Abstract

In the United States, millions of electric and hybrid vehicles have cumulatively been sold. Although the batteries in these vehicles are expected to last at least 8 years, end-of-life options must still be considered. There are several possible options for battery packs from electric vehicles when they reach end-of-life, including remanufacturing, repurposing for a different application, and recycling. Remanufacturing is the most desirable end-of-life scenario but is the most stringent in terms of battery quality. Recycling is less desirable because there are larger material and energy losses that occur in the process. Repurposing batteries for a different use lies between these two scenarios in terms of desirability. This review paper focuses on non-automotive reuse and explores several options for using electric car battery packs in grid energy storage applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Nature of the Problem and End-of-Life Options

In recent years, public interest in alternatives to the traditional internal combustion engine (ICE) has grown. Simultaneously, technological advancements in electric vehicle batteries have increased the range of both plug-in hybrid electric vehicles and pure electric vehicles, both of which are commonly referred to as PEVs. As a result, trips of longer distances are feasible, and these vehicles have become more attractive to customers. Accordingly, the PEV market has been growing for the past several years. For instance, in 2011, total PEV sales in the U.S. were less than 20,000 vehicles. For comparison, in 2016, over 150,000 PEVs were sold. Furthermore, within this time, 2015 was the only year in which PEV sales dropped slightly.1

It is uncertain how long PEV batteries will remain healthy enough for automotive use; however, the batteries of both the 2016 Nissan Leaf and 2016 Chevrolet Volt are warrantied for 8 years or 100,000 miles. Since significant PEV sales began in 2011, it is expected that many of these batteries may incur problems beginning in approximately 2019, meaning that, in the next couple of years, an end-of-life (EOL) management strategy is necessary for PEV batteries.

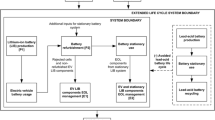

Consideration of end-of-life options should be a priority. This is because lithium-ion battery packs use large volumes of relatively costly materials; some of these materials also having significant environmental impacts. Several life cycle assessment studies of PEV batteries have shown that some environmental impact categories, such as global warming potential and cumulative energy demand, are lower than those of traditional ICEs.2 Then again, other categories of environmental impacts have been found to be higher for PEVs such as human toxicity potential.3 Furthermore, the cradle-to-grave impacts of PEV batteries are unclear because the results of these assessments depend on many assumptions and vary widely when comparing different battery chemistries, different EOL recycling processes, different functional unit sizes, and different sources of electricity. As an example of this uncertainty, Olofsson et al. compared the various environmental impacts of several PEV battery cathode chemistries including lithium iron phosphate, nickel manganese cobalt, lithium manganese phosphate, and lithium iron silicate, all of which have differing impacts depending on the environmental impact category.4 Since the specific battery chemistry differs based on the PEV brand, and because battery chemistry is often proprietary, it is difficult to achieve certainty in term of life-cycle impact. Nevertheless, developing and the implementation of a large-scale EOL strategy for PEV batteries will be important if the disposal of millions of tons of battery waste is to be avoided.

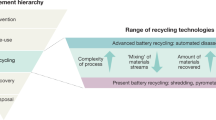

Three EOL options for battery packs from PEVs which can help mitigate some of the environmental impacts and enable material reuse rather than disposal are remanufacturing, recycling, and repurposing. Figure 1 conceptualizes the relative ability for used PEV battery packs to be remanufactured, repurposed, and recycled according to their health. The triangle in the figure shows that, at EOL, a relatively small number of battery packs are at a high enough state of health to be remanufactured. Repurposing a battery does not require as healthy a battery, and therefore more battery packs will be capable of being repurposed than remanufactured. Finally, the figure conceptually represents that the majority of battery packs will be capable of being recycled at EOL; therefore, the base of the triangle is wide.

