Abstract

The smoothed finite element methods (S-FEM) are a family of methods formulated through carefully designed combinations of the standard FEM and some of the techniques from the meshfree methods. Studies have proven that S-FEM models behave softer than the FEM counterparts using the same mesh structure, often produce more accurate solutions, higher convergence rates, and much less sensitivity to mesh distortion. They work well with triangular or tetrahedral mesh that can be automatically generated, and hence are ideal for automated computations and adaptive analyses. Some S-FEM models can also produce upper bound solution for force driving problems, which is an excellent unique complementary feature to FEM. Because of these attractive properties, S-FEM has been applied to numerous problems in the disciplines of material mechanics, biomechanics, fracture mechanics, plates and shells, dynamics, acoustics, heat transfer and fluid–structure interactions. This paper reviews the developments and applications of the S-FEM in the past ten years. We hope this review can shed light on further theoretical development of S-FEM and more complex practical applications in future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Motivation

As one of the most successful numerical methods, the finite element method (FEM) [1–3] has been widely accepted and used for solving mechanics problems in science and engineering. During the 1950s, Turner [4] proposed and generalized the direct stiffness method (DSM) as an efficient approach for structural design in aerospace industry, which may be regarded as the embryonic stage of the FEM. Since early 1960s, both the theoretical explorations and engineering applications of FEM, have gained substantial momentum. The FEM is now regarded as the one of best methodologies for solving practical problems efficiently in almost all areas of engineering and physical sciences, including structural analysis, mechanical and aeronautical engineering, material science, fluid flow, thermodynamics, biomechanics, soil mechanics, electromagnetism, etc..

The key idea of the FEM was mainly established over 1950s–1970s. Since then it has been found that the standard FEM has some limitations or drawbacks during its intensive applications, including [1–3, 5–7]:

-

Poor accuracy when linear triangular and tetrahedral mesh (T-mesh) is used. This is due to its overly-stiff behavior, rooted at the fully compatible Galerkin weak formulation. These elements, however, are the only types of elements which can be generated automatically for solids and structures with complicated geometries.

-

FEM demands for high quality mesh of quadrilateral (Q4) and hexahedral (H8) elements, leading to difficulties in automatic mesh generation, especially for geometry of irregular 3D shapes. Mapping procedures must be used in the FEM to ensure the compatibility along the interfaces of these Q4 and H8 elements. When an element is distorted, the Jacobin matrix becomes bad conditioned, leading to poor solutions or even breakdown during the computation process. For this reason, most commercial FEM software packages need a sophisticated pre-processor. The analysts have to be well-trained to use the FEM software properly and effectively. Failing to meet some of the rules can lead to serious computational consequences.

-

Much less accurate solution in stresses on the element interfaces.

-

The solution is always a lower bound (for force-driving problems) in the energy norm measure. The lack of upper bound solution, leads to difficulty to quantify the errors in the numerical solutions.

-

Volumetric locking phenomenon: The error of the solution increases significantly when the Poisson’s ratio approaches to 0.5 (incompressible solids), due to the fully enforced compatibility with assumed displacements, which allows the bulk modulus (that is infinite for incompressible solids) to dominate the energy in the entire system.

These issues are attributed to the nature of the fully compatible displacement approach following the standard variational principle [5, 7], in which all the operations are confined within the elements. Many numerical strategies such as hybrid FEM techniques [8] and meshfree methods [5], have sought to resolve these issues. These remedial methods are able to treat some of these issues. However, most of the critical issues have not been effectively addressed yet. For hybrid FEM, there is no effective formulation for triangular/tetrahedral elements so far, and its operation is still confined within the elements. The meshfree methods operate beyond the elements and have achieved remarkable progresses (a recent review of meshfree methods for solid mechanics problems can be found in [9]). However, the programming efforts and costs of computing in meshfree methods can be much more expensive than the FEM.

1.2 Background of Smoothed Finite Element Methods

To stabilize the nodal integrated Galerkin meshfree methods, Chen et al. [10] proposed a stabilized conforming nodal integration (SCNI) scheme, using the strain smoothing technique. On the other front in the development of FE techniques, Liu et al. [11–36] have applied the strain smoothing technique to the finite element settings, and proposed a class of smoothed finite element methods (S-FEMs or S-FEM), through a number of creative fashions to construct the smoothing domains. In the past few years, the S-FEM has been proven to be a valuable combination of meshfree techniques with the standard FEM, which effectively addresses almost all the above mentioned limitations of FEM, through the use of some meshfree concepts and techniques. A generalized gradient smoothing (GGS) technique [17] was further proposed as an extension of the strain smoothing technique to discontinuous functions. The GGS allows the utilization of a class of nodal shape functions created by the point interpolation method (PIM [6]) for creating novel numerical models. Based on the GGS, Liu established the G space theory and the so-called weakened weak (W2) formulation for various types of problems [37–45]. The W2 formulation offers fresh possibilities for developing a wide new class of compatible and incompatible (uniformly) “soft” models with attractive properties such as conformability, volumetric locking free, superconvergence, upper or lower bound, and ultra-accuracy. Typical W2 models are the recent smoothed point interpolation methods (S-PIMs or S-PIM) that can use both polynomial and radial basis functions (RBFs) to construct nodal shape functions using irregularly distributed nodes. Essentially, the S-FEMs is a simplified linear version of S-PIMs with most of their properties. The general idea of the S-FEM is to utilize a standard FE mesh (often but not limited to the T-mesh) to improve the performance of FEM without increasing the degrees of freedoms and much of the computational efforts [38, 41, 45–49]. It modifies the compatible strain field through smoothing the derivatives of the field functions by creating various types of smoothing domains on top of the element mesh. The earliest type of S-FEM models uses smoothing domains that are located within the quadrilateral elements, which is now termed as the cell-based FEM or CS-FEM [11–14, 50]. Only the shape function values (not the gradients or derivatives) at points on the boundaries of the smoothing cells are involved in the computation of the stiffness matrices in CS-FEM. This simplifies the computation, in which the mapping procedure in standard FEM is not required, and hence the Jacobian matrices are no longer involved. This also allows the use of elements of poor quality and enables severe mesh distortion during large deformation. The smoothing domains can also be constructed crossing element interface and over elements around a node, an edge or a face, which brings in the information from the adjacent elements, for desirable “smoothing effects”. Typical S-FEM models include the node-based S-FEM (NS-FEM) for both 2D and 3D problems [20, 40, 51], edge-based S-FEM (ES-FEM) for 2D and 3D [21–24, 52], and face-based S-FEM (FS-FEM) for 3D [27, 28]. In addition, hybrid types of smoothing domains can also be designed [16, 29, 32–35, 53–61], such as the αFEM [18, 25, 26, 53, 54] and βFEM [36].

Many studies have been conducted on the numerical aspects of S-FEMs in stability, convergence, accuracy, and efficiency. Each of these different S-FEM models has been found with different features or properties, and has been applied to solve a wide class of practical mechanics problems for desirable solutions, such as elastic–plastic analysis [23, 62], visco-elastoplastic analysis [24, 28, 51], contact analysis [55, 56, 63, 64], crystal plasticity modeling [36, 65], plates and shells [19, 59, 66–104], composites [79, 82, 83, 85–88, 90, 91, 95, 98, 102, 105–115], limit and shakedown analysis [116–120], fatigue and fracture mechanics [31, 32, 34, 121–141], stochastic analysis [142, 143], vibration and dynamic analysis [14, 52, 53, 68, 76–78, 80–83, 88, 89, 93, 99, 100, 103, 105, 144–153], structural acoustics [154–169], impact problems [170], adaptive analysis [56, 120, 134, 171, 172], heat transfer and thermo-mechanical problems [173–185], piezoelectricity and photonic devices [186–193], fluid–structure interaction [30, 194–203], hyperelasticity and applications in biomechanics [35, 61, 204–210]. Generally, some important features and properties of S-FEM found so far include:

-

S-FEM models can be created using any given FEM mesh including the T-mesh, without introducing additional degrees of freedom to the system.

-

The existed S-FEM models utilize the simplicial linear PIM shape functions for assuming the displacement field without isoparametric mapping, and the stiffness matrix can be computed using only the shape functions themselves (not the derivatives).

-

The stability of a S-FEM model for static problems is ensured by proper smoothing domain creation and by satisfying the condition of a minimum number of linearly independent smoothing domains [45].

-

Compared with the standard FEM, S-FEMs are more robust in dealing with mesh distortion and with extremely large deformation [35–37], because no mapping procedure is performed.

-

Because of the “softening effect”, S-FEM models alleviate the overestimation of stiffness in the compatible FEM [42–44, 211]. As such, they often show higher accuracy and higher convergence rates in displacement, especially in stress solutions [13, 42, 49].

-

S-FEM allows the use of elements of general shape, such as n-sided polygonal elements and even brick elements [15].

