Abstract

Soybeans are cultivated in the United States chiefly for cooking oil, while the residue after oil extraction (soybean meal) is mostly used in animal feed formulations. High protein content in the defatted soybean meals led to the extraction of pure protein and its application in food products. We selected 44 soybean lines to determine their moisture and protein contents, and their amino acid composition was investigated. Soybean lines with high protein content, one high yielding (R95-1705), and two high oleic acid (N98-4445A, S03-543CR), were selected for protein isolate preparation, hydrolysis using alcalase and gastro-intestinal (GI) resistance. Furthermore, the GI resistant hydrolysates were fractionated and tested for angiotensin-I-converting enzyme (ACE-I) inhibition activity. The amino acid analysis showed high methionine in the high protein and fatty acid lines (R05-4494 and R05-5491), and high cysteine content in one of the high oleic acid soybean line CRR05-188 in comparison to the check lines (UA-4805 and 5601-T). The protein isolate with the highest purity (90–93 %) was derived from the selected lines N98-4445A and S03-543CR, and hydrolyzed using alcalase enzyme. The protein hydrolysates (500 µg/mL) showed inhibition of the ACE-I by 49 %. The results from this study will promote the use of high oleic acid soybeans as a source of protein and peptides with functional activities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soybean is an excellent source of protein and oil and is the second major crop grown in the United States. The USA is the largest producer and exporter of soy in the world and the forecast for 2014 production is approximately 3.3 billion bushels (~27 kg/bushel) according to the Crop Production Report by the United States Department of Agriculture [1]. The American Soybean Association and the regional soybean boards have a major role in producing better quality soybeans using genetic engineering and plant breeding techniques by improving various attributes including enhanced yields, pest and disease resistance, lipid quality and quantity, and protein content and quality [2, 3]. Soybeans are primarily grown for the edible oil which is separated by various extraction methods, resulting in a leftover residue called soybean meal. Soybean meal is a major ingredient in animal feed formulations as a source of complete protein. It is also a chief source of high-quality plant-based protein in human diet. Hydrolysates prepared from the soybean proteins are in great demand as ingredients for food applications as well as in protein supplements that provide nutritional and health benefits [4, 5]. Improvements in soybean processing and functional characteristics have diversified the ever-increasing demand for soy protein ingredients [6, 7].

New soybean lines are produced with higher yields, higher protein content, and recently with higher amounts (up to 80 %) of oleic acid in their lipid composition [8]. A higher percentage of monounsaturated fatty acids such as oleic acid is preferred over polyunsaturated fatty acids which have lower oxidative stability [9, 10]. Variations in the plant genes are the cause of differences, not only in the oil content but also in the concentration of crude protein, possibly even in the amino acid composition [11–13]. Researchers have found an increase in lysine in the hybridized high oleic acid soybean seeds compared to the parent lines [14, 15]. The amino acid composition of the seed protein depends on the storage protein content, nitrogen supply during the growth phase, and asparagine levels in the embryonic stage of the plant [16]. There has not been much research in evaluating the essential amino acid content, specifically sulfur-containing amino acids in the soy protein from high oleic acid soybean seeds.

Oil-extracted soybean meals contain approximately 1 % residual oil and have 48 % crude protein with all the essential amino acids required for human health except for the sulfur amino acids methionine and cysteine [17]. Proteins have proved to be excellent sources for bioactive peptides, especially in reducing hypertension, which is a precursor for heart disease [18, 19]. Inhibition of angiotensin-1-converting enzyme (ACE-I) activity has a potential link to a hypertension lowering effect, by preventing the conversion of angiotensin I to aAngiotensin II, where the latter compound is responsible for contracting the epithelial layer of arteries causing an increase in blood pressure [20]. Previous studies have shown that peptides derived from soybean protein with limited enzymatic hydrolysis possess ACE-I inhibitory activity [21–23] and other bio-activities [24]. There have been no studies determining the presence of higher than normal amounts of methionine from high oleic acid soybean meals, or the influence of amino acid content and sequence which can elicit significant biological activities.

