Abstract

Palm oil biodiesel (POB) is characterized by a very high cold soak filtration time (CSFT), which places the acceptability of this biofuel at risk. Therefore, the effect of four adsorbents, namely diatomaceous earth, natural silicate (NS), neutral bleaching earth (NBE), and acid activated bleaching earth (AABE), at two levels of addition (1 and 5 wt%) or two temperatures (25 and 110 °C) on the precipitate content and CSFT of POB was investigated. The impact on total glycerin content, moisture content, and oxidative stability was also examined. All treatments significantly decreased the precipitate content, total glycerin content, and moisture content, but only treatments with NS, NBE, and AABE at 5 wt% and 25 °C achieved acceptable filterability. The OSI value was also decreased; however, it remained above the ASTM limit. Operational conditions of treatment with AABE were further optimized in a two-factor, five-level center composite design. The combination of 0.65 wt% AABE and 10 min at 25 °C decreased CSFT to below the ASTM limit. Lower adsorbent concentrations could be effective down to 0.44 wt%, given a corresponding increase in the contact time up to 30 min.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Diesel fuels from petroleum have long played an important role in world industry and transportation. However, alternative fuels have become important worldwide because they decrease dependence on fossil fuels. One of these alternatives is biodiesel, which is composed of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats [1]. Biodiesel offers the advantage that it is renewable, biodegradable, and non-toxic; it also improves lubricity when blended with diesel fuel and reduces greenhouse gas emissions [1]. However, precipitate formation is a concern for biodiesel producers. Precipitate induces a number of undesired consequences: it may affect process equipment upstream of the tank farm in biodiesel facilities; it may also settle at the bottom of tanks where biodiesel is stored. As a consequence, frequent maintenance is necessary in biodiesel facilities [2]. More important, precipitate has also caused clogging of fuel filters in engine fuel delivery systems and formed deposits on vehicle injectors [3].

In an effort to address the fuel filter clogging potential of biodiesel, the American Society for Testing and Materials (ASTM) developed a cold soak filtration test, which was included in the ASTM D6751 standard specification as cold soak filterability [4]. This test, denominated the ASTM D7501 Standard Test Method, was intended to determine if biodiesel is sufficiently free of precipitate capable of clogging fuel filters above the cloud point. The ASTM D6751 requires that biodiesel have a cold soak filtration time (CSFT) below 360 s.

Palm oil has several outstanding characteristics as a feedstock for biodiesel production. Palm is a perennial crop, unlike soybean and rapeseed [5]. Moreover, palm plantations have the highest oil yield in terms of oil production per hectare per year, i.e., 5950 L in comparison with 446 and 1190 L for soybean and rapeseed, respectively [6]. However, palm oil biodiesel (POB) is characterized by very poor filterability, resulting in failing CSFT [7]. Currently, there are seven POB plants in Colombia with an annual capacity of 550,000 tons, making Colombia one of the leaders of biodiesel production in Latin America [8]. These plants are the centerpiece of the Colombian Biofuel National Program, which was designed to develop the agricultural sector, generate permanent jobs, improve the air quality, and replace illicit crops. However, this program will be put at risk if POB filterability is not improved.

Characterization of biodiesel precipitate has revealed the predominant presence of steryl glucosides (SG) and saturated monoglycerides [9]. Researchers have reported that SG are the main cause of biodiesel precipitate formation because of their low solubility in biodiesel and their high melting point [10]. Although SG may be significantly removed during refining of vegetable oils [11], even SG contents lower than 50 ppm may result in precipitate formation [10]. In addition, acylated steryl glucosides, another minor component in vegetable oils, may be converted to SG during transesterification, resulting in an increased SG content in biodiesel in comparison with the initial amount in the feedstock oil [2]. Monoglycerides result from incomplete conversion of the oils during transesterification and remain in the final biodiesel; SG may form complexes with residual monoglycerides, exacerbating precipitate formation [3]. Thus, post-processing techniques for precipitate removal, especially removal of SG, are needed to improve biodiesel filterability.

Tang et al. [12] examined room temperature and cold soak filtration, treatment with diatomaceous earth, centrifugation, and vacuum distillation, and found that vacuum distillation was the most effective technique to decrease the SG content in soybean biodiesel. However, drawbacks of vacuum distillation include increased energy consumption, increased capital and operational costs, and reduced yield [13]. Several authors claimed the use of adsorbents on biodiesel refining [14, 15]; however, little or no characterization of the treated biodiesel was presented. Thus, the primary objective of this study was to improve POB filterability through selection of an adsorbent capable of substantially decreasing the precipitate content. Related objectives were to examine the effect of adsorbent treatment on several ASTM D6751 biodiesel properties and to optimize the operational conditions of the adsorbent treatment.