Remanufacturing

Remanufacturing is the preferred scenario when a PEV battery pack is sufficiently healthy, such that it can be reused in the same automotive application. However, well-used battery packs cannot always be reused for a ‘second life’ in the same automotive application. Battery packs are typically replaced when they can no longer provide sufficient power or energy. According to the US Advanced Battery Consortium (USABC) standard, electric vehicles are unfit for PEV use when the delivered capacity or power of a cell, module, or battery is less than 80% of its rated value.5 Tesla Motors has even greater expectations and expects users to be able to continue using batteries even until they reach 50% capacity.

Recycling

Recycling is another option, which can accept battery packs of all levels of health. This is the current EOL strategy for lead–acid batteries from traditional combustion vehicles; recycling is a very successful strategy because it is incentivized, profitable, and mandated by government regulations.6 In fact, the recycling rate in the U.S. for lead–acid batteries was 96.2% in 2011 and 99.0% in 2013.7,8 PEV battery recycling, on the other hand, is more complex and faces more challenges.

One challenge is that lithium-ion-based battery packs are inherently more complex, and use a greater number of materials that are difficult to separate in the recycling process than lead–acid batteries.9 However, several methods for recycling lithium-ion batteries have been developed and some are in commercial operation; these methods usually involve hydrometallurgic, pyrometallurgicl, or intermediate recycling methods.10,11,12,13,14,15 Pyrometallurgic recycling involves lithium-ion battery modules being smelted in a high-temperature furnace. Here, battery metals like cobalt, nickel, copper, and iron are reduced to form an alloy; these metals can then be recovered from the alloy by leaching. In addition, an oxidized slag fraction is produced that contains ignoble metals such as lithium, manganese, aluminum, etc., while any organic materials are burned off.16 In hydrometallurgic recycling, the battery’s flammable electrolyte must be safely removed, allowing the batteries to be shredded and separated by material. From there, lithium can be separated and converted to lithium carbonate. In addition, any cobalt can be recovered to produce lithium cobalt oxide.

Both pyrometallurgic and hyrometallurgic recycling have advantages and disadvantages. For instance, pyrometallurgic recycling has the advantage of high purity of recovered materials and low water usage. However, this method suffers from high energy use due to high-temperature processing. In contrast, hydrometallurgic processes use less energy and have high yields because they operate at a lower temperature. The disadvantage is that this method requires high water use and does not yield as high purity materials. Regardless of these tradeoffs, recycling by either method saves energy compared to primary materials extraction for battery manufacturing.

A second challenge with recycling lithium-ion PEV batteries is the cost. The processing costs for the aforementioned recycling methods are typically high.17 Thus, it is technically feasible to recover high-value materials; however, whether it is economically viable is dependent on factors like the current metal price and the cost of energy to perform the recycling process steps.

One final consideration for PEV battery recycling is that, when compared to repurposing or remanufacturing, recycling enables the recovery and reuse of the least amount of materials. This is because the higher-value metals are recovered, but lower-value materials like lithium and plastics are waste within these processes. Lithium, for instance, is present in the metallurgic slag from recycling processes, which is not able to be reused in batteries; instead, slags are commonly being used as supplementary materials in the concrete industry. Similarly, plastic contents from batteries are often burned for their energy content and therefore cannot be reused.

Repurposing

Repurposing is the other end of life strategy that bridges the gap between remanufacturing and recycling: it enables batteries to be used in a more extended lifetime after automotive use is no longer possible, and allows more value to be extracted. Since batteries may no longer be fit for automotive use after they have lost 20% of their capacity, second use in a less taxing stationary energy storage application is an attractive option. Therefore, the options for repurposing PEV batteries are the focus of this review paper as a way to extend the use of these battery packs. There are several business cases for the use of repurposed batteries in stationary applications; these are further discussed below.

Critical Questions Regarding Second-Use

Although repurposing would extend the life and value of PEV batteries, some critical questions have been posed regarding the ability of PEV batteries to be repurposed for a stationary energy storage use.

