Abstract

The optimization of gas pipeline networks plays a pivotal role in ensuring the efficient and economically viable transportation of natural gas. In this research, we have developed a comprehensive mathematical model capable of analyzing diverse network configurations, encompassing both linear and branched topologies. Our scientific investigation aims to explore the optimization potential of gas pipeline networks, employing a sophisticated and systematic approach to enhance network design and operation. The overarching objective is to achieve maximum efficiency and reliability in gas delivery to customers. The optimization process focuses on minimizing power requirements, maximizing gas flow rate, minimizing the fuel consumption, and maximizing line pack to ensure the optimal utilization of the pipeline infrastructure. To accomplish these objectives, our study employs advanced mathematical models that accurately depict network behavior, cutting-edge simulation tools to explore various operational scenarios, and state-of-the-art optimization algorithms to identify the most favorable network configuration and operating conditions. To facilitate this optimization process, we have incorporated the VIekriterijumsko KOmpromisno Rangiranje (VIKOR) method, a potent multi-criteria decision-making technique. Through the application of this approach to two case studies, we have demonstrated its effectiveness in identifying optimal network configurations. Furthermore, we have conducted an analysis to determine the total cost and fuel consumption associated with different network configurations, offering valuable insights for decision-making purposes. The results of our study underscore the superiority of our approach in identifying more economical networks compared to existing methods. By embracing the proposed approach, gas transportation networks can be optimized to achieve superior cost-efficiency and reduced fuel consumption.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The global landscape of energy infrastructure is undergoing a transformative shift, with an escalating emphasis on the role of natural gas as a sustainable alternative to traditional fossil fuels. This paradigm shift has spurred significant investments worldwide in the expansion and optimization of gas pipeline networks, which form the backbone of the natural gas transportation ecosystem. Recognizing the economic and environmental imperatives, researchers and industry professionals are actively engaged in refining the methodologies employed to optimize the performance of these intricate networks.

In this paper, we navigate through the complex terrain of gas pipeline network optimization, considering the distinct roles of long-distance transmission pipelines, distribution pipelines, gathering pipelines, and offshore pipelines. Furthermore, we delve into the structural configurations of gas pipelines, from linear and loop pipelines to lateral, radial, and grid pipelines. Understanding these diverse network types and configurations is crucial, as each presents unique challenges and opportunities for optimization. Various network types can be categorized based on their purpose and configuration. One classification focuses on the intended uses of the networks, including:

-

a.

Long-distance transmission pipelines: these pipelines are responsible for transporting natural gas over extensive distances, connecting production sites to major urban areas, industrial hubs, and power generation facilities. Spanning hundreds or even thousands of kilometers, these pipelines are typically designed to operate at high pressures, aiming to minimize energy losses during the transportation process [1].

-

b.

Distribution pipelines play a vital role in the transportation of natural gas to end-users in residential, commercial, and small industrial sectors. These pipelines are characterized by relatively smaller dimensions and operate at lower pressure levels compared to transmission pipelines. Their primary function is to supply natural gas to local distribution companies or utilities, which subsequently distribute it to end-users through a network of interconnected local distribution lines [2].

-

c.

Gathering pipelines have a critical role in the collection of natural gas from multiple production wells and the efficient transportation of the gathered gas to processing plants or transmission pipelines. These pipelines are primarily located in rural areas and operate at lower pressure levels compared to transmission and distribution pipelines. Their function is to facilitate the movement of natural gas from various production sources to the subsequent stages of processing and transmission, ensuring a reliable supply for further utilization [3].

-

d.

Offshore pipelines play a pivotal role in the transportation of natural gas from offshore production sites to onshore facilities or directly to the market. These specialized pipelines are meticulously engineered to endure the challenging offshore environment, which encompasses formidable conditions such as extreme temperatures, dynamic waves, and strong currents. The design and construction of offshore pipelines require robust engineering techniques and materials to ensure their integrity and functionality throughout their operational lifespan. By withstanding the harsh offshore conditions, these pipelines facilitate the efficient and secure transfer of natural gas resources from offshore locations to the onshore infrastructure or market, contributing to the overall energy supply chain [4].

Another classification considers the network configuration or layout, encompassing various types of gas pipelines based on their structural characteristics:

-

a.

Linear pipelines constitute the most prevalent form of pipeline configuration and find widespread application across all types of gas pipeline networks. These pipelines provide a straightforward and efficient means of transporting natural gas resources, facilitating the seamless flow of gas from its origin to the intended endpoint [5].

-

b.

A loop pipeline is a pipeline configuration characterized by its circuit-like structure, where the pipeline forms a closed loop or circuit. This type of pipeline is strategically designed to offer redundancy and ensure an uninterrupted flow of gas, particularly during disruptions or maintenance activities that may occur along the pipeline. By creating a looped pathway, the loop pipeline enables gas to be rerouted, bypassing any affected sections, thereby maintaining a continuous supply of gas to the intended destinations. This design feature enhances the reliability and resilience of the gas transportation system, mitigating the impact of potential disruptions and minimizing downtime during maintenance operations [6].

-

c.

A lateral pipeline is a branching pipeline configuration that diverges from the main pipeline and is dedicated to serving a specific geographical area or customer. This type of pipeline is frequently employed in distribution pipeline networks, where it facilitates the delivery of natural gas to localized regions or specific end-users. By branching off from the main pipeline, the lateral pipeline enables targeted distribution, ensuring the supply of gas to distinct areas or customers with specific demands. The utilization of lateral pipelines in distribution networks optimizes the delivery process, allowing for efficient and precise allocation of natural gas resources [7].

