Abstract

Reactions of epoxidized alkyl soyate with four different alcohols: ethanol, isopropyl alcohol, 2-ethylhexanol, benzyl alcohol, in the presence of Brønsted acid catalyst, were investigated. Products, not reported in prior studies of similar reactions, were found. These were furan fatty acid alkyl esters (FFE, mixture of alkyl 8-(5-hexyl-2-furyl) octanoate and alkyl 9-(5-pentyl-2-furyl)nonanoate) which were unambiguously identified by means of GC–MS and two-dimensional NMR. Evidence suggests that the FFE are formed by an acid-catalyzed rearrangement of the epoxidized linoleates. The FFE were formed in presence of all four alcohols tested and in the presence of either sulfuric acid or Amberlyst 15 catalyst. Yields of up to 13 %, as quantified by GC and NMR spectroscopies, were observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The ring-opening reaction of epoxidized vegetable oil or fatty acid alkyl esters is widely used for synthesis of biobased lubricants [1–9] and polyol precursors, which are used in the synthesis of biobased polyurethane polymers [10–13].The epoxidized alkyl oleate can be efficiently ring-opened with alcohols under acidic conditions, according to Scheme 1 [1, 14–16]. Since vegetable oil is a complicated mixture of triglycerides, often having different functional groups on each fatty chain, epoxidized methyl oleate is quite often used as a model system. This allows the researcher to evaluate the reactivity of the epoxy ring without further complications caused by the other groups in the epoxidized vegetable oil. Due to the complexity of the epoxidized vegetable oil system, it is hard to prove or disprove that the reaction of the more complicated chains occurs in the same way. In other words, the main products are often assumed, without evidence, to be the ones that would be obtained if each epoxy group in a fatty acid chain reacted independently in the same manner that the epoxy group in epoxidized methyl oleate reacts. The result is that the reaction schemes in many articles [2, 4, 8, 9, 12, 13] describing the synthesis of biobased lubricants and polyols are similar to Scheme 2.

However, there are some publications where ring-opening has been more carefully studied. Researchers studying epoxidized linoleic acid or esters, and similar systems having two epoxy groups separated by a–CH2–group, always reported that the products formed contain a cyclic group [17–23].These products are a result of the attack of the hydroxyl group, formed from the ring-opening of the first epoxide ring, on the second epoxide ring (Scheme 3). Thus, the close proximity of the two epoxide rings enables them to react with each other.

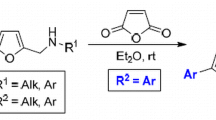

This contrast illustrates the need for a more detailed study of systems of intermediate complexity between methyl oleate and vegetable oil in order to better understand the products formed when biobased lubricants are synthesized from vegetable oils. The new model must contain the important feature of epoxides in close proximity, yet not have the intramolecular complications of a triacylglycerol system. Soybean oil alkyl ester gives such an opportunity. In the current work, we report a finding on the ring-opening reaction of epoxidized soybean alkyl esters with alcohol in the presence of Brønsted acid (H2SO4 or Amberlyst 15) catalysts. We report the observation that the epoxidized linoleic acid alkyl esters in these experimental conditions yield furan fatty acid esters (mixture of alkyl 8-(5-hexyl-2-furyl)octanoate and alkyl 9-(5-pentyl-2-furyl)nonanoate). Such products have erroneously been ignored in at least one earlier synthesis of lubricants from epoxidized vegetable oils [8].

Experimental Procedures

Materials

Amberlyst 15 catalyst ion exchange resin and 2-ethylhexanol were from Sigma-Aldrich. Amberlyst 15 catalyst is a strongly acidic, macroreticular polystyrene resin with sulfonic acid functionality. It has been used by other researchers [6, 8, 16, 24] for epoxide-ring opening studies. It has catalytic activity similar to sulfuric acid, but is easier to separate from the reaction products.

Epoxidized methyl soyate (EMS) and epoxidized 2-ethylhexyl soyate (E2ES) were supplied from Arkema (Philadelphia, PA, USA). They are sold under the trade names Vikoflex 7010 and Vikoflex 4050, respectively. GC–MS analysis showed that the E2ES contained significant amounts of EMS.

