIP are not fully captured in a model only considering \((T-{T}_{0})/{T}_{0}\). A cutoff of \((T-{T}_{0})/{T}_{0}=-0.2\) seems to strike a reasonable balance between capturing most of the TRIP capable alloys while reducing the number of false positives. For a simple model such as this, which considers only thermodynamic factors, these are encouraging results. Furthermore, since the \({T}_{0}\) temperature is being calculated based on currently available thermodynamic databases, some errors are induced by database errors, especially as calculation of \({T}_{0}\) involves extrapolation of free energy curves away from their stability ranges. It is expected that further database refinement will increase the accuracy of the proposed method.

The extension of this method to Ti-containing alloys was less successful, with no meaningful distinctions between the TRIP and non-TRIP data being made on the \(\Delta {G}^{\alpha \to \beta }\) versus \((T-{T}_{0})/{T}_{0}\) plots. Additionally, that a large fraction of non-TRIP BCC→HCP alloys was below \((T-{T}_{0})/{T}_{0} =0\) suggests other factors, beyond those considered here, are determining the TRIP behavior in Ti alloys. Potential other factors include strain rate effects during deformation and the presence of additional phases or interfaces. This is supported by work performed by Ahmed et al. that examined the effect of strain rate on the activation of TRIP behavior in a Ti-10 V-3Fe−3Al alloy.8 It was found that strain rate played a significant role in the activation of TRIP, with high strain rates acting to suppress TRIP behavior. While similar effects were seen in 304 stainless steel in a study performed by Hecker et al., the suppression of TRIP in 304 was ascribed to the adiabatic heating associated with high strain rate tests, and is thus a thermodynamic concern.32 In the Ti-10 V-3Fe−3Al alloy, while adiabatic heating may play a role in the suppression of \(\beta \to \alpha {^{\prime}}{^{\prime}}\) TRIP, other effects of strain rate, including the presence of athermal \(\omega \)-phase and interface mobility, both strongly strain rate dependent, are believed to have also contributed to the reduction of TRIP behavior. The athermal \(\omega \)-phase that forms in certain Ti alloys forms competitively with the \(a{^{\prime}}\) and \(\alpha {^{\prime}}{^{\prime}}\) martensites. While this does not reduce the volumetric driving force of the \(\beta \to \alpha {^{\prime}}{^{\prime}}\) martensitic transformation, it does introduce interfaces and strain that may alter the thermodynamic favorability of the transformation and result in suppression of TRIP behavior. Additional studies of the formation of the \(\omega \) phase would be required to accurately reflect its contribution to TRIP in candidate Ti alloys based on the proposed methodology alone.

Conclusion

A method to screen for TRIP behavior in multiple alloys using only thermodynamic factors easily accessed by CALPHAD methodologies was explored using Thermo-Calc® software for Fe- and Ti-based alloys as well as MPEAs. The results showed that for screening of FCC→BCC and FCC→HCP TRIP behavior, thermodynamic parameters like the diffusionless equilibrium temperature and driving force of the transformation are promising in predicting whether TRIP will occur in a material, with large \(\Delta {G}^{\alpha \to \beta }\) and low \(T/{T}_{0}\) corresponding to increased probability of TRIP. In Ti-based alloys, however, these factors were not adequate to screen for TRIP behavior, and it is believed that other factors are important in governing the activation of TRIP behavior.

References

L. Liu, B. He, and M. Huang, Adv. Eng. Mater. 20, 1701083 (2018).

S. Yan, T. Liang, Z. Wang, B. Yan, T. Li, and X. Liu, Mater. Sci. Eng. A 773, 138732 (2020).

S.S. Sohn, H. Song, M.C. Jo, T. Song, H.S. Kim, and S. Lee, Sci. Rep. 7, 1255 (2017).

F.G. Coury, D. Santana, Y. Guo, J.A. Copley, L. Otani, S. Fonseca, G. Zepon, C. Kiminami, M. Kaufman, and A. Clarke, Scr. Mater. 173, 70 (2019).

Z. Li, C.C. Tasan, K.G. Pradeep, and D. Raabe, Acta Mater. 131, 323 (2017).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Nature 534, 227 (2016).

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe, Acta Mater. 94, 124 (2015).

