Abstract

The effect of processing aids (2.5 % of talc, NaCl or KCl) on oil extractability and the profile of phenolic and volatile compounds of Istarska bjelica and Leccino oils was studied. Talc significantly increased extractability in both cultivars, while salts increased extractability in Leccino cv. In the laboratory extracted oils, phenols were determined by a RP-HPLC–DAD method, whereas volatiles were determined by SPME/GC–MS. Talc addition significantly decreased hydroxytyrosol and increased ligstroside derivatives in produced oils, but did not affect the total phenol content. Among volatile compounds, only Z-2-penten-1-ol in Leccino and 1-pentene-3-one in Istarska bjelica oils significantly increased by talc addition. Salts improved transfer of most individual phenols into oil, particularly oleuropein derivatives, and increased C6 aldehydes and C5 volatiles in Leccino oils. NaCl exerted a stronger effect in increasing individual phenols and volatiles than KCl.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the industrial extraction process of virgin olive oil (VOO), up to 20 % of oil can be lost with the olive by-products [1], mainly due to the oil dispersion and emulsion formation during the crushing process. Also, in the olive fruit, almost a quarter of oil is naturally dispersed in tiny droplets (diameter smaller than 30 µm) bound to colloids and hardly extractable [2]. Moreover, the presence of emulsifiers such as phospholipids, proteins, pectins along with a high water content in fruits (>50 %) contribute to emulsion formation and colloidal stability, disabling the coalescence of oil droplets and reducing the oil yield and extractability [1]. Oil extractability is cultivar-dependent and ranges from 31 to 73 % for 24 Spanish cultivars cultivated in the same olive orchard and processed by the laboratory olive mill [3]. An even wider extractability range (18–83 %) was determined for 6 Spanish cultivars from 3 different olive orchards applying the laboratory extraction [4].

Oil extractability can be improved by the modification of olive paste malaxation conditions (time, temperature, water addition) or by the addition of the processing aids; any processing aids having a physical action (e.g., talc) can be used. In VOO production, the use of processing aids having a chemical or biochemical action is not allowed by European Council Regulation [5]. Talc (hydrated magnesium silicate of particle size lower than 40 µm) is an intensively used natural mineral with an organophilic surface character. It adsorbs phospholipids and proteins from the oil droplet's lipoprotein membrane, stimulating oil coalescence [2] and releasing oils with lower water and suspended solids contents [6]. Talc is recommended for cultivars that have a tendency to form “difficult pastes”, in the mass portion from 0.5 to 3.0 % depending on the water content and olive paste characteristics [7]. In experiments conducted on a laboratory scale, talc powder was used in the concentration range from 0.3 to 5.7 % and significantly increased oil yields in most treatments and studied cultivars [2, 4, 8–10]. Lower talc doses, from 0.3 to 3 %, were tested in industrial trials [6, 11–13]. The addition of 1 and 2 % of micronized talc caused a significant reduction of the oil content in the dry pomace matter (up to 15 %) of industrial samples [12, 13]. In the above-mentioned studies, the main matter of interest was the influence of talc on VOO standard quality parameters (free fatty acids, peroxide value and specific extinctions in ultraviolet) which were insignificantly influenced [4, 6, 11]. Furthermore, quality improvement in terms of decrease of free fatty acids [2] and peroxide value by the talc addition were reported [8, 9, 13]. Considering the total phenol content in VOOs extracted from olive pastes with added talc, a slight and insignificant increase or even inconsistent effect depending on cultivars was observed [2, 6, 8, 9, 13]. A significant increase of total phenols was found by talc addition to unripe Picual paste for three consecutive crop years [14]. The effect of talc on VOO odour characteristics was evaluated only through sensorial characteristics with no significant changes of the fruitiness and the total sensory score [4, 11].