Materials and Methods

Materials

POB was supplied by Ecodiesel Colombia S.A. (Barrancabermeja, Colombia). The POB was prepared from degummed, bleached, and deodorized palm oil. The POB was obtained dynamically from a sampling loop in a distribution line in the processing facility and supplied in a 20 L plastic container. Diatomaceous earth (CELATOM FW-14) was supplied by EP Minerals, LLC (Reno, NV, USA). Natural silicate (SELECT-FF), neutral bleaching earth (B-80), and acid activated bleaching earth (PERFORM-4000) were supplied by Oil-Dri Corporation of America (Chicago, IL, USA).

HPLC grade methanol and dichloromethane were acquired from Alfa Aesar (Ward Hill, MA, USA). A SG standard mixture was obtained through Matryea, Inc. (Pleasant Gap, PA, USA) and was reported to be >98 % pure.

Sample Conditioning

Untreated POB was manually agitated for 5 min according to the European Standard EN 12662 to resuspend sediments before withdrawing 400 ml samples. Each sample was placed in a 500 ml bottle and heated for 3 h in a water bath at 80° C under a dry nitrogen atmosphere to erase the thermal history of the sample. This temperature was selected for this step because 40 °C was found unsuitable to redissolve the sediments (unpublished data). Each sample was then allowed to stand for 24 h at 25 °C before treatment with an absorbent.

Adsorbent Treatment

POB samples were treated with one of four adsorbents: diatomaceous earth (DE), natural silicate (NS), neutral bleaching earth (NBE), and acid activated bleaching earth (AABE). Each adsorbent was added to a 400 ml sample of POB and mixed at 250 rpm with a 5 cm stir bar for 2 h, then filtered through Whatman No. 2 filter paper under vacuum using the filtration apparatus described in the ASTM D7501. A bed of adsorbent of approximately 3 cm was formed above the filter paper during the filtration. The time to filter was recorded. The filter and bed of adsorbent was washed with 50 ml n-heptane, the n-heptane collected after washing was evaporated at 110 °C, and the POB residue was weighed. After filtration, one portion (300 ml) of treated POB was tested for CSFT, as described below. The other portion of treated POB was stored in a 250 ml dark bottle with fluoropolymer resin-lined cap at 25 °C under a dry nitrogen atmosphere. Each treatment was replicated three times.

DE and NS were each tested at two concentrations (1 and 5 wt%) and one temperature (25 °C) in accordance with Tang et al. [12]. NBE and AABE were each tested at three temperatures (25, 40, and 110 °C) and one concentration (5 wt%). 110 °C was chosen in accordance with the AOCS Official Method Cc 8b-52 [16] whereas 40 °C was chosen to improve the understanding of the temperature interaction with precipitate absorbance in potential biodiesel refining applications. In the case of bleaching earths, reduced pressure (60 kPa below atmospheric pressure) was maintained during all treatments. Samples treated at 40 and 110 °C were heated on a hot plate with manual temperature control, and samples treated at 110 °C were allowed to come to 80 °C before filtration.

Cold Soak Filtration Test

The cold soak filtration test was performed in accordance to the ASTM D7501 with minor modifications. After soaking at 4 °C for 16 h, 300 ml treated samples were allowed to warm to 25 °C in a water bath and held at this temperature for 4 h. The samples were then filtered through a 0.7 µm glass microfiber filter (Whatman GF/F, 47 mm diameter, Piscataway, NJ, USA) under 70–80 kPa below atmospheric pressure. ASTM D7501 filtration apparatus comprises a funnel, a funnel base with a filter support, the glass microfiber filter, and a receiving flask assembled as a unit by a clamp. The filtration proceeded to completion, in contrast to the ASTM D7501 where filtration is stopped after 720 s. The time required for the biodiesel to pass through the glass microfiber filter was recorded as the cold soak filtration time. The amount of precipitate retained on the glass microfiber filter was determined in accordance with the ASTM D7321 standard test method with minor modifications. After filtration, the sample container was rinsed with n-heptane previously filtered through a 0.45 µm glass microfiber filter (Millipore AP40, 47 mm diameter, Billerica, MA, USA), and the rinses were poured into the funnel and filtered through the glass microfiber filter. Similarly, the funnel was rinsed, and the rinses were filtered. With the vacuum applied, the funnel was carefully separated from the funnel base, and the periphery of the glass microfiber filter was washed with n-heptane by directing a gentle stream from the edge to the center. The vacuum was maintained for 10–15 s after washing to remove excess n-heptane from the glass microfiber filter. Using clean forceps, the glass microfiber filter was carefully removed from the filter support, and then dried in an oven at 110 °C for 30 min, in contrast to the ASTM D7321 where the drying temperature is 90 °C. When cooled, the glass microfiber filter was weighed using an analytical balance, and the mass was recorded to the nearest 0.1 mg. The precipitate content was calculated from the increase in the mass of the glass microfiber filter and reported in ppm.