Economic Feasibility

One important question is whether it is possible to economically move PEV batteries from automotive use and transition them into an energy storage use. For instance, in order for repurposed batteries to have a plausible business model, it must be economically feasible to purchase and refurbish batteries for less than it would cost to purchase a brand new battery. This question is addressed in depth by an economic model built at the National Renewable Energy Laboratory (NREL).18 The modeling quantified the costs to repurpose PEV battery packs for stationary energy storage, including battery module collection, electrical testing equipment, technician labor, capital costs of the facility, etc. This cost is sensitive to many factors, including vehicle usage, facility size, module size, cell fault rates, technician handling time, and testing time, among other factors. However, when vehicle diagnostics data are available to support used battery purchases, repurposing costs can be as low as US$20/kWh.

The modeling effort has shown that battery repurposing costs are expected to be lower than future battery selling prices, indicating a plausible business model. Another study conducted at the University of California, Davis, estimated repurposing costs as well as total costs to implement energy storage systems from repurposed PEV batteries.19 This study estimated repurposing costs for several different sizes and models of PEVs. For example, the cost to repurpose a Chevy Volt pack and a Nissan Leaf pack were found to be $1,150 and $1,780, respectively, which is significantly lower than the price of virgin batteries.

Other studies have found less positive conclusions for the economics of repurposing. A report by Lux Research demonstrateds that only certain utility uses would likely be economically viable, and that it is likely that reduced performance of used PEV batteries will limit them to applications with low economic viability. One further concern is that second-life batteries will provide very limited cost savings as prices for new batteries continue to decrease.20

Battery Health

Another topic of investigation has been how long a battery pack will be able to last in a stationary application. If automotive batteries are to be used in a ‘second life,’ they must be able to provide sufficient energy and power for a given application over the lifetime of the battery. This is an area of significant research because there are so many variables that can affect the health and degradation of a battery pack. The charging or discharging rate (C-rate), temperature, and state of charge (SOC) can all influence the health of a battery pack. These factors are discussed below.

First, high charge and discharge rates contribute to the loss of capacity and higher internal resistance of batteries. This is because high currents cause chemical modifications to the electrode layers in the battery, which can be permanent.21,22 Secondly, temperature also plays a huge role in battery aging. According to the US Department of Energy Freedom CAR and Vehicle Technologies Program, automotive lithium batteries should be operated between −30°C and 52°C.23 However, less damage occurs when cells operate towards the middle of this range. High temperatures are particularly damaging because the reactions of the electrode materials, which lead to decreased levels of cyclable lithium, occur at faster rates.24 Thus, at high temperatures, almost all aging mechanisms are accelerated leading to capacity loss and increased resistance.25 Thirdly, the SOC at which the battery is operated can have a significant affect on battery degradation. Using lithium-ion batteries at high SOC damages the electrodes and electrolyte, causing the growth of a solid electrolyte interphase layer as well as a reduction in cyclable lithium.26 Because these factors can greatly impact the rate of degradation of lithium-ion batteries, tight control by the battery management system (BMS) is necessary to prevent as much cell degradation as possible.

In order to determine how long batteries can last, several modeling theories have emerged. Some aging models aim to explain capacity loss and resistance growth as a mathematical function of time, temperature, SOC, C-rate, etc. Typically, calendar aging and cycle aging are both distinguished as contributors to the total aging of a battery. Calendar aging is aging based solely on time; cyclic aging is based on the amp-hour throughput, but is greatly impacted by temperature, SOC, and C-rate as mentioned above. Since cycle life degradation is affected by a multitude of factors, cycle life modeling is very difficult compared to calendar aging modeling.27

Much research has also focused on how to extend battery life. As mentioned above, tight control over important factors such as temperature, SOC, and C-rate can greatly extend battery life. Each PEV battery pack is equipped with a battery management system (BMS), which allows these elements to be monitored and controlled. A BMS performs many functions, such as controlling temperature, charging and discharging, measuring cell voltages, performing cell balancing, and ensuring all measurements are in a safe range. Most importantly, a BMS enables data acquisition and estimation of the battery’s state of charge and state of health.28

Since PEV batteries at the end of their automotive lives will be in varying states of health, the best way to ensure that the battery pack can last in a second life will be to perform state of health testing and to connect an appropriately configured BMS for the application. State of health testing ensures the battery pack has significant capacity and power remaining, and a reconfigured BMS ensures that the batteries are not taxed too hard in the new stationary application. At this point, it is not possible to predict with great accuracy when a battery would fail in a second life. However, it is possible to test a battery’s state of health before use in a second-life application and to monitor its state of health as it is used.