Although talc is the most known one, the use of other physical coadjuvants can be very promising. Common salt (NaCl) can also be used as a processing aid in VOO extraction in order to improve extractability and oil nutritional properties. Its addition to the olive paste leads to the increased density and ionic charge of the aqueous phase resulting in stronger repulsions toward the oil phase and easier oil extraction. In the experiments of Cruz et al. [4], NaCl addition (0.6 and 1.2 %) to the olive paste of six Spanish cultivars significantly improved the oil extractability with the same or slightly lower efficiency than that of talc (1.2 %). Treatment with NaCl increased the pigment contents and bitterness index but did not affected quality indices and the total sensory score. Pérez et al. [15] investigated the simultaneous addition of talc (1.2 %) and NaCl in different concentrations (1.0, 2.5, 5.0, 10.0 %) on oil extractability from green Picual olive pastes. NaCl applied in concentrations equal to or higher than 2.5 % significantly increased extractability and pigment content in oil. They also reported a proportional increase of total phenols, o-diphenols and secoiridoid derivatives in oils along with the increase of NaCl concentration, as well as the content of volatile compounds with positive attributes. Furthermore, a recent study of Koprivnjak et al. [10] showed a significant increase of oil extractability, o-diphenols and total C6 volatile alcohols in Buža VOO obtained by 3 % NaCl addition.

The objective of the present study is to determine the effect of processing aids, talc and two salts of different ionic strength (NaCl and KCl) used at the beginning of malaxation, on oil extractability and the profile of volatile and phenolic compounds in oils of Istarska bjelica and Leccino cultivars. The autochthonous Croatian cultivar Istarska bjelica and the Italian cultivar Leccino were selected due to the known differences in the oil mass fraction in fruits and extractability as well as in the profile of minor components such as phenols and volatiles [16, 17]. At the moment of olive fruits being crushed, most of VOO volatiles are synthesised through the lipoxygenase pathway. Also, phenolic compounds are modified due to endogenous enzymes activation by tissue disruption, facilitating their solubility in oil. The addition of extraction coadjuvants in the malaxation step could influence the solubility and partition of these compounds between water and the oil phase in the olive paste. Moreover, the influence of talc as a widely used technological coadjuvant in VOO processing on the phenolic and volatile compounds profile has not been studied so far.

Materials and Methods

Plant Material and Olive Oil Extraction

Olive fruits of Istarska bjelica and Leccino cultivar were hand-picked in the western part of the Istria region (Croatia) at the end of October 2010. The maturity index of the fruits was determined according to the International Olive Council (IOC) method [7] and was 1.3 for Istarska bjelica (yellow–green fruits) and 4.3 for Leccino olives (dark purple fruits). Olive samples were extracted within 24 h after harvesting, using the laboratory olive mill (Abencor, MC2 Ingeniería y Sistemas, Seville, Spain), which consisted of a hammer crusher, thermostated vertical olive paste mixers and a centrifuge. After milling of 1 kg of olive fruits, in the olive paste (850 g) of each cultivar was added 2.5 % (w/w) of micronized talc (Microtal Olv-32, San Juan, Argentina), NaCl and KCl separately. Control samples were prepared without processing aids addition. All samples were malaxed for 45 min at 25.5 ± 1.0 °C and centrifuged at 3600 rpm for 70 s. Oil sample preparation was done in duplicate for each olive paste treatment. Extracted olive oil samples were stored at room temperature in darkness using glass bottles without headspace prior to analyses.

Olive Paste and Pomace Analyses

The water content in the olive paste of control samples was determined by drying at 70 °C to constant weight. The oil content in olive paste control samples and olive pomace after each treatment was determined by the Soxhlet extraction method. The oil extractability (%) was calculated for each cultivar under different processing aid treatment. Extractability represents a percentage of oil extracted by processing in relation to the total oil contained in olive fruits.