-

A smoothing domain in S-FEM models may involve parts of adjacent elements. It has more supporting nodes for the smoothing domain than the nodes of an element. Hence, the bandwidth of the stiffness matrix of a S-FEM model is larger than those in the FEM counterpart, which may lead to higher computational cost for the same mesh structure. However, for a given computational cost, the S-FEM models can be more accurate and achieve higher efficiency [20, 22, 27].

-

Some S-FEM models show unique properties, such as upper bound in strain energy, and free from volumetric locking, which is suitable for incompressible materials.

-

As a class of displacement-like models similar to FEM, many existing algorithms of FEM are compatible or can be easily modified and applied to S-FEM [13].

In this work, the S-FEM will be comprehensively reviewed for the first time in both methodology and applications. The rest of the paper is organized as follows: In Sect. 2, the formulations of S-FEM are briefly introduced; Sect. 3 covers the classification of main S-FEM models and their major properties; several important aspects of the fundamental theories are discussed and summarized in Sect. 4; in Sect. 5, we examine the major applications of S-FEM models to various problems. The final section provides a summary and some concluding remarks.

2 S-FEM Formulations

2.1 Basics of Gradient Smoothing Operation

For S-FEM models, the numerical implementations related to the evaluation of stiffness matrix are based on smoothing domains (or cells for CS-FEM), which can be performed within elements but more often beyond the elements. The smoothed strains can be computed via curves for 2D (or surfaces for 3D) integrations along the boundary of the smoothing domains, using the assumed displacement values and the normal components on the boundary. The procedure is as follows.

Consider a solid mechanics problem whose problem domain is divided into a set of elements as in the standard FEM. On top of the element mesh, the domain is further divided into a set of non-overlapping and non-gap representative smoothing domains \(\Omega _{k}^{s} {\kern 1pt} (k = 1,2, \ldots ,N_{s} )\) with boundary \(\Gamma _{k}^{s}\) for each, such that \(\Omega \approx \bigcup\nolimits_{k = 1}^{{N_{s} }} {\Omega _{k}^{s} }\) and \(\Omega _{i}^{s} \cap\Omega _{j}^{s} = \emptyset\) for i ≠ j, in which N s is the number of all the smoothing domains. The smoothed strain at a point x C in a smoothed domain can be computed by

where \({\varvec{\upvarepsilon}}^{h} ({\mathbf{x}})\) is the compatible strain that is obtained using the assumed strain by differentiation, \({\mathbf{L}}_{d}\) is a matrix of differential operators with following format for 2D and 3D cases respectively

In Eq. (1), \(\Phi_{k} ({\mathbf{x}} - {\mathbf{x}}_{C} )\) is an assumed smoothing function which satisfies at least the positivity and unity properties:

The Heaviside-type piecewise constant function is the mostly popular adopted smoothing function, which can be defined as

where \(V_{k}^{s} = \int_{{\Omega _{k}^{s} }} {{\text{d}}\Omega }\) is the volume (for 3D) or \(A_{k}^{s} = \int_{{\Omega _{k}^{s} }} {{\text{d}}\Omega }\) is the area (for 2D) of the smoothing domain \(\Omega _{k}^{s}\). If we substituting Eq. (4) into Eq. (1) and introduce the divergence theorem, it then yields the following form of smoothed strains

where \(V_{k}^{s}\) can be replaced by \(A_{k}^{s}\) for 2D smoothing domains, \({\mathbf{n}}_{k}^{s} ({\mathbf{x}})\) is a matrix containing the components of the unit outward normal on the boundary \(\Gamma _{k}^{s}\), defined as

where \(n_{kx}^{s}\) and \(n_{ky}^{s}\) and \(n_{kz}^{s}\) represent the unit outward normal components on \(\Gamma _{k}^{s}\) projected on, respectively, the x-, y-, and y-axis. It is seen from the LHS of Eq. (5) that the strain is now computed using integration rather than differentiation, which is a weak formulation at the stage of strain evaluation.

Note also that when the smoothing domain shrinks to zero, while keeping the center at \({\mathbf{x}}_{\text{C}}\), we have

which means that the smoothed strain becomes the compatible strain at the center of the smoothing domain.

2.2 Techniques for Strain Smoothing

In Eq. (5), we need the value of the assumed displacements \({\mathbf{u}}^{h} ({\mathbf{x}})\). It can be approximated through the similar manner as in the FEM, by using the nodal shape functions, for which we use a finite element mesh. However, one does not have to generate the shape function in S-FEM. The art of S-FEM starts with smoothing domain creation, which works as follows.

It first creates the smoothing domains based on the elements in a background mesh. For example, in the CS-FEM, we may use quadrilateral elements with 4 nodes (Q4). In this case, typical smoothing domains can be created as shown in Fig. 1, where one Q4 elements can be divided into 1, 2, 3, 4, 8, or 16 smoothing domains. Each of the smoothing domains has a quadrilateral shape bounded by four boundary segments, and it is supported by the same Q4 element with 4 nodes.

When an FEM mesh of triangular elements with 3 nodes (T3 or Tr3) are used, one may create smoothing domains based on edges, leading to an ES-FEM-T3 (or ES-FEM-Tr3) model, as shown in Fig. 2a for 2D problems. In this case a smoothing domain in the interior of the domain is supported by two elements and bounded by four boundary segments to shape a quadrilateral. Each of the segments connects a node to the center of the involved T3 element. The smoothing domains on boundary edges are triangular and bounded by three edge segments (one of which is the boundary edge), and it is supported only by one element.

Schematic illustration of edge-based smoothing domains based on triangular or tetrahedral elements: a the smoothing domain \(\Omega _{l}^{s}\) is a triangle AOC for a boundary edge l and the smoothing domain \(\Omega _{k}^{s}\) is the four-sided convex polygon DPFQ for an interior edge k and b the sub-smoothing domain \(\Omega _{k,j}^{s}\) for edge k in the element j is a double tetrahedron ACPOQ

Alternatively, one may create smoothing domains based on nodes, as shown in Fig. 3a. In this case, a smoothing domain is generally a polygon bounded by multiple straight boundary segments, each of which connects the midpoint of an edge to a center of the T3 element. For the shaded node-based smoothing domain, it is supported by five elements and is bounded by 10 segments of straight lines.

Schematic illustration of node-based smoothing domains based on triangular or tetrahedral elements: a the smoothing domain \(\Omega _{k}^{s}\) for node k is a polygon with \(2n_{k}^{e}\) sides (where \(n_{k}^{e}\) is the number of elements surrounding node k) and b the sub-smoothing domain \(\Omega_{k,j}^{s}\) for node k in the element j is a polyhedron AELGMFKO

The similar approach can be extended to 3D problems, where the smoothing domains will be constructed upon 3D mesh with boundary surfaces. For example, if the linear tetrahedral elements with 4 nodes (T4 or Te4) are adopted, the smoothing domains can be created based upon the edges of elements and formulated as an ES-FEM-T4 (or ES-FEM-Te4) model, as shown in Fig. 2b. Similarly, we can create NS-FEM-T4 by creating smoothing domains based on the nodes, as shown in Fig. 3b. One may also create smoothing domains associated with the faces of the T4 element, known as the FS-FEM-T4 model. As shown in Fig. 4, the face-based smoothing domain \(\Omega _{k}^{s}\) is created by connecting three nodes of the face (A, B, C) to the centers of the two neighboring elements (P, Q). Several representative smoothing domains are summarized in Table 1. More detailed procedure for constructing the smoothing domains can be found in [45].

Once the smoothing domains are created, we know exactly the relationship between the smoothing domain boundaries and their supporting elements and nodes. The values of shape functions of all the nodes at any point on a segments can be easily calculated via simple point interpolation method (PIM) [6, 45]. For example, the values of the four nodal shape functions at the 12 Gauss points on the boundary of four smoothing domains of a Q4 element (shown in Fig. 5a) can be computed by simple point interpolation, as listed in the Table 2. Similar point interpolations can be easily implemented for the six-sided polygonal element (see Fig. 5b), and the results are listed in Table 3. The point here is that it is not required to explicitly generate the shape functions.

Positions of Gauss points at mid-segment-points on segments of smoothing domains. a Four quadrilateral smoothing domains in a Q4 element and b six triangular smoothing domains in a six-sided polygonal element (from [45])

Now, we can rewrite the assumed displacement \({\mathbf{u}}^{h} ({\mathbf{x}})\) in Eq. (5) using the values of shape functions \({\mathbf{N}}_{I} ({\mathbf{x}})\) and the nodal displacements \({\mathbf{d}}_{I}\) for all the elements and their nodes that support the smoothing domain:

where \(S_{k}^{n}\) is the set of supporting nodes of the elements supporting \(\Omega _{k}^{s}\), and the smoothed strain–displacement matrix can be computed by

where

Consider the ES-FEM for 2D problem as an example. In this case, the (shaded) edge-based smoothing domain DPFQ shown in Fig. 2 is supported by 4 nodes D, E, F, G of two elements DEF and DFG. The smoothed strain–displacement matrix for the whole smoothing domain \(\Omega _{k}^{s}\) can be written as

It is noted that in Eq. (10) the derivatives of the shape functions N I are not required. If we use the 1-point Gauss quadrature for the numerical integration along each segment \(\Gamma _{k,t}^{s}\) of the boundary \(\Gamma _{k}^{s}\), the Eq. (10) becomes

where \(n_{\Gamma }^{s}\) is the total number of the boundary segments \(\Gamma _{k,t}^{s} \subset\Gamma _{k}^{s}\), with \(n_{\Gamma }^{s} = 3\) for smoothing domain of a boundary edge, and \(n_{\Gamma }^{s} = 4\) for smoothing domain of an interior edge (Fig. 2a). For this ES-FEM-T3 model, only one Gauss point is needed for the numerical integration along any of the boundary segments, because the shape function changes linearly along it and the unit normal vector components is a constant on a segment.