This is the first time that amino acid analysis of soybean lines with varying oleic acid composition and ACE-I inhibitory activity assessment of alcalase enzyme-derived peptides from their protein isolates has been studied. The 44 soybean lines used in this study were bred for attributes including yield, protein content, low linoleic acid, high oleic acid content, high yield and high protein. The major objectives of this study were to analyze the amino acid composition of the protein among 44 soybean lines, select 3 based on highest protein content and prepare protein hydrolysates (peptide fractions) and test for ACE-I inhibitory activity.

Materials and Methods

The seeds of 44 soybean lines (R05-4509, R95-1705 (non-GMO), R05-4476, R05-4487, R05-4473, R05-4507, R05-4492, Satellite, R05-4494, S03-543CR, N98-4445, R05-5491, R05-5340, R05-4457, R05-4478, R05-4505, R05-5362, Osage, S01-9265, UA-4805, 5601-T, R05-5351, S04-4729RR, TN01-235, S04-3835 RR, R05-5510, Satellite, N98-4445, Kristine, 5002-T, IA-3017, TN-5123, R05-4481, R05-5342, R05-5494, CRR05-188, V01-1693, V01-6338, V01-1702, S01-9364, Ozark, IA-2064, R05-5358, KS-5007) from two Arkansas Agricultural Research Stations (ARS) based in Fayetteville (FAY) and Stuttgart (STU) were provided by Dr. Pengyin Chen, Plant breeder and Professor, Department of Crop Soil and Environmental Sciences, University of Arkansas. The Kjeltec 2200 auto-distillation unit (Foss, Eden Prairie, MN, USA) was used to determine the protein content in the flour. Rotovapor (Buchi, Flawil, Switzerland) was used for vacuum distillation and a Beckman HPLC system (Fullerton, CA, USA) was used for quantitative amino acid analysis. An Ika mill (Ika-Werke, Staufen, Germany) was used for grinding the samples. Food grade enzyme alcalase 2.5L (EC 3.4.21.62) was purchased from Novozyme (Bagsvaerd, Denmark) for preparing the protein hydrolysates. All chemicals, solvents, and reagents with highest purity were purchased from Sigma (St. Louis, MO, USA).

Moisture and Protein Content Determination

The seeds were ground, passed through a 60-mesh sieve, and the flour was collected, bagged and stored at 5 °C. The moisture percentage of the flour was calculated based on the AACC official method [25]. The soybean flour samples were weighed in aluminum pans and dried at 135 °C for 3 h. The moisture percentage was calculated as the ratio between the moisture lost from the sample and the actual weight of the sample before drying. This was done in triplicate for all the 44 seed samples.

Protein content of the soybeans was performed using the Kjeldahl method [26]. The soybean flour samples were weighed in digestion tubes and digested for 1 h at 420 °C after adding the Kjeldahl tablets and 10 mL sulfuric acid. The samples were distilled and titrated against 0.1 N HCl in the automated Kjeldahl distillation unit. The protein percentage was calculated with a conversion factor of 6.25 for nitrogen. The moisture percentage was used to calculate the protein content by dry weight for all the samples. All analyses were conducted in triplicate.

Determination of Amino Acid Composition

The amino acid analysis of the flour from the 44 lines was conducted using the AOAC method [26]. The approximate weight of each soybean meal test sample for amino acid analysis was calculated by the formula: \(W_{\text{s}} = 1000/N_{\text{s}}\); where W s is the weight of the sample in milligrams, and N s is the nitrogen content (%) in each sample.

Performic acid solution was prepared and kept at room temperature for 30 min and cooled in an ice bath for 15 min before adding to the samples. All flour samples were weighed into 250-mL Erlenmeyer flasks and cooled in an ice bath. Five milliliters of performic acid was added to each flask with the sample, stirred for 15 min, and all flasks were kept in an ice bath for 16 h for oxidation. After oxidation, the performic acid was decomposed by adding 0.84 g of sodium metabisulfite to each sample flask under a fume hood and stirring for 10 min. The oxidized products were hydrolyzed in 6 M HCl-phenol solution for 24 h at temperatures between 110 and 120 °C. The hydrolyzed sample solution was cooled to room temperature, and 20 mL nor-leucine solution was added as HPLC elution standard. The solutions were evaporated using a rotary evaporator under vacuum (until 5–10 mL remained), diluted with sodium citrate buffer and the pH adjusted to 2.2. The volume of the hydrolyzed sample solution was made up to 50 mL with the buffer solution and stored at 5 °C in polyethylene bottles. The solutions were injected into a C18 ion exchange column (heated to 70 °C) using an auto-sampler attached to the HPLC system, and the amino acids were detected based on the absorbance measured at 254 nm. Eluent buffer solutions, procured from Pickering Laboratories (Mountain View, CA, USA), containing sodium citrate and hydrochloric acid at varying pH (3.2, 4.2 and 6.4) were used. The elution times of each amino acid on the column were compared to an amino acid standard and the amount of each amino acid was calculated in mg/g based on the peak area.