Biodiesel Analysis

As-received POB and samples collected after filtration through the bed of adsorbent and the Whatman No. 2 filter paper were analyzed to examine the effect of adsorbent treatment on several ASTM D6751 biodiesel properties. Moisture content was determined with a Karl Fischer coulometric titrator DL32 (Mettler Toledo, Columbus, OH, USA) following the ASTM D6304 Standard Test Method. Total glycerin was quantified by the SafTest (MP Biomedicals, LLC., Solon, OH, USA) according to the manufacturer’s recommendations. Reagents in the SafTest cleave molecules of mono-, di-, and triglycerides. The resulting glycerin is digested enzymatically, and the break down product is measured spectrophotometrically at 570 nm [17]. Oxidative stability index (OSI) was determined with a six-channel oxidative stability instrument (Omnion Inc., Rockland, MA, USA) following the AOCS official method Cd 12b-92 at 110 °C [18]. Analyses were all performed twice for each replicate of treated biodiesel.

Steryl Glucosides Analysis

Centrifugation near the POB cloud point temperature was used to concentrate SG for quantification. Thirty milliliters of biodiesel was centrifuged at 4300×g for 60 min at 15 °C. The supernatant was decanted, and the tubes were inverted on paper towels for 30 min to remove any excess biodiesel from the tubes. Tubes containing untreated POB yielded a visible pellet after centrifugation, but a visible pellet was often not observed among adsorbent treatments. Vacuum distillation (150–175 °C, 98 kPa below atmospheric pressure, 190 min) confirmed that the amount of SG remaining in the supernatant was below our limits of detection (0.025 mg/ml), and therefore, centrifugation isolated the SG in the pellet. Working in a cold room to minimize evaporation of dichloromethane, 0.5 ml of dichloromethane/methanol (2:1, v/v) was added to the sample tube. The tubes were capped and stored at 25 °C for 15 min and were resuspended with occasional vortexing. After 15 min, samples were centrifuged for 30 s at 4300×g and 15 °C to concentrate the SG on the tube bottom. The samples were filtered through 0.45 μm nylon filters directly into vials for HPLC SG analysis as reported by Haagenson et al. [19]. Before filtration, the sample arising from the centrifuged untreated POB was diluted 1:10 with dichloromethane/methanol (2:1, v/v) to bring the SG content within the range of the calibration equation. The sample arising from the centrifuged treated biodiesel, in contrast, was not diluted because of the suspicion that it had very low SG content. ELSD detectors are well known to have a limited range of non-linear concentration response. Thus, concentrations ranging from 100 to 300 µg/ml were chosen to achieve a standard curve with good linearity. The parameters of the standard curve were obtained by fitting the experimental data points to a linear equation, resulting in the calibration equation:

where y is the peak area (mV min) and x represents the analyte (SG) concentration (mg/ml).

Statistical Analysis

Data were analyzed by ANOVA followed by the Tukey test for multiple comparisons using Statgraphics Centurion software (free trial version, StatPoint Technologies, Inc., Warrenton, VA, USA). A p value of <0.05 was considered statistically significant.

A two-factor, five-level central composite design (CCD) was conducted to examine the combined effect of adsorbent concentration and contact time on CSFT. CCD has the advantage of predicting a response based on a few sets of experimental data, in which independent factors vary within a fixed range. CCD consists of the standard 2k factorial points, a replicated center point, and 2k points fixed axially at a distance from the center given by the general formula α = 2k/4, where k is the number of factors. For two factors, α is equal to 1.414, which made the design rotatable. Five replicates of the center point were used to determine the experimental error and the reproducibility of the data. Thus, a set of 13 experiments points including four factorial points, four axial points, and one center point replicated five times was carried out in randomized order to minimize the effects of uncontrolled factors.

The low and high actual levels of the factors were initially fixed at 1 and 5 wt% for adsorbent concentration, and 30 and 120 min for contact time, respectively. The actual levels of the axial points were calculated using Eq. (2):

where α i represents the coded value, X i represents the actual value, X o represents the average value of the factor in low (−1) and high levels (+1) and X may be calculated as follows:

Multiple regression analysis was used to fit the response values by the second-order polynomial model:

where Y represents the predicted response, β o represents the constant coefficient, β i represents the linear effect, β ij represents the interaction effect, β ii represents the squared effect, and x i and x j represent the independent factors. The model was satisfactory when ANOVA showed a high statistical significance (p value <0.05). Regression coefficients were also tested for statistical significance. Confirmatory experiments were carried out using four combinations of factors that were not part of the original CCD experiments, but within the design space, where favorable CSFT (<360 s) was expected. The confirmatory experiments involved adsorbent treatment of untreated POB followed by cold soak filtration test of the resulting treated POB as described above.

Results and Discussion

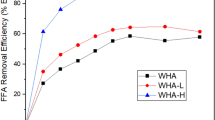

Improving POB filterability, through selection of an adsorbent capable of removing the precipitate, was the primary objective of this study. CSFT was markedly higher than the 360 s limit specified in the ASTM D6751, confirming that POB as received had very poor filterability (Fig. 1a). The precipitate content was also markedly higher in comparison with other biodiesel feedstocks [20]. This indicated that it was necessary to make a great effort to improve POB filterability.

