Abstract

The reliability of a method using 1H NMR analysis for assessment of oil oxidation at frying temperatures was examined. During heating and frying at 180 °C, changes of soybean oil signals in the 1H NMR spectrum including olefinic (5.16–5.30 ppm), bisallylic (2.70–2.88 ppm), and allylic (1.94–2.15 ppm) proton signals relative to glyceride backbone CH2 (5.30–5.46 ppm) and aliphatic CH2 (1.05–1.71 ppm) signals showed strong correlations with conventional analytical methods including total polar compounds, polymerized triacylglycerols, and changes of linoleic acid and linolenic acid peaks in gas chromatography. For oils rich in oleic acid, mid-oleic sunflower oil (NuSun) and high oleic soybean oil, only the olefinic and allylic proton signals are recommended for analysis due to the relatively low intensity of the bisallylic proton signal. Under these heating and frying conditions, signals indicating intermediate oxidation products, hydroperoxides, were not detected while very small signals corresponding to a variety of aldehydes including alkanal, branched alkenal, 2-alkenal, and aldehydes of conjugated dienes and epoxides were observed. In this study, it was found that the 1H NMR method is a fast, convenient, and reliable analytical method to determine the oxidation state of frying oil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lipid oxidation during storage, heating, or frying can be determined by many analytical methods including peroxide value, conjugated diene value, thiobarbituric acid reactive substances (TBARS) assay, and p-anisidine value, total polar compounds (TPC), quantification of the loss of polyunsaturated fatty acids (PUFAs), and the analysis of polymerized triacylglycerols (PTAGs) [1]. However, a lack of consistency in results obtained from these analytical methods is very common. The reason for the inconsistency is that most methods are designed to detect one type of oxidation product although lipid oxidation is a very complicated process producing numerous products. Hence, the development of methods that combine the concomitant detection of different types of oxidation products is necessary for the consistent assessment of lipid oxidation [2].

NMR spectroscopy technology has made great contributions in elucidating molecular structures of oxidation products from lipids and in revealing mechanisms of lipid oxidation. For example, Chan et al. used 1H NMR spectroscopy to elucidate the molecular structures of major oxidation products including 3-l-hydroperoxy-cis-9-trans-11 octodecadienoate, 9-d-hydroperoxy-trans-10-cis-12-octadecadienboate, 13-hydroperoxy-trans, trans-9,11-octadecadienoate, and 9-hydroperoxy-trans, trans-10,12-octadecadienoate formed during oxidation of methyl linoleate [3]. Further studies on oxidation products using 1H NMR spectroscopy indentified many other oxidation products such as 6-membered hydroperoxy cyclic peroxides, hydroperoxides of conjugated diene systems, aldehydes, and epoxides [4, 5] and helped establish the current fundamental understanding of lipid oxidation.

A few other research groups have also suggested the use of NMR spectroscopy as a method to assess lipid oxidation during storage or heating by measuring changes in the intensity of a specific NMR signal. Saito [6] reported that the ratios of olefinic protons (Ro, 4.9–5.8 ppm) and diallylmethylene protons (Rm, 2.6–3.0 ppm) to aliphatic protons (0.5–3.0 ppm) decreased as pollack oil and sardine oil were heated at 40 °C, and these value were very well correlated with peroxide values. Wanasundara and Shahidi also observed strong correlations between the intensity changes of the olefinic proton peak (5.1–5.4 ppm) and the diallylmethylene proton peak (2.6–2.9 ppm) and TOTOX value (total oxidation value = 2 × peroxide value + anisidine values) during storage of a few different oils at 65 °C in the dark [7]. One of the major problems of widely used conventional analytical methods such as the peroxide value and the carbonyl value is that they reach a peak value and decrease in a short period of time. In the study by Wanasundara and Shahidi [7], the peroxide value and the carbonyl value reached the peak value in 10–20 days, respectively, while the change in 1H NMR signals continued for up to 50 days. Therefore, the NMR method showed an important advantage over these conventional methods. Falch et al. [ [8].] used signals at 8–10.5 ppm, which correspond to secondary oxidation products such as aldehydes, as an indicator for oxidation of the ethyl ester of docosahexaenoic acid stored at 25 °C. This research group observed strong correlations between these NMR signals and traditional analytical values (the coefficient of determination, R 2 = 0.97 with the peroxide value, R 2 = 0.95 with the conjugated diene value, and R 2 = 0.97 with TBARS). Tyl et al. [9] also used 1H NMR signals to determine the content of n-3 PUFAs in fish oil stored at 40 °C and found that the result obtained by NMR spectroscopy was in good agreement with data obtained by gas chromatography.