Preparation of Protein Isolate and Enzymatic Hydrolysis to Prepare Gastro-Intestinal Resistant Peptide Fractions

Seeds from the three selected (based on high protein content) soybean lines (high oleic acid: N98-4445A, S03-543CR; high yield: R95-1705) were ground, defatted and passed through a 60-mesh (250 µm particle size) sieve. Suspensions of the flours were prepared for solubilizing the protein at an alkaline pH of 9.5. The protein solutions were separated from the residue using a centrifuge (3000g for 15 min) and precipitated at isoelectric pH of 4.5 to prepare the protein isolates. The protein isolate was digested using the enzyme alcalase under optimized conditions to derive varying size protein fragments or hydrolysates, as per the previous study. The hydrolysis was conducted at pH 8.0 with 1.675 AU of enzyme incubated at 55 °C for 1 h for a 30 % degree of hydrolysis [24]. The hydrolysates were then passed through a simulated gastro-intestinal (GI) environment using the enzymes, pepsin and pancreatin, at 37 °C to derive GI-resistant protein hydrolysates [24, 27]. Ultrafiltration membrane columns with molecular cut-off—5, 10 and 50 kDa were used to separate the GI resistant hydrolysates. The hydrolysates were passed through each column starting with 5 kDa as the permeates were collected and retentates were passed through 10 kDa and then through a 50-kDa column following the similar process. The specific peptide fractions, <5, 5–10 and 10–50 kDa, were obtained as a results of ultrafiltration process, which were freeze-dried and stored at 4 °C.

ACE-I Inhibitory Activity Assay

A modified method of Cushman and Cheung [28] was used to conduct the ACE-I inhibition activity assay. Protein hydrolysates at 500 µg/mL (30 μL), N-hippuryl-l-histidyl-l-leucine (HHL: 150 μL, 6.5 mM), and ACE-I (25 μL, 2.5 mU) were incubated at 37 °C for 1 h. Hydrochloric acid (250 μL, 1 N) and ethyl acetate (1.5 mL) were added to stop the reaction. The contents were mixed by vortexing before centrifugation at 2000g for 5 min. One milliliter of the top layer (containing hippuric acid extracted with ethyl acetate) was collected, and ethyl acetate was removed using a roto evaporator. The residual hippuric acid was dissolved with deionized water (1 mL) and absorbance was measured at 228 nm. Captopril (10 mM) was used as positive control while a solution containing ACE-I and HHL was used as blank solution. Inhibition of ACE-I was calculated using the formula:

The % ACE-I inhibition was defined as the percentage of ACE-I activity inhibited by a specific amount of peptides and a dose response was conducted to determine the IC50 value for the peptide fractions with highest activity.

Statistical Analysis

The JMP software from SAS Institute (Cary, NC, USA) was used for the statistical analyses—Student’s t test, analysis of variance, means and standard deviations (P value <0.05). The data were collected in triplicate for all the experiments.

Results and Discussion

Moisture and Protein Content

The moisture percentage in the flour among the 44 soybean lines ranged between 5.2 ± 0.0 and 12.9 ± 0.1 % (Table 1). The moisture values varied due to the difference in the agronomic growing conditions of the lines, moisture content at harvest and the processing conditions of the 44 lines. Nevertheless, the moisture content did not have a significant impact on the protein content in the seeds.