Cold soak filtration time (CSFT) (a) and precipitate content (b) for treated palm oil biodiesel (POB). Control denotes the untreated POB. Treatments having different letters are significantly different by Tukey multiple range test (p value <0.05). DE diatomaceous earth, NS natural silicate, NBE neutral bleaching earth, AABE acid activated bleaching earth. The dotted line in a indicates the 360 s ASTM maximum limit for CSFT. Error bars show standard deviation

Adsorbent Treatment

Influence on CSFT

Of the eight adsorbent treatments tested, only three (5 wt% NS, NBE, or AABE at 25 °C) resulted in POB that had a passing CSFT (<360 s) (Fig. 1a). DE was first tested due to its widespread use as a filter aid and its potential use in biodiesel facilities [14, 15]. Although precipitate content was decreased to almost one third that of the untreated biodiesel (Fig. 1b), the use of either 1 or 5 wt% DE had no significant effect on CSFT. Therefore, additional optimization of DE was not considered.

Using 1 wt% NS, the precipitate content was markedly lower (80.6 %) than that for the untreated biodiesel. However, this was insufficient to decrease CSFT to below the ASTM limit. In contrast, using 5 wt%, CSFT decreased to 71 s with a concomitant reduction (97.9 %) in precipitate content. This confirmed that NS can achieve the needed POB filterability.

Effectiveness of bleaching earths on improving POB filterability was then assessed. Since the CSFT was not achieved with DE and NS at 1 wt%, a concentration of 5 wt% was used with bleaching earths. CSFT for POB treated with either NBE or AABE at 25 °C was 58 s, similar to the superior CSFT provided by NS at 5 wt%. The improved CSFT was consistent with a marked reduction (95.3 and 97.3 %, respectively) in the precipitate content of both treatments. This suggested the potential of bleaching earths for improving POB filterability. However, the efficacy of bleaching earths on POB precipitate removal and CSFT at 110 °C was decreased. When compared to untreated POB, NBE and AABE tested at 110 °C markedly decreased precipitate content (77.2 and 82.1 %, respectively), but were still higher than that from the bleaching earths tested at 25 °C. These results showed that removal of components responsible for precipitate formation in POB is favored at lower temperature. An explanation for the reduced efficacy at higher temperature may be the alteration in van der Waals physical forces at elevated temperature. These forces have been demonstrated to be disrupted when temperatures rise, especially above 100 °C, making the adsorption reaction shift to the desorption side [21]. In addition, since the results were not the same at the two temperatures, removal of components responsible for precipitate formation in POB by adsorption rather than filtration was supported.

The reduced effectiveness of bleaching earths at increased temperatures was concerning since POB processing often occurs in tropical locations where the average ambient temperature is ≥40 °C. Because of this, two additional experiments were conducted at 40 °C to improve the understanding of the temperature interaction with precipitate absorbance in potential biodiesel refining applications. In agreement with our early finding, the precipitate content was higher for the treatments at 40 °C relative to 25 °C, and consequently, CSFT was also higher. However, the precipitate content at 40 °C were higher for POB treated with NBE than that for POB treated with AABE. Moreover, CSFT for POB treated with NBE was well above the ASTM limit whereas CSFT for POB treated with AABE at 40 °C met the ASTM limit. This suggested the use of AABE instead of NBE for further optimization studies.

As depicted in Fig. 2, CSFT increased as the precipitate content rose from 3.68 to 14.44 ppm, but still met the ASTM limit. POB failed to meet this limit once the precipitate content exceeded 20 ppm. With a further increase in precipitate content, CSFT underwent a sharp rise to very high values beyond the useful range of the ASTM D7501. A curve fitted through these data suggests that there is a precipitate content threshold around 20 ppm above which POB filterability becomes unacceptable. A similar relationship was found by Lin et al. [17], who examined the impact of minor components on the precipitate formation in canola oil biodiesel and its filterability. These authors spiked refined canola oil biodiesel with different levels of saturated monoglycerides and tested the biodiesel for CSFT, quantifying the precipitate content. Their results showed that below 0.26 wt% saturated monoglycerides, CSFT increased only slightly with increasing precipitate content. However, above this critical point, a small rise in the precipitate content corresponded to a sharp increase in CSFT, at which point the canola oil biodiesel failed to meet the ASTM limit. These authors also mentioned that CSFT was less repeatable once the critical point was exceeded, in accordance with the results reported in this study.

Relationship between CSFT and precipitate content of POB subjected to different adsorbent treatments. The dotted line indicates the 360 s ASTM maximum limit for CSFT. Only treatments for which precipitate content was lower than 40 ppm (1 and 5 wt% NE, NBE at 25 °C, AABE at 25 and 110 °C) are represented in this plot, including treatments with NBE (precipitate content = 26.2 ppm) and AABE (precipitate content = 14.8 ppm) at 40 °C. Error bars show standard deviation. For details on abbreviations, refer to Fig. 1

Because of the interest in selecting one adsorbent for investigating the effect of adsorbent concentration and contact time on POB filterability in the second part of this study, a criterion was sought to choose between NS and AABE. The amount of POB retained by each spent adsorbent was considered first. However, no significant difference was observed (p value = 0.5013): NS retained 0.68 ± 0.01 g POB per g adsorbent whereas AABE retained 0.65 ± 0.08 g POB per g adsorbent. The adsorbent price was then considered, and NS cost per ton was almost four times that of AABE. Thus, NS was not evaluated for additional optimization experiments.