However, most previous studies focused on lipid oxidation at relatively low temperatures, and very few studies have been conducted for oils heated or used for frying. Guillen and Uriarte [10] used the 1H NMR spectrum of sunflower oil heated at a frying temperature (190 °C) to calculate the molar percentages of acyl groups such as linoleic and monounsaturated acyl groups and iodine values and found that these values followed a linear trend with the heating time. Our research group demonstrated that the NMR spectroscopy could be a very convenient method to evaluate the oxidation of soybean oil heated at 190 °C [11]. However, no systematic study validating the reliability of the NMR method was reported. Therefore, this study aimed to evaluate correlations of the 1H NMR analysis with conventional methods including total polar compounds (TPC), polymerized triacylglycerols (PTAG) and the loss of polyunsaturated fatty acids (PUFAs), which are recognized as the most reliable analytical methods for studying the degradation of oils under frying conditions. Furthermore, we also tested the reliability of the 1H NMR method for mid-oleic sunflower oil (NuSun) and high oleic soybean oil (HOSBO) in addition to regular soybean oil (SBO) heated at 180 °C, since one major recent trend in frying is to use oils containing lower contents of polyunsaturated fatty acids (PUFAs) and a high content of oleic acid due to the oxidation problem of PUFAs.

Experimental Procedures

Materials

Refined, bleached, and deodorized (RBD) soybean oil (SBO), RBD mid-oleic sunflower oil (NuSun®), and RBD high oleic soybean oil (HOSBO) were kindly provided by ADM (Decatur, IL, USA). They were kept frozen at −20 °C before use. HPLC-grade solvents including petroleum ether, diethyl ether, chloroform, methanol, and dichloromethane were purchased from Fisher Scientific (Fair Lawn, NJ, USA). Deuterated chloroform (CDCl3) was purchased from Cambridge Isotope Laboratories, Inc. (Andover, MA). SPE columns (Discovery® SPE, 6 mL, 1 g) were purchased from Supelco (Bellefonte, PA, USA). Fatty acid methyl ester (FAME) standards were purchased from Nu-Chek Prep (Elysian, MN, USA) and Supelco 37 component FAME Mix was purchased from Sigma-Aldrich (St. Louis, MO, USA).

Heating Studies

Oil (2.0 g) was added to a vial (60 mm height, 26.2 mm i.d.; the surface area to volume ratio of the sample: 1.65 cm2/cm3) and heated at 180 ± 1 °C in an oven (HF4-2 Shel Lab High Performance Oven, Cornelius, OR) for 1, 2, 3, 4, and 6 h for SBO, 2, 4, 6, 8, and 10 h for NuSun, and 2, 4, 6, 8, and 12 h for HOSBO. Three replicate experiments were carried out for each treatment. All samples were kept in the freezer (−20 °C) before analysis.

Frying Studies

RBD SBO was kept frozen at −20 °C in 1 gallon glass jars until the day before each frying study. Commercial corn tortillas made from a mixture of white and yellow corn (Gran Sazón, Wyoming, MI, USA) were purchased from a local food service grocery and kept frozen until the day before they preparation. After thawing, tortillas were cut into eight wedges of approximately equal size. One frying batch consisted of three tortillas (~40 g). Frying was carried out in two Cuisinart (CDF-100) 1 L capacity fryers. Fryers were first weighed, and then 900 g oil was added. The fryer temperatures were set to 180 °C; oil temperature was monitored continuously with J-KEM (St. Louis, MO, USA) temperature monitors, and the temperature was collected and stored every 30 s using JKEM software. Once the fryers reached the set temperature, a batch of tortillas was fried in each fryer for 2 min; subsequent batches were fried every 20 min for a total of 6 h. After the last batch, fryers were turned off and allowed to cool down to room temperature, then loosely covered and kept at room temperature overnight. On the second fry day, the oil in the fryers was removed and filtered through a rapid-flow filter to remove crumbs. The used oils were returned to the fryers and the oil weights were replenished to 900 g and this procedure was repeated until the fifth fry day. Two replicate experiments were carried out for each treatment.

Determination of Total Polar Compounds (TPC)

Total polar compounds were determined according to a micro-gravimetric method using solid phase extraction (SPE) with vacuum elution developed in our laboratory. This method is a modification of the American Oil Chemists’ Society (AOCS) official method Cd 20–91 [12, 13]. Briefly, an SPE column (Discovery® SPE, 6 mL, 1 g) was inserted into the top of a Vac-Elut 12 (Agilent Technologies, Santa Clara, CA, USA) and rinsed with 10 mL E1 solvent (petroleum ether:diethyl ether 90:10 v/v). Oil samples (0.0750 g) were dissolved in 1 mL E1 solvent, and added to the SPE column with two 1 mL rinses. After the sample was loaded into the column, 7 mL E1 was used to elute the non-polar fraction, followed by 10 mL E2 solvent (chloroform:methanol, 50:50 v/v). Solvent was partially removed from the fractions under a gentle nitrogen stream then pipetted into pre-weighed aluminum pans on a hotplate set to 60 °C. After drying completely, the pans were placed in an oven set at 100 °C and weighed every 5 min until a constant weight was achieved. The percentages of total polar compounds were calculated as: 100 − [100 × (non-polar fraction(g)/sample weight(g))]. The weight of the polar fraction was used to determine the final yield to verify complete elution of the two fractions. Each sample was analyzed in duplicate.