For T3 elements, the area of a smoothing domain can be calculated using the areas of the elements supporting the smoothing domain:

where \(n_{k}^{e}\) is the number of elements attached to the edge and \(A_{j}^{e}\) is the area of a supporting element.

The above equations show the standard way to compute the smoothed strain–displacement matrix \({\bar{\mathbf{B}}}_{Ik}\) for a node I of a smoothing domain k, which can be coded without much difficulty. An alternative way to compute \({\bar{\mathbf{B}}}_{Ik}\) is to use directly the \({\mathbf{B}}_{j}^{e}\) obtained by the jth element associated with the edge k. The FE \({\mathbf{B}}_{j}^{e} ({\mathbf{x}})\) for the node I in an element is given by

where the entries of matrix \({\mathbf{B}}_{j}^{e}\) are constants for linear triangle elements. The equation can be derived using the divergence theorem reversely to convert the line integral along \(\Gamma _{k}^{s}\) to an area integration over \(\Omega _{k}^{s}\):

It is apparently from the above equation that the smoothed \({\mathbf{B}}\) matrix is the weighted average of the standard compatible \({\mathbf{B}}\) matrices in the smoothing domain. For the ES-FEM-T3 model, as an example, we have:

where \({\mathbf{B}}_{j}^{e} = \sum\nolimits_{{I \in S_{j}^{e} }} {{\mathbf{B}}_{I} }\), and the summation stands for assembly or more precisely “node-matched summation” at the strain–displacement matrix level for all the elements in the supporting set \(S_{j}^{e}\). For example in Fig. 2a, elements DEF and DFG support the red shaded smoothing domain \(\Omega _{k}^{s}\). However, element DFG does not contribute to node E, and hence when \({\bar{\mathbf{B}}}_{E}\) is computed, it has only 1/3 contribution of \({\mathbf{B}}_{E}\) for the matched node E from element DEF. Likewise, when \({\bar{\mathbf{B}}}_{G}\) is computed, it has only 1/3 contribution of \({\mathbf{B}}_{G}\) from element DFG. When \({\bar{\mathbf{B}}}_{D}\) or \({\bar{\mathbf{B}}}_{F}\) is computed, however, it has a sum contribution (of \({\mathbf{B}}_{D}\) or \({\mathbf{B}}_{F}\)) from both elements, as they all have matched nodes D and F. The smoothed strain matrix for the whole smoothing domain \(\Omega _{k}^{s}\) can be written as

It has to be noted that Eqs. (11) and (17) are identical, if T3 elements (linear PIM) are used. For other strain smoothing techniques, they follow a quite similar fashion of smoothing operation as illustrated above to evaluate the smoothed strain–displacement matrix \(\overline{{\mathbf{B}}}_{I}\).

Once the smoothed \({\mathbf{B}}\) matrices are obtained, following a similar assembling procedure of the FEM, the components of the local stiffness matrices of smoothing domains can be assembled to a global stiffness matrix for generating a global equation system. The smoothed global stiffness matrix \({\bar{\mathbf{K}}}\) can be assembled from the contributions of stiffness from all the individual smoothing domains, in which its entries reads

where the summation is a node-matched summation at the stiffness matrix level. The derivation of the above equation is essentially the same as that performed in the FEM. The difference is that FEM is element-based, while the S-FEM is now smoothing domain based. When I and J are “far” apart, \({\bar{\mathbf{K}}}_{IJ}\) will vanish, and hence the global stiffness matrix \({\bar{\mathbf{K}}}\) is a sparse, and banded when the numbering of the nodes are proper. It is a symmetric positive definite (SPD) matrix, after (sufficient) essential boundary conditions are imposed [3, 45]. The bandwidth (assuming optimized node numbering) of \({\bar{\mathbf{K}}}\) depends on the types of S-FEM model. For CS-FEM, it is the same as the FEM. For ES-FEM-T3, the bandwidth of \({\bar{\mathbf{K}}}\) is about 30% larger than the FEM counterpart and it is about double for NS-FEM-T3.

3 Major S-FEM Models and Their Properties

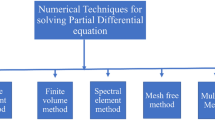

In the past decade, considerable effort has been devoted to developing these smoothing techniques based FEM, a broad classification of these S-FEM models so far can be based upon the element types used in the models:

-

Quadrilateral or hexahedral elements (e.g., Q4 or H8) based models: a typical cell-based S-FEM model constructed upon Q4 or H8 mesh.

-

Triangular or tetrahedral elements (e.g., T3 or T4) based models: this type of S-FEM models usually conduct the smoothing operation beyond elements and bring in the information from the neighboring elements, including the node-based and edge-based S-FEM models. It is important to note that simplex elements (triangles or tetrahedrons) have much flexibility to create high quality mesh and they are the only elements to automatically generate mesh for objects with arbitrary shapes, though they are not recommended in the standard FEM due to undesired features.

-

n-sided polygonal or polyhedral elements based models: The problem domain can be discretized by a set of polygons or polyhedrons with an arbitrary number of sides. The cell-based smoothing technique is employed within this type of elements, known as nCS-FEM models [15, 150, 212–214]. However, the smoothing domain can also be constructed upon edges [215] or nodes [20] to obtain different models (e.g., nES-FEM).

Based on the types of smoothing domains, the S-FEM models are generally classified into: Cell-based S-FEM (CS-FEM), Node-based S-FEM (NS-FEM), Edge-based S-FEM (ES-FEM), Face-based S-FEM (FS-FEM), Selective S-FEM, alpha FEM (αFEM), beta FEM (βFEM), and other variations. This classification is more convenient for discussions of properties of the S-FEM models, since the properties are largely determined by the smoothing effect that is mainly affected by the smoothing domain type(s).

3.1 Cell-Based S-FEM (CS-FEM)

As the earliest S-FEM model, the CS-FEM [11] creates smoothing cells/domains located inside the Q4 elements (Fig. 1). The numerical implementation of CS-FEM is very similar to that of the FEM, and the bandwidth of stiffness matrix of CS-FEM is as same as that of FEM. The smoothing operations are implemented inside the elements, i.e., without crossing element manipulations, thus the CS-FEM can be realized via user-defined subroutines in some commercial finite element software packages, including ABAQUS user-defined elements (UEL [216] or VUEL).

The CS-FEM has been extended to free and forced vibration analysis [14], general n-sided polygonal element (or nCS-FEM) [15], volumetric locking problems [16], plate/shell analysis [66, 67, 76, 77], and coupling with the extended finite element method (X-FEM) [49]. The idea of cell-wise strain smoothing was also formulated with 3D hexahedral elements in [49] and [50] and higher order elements [217]. Through extension of CS-FEM for triangular elements combined with the stabilized DSG technique or Mindlin plate element, a number of applications have been presented for static and dynamic analysis of plates and shells [77–93, 95–103]. The major features of the CS-FEM can be summarized as:

-

1.

Due to the transformation of area (volume for 3D) integration into the line (surface for 3D) integration [11, 13], the integrations for computing the strain matrix can be implemented along the boundary of the smoothing cells. Thus the strain is computed in a weak fashion without coordinate transformation or isoparametric mapping involved, which helps the CS-FEM have better performance than standard FEM when elements are distorted.

-

2.

When single smoothing cell (n SC = 1) is used in Q4 or H8 elements, the solution of CS-FEM is the same as the FEM with reduced integration. While for n SC → +∞, it approaches the standard FEM with full integration. Compared with the exact solutions, there exists some optimal number of smoothing cells to obtain the best accuracy (generally n SC = 4 for Q4 elements [13] and n SC = 8 for H8 elements). Figure 6 shows the comparisons of relative errors of the deflection along centerline for a cantilever beam under a downward loading at the tip [142]. It is clearly shown that a softer S-FEM model can be created using less (but larger) smoothing domains.

-

3.

For CS-FEM, the convergence rates were found higher than FEM in both displacement and energy norms and the error is smaller than that of FEM (n SC = 4).