M. Ahmed, D. Wexler, G. Casillas, D.G. Savvakin, and E.V. Pereloma, Acta Mater. 104, 190 (2016).

C. Brozek, F. Sun, P. Vermaut, Y. Millet, A. Lenain, D. Embury, P.J. Jacques, and F. Prima, Scr. Mater. 114, 60 (2016).

H. Huang, Y. Wu, J. He, H. Wang, X. Liu, K. An, W. Wu, and Z. Lu, Adv. Mater. 29, 1701678 (2017).

Y. Jung, K. Lee, S.J. Hong, J.K. Lee, J. Han, K.B. Kim, P.K. Liaw, C. Lee, and G. Song, J. Alloys Compd. 886, 161187 (2021).

J.A. Venables, Philos. Mag. 7, 35 (1962).

G.B. Olson, and M. Cohen, Metall. Trans. A 7A, 1905 (1976).

G.B. Olson, and M. Cohen, Metall. Trans. A 7A, 1897 (1976).

M.K. Koul, and J.F. Breedis, Acta Metall. 18, 579 (1970).

E. Bertrand, Elaboration et Caractérisation d’alliages Biocompatibles Ti-Ta-Nb Présentant Des Propriétés Superélastiques et à Mémoire de Forme (INSA de Rennes, 2011).

G.H. Narayanan, and T.F. Archbold, Metall. Trans. 1, 2281 (1970).

H.Y. Kim, and S. Miyazaki, Mater. Trans. 56, 625 (2015).

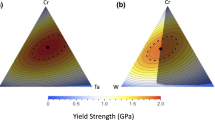

Z. Yang, S. Lu, Y. Tian, Z. Gu, H. Mao, J. Sun, and L. Vitos, Designing Transformation-Induced Plasticity and Twinning-Induced Plasticity Cr-Co-Ni Medium Entropy Alloys: Theory and Experiment (Elsevier BV, 2020).

D. Ma, B. Grabowski, F. Körmann, J. Neugebauer, and D. Raabe, Acta Mater. 100, 90 (2015).

T.B. Massalski, and D.E. Laughlin, Calphad 33, 3 (2009).

M. Morinaga, Y. Murata, and H. Yukawa, Applied Computational Materials Modeling (Springer, 2007), pp255–306.

M. Morinaga, in Titanium in Medical and Dental Applications (Elsevier, 2018), pp. 39–64.

D. Kuroda, M. Niinomi, M. Morinaga, Y. Kato, and T. Yashiro, Mater. Sci. Eng. A 243, 244 (1998).

U.R. Kattner, Tecnol. Metal Mater. Min. 13, 3 (2016).

Y.-M. Muggianu, M. Gambino, J.-P. Bros, and J. Chim, Phys 72, 83 (1975).

D.E. Laughlin, J. Phase Equilibria Diffus. 39, 274 (2018).

M. Madivala, A. Schwedt, S.L. Wong, F. Roters, U. Prahl, and W. Bleck, Int. J. Plast. 104, 80 (2018).

F.D. Fischer, G. Reisner, E. Werner, K. Tanaka, G. Cailletaud, and T. Antretter, Int. J. Plast. 16, 723 (2000).

S. Martin, S. Wolf, U. Martin, L. Krüger, and D. Rafaja, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 47, 49 (2016).

G. C. Soares, M. C. M. Rodrigues, and L. De Arruda Santos, in Materials Research (Universidade Federal de Sao Carlos, 2017), pp. 141–151.

S.S. Hecker, M.G. Stout, K.P. Staudhammer, and J.L. Smith, Metall. Trans. A 13, 619 (1982).

M. Eskandari, A. Zarei-Hanzaki, and A. Marandi, Mater. Des. 39, 279 (2012).

I. Tamura, Metal Sci. 16, 245 (1982).

Z. Li, C.C. Tasan, H. Springer, B. Gault, and D. Raabe, Sci. Rep. 7, 40704 (2017).

T. Furukawa, H. Huang, and O. Matsumura, Mater. Sci. Technol. 10, 964 (1994).

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, and J.E. Wittig, Acta Mater. 100, 178 (2015).

Y.H. Jo, W.M. Choi, D.G. Kim, A. Zargaran, S.S. Sohn, H.S. Kim, B.J. Lee, N.J. Kim, and S. Lee, Sci. Rep. 9, 2948 (2019).