Analysis of Fatty Acid Composition

Oil samples were converted to fatty acid methyl esters (FAME) using the method described by Ichihara et al. [14]. Fatty acid compositions were analyzed by GC as described by Bakota et al. [15]. In brief, about 10 mg of the oil sample was dissolved in 1.4 mL hexane. Methanolic KOH (2 N, 200 μL) was added and the solution was vortexed for 2 min. After allowing to sit for 1 min, the hexane portion was transferred to autosampler vials. A Supelco SP-2380 capillary column (Bellefonte, PA, USA, 30 × 0.25 mm ID × 0.20 μm film) equipped in an Agilent 6890 GC (Palo Alto, CA, USA) was used to analyze fatty acid concentrations of each sample. The flow rate of the carrier gas, Helium, was 1 mL/min, the injector temperature was 220 °C, the split ratio was 50:1, the oven temperature was 185 °C, and the FID temperature was 220 °C. Commercial FAME standards were used to identify peaks. For each chromatogram, peaks were integrated and the relative area ratio (%) of a fatty acid peak to the sum of the areas of all the fatty acid peaks is reported. Samples were analyzed in duplicate.

Analysis of Polymerized Triacylglycerols (PTAG)

A standard method, AOAC Official Method 993.25 was slightly modified and used to determine the PTAG formed during heating and frying [16]. In brief, the oil sample (10.0 ± 1 mg) was dissolved in dichloromethane (10 mL) and 1.0 mL of the solution was transferred to an autosampler vial. The solution (10 μL) was injected into a size exclusion column (PLGel 5 μm, 100 Å pore size, 300 × 7.5 mm, Polymer Labs, Amherst, MA, USA) equipped in a Shimadzu HPLC (model LC20AT, Kyoto, Japan). The ELSD was used as a detector, which was operated with nitrogen as the nebulizer gas (99.999%, pressure: 3.0 Bar, Gain: 1) at a temperature of 40 °C. Shimadzu EZStart Chromatography Software Version 7.3 was used for HPLC control, data collection and analysis. The ELSD was reported to be more reliable, more sensitive, and less influenced by the molecular structure of the substance than the refractive index (RI) detector [17]. All samples were analyzed in duplicate. Peak area percentages are reported.

1H NMR Spectroscopy

Relative Peak Change Analysis [11]

An approximate amount of oil sample (about 50–80 mg) and an approximate amount of CDCl3 (0.9 mL) were added a 2 mL vial and mixed. The solution was transferred to an NMR sample tube (5 mm dia. 7 inch length, Wilmad-LabGlass, Vineland, NJ, USA). 1H NMR spectra were acquired with a Bruker Avance 500 spectrometer (Billerica, MA, USA) operating at 500 MHz. Chemical shifts are reported relative to the chloroform peak (7.29 ppm). SpinWorks 3.1.7 software was used for analysis of spectra. Signals were integrated using four protons of the glyceride backbone CH2 signal (5.30–5.46 ppm). The 1H NMR spectra of oils used in this study is shown in Fig. 1 and proton numbers of all the peaks are summarized in Table 1. As shown in Fig. 1, the glyceride methine (CH) peak (peak B, 5.30–5.46 ppm) was overlapped with the olefinic signal (peak A, 5.16–5.30 ppm) and it was practically impossible to accurately divide these two peaks. Therefore, one proton (the glyceride CH) was subtracted from the number of protons shown in the range of 5.16–5.46 ppm to obtain the number of olefinic protons in an assumption that the bond breaking between the glyceride methine (CH) and glyceride methylene (CH2) was impossible under the typical heating and frying conditions.