3.2 Edge-Based S-FEM (ES-FEM)

The ES-FEM evaluates the weak form based on edge-based smoothing domain, which are constructed associated with edges of T-elements (T3 for 2D and T4 for 3D), as illustrated in Fig. 2. The ES-FEM is applicable to other shapes of element, including the general polygonal or polyhedral elements. So far the work on ES-FEM has been focused on T-elements, since it has advantages in automatic mesh generation and for adaptive mesh rezoning. As a most popular S-FEM model, intensive applications of ES-FEM lead to the major findings as follows:

-

1.

The ES-FEM-T3 has a close-to-exact stiffness and often offers super-convergent and very accurate solutions, which may be often better than the standard FEM using Q4 elements with the same sets of nodes.

-

2.

It is always temporally stable and works well with poor quality mesh, and hence ideal for dynamic analysis, and eigenvalue analysis.

-

3.

To deal with volumetric and/or bending locking, special treatments have been implemented in ES-FEM, including the use of bubble functions [33, 218, 219], enrichment of drilling rotations [220], and F-bar aided technique (F-barES-FEM-T4) [208].

-

4.

For acoustic analysis, the ES-FEM is less sensitive to the wave number for solving the Helmholtz equation, which can provide much accurate frequency response for a wide range of wave numbers [21, 155, 157, 158].

-

5.

The ES-FEM equipped with stabilized discrete shear gap (DSG) technique can effectively avoid the shear locking in the analyses of Reissner–Mindlin plates [69, 70].

3.3 Node-Based S-FEM (NS-FEM)

The NS-FEM was initially inspired by the linear conforming point interpolation method (LC-PIM) [221–223], and the linearly conforming radial point interpolation method (LC-RPIM) when the RBFs are included later [224]. The strain smoothing in NS-FEM is performed over the smoothing domain that cover the nodes (see Fig. 3). Numerical applications have shown that the NS-FEM has the following properties:

-

1.

The NS-FEM is even softer than the ES-FEM, which is also known as “overly soft” or underestimation property. Because of this unique property, it can produce upper-bound solutions in strain energy (for force driving problems) and it is so far the only displacement model that can offer upper bound solution. This is because the number of smoothing domains used in an NS-FEM model is much smaller than that of the ES-FEM counterpart, due to the fact that the number of nodes is always less than that of edges in a T-mesh. Based on the W2 formulation theory, a S-FEM model is in general softer when the number of smoothing domain is less, and vice versa. The similar phenomenon was observed in Fig. 6 for the CS-FEM.

-

2.

The NS-FEM can alleviate effectively the volumetric locking for nearly incompressible materials. However, the accuracy of the NS-FEM may not be ideal for some problems. To improve the accuracy, it has been combined with the ES-FEM, known as NS/ES-FEM, in a “selective” formulation for hyperelastic materials undergoes extremely large deformation [35, 115, 172, 205–208]. It has been pointed out that NS-FEM (or NS/ES-FEM) is not fully locking-free for idealized fully incompressible materials. Improvements by including bubble functions have been made in ES-FEM for handling idealized purely incompressible materials [33].

-

3.

It is able to produce very accurate and often super-convergent stress solutions, measured in energy norm.

-

4.

The stress at nodes can be calculated directly from the nodal displacements without any post-processing process [51].

-

5.

The NS-FEM is usually less efficient computationally. This is due to the larger bandwidth in the stiffness matrix caused by the use of more supporting elements (hence nodes) for node-based smoothing domains.

-

6.

Though it is proven spatially stable, the NS-FEM may be “temporally” unstable. This is because for dynamic problems, we have additionally the mass matrix in addition to the stiffness matrix. Therefore, there is a competition between the eigenvalues of the stiffness matrix and the mass matrix. In NS-FEM models, the stiffness is reduced quite significantly due to the overly-soft behavior, and hence the eigenvalues for some modes could be (relatively) lower than that of the mass matrix. Such modes are observed as the non-zero-energy spurious modes. Thus without special treatments, it is not preferred to use NS-FEM for dynamic problems [204]. Some stabilization techniques [144, 151, 165, 185] (e.g., squared-residual) were recently proposed to cure the temporal instability of the NS-FEM. Note that the use of such a stabilization technique may result in the loss of upper bound property of NS-FEM. It is recommended that the NS-FEM should be used only when we are interested in obtaining an upper bound solution, or for nearly incompressible materials.

3.4 Face-Based S-FEM (FS-FEM)

The ES-FEM has been further extended for 3D problems to form the so-called face-based S-FEM (FS-FEM), which creates smoothing domains associated with the faces of tetrahedral elements as shown in Fig. 4. Similar to ES-FEM, the FS-FEM is significantly more accurate than FEM using same T4 mesh for dynamic [162] and both linear and nonlinear problems (e.g., visco-elastoplastic analysis [28]). As a 3D S-FEM model, the FS-FEM is very attractive for practical applications. For example, Duong [225, 226] has integrated the FS-FEM into the open source software Code Aster for large scale nonlinear applications, including biomedical problems.

3.5 Selective S-FEM

The idea of selective S-FEM schemes was first introduced in [16] with cell-based smoothing technique to eliminate volumetric locking, and to improve numerical performance at the same time. A typical selective scheme of S-FEM applies two different types of smoothing domains, i.e., edge/face-based and node-based domains, selectively for two different material “part” [45] (e.g., deviatoric part and volumetric part). For the volumetric or hydrostatic part, the node-based scheme is used to “soften” the large bulk modulus to avoid locking issues [55, 56, 205–207]. The edge or face-based scheme will be utilized for the deviatoric part for good accuracy. Both the high accuracy and locking-free features of selective S-FEM have been verified by many examples of nearly incompressible materials. It already has some and will have more potential applications in biomechanics of soft biomaterials [35, 115, 205, 207] with properties of micromechanical incompressibility.

3.6 Alpha FEM (αFEM)

To avoid the spurious non-zero energy modes existed in NS-FEM for dynamic problems, Liu et al. [18] presented an effective way to formulate a numerical method with “right” stiffness, which is named as the alpha finite element method (αFEM). In αFEM, nearly exact solution for a given problem can be obtained by scaling the gradient of strains in the physical coordinates and/or Jacobian matrices via an adjustable factor “α”. [18, 25, 26]. Several versions of αFEM have also been developed, including Aα-DSG3 method with approximation of displacements and rotations by FEM and bending, geometrical and shear strains by NS-FEM [74, 107]. As the αFEM can alleviate the locking issues and performs well for dynamic problems, it is widely applied in vibration and acoustic problems [53, 154, 164, 167, 168], and plate analysis [74, 107]. These methods are proven to be stable and convergent. However, a αFEM may or may not be variationally consistent, depending how it is formulated [54].

3.7 Beta FEM (βFEM)

Inspired by the idea of αFEM, a more general, versatile and ultra-accurate smoothed βFEM was developed by Zeng et al. [36, 227]. In the βFEM, the stiffness matrix is computed utilizing strains smoothed over the smoothing domains constructed by both the edges/faces and nodes of T-meshes. Figure 7 shows the creation of smoothing domain for βFEM: the node-based smoothing domains [the domain surrounding a node, e.g., node B as shown in Fig. 7a and node A(q) in (b)] and the edge/face-based smoothing domains. Exact solution in strain energy can be approached by a proper adjustable parameter β, due to the fact that the exact solution is within the narrow interval bounded by the solutions of NS-FEM and ES/FS-FEM. The effectiveness of the βFEM has already been demonstrated in some numerical applications including crystal plasticity modeling and vibration analysis. The method is found to be temporal stable, insensitive to mesh distortion and immune from volumetric locking. The good performance is attributed to its key features inherited from both NS-FEM and ES/FS-FEM.

3.8 Other Variations

In order to resolve issues or drawbacks in standard FEM or even some S-FEM models, a few variations of smoothing technique based FEM models have been proposed in the past several years. For example, to solve fracture mechanics problems, some smoothed singular elements have been formulated with ES-FEM [121, 123–128, 130–132, 134, 140, 141], NS-FEM [122] or X-FEM [31, 32, 122, 129, 133, 138] to capture a proper order of singularity near the crack-tip. The stabilized node-based smoothed finite element method (sNS-FEM) [144, 151, 165, 185] can eliminate the spurious non-zero energy modes that exist in NS-FEM for vibration analysis. The F-bar aided ES-FEM (F-barES-FEM-T4) inherits the shear locking-free property of ES-FEM and volumetric locking-free property of the F-bar method, which is able to relax the corner locking issue and suppress the pressure oscillation in nearly incompressible materials [208]. In [219], a bubble-enhanced ES-FEM was performed to analyze volume-constrained problems in 2D linear elasticity. A hybrid smoothed extended finite element/level set method incorporated with the interfacial energy effect [58] was proposed to model nanoscale inhomogeneities without remeshing involved in interface geometry changes. In [213], the polyhedral elements combined with cell-based smoothing technique were developed for treating nonmatching interfaces between dissimilar hexahedral meshes.

