Abstract

Natural antioxidants to inhibit oxidation in edible oils are in high demand. Grape pomace is an abundant, inexpensive source of polyphenolic antioxidants, which are responsible for numerous health benefits. We examined pomace from eight varieties of Midwestern hybrid grapes for phenolic content and antioxidant activity. Ethanolic extracts produced from the pomace of each grape variety were added to two model systems, bulk soybean oil and oil-in-water emulsions, to determine antioxidant activity. Oxidation was monitored in each model system at a temperature appropriate to that particular system. While the extracts had relatively little effect in bulk oil, we observed dose-dependent antioxidant effects of some extracts in oil-in-water emulsions. Oxidation in bulk oils was assessed via total polar compounds and polymerized triacylglycerols. Oxidation in emulsions was assessed by peroxide value, headspace oxygen measurements, gas chromatography of headspace volatiles, and fatty acid analysis. Pomace extracts derived from red grapes generally outperformed those from white grapes, with the Marechal Foch variety showing high antioxidant activity at intermediate concentrations. At higher concentrations, Marechal Foch, Corot Noir, Frontenac, and Norton extracts showed promising antioxidant activity. This is the first report on antioxidant activity in an oil and emulsion setting for many of these grape varieties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Liquid cooking oils such as soybean oil are highly susceptible to oxidation as a result of their polyunsaturated fatty acid (PUFA) content. Traditionally, synthetic antioxidants have been used to suppress oxidation in edible oil systems. However, there is increasing consumer resistance toward the use of synthetic compounds, creating new demand for natural antioxidants to take their place [1–3]. It is an ongoing challenge for the food industry to identify antioxidant compounds that are both naturally sourced and can compete on a cost basis with their synthetic counterparts. Agricultural byproducts are ideal for solving this problem while simultaneously providing a way to dispose of agricultural waste. Many agricultural materials are discarded as a normal part of processing, but some of these materials contain useful compounds such as polyphenols. Because these materials are considered byproducts or waste products, the raw materials from which antioxidants are extracted remain both abundant and inexpensive [3]. Grapes (Vitis vinifera) and wines are known to be high in phenolic compounds, as are their waste products [1, 2]. Antioxidant activity has been observed in whole pomace extracts [1, 2, 4–6] as well as grape seed extracts [4], and this antioxidant activity has been largely attributed to phenolics.

Phenolic compounds have long been investigated as antioxidants for food systems [5] as a result of their ability to scavenge free radicals [7]. Because free radical mechanisms are instrumental in lipid oxidation and phenolic compounds are known radical scavengers, phenolics represent a promising avenue of investigation for use in edible oils. In particular, two groups of phenolic compounds present in grapes that are of particular interest are the anthocyanins [8] and the phenolic acids [9, 10]. Anthocyanins are part of the larger class of flavonoids and are often responsible for the rich red and purple hues that are characteristic of grape juice and wine [11]. Anthocyanins have shown antioxidant activity in a number of different food systems, including wine [12], juice [13], and protein emulsions [14]. Phenolic acids are aromatic molecules with a carboxylic acid moiety and include salicylic acid, cinnamic acid, gallic acid, caffeic acid, and others. Some phenolic acids, such as gallic acid, have been shown to have antioxidant activity, and it has been suggested that phenolic antioxidants may synergize with one another, further increasing antioxidant activity [15]. In addition to delaying oxidation in foods, phenolic compounds that are still present in the food at the time of consumption may also have beneficial effects in the body, limiting the development or progression of a variety of diseases.

Over 8000 phenolics have been found in plants [16]. The particular profile of phenolic species present depends not only on the species of fruit or vegetable but also on the specific cultivar within a species [16]. Grape varieties, as well as their phenolic compositions and their derivative flavors, vary widely by geographical region and soil composition, a concept known as terrior [17, 18]. This, in turn, leads to differing phenolic compositions in the resulting wines. Grape varieties endemic to one wine-producing region of the world may not grow well in other regions. As a result, grape varieties have been developed to thrive in particular regions and climates, creating a multitude of varieties that are unique to different regions of the world. Because these cultivars are unique, it is important to explore the phenolic composition and antioxidant activities of grape varieties from a wide array of locations worldwide. Here we explore eight hybrid grape varieties that are currently grown in Illinois in the Midwestern United States, varieties whose antioxidant activities, to our knowledge, have not been reported previously. These varieties have been bred to be more cold tolerant than the cultivars associated with a traditional Mediterranean climate, and all are cultivated in the Midwestern and Northeastern United States, where cold tolerance is necessary. Extracts were produced from pomace from each wine varietal, and these extracts were investigated as antioxidants in two food systems: a bulk oil system and a soybean oil-in-water emulsion system. Both systems are intended to simulate real food environments. Bulk oil is a model system for retail or industrial frying, while an emulsion system is a model for emulsified food products, such as salad dressings, mayonnaise, and a variety of dairy products. The pomace extracts showed varying abilities to suppress lipid oxidation in these systems.

Materials and Methods

Materials

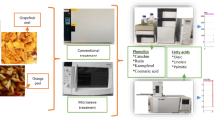

Grape pomace from the winemaking process was kindly provided by two local wineries: Kickapoo Creek Winery (Edwards, IL, USA) and Mackinaw Valley Vineyard (Mackinaw, IL, USA). Nine samples of grape pomace from eight different grape varieties (Corot Noir, Frontenac, Marechal Foch, Norton, Prairie Star, Sabrevois, Seyval, and Vignoles) were collected. Corot Noir, a red grape, was developed at Cornell University, and Frontenac (red) was developed at the University of Minnesota. Marechal Foch (red) and Vignoles (white) were developed in France, although today they are cultivated more extensively in the USA than in Europe. Norton (red) was developed in Richmond, Virginia, while Prairie Star (white) and Sabrevois (red) were first cultivated in Osceola, Wisconsin. Seyval is a white grape mainly grown in England. Frontenac grapes were sampled twice, as this grape was in preparation by a local winery as two different wines: Frontenac and Frontenac Gris. In the preparation of Frontenac wine, the pomace is fermented with the juice to produce a red wine. In the preparation of Frontenac Gris, identical (red) grapes are used, but the grape pomace is separated from the juice prior to fermentation, as with a white wine, and the grape juice is subsequently treated as a white wine. Grape pomace from the 2011 harvest was collected in clean plastic buckets as soon as possible after crushing of the grapes (for white wines) or after pressing of the pomace (for red wines). Pomace was immediately divided into glass jars, which were sealed under argon and stored at −20 °C until use. Samples were then lyophilized. Large seeds were removed by sieving, and the remaining mixture was lightly ground and stored at −20 °C until use.