The protein percentage among all 44 lines ranged between 40.8 ± 0.2 and 53.5 ± 0.1 % approximately by dry weight. The differences in the protein content among the soybean lines could be due to the genetic variation among the soybean lines. There was a statistically significant difference in the protein content of the soybean lines as shown in Table 1. Both Fayetteville and Stuttgart Agricultural research stations produced high protein lines. The variation in the protein content among the lines could be attributed to the dissimilarities in the soils of the two regions. Soybean lines R05-4509 (STU), R05-4476 (STU), R05-4487 (STU), R05-4473 (STU), and R95-1705 had the highest protein yields which are not significantly different from each other according to the Student’s t test (P > 0.05) while R05-4509 (STU) showed the highest protein content of 53.5 ± 0.1 % among all the lines.

The highest protein content on dry basis (d. b.), 53.5 ± 0.1 % was from high protein line and fatty acid line, R05-4509, which was not significantly different (statistically) from that of the high yielding line, R95-1705 with 52.7 ± 0.4 % protein. The high oleic acid line S03-543CR had the highest protein content of 48.4 ± 0.5 % among all high oleic acid soybean lines. The protein content of R05-4509 (STU), R95-1705 R05-4476 (STU), R05-4487 (STU), and R05-4473 (STU) was much higher than normal and those with high oleic acid, S03-543CR and N98-4445A (Fay), are also found to have significantly high protein content. Lines grown for the high yield and high protein attributes had higher protein content than the high oleic acid lines which is consistent with previous studies [2]. Two other high oleic acid lines, CRR05-188 and TN-5123 from the Fayetteville ARS stations, had 45.2 and 44.5 % protein which are not statistically different from each other and similar to the ‘check’ lines—N98-4445A foundation and 5002-T. The ‘check’ soybean lines are used as positive control for comparison of an attribute (high yield, high protein or high oleic acid, etc.) among the new breeds of soybean seeds developed. ‘Foundation’ lines are those developed by the breeder (copyrighted) for distribution among the growers. The lowest amount of protein on dry basis was found in the KS-5007 low linolenic acid soybean which is 40.8 %.

Amino Acid Content

The amino acid analysis of the 44 soybean lines showed variability in protein composition, while the presence of high oleic acid content did not provide a wide variation. Hence, other components, including isoflavones and oligosaccharides in the seed, could utilize the available carbon skeletons during development. A positive correlation between protein, lipid, sugars and isoflavones during the soy seed growth and maturity have been observed in previous studies [29]. The essential amino acid composition of the seed protein in 44 lines is given in Table 2. The amino acid composition among the high oleic acid soybeans lines did not differ significantly (P value <0.05, data not included). High methionine and cysteine content were observed in lines: R05-4494, R05-5491, 5002 T, Kristine, R05-5362 and R05-5352, which were 53.7 ± 1.4, 43.5 ± 0.1, 41.8 ± 4.8, 41.0 ± 0.8, 35.2 ± 3.6 and 39.9 ± 0.4 mg/g, respectively. Table 3 shows the list of soybean lines which had the highest amounts of methionine content which can be sources of complete protein. This could be due to the nitrogen assimilation during the seed development which determines the amino acid composition of the seeds [16]. The methionine content in the six soybean lines (addressed above) are significantly higher in comparison to egg (34 mg/g) and milk (20 mg/g) proteins (Table 4). Cysteine is the other sulfur containing amino acid which is non-essential to humans but is required for the maintenance of protein structure and function. Table 3 shows the soybean lines which had the highest cysteine content: R05-4505—35.5 ± 0.3 mg/g, S01-9265—30.8 ± 4.8 mg/g, Satellite STU 23.7 ± 1.5 mg/g and CRR05-188—25.5 ± 3.3 mg/g which is a high oleic acid line. These values are higher than those found in milk protein (8 mg/g) and are equal or higher in comparison to egg protein (24 mg/g).

The CRR05-188 is the only high oleic soybean line that showed higher cysteine content, although its seed protein content is lower in comparison to S03-543CR and N98-4445A (high oleic acid lines). This indicates that sulfur amino acid content in soybeans is not related to the amount of total seed protein. The soybean line S03-543CR showed the highest amounts of essential amino acids—threonine, valine, isoleucine and leucine among all the lines tested irrespective of their traits. It also showed significantly high amounts of lysine amino acid when compared with the 44 soybean lines. This shows that soybean lines bred for high oleic acid can also provide substantial essential amino acid content along with high protein. The protein content in the TN-5123 high oleic acid soybean line was not significantly different in comparison to CRR05-188, but the essential amino acid content was lower in comparison to other high oleic acid lines. Hence, other factors, including soil environment and growth conditions, affect the protein formation during seed development.