-

d.

A radial pipeline is a configuration in which a pipeline originates from a central point and extends outward in multiple directions to supply various areas or customers. This pipeline design is frequently employed in distribution pipeline networks, where it facilitates the efficient delivery of natural gas to multiple locations or customers from a central source. By extending radially, the pipeline ensures a reliable and direct distribution of gas to different areas or customers, allowing for effective resource allocation and optimized delivery. The implementation of radial pipelines in distribution networks enhances the overall system performance, enabling the seamless and efficient supply of natural gas to meet the specific demands of diverse end-users [8].

-

e.

A grid pipeline refers to an intricate network of interconnected pipelines that are arranged in a grid-like pattern. This configuration is frequently employed in distribution pipeline networks, particularly in densely populated areas with a significant demand for natural gas. The grid pipeline system is designed to provide a comprehensive coverage of the target region, allowing for efficient distribution and delivery of natural gas to multiple locations within the network. By utilizing a grid-like layout, the pipeline network ensures reliable and equitable access to natural gas resources, accommodating the high demand and complex distribution requirements in densely populated areas. The grid pipeline configuration optimizes the utilization of pipeline infrastructure and enables effective management of gas supply, contributing to the seamless and uninterrupted delivery of natural gas to end-users in the designated regions [6].

While optimization techniques have been widely applied to improve the performance of gas pipeline networks, most existing research has focused narrowly on conventional metrics like gas flow rate, power consumption, and line pack [9]. The multidimensional nature of pipeline optimization necessitates a more comprehensive framework that holistically considers the various trade-offs involved.

Current pipeline optimization strategies lack robust economic measures that account for operational costs like fuel consumption. The failure to integrate such pivotal economic factors into the optimization calculations restricts the ability to effectively evaluate scenarios and identify pathways to maximize profitability. This represents a critical gap in contemporary pipeline optimization research.

To address this limitation, this paper is an expansion of study conducted by Mohammad et al. [9] and proposes a new approach that seamlessly incorporates fuel consumption as an additional optimization criterion using the VIKOR method. By considering fuel consumption alongside delivery flow rate, power consumption, and line pack, the proposed technique enriches the economic calculus and provides a more complete basis for optimization.

The integration of VIKOR enables a structured methodology for establishing criteria weights based on their relative importance. This allows the various objectives to be balanced in an optimization framework tailored to the specifics of a given pipeline network. The technique's ability to handle multiple criteria and provide ranked compromise solutions makes it well-suited for resolving the complex trade-offs involved in pipeline optimization scenarios.

By expanding the scope of optimization to holistically account for pivotal economic factors, the proposed VIKOR-based approach aims to overcome the limitations in existing pipeline optimization research. This has the potential to significantly enhance optimization calculations, decision-making capabilities, and ultimately the profitability of gas pipeline network operations. The introduction of a robust multicriteria methodology represents an important advancement over conventional single-objective or narrow optimization techniques.

This study employs the robust VIKOR method, a powerful multi-criteria decision-making technique introduced by Hwang and Opricovic [10, 11]. By integrating the VIKOR method with standard deviation \({\sigma }_{i}\) weighting, as proposed by Paradowski [12], this research establishes and justifies criteria weights for delivery flow rate, power consumption, line pack, and fuel consumption based on their relative importance in gas transmission network optimization.

In the context of this research, the VIKOR method is chosen for its ability to comprehensively assess the performance of the gas pipeline network, considering various criteria and trade-offs. The VIKOR method in multi-criteria decision making (MCDM) offers several advantages, including: (a) simplicity: VIKOR is characterized by its straightforward comprehension and easy implementation, requiring only basic mathematical computations. (b) Flexibility: the method efficiently handles a significant number of criteria and alternatives, making it suitable for complex decision-making scenarios. (c) Consideration of compromise solutions: unlike some other MCDM methods, VIKOR accommodates compromise solutions, enabling decision-makers to reconcile competing objectives for resolutions acceptable to all stakeholders. (d) Alternative ranking: VIKOR provides an alternative ranking based on proximity to the ideal solution, offering decision-makers an efficient framework for evaluation and comparison.

In parallel, various other MCDM models, including the analytic hierarchy process (AHP), technique for order preference by similarity to ideal solution (TOPSIS), and grey relational analysis (GRA), have been employed in gas pipeline network optimization. These models contribute to ongoing efforts aimed at improving decision-making processes within the field. However, the current state of research on gas pipeline operations lacks comprehensive strategies for effectively implementing optimization techniques to achieve maximum profitability.

However, the use of the VIKOR method is not without limitations, including: (a) sensitivity to input data: the performance of the VIKOR method can be significantly influenced by variations in input data, with even small changes resulting in considerably different rankings of alternatives. (b) Unaddressed uncertainty: the method does not explicitly handle uncertainty within input data, posing a substantial constraint when dealing with decision-making challenges characterized by high levels of uncertainty.

The VIKOR method is a widely recognized technique in MCDM and has found extensive applications in diverse domains, such as operations, supply chain management, and environmental management. It has been successfully applied in sustainable energy development, material selection, stochastic data analysis, and risk evaluation of construction projects [13,14,15,16,17,18,19].

Literature Review

In a recent study by Ali et al. [20], a comparative assessment was carried out to evaluate the feasibility of the IPI and TAPI projects, taking into account multiple objectives. The primary focus of their investigation was to pinpoint critical activities and enhance the efficiency of material and transportation costs, particularly in the context of the TAPI pipeline project. The researchers employed methodologies such as fuzzy TOPSIS, fuzzy critical path method (CPM), and genetic algorithm (GA) to attain these objectives. The research paper is structured with several subsections, each providing insights into the applications of these methodologies [21].