Risks and Liability

Finally, a topic that has been examined concerns the regulatory problems, risks, and liability inherent in using battery packs in applications different from the original use case. Although these barriers are not technical, they represent major challenges to using PEV batteries in second-life applications.29 Utility and electric grid regulations are very complex; in addition, stationary energy storage on the grid is a relatively new concept. Only recently have federal regulations passed the aim to incentivize the deployment of grid energy storage installations. For instance, until the Federal Energy Regulatory Commission (FERC) passed FERC Order 784 in 2013, the ancillary services market within electricity markets was not open to storage projects. Until then, energy storage was not considered a generating resource and thus there were no financial incentives for energy storage installations.30 Similarly, FERC Order 792 added energy storage as a power source eligible to connect to the grid.31 Although these orders represent significant improvements, regulatory barriers still remain that inhibit potential financial incentives of energy storage. For example, energy storage is perhaps the best resource for integrating larger quantities of renewable energy on the grid because of its ability for fast ramping. But without further changes in the structure of the electricity markets, the benefit of energy storage is not accurately reflected. Thus, the business model for energy storage is not yet mature and will depend on continued policy development.

There are also concerns about the risks and liability inherent in using lithium-ion automotive batteries in a non-original use. Lithium-ion automotive batteries represent hazards in terms of both high voltage and toxicity. Generally, liability for automotive battery defects and damage reside with the vehicle manufacturer because they have ensured it is safe for automotive use. However, manufacturers of PEVs typically do not anticipate battery use in an application other than automotive use. Thus, it is reasonable that battery and car manufacturers would want to limit and discourage secondary PEV battery use to alleviate any risk. A collaborative report from the Center for Law, Energy, and the Environment at the University of California and the University of California, Los Angeles School of Law suggests that a solution to this problem is to improve and develop liability standards for PEV batteries.32 In addition, industry leaders should develop technical performance standards for second-life batteries, and perhaps the insurance market could be of help in diffusing liability problems with second-life batteries. Work in this arena has subsequently grown, and reference guides and standards such as the Electric Vehicle Regulatory Reference Guide by the World Forum for Harmonization of Vehicle Regulations have been developed.33

Summary of Second-Use Applications

The last major topic to discuss with regards to PEV battery repurposing is the possible applications for their reuse and where energy storage systems should be placed.

As was mentioned, the use of energy storage in the U.S. is growing. One driver of this is the increase in renewable energy implementation in the U.S., which makes the installation of energy storage more critical due to the decreased ability to match electricity generation with electricity demand.34 For instance, in 2000, wind and solar generation were less than 10 billion kWh. In 2013, combined wind and solar were 200 billion kWh; by 2040, the Energy Information Administration (EIA) projects their combined generation to exceed 400 billion kWh.35,36 For reference, the net generation of electricity in the US in 2015 was 4 trillion kWh.37

The intermittent nature of renewable resources like solar and wind suggest that a means of storing this energy would be very beneficial, so that this electricity can be used when it is demanded. This idea is conceptualized in Fig. 2; energy storage can fill the gaps in generation that occur with high levels of adoption of renewable energy generators. Furthermore, as will be discussed in the following section, the nature of the electric grid is such that increased use of energy storage at different locations on the grid is advantageous. Accordingly, energy storage is becoming increasingly useful at both small and large scales. In the following section, the potential options for using PEV batteries as energy storage on the grid are discussed in more detail.

There are significant benefits when energy storage is installed on the grid. The electric grid is a large interconnected system in which electricity is generated, transmitted, and distributed to match the demand of customers.38 In general, it is critical that the amount of electricity generated matches the demand for electricity as it changes over time.39 This is a challenging task since most power plants are optimally operated at a steady rate of electricity output; however, electricity demand changes significantly throughout the day.40 This problem is only exacerbated when intermittent renewable resources further penetrate the electricity supply. The following sections describe the most common use cases for energy storage systems that could employ PEV batteries to improve some of the current problems on the grid.