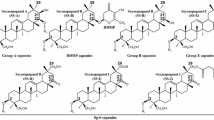

Among all the soybean lines, the compositions of glutamine, asparagine and lysine amino acids are highest in that order, respectively (Fig. 1). Glutamine is essential for gut health while asparagine maintains the integrity of the nervous system [30, 31]. Lysine is known to be an essential amino acid which helps in serotonin regulation and has a moderating effect on blood pressure and the incidence of stroke [31, 32]. The amino acid analysis procedure from AOAC official methods (994.12) was selected to quantify the sulfur-containing amino acids methionine and cysteine. However, quantification of aromatic amino acids, tryptophan and tyrosine, was affected during hydrolysis and oxidation and these were not detected during the ion-exchange liquid chromatography.

All 44 soybean lines showed high amounts of lysine which agrees with the accepted notion that legume seeds are rich in this amino acid [33]. While glutamine and asparagine were non-essential amino acids, supplementation of lysine is essential to humans since it is not synthesized in the body. Lysine plays an important role in transamination reactions and is utilized to produce vital proteins, including elastin and collagen [34–36]. The comparison of essential amino acids (range) among the tested 44 soybeans and other protein sources including eggs and milk are given in Table 4.

Researchers have engineered quality traits through plant breeding to enhance the sulfur amino acid content, even though natural mutations in soybeans have also expressed these beneficial effects. The genetic alterations have been tested specific to the trait loci that trigger the formation of methionine and cysteine during the seed growth [17, 37]. Soil sulfur and nitrogen content during the growth of the soybeans also affects the methionine and cysteine content in the soybean protein [38]. Other genetic attributes like high protein, high monounsaturated fatty acid content, and higher yields or disease resistance may contribute to enhanced sulfur amino acids, but this is inconclusive.

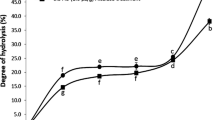

Activity of Protein Hydrolysates

Three soybean lines, S03-543CR and N98-4445A (with high oleic acid) and R95-1705 (high yield and non-GMO), were selected based on their high protein content. The alkali extraction method provided >90 % protein yield in the isolates (yield: >83 % d. b. by mass balance) which were used to prepare the protein fragments. The optimal conditions to accomplish the alcalase enzymatic hydrolysis of the proteins in order to derive peptides of varying sizes were achieved using a statistical design for a 30 % degree of hydrolysis to derive protein hydrolysates or peptides of varying sizes [24]. The ultrafiltration of GI-resistant protein hydrolysates using molecular cut-offs columns—5, 10 and 50 kDa provided the fractions <5, 5–10 and 10–50 kDa (yield: 1.8–2.1 % d. b. by mass balance, derived from the isolate) for each soybean line with protein content ranging between 89 and 92 %. These peptide fractions were tested for ACE-I inhibitory activity.

The nine fractions (3 fractions from 3 soybean lines) obtained from enzymatic hydrolysis of the protein from three soybean lines were tested for ACE-I inhibitory property at a concentration of 500 µg/mL. The results showed low activity in comparison to the positive control, captopril (approximately 75 % inhibition). The highest inhibition among the fractions was 48.9 ± 4.0 % by the 5–10 kDa obtained from R95-1705 soybean line (Fig. 2), and this fraction was chosen for the dose response study to determine the minimum inhibitory concentration. The <5-kDa fraction from the high oleic acid soybean line N98-4445A showed an inhibition of 42.2 ± 1.3 % which was the only other significant activity observed against the ACE-I enzyme among all the protein hydrolysate fractions. Peptides of both large and small sizes have shown bioactivities in previous studies and have exhibited functionalities that can be used in food products [21, 39]. The hydrolysates tested for GI resistance could potentially be available for absorption through the intestine when consumed as food and elicit the health beneficial bioactivities in the target tissues. Researchers have shown that peptides of various molecular sizes are absorbed through the intestinal wall but the ability of absorption decreases with an increase in molecular size [40].