Extraction

Polyphenols were extracted from lyophilized, ground pomace samples using a Dionex ASE 300 solvent extractor with 100-mL cartridges. The method was as follows: heat for 5 min, static for 5 min, flush at 150 % cartridge volume, purge for 60 s, repeat for five cycles. The solvent used was 100 % ethanol at a pressure of 1500 psi and 100 °C. These extracts were then dried under nitrogen and stored at −20 °C until use.

LC Sample Preparation and Extraction

Samples were ground to fine powder with an electric mill, followed by grinding with a mortar and pestle, then sieved through a #40 mesh sieve to remove unground elements. For HPLC analysis, 0.05–0.1 g of the powder was placed in a capped vial with 2–5 mL of methanol or methanol acidified with 0.1 % HCl. The vials were sonicated for 15 min and allowed to stand overnight. After another brief sonication, a portion of this extract was filtered through a 0.45-µm filter into an autosampler vial.

LC–ESI–MS Analysis for Anthocyanins and Other Phenolics

Mass spectrometry was performed on samples as described previously [19]. Samples were run on an Thermo Electron LTQ Orbitrap Discovery Mass Spectrometer—a linear ion trap (LTQ XL) MS, coupled to a high precision electrostatic ion trap (orbitrap) MS with a high energy collision (HCD) cell—with an Ion Max electrospray ionization (ESI) source, and a Thermo Scientific ACCELA series HPLC system (ACCELA 1250 UHPLC pump, ACCELA1 HTC cool stack autoinjector, and an ACCELA 80-Hz photodiode array (PDA) detector, all running under Thermo Scientific Xcalibur 2.1.0.1140 LC–MS software. The MS was calibrated at least monthly with a standard calibration mixture recommended by Thermo Scientific and the signal detection optimized by running the autotune software feature as needed. The source inlet temperature was 300 °C, the sheath gas rate was set at 50 arbitrary units (AU), the auxiliary gas rate was set at 5 AU, and the sweep gas rate was set at 2 AU. The maximal mass resolution was set at 30,000, the spray voltage was set at 3.0 kV, and the tube lens was set at −100 V. Other parameters were determined and set by the calibration and tuning process. The column was a 3 mm × 150 mm Inertsil reversed-phase C-18, ODS3, 3-µm column (GL Sciences, Rolling Hills Estates, CA, USA).

For anthocyanin analysis, the MS was run with the ESI probe in positive mode. The initial conditions were 5 % methanol and 0.2 % acetic acid in water, at a flow rate of 0.25 mL/min. After a delay of 2 min, the column was developed to 100 % methanol with a linear gradient over 60 min. The effluent was monitored at 520 nm on the PDA. The software package was set to collect mass data between 150 and 1000 AMUs. The most significant anthocyanin ions generated under these conditions were [M]+. Detection limits were 0.1 ng/µL.

For phenolic analysis, the MS was run with the ESI probe in the negative mode. The initial solvent system was 20 % methanol and 80 % water with 0.25 % formic acid at a flow rate of 0.25 mL/min. After injection (15 µL) the column was developed with a linear gradient to 100 % methanol over 50 min. The column effluent was monitored at 280 nm in the PDA detector. The software package was set to collect mass data between 150 and 1000 AMUs. Generally the most significant sample ions generated under these conditions were [M−1]− and [M+HCOO]−. Detection limits were 0.1 ng/µL. Compounds were quantified as described below.

HPLC Analysis of Anthocyanins

HPLC analysis was conducted on a Shimadzu LC-20 HPLC system (LC-20AT quaternary pump, DGU-20A5 degasser, SIL-20A HT autosampler, and an SPD M20A PDA, running under Shimadzu LCsolutions version 1.22 chromatography software). The column used was an Inertsil ODS-3 reversed-phase C-18 column (5 µm, 250 × 4.6 mm from GL Sciences, Rolling Hills Estates, CA). For anthocyanin analysis, the initial conditions were 2 % acetonitrile and 0.5 % acetic acid in water, at a flow rate of 1 mL/min. The effluent was monitored at 520 nm on the PDA. After injection (typically 15 µL), the column was held at the initial conditions for 2 min, and then developed to 100 % acetonitrile in a linear gradient over 60 min. Standard curves based on nanomoles injected were prepared from pure standards of petunidin, malvidin, cyanidin, delphinidin, and pelargonidin purchased from commercial suppliers. Detection limits for these compounds were approximately 5 ng/µL.

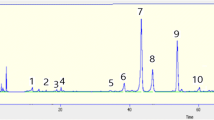

HPLC Analysis of Phenolic Compounds

HPLC analysis was conducted on a Shimadzu LC-20 HPLC system (LC-20AT quaternary pump, DGU-20A5 degasser, SIL-20A HT autosampler, and an SPD M20A photodiode array detector, running under Shimadzu LCsolutions version 1.22 chromatography software). The column used was an Inertsil ODS-3 reversed-phase C-18 column (5 µm, 250 × 4.6 mm from GL Sciences, Rolling Hills Estates, CA). For phenolic compound analysis, the initial conditions were 20 % methanol and 80 % water with 0.05 M phosphoric acid, at a flow rate of 1 mL/min. The effluent was monitored at 280 and 340 nm on the PDA. After a 25-µL injection, the column was held at the initial conditions for 2 min, then developed to 100 % methanol in a linear gradient over 55 min. A standard curve based on nanomoles injected was prepared from pure standards of apigenin, catechin, chlorogenic acid, trans-cinnamic acid, p-coumaric acid, (−)-epicatechin, (−)-epigallocatechin, eriodictyol, gallic acid, hesperidin, kaempferol, laricitrin, myricetin, quercetin, trans-resveratrol, and salicylic acid. Detection limits for these compounds were approximately 5 ng/µL.

Total Phenolics Assay

Total phenolic content of grape pomace extracts was determined using the Folin–Ciocalteu assay, using gallic acid as a standard. Dried extracts were dissolved in water at 400 µg/g. Absorbance at 765 nm was obtained on a PerkinElmer Lambda 35 ultraviolet/visible (UV/VIS) spectrophotometer. Results are expressed as milligrams of gallic acid equivalents (GAE) per gram of extract.