Influence on Minor Components Content and Biodiesel Properties

Total Glycerin

Total glycerin is the sum of free glycerol and glyceride species (mono-, di-, and tri-) remaining in the final biodiesel; of these minor components, monoglycerides are expected to be the most abundant [3]. Since palm oil has a high percentage of saturated fatty acids, the monoglycerides remaining in POB are expected to have a similar, high percentage of saturates. When compared to unsaturated monoglycerides, saturated monoglycerides have been demonstrated to increase CSFT negatively [17], and therefore, it was expected that reduction in total glycerin content would decrease CSFT of POB.

Adsorbent treatments all markedly decreased the total glycerin content (Fig. 3). However, reduction in total glycerin content did not correspond to a systematic reduction in CSFT (Figs. 1a, 3). Samples treated with either NBE or AABE at 110 °C did not meet the ASTM CSFT limit, even though total glycerin content for both treatments was the lowest (0.036 and 0.040 wt%, respectively). Although these treatments had the lowest total glycerin content, the precipitate content exceeded the 20 ppm threshold associated with failing CSFT (Fig. 2). The best CSFT was obtained from treatments possessing total glycerin content between 0.078 and 0.091 wt% (5 wt% NS, NBE, or AABE at 25 °C, Figs. 1b, 3), and these treatments had the lowest precipitate content. This suggested that factors other than saturated monoglycerides, such as SG, played an important role in POB filterability.

Total glycerin content for treated POB. Treatments having different letters are significantly different by Tukey multiple range test (p value <0.05). The dotted line indicates the 0.24 wt% ASTM maximum limit for total glycerin content. For details on abbreviations, refer to Fig. 1

Steryl Glucosides

SG content of the untreated POB was 65 ppm. Samples treated with adsorbent showed a marked reduction in SG peaks, including no visible SG peak in some instances. This indicated that all adsorbent treatments decreased the SG content, even to below our levels of detection (Fig. 4). This was in agreement with Na-Ranong et al. [22], who treated POB containing 97.6 ppm SG at temperatures in the range of 65–80 °C for 10 min and reduced the SG content to as low as 20 ppm using 3 wt% bleaching earths. As suggested above, the superior CSFT of samples treated with 5 wt% NS, NBE, or AABE at 25 °C may have been due to a higher reduction in SG content compared with the other treatments; this is consistent with Pfalzgraf et al. [23] in their finding that the impact of SG on soybean oil biodiesel CSFT was the most dramatic, much more dramatic than that of saturated monoglycerides.

Reverse phase HPLC-ELSD chromatogram of (a) centrifuged untreated and (b) centrifuged treated (25 °C and 5 wt% of AABE) POB. Peaks detected in the range of 5.8–8.2 min corresponded to steryl glucosides (SG) while in the range of 2.2–3.1 min corresponded to monoglycerides (MG) and in the range of 4.0–5.5 min corresponded to fatty acid methyl esters (FAME) of residual POB. Before analysis, sample A was diluted 1:10 with dichloromethane/methanol (2:1, v/v); sample B, in contrast, was not diluted

Moisture

Increased biodiesel moisture may negatively impact filtration, and the impact of adsorbent on moisture was determined (Fig. 5). Moisture content for the untreated POB (542.3 ppm) was slightly higher than the 500 ppm limit specified in the European Standard EN 14214 [24], but all samples treated with adsorbent met the EN 14214 limit. The samples possessing superior CSFT (5 wt% NS, NBE, or AABE at 25 °C, Figs. 1a, 5) had similar moisture contents to the sample treated with 5 wt% DE or the untreated POB, indicating that moisture has no significant effect on CSFT of POB. Samples treated with bleaching earths at 110 °C had markedly decreased moisture content. The elevated temperature (110 °C) may have contributed to evaporative loss rather than contact with adsorbent.

Moisture content for treated POB. Treatments having different letters are significantly different by Tukey multiple range test (p value <0.05). The dotted line indicates the 500 ppm EN 14214 maximum limit for moisture content. For details on abbreviations, refer to Fig. 1

Oxidative Stability Index

As expected, untreated POB had a very high OSI value, well above the 3 h limit specified in the ASTM D6751 (Fig. 6). The high oxidative stability of the untreated POB may be attributed to its high percentage of saturated fatty acids. Biodiesel is more susceptible to oxidation if it contains a high level of unsaturated fatty acids, especially methyl linolenate [25], not found in POB. In addition, POB has natural antioxidants that impart high oxidative stability to biodiesel [26].