Absolute Peak Change Analysis

Although the relative peak change analysis is recommended for the practical application of the NMR method for assessment of oil oxidation, the absolute peak change analysis was conducted in this study in an attempt to determine which signal is the best signal as the standard signal for the relative peak change analysis. For this, the same procedure in the relative peak change analysis was followed except that the exact amounts of sample (80 mg) and the solvent (CDCl3, 1.00 g) were weighed in the NMR tube and the CHCl3 peak (7.28 ppm) was used as the standard peak for integration of other peaks, which existed in the NMR solvent (CDCl3). Actual weights were recorded and errors in weighing were corrected in the calculation of peak areas. Initially, the intensity of the CHCl3 peak in the spectrum was determined as 0.14 protons by comparison with four protons of the glyceride methylene (CH2) of fresh oil. Then, all the other signals of oxidized oils were integrated based on the CHCl3 peak.

Statistical Analysis

All heating experiments were carried out in triplicate and the frying experiment was conducted in duplicate. All the oil analyses were conducted at least in duplicate for each sample except for 1H NMR analysis. For the 1H NMR analysis, analytical replicates were not needed because no substantial differences were observed with repeated analyses with one sample. The standard deviations of signal intensities of olefinic, bisallylic, and allylic signals determined by three replicates of three different samples were 0.02–0.06%. One-way analysis of variance (ANOVA) was performed with the program JMP 9 (SAS Institute, Cary, NC, USA) for TPC, PTAG, fatty acid composition, and all the peak areas in the NMR spectrum. Means of data were compared by Tukey–Kramer HSD test with statistical significance at P < 0.05. Correlation tests were conducted with simple linear regressions with the program JMP 9.

Results and Discussion

Table 1 shows fatty acid compositions (the relative peak areas in GC) of oils used in this study. The contents of oleic acid (18:1) were 23.40, 66.70, and 79.24% for SBO, NuSun, and HOSBO, respectively. Accordingly, the contents of linoleic acid (18:2) were lower for oils with the higher content of oleic acid (SBO: 53.49%; NuSun: 23.49%; HOSBO: 7.54%). Signals of 1H NMR of the three oils well reflected the fatty acid compositions analyzed by GC (Table 1). For example, theoretical integration values (=number of protons) of olefinic protons [3 × (2 × %oleic acid + 4 × %linoleic acid + 6 × %linolenic acid) ÷ 100] calculated from the fatty acid composition [18] were 9.05, 6.88, and 6.05 protons for SBO, NuSun, and HOSBO, respectively, and were very close to the values determined by the 1H NMR spectra (Table 1). Similarly, theoretical integration values of allylic protons calculated from the fatty acid composition [3 × (4 × %oleic acid + 4 × %linoleic acid + 4 × %linolenic acid) ÷ 100] were 10.05, 10.86, and 10.67, for SBO, NuSun, and HOSBO, respectively, which was well matched the proton numbers determined from the NMR spectra. Theoretical integration values of bisallylic protons (3.25, 1.67, and 0.45 protons for SBO, NuSun, and HOSBO, respectively) calculated by the equation [3 × (2 × %linoleic acid + 4 × %linolenic acid) ÷ 100] were somewhat different from the empirical values from the NMR spectra. The reason for this relatively large deviation is likely that the relatively small bisallylic signal in the NMR spectrum was affected by background noises and peaks of other minor ingredients in oil.

1H NMR of SBO Heated at 180 °C

Because of the time and extensive labor required for an actual frying study, heating studies are popularly used in many laboratories for a preliminary comparison of oxidative stabilities of different oils, an initial evaluation or a screening of a variety of antioxidants, and other basic oil oxidation studies before conducting actual frying studies. For this reason, the reliability of the NMR method for heating studies was evaluated. Soybean oil (SBO) is of great interest for frying due to its low price, availability, and healthfulness regardless of its vulnerability to oxidation. Therefore, the heating study with SBO was conducted, in which SBO was oxidized at 180 °C until it reached beyond the 25% TPC level, which is the regulatory limit for frying oils in many countries [19].

The use of signal changes of reactive to non-reactive protons was suggested for the practical application of the NMR method for evaluation of oil oxidation [6, 11]. This is because new analytical methods must be not only reliable but also fast and convenient. The method using the relative peak changes in 1H NMR spectrum offers a very short time for analysis: the time required for sample preparation is typically about 1 min per sample, the acquisition of one spectrum takes less than 10 min, and analysis of data takes about 1 min per sample. In addition, since there are no substantial opportunities for the introduction of human errors, typically no analytical replicates are needed. Therefore, in general, only occasional checking on the repeatability is required. The repeatability ranged at ±0.03–0.06%.