4 Theoretical Aspects of S-FEM: G Space and W2 Formulation

Numerous numerical examples have demonstrated that all these models mentioned above are stable and converge to the exact solution when the mesh is refined. Special properties for different S-FEM models have also been observed in a large number of numerical examinations. However, it is still important to theoretically prove the stability, convergence, convergence rate and the predictable properties since it is not possible to exhaust all the possible problems via numerical tests. Therefore, the safest way is to prove in theory for general settings with a set of conditions, and then test with numerical examples under the same conditions. Theoretical study on S-FEM has two paths. The first path is the most general one and it uses the G space theory [5, 43, 44]. The second path uses the standard variational principle, prove the orthogonality of the smoothed strain field, and then show that the smoothed Galerkin weak form is variationally consistent. Finally, we argue from the fact that when the number of the smoothing domain approach infinite and the size of the smoothing domain approaches to zero, the smoothed strain field approaches the compatible strain field. Because the FEM can converge to the exact solution, and the S-FEM uses also compatible displacements, the S-FEM shall also converge to the exact solution when the mesh is refined. This proof is rather straightforward, and is detailed in [42] and in the Sect. 4.7 of [45], which we will not repeat here. Instead, we now summarize the first path of the proof as below, since it is more general. As a set of stand-alone theorems, it is also applicable to the S-PIM models [6].

4.1 G Space Theory

A detailed discussion on G space theory can be found in the Chap. 3 of [5] and also in [37]. Here we only brief the necessary part of the theory for this review article. A \({\mathbf{\mathbb{G}}}_{h}^{1}\) space is of finite dimension established for a discretized problem domain with nodes. It can be defined as:

where \({\mathbf{d}} = \left\{ {\begin{array}{*{20}c} {d_{1} } & {d_{2} } & \cdots & {d_{{N_{n} }} } \\ \end{array} } \right\}^{\text{T} }\) is the vector of nodal function values, and \({\mathbf{N}}({\mathbf{x}})\) is the matrix of nodal shape functions of arbitrary order constructed using the element-based method in FEM, or a meshfree method such as PIM and radial PIM (or RPIM for short), and can be written as

For creating functions in \({\mathbf{\mathbb{G}}}_{h}^{1}\) spaces, we do not restrict on how these shape functions are created, as long as they satisfy the following conditions:

-

1.

Linearly independency condition all these nodal shape functions are linearly independent over the problem domain and hence are capable to form a basis. Naturally, the FEM shape functions satisfy this condition. The simple PIM (e.g., Tables 2, 3) also satisfies this condition, because of the independent local nature of the interpolations performed.

-

2.

Bound condition all the functions constructed using these shape functions must be square integrable over the problem domain. This is to ensure the convergence of a numerical model to be created. The shape functions of FEM, PIM and RPIM all satisfy this condition.

-

3.

Positivity conditions there exists a division of \(\Omega _{i}^{s}\) such that \(\sum\nolimits_{n = 1}^{{N_{s} }} {\left( {\int_{{\Gamma _{n}^{s} }} {v\left( s \right)n_{i} {\text{d}}s} } \right)^{2} > 0}\), if and only if \(v \ne c \in {\mathbf{\mathbb{R}}}\), \(\forall {\mathbf{d}} \in {\mathbf{\mathbb{R}}}^{{N_{n} }}\) and i = 1, …, d. It (together with the linearly independent condition) is to ensure the stability of a numerical model to be created. This condition can be satisfied when the number of the smoothing domains exceeds that given in Table 4.

Table 4 Minimum number of smoothing domains \(N_{s}^{ \hbox{min} }\) for problem domain discretized with n t total nodal unknowns

As in the standard FEM we require the shape functions satisfy the basic properties of partitions of unity [228], Delta function property and (local) linear consistency [6].

The major difference between a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space and FEM \({\mathbf{\mathbb{H}}}_{h}^{1}\) space is that the \({\mathbf{\mathbb{H}}}_{h}^{1}\) space requires both the function and its first gradient of the function square integrable, but in the \({\mathbf{\mathbb{G}}}_{h}^{1}\) space we require only the function itself square integrable. Therefore, the requirement on function is now further weakened upon the already weakened requirement for functions in a \({\mathbf{\mathbb{H}}}_{h}^{1}\) space. Hence a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space can be viewed as space of a set of functions with weakened weak (W2) requirements on continuity. In a \({\mathbf{\mathbb{H}}}_{h}^{1}\) space, the bound condition is achieved by imposing the smoothness upon the first derivatives of the function to be square integrable. Therefore, in an FEM model, we typically require the nodal shape functions to be continuous over the problem domain. The stability is automatically ensured for functions in a \({\mathbf{\mathbb{H}}}_{h}^{1}\) space as long as the smoothness is satisfied, due to the Poincare-Friedrichs inequality. In the \({\mathbf{\mathbb{G}}}_{h}^{1}\) space, the smoothness requirement is only on the function being square integrable. The stability in the \({\mathbf{\mathbb{G}}}_{h}^{1}\) space, however, is ensured by imposing the positivity condition, which needs to be ensured by proper construction of the smoothing domains.

Because a member in a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space is also a member of a \({\mathbf{\mathbb{L}}}_{{}}^{2}\) space, therefore a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space is a subspace of \({\mathbf{\mathbb{L}}}_{{}}^{2}\) space: \({\mathbb{G}}_{h}^{1} (\Omega ) \subset {\mathbb{L}}^{2} (\Omega )\). Note that any function created using FEM shape functions satisfies the above mentioned three conditions, it belongs to a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space, as long as the condition given in Table 4 are met. The proof on this is a little lengthy, but can be found in [37, 229]. Therefore, all the theorems proven for functions in \({\mathbf{\mathbb{G}}}_{h}^{1}\) space also applies to \({\mathbf{\mathbb{H}}}_{h}^{1}\) space: \({\mathbf{\mathbb{H}}}_{h}^{1} \subseteq {\mathbf{\mathbb{G}}}_{h}^{1}\). Finally, we note \(\mathop {\lim }\limits_{\begin{subarray}{l} N^{s} \to \infty \\ \Omega^{s} \to 0 \end{subarray} } {\mathbf{\mathbb{G}}}_{h}^{1} \to {\mathbf{\mathbb{H}}}_{h}^{1}\), which is due to Eq. (7).

The displacement (vector) field, we require the components all in the \({\mathbf{\mathbb{G}}}_{h}^{1}\). The associated inner product as

The associated \({\mathbf{\mathbb{G}}}_{h}^{1}\) semi-norm is defined as

and the \({\mathbf{\mathbb{G}}}_{h}^{1}\) full norm becomes

We finally define a space for functions that are fixed on the Dirichlet boundaries and hence the functions cannot “float”

4.2 Key Inequalities for Functions in \({\mathbf{\mathbb{G}}}_{h}^{1}\) Spaces

4.2.1 The 0th Inequality

Based on the definition, we have the most basic inequality:

which means that the \({\mathbf{\mathbb{G}}}_{h}^{1}\) full norm is always larger than the \({\mathbf{\mathbb{G}}}_{h}^{1}\) semi-norm.

4.2.2 The 1st Inequality

Functions in a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space satisfy the 1st inequality

or equivalently

where \(c_{dw}^{f}\) and \(c_{wd}^{f}\) are nonzero positive constant independent of w and \({\mathbf{d}}\). This means that the full \({\mathbf{\mathbb{G}}}_{h}^{1}\) norm of a function is equivalent to the L2 norm of the nodal values of the function. A proof for these inequalities is given in [43].

4.2.3 The 2nd Inequality

If at least a minimum number of linearly independent smoothing domains are used in a S-FEM model to evaluate the \({\mathbf{\mathbb{G}}}_{h}^{1}\) norms, it should have

or equivalently

This means that the semi-norm \(\left| w \right|_{{{\mathbf{\mathbb{G}}}^{1} (\Omega )}}\) and the norm \(\left\| {\mathbf{d}} \right\|_{{{\mathbf{\mathbb{L}}}^{2} (\Omega )}}\) is equivalent. The proof on this is uses a positivity relay, which is lengthy and given in [43].

4.2.4 The 3rd Inequality

When a minimum number of independent node-based smoothing domains are used to evaluate the \({\mathbf{\mathbb{G}}}_{h}^{1}\) norms, there exists a positive nonzero constant c G such that,

meaning that the \({\mathbf{\mathbb{G}}}_{h}^{1}\) full norm and the \({\mathbf{\mathbb{G}}}_{h}^{1}\) semi-norm of any function in a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space are equivalent. This is a generalized Poincare–Friedrichs inequality for a finite \({\mathbf{\mathbb{G}}}_{h}^{1}\) space. It is fundamentally important for stability of weakened weak formulation based on G spaces. A detailed proof on this norm equivalence theorem in G space theory requires the 1st and 2nd inequalities, and the details are given in [43, 229], when the FEM and PIM shape functions are used.

4.3 Weakened Weak (W2) Form

4.3.1 Essential Chain Inequality

Combination of the 0th and 3rd inequalities, it provides the following chain inequalities.