ABTS Assay

Antioxidant activities of the grape pomace extracts were assessed using an improved 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) decolorization assay. Briefly, 7 mM ABTS in water was reacted with 2.45 mM (final concentration) potassium persulfate overnight in the dark. The radical solution was diluted in ethanol to an absorbance of 0.700 ± 0.020 at 734 nm on a Perkin Elmer Lambda 34 UV/VIS spectrophotometer. Trolox® (6-hydroxy-2,5,7,8-tetramethylchroman-2-carboxylic acid), dissolved in ethanol, was used as the standard. A Trolox standard curve was constructed at concentrations of 200, 500, 1000, and 1500 µM. Grape pomace extracts were tested in triplicate in concentrations ranging from 0.2 to 3.2 mg/mL in ethanol. Then, 1 mL of the diluted ABTS radical was added to a cuvette containing 10 µL standard or ethanol and the absorbance was measured automatically on a Perkin Elmer Lambda 35 UV/VIS spectrophotometer every 30 s for 5 min. The % inhibition was calculated and compared to a control (ABTS radical added to 10 µL ethanol with no additives) using the following equation:

where A c is the absorbance of the control, and A s is the absorbance of the sample. The % inhibition was plotted vs. the concentration, and the slope of each line was calculated using simple regression. To calculate the Trolox equivalent antioxidant capacity (TEAC), the slope of the sample line was divided by the slope of the Trolox line.

Bulk Oil Heating Studies

Flat-bottomed 10-mm glass tubes were filled with either a control soybean oil or a soybean oil with added pomace extract to a height of 4 ± 0.5 cm (approximately 3 mL). Tubes were randomly positioned in a forced air oven at 180 °C and heated, exposed to air, for 0, 2, 4, 6, 8, 16, 24, or 48 h. Three replicates were heated for each time point. After the specified amount of time, the tubes were removed from the oven, cooled briefly, and the headspace of the tube was then filled with argon and capped until further measurements could be made. Heating studies were carried out in two phases: samples in the first heating study contained grape pomace extracts at a final concentration of 400 µg/g and samples in the second heating study contained grape pomace extracts at a final concentration of 1000 µg/g. All studies used soybean oil with no additive as a control.

Polymer Determination

Total triacylglycerol (TAG) dimers, trimers, and higher molecular weight polymers were analyzed by high-performance size exclusion chromatography (HP-SEC) using a Shimadzu LC 20AT pump equipped with membrane degasser and autosampler. A 10-μL aliquot of a 5.0 mg/mL solution of oil in methylene chloride was injected onto a PLgel column (5 µM, 100 Å, 300 x 7.5 mm; Agilent Technologies, Santa Clara, CA, USA). The mobile phase was methylene chloride and was run at 0.8 mL/min. Peaks were detected with an evaporative light scattering detector (ELSD) maintained at 40 °C with nebulizer gas (ultra-pure N2) pressure set to 3.5 bar and the gain set at 1. Instrument control and data analysis were performed with Shimadzu EZStart Chromatography Software Version 7.3. TAG monomer, dimer, and polymer peaks were identified and integrated. Results are presented as the percentage area of TAG.

Total Polar Compounds

Total polar compounds were determined according to a variation on a micro method developed by Marquez-Ruiz et al. [20], which is a modification of the American Oil Chemists’ Society (AOCS) official method Cd 20-9. Oils were separated on a 1-g silica SepPak (Waters Corporation). The column was conditioned with 10 mL of 90:10 petroleum ether/diethyl ether, and then 1 mL of a 25 mg/mL oil solution in CHCl3 was loaded onto the SepPak. The nonpolar fraction was eluted with an additional 10 mL of 90:10 petroleum ether/diethyl ether, followed by 10 mL of 50:50 chloroform/methanol to elute the polar fraction. Fractions were dried under nitrogen and gentle heat for several hours and weighed upon dryness. Three samples were analyzed for each time point, and each sample was analyzed in duplicate.

Oil-in-Water Emulsion Studies

Stripping of Minor Components from Soybean Oil

A protocol for stripping oil of tocopherols was adapted from Lampi et al. [21]. A glass column with a 24/40 opening at the top was packed with packed with less than 1 mL glass wool and 3 g of sand. Then a slurry consisting of 100 g activated alumina (baked at 110 °C overnight) and 200 mL hexane was added to the column, and excess hexane was drained from the column. The column was then topped with 5 g of sand and washed with 300 mL pure hexane. Then, soybean oil (200 g) dissolved in 200 mL hexane was added to the column and eluted by gravity with assistance by 1–2 psi argon run through the 24/40 fitting at the top of the column. The oil/hexane mixture was followed by 400 mL hexane. Stripped oil was eluted into a tared round-bottom flask with nitrogen gently blowing over it to prevent oxidation and accelerate hexane evaporation. The column and flask were covered with aluminum foil to prevent photooxidation. Then the oil was dried under rotary evaporation using an R-215 rotary evaporator with a V-855 vacuum controller and a water bath set to 35 °C. Aluminum foil was placed in dome over the water bath so as not to expose the rotating flask to unnecessary light. Stripped oil was assayed for tocopherols by HPLC as described below. All stripped oil had less than 0.5 μg/g of tocopherols. Stripped oils were stored in amber vials under argon at −80 °C until the start of experiments.

HPLC Analysis of Tocopherols in Stripped Oil

Approximately 50 mg stripped oil was weighed into a test tube and 1 mL of hexane was added. The test tube was vortexed for 30–60 s and the sample was then filtered through a 0.45-μm filter (Chrom Tech, Inc., Apple Valley, MN). A 10-μL aliquot was immediately analyzed in triplicate by HPLC on a Thermo Separation Products SpectraSYSTEM pump and autosampler connected by a Starrett column splitter (40:60) to a Thermo Scientific Surveyor fluorescence detector and SpectraSYSTEM UV2000 in parallel. The column was a YMC-Pack-Diol-NP, 5 μm, 4.6 × 250 mm column (YMC, Wilmington, NC). The mobile phase consisted of 97:3 v/v hexane/THF with a continuous flow rate of 2.0 mL/min. Tocopherols and tocotrienols were identified by retention time when compared with known standards using fluorescence detection (excitation 292 nm, emission 344 nm). Tocopherols and tocotrienols were quantified by external calibration with pure standards.