Analysis of Phenolic Compounds

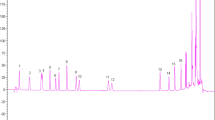

Phenolic compounds were isolated by liquid–liquid extraction from the olive oil sample (5 g) to which a solution of internal standard was added (syringic acid, 0.015 mg/mL). After vigorous shaking, oil was dissolved in n-hexane and phenols were extracted with three portions of 10 mL of methanol/water (60:40, w/w). The obtained phenolic extracts were dried using a rotary evaporator at 40 °C and dissolved in 1 mL of methanol, and filtered through 0.45-μm syringe filters (Supelco, Bellefonte, PA, USA). The reconstructed phenolic fraction was analysed by reverse phase high-performance liquid chromatography (RP-HPLC) using the Agilent Technologies (Waldbronn, Germany) 1100 series HPLC system chromatograph equipped with a diode array detector. The Phenomenex Synergi 4 μm Hydro-RP 80 Å (250 × 4.6 mm i.d.) column (Torrance, CA, USA) was used and maintained at 15 °C, with an injection volume of 10 μL and a flow rate of 1.0 mL/min. Phenolic compounds were determined according to a slightly modified method published by the IOC [18]. A binary elution gradient (0.1 % formic acid in water and acetonitrile/methanol) was used. Phenolic compounds were detected at 280 nm, while flavonoids (luteolin, methyl luteolin and apigenin) were recorded at 340 nm. Calibration curves for tyrosol, luteolin and apigenin were constructed using standard compounds purchased from Fluka (Buchs, Switzerland) and Sigma (St. Louis, MO, USA). Other phenol compounds were assigned according to the IOC publication [18] and quantified using the response factor for tyrosol, with the exception of methyl luteolin which was quantified on the basis of luteolin response. Two parallel extractions of phenols for each VOO sample and four HPLC determinations for each extract were done.

Analysis of Volatile Compounds

Volatile composition of VOO samples was determined by solid-phase microextraction and gas chromatography/mass spectrometry (SPME/GC–MS) using identical extraction and analysis conditions described in our previous work [19]. The identification of volatile compounds was carried out by comparing their mass spectra with those contained in the mass spectra libraries Wiley 6 and NIST 21 and by comparing their Kováts’ retention indices (KIs, Table 4) with those reported in the literature [20–22]. KIs were determined for each volatile compound using a mixture of homologous n-alkanes (C5–C15). The relative response factor of internal standard 4-methyl-2-pentanol (purity 99 %, Sigma-Aldrich, Steinheim, Germany) was used for the volatile compounds semiquantification. An internal standard solution (5.2 μg/mL) was prepared in squalene (purity >97 %, Sigma-Aldrich, Steinheim, Germany) and 40 μL was added to oil samples. VOO volatiles were analysed in two parallel repetitions, and results are expressed in milligrams per kilogram of oil.

Statistical Analysis

Differences among oil samples obtained by the addition of different processing aids were tested by a one-way analysis of variance at the 5 % significance level. The homogeneity of variance was tested by the Brown–Forsythe test. The mean values were compared by Tukey’s honest significant difference test (p ≤ 0.05). Statistical analyses were performed using the software package Statistica 10 (Stat-Soft, Tulsa, OK, USA).