In a study conducted by Li et al. [22], a mixed integer nonlinear programming (MINLP) model was developed for optimal flow rate allocation in a complex treated oil pipeline network. The study considered social and economic benefits simultaneously, incorporating objectives such as user satisfaction and economic gain. Another notable contribution comes from Xiang et al. [23], who focused on emergency scheduling optimization for natural gas pipeline networks (NGPS). The study utilized particle swarm optimization (PSO) to address emergency scheduling and maximize overall system satisfaction during disturbances.

Additionally, Kazi et al. [24], have made strides in modeling and optimizing gas–hydrogen mixtures in pipelines. Their work extends gas flow simulation and optimization problems to include heterogeneous gas mixtures, specifically addressing the blending of hydrogen into natural gas pipelines for clean energy. Table 1 provides information on studies related to pipeline optimization.

Methodology

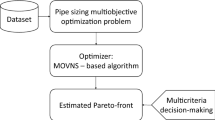

VIKOR seeks to identify the optimal alternative from a range of available options by discerning the one closest to the ideal positive solution and furthest from the ideal negative solution [10]. Figure 1 illustrates the standard procedural steps inherent in the proposed approach The VIKOR method employs a vector approach to compute compromise rankings, taking into account both the best and worst performance of each alternative, which are employed in this study.

The subsequent steps are used for optimizing and ranking of alternatives in complex systems. It is particularly suitable for problems with conflicting criteria where a compromise solution needs to be found.

Step 1: Identification of Objective Functions

A suitable optimization or simulation approach is employed to ascertain the optimal solution that meets the criteria of the given problem. The choice of the most fitting mathematical method and optimization or simulation approach is contingent upon the defined characteristics of the gas pipeline network and the specific problem under consideration [21].

Gas Properties

Understanding and predicting gas behavior in various applications such as process design, combustion analysis, and gas transportation relies significantly on gas properties. The computation of these properties is based on fundamental principles from thermodynamics, fluid mechanics, and molecular theory [8]. Appendix A showcases some of the calculated properties for gases.

Low Heating Value

The lower heating value of a gas, referred to as the lower calorific value or net heating value signifies the thermal energy liberated during the complete combustion of a specific quantity or mass of the gas. In the case of a gas mixture, the (\({\text{LHV}})\) can be determined by taking into account the lower heating values of each individual gas component and their respective mole fractions in the mixture, as denoted by the subsequent equation:

Pipeline Mass Flow Rate Equation

By quantifying the mass flow rate within a pipeline, engineers and operators are able to evaluate the mass transport phenomena, ascertain the energy demands, and monitor the efficacy and functionality of the pipeline system. Furthermore, this calculation is instrumental in the optimization of gas transportation and distribution processes. The mass flow rate can be determined using the subsequent equation:

Pipeline Volume Flow Rate Equation

The volume flow rate in a pipeline refers to the amount of fluid (gas or liquid) that passes through the pipeline per unit of time. It represents the volume of fluid that flows past a specific point in the pipeline over a given period. The volume flow rate of gas in a pipeline depends on several factors, including the diameter of pipeline, pressure of suction and discharge, length of pipe segment, friction factor and the gas properties being transported (such as base pressure and temperature, gravity, compressibility factor). One common formula used to calculate the volume flow rate is the general equation [35]:

Friction Factor

The friction factor \((f)\) in pipeline flow is a dimensionless quantity that characterizes the resistance to flow caused by the roughness of the pipeline surface and other factors such as turbulence and viscosity. It is an important parameter in pipeline design and operation, as it affects the pressure drop and energy losses. It can be determined using empirical equations or experimental data. The most commonly used equation for estimating the friction coefficient is the Nikuradse equation, which is an implicit equation that relates the friction factor to the roughness height of the pipeline surface (\(\varepsilon \)), and the diameter of the pipeline (D). The Nikuradse equation is given by [36]:

Power Demand Reduction

In transition systems of natural gas, compressor stations consume a significant portion of energy. Thus, decreasing their energy requirements can efficiently raise the competence of the pipeline system and the operating revenue. In addition, most compressors run on gas. Efforts to reduce the energy consumption of compressor stations in gas transmission systems are of paramount importance due to their potential to decrease greenhouse gas emissions and improve environmental conditions. Compressor stations play a crucial role in the operation of natural gas pipelines as they provide the necessary energy to ensure continuous gas flow and maintain desired pressures throughout the pipeline network. The energy supplied by the compressor can be quantified as head \(H\), which represents the amount of energy supplied per unit mass of gas. The determination of the head value can be achieved through the utilization of the following equation [37]:

We can estimate the energy provided to the gas in the compressor by Demissie [39]:

Line Pack in Pipeline

Line pack indicates the amount of gas that is stored in a pipeline to maintain system pressure and meet fluctuations in demand. When natural gas is delivered through a pipeline system, the gas flow rate and pressure can vary depending on the demand from customers. To ensure that the system pressure remains within a safe and efficient range, pipeline operations often use line pack to store excess gas during periods of low demand and release it during periods of high demand. Line pack is typically measured in terms of the amount of gas stored per unit length of pipeline, such as cubic feet per mile, or cubic meters per kilometer. The amount of line pack that is required depends on a variety of factors, including the size and capacity of the pipeline, the demand patterns of the customers, and the characteristics of the gas flow, such as pressure and temperature.