Emulsion Preparation

Emulsions consisted of 16.0 g of stripped soybean oil, 1.6 g Tween 20, and 144 g of 10 mM phosphate buffer at pH 7.0 (containing 64 mg of grape pomace extract for the 400 µg/g emulsion). The 1:10 ratio of Tween 20 to oil was chosen on the basis of work by Cardenia et al. [22] and Kittipongpittaya et al. [23]. Emulsions were premixed using a Tekmar Ultra Turrax mixer for 2 min and immediately homogenized using a high pressure NS1001L PANDA 2K. The pressure was set to 700 bar but varied from 610 to 720 bar during homogenization. Emulsions were circulated for 10 min at approximately 200 mL/min before being collected into glass jars. The homogenizer was cleaned between each emulsion by a sequence of distilled water, soapy water, and a copious distilled water rinse. After collection, emulsions were kept on ice until sodium azide (0.002–0.005 % w/v) was added and then refrigerated until dispersed into vials. All emulsions within a study were prepared and dispensed into vials on the same day. For the next two emulsion studies, the volume of emulsion prepared was reduced from 160 to 150 mL. Final concentrations of grape pomace extracts were 400 µg/g (64 mg in 160 mL), 1000 µg/g (150 mg in 150 mL), and 1600 µg/g (240 mg in 150 mL). Emulsion droplet size was checked periodically throughout the study via dynamic light scattering (DLS) to ensure that the emulsions were stable.

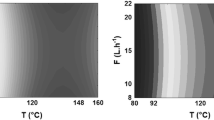

Experimental Design

Emulsion studies were carried out in three phases: one at 400 µg/g pomace extract, one at 1000 µg/g, and one at 1600 µg/g. For each study, ten emulsions were prepared (one control and nine experimental emulsions, one for each grape variety). For each of the ten emulsions, 48 headspace GC vials were prepared and sealed: six vials/treatment/day for 8 days, for a total of 480 vials. Sealed vials were incubated in the dark in an STM 135 convection oven at 50 °C for 8 days. Each day, six vials were removed for each of the ten treatments. Three of these six vials were immediately analyzed via headspace solid-phase microextraction gas chromatography (SPME-GC). The other three vials were used for headspace oxygen measurements, after which they were opened and the contents extracted for peroxide value measurement and fatty acid methyl ester (FAME) preparation.

Headspace Oxygen Measurements

The oxygen content of vial headspace was assessed with a CheckMate 3 headspace gas analyzer. Measurements were executed by inserting the needle through the rubber/PTFE septum of each vial and manually starting a 5-s measurement. Samples were run in triplicate.

Particle Size Analysis

Particle size of soybean oil-in-water emulsions was checked sporadically (days 1, 5, and 7 during the 400 µg/g study) to ensure that emulsions were stable. Measurements were taken using dynamic light scattering (DLS) with a Horiba LB-550 particle size analyzer. Samples were made by diluting one drop of emulsion in 2 mL of miliQ water in a plastic cuvette. Water was used to perform the cell check. Measurements were taken for 1.5 min and were performed in triplicate.

Peroxide Value (PV) Determination

PVs were utilized to assess primary oxidation products in emulsions and were determined using the ferric thiocyanate method developed by the International Dairy Federation (IDF) and described by Shantha and Decker [24]. After headspace oxygen measurements, vials were opened and 300 µL of each emulsion was added to 1.5 mL of isooctane/isopropanol (3:1, v/v) and vortexed for 1 min. Samples were then centrifuged for 3 min at 1000 rpm (105 g) and 25 °C using a Hettich Mikro 22R centrifuge to separate the layers. A 200-µL aliquot of the upper layer was removed and added to 2.8 mL methanol/butanol (2:1, v/v). Then, 15 μL ammonium thiocyanate was added, followed by 15 μL ferrous chloride, vortexing between each addition. After 20 min of incubation at room temperature, absorbance was measured at 510 nm using a Perkin Elmer Lambda 35 UV/VIS spectrometer. A calibration curve was developed using 1.0–35.0 μg Fe3+ (ferric chloride). Measurements were made in duplicate.

Fatty Acid Composition

FAME were derived according to the method published by Ichihara et al. [25]. Briefly, 600 µL of the organic layer of the isooctane/isopropanol extraction (described above in “Peroxide Value (PV) Determination”) was dissolved in 1.4 mL hexane and 200 µL methanolic KOH (2 N) was added. The solution was then vortexed for 2 min and allowed to sit for 1 min at room temperature. The hexane portion (upper layer) was transferred to autosampler vials. Fatty acid concentrations of each sample were determined by GC on an Agilent 6890 GC (Palo Alto, CA, USA) with a Supelco (Bellefonte, PA, USA) SP-2380 capillary column (30 × 0.25 mm ID × 0.20 µm film). Helium was used as a carrier gas with a flow rate of 1 mL/min, the injector was held at 220 °C, with a 50:1 split ratio, the oven was held at 185 °C, and the FID was held at 220 °C. Commercial FAME standards GLC 15a (Nu-Chek Prep, Elysian, MN, USA) and Supelco 37 component FAME Mix were used to identify peaks and verify GC performance. For each chromatogram, peaks were integrated, and the sum of the integrated areas was calculated. Each peak was then calculated to be a fraction of the sum of the areas. This number was multiplied by 100 to achieve % composition for that compound. Results are reported as % composition (relative composition). Samples were measured in triplicate.

Headspace Gas Chromatography

Analysis of headspace volatiles was used to measure secondary oxidation products and was performed as described previously [26]. Measurements were conducted in triplicate (staggered, randomized replicates) using a Varian 3800 gas chromatograph equipped with a Combi-Pal autosampler with preheating unit and a flame ionization detector. Samples were preheated to 45 °C for 5 min while rotating at 250 rpm to facilitate volatile compound migration into the headspace, then rotation was stopped and the septum was pierced with an SPME needle equipped with a retractable 50/30-μm divinylbenze/Carboxen™ on polydimethylsiloxane coated fiber (Supelco, Bellefonte, PA). The fiber was exposed to the headspace for 15 min, then retracted and immediately injected and desorbed at 250 °C for 7 min. Volatiles were separated on a DB-WAX (30 m × 0.25 mm i.d. × 0.25 μm) column (Agilent, Santa Clara, CA) using helium (1 mL/min) as the carrier gas. The oven temperature program was held at 40 °C for 1 min, ramped at 10 °C/min to 240 °C and then held again at 240 °C for 2 min. The injection port was splitless until complete desorption (7 min) followed by split (1:50), and the detector was set to 250 °C. Hexanal and pentanal were identified by retention time relative to a commercial standard. Peaks were integrated and analyzed using Varian Galaxy Chromatography Software. Standard curves of peak area vs. concentration for pentanal and hexanal in the concentration range from 0.05 to 50.0 μg/mL were developed for each fiber by preparing stock solutions in ethanol and adding to an unoxidized control emulsion, then analyzing as described for samples. Two fibers were used for each emulsion study for a total of six fibers.