Results and Discussion

Characteristics of processed olive fruits and the effects of using coadjuvants on oil extractability are reported in Table 1. Comparing the two studied cultivars, a low oil extractability (49.6 %) can be noticed for Leccino, despite its relatively high maturity index (4.3). In general, “difficult” olive pastes are produced from olives at the green ripening stage and with water content higher than 50 % [1]. Istarska bjelica is a cultivar of high oil content and, despite its low maturity index (1.3), it has achieved much better laboratory oil extractability (67.2 %). The talc addition significantly improved the oil extraction from olive pastes of both studied cultivars, although more efficiently from Leccino (extractability improvement by 45 % and the reduction of oil content in pomace by 40 % compared to control) than from Istarska bjelica (extractability improvement by 17 % and the reduction of oil content in pomace by 30 % compared to control). The two cultivars had a similar water content but oil content in Leccino paste was notably lower and oil droplets in it were probably more dispersed than in the case of Istarska bjelica. The organophilic character of talc and its ability to facilitate oil coalescence explain its higher efficiency in Leccino paste. The treatments with salts significantly increased extractability only in the Leccino cultivar, but to a lower extent than treatment with talc. The extractability in Leccino was increased up to 56.0 and 57.7 % by the NaCl and KCl addition, respectively. A significant increase of extractability was also achieved by the NaCl treatment (3 % w/w) in the Buža cultivar [10] and in five Spanish cultivars, even at a lower addition level (1.2 % w/w) than in this trial [4]. The extractability improvement by salts is based on the increase of density and ionic charge of the aqueous phase in the olive paste. In this regard, NaCl has the advantage since a contribution to the density is equal for both salts while NaCl creates somewhat higher ionic strength of water solution. Nevertheless, no significant differences in extractability and the residual oil content in pomace were found between the two salts.

Compositional changes of phenols in VOOs of Istarska bjelica and Leccino cv. affected by the addition of processing aids are shown in Tables 2 and 3, respectively. As regards individual phenolic compounds, an increase and decrease by the talc addition can be observed, although significant changes are mainly related to minor components such as hydroxytyrosol, tyrosol, vanillin, vanillic and caffeic acid in Istarska bjelica oil, or hydroxytyrosol, O-Agl-dA, L-Agl-A, flavones and lignans in Leccino oils. Only for a few components contained in major proportions, such as DML-Agl-dA and L-Agl-A in Istarska bjelica oil, as well as DML-Agl-dA and its oxidised form in Leccino oil, a slight but significant increase (by around 11 % compared to controls) was observed. A relative decrease of the oil–water contact surface caused by the coalescence of the dispersed oil droplets assisted with talc could reduce the transfer rate of the individual phenolic compounds from water to the oil phase. On the other hand, this rate could be enhanced as talc adsorbs natural emulsifiers from the surface of the oil droplets, facilitating the passage of phenols through the free surface. These two presumptive and contrary effects of talc resulted in a slight or no change of the total phenols in obtained oils of both studied cultivars. Although the influence of talc on the VOO phenol composition has not been studied, a few works deal with its influence on the total phenol content spectrophotometrically determined using Folin–Ciocalteu reagent. In these studies, an increase and decrease of total phenol content by talc addition can be observed. Most of these works [6, 9, 11, 13, 14] reported an increase of the total phenol content but were mainly statistically insignificant. Ben-David et al. [8] noticed a reduced total phenol content in Picual oils, while Canamasas and Ravetti [2] observed a lower content in Arbequina oils obtained with talc as the processing aid.