A dose response study of the 5- to 10-kDa fraction (R95-1705) revealed an increase in ACE-I inhibitory activity as the dosage of the fractions increased from 200 to 1200 µg/mL (data not shown). The highest inhibition was achieved at 1200 µg/mL concentration (75.5 ± 2.8 %) which was not significantly different from that shown by 1000 µg/mL concentration (72.4 ± 1.4 %). An increase in ACE-I inhibition was observed at ≥800 µg/mL concentration, although the highest inhibition by the fractions was significantly lower in comparison to the positive control. The dose response provided the inhibitory concentration at 50 % activity (IC50) of the 5- to 10-kDa protein fraction from R95-1705 to be 563 µg/mL. These results are significant as R95-1705 is a non-GM soybean line, which can have a potential impact on its utilization in foods or supplemental therapeutics. The ACE-I inhibitory activity can be attributed to the pool of peptides from 5–10 kDa and their amino acid sequences. However, other studies have reported significant ACE-I inhibitory activity by similar molecular size peptide fractions which were derived from marine protein sources [41]. Previous studies from the current research group have shown the ability of large molecular size protein hydrolysates (>50 kDa) to have ACE-I inhibition [42]. Researchers have also reported ACE-I and atherosclerosis inhibition by hydrolysates obtained from both glycinin and β-conglycinin fractions of soy protein [43, 44]. Hence, the peptide fraction from R95-1705 (5–10 kDa) with anti-ACE-I activity may have been derived from either the glycinin (11S) or β-conglycinin (7S) fractions of the proteins which needs further examination.

Several factors can be attributed to the substantial anti-ACE-I activity that can be studied, starting with the purification of the peptide pool from the 5- to 10-kDa fractions. Amino acid composition of the fractions, specifically of the peptides which elicit the activity, will reveal their chemical nature and provide an explanation which needs to be investigated. Studies have also shown that protein hydrolysates and peptides derived from various food sources possess anti-ACE-I activities [41, 42, 45]. Although most researchers tested (pure) peptides derived from either fermentation or enzymatic hydrolysis, very few studies have demonstrated the bioactivity of GI-resistant protein hydrolysates which contain a pool of peptides. Preparation of hydrolysates is economical in comparison to derivation of pure peptides. Protein hydrolysates can provide synergistic effects and have shown multiple bioactivities [24, 27].

Conclusion

The protein contents of soybean lines R05-4509, R95-1705, R05-4476 and R05-4487 were higher among all the lines tested. Soybean lines with ‘high oleic acid’ (S03-543CR and N98-4445A) were also found to have substantially enhanced protein content (approximately 48 % d. b.). Lines grown for the ‘high protein and fatty acid’ attribute had 47–52 % (d. b.) protein content which was comparable to that in the ‘high oleic acid’ lines. Amino acid analysis showed a significantly higher methionine levels (P value <0.05) in soybean lines recognized for protein and fatty acid content (R05-4494 and R05-4478). Both methionine and cysteine contents were elevated in the soybean lines attributed for protein and fatty acid.

The protein fraction from the R95-1705, a non-GM soybean, showed highest ACE-I inhibition. This is the first time ACE-I inhibition has been achieved with GI-resistant non-GMO soy protein hydrolysates derived by enzymatic digestion of high purity protein isolates. The 5- to 10-kDa protein fraction at a higher dose presented an enhanced ACE-I inhibitory activity. In conclusion, this study provides amino acid composition of soybean lines that are grown for definite yield attributes and demonstrates functional activity of protein/peptide fractions derived from selected soybean lines. The impact of ACE-I inhibition by protein hydrolysates from the R95-1705 soybean line is significant as it is a non-GMO soybean line.