Statistical Analysis

All experiments were performed with triplicate samples, and all measurements were made in duplicate or in triplicate, as indicated above. Data are represented as means with error bars corresponding to standard deviation. Pearson’s r coefficients were obtained via linear regression.

Weighted regression equations were obtained for nine grape pomace variety extracts and a control at the 1000 µg/g concentration, measuring seven dependent variables (headspace oxygen, peroxide value, pentanal, hexanal, and three fatty acids: 16:0, 18:2, and 18:3) as a function of time. Weighted regression was chosen since mean values were used, with weights consisting of 1/variance of the mean values of the dependent variable. Full and reduced models [27] were used to compare the ten treatment equations for each dependent variable. If a significant SSDrop (sum of squares drop) F * value was obtained from a full and reduced model comparison, then at least one of the equations was declared significantly different from the others. According to this approach, only one pomace variety was determined to be significantly different (at p ≤ 0.05 or p ≤ 0.01) from the others on the basis of non-overlap in 95 % confidence intervals of largest and smallest parameter estimates from the equations. Two sets of ten equations for peroxide value at 400 and 1600 µg/g concentrations were also examined and tested for pomace variety differences.

Results and Discussion

Nine samples of grape pomace from eight different grape varieties (Corot Noir, Frontenac, Marechal Foch, Norton, Prairie Star, Sabrevois, Seyval, and Vignoles) were collected from two different wineries in central Illinois. Pressing of the pomace took place at the appropriate time in the winemaking process for both red and white wines. Regardless of whether a red or white wine is produced, it is expected that many of the phenolic compounds present in the grape skins, seeds, and stems will be extracted into the wine. However, it is also known that many phenolic compounds are left behind. Some of these compounds are free; others may be linked to cell wall components of the grape [16]. Whether the phenolics present in pomace partition into the extract or remain bound to the pomace is a function of the extraction procedure.

Characterization of Grape Pomace Extracts

The ethanolic extracts obtained from the grape pomace contained a variety of polyphenolic compounds, including anthocyanins and phenolic acids. The extracts were dried and dissolved in water at 400 µg/g, and then characterized for total phenolics using the Folin–Ciocalteu assay. Red grape varieties were generally found to have higher levels of total phenolics than white grape varieties, with the exception of Vignoles, a white grape variety (Table 1). This was expected, as the deep red color that is characteristic of wine is known to be derived from phenolics such as anthocyanins and their derivatives [11]. Shaker found much higher concentrations of phenolics for 200 µg/g extracts of grape seed and peel [4]. It is not surprising, though, that the concentrations found here are lower, as phenolics from the pomace have already been extracted into the wine during the winemaking process.

While many phenolic compounds are known to be antioxidants, assessment of total phenolics alone is insufficient to predict antioxidant activity, as some phenolic compounds have greater antioxidant capacity than others, and some antioxidants contain multiple phenolic groups, which may not be correctly quantified by the assay. Antioxidant assays such as the ABTS and DPPH assays measure the radical-scavenging capacity of antioxidant molecules and are more effective at predicting antioxidant behavior than total phenolic content alone. Although results from ABTS and DPPH assays are not identical, they are usually highly correlated with one another [28, 29], and both assays have been widely used to characterize the antioxidant activity of natural products [30]. Both assays rely on electron transfer reactions, as opposed to the hydrogen atom transfer employed by the oxygen radical absorbance capacity (ORAC) assay [28]. Of these two similar assays, the ABTS assay was chosen here to evaluate antioxidant activity of the grape pomace extracts, as it has been suggested that the ABTS assay may be better for detecting antioxidant activity in foods, especially for fruits and beverages [28]. All of the grape pomace extracts showed some antioxidant activity. This was not unexpected, considering that all pomace extracts demonstrated phenolic content. The extracts from red grape varieties generally showed higher radical-scavenging activity than those derived from white grapes, although this was not true in every case (Table 1). Vignoles (a white grape) extract showed the highest antioxidant activity of all the grape varieties, although the other two white grape varieties yielded the extracts that showed the lowest antioxidant activity. A strong correlation was observed between phenolic content and TEAC values, with a Pearson’s r coefficient of 0.74.

As both the total phenolics and ABTS assays suggested that antioxidant compounds were present in the pomace extracts, we characterized the pomace extracts for their phenolic composition via HPLC and LC–MS. Mass spectrometry has been successfully applied to identify wine phenolics in the past [31]. A variety of phenolic compounds were identified in the grape pomace extracts, and the particular phenolic composition differed between grape varieties. Several anthocyanins, including the glucosides of delphinidin, petunidin, malvidin, and peonindin, were detected and quantified (Table 2). Delphinidin, petunidin, and malvidin specifically are known to occur at high levels in hybrid red grape varieties [32]. We also detected and quantified the flavonoids hesperidin, quercetin, myricetin, and the phenolic resveratrol (Table 2). All compounds identified and quantified in Table 2 have all been previously reported in grapes and/or grape pomace [33, 34]. A variety of other phenolic compounds were detected and identified by retention time and mass ion, although we were not able to quantify all compounds. This was partially due to the presence of interfering tannins and proanthocyaninins in the HPLC chromatograms, which contributed to broad peaks that were not quantifiable and overshadowed other compounds in the chromatogram. As a result, we were only able to quantify a subset of the compounds identified in this work. A comprehensive list of all compounds that were positively identified (via matching retention times with a commercial standard, coupled with mass spectral data) appears in Table 3. In addition, a number of compounds were positively identified by mass spectral data alone, where a commercial standard was not available. These were astilbin (m/z = 450.4), caffeoyl-tartaric acid (312.0), cis-coutaric acid (296.2), galloyl-catechin (442.0), isorhamnetin (316.3), protocatecuic acid (154.1), syringetin (346.3), trans-coutaric acid (296.2), engeletin (434.4), and feroyl-tartaric acid (326.0).