The treatment with salts (NaCl and KCl) produced a completely opposite effect on the phenol composition than talc. Both salts improved the transfer of most individual phenols from water to the oil phase in Istarska bjelica and Leccino cultivars (Tables 2 and 3). NaCl strongly increased O-Agl-dA and L-Agl-dA in oils of Istarska bjelica and Leccino. Pérez et al. [15] demonstrated a significant increase of secoiridoid derivatives and an aldehydic form of oleuropein aglycone in Picual oils obtained after the simultaneous addition of NaCl (2.5 %) and talc (1.2 %) as processing aids. Although NaCl increased most individual phenols, its addition caused a significant decrease of tyrosol in Istarska bjelica oil only. KCl significantly increased the content of hydroxytyrosol in oils of both cultivars, on average by 54 %. KCl increased aldehydic and dialdehydic forms of O-Agl and L-Agl, with a higher influence of their aldehydic forms in Istarska bjelica oils, and dialdeydic forms in Leccino oils. When salts dissolve in the aqueous phase of the olive paste, a hydration of their ions occurs. As a consequence, the quantity of free water molecules for the solution of other polar compounds, such as phenols, is reduced. In the presence of salts in water, the solubility of phenols is decreased [23], what is known as a “salting out” effect and could stimulate the transfer and solution of individual phenols into the oil phase. NaCl significantly increased the total phenol content in Leccino oils by 45 % (Table 3) and in Istarska bjelica oils by 32 % (Table 2). The disparity in phenol content in oils of two cultivars could be attributed to their considerably different “natural” phenol mass ratio in oil (i.e., obtained without coadjuvants) and also to the possible differences in the natural mineral content in their fruits. Fernández-Hernández et al. [24] reported the mineral composition of the fruits of five cultivars cultivated in Spain in which sodium content varied from 783 mg/kg in the Arbequina cultivar to 1389 mg/kg of dry weight in the Picual cultivar. The effect of KCl on the total phenol content was less expressed than that of NaCl. KCl has showed a similar effect in both cultivars; total phenols significantly increased by 25 % and by 24 % in Istarska bjelica and Leccino oils, respectively. Moreover, KCl addition in Leccino olive paste slightly decreased flavonoids (apigenin and luteolin) in oil. A better efficiency of NaCl than KCl on oil phenols is probably a consequence of its higher ionic strength; i.e., the extent of hydration of its dissociated ions. Sodium ions are more strongly hydrated due to a smaller ion diameter, leaving less free water available and thus enhancing the transfer of phenols in oil.

The influence of applied processing aids on compositional changes of volatile compounds, responsible for the pleasant olive oil aroma, in Istarska bjelica and Leccino oils are presented in Tables 4 and 5. Besides quantitative differences in the composition of volatiles of control samples of Istarska bjelica and Leccino oils, these two cultivars also differed regarding the effect of studied processing aids on volatile compounds. Apart from a significant decrease of Z-3-hexenal (by 43 %) or the increase of 1-penten-3-one (by 20 % compared to the control sample), changes of other volatile compounds in Istarska bjelica oil caused by the talc addition were quite restricted. As regards Leccino oil, a significant change was found only in the case of Z-2-penten-1-ol (an increase of 33 % compared to the control sample). A marked increase of E-2-hexen-1-ol (from 0.03 to 0.80 mg/kg) was not statistically certain due to a high processing repetition variability in this particular case and, therefore, could not be safely assigned to the influence of talc. An increase of volatile compounds could be contributed to the ability of talc to adsorb emulsifiers from the surface of the oil droplets, liberating the surface where the transfer of these compounds takes place. However, it must be considered that the olive paste is a complex three-phase system in which the transfer of volatile compounds in the oil phase could be influenced by a relative ratio of phases and physicochemical characteristics of paste, such as rheological properties, pH and polarity [25].

Both salts added to the olive paste significantly increased hexanal in Istarska bjelica oils, as well as hexanal and E-2-hexenal in Leccino oils. This positive effect on volatile compounds could be again ascribed to the “salting out” phenomenon and lower solubility of other solutes in the aqueous phase with a reduced degree of water molecule freedom [26]. As the synthesis of volatile compounds mainly takes place during the crushing step of the VOO production process [27], the addition of salts before the malaxation results in a competition among flavour molecules and dissociated salt ions for hydration water. The affinity of water for salt ions is stronger and, therefore, a decreased quantity of free water contributed to the solubilisation of volatile molecules in the oil phase. C6 alcohols and C6 esters were unaffected by the addition of salts in Leccino oils while they were significantly decreased in Istarska bjelica oils upon NaCl addition, mainly due to the change of the E-3-hexen-1-ol mass ratio. Pérez et al. [15] have also found a decrease of E-2-hexen-1-ol and E-3-hexen-1-ol in Picual VOO obtained by the addition of 5.0 % NaCl during malaxation. The solubility of C6 alcohols in the oil phase could be reduced due to their more hydrophilic character than the other VOO volatiles and better solubility in the water phase [28]. Both salts significantly increased the total C5 volatile compounds in oils of the two studied cultivars, especially 1-penten-3-one and Z-2-penten-1-ol, with a similar effect in Leccino oils but with a more pronounced effect of NaCl in Istarska bjelica oil.