Peak Shaving

From time to time, increases in grid infrastructure must occur to keep up with growing demand for electricity. In particular, electricity use at times of peak demand tends to increase over time;41 thus, to supply electricity to the load, extra grid generation and transmission infrastructure must be installed. To avoid these installations, it is instead possible to use energy storage systems to level the electricity load experienced at peak hours. Storing electricity in times of low demand and discharging batteries during peak demand accomplishes this. Accordingly, less electricity must be generated from peaking power plants and there is less strain on transmission and distribution infrastructure. Several studies have considered in depth both the operation and economics of energy storage for peak demand reduction.42,43,44 At this time, battery technologies such as sodium sulfur (NaS) are common in this type of utility-scale applications because they exhibit high power and energy density, long cycle life, good safety, and good temperature stability.45 They are also good for high-volume applications. However, used automotive batteries from pure electric vehicles also have high energy density because lithium-ion batteries also have the characteristics of high energy densities and high efficiencies, making them a possible option for battery energy storage systems.

Energy Arbitrage

Energy arbitrage is another possible use for PEV batteries. With peak shaving use, battery systems are operated to minimize the peak load that grid infrastructure must provide. With energy arbitrage, the goal is to charge and discharge the battery system in order to make a profit, as has been discussed in the literature.56,47,48 When energy is cheap (such as at night), the battery system is charged; later, when prices are higher, the stored electricity is discharged.49 Energy arbitrage can be used at both small and large scales. For instance, a company could use an energy storage system to lower their electricity costs by using cheaper, stored electricity. Similarly, utilities can sell cheaper electricity, which has been generated when electricity prices are low, and sell it in the afternoon when prices are higher to turn a profit.

Frequency Regulation

A third possible use for PEV batteries is known as frequency regulation, which for the electricity grid refers to the need to tightly control the alternating current (AC) frequency. When electricity demand at any given moment exceeds generation, there is missing energy which must somehow be supplied. Typically, this gap in energy is supplied by the kinetic energy of a generator’s rotors. However, this slows down the rotors as well as the grid frequency. If it is slowed enough, damage or blackouts can occur. Therefore, grid frequencies are regulated by ancillary services; they provide stored power which safeguards the grid against imbalances.50

Frequency regulation can be achieved by several types of systems or grid ‘assets’. For example, thermal power plants, flywheels, and batteries can all be used. However, different assets react to grid imbalances at different speeds. For instance, thermal power plants are slow assets, which take on the order of minutes to inject power. Flywheels and batteries, on the other hand, are fast assets and can provide frequency regulation in less than 1 s. Reaction time is critical for frequency regulation; thus, fast assets have greater value than slow assets.51 For this reason, battery energy storage systems from PEV battery packs have been analyzed as an option to provide frequency regulation.

Renewables Integration

Renewable resources such as wind and solar are increasingly penetrating the resource portfolio as governments aim to reduce the carbon impact of electricity generation. Although increased solar and wind generation is beneficial in terms of using cleaner resources, there are consequences that must be dealt with. For instance, wind and solar are intermittent resources, which means that variations in their output occur over various timescales including season-to-season, day-to-day, and minute-to-minute. This irregular nature of wind and solar causes voltage and frequency fluctuations on the grid and should be matched with additional generation capacity to stabilize the energy output.52

To enable wind energy integration, it has been estimated that, for every 10% adoption of wind power on the grid, other generation sources must be used to provide between 2% and 4% of the installed wind capacity to stabilize operation of the system.53

An additional downside associated with renewable energy sources is that they often produce energy when it is not needed and the price is very low; this is called over-generation. For instance, wind turbines often generate the most electricity at night when it is not as valuable. Similar problems can occur with solar generation. For instance, solar generation is a maximum at midday, but electricity demand peaks in the late afternoon and early evening. For both these problems, battery energy storage systems such as those from PEV batteries could be used instead of additional generation sources. Many studies have discussed the need for energy storage on the grid in order to integrate renewable power [54,55,56,57,58]. If energy storage systems are used to integrate wind and solar, electricity can be stored at times of over-generation and be used during peak hours.