Anthocyanins were present at higher concentration than the phenolic acids. In general, all phenolic compounds detected were present at much lower concentrations than those found in wine, which is not surprising, as anthocyanins are known to be extracted into the wine during fermentation. Furthermore, longer contact times between the must and grape skins during the winemaking process are known to produce higher concentrations of some phenolics in the finished wine. Thus, long contact times during winemaking would lead to further depletion of phenolic compounds in the pressed grape pomace. Nevertheless, anthocyanins were present at much higher concentrations in pomace extracts from red grapes than those from white grapes.

Bulk Oil Studies

The utility of the pomace extracts as antioxidants was first examined in bulk soybean oil. Pomace extracts were added to soybean oil at concentrations of 400 and 1000 µg/g, which was then heated to 180 °C for 24 h. This system is analogous to a frying oil, which under restaurant or industrial conditions, may be heated to 180 ± 10 °C for many hours. Under these conditions, triacylglycerols react with oxygen to form compounds that are more polar than the original starting oil. In addition, at temperatures higher than 140 °C, triacylglycerol monomers polymerize to dimers, trimers, and higher molecular weight polymers. Therefore, lipid oxidation of the bulk oil was tracked via total polar compounds and triacylglycerol polymerization. No significant antioxidant effect was observed by either metric in the bulk oil at 400 µg/g (Fig. 1). At 1000 µg/g, Corot Noir and Marechal Foch extracts showed some antioxidant activity, but most extracts were prooxidants. The absence of appreciable antioxidant activity in the bulk oil phase has also been observed by others [2]. As the extracts were ethanolic and contained a variety of phenolic compounds, one possibility is that the lack of antioxidant activity can be attributed to poor solubility of the extracted compounds in soybean oil. A second possibility is that the extracted compounds are thermolabile and decompose upon heating to such high temperatures. It has also been shown that antioxidant activity as measured by traditional antioxidant assays at room temperature is not predictive of antioxidant activity at 180 °C [35].

Total polar compounds and triacylglycerol (TAG) concentrations of heated soybean oil containing grape pomace extracts. Increases in total polar compounds and decreases in the relative proportion of TAGs indicate the presence of lipid oxidation. Error bars denote standard deviation. Some error bars lie within data points

Oil-in-water Emulsion Studies

Next, antioxidant activity of the grape pomace extracts was investigated in an oil-in-water emulsion system. An oil-in-water emulsion system is an appropriate model system for food matrices, since many food products are actually emulsions, including mayonnaise, salad dressings, butter, and homogenized milk. Although they are commonly found in food products, oil-in-water emulsions are particularly susceptible to oxidation [22], leading to off-flavors and shorter shelf lives. Furthermore, the mechanism of lipid oxidation in emulsions can also be very different from that in bulk oils [23]. Thus, antioxidant development for emulsion applications is a particularly important field of study and could lead to increased shelf life of processed emulsions [15]. In this case, because the grape pomace extracts were water-soluble, an emulsion system also maximized the potential for hydrophilic phenolic antioxidant compounds to act as radical scavengers.

Grape pomace extracts were incorporated into emulsions at 400, 1000, and 1600 µg/g. Each of these concentrations constituted a separate emulsion study that lasted 8 days, each with nine experimental emulsions and one control emulsion. Particle sizes of emulsions were checked sporadically during the 400 µg/g study to monitor the stability of the emulsions (data not shown). It was found that the emulsions were stable over the time period measured here. Emulsions were subjected to accelerated oxidation using a convection oven at 50 °C during the course of the study. Each day, emulsions were removed from the oven and the degree of lipid oxidation was assessed. First, the percentage of oxygen (O2) in the vial headspace was measured. Lipid oxidation is accompanied by O2 uptake, so lower levels of O2 present in the vial headspace are indicative of oxidation of the lipid component of the emulsion. Primary oxidation products were assessed by measuring peroxide value. Together, headspace oxygen concentrations and peroxide values provide insight into the extent of initial oxidation processes (Fig. 2). The level of variation in headspace oxygen values was relatively high, probably as a result of using headspace GC vials for these measurements rather than larger containers (which are recommended for use with a headspace oxygen meter such as the one used in this study). Had we used larger vials, standard deviations for headspace oxygen might have been lower, although then the samples used for these measurements would not have had identical sample histories to those used for the other measurements. The headspace oxygen data is included here because it correlated well with peroxide value measurements. Secondary oxidation products were evaluated through determination of pentanal and hexanal, which are volatile aldehydes that are produced in later stages of lipid oxidation (Fig. 3). These volatile aldehydes contribute to rancid off-flavors and other odors in oxidized food products, so suppression of these products via antioxidant usage would improve the quality of food products during their shelf life. Fatty acid compositions were also analyzed (Fig. 4), as a relative decrease in unsaturated fatty acids would be expected as the samples oxidize. This would lead to a decrease in the amounts of 18:2 and 18:3 acids present, and a relative increase in saturated fatty acids, such as palmitic and stearic acids.

At 400 µg/g, the lowest concentration, the extent of oxidation in emulsions containing pomace extracts did not differ significantly from that of the control emulsion. Under these conditions, the F * value from the full and reduced model for peroxide value was not significant, indicating no differences between the pomace variety equations (Fig. 2b). At 1000 µg/g, differences among emulsions became apparent, with the Marechal Foch samples showing a delay in lipid oxidation compared with both the other extract-containing emulsions and the control emulsion. This effect was statistically significant, as all F * values from the full and reduced models were significant at p ≤ 0.05, indicating that at least one of the regression equations for the treatments was different from the others. The induction period that characterizes the beginning of the lipid oxidation process was clearly extended from approximately 2 days to at least 4 days, as tracked by headspace O2 in the sample vials and peroxide value of the lipid portion of the emulsion (Fig. 2c, d). Both pentanal and hexanal remained lower at all time points after day 1 in the samples containing Marechal Foch extracts than in the other samples (Fig. 3c, d). Marechal Foch, a red grape variety, possessed relatively high levels of total phenolics, although Corot Noir and Sabrevois both had higher levels of total phenolics. Marechal Foch showed the second highest antioxidant capacity of the samples, with a TEAC value of 0.42 mmol Trolox/g sample. Fatty acid analysis revealed that unsaturated linoleic and linolenic acids were preserved at higher levels in the Marechal Foch samples and remained higher at the end of the study (Fig. 4e, f). Changes in fatty acid composition appeared to take place in a more linear fashion over the course of the study rather than the usual induction period followed by an exponential increase in oxidation.