It essentially says that the semi-norm of any function in a \({\mathbf{\mathbb{G}}}_{h}^{1}\) space can be bounded from both sides by its full norm; it can only be zero if and only if the function is zero everywhere, and it is finite as long as the function is finite. This chain inequality is essential and fundamentally important to ensure the stability and convergence of a W2 formulation that uses smoothed derivatives to construct the stiffness matrix of a model.

4.3.2 Cauchy–Schwarz Inequality

The \({\mathbf{\mathbb{G}}}_{h}^{1}\) inner product defined in Eq. (21) has the Cauchy–Schwarz inequality:

To show this, we first observe its symmetry: because swapping places for w and v will not change the value of the inner product. Second, it is positive definite, because of the positivity of the \(\left( {w,v} \right)_{{{\mathbf{\mathbb{L}}}_{{}}^{2} (\Omega )}}\) and semi-positivity of \(\left( {\bar{\varepsilon }(w),\bar{\varepsilon }(v)} \right)_{{{\mathbf{\mathbb{L}}}_{{}}^{2} (\Omega )}}\). Finally, it is bilinear, because of the bilinear property of \(\left( {w,v} \right)_{{{\mathbf{\mathbb{L}}}_{{}}^{2} (\Omega )}}\) and \(\left( {\bar{\varepsilon }(w),\bar{\varepsilon }(v)} \right)_{{{\mathbf{\mathbb{L}}}_{{}}^{2} (\Omega )}}\).

The Cauchy–Schwarz inequality is fundamentally important for the continuity of the W2 formulation.

4.3.3 Bilinear Forms in \({\mathbf{\mathbb{G}}}_{h}^{1}\) Spaces for Solid Mechanics

Consider again a stable solid (with symmetric positive definite or SPD material constant matrix \({\mathbf{c}}\)) defined in a problem domain that is discretized with a set of elements. We require also that at least the minimum number of linearly independent smoothing domains is used (Table 4) [43, 44]. The smoothed bilinear form is then defined as:

where \({\bar{\varvec{\varepsilon}}}_{i}^{{}}\) is the vector of the smoothed strains in the smoothed domain \(\Omega _{i}^{s}\) [see Eq. (5)]:

We noticed that L2 norm of the strain vector is the \({\mathbf{\mathbb{G}}}_{h}^{1}\) semi-norm:

which is useful in proving important properties in the following sections. We shall also immediately have the following inequality.

4.3.4 The 4th Inequality

which is equivalent to the 2nd Korn’s inequality for functions in a \({\mathbf{\mathbb{H}}}_{h}^{1}\) space.

Combining the 0th inequality and Eq. (35), we have the following chain inequality:

Theorem 1

(Ellipticity with respect to G semi-norm) For solids of stable materials, there exists a nonzero positive constant \(c_{aw}^{s}\) independent of \({\mathbf{w}}\) , such that

The proof needs to use smallest eigenvalue of the material constant matrix \({\mathbf{c}}\) that is SPD, L2 norm definition by inner product, and that the L2 norm of the strain vector is the same as the semi-norm. Finally, we have this inequality and the detailed proof can be found in the Sect. 5.4 of [5].

Theorem 2

(Ellipticity or coercivity: 5th inequality) For solids of stable materials, there exists a nonzero positive constant \(c_{aw}^{f}\) such that

which implies the ellipticity or coercivity of bilinear forms.

This is the outcome of the 3rd inequality and Theorem 1. It is important because it ensures the existence (and hence the uniqueness) and consequently stability of the solution of a W2 formulation.

Theorem 3

(Continuity: 6th inequality) For solids of stable materials, there exists a nonzero positive constant \(c_{awv}^{f}\) such that

The proof needs the largest eigenvalue of the SPD matrix \({\mathbf{c}}\), the Cauchy–Schwarz inequality, the fact that an L2 norm preservation property of the unitary matrix, Eq. (35), and the 0th inequality. The detailed proof can be found in Sect. 5.4 of [5].

Theorem 3 ensures that the bilinear from is continuous. Together with the ellipticity, it ensures the stability of the solution of a W2 formulation.

4.3.5 The 7th Inequality: Softened Model

For stable solid materials and any \({\mathbf{w}} \in {\mathbb{H}}_{h}^{1}\) the smoothed bilinear form is smaller than the standard bilinear form used in FEM:

The proof can be found in the Chap. 4 of [5] and a more general inequality than Eq. (41) can be found in [17]. The 7th inequality implies that a model established based on the smoothed bilinear form will be “softer” than that of bilinear form, which was initially revealed in [223].

4.3.6 Monotonic Convergence Property: 8th Inequality

Consider a division \(D_{ 1}\) that divides domain Ω into a set of smoothing domains \(\boxed\Omega = \cup_{i = 1}^{{N_{s} }} \boxed\Omega_{i}^{s}\) where the box stands for enclosed domain. If a new division D 2 is performed by sub-dividing a smoothing domain in \(D_{ 1}\) into n sd sub-smoothing-domains: \(\boxed\Omega_{i}^{s} = \cup_{j = 1}^{{n_{sd} }} \boxed\Omega_{,j}^{s}\), then the following inequality stands

This is known as the 8th inequality first presented in [223]. It implies that the “softening” effect in a W2 formulation will be reduced monotonically with the increase of the number of smoothing domains in a nested manner. Based on this inequality, one knows how to reduce or increase the stiffness or softness of a W2 model. Arguing along this line, we can expect that \(\mathop {\lim }\limits_{\begin{subarray}{l} N^{n} \to \infty \\ \Omega^{s} \to 0 \end{subarray} } \bar{a}\left( {{\mathbf{w}},{\mathbf{w}}} \right) \to a\left( {{\mathbf{w}},{\mathbf{w}}} \right)\). In other word, the S-FEM approaches to an FEM model at the limit that the dimension of all the smoothing domains approaches to zero. We can also say that an FEM model is a special case of S-FEM at such a limit. This limit property is also rooted at Eq. (7).

4.3.7 A Weakened Weak (W2) Statement

We are now ready to express the W2 statement for solid mechanics problems. An approximated solution \({\bar{\mathbf{u}}} \in {\mathbb{G}}_{h,0}^{1}\) satisfies the following weakened weak (W2) form:

where f(v) is a linear functional defined as

in which \({\mathbf{t}}\) and \({\mathbf{b}}\) are the traction force applied on the natural boundary of the problem domain and the body force applied over the problem domain, respectively.

It is noted that the linear functional \(f\left( {\mathbf{w}} \right)\) is exactly the same as that in the standard FEM. The Eq. (43) is also called the generalized smoothed Galerkin weak from.

If we substitute \({\bar{\mathbf{u}}} = \sum\nolimits_{J = 1}^{{N_{n} }} {{\mathbf{N}}_{J} \left( {\mathbf{x}} \right){\bar{\mathbf{d}}}_{J}^{{}} }\) as the trial function, and set \({\mathbf{N}}_{I} ({\mathbf{x}})\), I = 1, …, N n , as the test function \({\mathbf{v}}\) into the W2 statement, it becomes the following system of N n equations.

which yields Eq. (18).

Theorem 4

(W2 solution in \({\mathbf{\mathbb{H}}}_{h}^{1}\) spaces: variationally consistent) If the solution is sought from a \({\mathbf{\mathbb{H}}}_{h}^{1}\) space, the W 2 statement Eq. (43) is variationally consistent in the standard weak formulation and hence the solution will be stable, unique and convergent to the exact solution of the strong statement when h → 0 (therefore \(\Omega _{i}^{s} \to 0\)).

The proof for this theorem needs two ingredients. First, it is that the smoothed strain is an orthogonal projection (the Theorem 4.1 in [5]) of the compatible strain and hence is variationally consistent. The W2 solution is thus stable and convergent. Second, the discretized FEM space is a subspace of the continuum Hilbert space. When h → 0 (and \(\Omega _{i}^{s} \to 0\)), the solution shall approach to the exact solution of the corresponding strong form PDE. More discussion on this topic can be found in the Chap. 5 of [5].

Theorem 5

(W2 solution in \({\mathbf{\mathbb{G}}}_{h}^{1}\) spaces: convergence to the exact solution) For solids of stable materials, the solution of the W 2 statement Eq. (43) is stable, unique and convergent to the exact solution of the strong statement when h → 0 (\(\Omega _{i}^{s} \to 0\)).

Proof:

We need here three key pieces in this proof: (1) the ellipticity of the bilinear form, (2) the continuity of the bilinear form, and (3) the convergence of the solution to the exact solution. The ellipticity has already been given by Theorem 2, and the continuity is given by Theorem 3. Based on the Lax–Milgram theorem, Theorems 2 and 3 ensures that a W2 formulation has a stable and unique solution for any given discrete model. However, we do not know where the solution converges to, when the mesh of the model is refined. We need to show that the solution of the W2 formulation converges to the exact solution. To this end, we present the following arguments:

-

1.

First, in any of the smoothing domains we see that the smoothed strain field is constant in each and every smoothing domain. Such a constant strain field fully satisfies the strong form equation (in its homogeneous form) in each and every smoothing domain; this means the complementary energy principle is satisfied in all these smoothing domains. There are energy leaks.