Requirements

For all these possible applications, knowing the technical requirements is very important in assessing whether a battery energy storage system could be used for that application. However, there are no set power ratings or energy ratings that are required for each application because there is a range of needs within each application. For instance, there is a wide range of renewable energy installations all of which have a range of energy and power rating requirements. However, there are general trends in requirements for each application.

Vasquez et al. showed graphically the range of power requirements for several grid applications using energy storage systems.53 Table I shows the range of power that could be required as well as the duration for which energy storage must be able to provide power for each application. Due to the varied power and time range requirements, an appropriate application can be matched to the power and energy availability of a used PEV battery.

From the data given above, it can be noted that the behind-the-meter energy storage application has some of the least stringent requirements compared to the power and energy requirements for reuse in a PEV; therefore, the applications in the table are some of the best potential options for repurposing PEV batteries.

Conclusion and Recommendations

The applications presented above are some of the most feasible options for repurposing PEV battery packs after automotive use. If repurposing becomes an employed EOL strategy, recycling used PEV batteries can be postponed and reuse of battery materials can be improved.

As has been mentioned, the main barriers to the deployment of PEV batteries in secondary applications are economic uncertainty, battery health uncertainty, and battery liability. In addition to studying questions related to these areas, it would be beneficial to advance knowledge in the area of pilot and demonstration projects and technical requirements for each application. Demonstrating large-scale or long-term performance of automotive batteries in other applications would validate capability and encourage other deployments. Similarly, documentation of the technical requirements of repurposing, such as capacity and power requirements for different applications, would help match different electric car battery types to the appropriate secondary use case.

Abbreviations

- BMS:

-

Battery management system

- CAES:

-

Compressed air energy storage

- EIA:

-

Energy Information Administration

- EOL:

-

End-of-life

- ICE:

-

Internal combustion engine

- PEV:

-

Plug-in electric vehicle

- SMES:

-

Superconductive magnetic energy storage

- SOC:

-

State of charge

- TEES:

-

Thermoelectric energy storage

- TOU:

-

Time-of-use

References

R. Rapier, U.S. Electric Vehicle Sales Soared in 2016 (Forbes, 2016), http://www.forbes.com/sites/rrapier/2017/02/05/u-s-electric-vehicle-sales-soared-in-2016/-2d470e6353a7. Accessed 25 Nov 2016.

Advancing Sustainable Materials Management: 2013 Fact Sheet (U.S. EPA), https://www.epa.gov/sites/production/files/2015-09/documents/2013_advncng_smm_fs.pdf. Accessed 22 Oct 2016.

Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2011 (U.S. EPA), https://www.epa.gov/smm/advancing-sustainable-materials-management-facts-and-figures-report. Accessed 6 Oct 2016.

Y. Olofsson, Report 2013:5 (Department of Energy and Environment, Chalmers University of Technology, Goteborg, Sweden, 2011).

J. Hesselbach and C. Herrmann, Glocalized Solutions for Sustainability in Manufacturing (Braunschweig, Germany: Springer Science & Business Media, 2011).

E. Worrell and M. Reuter, Handbook of Recycling: State-of-the-art for Practitioners, Analysts, and Scientists (Amsterdam, Netherlands: Elsevier, 2014).

E. Gies, Nature 526, 100 (2015).

A. Changes and B. Pospiech, J. Chem. Technol. Biotechnol. 88, 1191 (2013).

C. Hanisch, J. Diekmann, A. Stieger, W. Haselrieder, and A. Kwade, Handbook of Clean Energy System (New York, NY: Wiley, 2015).