For this relative peak change analysis method, the aliphatic protons (the region of signals G–I) [6, 20] and the glyceride methylene (CH2) protons (signal C) [11] were suggested as the internal standard for integration of other signals. There are also some other non-reactive protons that can be used as a standard signal such as the methylene protons (CH2) at α-position of a fatty acid (signal E) and terminal CH3 (signal I). We monitored the absolute peak changes of these four signals during heating SBO at 180 °C to evaluate these peaks as the standard signal for integration of other peaks. Figure 2a shows the changes of non-reactive signals in 1H NMR. Difference between changes of these four signals was not statistically significant at P = 0.05 indicating that using any of these signals as a standard signal would not make significant differences. Although the difference was not statistically significant and all these four signals may be good standard peaks, the glyceride backbone CH2 (signal C) and methylene protons at α-position of a fatty acid (signal E) appeared to change the least (0.79% decrease and −0.43% increase, respectively). We preferred the glyceride backbone CH2 (signal C) to the methylene protons at α-position (signal E) simply because the range of 1.52–1.71 ppm is, in general, more crowded than the lower field area (4.04–4.39 ppm) and there may be a higher chance to have interferences with signals of some other components in oil such as antioxidants.

Oxidation of heated SBO at 180 °C. a Change of NMR signals of less sensitive sites (C: glyceride methylene (CH2), E: (C=O)CH2, G: aliphatic CH2, I: terminal CH3), b change of NMR signals relative to glyceride CH2 signal (A: olefinic protons, B: glyceride methine (CH), D: bisallylic CH2, F: allylic CH2, H: terminal CH3 of linolenic acid), c %TPC and %PTAG, and d losses of linoleic acid (18:2) and linolenic acid (18:3). Error bars represent standard deviations

Figure 2b shows the NMR signal changes relative to the glyceride CH2 signal. All the signals including olefinic protons (A), bisallylic protons (D), allylic protons (F), and the terminal CH3 group of linolenic acid (H) of SBO gradually decreased over the heating process. The most reactive bisallylic protons (D) decreased the fastest. The trends of the four NMR signals were very similar to the curves of TPC, TPAG, and losses of linoleic acid and linolenic acid observed by GC (Fig. 2c, d). Since fatty acids were analyzed by the relative peak areas to the total peak area and the reactivity of oleic acid is much lower compared to linoleic and linolenic acids, the relative peak area percentages of oleic acid appeared to increase by time due to faster decreases of peak areas of linoleic acid and linolenic acid. For this reason, the loss of oleic acid was not used for comparison with the NMR analysis.

Correlation tests between the losses of four NMR signals (signals A, D, F, and H) and conventional methods showed very strong correlations conferring R 2 values (the coefficient of determination), ranging from 0.9704 to 0.9925 (Table 2). These correlations were as strong as the correlations between the four conventional analytical methods, of which the R 2 values ranged from 0.9586 to 0.9919. Saito and Shahidi research groups [6, 20] used ratios of olefinic and bisallylic protons to the aliphatic protons at 0.6–2.5 ppm to measure oil oxidation. We also tested reliability of methods using changes of olefinic (Rao), bisallylic (Rab = Rad in the literature), and allylic (Raa) protons relative to the aliphatic proton signal during the heating process of SBO at 180 °C. In this study, we slightly modified the previous methods and used a narrow area (1.05–1.71 ppm) for aliphatic CH2 protons (signal G) to exclude the area where the CH3 signal of linolenic acid appeared and showed the significant intensity change over time. Correlation tests of Rao, Rab, and Raa with conventional analytical methods also showed strong correlations (R 2 = 0.9711–0.9954) indicating that these methods are also very reliable.

It is interesting that the change of the linolenic CH3 signal (signal H) also showed a strong correlations with conventional methods even though the peak intensity was smaller than other peaks (0.67 protons). Although it showed high reliability in this study, this peak is not preferred to other three signals (signals A, D and F) because of the relatively low peak intensity that can be easily influenced by the adjacent large aliphatic CH2 peak (signal G, 1.05–1.71 ppm) and other terminal CH3 peaks (signal I, 0.74–0.95 ppm).

1H NMR of Oils Rich in Oleic Acid Heated at 180 °C

Oils rich in oleic acid are of great interest for frying due to their outstanding oxidative stability and a variety of health benefits of oleic acid [21]. Therefore, we examined the NMR method for two oils rich in oleic acid, mid-oleic sunflower oil (NuSun®), and high oleic soybean oil (HOSBO). When the oxidative stabilities of different oils are to be compared, it is important to choose a signal that is reliable for all different oils. We expected that, due to their stronger peak intensity, olefinic proton and allylic proton signals would be more reliable than bisallylic proton and linolenic CH3 signals. Figure 3 shows changes of NMR signals relative to the glyceride CH2 signal, TPC, PTAG, and %losses of linoleic acid and linolenic acid in the GC chromatogram for these two oils during heating at 180 °C. The trends of NMR signals relative to the aliphatic CH2 signal (Rao, Rad, and Raa) were almost identical to Fig. 3a, d and data are not shown in this paper. The linolenic CH3 signal (signal H) was too small to produce reliable data for NuSun and HOSBO and was not included in Fig. 3a, d. The order of the signal reduction rate found in heated SBO, bisallylic H > olefinic H > allylic H, was also observed with NuSun® and HOSBO.