Ethyl acetate (HPLC grade) was from EMD Chemicals Inc. (Gibbstown, NJ, USA). Hexanes (HPLC grade), isopropyl alcohol (IPA, certified ACS plus) were from Fisher Scientific (Fairlawn, NJ, USA). Benzyl alcohol (99 %) was from Acros Organics (Geel, Belgium). Sulfuric acid (95–98 %, A.C.S. Reagent) was from Sigma-Aldrich (St. Louis, MO, USA). PVDF 0.2 μm pore size syringe filter (13 mm disposable) and #52 filter paper were from Whatman (Clinton, NJ, USA).

Methods

Syntheses

First, 500 ml (456 g, estimated 1.65 mol epoxide groups) E2ES and 500 ml (421 g, 3.24 mol) 2-ethylhexanol were placed in a 2-L reactor with a mechanical stirrer and proportional/integral/derivative temperature control. The reaction mixture was heated to the preset temperature (60 or 120 °C) and, when it was reached, 10 g Amberlyst 15 catalyst was added. Samples (~0.1 ml) were periodically taken for analysis with NMR and GC–MS. Before tests, they were filtered through a 0.2 μm pore size syringe filter.

The reaction at 60 °C was stopped after 400 h. For the reaction, carried out at 120 °C, the ring-opening reaction was deemed essentially complete and the reaction was stopped after 24 h. The reaction mixture was filtered through Whatman#52 filter paper, and the reactor and the catalyst were rinsed with hexane. The rinse was collected with the product. The hexane and the unreacted 2-ethylhexanol were removed by Kugelrohr distillation (110 Pa, up to 110 °C).

Small-Scale Reactions

Briefly, 0.3 mL EMS, 6 ml alcohol (ethanol, isopropanol or benzyl alcohol) and 0.20 g Amberlyst 15 catalyst were placed in a 100-mL Pyrex test tube, capped, and the test tubes were placed in a multireactor (PRS120R) with a digital controller (PRST120) from J-Kem Scientific, Inc. (St. Louis, MO, USA). Control test tubes, without catalyst, were also prepared and placed in the multireactor. The controller was set at 60 °C. Periodically, samples were taken and analyzed with GC–MS. After 24 h, the reaction was stopped, the excess alcohol removed and the samples were analyzed with NMR. The GC–MS showed that, in addition to the reaction of the epoxide ring, partial transesterification of the ester group had occurred.

Small-Scale Reactions with Sulfuric Acid as a Catalyst

First, 0.3 mL EMS, 6mL EtOH and 60 μL H2SO4 were placed in a test tube, and the test tubes were then placed in the multi-reactor for 45 min at 120 °C, 260 min at 60 °C, or 305 min at room temperature. Afterwards, samples were taken for GC. The GC–MS showed that, in addition to the reaction of the epoxide ring, partial transesterification of the methyl ester group had occurred.

GC–MS

First, 40 μL of the reaction mixture were diluted in 1 mL ethyl acetate then 0.2 μL of the diluted solution was injected into the GC–MS. The GC–MS was from Agilent Technologies (Santa Clara, CA, USA). The oven was a model 7890A, with triple axis detector 5975C inert XL EI/CI MSD. The instrument was equipped with an SPB-1 column (30 m × 0.25 mm × 0.25 µm) from Supelco (Bellefonte, PA, USA).The inlet conditions were 250 °C with a He flow rate of 1 mL/min. The oven program was a ramp of 4 °C/min from 100 to 300 °C, followed by a 12 min hold at 310 °C. MS in the Electron Impact (EI) mode was used. The conditions were: mass range 34–720 amu, 22 sampling rate and electron multiplier 0 V relative. The peak areas were normalized by the sum of the peak areas for the palmitate and stearate. No adjustments were made for the difference in the response factors.

Some of the GC–MS fragments of the compounds are listed below:

Methyl 9-(5-pentyl-2-furyl) nonanoate:ret. time: 28.65 min.m/z(ab. %): 309(4), 308(21), 278(2), 277(9), 237(12), 179(13), 166(17), 165(100), 151(3), 108(11), 107(22), 95(42), 94(15), 81(16), 55(15), 43(20).