The value of line pack in MMscf is determined by using the following equation, Menon [8]:

The Fuel Consumption of Compressor

The fuel consumption of compressors \({(\dot{m}}_{{\text{f}}})\) is essential for ensuring energy efficiency, reducing operational costs, and promoting sustainability in various industries that rely on compression systems, including oil and gas, petrochemicals, and power generation. Fuel consumption increases with compressor gas flow rate, head and decreases with increased efficiencies [40], as shown in Eq. (9):

Step 2: Normalization of Objective Functions

It is important to utilize a robust and transparent decision-making process that involves various stakeholders with continuous evaluation and adjustment of criteria and weights based on updated information:

where \(\gamma_{i}\), \(\left( {i = 1,2, \ldots ,m} \right)\) are alternative \(\beta_{j}\), \(\left( {j = 1,2 \ldots ,n} \right)\) are criteria.

The prevalent normalization method is

-

1.1.1.

for max, we have

$$ \eta_{ij} = \frac{{\lambda_{ij} - \min \left( {\lambda_{ij} } \right)}}{{\max \left( {\lambda_{ij} } \right) - \min \left( {\lambda_{ij} } \right)}},\left( {i\varepsilon m,j\varepsilon n} \right), $$(11) -

2.2.2.

for min, we have

Consequently, obtaining a standardized decision matrix \(\mu \) that illustrates the relative performance of the substitutions as:

Step 3: Determination of Weight Functions

-

1.

The conventional deflection method determines purpose weights through

$$ \tau_{i} = \frac{{\sigma_{i} }}{{\mathop \sum \nolimits_{k}^{m} \sigma_{k} }},{\text{where}} $$(14)$$ \sigma_{i} = \sqrt {\frac{{\mathop \sum \nolimits_{i = 1}^{m} \left( {\lambda_{i} - \lambda^{\sim } } \right)^{2} }}{n - 1}} $$(15)And \(\lambda^{\sim }\) = mean variable

$$ \lambda^{\sim } = \mathop \sum \limits_{i = 1}^{m} \lambda_{i} /n. $$(16) -

2.

Determining the optimal \(\gamma_{i}^{ + }\) and the worst \(\gamma_{i}^{ - }\) values of all criterion function, i = 1, 2, …, n

$$ \gamma_{i}^{ + } = \max \gamma_{ij} , $$(17)$$ \gamma_{i}^{ - } = \min \gamma_{ij} . $$(18) -

3.

Calculate "utility" and "feasibility" metrics for each alternative. The utility metric \(\alpha_{j}\) signifies the relative proximity of each alternative to the optimal value for each criterion, taking into account the assigned weights. The feasibility value \(\vartheta_{j}\) indicates the relative distance of each alternative from the least favorable value for each.

$$ \alpha_{j} = \mathop \sum \limits_{i = 1}^{n} W_{i} \frac{{\left( {\gamma_{i}^{ + } - \gamma_{ij} } \right)}}{{\left( {\gamma_{i}^{ + } - \gamma_{i}^{ - } } \right)}}, $$(19)$$ \vartheta_{j} = \max \left[ {W_{i} \frac{{\left( {\gamma_{i}^{ + } - \gamma_{ij} } \right)}}{{\left( {\gamma_{i}^{ + } - \gamma_{i}^{ - } } \right)}}} \right],{\text{where }}j = 1, 2 \ldots ,m. $$(20) -

4.

The closeness coefficient (\(\beta_{j}\)) gauges the trade-off between utility and feasibility values for each alternative. It is computed through a weighted linear combination of utility and feasibility values, with the flexibility to adjust weights according to the decision maker's preferences. The parameter v, representing the weight assigned to the strategy or maximum group utility of most criteria, is introduced and set as v = 0.5

\(\beta_{j} = \left[ {v\frac{{\left( {\alpha_{j} - \alpha^{ + } } \right)}}{{\left( {\alpha^{ - } - \alpha^{ + } } \right)}} + \left( {1 - v} \right)\frac{{\left( {\vartheta_{j} - \vartheta^{ + } } \right)}}{{\left( {\vartheta^{ - } - \vartheta^{ + } } \right)}}} \right]{\text{ where}}\) (21)

$$ \alpha^{ + } = \min \alpha_{j} , $$(22)$$ \alpha^{ - } = \max \alpha_{j} , $$(23)$$ \vartheta^{ + } = \min \vartheta_{j} , $$(24)$$ \vartheta^{ - } = \max \vartheta_{j} . $$(25)

Step 4: Alternatives Ranking

Rank alternatives according to the closeness coefficient. The alternative with the minimum \(\left({\beta }_{j}\right)\) is the optimal compromise solution or best choice.

Step 5: Calculation of Total Costs

The total cost of a natural gas network is influenced by several factors, including the length and diameter of the pipelines, the required pressure and flow rate capacity, and any specific engineering requirements [41]:

Case Studies

Case 1 (Tree)

The gas pipeline network under investigation adopts a tree-topology configuration, comprising of two compressor stations featuring a parallel arrangement of six compressors each. Within this network, a gas source is responsible for supplying natural gas to three distinct customer types located at the extremities of the network branches. The fundamental parameters outlining this configuration can be found in Fig. 2. The internal diameter of all pipes is 24 inches, and the friction factor is set to 0.009. The base temperature and pressure conditions are specified as 520°R and 14.5 psia, respectively. The compressors are arranged in two pairs, each compressor station consisting of six centrifugal units operating in parallel. The physical properties of the gas mixture used in the network can be found in Table 2 [42].