E. Gratz and Q. Sa, J. Power Sources 262, 752 (2015).

H. Zou, E. Gratz, D. Apelian, and Y. Wang, Green Chem. 15, 1183 (2013).

L. Gaines, Sustain. Mater. Technol. 1, 2 (2014).

M. Foster, P. Isely, and C.R. Standridge, J. Ind. Eng. Manag. 7, 698 (2014).

J. Neubauer, K. Smith, E. Wood, and A. Pesaran, Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries (National Renewable Energy Laboratory, 2015), http://www.nrel.gov/docs/fy15osti/63332.pdf. Accessed 20 Oct 2016.

B. Williams, J. Transp. Resour. Board (2012). doi:10.3141/2287-08.

C. Robinson, Reuse of Recycle: The Billion Dollar Question (Lux Research, 2016), https://members.luxresearchinc.com/research/report/21100. Accessed 13 Dec 2016.

J. Vetter, P. Novak, and M.R. Wagner, J. Power Sources 147, 269 (2005).

J. Belt, Battery Test Manual for Plug-In Hybrid Electric Vehicles (Idaho National Laboratory, 2010), https://www.osti.gov/scitech/biblio/1010675. Accessed 17 Sept 2016.

J. Wang, P. Liu, J. Hicks-Garner, and E. Sherman, J. Power Sources 196, 3942 (2011).

M. Fleckenstein, O. Bohlen, M.A. Roscher, and B. Baker, J. Power Sources 196, 4769 (2011).

P. Arora, R.E. White, and M. Doyle, J. Electrochem. Soc. 145, 3647 (1998).

G. Ning, R.E. White, and B.N. Popov, Electrochim. Acta 51, 2012 (2006).

Z. Guo, X. Qiu, and G. Hou, J. Power Sources 249, 457 (2014).

R. Sioshansi, P. Denholm, and T. Jenkin, Econ. Energy Environ. Policy 1, 47 (2012).

Third-Party Provision of Ancillary Services; Accounting and Financial Reporting for New Electric Storage Technologies (Federal Energy Regulatory Commission, 2013), https://www.ferc.gov/whats-new/comm-meet/2013/071813/E-22.pdf. Accessed 11 Oct 2016.

Small Generator Interconnection Agreements and Procedures (Federal Energy Regulatory Commission, 2013), https://www.ferc.gov/whats-new/comm-meet/2013/112113/E-1.pdf. Accessed 12 Oct 2016.

E.N. Elkind, Reuse and Repower: How to Save Money and Clean the Grid with Second-Life Electric Vehicle Batteries (UCLA School of Law and UC Berkeley School of Law, 2014), https://www.law.berkeley.edu/files/ccelp/Reuse_and_Repower_–_Web_Copy.pdf. Accessed 8 Sept 2016.

Proposal for an Electric Vehicle Regulatory Reference Guide (World Forum for Harmonization of Vehicle Regulations, 2014), https://www.unece.org/fileadmin/DAM/trans/doc/2014/wp29/ECE-TRANS-WP29-2014-81e.pdf. Accessed 27 Sept 2016.

P. Denholm, E. Ela, B. Kirby, and M. Milligan, “The Role of Energy Storage (National Renewable Energy Laboratory, 2010), http://digitalscholarship.unlv.edu/cgi/viewcontent.cgi?article=1005&context=renew_pubs. Accessed 30 Aug 2016.

Annual Energy Outlook 2015(Energy Information Administration, 2015), http://www.eia.gov/outlooks/aeo/pdf/0383(2015).pdf. Accessed 9 Aug 2016.

Natural Gas, Renewables Projected to Provide Larger Shares of Electricity Generation (Energy Information Administraton, 2015), http://www.eia.gov/todayinenergy/detail.php?id=21072. Accessed 10 Oct 2016.

Electricity Data Browser (U.S Energy Information Administration, 2016), http://www.eia.gov/electricity/data/browser/. Accessed 3 Nov 2016.

What we do in the Electricity Industry: About Us (National Grid, 2015), http://www2.nationalgrid.com/uk/our-company/electricity/. Accessed 24 Sept, 2016.

Electricity Storage Can Smooth Out Moment-to-Moment Variations in Electricity Demand (Energy Information Administration, 2012), http://www.eia.gov/todayinenergy/detail.php?id=6370. Accessed 29 Sept 2016.