OSI value for treated POB. Treatments having different letters are significantly different by Tukey multiple range test (p value <0.05).The dotted line indicate the 3 h ASTM minimum limit for OSI value. For details on abbreviation, refer to Fig. 1

All the adsorbent treatments markedly decreased the OSI value compared to the untreated POB, but all samples met the ASTM limit. Biodiesel treated with DE (5 wt%) or with either NBE or AABE at 110 °C had the largest reduction in oxidative stability. Although antioxidant contents were not quantified in this current study, the reduction in OSI may be partly attributed to the removal of antioxidants. Tang et al. [12] reported that adsorbent treatment decreased the soybean oil biodiesel tocopherol content from 36 to 17 ppm on average. These authors suspected that this reduction in the tocopherol content was enough to compromise the soybean oil biodiesel oxidative stability. However, OSI values remained well above the ASTM limit for treatments for which CSFT was the best (5 wt% NS, NBE, or AABE at 25 °C, Figs. 1a, 6), and therefore, POB thus treated had not only very good filterability but also very good oxidative stability.

Because of the marked decline in the OSI value after treatment with all the adsorbents, an extra experiment was conducted to examine if this decline was exclusively due to the adsorption of POB antioxidants. The experiment consisted of conditioning an untreated POB sample according to the procedure described in the materials and method section and filtering it directly through Whatman No. 2 filter paper under vacuum. No adsorbent was used to treat the sample. After filtration, the treated sample was tested for OSI value. The OSI value for this negative control (14.6 ± 1.7 h) was significantly lower than that for the untreated POB (p value = 0.0008). This showed that even filtration through Whatman No. 2 filter paper reduced oxidative stability.

Model Fitting

After choosing AABE over NBE and NS for optimization studies, an initial CCD experiment was conducted to examine the combined effect of adsorbent concentration and contact time on CSFT (Table 1). Disappointingly, little variation in CSFT was observed, and all but one treatment decreased CSFT to well below the ASTM limit. The exception was the treatment at 0.18 wt% and 75 min, for which CSFT remained exceptionally high (>1800 s). No statistically significant variation was observed within the design space, indicating that AABE was capable of effectively improving POB filterability even at 1 wt% and 30 min. These results suggested that acceptable POB filterability could be achieved using less than 1 wt% and less than 30 min. Thus, a second CCD experiment was conducted with lower levels of adsorbent concentration and contact time in order to provide a more sound statistical basis for adsorbent loading and retention time (Table 1).

The adsorbent concentration values in the second CCD experiment were chosen so that the highest and lowest axial values equaled the lowest factorial value (1 wt%) and lowest axial value (0.18 wt%) of the first CCD experiment, respectively. Additional adsorbent concentrations values were calculated using Eq. (2) and (3). The new contact time values were chosen in accordance with Barrios and Skelton [27], who examined the efficiency of magnesium silicate for removal of methanol, glycerin, and fatty acid soaps from used cooking oil-based biodiesel.

The response values from the second CCD experiment supported that acceptable POB filterability could be achieved using less than 1 wt% and less than 30 min. All center point treatments, with the exception of treatment 10, produced biodiesel that met the ASTM limit using just 0.6 wt% and 20 min.

The response values reported in Table 1 were fitted to the second-order polynomial model described in Eq. (4) using multiple regression analysis. According to the ANOVA results, most coefficients were statistically significant, except for x 2 and \(x_{2}^{2}\) (p value > 0.05). The latter was removed from the model, but the former was kept due to the significance of the interaction term x 1 x 2. The resulting model, after excluding the insignificant terms, is given in Eq. (5):

where x 1 and x 2 denote adsorbent concentration (wt%) and contact time (min), respectively. The model was statistically significant (p value = 0.0003). The goodness of fit was evidenced by the high coefficient of determination of the model (R 2 = 0.9886), indicating that the model may be used for prediction within the design space with high precision.

Good agreement was shown to exist between the predicted CSFT values and the measured values from confirmatory experiments (Table 2). No marked differences were observed, and the average deviation was 6.3 %. This validated the model given in Eq. (5) within the design space.

Effect of Adsorbent Concentration and Contact Time

Adsorbent concentration had a much larger effect on CSFT than contact time within the ranges used in the second CCD experiment. CSFT varied from values well below the ASTM limit (106 s for treatment 2 and 88 s for treatment 4) to values unacceptably high (1878 s for treatment 1 and 729 s for treatment 3) when adsorbent concentration decreased from 0.9 to 0.3 wt%. The effect of adsorbent concentration was less pronounced at high contact times: CSFT increased by 641 s when adsorbent concentration decreased from 0.9 to 0.3 wt% and contact time was held at 30 min in comparison with 1772 s when adsorbent concentration decreased by the same amount and contact time was held at 10 min, confirming the strong interaction between the adsorbent concentration and contact time. Thus, when decreasing adsorbent concentration, contact time should increase to ensure CSFT limits are met.

To illustrate the relationship between adsorbent concentration and contact time, a contour plot was created (Fig. 7). The region where CSFT was predicted to be lower than 360 s extends from 0.65 up to 0.9 wt% for adsorbent concentration at the lowest level contact time. This indicates that any combination of absorbent at ≥0.65 wt% and 10 min should decrease CSFT to below 360 s. Lower concentrations (up to 0.44 wt%) could be effective, but increasing the contact time up to 30 min would be necessary.