Methyl 8-(5-hexyl-2-furyl) octanoate:ret. time: 28.75 min.: m/z(ab. %): 309(4), 308(18), 277(9), 251(9), 237(1), 165(16), 152(17), 151(100), 107(19), 95(39), 94(16), 81(14), 55(13).

Ethyl 9-(5-pentyl-2-furyl) nonanoate: ret. time: 30.15 min.: m/z(ab. %): 323(5), 322(20), 277(16), 251(10), 179(14), 166(18), 165(100), 151(4), 108(11), 107(24), 95(39), 94(16), 81(16), 55(14), 43(19).

Ethyl 8-(5-hexyl-2-furyl) octanoate: ret. time: 30.24 min.: m/z(ab. %): 323(4), 322(17), 277(15), 165(18), 152(17), 151(100), 107(20), 95(37), 94(17), 81(14), 55(12).

Isopropyl 9-(5-pentyl-2-furyl) nonanoate: ret. time: 30.82 min.: m/z(ab. %): 336(12), 294(5), 293(25), 277(16), 207(10), 165(44), 107(14), 95(18), 44(51), 40(100).

Isopropyl 8-(5-hexyl-2-furyl) octanoate: ret. time: 30.94 min.: m/z(ab. %): 337(2), 336(17), 294(10), 293(41), 277(25), 207(11), 165(14), 152(13), 151(71), 107(20), 95(29), 94(15), 81(14), 55(14), 44(55), 40(100).

Benzyl 9-(5-pentyl-2-furyl) nonanoate: ret. time: 41.16 min.:m/z(ab. %): 385(4), 384(13), 294(19), 293(98), 165(43), 108(10), 107(20), 95(20), 91(100), 81(12), 55(12), 43(16).

Benzyl 8-(5-hexyl-2-furyl) octanoate: ret. time: 41.27 min.: m/z(ab. %):385(4), 384(13), 294(20), 293(97), 165(6), 151(47), 107(18), 95(20), 91(100), 81(11), 55(11).

2-Ethylhexyl 9-(5-pentyl-2-furyl)nonanoate: ret. time: 40.18 min.m/z(ab. %):407(9), 406(33), 294(38), 293(58), 277(37), 223(16), 179(18), 166(26), 165(100), 151(5), 108(12), 107(27), 95(32), 94(18), 81(16), 71(25), 57(38), 55(22), 43(30).

2-Ethylhexyl 8-(5-hexyl-2-furyl) octanoate: ret. time:40.30 min. m/z(ab. %):407(9), 406(30), 294(37), 293(55), 277(39), 165(20), 152(22), 151(100), 107(23), 95(30), 94(17), 81(14), 71(25), 57(37), 55(20), 43(20).

NMR

NMR spectra were obtained in CDCl3 on a Bruker Avance 500 NMR spectrometer (Billerica, MA, USA) operating at 500.11 MHz for 1H and 125.75 MHz for 13C, using a 5-mm BBO probe. Chemical shifts are reported in parts per million (ppm) from tetramethylsilane calculated from the lock signal. For some of the samples DEPT, COSY, HSQC, and HMBC correlation experiments were conducted to help with the assignments of the spectral peaks.

Results and Discussion

Identification

We attempted to synthesize bio-based lubricant additives following the procedure described in the literature [8]. When E2ES reacted with 2-ethylhexanol in the presence of Amberlyst 15 catalyst, it produced an interesting product distribution. Most interestingly, the product mixture also showed distinct NMR signals which could not be attributed to any of the groups formed by Schemes 1,2 and 3. It was determined that these signals were due to the presence of furan fatty acid esters (FFE) (Scheme 4). The NMR signals, listed in Scheme 4 and circled in Fig. 1, are in good agreement with the literature data [25]. The other NMR signals of FFE could not be unambiguously identified due to overlap with those from the other fatty acids in the mixture, such as palmitic acid alkyl ester.