At 1600 µg/g, the highest concentration, several of the pomace extracts showed significant antioxidant activity. Marechal Foch extracts continued to perform well, as did Corot Noir, Frontenac, and Norton extracts. Headspace O2 was higher in all four of these samples and peroxide values were lower (Fig. 2e, f), indicating that the extent of oxidation was lower in these samples. At 1600 µg/g, the F * value from the full and reduced model for peroxide value indicated that at least one of the equations for pomace variety was different from the others (Marechal Foch). These trends were less apparent in the amounts of hexanal measured: these four samples contained consistently lower levels of hexanal than some of the other extracts (Fig. 3f) but did not differ significantly from most samples. There were large variations between treatments in the concentrations of pentanal and hexanal measured. Fatty acid composition, however, was more consistent with the primary oxidation data, as Marechal Foch, Corot Noir, Frontenac, and Norton samples consistently showed higher proportions of linoleic and linolenic acids remaining than the other varieties.

The four varieties that showed the best antioxidant activity in emulsions (Marechal Foch, Corot Noir, Frontenac, and Norton) are all red grape varieties. Two of these four varieties, Marechal Foch and Corot Noir, have previously been examined for their phenolic content, although the capacity of these varieties to act as antioxidants has never been studied. Pomace extracts from red varieties typically showed higher levels of total phenolics than white varieties, which is not surprising, since red grape varieties tend to be inherently higher in many phenolic compounds, especially anthocyanins. However, total phenolic levels alone were ineffective at predicting the best-performing grape varieties for inhibition of lipid oxidation. The ABTS assay was a better overall predictor of antioxidant activity than total phenolics. However, the relatively high TEAC value for Vignoles is surprising, as samples incorporating Vignoles extracts did not perform better than soybean oil controls in any of the studies. While it is not unexpected that some correlation between TEAC value and inhibition of oxidation exists, the ABTS assay is clearly an imperfect system for predicting the inhibition of lipid oxidation in this case. One reason for this was that the ABTS assay was performed in ethanol, not bulk oil or an oil-in-water emulsion, so the ABTS assay does not address solubility effects or other solvent effects. A second reason that ABTS may not be ideal for this prediction is that the ABTS assay is performed over a time scale that is much more rapid than the lipid oxidation in this study, even though the initiation of peroxide formation is rapid regardless of the solvent. Finally, different phenolic molecules may have different affinities for lipid radicals relative to the ABTS radical, leading to different levels of antioxidant activity than those predicted via assays.

The four extracts that showed ability to inhibit lipid oxidation all contained measurable levels of anthocyanins and other phenolic compounds. As the red grape extracts showed both higher total phenolic levels and higher antioxidant activity (both via the ABTS assay and in the emulsion studies described here), it is likely that anthocyanins are responsible for the antioxidant activity of the active grape pomace extracts. In general, the polar paradox theory would suggest that lipophilic antioxidants, rather than hydrophilic phenolic antioxidants, would provide superior protection for emulsion systems such as this one, while more hydrophilic antioxidants would suppress lipid oxidation in the bulk oil phase. This was not observed here, as antioxidant activity was not observed in the bulk oil phase. Our findings agree with previous work by Torres et al., who found that phenolic extracts of grape pomace were more protective of lipids in emulsions than in bulk oil [2]. It has also been suggested that the action of antioxidants in emulsions may be governed by more complex phenomena than just the polar paradox theory, in which factors other than polarity (such as antioxidant mobility and the presence and type of emulsifiers in the system) must also be taken into account.

Conclusion

Ethanolic extracts derived from pomace of four varieties of Midwestern grapes, Marechal Foch, Corot Noir, Frontenac, and Norton, were effective in inhibiting lipid oxidation in an oil-in-water emulsion system at 1000 ppm and 1600 ppm. Extracts from pomace derived from red grapes consistently outperformed those derived from white grapes, which is consistent with the higher overall levels of phenolic compounds, and especially anthocyanins, in red varieties. Utilizing the waste pomace produced during the manufacture of these four wines offers a promising opportunity as a source of cheap, naturally derived antioxidants for food applications.

References

Selani MM, Contreras-Castillo CJ, Shirahigue LD, Gallo CR, Plata-Oviedo M, Montes-Villanueva ND (2011) Wine industry residues extracts as natural antioxidants in raw and cooked chicken meat during frozen storage. Meat Sci 88:397–403

Torres JL, Varela B, Garcia MT, Carilla J, Matito C, Centelles JJ, Cascante M, Sort X, Bobet R (2002) Valorization of grape (Vitis vinifera) byproducts. antioxidant and biological properties of polyphenolic fractions differing in procyanidin composition and flavonol content. J Agric Food Chem 50:7548–7555

Moure A, Cruz JM, Franco D, Dominguez JM, Sineiro J, Dominguez H, Nunez MJ, Parajo JC (2001) Natural antioxidants from residual sources. Food Chem 72:145–171

Shaker ES (2006) Antioxidative effect of extracts from red grape seed and peel on lipid oxidation in oils of sunflower. LWT Food Sci Technol 39:883–892

Neira JI, Pazos M, Maestre R, Torres JL, Medina I (2011) Galloylated polyphenols as inhibitors of hemoglobin-catalyzed lipid oxidation in fish muscle. J Agric Food Chem 59:5684–5691

Negro C, Tommasi L, Miceli A (2003) Phenolic compounds and antioxidant activity from red grape marc extracts. Bioresour Technol 87:41–44

Soobrattee MA, Neergheen VS, Luximon-Ramma A, Aruoma OI, Bahorun T (2005) Phenolics as potential antioxidant therapeutic agents: mechanism and actions. Mutat Res 579:200–213

Francis FJ (1992) A new group of food colorants. Trends Food Sci Technol 3:27–30

Singleton VL, Timberlake CF, Lea AGH (1978) The phenolic cinnamates of white grapes and wine. J Sci Food Agric 29:403–410

Singleton VL, Zaya J, Trousdale EK (1986) Caftaric and coutaric acids in fruit of Vitis. Phytochemistry 25:2127–2133