-

2.

Second, on all the interfaces of the smoothing domains the displacement field is continuous (compatible); therefore, any discrepancy on (smoothed) stresses on the interface will not generate any work, and hence no leak of energy. The work done by the external forces (body forces and tractions on the boundary, the linear form in the W2 statement) are counted via the potential energy principle (the W2 formulation does not change the linear functional), and thus there is no leak of energy, either. In addition, all these displacement (essential) boundary conditions are satisfied in a S-FEM model. Since the potential energy principle is satisfied on all these places (except within the smoothing domains), there is no energy leak there either.

-

3.

Therefore, when the mesh (background cells together with the smoothing domains) is refined, all the strong form equations will be better satisfied at every point in all these smoothing domain, and the external forces are balanced by the potential energy principle with compatible displacements. There will be no energy leaks at any places in the problem during the process. The solution will surely converge to the exact solution at any point in the problem domain.

In the numerical tests, we have confirmed that all these S-FEM models pass the linear patch test to machine accuracy [5]. This implies that as long as the exact solution of a problem is at least of linear consistency, a S-FEM model may approach the exact solution when the mesh is refined enough. This partially verifies Theorem 5.

The above “argument” proof offers a critical insight to be understanding of a S-FEM model. It is, in fact, a very special “space-hybrid” model that satisfies both the complimentary energy principle and the potential energy principle. The former is satisfied within all smoothing domains, and the latter is satisfied on the rest of places in the model. On one hand, a S-FEM model is a “partial” compatible model (that obeys the total potential energy principle), because it satisfies: (1) the displacement conditions, (2) the displacements are continuous on the interfaces of all the smoothing domains, and (3) the measure of the work done by the external forces. However, the S-FEM is not a fully compatible model, since the differential stain-displacement condition is not satisfied within the smoothing domains, due to the use of the smoothing strains. This partial compatibility makes the S-FEM model “stiffer”. On the other hand, the S-FEM is a partially equilibrium model (that obeys the total complimentary energy principle), because the equilibrium conditions are satisfied within all the smoothing domains, but the stress boundary conditions are not satisfied at the points on the stress boundary and on the interfaces of the smoothing domains. This partial equilibrium feature makes the S-FEM model “softer”. Therefore, a S-FEM model is equipped with a very important “knob” to tune the softening effects, enabling us to build softer model (NS-FEM) for upper bound solutions, stiffer model (ES-FEM) for mostly lower bound with very accurate solutions, and right-stiffness model (αFEM and βFEM) for close to exact or nearly exact solutions. The art of the S-FEM is that is gives creative ways to construct smoothing domains or performing the strain smoothing operations [5].

Theorem 6

(Upper bound to the FEM solution) The strain energy of the S-FEM solution \({\bar{\mathbf{u}}} \in {\mathbf{\mathbb{H}}}_{h,0}^{1}\) is no less than that of the FEM solution \({\tilde{\mathbf{u}}} \in {\mathbf{\mathbb{H}}}_{h,0}^{1}\) , when the same mesh is used for creating the numerical models.

The proof is lengthy and can be found in [17] by variational formulation and in [223] by energy principle formulation. Although we will not repeat the proof here, we will provide an intuitive physical understanding of Theorem 6. From the 7th inequality, we know that a S-FEM model is always softer than its FEM counterpart. Therefore, the displacement field obtained from the model should be “larger” and so is the strain field. The strain energy obtained using such a “larger” strain field should also be “larger” compared to that of the FEM model. In other words, the upper bound property is the consequence of the fact that an S-FEM model is always “softer” than its FEM counterpart.

4.3.8 Upper Bound to the Exact Solution: Special Cases

The strain energy of a S-FEM solution \({\bar{\mathbf{u}}}\) is no less than that of the exact solution \({\mathbf{u}}\), if \({\bar{\mathbf{u}}}\) is found from a \({\mathbf{\mathbb{H}}}^{1}\) space that contains the exact solution:

When the \({\mathbf{\mathbb{H}}}_{h}^{1}\) space contains the exact solution, the FEM model will reproduce the solution [3] and Eq. (46) becomes (47).

We noted that the S-FEM will produce the exact solution if it is linear. Although the solution space may contain the exact solution, if a finite division of smoothing domain is used, the S-FEM will not necessarily reproduce the exact solution. It produces an approximated solution that approaches to the exact solution when the dimension of the smoothing domains approaches zero.

It is worth emphasizing that Eq. (47) has only theoretical significance, because generally it is difficult to assume a space that contains the exact solution, unless the exact solution has a very simple form. Even if it can be done, one can simply use the FEM to produce the exact solution, and there is no need for any other form of solution method.

4.3.9 Upper Bound to the Exact Solution: Usual Occurrences

The strain energy of the solution \({\bar{\mathbf{u}}} \in {\mathbf{\mathbb{G}}}^{1}\) of a sufficiently large S-FEM model is no less than that of the exact solution \({\mathbf{u}}\), when the smoothing domains are properly chosen for sufficient smoothing effects:

Precise proof for this property is difficult due to the challenge in quantifying the exceptions. This important upper bound property was found always true when NS-FEM models are used with not too small number of elements in any of the dimensions. An intuitive explanation and “proof” by numerical examples can be found in [17, 222, 223, 230]. A discussion can also be found in the Chap. 8 of [5]. The upper bound property is practically important because it implies that a sufficiently large S-FEM model can provide upper bound to the exact solution in energy norm by properly chosen smoothing domains. Here we emphasis how the smoothing domains are constructed rather than how many smoothing domain is used in an actual S-FEM model.

4.3.10 Rate of Convergence

Once a model is confirmed to be stable and convergent, the error in the solution will depend on the error in the interpolation of the displacement and the approximation of the strains. Therefore, the rate of convergences can be analyzed via the errors during the displacement interpolation and strain approximations. On the rate of convergence for the displacement solution (in L2 norm), some theoretical studies have shown that it is largely the same for S-FEM and its FEM counterpart [43, 44]. Numerical tests frequently found the rate of S-FEM is often higher.

On the rate of convergence of solutions in stresses (in energy norm), we know that the linear FEM is 1.0 [1, 7]. The S-FEM is usually found to be much higher and Liu [43] has proven an ideal rate of around 1.5 for the NS-FEM. In many numerical examples, S-FEM can achieve a rate of larger than 1.5. The precise proof on this is not yet available. Intuitively, we know that the smoothing operation has helped a great deal to improve the rate of convergence. We know the low rate convergence of the FEM is the compatible formulation, which does not influence the derivatives of the assumed function. When the solution error is measured in H1 norm, it loses 1 order. It can also be argued that the stresses on the interfaces of the FEM elements jumps, which naturally reduce the accuracy and the rate of convergence. On the S-FEM, however, the compatible strains are subjected to smoothing operations (that is an orthogonal projection, the Theorem 4.1 in [5]). The jumping stresses on the original element interfaces are smoothed out in many S-FEM models. This helped to reduce the error in stresses.

It is worthwhile, however, to emphasize that the study on G space and W2 formulation is relatively new and the work is far from perfect and complete. As engineers, we hope our preliminary studies can inspire more profound studies of G space and W2 mathematical formulations, which can provide a solid theoretical basis for even more effective computational methods.

5 Applications

The original applications of S-FEM were in linear elasticity, including basic elastostatics [11, 18, 20], and free and forced vibration analysis [14, 22]. Because of the capability, robustness and versatility of S-FEM, it has been further developed and applied to a large range of problems. This section will review the major application areas of S-FEM in several aspects: material nonlinearity, fracture mechanics, plates/shells/membranes and composite structures, vibration analysis and acoustic problems, piezoelectric structures and photonic devices, heat transfer and thermo-mechanical problems, and fluid–structure interaction (FSI) simulations. Some special treatments for different problems will also be briefly introduced.

5.1 Nonlinear Material Behavior

In the past 30 years, there has been considerable interest in the computational area of the material behaviors under extreme environments, especially computational material nonlinearity [231–233]. Though grid based methods, particularly the FEM approaches, have made achievements in numerous problems, some numerical difficulties still exist, which limit their applications in some aspects [234–239]. Most of these numerical issues mainly result from large deformation and/or incompressibility of materials. Because of the insensitivity of mesh distortion and locking-free characteristics of some S-FEM models, they can achieve more accurate solutions in modeling nonlinear materials and/or provide simple and effective tools for overcoming the severe volumetric locking in simulating deformation behavior of incompressible or nearly incompressible materials.