Conclusion

Based on the results of the present research, it can be concluded that using 2.5 % of talc or salts during the malaxation process can significantly increase the oil extractability of the olive paste; particularly in Leccino cv. Talc produced minor changes in individual phenol compounds, not affecting the total phenol content in oils of both studied cultivars. Moreover, in Leccino oils, volatile compounds with desirable sensory attributes were increased more by salts than by talc addition. Salts, especially NaCl, significantly increased most phenols in oils as well as the total phenol content, and its use can be considered as an effective tool in the enhancement of the nutritive value and concentration of antioxidants and volatiles.

References

Di Giovacchino L (2013) Technological aspects. In: Aparicio R, Harwood J (eds) Handbook of olive oil. Analysis and properties, 2nd edn. Springer, New York, pp 57–96

Canamasas P, Ravetti LM (2014) Evaluation of traditional and new processing aids for olive oil extraction. Acta Hortic 1057:677–684

Beltrán G, Uceda M, Jiménez A, Aguilera MP (2003) Olive oil extractability index as a parameter for olive cultivar characterization. J Sci Food Agr 83:503–506

Cruz S, Yousfi K, Pérez AG, Mariscal C, Garcia JM (2007) Salt improves physical extraction of olive oil. Eur Food Res Technol 225:359–365

European Commission (2001) Council regulation (EC) No 1513/2001 of 23 July 2001 amending Regulations 136/66/EEC and (EC) No 1638/98 as regards the extension of the period of validity of the aid scheme and the quality strategy for olive oil. Off J Eur Commun L201: 4–7

Cert A, Alba J, León-Camacho M, Moreda W, Pérez-Camino MC (1996) Effects of talc addition and operating mode on the quality and oxidative stability of virgin olive oils obtained by centrifugation. J Agr Food Chem 44:3930–3934

IOC (2011) Guide for the determination of the characteristics of oil-olives. International Olive Council COI/OH/Doc. no 1 November 2011

Ben-David E, Kerem Z, Zipori I, Weissbein S, Basheer L, Bustan A, Dag A (2010) Optimization of the Abencor system to extract olive oil from irrigated orchards. Eur J Lipid Sci Technol 112:1158–1165

Carrapiso AI, García A, Petrón MJ, Martín L (2013) Effect of talc and water addition on olive oil quality and antioxidants. Eur J Lipid Sci Technol 115:583–588

Koprivnjak O, Brkić Bubola K, Kosić U (2015) Sodium chloride compared to talc as processing aid has similar impact on volatile compounds but more favorable on ortho-diphenols in virgin olive oil. Eur J Lipid Sci Technol. doi:10.1002/ejlt.201500014

Moya M, Espínola F, Fernández DG, de Torres A, Marcos J, Vilar J, Josue J, Sánchez T, Castro E (2010) Industrial trials on coadjuvants for olive oil extraction. J Food Eng 97:57–63

Aguilera MP, Beltran G, Sanchez-Villasclaras S, Uceda M, Jimenez A (2010) Kneading olive paste from unripe ‘Picual’ fruits: I. Effect on oil process yield. J Food Eng 97:533–538

Caponio F, Monteleone JI, Martellini G, Summo C, Paradiso VM, Pasqualone A (2014) Effect of talc addition on the extraction yield and quality of extra virgin olive oils from Coratina cultivar after production and during storage. J Oleo Sci 63(11):1125–1132

Aguilera MP, Jimenez A, Sanchez-Villasclaras S, Uceda M, Beltran G (2015) Virgin olive oil bitterness and pungency from unripe ‘Picual’ fruits can be modulated by malaxation conditions. Eur J Lipid Sci Technol. doi:10.1002/ejlt.201400432