Oxidation of oils rich in oleic acid heated at 180 °C. a Change of NMR signals of NuSun relative to glyceride CH2 signal (A: olefinic protons, D: bisallylic CH2, F: allylic CH2, H: terminal CH3 of linolenic acid), b %TPC and %PTAG of NuSun, c losses of linoleic acid (18:2) and linolenic acid (18:3) of NuSun, and d change of NMR signals of HOSBO relative to glyceride CH2 signal (A: olefinic protons, D: bisallylic CH2, F: allylic CH2, H: terminal CH3 of linolenic acid), e %TPC and %PTAG of HOSBO, and f losses of linoleic acid (18:2) and linolenic acid (18:3) of HOSBO. Error bars represent standard deviations

Table 3 shows the results of correlations tests. Since there were no statistical differences (P = 0.05) between changes of non-reactive signals including the glyceride CH2 (signal C), the methylene protons at α-position of a fatty acid (signal E), aliphatic CH2 (signal G), and terminal CH3 (signal I) after 10-h heating for NuSun and 12-h heating for HOSBO (data not shown), we used only the two signals, the glyceride backbone CH2 and aliphatic CH2 signals, as the standard signal. For NuSun, the NMR method using both the standard signals had strong correlations with PTAG (R 2 = 0.9700–0.9820) and %loss of linoleic acid (18:2) (R 2 = 0.9546–0.9691). However, the weaker correlation between the NMR data and the %linoleic acid determined by GC (R 2 = 0.8660–0.9125) was expected due to the low content of linolenic acid (0.34 ± 0.01%) in NuSun. The weaker correlations between the NMR data and TPC (R 2 = 0.9546–0.9691) were possibly caused by the greater experimental errors in measurements of TPC. For HOSBO, all R2 values were high (R 2 = 0.9185–0.9844) except for the correlations between PTAG and bisallylic protons relative to the glyceride CH2 signal (R 2 = 0.8367) and between PTAG and Rab (R 2 = 0.8252), which were likely caused by the smaller number of bisallylic protons (0.6 protons per oil molecule).

As hypothesized, the bisallylic proton signal showed a relatively low reliability and the linolenic acid CH3 signal cannot be used for NuSun and HOSBO as the intensity of this peak is too small to produce reliable responses to oil oxidation. Correlation tests showed weak correlations of the linolenic acid CH3 signal giving R 2 values of 0.4085, 0.3699, 0.3847, and 0.4825 for NuSun and 0.7423, 0.5466, 0.7158, and 0.7588 for HOSBO with TPC, PTAG, %loss of linoleic acid (18:2) and %loss of linolenic acid (18:3), respectively. Therefore, for oils rich in oleic acid, olefinic protons, and allylic protons relative to either the glyceride CH2 or the aliphatic CH2 protons are the best indications of oil oxidation. In addition, among conventional analytical methods, the GC method monitoring linolenic acid is not recommended due to the relatively small amount of linolenic acid in oils rich in oleic acid.

1H NMR of SBO During Frying at 180 °C

Results found in a heating study sometimes differ from those observed in a frying study and observations found in a heating experiment must be confirmed with an actual frying experiment. For this reason, the reliability of the NMR method was examined for the frying process in which tortilla chips were fried in RDB SBO for five consecutive days. Again, as seen in heated SBO, NuSun, and HOSBO, there were no statistical differences (P = 0.05) between changes of the four non-reactive signals (data not shown) and, therefore, we used the glyceride backbone CH2 and aliphatic CH2 signals as the standard signal. Figure 4 shows the results of the NMR methods along with those of the conventional methods. Both the data from the NMR analysis and from the conventional methods indicated that the oil oxidized rapidly after day 3 unlike the smoother trend found in the heating study with SBO (Fig. 2). The difference might have been caused by the different oil oxidation pattern due to ingredients leached out from tortilla chips, different oxidation products produced, and the different experimental procedure (e.g. replenishing oil for frying). It should be noted that the NMR signals and %loss of linolenic acid in GC were more sensitive to oxidation during the first 3 days than PTAG, TPC, and %loss of linoleic acid in GC, which may be an advantage of the NMR methods and GC method for linolenic acid over other conventional methods. Strong correlations between the NMR methods and conventional methods (R 2 = 0.9598–0.9950) confirmed the high reliability of the NMR methods for the frying process in SBO (Table 4).