Contour plot for the combined effect of adsorbent concentration and contact time on cold soak filtration time for treated palm oil biodiesel. The adsorbent was acid activated bleaching earth. The ASTM D6751 standard specification stipulates that cold soak filtration time (CSFT) should not exceed 360 s. In some instances, a more stringent limit of 200 s is used

The ASTM D6751 standard specification also prescribes that biodiesel intended for blending into diesel in cold climates (at or below −12 °C) should have a CSFT of ≤200 s. Thus, the region where CSFT was predicted to be lower than 200 s was also identified in the contour plot. Any combination of ≥0.72 wt% of adsorbent and 10 min was sufficient enough to decrease CSFT to below 200 s. Again, lower adsorbent concentrations could be effectively used (up to 0.55 wt%), but it would be necessary to increase the contact time up to 30 min.

It is important to note that the improved filtration values were obtained from an untreated biodiesel feedstock containing 65 ppm SG. SG content of biodiesel may vary markedly depending on the oil refining processes and the biodiesel production processes [12]. It may range from not detectable to 158 ppm for soybean oil biodiesel, and from 55 to 275 ppm for POB [2]. Thus, the biodiesel precipitate content may be quite different, and it may be necessary to adjust adsorbent concentrations and contact times for different process batches. In addition, costs associated with the AABE, loss of POB during filtration, and related costs must be taken into account to determine the economic feasibility of the process.

The cost of this treatment was estimated on the assumption that it would be comparable to the cost of bleaching. Morad et al. [28] reported that 20 % of refining cost was due to combined degumming and bleaching; the consumption of expensive bleaching agents along with oil losses in the spent bleaching agents makes bleaching cost-intensive. The refining cost for palm oil during the last year was estimated at US$44.02 per ton [29], thus our AABE treatment of biodiesel was estimated at US$8.80 per ton.

An estimate of POB losses using 3 wt% AABE may be made from the amount of POB retained by the spent AABE, which was 2.07 ± 0.27 wt%. This value is similar to that reported by Na-Ranong et al. [22] (1.93 wt%). The optimum adsorbent concentration may actually be much lower than 3 wt%, which would reduce both adsorbent cost and POB loss; the optimum for our POB was 0.65 wt%, as noted above.

Conclusion

POB as received from a local supplier was characterized by an exceptionally high CSFT (>5 h), confirming the poor filterability typical of POB. This was consistent with a high precipitate content (>175 ppm), much higher than for biodiesel from other feedstocks. Reduction of the precipitate content to below 20 ppm resulted in POB that had a passing CSFT (<360 s). DE was not successful in improving POB filterability. In contrast, NS, NBE, and AABE achieved the needed filterability at 5 wt% and 25 °C. AABE was selected optimization because of its cost and its better performance at room temperatures. The improvement in filterability was diminished at higher temperatures, perhaps because of the alteration in van der Waals physical forces at elevated temperature.

All adsorbent treatments significantly decreased the total glycerin content and moisture content. Reduction in total glycerin content did not correspond to a systematic reduction in CSFT, suggesting that factors other than saturated monoglycerides played an important role in POB filterability. The OSI value was also decreased, but it remained above the ASTM limit.

A model for the prediction of CSFT of POB, given AABE concentration and contact time, had high statistical significance (p value = 0.0003). The combination of 0.65 wt% AABE and 10 min at 25 °C decreased CSFT to below the ASTM limit. Lower adsorbent concentrations could be effective down to 0.44 wt%, given a corresponding increase in the contact time up to 30 min.

References

Knothe G (2005) Introduction. In: Knothe G, Van Gerpen J, Krahl J (eds) The biodiesel handbook. AOCS Press, Champaign, pp 1–3

Van Hoed V, Zyaykina N, De Greyt W, Maes J, Verhé R, Demeestere K (2008) Identification and occurrence of steryl glucosides in palm and soy biodiesel. J Am Oil Chem Soc 85:701–709

Dunn RO (2009) Effects of minor constituents on cold flow properties and performance of biodiesel. Prog Energy Combust Sci 35:481–489

American Society for Testing and Materials (2012) Standard specification for biodiesel fuel blend stock (B100) for middle distillate fuels. In: Annual book of ASTM standards. ASTM International, West Conshohocken

Mekhilef S, Siga S, Saidur R (2011) A review on palm oil biodiesel as a source of renewable fuel. Renew Sustain Energy Rev 16:2070–2093

Atabani AE, Silitonga AS, Anjum Badruddin I, Mahlia TMI, Masjuki HH, Mekhilef S (2012) A comprehensive review on biodiesel as an alternative energy resource andits characteristics. Renew Sustain Energy Rev 15:1937–1949

Tang H, De Guzman RC, Salley OS, Simon KY (2008) Formation of insolubles in palm oil-, yellow grease-, and soybean oil-based biodiesel blends after cold soaking at 4° C. J Am Oil Chem Soc 85:1173–1182