Pipeline network for Case 1 [42]

Case 2 (Branched-Cyclic)

The second case study, focusing on network characteristics, draws from real-world data provided by the French Company Gas de France (GdF) Suez. Figure 3 illustrates the transmission network in a schematic manner, highlighting its multi-supply and multi-delivery nature. This case study presents a more complex combinatorial aspect compared to the first case study, featuring three loops and seven compressor stations. The transmission network comprises a total of 19 delivery points, denoted by small empty circles, and gas supply can be obtained from 6 different points, represented by hexagons. Additionally, the network includes 20 intermediate nodes facilitating interconnections and, in certain instances, specifying modifications in design parameters. Overall, the network spans 45 nodes and 30 pipe arcs. Seven compressors strategically placed throughout the network compensate for pressure losses. Base temperature and pressure conditions are specified as 520°R and 14.5 psia, respectively [43].

Pipeline network for Case 2 (by courtesy of Gaz de France). [43]

Results and Discussion

The results demonstrate the effectiveness of the proposed multi-objective optimization model in identifying the optimal configuration for the gas pipeline network through illustrative case studies. In Case 1, as shown in Table 7, the VIKOR method determined Scenario 5 as the optimal outcome, with the minimum closeness coefficient value of 0.08461. This optimal scenario is characterized by a pressure range of 580–1000 psi, flow rate of 284.44 MMscf, power consumption of 2506 hp, line pack of 122.718 MMscf, and fuel consumption of 121.395 klb/s (Table 3). The model's ability to reconcile the conflicting objectives of maximizing flow rate and line pack while minimizing power and fuel consumption is evident in the optimal solution. Notably, Scenario 5 does not have the maximum flow rate (Scenario 4) or line pack (Scenario 5), indicating the optimization balances these priorities against power and fuel consumption. This highlights the value of a multi-objective approach compared to single objective optimization. The total cost calculations further validate the effectiveness of the VIKOR method in pinpointing the most economical solution. Scenario 5 has the minimum total annual cost of $5.79 million, aligned with its identification as the optimal compromise based on the closeness coefficient (Table 8). The model demonstrates robust performance across a range of input parameters encompassing pressure range, flow rate, power consumption, line pack, and fuel consumption. The normalized decision matrix (Table 4) and systematic application of the VIKOR technique (Tables 5, 6, 7) enables the relative comparison of scenarios to determine the ideal trade-off. Table 3 displays data specifications for different scenarios including flow rate, power, line pack and fuel consumption for case 1.

The normalized decision matrix results by using Eqs. (11–12) are shown in Table 4.

By using VIKOR method which presented previously, the results of calculation of the standard deviation (\({\sigma }_{i}\)) and the objective weight \({(\tau }_{i})\) using Eqs. (14–15) are presented in Table 5.

The next step is calculating the \({\varvec{\mu}}\) matrix. The results are presented in Table 6 for each scenario.

The results of utility \({\alpha }_{j}\), feasibility \({\vartheta }_{j}\), and closeness coefficient \({\beta }_{j}\) are presented in Table 7 for each scenario.

Total cost is calculated for each scenario using Eqs. 26–28 and results are shown below through Table 8.

While both cases involve a simple tree configuration and a branched cyclic configuration, the results establish the proposed approach's capability for multi-objective optimization of key gas pipeline network parameters. Ongoing research should focus on evaluating more complex system configurations. Overall, the model shows promise in enhancing decision-making during the design and operation of gas transportation networks. Details regarding the length, diameter, and roughness of each pipe are provided in Table 9 for Case 2 [43].

Table 10 displays data specifications for different scenarios including flow rate, power, and line pack for case 2.

The normalized decision matrix results are shown in Table 11.

The results of calculation of the standard deviation (\({\sigma }_{i}\)) and the objective weight \({(\tau }_{i})\) using Eqs. (14–15) for Case 2 are presented in Table 12.

Step 3 results are presented in Table 13 for each scenario for Case 2.

Results obtained by the VIKOR method and total cost are presented in Tables 14 and 15 for each scenario.

In Case 2, as shown in Table 14, the VIKOR method determined Scenario 3 as the optimal outcome, with the minimum closeness coefficient value of 0.41040. This optimal scenario is characterized by a pressure range of 668–1089 psi, flow rate of 67,718.16 MMscf, power consumption of 3465 hp, line pack of 13,123 MMscf, and fuel consumption of 167.80 klb/s (Table 10). Notably, Scenario 3 does not have the maximum flow rate or power consumption (Scenario 1), indicating the optimization balances these priorities against line pack and fuel consumption. This highlights the value of a multi-objective approach compared to single objective optimization. The total cost calculations further validate the effectiveness of the VIKOR method in pinpointing the most economical solution. Scenario 3 has the minimum total annual cost of $11.65 million, aligned with its identification as the optimal compromise based on the closeness coefficient (Table 14). The model demonstrates robust performance across a range of input parameters encompassing pressure range, flow rate, power consumption, line pack, and fuel consumption. The normalized decision matrix (Table 11) and systematic application of the VIKOR technique (Tables 12, 13, 14) enables the relative comparison of scenarios to determine the ideal trade-off.

By incorporating the VIKOR compromise-solution approach, the trade-offs between competing objectives can be balanced to find the most favorable scenarios. The model offers key insights into the pressure settings, equipment parameters, and operating conditions that maximize the network's technical and economic performance.

The results highlight the significance of fuel consumption, often overlooked, as a pivotal optimization criterion. Its inclusion leads to more profitable solutions. The comparison of total annual costs further validates the model's capabilities in pinpointing optimal network configurations.