Electricity Generation (Energy Information Administration, 2012), https://www.eia.gov/electricity/. Accessed 17 Nov 2016.

Peak-to-Average Electricity Demand Ratio Rising in New England and Many Other U.S. Regions (Energy Information Administration, 2014), http://www.eia.gov/todayinenergy/detail.php?id=15051. Accessed 14 Aug 2016.

C.H. Lo and M.D. Anderson, Trans. Energy Convers. 14, 824 (1999).

A. Mohd, E. Ortjohann, and A. Schmelter, University of Bolton (2008). doi:10.1109/ISIE.2008.467896.

A. Oudalov, D. Chartouni, C. Ohler, and G. Linhofer, Power Systems Conference and Exposition (2006). doi:10.1109/PSCE.2006.296284.

D. Lindley, Nature (2010). doi:10.1038/463018a.

R. Walawalkar, J. Apt, and R. Mancini, Energy Policy 35, 2558 (2007).

J.M. Eyer, J.J. Lannucci, and G.P. Corey, Energy Storage Benefits and Market Analysis Handbook (Sandia National Laboratories, 2004), http://prod.sandia.gov/techlib/access-control.cgi/2004/046177.pdf. Accessed 6 Sept 2016.

R. Sioshansi, P. Denholm, T. Jenkin, and J. Weiss, Energy Econ. 31, 261 (2009).

G.D. Rodriguez, Power and Energy Society General Meeting (2010). doi:10.1109/PES.2010.5589870.

B.J. Kirby, Frequency Regulation Basics and Trends (Oak Ridge National Laboratory, 2013), http://www.consultkirby.com/files/TM2004-291_Frequency_Regulation_Basics_and_Trends.pdf. Accessed 15 Oct 2016.

Energy Storage—A Cheaper, Faster & Cleaner Alternative to Conventional Frequency Regulation (California Energy Storage Association, 2013), https://www.ice-energy.com/wp-content/uploads/2016/04/cesa_energy_storage_for_frequency_regulation.pdf. Accessed 14 Oct 2016.

J. McDowal, J. Power Sources 162, 959 (2006).

S. Vazquez, S.M. Lukic, and E. Galvan, Trans. Ind. Electron. 57, 3881 (2010).

M. Korpaas, A.T. Holen, and R. Hildrum, Int. J. Electr. Power Energy Syst. 25, 599 (2003).

A.J. Cavallo, J. Solar Energy Eng. 123, 387 (2001).

P. Denholm, E. Ela, B. Kirby, and M. Milligan, The Role of Energy Storage with Renewable Electricity Generation (National Renewable Energy Laboratory, 2010), http://www.nrel.gov/docs/fy10osti/47187.pdf. Accessed 9 Dec 2016.

C.A. Hill, Smart Grid 3, 850 (2012).

M. Beaudin, H. Zareipour, A. Schellenberglabe, and W. Rosehart, Energy Sustain. Dev. 14, 302 (2010).

R.K. Lam, D.H. Tran, and H.G. Yeh, Green Energy and Systems Conference (2015). doi:10.1109/IGESC.2015.7359453.

A. Notrott, J. Kleissl, and B. Washom, Renew. Energ. 55, 230 (2013).

L. Paciello, Environmental Energy and Structural Monitoring Systems (2014). doi:10.1109/EESMS.20146923278.

S. Kahrobaee, R.A. Rajabzadeh, L.-K. Soh, and S. Asgarpoor, IEEE Trans. Smart Grid 4, 659 (2013). doi:10.1109/TSG.2012.2215349.

R. Kaiser, J. Power Sources 4, 659 (2007).

Acknowledgements

This work is funded by the Center for Resource Recovery and Recycling (CR3). We acknowledge the helpful discussions with the center industrial members and colleagues at WPI’s Center for Resource Recovery and Recycling.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

DeRousseau, M., Gully, B., Taylor, C. et al. Repurposing Used Electric Car Batteries: A Review of Options. JOM 69, 1575–1582 (2017). https://doi.org/10.1007/s11837-017-2368-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2368-9