References

United States Department of Agriculture–Economic Research Service (2012) Soybeans and oil crops—related data and statistics. Accessed from http://www.ers.usda.gov/ (Citation in the text: USDA-ERS 2012)

Cober ER, Voldenga HD (2000) Developing high-protein, high-yield soybean populations and lines. Crop Sci 40:39–42

Cahoon EB (2003) Genetic enhancement of soybean oil for industrial uses: prospects and challenges. AgBioForum 6(1 and 2):11–13

Reynolds K, Chin A, Lees KA, Nguyen A, Bujnowski D, He J (2006) A Meta-analysis of the effect of soy protein supplementation on serum lipids. Am J Cardiol 98(5):633–640

de Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson L (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

Uzzan M, Labuza TP (2004) Critical issues in R&D of soy isoflavone—enriched foods and dietary supplements. J Food Sci 69(3):77–86

Genovese MI, Barbosa ACL, Pinto MD, Lajolo FM (2007) Commercial soy protein ingredients as isoflavones sources for functional foods. Plant Foods Hum Nutr 62:53–58

Clemente TE, Cahoon EB (2009) Soybean oil: genetic approaches for modification of functionality and total content. Plant Physiol 151(3):1030–1040

O’Keefe SF, Wiley A, knauft DA (1993) Comparison of oxidative stability of high- and normal-oleic peanut oils. J Am Oil Chem Soc 70(5):489–492

Warner K, Knowlton S (1997) Frying quality and oxidative stability of high-oleic corn oils. J Am Oil Chem Soc 74(10):1317–1322

Takagi Y, Rehman SM (1996) Inheritance of high oleic acid content in the seed oil of soybean mutant M23. Theor Appl Genet 92(2):179–182

Mazur B, Krebbers E, Tingey S (1999) Gene discovery and product development for grain quality traits. Science 285(5426):372–375

Monteros MJ, Burton JW, Boerma HR (2008) Molecular mapping and confirmation of QTLs associated with oleic acid content in N00-3350 soybean. Crop Sci 48:2223–2234

Dixon WJ (1996) High oleic acid transgenic soybean—biotechnology consultation memorandum of conference, USDA. Accessed from http://www.cfsan.fda.gov/~rdb/bnfm039.html

Health Canada (2000) high oleic soybean lines G94-1, G94-19, and G168, 2000. Novel food information—food biotechnology. Food directorate, health products and food branch, health. Accessed from http://www.hc-sc.gc.ca/fn-an/gmf-agm/appro/oleic_soybean-soja_oleique-eng.php

Sebastia CH, Marsolais F, Saravitz C, Israel DW, Dewey RE, Huber SC (2005) Metabolic profiling of amino acids in soybean developing seeds: possible role of asparagine in the control of storage product accumulation. J Exp Bot 56:1951–1964

Krishnan HB (2005) Engineering soybean for enhanced sulfur amino acid content. Crop Sci 45:454–461

Leppälä AP (2000) Bioactive peptides derived from bovine whey proteins: opioid and ace-inhibitory peptides. Trends Food Sci Technol 11(9–10):347–356

Palatini P, Julius S (2009) The role of cardiac autonomic function in hypertension and cardiovascular disease. Curr Hypertens Rep 11(3):199–205

Boudier HAJS, le Noble JLML, Messing MWJ, Huijberts MSP, le Noble FAC, van Essen H 1(992) The microcirculation and hypertension. J Hypertens 10(7):S147–S156

Wu J, Ding X (2002) Characterization of inhibition and stability of soy-protein-derived angiotensin I-converting enzyme inhibitory peptides. Food Res Int 35(4):367–375

Kuba M, Tana C, Tawata M (2005) Production of angiotensin I-converting enzyme inhibitory peptides from soybean protein with Monascus purpureus acid proteinase. Process Biochem 40(6):2191–2196

Margatan W, Ruud K, Wang Q, Markowski T, Ismail B (2013) Angiotensin converting enzyme inhibitory activity of soy protein subjected to selective hydrolysis and thermal processing. J Agric Food Chem 61(14):3460–3467

Rayaprolu SJ, Hettiarachchy NS, Chen P, Kannan A, Mauromostakos A (2014) Peptides derived from high oleic acid soybean meals inhibit colon, liver and lung cancer cell growth. Food Res Int 50(1):282–288

AACC (2000) Official method: 44-15A, “Moisture content determination—air oven method”, vol 2, 2nd edn. American Association of Cereal Chemists approved methods, St. Paul, MN

AOAC (1997) Official method: 994.12, “Amino acids in feeds”—performic acid oxidation with acid hydrolysis-sodium metabisulfite method. Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Arlington, VA

Kannan A, Hettiarachchy NS, Johnson MG, Nannapaneni R (2008) Human colon and liver cancer cell proliferation inhibition by peptide hydrolysates derived from heat-stabilized defatted rice bran. J Agric Food Chem 56:11643–11647