Overall, the case study results offer convincing proof of concept of the proposed methodology's potential in improving real-world gas transmission network operations. Further testing on larger systems is recommended to fully ascertain its scalability. Integrating the model into pipeline management can lead to substantial efficiency gains and cost savings.

Conclusion

This study presents an expansion of a novel approach for optimizing natural gas transmission networks, taking into account the operational considerations of pipelines through a multi-criteria decision-making process. The proposed model aims to address the simultaneous optimization of four conflicting objectives: maximizing the delivery flow rate, minimizing power consumption, minimizing fuel consumption, and maximizing line pack. To validate the effectiveness of the model, it was applied to two distinct network well-known cases, and the VIKOR method was utilized to determine the optimal scenario. Through this analysis, important insights were obtained concerning the total cost and fuel consumption, providing valuable information for decision-making processes. The proposed multi-objective optimization approach can be extended to tackle other gas pipeline network optimization problems that involve conflicting objectives. Additionally, combining this approach with conventional techniques has the potential to further enhance the optimization process. Future research in this field could explore alternative optimization techniques and consider additional factors such as environmental impact and safety. Furthermore, it is crucial to examine the scalability of the proposed approach to ensure its effectiveness in larger and more complex gas transmission networks. By continuing to advance the understanding and application of this optimization approach, significant advancements can be made in optimizing gas pipeline networks, leading to improved efficiency, cost-effectiveness, and overall performance in the transportation of natural gas.

Data availability

Data will be available upon request.

Abbreviations

- MMscf:

-

Million standard cubic feet per day

- MCDM:

-

Multi-criteria decision making

- AHP:

-

Analytic hierarchy process

- TOPSIS:

-

Technique for order preference by similarity to ideal solution

- GRA:

-

Grey relational analysis

- IPI:

-

Iran–Pakistan–India

- TAPI:

-

Turkmenistan–Afghanistan–Pakistan–India

- CPM:

-

Critical path method

- GA:

-

Genetic algorithm

- MINLP:

-

Mixed integer nonlinear programming

- NGPS:

-

Natural gas pipeline networks

- PSO:

-

Particle swarm optimization

- DIMENS:

-

Decoupled implicit method for efficient network simulation

- BNs:

-

Bayesian networks

- MINLP:

-

Mixed integer nonlinear programming

- \({\text{LHV}}\) :

-

Is the lower heating value of gas mixture in kJ/kg

- \({{\text{LHV}}}_{i}\) :

-

The mass low heating value of molecules composing the gas in kJ/kg

- Q :

-

Is volumetric flow rate in MMscf

- P b :

-

Is base pressure in psia

- T b :

-

Is base temperature in °R

- P 1 :

-

Is upstream pressure in psia

- P 2 :

-

Is downstream pressure in psia

- T f :

-

Is gas flowing temperature in °R

- G :

-

Is gas gravity, dimensionless

- \({\rho }_{{\text{g}}}\) :

-

Is gas density in lb/\({{\text{ft}}}^{3}\)

- \({\rho }_{{\text{air}}}\) :

-

Is air density in lb/\({{\text{ft}}}^{3}\)

- Z :

-

Is gas compressibility factor

- D :

-

Is pipe inside diameter in inch

- L e :

-

Is equivalent length in mile

- \({p}_{{\text{d}}}\) :

-

Is discharge pressure of compressor

- \({p}_{{\text{S}}}\) :

-

Is suction pressure of compressor

- \({C}_{{\text{pi}}}\) :

-

Is heat capacity flow rate of the streams gas component i

- \({T}_{{\text{SC}}}\) :

-

Is the suction temperature of compressor

- \({P}_{{\text{SC}}}\) :

-

Is the suction pressure of compressor

- \(\dot{m}\) :

-

Is gas flow rate in lb/s

- \({{\text{M}}.{\text{wt}}}_{ ({\text{avg}}.)}\) :

-

Is average molecular weight of gas

- \({\mathrm{mole \%}}_{ (i)}\) :

-

Is the mole percent of each component in gas

- \({M}_{i}\) :

-

Is the molecular weight of gas component i

- \({T}_{{\text{PC}}}\) :

-

Is the pseudo critical temperature °R

- \({y}_{i}\) :

-

Is the mole fraction of percent of gas component i, dimensionless.

- \({P}_{{\text{PC}}}\) :

-

Is the pseudo critical pressure psi

- P avg . :

-

Is average pressure in psi

- T :

-

Is gas temperature in K

- T c :

-

Is the critical temperature in k

- P c :

-

Is the critical pressure in psi

- K :

-

Is specific heat ratio (Cp/Cv) assume it to be 1.26

- T 1 :

-

Is suction temperature in °R

- W :

-

Is rate of power in hp

- P :

-

Station horsepower

- \({\dot{m}}_{{\text{f}}}\) :

-

Is the mass flow rate of consumed gas as fuel for the compressor in lb/s

- \({m}_{{\text{c}}}\) :

-

Is the gas flow throughput in the compressor

- \({\eta}_{{\text{m}}}\) :

-

Is the mechanical efficiency of compressor it is ranging between 0.8–0.9 (taking = 0.9)

- \({\eta}_{i}\) :

-

Is the isentropic efficiency of compressor

- \({\eta}_{{\text{d}}}\) :

-

Is the driver efficiency of compressor its value up to 0.5 for centrifugal compressor (taking = 0.35)

- \(\varepsilon \) :

-

Roughness height of pipeline surface

- \(f\) :

-

The friction factor

- b:

-

Base

- f:

-

Flowing

- g:

-

Gas

- e:

-

Equivalent

- d:

-

Discharge

- s:

-

Suction

- i :

-

Component i

- SC:

-

Suction of compressor

- PC:

-

Pseudo critical

- avg:

-

Average

- c:

-

Critical

- f:

-

Fuel

- m:

-

Mechanical

- i:

-

Isentropic

- d:

-

Driver

References

C. Zou, Q. Zhao, G. Zhang, B. Xiong, Energy revolution: from a fossil energy era to a new energy era. Nat Gas Ind B 3(1), 1–11 (2016)

C.P. Vetter, L.A. Kuebel, D. Natarajan, R.A. Mentzer, Review of failure trends in the US natural gas pipeline industry: an in-depth analysis of transmission and distribution system incidents. J. Loss Prev. Process Ind. 60, 317–333 (2019)

B. Guo, A. Ghalambor, Natural Gas Engineering Handbook (Elsevier, Amsterdam, 2014)

B. Guo, S. Song, A. Ghalambor, Offshore Pipelines: Design, Installation, and Maintenance, 2nd edn. (Elsevier Science, Amsterdam, 2013)

E.W. McAllister, Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering Problems (Gulf Professional Publishing, Mexico, 2013)

E.S. Menon, Pipeline Planning and Construction Field Manual (Gulf Professional Publishing, Mexico, 1978)

R.W. Revie, Oil and Gas Pipelines: Integrity and Safety Handbook (Wiley, New York, 2015)

E.S. Menon, Gas Pipeline Hydraulics (CRC Press, Boca Raton, 2005)

N.E.G. Mohammad, Y.Y. Rawash, S.M. Aly, M.E.S. Awad, M.H.H. Mohamed, Enhancing gas pipeline network efficiency through VIKOR method. Decis. Mak. Appl. Manag. Eng. 6(2), 853–879 (2023)

C.-L. Hwang, K. Yoon, C.-L. Hwang, K. Yoon, Methods for multiple attribute decision making. Multiple Attribute Decision Making: Methods and Applications a State-of-the-Art Survey, pp. 58–191 (1981)

S. Opricovic, G.-H. Tzeng, Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 156(2), 445–455 (2004)

B. Paradowski, A. Shekhovtsov, A. Bączkiewicz, B. Kizielewicz, W. Sałabun, Similarity analysis of methods for objective determination of weights in multi-criteria decision support systems. Symmetry (Basel) 13(10), 1874 (2021)

H. Li, W. Wang, L. Fan, Q. Li, X. Chen, A novel hybrid MCDM model for machine tool selection using fuzzy DEMATEL, entropy weighting and later defuzzification VIKOR. Appl. Soft Comput.Comput. 91, 106207 (2020)

K. Yang, T. Duan, J. Feng, A.R. Mishra, Internet of things challenges of sustainable supply chain management in the manufacturing sector using an integrated q-Rung Orthopair Fuzzy-CRITIC-VIKOR method. J. Enterp. Inf. Manag. 35(4/5), 1011–1039 (2022)

C.-N. Wang, N.-A.-T. Nguyen, T.-T. Dang, C.-M. Lu, A compromised decision-making approach to third-party logistics selection in sustainable supply chain using fuzzy AHP and fuzzy VIKOR methods. Mathematics 9(8), 886 (2021)

J. Brodny, M. Tutak, Assessing sustainable energy development in the central and eastern European countries and analyzing its diversity. Sci. Total. Environ. 801, 149745 (2021)

A. Jahan, F. Mustapha, M.Y. Ismail, S.M. Sapuan, M. Bahraminasab, A comprehensive VIKOR method for material selection. Mater. Des. 32(3), 1215–1221 (2011). https://doi.org/10.1016/j.matdes.2010.10.015

M. Tavana, R. Kiani Mavi, F.J. Santos-Arteaga, E. Rasti Doust, An extended VIKOR method using stochastic data and subjective judgments. Comput. Ind. Eng.. Ind. Eng. 97, 240–247 (2016). https://doi.org/10.1016/j.cie.2016.05.013

L. Wang, H. Zhang, J. Wang, L. Li, Picture fuzzy normalized projection-based VIKOR method for the risk evaluation of construction project. Appl. Soft Comput.Comput. 64, 216–226 (2018). https://doi.org/10.1016/j.asoc.2017.12.014

Y. Ali, M. Ahmad, M. Sabir, S.A. Shah, Regional development through energy infrastructure: a comparison and optimization of Iran-Pakistan–India (IPI) & Turkmenistan–Afghanistan–Pakistan–India (TAPI) gas pipelines. Oper. Res. Eng. Sci. Theory Appl. 4(3), 82–106 (2021)

X. Wu, C. Li, Y. He, W. Jia, Operation optimization of natural gas transmission pipelines based on stochastic optimization algorithms: a review. Math. Probl. Eng. 2018, 1267045 (2018). https://doi.org/10.1155/2018/1267045

H. Li et al., An optimal flow rate allocation model of the oilfield treated oil pipeline network. Petroleum 10(1), 93–100 (2024). https://doi.org/10.1016/j.petlm.2023.11.001

Q. Xiang, Z. Yang, Y. He, L. Fan, H. Su, J. Zhang, Enhanced method for emergency scheduling of natural gas pipeline networks based on heuristic optimization. Sustainability 15(19), 14383 (2023)

S.R. Kazi, K. Sundar, S. Srinivasan, A. Zlotnik, Modeling and optimization of steady flow of natural gas and hydrogen mixtures in pipeline networks. Int. J. Hydrog. EnergyHydrog. Energy 54, 14–24 (2024)