He J, Carvalho AR, Mateus N, De Freitas V (2010) Spectral features and stability of oligomeric pyranoanthocyanin–flavanol pigments isolated from red wines. J Agric Food Chem 58:9249–9258

Rivero-Perez MD, Muniz P, Gonzalez-Sanjose ML (2008) Contribution of anthocyanin fraction to the antioxidant properties of wine. Food Chem Toxicol 46:2815–2822

Vegara S, Mena P, Marti N, Saura D, Valero M (2013) Approaches to understanding the contribution of anthocyanins to the antioxidant capacity of pasteurized pomegranate juices. Food Chem 141:1630–1636

Viljanen K, Kylli P, Hubbermann E-M, Schwarz K, Heinonen M (2005) Anthocyanin antioxidant activity and partition behavior in whey protein emulsion. J Agric Food Chem 53:2022–2027

Conde E, Moure A, Domínguez H, Gordon MH, Parajó JC (2011) Purified phenolics from hydrothermal treatments of biomass: ability to protect sunflower bulk oil and model food emulsions from oxidation. J Agric Food Chem 59:9158–9165

Bravo L (1998) Polyphenols: chemistry, dietary sources, metabolism, and nutritional significance. Nutr Rev 56:317–333

Granato D, Katayama FCU, Castro IA (2010) Assessing the association between phenolic compounds and the antioxidant activity of Brazilian red wines using chemometrics. LWT Food Sci Technol 43:1542–1549

Koundouras S, Marinos V, Gkoulioti A, Kotseridis Y, Van Leeuwen C (2006) Influence of vineyard location and vine water status on fruit maturation of nonirrigated Cv. Agiorgitiko (Vitis vinifera L.). Effects on wine phenolic and aroma components. J Agric Food Chem 54:5077–5086

Angelino D, Berhow M, Ninfali P, Jeffery EH (2013) Caecal absorption of vitexin-2-O-xyloside and its aglycone apigenin, in the rat. Food Funct 4:1339–1345

Marquez-Ruiz G, Jorge N, Martin-Polvillo M, Dobarganes MC (1996) Rapid quantitative determination of polar compounds in fats and oils by solid-phase extraction and size-exclusion chromatography using monostearin as internal standard. J Chromatogr A 749:55–60

Lampi A-M, Dimberg LH, Kamal-Eldin A (1999) A study on the influence of fucosterol on thermal polymerisation of purified high oleic sunflower triacylglycerols. J Sci Food Agric 79:573–579

Cardenia V, Waraho T, Rodriguez-Estrada MT, Julian McClements D, Decker EA (2011) Antioxidant and prooxidant activity behavior of phospholipids in stripped soybean oil-in-water emulsions. J Am Oil Chem Soc 88:1409–1416

Kittipongpittaya K, Chen B, Panya A, McClements DJ, Decker EA (2012) Prooxidant activity of polar lipid oxidation products in bulk oil and oil-in-water emulsion. J Am Oil Chem Soc 89(12):2187–2194

Shantha NC, Decker EA (1994) Rapid, sensitive, iron-based spectrophotometric methods for determination of peroxide values of food lipids. J AOAC Int 77:421–424

Ichihara K, Shibahara A, Yamamoto K, Nakayama T (1996) An improved method for rapid analysis of the fatty acids of glycerolipids. Lipids 31:535–539

Winkler-Moser JK, Logan A, Bakota EL (2014) Antioxidant activities and interactions of α- and γ-tocopherols within canola and soybean oil emulsions. Eur J Lipid Sci Technol 116:606–617

Neter J, Wasserman W, Kutner MH (1974) Applied linear statistical models: regression, analysis of variance, and experimental designs, 3rd edn. Irwin, Homewood

Floegel A, Kim D-O, Chung S-J, Koo SI, Chun OK (2011) Comparison of ABTS/DPPH assays to measure antioxidant capacity in popular antioxidant-rich US foods. J Food Compos Anal 24:1043–1048

Tourino S, Selga A, Jimenez A, Julia L, Lozano C, Lizarraga D, Cascante M, Torres JL (2005) Procyanidin fractions from pine (Pinus pinaster) bark: radical scavenging power in solution, antioxidant activity in emulsion, and antiproliferative effect in melanoma cells. J Agric Food Chem 53:4728–4735

Moon J-K, Shibamoto T (2009) Antioxidant assays for plant and food components. J Agric Food Chem 57:1655–1666

Monagas M, Bartolome B, Gomez-Cordoves C (2005) Updated knowledge about the presence of phenolic compounds in wine. Crit Rev Food Sci Nutr 45:85–118

Manns DC, Coquard Lenerz CT, Mansfield AK (2013) Impact of processing parameters on the phenolic profile of wines produced from hybrid red grapes Marechal Foch, Corot noir, and Marquette. J Food Sci 78:C696–C702

Sagdic O, Ozturk I, Ozkan G, Yetim H, Ekici L, Yilmaz MT (2011) RP-HPLC–DAD analysis of phenolic compounds in pomace extracts from five grape cultivars: evaluation of their antioxidant, antiradical and antifungal activities in orange and apple juices. Food Chem 126:1749–1758

Lu Y, Foo LY (1999) The polyphenol constituents of grape pomace. Food Chem 65:1–8

Hwang H-S, Winkler-Moser JK, Liu SX (2012) Structural effect of lignans and sesamol on polymerization of soybean oil at frying temperature. J Am Oil Chem Soc 89:1067–1076

Acknowledgments

The authors wish to thank Julie Anderson, Sandra Duval, Ray Holloway, Steve Lyle, and Kathy Rennick for their excellent and careful technical assistance. We are also grateful to Kickapoo Creek Winery and Mackinaw Valley Vineyard for generously donating the grape pomace used in this study and for thoughtful discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this article is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the US Department of Agriculture (USDA). USDA is an equal opportunity provider and employer.

Electronic supplementary material

Below is the link to the electronic supplementary material.

About this article

Cite this article

Bakota, E.L., Winkler-Moser, J.K., Berhow, M.A. et al. Antioxidant Activity of Hybrid Grape Pomace Extracts Derived from Midwestern Grapes in Bulk Oil and Oil-in-Water Emulsions. J Am Oil Chem Soc 92, 1333–1348 (2015). https://doi.org/10.1007/s11746-015-2698-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2698-0