Cushman DW, Cheung HS (1971) Spectrophotometric assay and properties of the angiotensin-converting enzyme of rabbit lung. Biochem Pharmacol 20(7):1637–1648

Kim SL, Berhow MA, Kim JT, Chi HY, Lee SJ, Chung IM (2006) Evaluation of soyasaponin, isoflavone, protein, lipid, and free sugar accumulation in developing soybean seeds. J Agric Food Chem 54(26):10003–10010

Newburg DS, Fillios LC (1982) Brain development in neonatal rats nursing asparagine-deprived dams. Dev Neurosci 5(4):332–344

Tuohy KM, Probert HM, Smejkal CW, Gibson GR (2003) Using probiotics and prebiotics to improve gut health. Drug Discov Today 8(15):692–700

Smriga M, Kameishi M, Uneyama H, Torii K (2002) Dietary l-lysine deficiency increases stress-induced anxiety and fecal excretion in rats. J Nutr 132(12):3744–3746

Iqbal A, Khalil IA, Ateeq N, Sayyar Khan M (2006) Nutritional quality of important food legumes. Food Chem 97(2):331–335

Eyre DR, Paz MA, Gallop PM (1984) Cross-linking in collagen and elastin. Annu Rev Biochem 53:717–748

Reiser K, McCormick RJ, Rucker RB (1992) Enzymatic and non-enzymatic cross-linking of collagen and elastin. FASEB J 6(7):2439–2449

Akagawa M, Suyama K (2001) Characterization of a model compound for the lysine tyrosylquinone cofactor of lysyl oxidase. Biochem Biophys Res Commun 281:193–199

Fujiwara T, Hirai MY, Chino M, Komeda Y, Naito S (1992) Effects of sulfur nutrition on expression of the soybean seed storage protein genes in transgenic petunia. Plant Physiol 99(1):263–268

Krishnan HB, Bennett JO, Kim WS, Krishnan AH, Mawhinney TP (2005) Nitrogen lowers the sulfur amino acid content of soybean (Glycine max [L.] Merr.) by regulating the accumulation of Bowman-Birk protease inhibitor. J Agric Food Chem 53(16):6347–6354

Wu WU, Hettiarachchy NS, Qi M (1998) Hydrophobicity, solubility, and emulsifying properties of soy protein peptides prepared by papain modification and ultrafiltration. J Am Oil Chem Soc 75(7):845–850

Roberts PR, Burney JD, Black KW, Zaloga GP (1998) Effect of chain length on absorption of biologically active peptides from the gastrointestinal tract. Digestion 60(4):332–337

Lee S-H, Qian Z-J, Kim S-K (2010) A novel angiotensin I converting enzyme inhibitory peptide from tuna frame protein hydrolysate and its antihypertensive effect in spontaneously hypertensive rats. Food Chem 118(1):96–102

Lassissi TA, Hettiarachchy NS, Rayaprolu SJ, Kannan A, Davis M (2014) Functional properties and Angiotensin-I converting enzyme inhibitory activity of soy–whey proteins and fractions. Food Res Int 64:598–602

Kuba M, Tana C, Tawata S, Yasuda M (2005) Production of angiotensin I-converting enzyme inhibitory peptides from soybean protein with Monascus purpureus acid proteinase. Process Biochem 40(6):2191–2196

Adams MR, Golden DL, Franke AA, Potter SM, Smith HS, Anthony MS (2004) Dietary soy β-conglycinin (7S globulin) inhibits atherosclerosis in mice. J Nutr 134(3):511–516

Balti R, Nedjar-Arroume N, Bougatef A, Guillochon D, Nasri M (2010) Three novel angiotensin I-converting enzyme (ACE) inhibitory peptides from cuttlefish (Sepia officinalis) using digestive proteases. Food Res Int 43(4):1136–1143

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Rayaprolu, S., Hettiarachchy, N., Horax, R. et al. Amino Acid Profiles of 44 Soybean Lines and ACE-I Inhibitory Activities of Peptide Fractions from Selected Lines. J Am Oil Chem Soc 92, 1023–1033 (2015). https://doi.org/10.1007/s11746-015-2655-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2655-y