Pérez AG, Romero C, Yousfi K, García JM (2008) Modulation of olive oil quality using NaCl as extraction coadjuvant. J Am Oil Chem Soc 85:685–691

Poljuha D, Sladonja B, Brkić Bubola K, Radulović M, Brščić K, Šetić E, Krapac M, Milotić A (2008) A multidisciplinary approach to the characterisation of autochthonous Istrian olive (Olea europaea L.) varieties. Food Technol. Biotech 46(4):347–354

Koprivnjak O, Majetić V, Brkić Bubola K, Kosić U (2012) Variability of phenolic and volatile compounds in virgin olive oil from Leccino and Istarska bjelica cultivars in relation to their fruit mixtures. Food Technol Biotech 50(2):216–221

IOC (2009) Determination of biophenols in olive oils by HPLC. International Olive Council COI/T.20/Doc No 29 November 2009

Majetić Germek V, Koprivnjak O, Butinar B, Pizzale L, Bučar-Miklavčič M, Conte SL (2013) Influence of phenols mass fraction in olive (Olea europaea L.) paste on volatile compounds in Buža cultivar virgin olive oil. J Agr Food Chem 61:5921–5927

Vichi S, Castellote AI, Pizzale L, Conte LS, Buxaderas S, Lopez-Tamames E (2003) Analysis of virgin olive oil volatile compounds by headspace solid-phase microextraction coupled to gas chromatography with mass spectrometric and flame ionization detection. J Chromatogr A 983:19–33

Garcia-Esteban M, Ansorena D, Astiasarán I, Ruiz J (2004) Study of the effect of different fiber coatings and extraction conditions on dry cured ham volatile compounds extracted by solid-phase microextraction (SPME). Talanta 64:458–466

Mildner-Szkudlarz S, Jelen HH (2008) The potential of different techniques for volatile compounds analysis coupled with PCA for the detection of the adulteration of olive oil with hazelnut oil. Food Chem 110:751–761

Noubigh A, Abderrabba M, Provost E (2007) Temperature and salt addition effects on the solubility behaviour of some phenolic compounds in water. J Chem Thermodyn 39:297–303

Fernández-Hernández A, Mateos R, Garcia-Mesa JA, Beltrán G, Fernández-Escobar R (2010) Determination of mineral elements in fresh olive fruits by flame atomic spectrometry. Span J Agric Res 8:1183–1190

McClements DJ (2007) Critical review of techniques and methodologies for characterization of emulsion stability. Crit Rev Food Sci 47(7):611–649

Pérez-Juan M, Flores M, Toldrá F (2007) Effect of ionic strength of different salts on the binding of volatile compounds to porcine soluble protein extracts in model systems. Food Res Int 40:687–693

Inarejos-García AM, Fregapane G, Desamparados Salvador M (2011) Effect of crushing on olive paste and virgin olive oil minor components. Eur Food Res Technol 232:441–451

Rabe S, Krings U, Berger RG (2003) Initial dynamic flavour release from sodium chloride solutions. Eur Food Res Technol 218:32–39

Acknowledgments

This work was supported by the Ministry of Science, Education and Sports of Republic of Croatia (Project no. 062-0580696-0284) and has been supported in part by the University of Rijeka under the Project Number: 13.06.1.4.50. Ph.D. student V. Majetić Germek was partially supported by an Alpe-Adria Research Grant from the University of Udine and a Bilateral Mobility Grant from the Ministry of the Republic of Slovenia for Higher Education, Science and Technology. The authors gratefully acknowledge Vasilij Valenčič and Milena Marega for providing technical assistance and to Ervin Bellè for the olive fruit donation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Majetić Germek, V., Butinar, B., Pizzale, L. et al. Phenols and Volatiles of Istarska Bjelica and Leccino Virgin Olive Oils Produced with Talc, NaCl and KCl as Processing Aids. J Am Oil Chem Soc 93, 1365–1372 (2016). https://doi.org/10.1007/s11746-016-2893-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2893-7