G. Habibvand, R.M. Behbahani, Using genetic algorithm for fuel consumption optimization of a natural gas transmission compressor station. Int. J. Comput. Appl.Comput. Appl. 43(1), 1–6 (2012)

H. Üster, Ş Dilaveroğlu, Optimization for design and operation of natural gas transmission networks. Appl. Energy 133, 56–69 (2014)

Y. Hu, Z. Bie, T. Ding, Y. Lin, An NSGA-II based multi-objective optimization for combined gas and electricity network expansion planning. Appl. Energy 167, 280–293 (2016)

A.K. Arya, S. Honwad, Multiobjective optimization of a gas pipeline network: an ant colony approach. J. Pet. Explor. Prod. Technol.Explor. Prod. Technol. 8(4), 1389–1400 (2018)

A.J. Osiadacz, N. Isoli, Multi-objective optimization of gas pipeline networks. Energies (Basel) 13(19), 5141 (2020)

K. Jiao et al., Study on the multi-objective optimization of reliability and operating cost for natural gas pipeline network. Oil Gas Sci. Technol. Revue d’IFP Energies nouvelles 76, 42 (2021)

J. Zhou, J. Peng, G. Liang, C. Chen, X. Zhou, Y. Qin, Technical and economic optimization of natural gas transmission network operation to balance node delivery flow rate and operation cost. J. Intell. Fuzzy Syst. 40(3), 4345–4366 (2021)

K. Wen et al., Multi-period optimal infrastructure planning of natural gas pipeline network system integrating flow rate allocation. Energy 257, 124745 (2022)

L. Fan et al., A systematic method for the optimization of gas supply reliability in natural gas pipeline network based on Bayesian networks and deep reinforcement learning. Reliab. Eng. Syst. Saf.Saf. 225, 108613 (2022)

Y. Ruan et al., Collaborative optimization design for district distributed energy system based on energy station and pipeline network interactions. Sustain. Cities Soc. 100, 105017 (2024)

P.M. Coelho, C. Pinho, Considerations about equations for steady state flow in natural gas pipelines. J. Braz. Soc. Mech. Sci. Eng. 29(3), 262–273 (2007)

M. Mohitpour, H. Golshan, M.A. Murray, Pipeline design & construction: a practical approach. American Society of Mechanical (2003)

A.H.A. Kashani, R. Molaei, Techno-economical and environmental optimization of natural gas network operation. Chem. Eng. Res. Des. 92(11), 2106–2122 (2014)

K.A. Pambour, R. Bolado-Lavin, G.P.J. Dijkema, An integrated transient model for simulating the operation of natural gas transport systems. J. Nat. Gas Sci. Eng. 28, 672–690 (2016)

A. Demissie, W. Zhu, C.T. Belachew, A multi-objective optimization model for gas pipeline operations. Comput. Chem. Eng.. Chem. Eng. 100, 94–103 (2017)

M.E. Takerhi, K. Dąbrowski, Optimization of a gas network fuel consumption with genetic algorithm. Energy Explor. Exploit.Explor Exploit 41(2), 344–369 (2023)

T.F. Edgar, D.M. Himmelblau, L.S. Lasdon, Optimization of chemical processes. McGraw-Hill chemical engineering series, 2nd editon (2001). https://cir.nii.ac.jp/crid/1130282270768160896

H. Su et al., A method for the multi-objective optimization of the operation of natural gas pipeline networks considering supply reliability and operation efficiency. Comput. Chem. Eng.. Chem. Eng. 131, 106584 (2019)

F. Tabkhi, L. Pibouleau, G. Hernandez-Rodriguez, C. Azzaro-Pantel, S. Domenech, Improving the performance of natural gas pipeline networks fuel consumption minimization problems. AIChE J. 56(4), 946–964 (2010)

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors

Author information

Authors and Affiliations

Contributions

Conceptualization, SA, MH; methodology, MH, SA; investigation, NE, YY; resources, YY, NE, MH; writing—original draft preparation, NE; writing—review and editing, MH; supervision, SA, MH; all authors have read and agreed to the published version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

Gas Density

The density and pressure of a gas as shown in the following equation form are associated by entering the compression coefficient, Z in the paradigm.

where, R is universal gas constant, M: is the gas average molecular weight and relies on its composition. Gas molecular weight is estimated by means of easy blending rule stated in the succeeding equation form in which Yi and Mi are the mole fractions and molecular weights of sorts, respectively:

Compressibility Factor

The compression coefficient compressibility factor, Z, is utilized to change the perfect gas equation to consideration for the real gas demeanor. Conventionally, the compression coefficient is estimated by means of an equation of status:

The Average Pseudo-critical Properties of the Gas Mixture

The pseudo-critical temperature (Tc) and pseudo-critical pressure (Pc) of natural gas can be approximated using appropriate blending rules based on the critical properties of individual gas components:

Average Pressure

The average pressure of gas can be calculated from the below formula by [35]:

Specific Gravity

The specific gravity of a fluid is calculated by dividing the density of the fluid by the density of a reference fluid, such as water or air, at a standard temperature:

Average Molecular Weight of Gas Mixture

The gas molecular weight is estimated through blending rule as:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammad, N.E., Yassmen, Y.R., Aly, S. et al. A Multi-objective Optimization Method for Simulating the Operation of Natural Gas Transport System. Korean J. Chem. Eng. 41, 1609–1624 (2024). https://doi.org/10.1007/s11814-024-00136-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00136-y