5.1.1 Elastic–Plastic Analysis, Shakedown and Limit Analysis

Cui et al. [23] presented the ES-FEM formulations for elastic–plastic problems based on Hencky’s deformation theory. Three material models, elastic-perfectly plastic material, work-hardening material and Ramberg–Osgood model, are used and compared with ABAQUS quadrilateral elements to verify the numerical implementations. Cui and Li [64] extended the ES-FEM to simulate metal forming processes with contact algorithms. Liu et al. [240] utilized the selective ES/NS-FEM to treat volumetric locking problems in large-deformation plasticity analysis. The CS-FEM has been applied on two-dimensional elasto-plastic deformations by Bordas et al. [241]. Lee et al. [62] extended the 3D CS-FEM for elasto-plastic finite deformation with emphasis on variable-node elements. Through modifying the volumetric strain in some fashion consistent with the B-bar approach in CS-FEM, the volumetric locking arising from nearly incompressible behavior of elastic–plastic deformations is avoided.

The ES-FEM is firstly extended by Tran et al. [116] for limit and shakedown analysis of structures with elastic-perfectly plastic material. The numerical procedure involves a primal–dual algorithm based on the von Mises yield criterion and a non-linear optimization procedure for the evaluation of the upper and lower bounds of the plastic collapse limit and the shakedown limit. Similar application combined with a primal–dual algorithm by NS-FEM was presented in [118] and a selective ES-FEM of kinematic theorem was introduced in [172] for plastic collapse analysis of structures. Through incorporating the CS-FEM with second-order cone programming (SOCP), Le et al. [117] proposed a numerical procedure of kinematic limit analysis for plane problems.

5.1.2 Visco-elastoplastic Analysis

Nguyen-Thoi et al. extended the ES-FEM and FS-FEM for visco-elastoplastic analyses with the von-Mises yield function and the Prandtl–Reuss flow rule, based on the work of the standard FEM by Carstensen and Klose [242]. They investigated the material behavior of perfect visco-elastoplasticity, and visco-elastoplasticity with isotropic hardening and linear kinematic hardening in a dual model [24, 28]. They found the ES-FEM in 2D and FS-FEM in 3D performed more efficiently (computation time for the same accuracy) than the FEM. A similar study has been carried out in [51] for visco-elastoplasticity by the NS-FEM using both triangular (NS-FEM-T3) and tetrahedral (NS-FEM-T4) meshes.

5.1.3 Hyperelasticity and Applications in Biomechanics

Since the NS-FEM has the properties of strong softening effects and volumetric locking free, it is attractive to deal with volumetric locking, especially for hyperelastic materials. However, pure NS-FEM-T3 shows oscillation phenomena, which leads to the divergent iterative solving process [204]. This instability during large deformation can be explained by eigenvalue analysis for the tangent stiffness, which is essentially the same as the temporal instability with spurious non-zero eigenmodes for dynamics problems [144]. Therefore, the combination of edge-based smoothing techniques or even FEM with the NS-FEM has been proposed to stabilize the system, such as the selective ES/NS-FEM or FS/NS-FEM, αFEM, and βFEM. In [204], Zhang and Liu formulated the nonlinear forms for NS-FEM, ES-FEM and αFEM based on the total Lagrangian formulation. The performances of these methods are compared by numerical examples of compressible Neo-Hookean materials. Later on Jiang et al. extended and implemented the selective FS/NS-FEM and 3D-ES/NS-FEM under the framework of explicit time integration for analysis of extremely large deformation of incompressible isotropic materials and anisotropic incompressible bio-tissues [35, 205, 207].

Figure 8 shows the deformed configurations of a bonded rubber block with nearly-incompressible Mooney–Rivlin hyperelastic material model under torsion. The analysis procedure automatically stops while \(J = \det \left( {\mathbf{F}} \right) \le 0\) appears, which will yield unphysical strain energy due to the excessively element distortion. The second order FEM-T10 with reduced integration (FEM-T10-SRI) stops when the torsion reaches θ = 1.14π shown in Fig. 8a, while the FS/NS-FEM-T4 reaches much larger torsion deformation with θ = 2.15π as illustrated in Fig. 8b. Figure 9 plots the displacement and Von Mises stress distributions of a left rabbit ventricle filled with 30 mmHg blood pressure. The rabbit ventricles with anisotropic Holzapfel–Gasser–Ogden (H–G–O) model was meshed with 19,677 elements and 4328 nodes and the results show the FS/NS-FEM-T4 matches well with the FEM-T10-SRI.

Final deformed configurations for modeling of a bonded rubber block with 65,224 elements under torsion: a the torsion reaches θ = 1.14π obtained by FEM-T10-SRI and b the torsion reaches θ = 2.15π obtained by FS/NS-FEM-T4 (from [205])

Simulation of rabbit ventricles in diastole (30 mmHg LV pressure): a contour of displacement obtained by FS/NS-FEM-T4 (max value: 3.146 mm), b contour of displacement obtained by FEM-T10-SRI (max value: 3.526 mm), c contour of von Mises stress (MPa) obtained by FS/NS-FEM-T4 (max value: 0.0778 MPa) and d contour of von Mises stress (mPa) obtained by FEM-T10-SRI (max value: 0.0906 MPa) (from [207])

Onishi and Amaya [206] proposed a locking-free selective smoothed finite element method with adaptive mesh rezoning (2D ES/NS-FEM-T4 and 3D FS/NS-FEM-T4) for static implicit analysis of large deformation problems based on the total Lagrangian formulation. Similar to [35, 205, 207], the µ/λ split formulation in the original selective S-FEM [16] was updated by the split of deviatoric and volumetric parts, in order to avoid locking issues in modeling nonlinear materials. In the example shown in Fig. 10, a displacement controlled tensioning along the horizontal direction is performed on a filler particle composite. The selective ES/NS-FEM-T3 with mesh rezoning is compared with the analysis without mesh rezoning. Onishi et al. [208] also combined the F-bar method with ES-FEM-T4 to formulate a method named “F-barES-FEM-T4” to suppress pressure oscillation for nearly incompressible solids.

Contours of von Mises stress on deformed configurations of the filler particle composite tension analysis. The analysis with mesh rezoning in (b) and (c) lasted further with 4-times and 8-times mesh rezonings, respectively. In (d), the computation fails due to excessively element distortion without mesh rezoning (from [206]). a Initial mesh: gray area represents soft matrix, pink area represents hard filler particles. b 100% nominal stretch through 4 times of mesh rezoning. c 180% nominal stretch through 8 times mesh rezoning. d 147% nominal stretch without any mesh rezoning. (Color figure online)

Duong [225] employed the FS-FEM for simulation of stress-driven isotropic and transversely isotropic growth for soft tissues. Li et al. applied S-FEM models into analyses of elastography problems [210] and modeling multi-layer biomaterial systems [209], such as human tooth, mucosal tissue and spinal disk. These applications utilized some good numerical features of different S-FEM models, including the promising accuracy when using T-mesh to capture the anatomical details of bio-structures and immunity of volumetric locking for incompressible soft tissues.

5.1.4 Crystal Plasticity Modeling

In view of the plastic incompressibility of single crystals, it is very necessary to use appropriate numerical approaches to resolve the volumetric locking issue. Because of the poor performance of the standard FEM in treating large strain problems of nearly incompressible solid, the S-FEM models become a potential tool for modeling crystal plasticity. On the other hand, to generate meshes for polycrystalline samples with a large collection of grains in arbitrary complex shapes, triangular and tetrahedral elements are the best option for mesh generation. Therefore, the S-FEM models with T-meshes are very appealing in crystal plasticity simulations.

Zeng et al. [65] developed a computational framework of S-FEM for modeling crystalline plasticity at finite strains. The conceived βFEM with mixed smoothing techniques was also applied to modeling crystal plasticity [36]. The single crystalline strain localization and shear band development are consistent with literature, in which special elements such as Q1E4 elements or F-bar elements are utilized. Figure 11 shows the application of βFEM in the necking and asymmetrical localization of an f.c.c. single crystal under vertical tension. The proposed numerical algorithms have been also implemented to simulate the mechanical behavior of polycrystalline aggregates through modeling the synthetic microstructure constructed by Voronoi tessellation technique [65]. In Fig. 12, a specimen with the dimension W = 800 µm and H = 400 µm is constrained on the left edge and stretched up to 10% total length in the horizontal direction. Figure 12a illustrates a representative microstructure with 250 random grain cells, where varied color shows a number of randomly distributed grains with different initial lattice orientations. The local equivalent stresses are up to almost 500% of macroscopic nominal equivalent stress in Fig. 12b. The equivalent stress–strain curves with six different virtual grain microstructures in Fig. 12c shows the convergence of macroscopic response.

Asymmetrical localization of a crystalline strip (W/H = 20 mm/60 mm) under vertical tension: a geometrical dimensions and initial crystal orientations (θ 0 = 45.0° and ϕ 0 = 60.0°) and b final deformed configuration at ΔD = 8.0 mm (from [36])

Simulation of polycrystalline stretch using S-FEM: a a representative grain structure with 250 cells generated by Voronoi Tessellation, b the equivalent stress (MPa) distribution on the deformed configuration and c the equivalent stress–strain curves of different grain structures with 100, 150, 200, 250, 300 and 350 grain cells, respectively (from [65])

5.2 Fracture Mechanics and Fatigue Behavior