Oxidation of SBO during frying at 180 °C. a Change of NMR signals relative to glyceride CH2 signal (A: olefinic protons, B: glyceride methine (CH), D: bisallylic CH2, F: allylic CH2, H: terminal CH3 of linolenic acid), b %TPC and %PTAG, (18:3), and c losses of linoleic acid (18:2) and linolenic acid. Error bars represent standard deviations

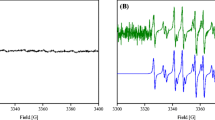

Detection of Oxidation Products

Unlike the 1H NMR spectra of oils oxidized at lower temperatures, intermediate oxidation products, hydroperoxides (8.3–8.9 ppm), did not appear in the 1H NMR spectra of SBO, NuSun, and HOSBO heated at 180 °C, or SBO under frying conditions, which was consistent with the previous observation with sunflower oil heated at 190 °C [10]. Some oxidation products such as aldehydes, aldehydes of conjugated dienes and epoxides were observed in oils heated at the frying temperature and signals of these products increased by time as shown in Fig. 5. The aldehyde proton (CHO) of alkanals was shown at 9.76 ppm as a triplet signal (signal a) [4]. The signals in the region of 9.48–9.66 ppm (signal b) in Fig. 5 are assigned as aldehyde proton (CHO) of different kinds of aldehydes. The peak appeared at 9.51 ppm is likely the aldehyde proton (CHO) of a kind of 2-alkenal for its splitting pattern (doublet) and the chemical shift [5]. The doublet shown at 9.54 ppm is the aldehyde proton (CHO) of a branched alkanal according to the literature [4]. It is interesting that SBO under heating and frying conditions produced similar concentrations of the two aldehydes, branched alkenals and 2-alkenals (the peaks at 9.54 and 9.51 ppm) while NuSun and HOSBO produced mainly 2-alkenals indicating that branched alkenals or any alkenals at 9.54 ppm were produced mainly by linoleic acid and/or linolenic acid. The signals appearing at 5.8–7.2 ppm (signals c) are known to be signals of conjugated dienic systems of aldehydes and of other secondary oxidation products [10]. According to the reports by Guillén et al. and Ruiz [4] and Patrikios and Mavromoustakos [22], signals shown in 3.5–3.8 ppm (signal d) can be either CH 2-OH of an alcohol or -O-CHR1R2 of an ether linkage in polymers. Signals at 2.85–3.18 ppm (signal e) are possibly the sign of epoxides [5]. Signals at 2.65 ppm (signal f) and 2.52 ppm (signal g) are unknown. Signal f appeared only in the spectra of SBO under heating and frying indicating that linoleic acid and/or linolenic acid can produce the oxidation product giving this signal. Signals indicating carboxylic acids (10–12 ppm in 1H NMR and 180 ppm in 13C NMR) were not observed under the experimental conditions used in this study.

Oxidation products detected in 1H NMR of a SBO, b NuSun and c HOSBO heated at 180 °C, and d SBO under frying at 180 °C. a aldehyde proton (CHO) of alkanals, b aldehyde proton (CHO) branched alkenal and 2-alkenal, c conjugated dienic systems, d CH 2-OH of an alcohol or -O-CHR1R2 of an ether, e epoxides, f and g unknown

Conclusions

Signal changes of olefinic and allylic protons relative to the glyceride backbone CH2 signal (5.30–5.46 ppm) showed very strong correlations with the conventional analytical methods for oil oxidation including TPC, PTAG, and %linoleic acid and %linolenic acid determined by GC. We also slightly modified the previously reported method in which 1H NMR signals relative to the aliphatic protons were monitored and tested its reliability. The signal changes of olefinic and allylic protons (Rao and Raa) relative to the aliphatic CH2 (1.05–1.71 ppm) showed strong correlations with the conventional methods. We strongly recommend this NMR method as a tool to assess lipid oxidation since this method was found to be a very convenient, fast, reliable, and non-destructive analytical method.

In conclusion, the following experimental procedure is recommended for the routine oil analysis: (1) approximately 50–100 mg of oil sample is dissolved in CDCl3 in an NMR tube (no need to weigh the exact amount of the sample since the relative peak intensity will be measured), (2) the NMR spectrum is obtained, (3) olefinic and allylic proton peaks (and bisallylic proton peak if the oil is not a high-oleic oil) are integrated using the glycerol CH2 peak as standard, and (4) peak changes are recorded to determine the deterioration of lipid. If TPC, PTAG, or the fatty acid composition is needed to be determined, a calibration curve prepared with known samples may be used. Especially, to determine the discard point of frying oil based on TPC, a calibration curve with TPC is needed.