Janssen R, Rutz DD (2011) Sustainability of Biofuels in Latin America: risks and opportunities. Energy Policy 39:5717–5725

Plata V, Gauthier-Maradei P, Romero-Bohórquez AR, Kafarov V, Castillo E (2015) Characterization of insoluble material isolated from colombian palm oil biodiesel. Biomass Bioenergy 74:6–14

Lacoste F, Dejean F, Griffon H, Rouquette C (2009) Quantification of free and esterified steryl glucosides in vegetable oils and biodiesel. Eur J Lipid Sci Technol 111:822–828

Murui T, Siew YH (1997) Effect of refining process on the content of sterylglycosides and alcohols in palm oil. J Jpn Oil Chem Soc 46:683–686

Tang H, De Guzman RC, Salley OS, Simon KY (2010) Comparing process efficiency in reducing steryl glucosides in biodiesel. J Am Oil Chem Soc 87:337–345

Smith W (2012) Biodiesel purification: finding the right fit. Biodiesel Mag. http://www.biodieselmagazine.com/articles/8462/biodiesel-purification-finding-the-right-fit (accessed Apr 2014)

Lee I, Mayfield J, Pfalzgraf L, Solheim L, Bloomer S (2007) Processes of producing biodiesel and biodiesel produced therefrom. US Appl Patent 20070151146

Danzer MF, Ely TL, Kingery SA, McCalley W, McDonald W, Mostek J, Schultes ML (2011) Biodiesel cold filtration process. Canada Patent 2576750

Firestone D (2013). Bleaching test for soybean oil (refined). In: Official methods and recommended practices of the AOCS. AOCS press, Champaign

Lin H, Haagenson DM, Wiesenborn DP, Pryor SW (2011) Effect of trace contaminants on cold soak filterability of canola biodiesel. Fuel 90:1771–1777

Firestone D (2013). Oil stability index (OSI). In: Official methods and recommended practices of the AOCS. AOCS press, Champaign

Haagenson DM, Perleberg JR, Wiesenborn DP (2014) Fractionation of canola biodiesel sediment for quantification of steryl glucosides with HPLC/ELSD. J Am Oil Chem Soc 91:497–502

Tang H, Salley OS, Simon KY (2008) Fuel properties and precipitate formation at low temperature in soy-, cottonseed-, and poultry fat-based biodiesel blends. Fuel 87:3006–3017

Kaynak G, Ersoz M, Kara H (2004) Investigation of the properties of oil at the bleaching unit of an oil refinery. J Colloid Interface Sci 280:131–138

Na-Ranong D, Laungthaleongpong P, Khambung S (2015) Removal of steryl glucosides in palm oil based biodiesel using magnesium silicate and bleaching earth. Fuel 143:229–235

Pfalzgraf L, Lee I, Foster J, Poppe G (2007) Effect of minor components in soy biodieselon cloud point and filterability. In: Inform supplement—biorenewable resources No. 4. AOCS press, Champaign, pp 17–21

European Committee for Standardization (2012) Liquid petroleum products. fatty acid methyl esters (FAME) for use in diesel engines and heating applications. Requirements and test methods. Brussels: European Committee for Standardization (CEN). Method EN 14214

McCormick RL, Ratcliff MA, Moens L, Lawrence R (2007) Several factors affecting the stability of biodiesel in standard accelerated tests. Fuel Process Technol 88:651–657

Fröhlich A, Schober S (2007) The influence of tocopherols on the oxidation stability of methyl esters. J Am Oil Chem Soc 84:579–585

Berrios M, Skelton RL (2008) Comparison of purification methods for biodiesel. Chem Eng J 144:459–465

Morad NA, Mohd Zin R, Mohd Yusof K, Abdul Aziz MK (2010) Process modelling of combined degumming and bleachingin palm oil refining using artificial neural network. J Am Oil Chem Soc 87:1381–1388

Fedepalma Indicadores. http://web.fedepalma.org/. Accessed Dec 2014

Acknowledgments

The authors gratefully acknowledge the support of the Departamento Administrativo de Ciencia, Tecnología e innovación, COLCIENCIAS, through the Francisco José de Caldas doctoral training program; the Scientific and Technological Research Council of Turkey (TÜBİTAK); and the North Dakota Agricultural Experiment Station and North Dakota Center of Excellence for Oilseeds Development. The authors also gratefully acknowledge Ecodiesel Colombia S.A. for providing the palm oil biodiesel samples for this study, and EP Minerals, LLC and Oil-Dri Corporation of America for providing the adsorbent samples for this study. Sincere appreciation is also extended to Dr. Gülcan Özkan for guidance on the SG analysis.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Plata, V., Haagenson, D., Dağdelen, A. et al. Improvement of Palm Oil Biodiesel Filterability by Adsorption Methods. J Am Oil Chem Soc 92, 893–903 (2015). https://doi.org/10.1007/s11746-015-2646-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2646-z