W. Fang, R. Chang, P. Ji, X. Zhang, B. Liu, X. Qu, and F. Yin, Metals (Basel) 8, 369 (2018).

B. Cai, B. Liu, S. Kabra, Y. Wang, K. Yan, P.D. Lee, and Y. Liu, Acta Mater. 127, 471 (2017).

J. Liu, C. Chen, Y. Xu, S. Wu, G. Wang, H. Wang, Y. Fang, and L. Meng, Scr. Mater. 137, 9 (2017).

J.A. Copley, F.G. Coury, B. Ellyson, J. Klemm-Toole, J. Frishkoff, C. Finfrock, Z. Fisher, N. Kedir, C. Kirk, W. Chen, N. Parab, T. Sun, K. Fezzaa, K.D. Clarke, and A.J. Clarke, Metall. Mater. Trans. A 53, 1821 (2022).

D. Wei, X. Li, J. Jiang, W. Heng, Y. Koizumi, W.-M. Choi, B.-J. Lee, H.S. Kim, H. Kato, and A. Chiba, Scr. Mater. 165, 39 (2019).

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Acta Mater. 128, 292 (2017).

Y. Wang, B. Liu, K. Yan, M. Wang, S. Kabra, Y.-L. Chiu, D. Dye, P.D. Lee, Y. Liu, and B. Cai, Acta Mater. 154, 79 (2018).

M. Marteleur, F. Sun, T. Gloriant, P. Vermaut, P.J. Jacques, and F. Prima, Scr. Mater. 66, 749 (2012).

X. Ji, S. Emura, X. Min, and K. Tsuchiya, Mater. Sci. Eng. A 707, 701 (2017).

X.H. Min, S. Emura, T. Nishimura, K. Tsuchiya, and K. Tsuzaki, Mater. Sci. Eng. A 527, 5499 (2010).

X.H. Min, S. Emura, N. Sekido, T. Nishimura, K. Tsuchiya, and K. Tsuzaki, Mater. Sci. Eng. A 527, 2693 (2010).

C. Li, J.H. Chen, X. Wu, and S. van der Zwaag, Mater. Sci. Eng. A 573, 111 (2013).

S. Hanada, and O. Izumi, Metall. Trans. A 18, 265 (1987).

F. Sun, J.Y. Zhang, M. Marteleur, T. Gloriant, P. Vermaut, D. Laillé, P. Castany, C. Curfs, P.J. Jacques, and F. Prima, Acta Mater. 61, 6406 (2013).

Z.Y. Yang, X.H. Zheng, and W. Cai, Scr. Mater. 99, 97 (2015).

W. Wang, X. Zhang, and J. Sun, Mater. Charact. 142, 398 (2018).

L. Lilensten, J.P. Couzinié, J. Bourgon, L. Perrière, G. Dirras, F. Prima, and I. Guillot, Mater. Res. Lett. 5, 110 (2016).

F.W. Ling, H.J. Rack, and E.A. Starke, Metall. Trans. 4, 1671 (1973).

S. Semboshi, T. Shirai, T.J. Konno, and S. Hanada, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 39, 2820 (2008).

S. Sadeghpour, S.M. Abbasi, M. Morakabati, A. Kisko, L.P. Karjalainen, and D.A. Porter, Scr. Mater. 145, 104 (2018).

A. Zafari, and K. Xia, Mater. Sci. Eng. A 724, 75 (2018).

H. Y. Kim, J. Fu, H. Tobe, J. Il Kim, and S. Miyazaki, Shape Memory and Superelasticity 1, 107 (2015).

T. Zhou, M. Aindow, S.P. Alpay, M.J. Blackburn, and M.H. Wu, Scr Mater 50, 343 (2004).

Funding

This work was supported by the US Department of the Navy, Office of Naval Research, under ONR Award Number N00014-18-1-2567. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Office of Naval Research. FGC acknowledges the Center for Advanced Non-Ferrous Structural Alloys (CANFSA), a National Science Foundation Industry/University Cooperative Research Center (I/UCRC) [Award No. 2137243], at the Colorado School of Mines (Mines) and CNPq, Conselho Nacional de Desenvolvimento Científico e Tecnológico—Brasil (CNPq) [Grant Number 424645/2018-1].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Copley, J.A., Coury, F.G., Ellyson, B. et al. Identification of Potential TRIP Alloys by CALPHAD Methods, an Accessible Approach. JOM 75, 4039–4046 (2023). https://doi.org/10.1007/s11837-023-05930-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05930-3