References

Schaich KM (2013) Chapter 2: challenges in analyzing lipid oxidation: are one product and one sample concentration enough? In: Nienaber U, Pan X (eds) Lipid Oxidation. AOCS Press, Champaign

Gray JI (1978) Measurement of lipid oxidation: a review. J Am Oil Chem Soc 55:539–546

Chan HS, Levett G (1977) Autoxidation of methyl linoleate. Separation and analysis of isomeric mixtures of methyl linoleate hydroperoxides and methyl hydroxylinoleates. Lipids 12:99–104

Guillén MD, Ruiz A (2001) High resolution 1H nuclear magnetic resonance in the study of edible oils and fats. Trends Food Sci Technol 12:328–338

Goicoechea E, Guillen MD (2010) Analysis of hydroperoxides, aldehydes and epoxides by 1H nuclear magnetic resonance in sunflower oil oxidized at 70 and 100 °C. J Agric Food Chem 58:6234–6245

Saito H (1987) Estimation of the oxidative deterioration of fish oils by measurements of nuclear magnetic resonance. Agric Bio Chem 51:3433–3435

Wanasundara UN, Shahidi F (1993) Application of NMR spectroscopy to assess oxidative stability of canola and soybean oils. J Food Lipids 1:15–24

Falch E, Anthonsen HW, Axelson DE, Aursand M (2004) Correlation between 1H NMR and traditional methods for determining lipid oxidation of ethyl docosahexaenoate. J Am Oil Chem Soc 81:1105–1110

Tyl CE, Brecker L, Wagner KH (2008) 1H NMR spectroscopy as tool to follow changes in the fatty acids of fish oils. Eur J Lipid Sci Technol 110:141–148

Guillén MD, Uriarte PS (2009) Contribution to further understanding of the evolution of sunflower oil submitted to frying temperature in a domestic fryer: study by 1H nuclear magnetic resonance. J Agric Food Chem 57:7790–7799

Hwang HS, Winkler-Moser JK, Liu SX (2012) Structural effect of lignans and sesamol on polymerization of soybean oil at frying temperature. J Am Oil Chem Soc 89:1067–1076

Marquez-Ruiz G, Jorge N, Martin-Polvillo M, Dobarganes MC (1996) Rapid quantitative determination of polar compounds in fats and oils by solid-phase extraction and size-exclusion chromatography using monostearin s internal standard. J Chromatogr A 749:55–60

Sebedio JL, Septier Ch, Grandgirard A (1986) Fractionation of commercial frying oil samples usig Sep-Pak cartridges. J Am Oil Chem Soc 63:1541–1543

Ichihara K, Shibahara A, Yamamoto K, Nakayama T (1996) An improved method for rapid analysis of the fatty acids of glycerolipids. Lipids 31:535–539

Bakota EL, Winkler-Moser JK, Berhow MA, Palmquist DE, Liu SX (2015) Antioxidant activity of hybrid grape pomace extracts derived from midwestern grapes in bulk oil and oil-in-water emulsions. J Am Oil Chem Soc 92:1333–1348

Hwang HS, Winkler-Moser JK, Vermillion K, Liu SX (2014) Enhancing antioxidant activity of sesamol at frying temperature by addition of additives through reducing volatility. J Food Sci 79:C2164–C2173

Hopia AI, Ollilainen VM (1993) Comparison of the evaporative light scattering detector (ELSD) and refractive index detector (RID) in lipid analysis. J Liq Chromatogr 16:2469–2482

Knothe G, Kenar JA (2004) Determination of the fatty acid profile by 1H-NMR spectroscopy. Eur J Lipid Sci Technol 106:88–96

Rossell JB (2001) Frying—improving quality, 1st edn. Woodhead Publishing, Cambridge

Shahidi F, Wanasundara U, Brunet N (1994) Oxidative stability of oil from blubber of harp seal (Phoca groenlandica) as assessed by NMR and standard procedures. Food Res Int 27:555–562

Matthäus B (2006) Utilization of high-oleic rapeseed oil for deep-fat frying of French fries compared to other commonly used edible oils. Eur J Lipid Sci Technol 108:200–211

Patrikios IS, Mavromoustakos TM (2014) Monounsaturated fatty acid ether oligomers formed during heating of virgin olive oil show agglutination activity against human red blood cells. J Agric Food Chem 62:867–874

Acknowledgement

The authors would like to express appreciation to Lynne Copes, Julie Anderson, and Ashley Wayman for excellent technical work and to Dr. Karl Vermillion for NMR spectra.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this article is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

About this article

Cite this article

Hwang, HS., Winkler-Moser, J.K. & Liu, S.X. Reliability of 1H NMR Analysis for Assessment of Lipid Oxidation at Frying Temperatures. J Am Oil Chem Soc 94, 257–270 (2017). https://doi.org/10.1007/s11746-016-2945-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2945-z