Ring-opening, accompanied by intra- molecular ring opening in bis-epoxy systems [17–22]. The nucleophile (ROH) is water or acetic acid. Most of the authors report the formation of five-member rings; Morten et al. [23]. report conditions at which six-membered cycles are predominantly formed. In their work, ROH is an internal alcohol group

Furan fatty acid methyl esters. The top isomer also shows the characteristic MS fragmentation pattern; the bottom one also shows the labels for the characteristic atoms in the NMR spectra. 1H NMR: a δ = 2.54 ppm, triplet, J = 7.6 Hz; c δ = 5.81 ppm, singlet; 13C NMR: a δ = 28.3 ppm, b δ = 154.4-154.6 ppm, c: δ = 104.75-104.82 ppm

The GC retention times of the FFE were slightly higher than for the corresponding alkyl stearate; the triads of compounds: alkyl stearate, alkyl 9-(5-pentyl-2-furyl)nonanoate and alkyl 8-(5-hexyl-2-furyl) octanoate eluted very close to each other and in the order listed, but without overlap of their peaks. We did not find MS of FFE with other alkyl group but methyl. The MS of the methyl 8-(5-hexyl-2-furyl) octanoate and methyl 9-(5-pentyl-2-furyl) nonanoate are available in the literature [26, 27]. Our results were close to the MS spectra reported by White et al. [27]. Abbott and Gunstone [26] reported the same main fragments, but with differing abundances, putatively due to the variation in the parameters of the employed mass spectrometers. Our MS results are listed in the Methods section.

We did not test the reaction with Lewis catalyst, but we found a reference that boron trifluoride etherate in dioxane at room temperature overnight catalyzes the rearrangement of epoxidized methyl linoleate to several compounds, including furan fatty methyl esters (21 % yield) [26].

Kinetics and Mechanism of the Reaction

One hypothesis for the formation of the FFE involves the rearrangement of epoxidized linoleic esters (ELE) with a loss of water. The mechanism can be written in two steps. The first step is an acid-catalyzed rearrangement of one of the epoxide groups in ELE to a keto group. The second step is the rearrangement leading to the formation of the furan group (See Scheme 5). Both steps have literature precedent. Rios et al. [16] reported that epoxidized methyl oleate, when reacting with alcohol in presence of Amberlyst 15 catalyst, also yields keto fatty acids, due to rearrangement. The second step was reported by Foglia et al. [28].

If this is the correct mechanism for this reaction, we would expect to observe two characteristic pieces of evidence. First, Rios et al. [16] have reported that in their system, the yield of keto fatty acids, as a proportion of the products, increases with the increase in the reaction temperature. In other words, increasing the relative rate of step 1 means that the yield of the FFE should increase with the increase of temperature. Second, an induction period in the formation of the FFE should be expected, since they are secondary products only formed after the formation of one keto group.

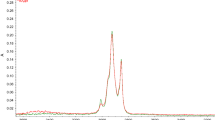

Figure 2 shows the disappearance of the ELE and the appearance of the FFE, as monitored by GC–MS, at two temperatures: 60 and 120 °C. The linear parts of the curves were used to estimate the apparent activation energies of the reactions. The disappearance of epoxidized methyl oleate, disappearance of epoxidized methyl linoleates and appearance of methyl furan fatty acids each had apparent activation energies of ~85 kJ/mol. We could not discern an effect of the temperature change on the proportion of epoxidized methyl linoleate that was transformed to FFE. This suggests that the main reactions of the bis-epoxy ring shared a common initial step, which was rate-determining. Because there was no induction period or lag in the formation of the FFE, it was either formed directly from the epoxidized methyl linoleate, or from an intermediate that reacted relatively fast to form FFE.On the basis of these observations, we offer another possible mechanism for the formation of FFE,which does not involve the formation of a keto group (Scheme 6).

Proposed possible alternative mechanism for the formation of furan fatty acids from bis-epoxy fatty acids, based on the current kinetics data. The beginning of this reaction is the rate-determining and is common with the other ring-opening reactions in the system. This leads to them having the same activation energy

The concentration profile of FFE showed that they decompose at higher reaction times. This decomposition is beyond the scope of this paper. It is a reasonable explanation, however, that the furan ring hydrolyzes to form 9,12 (10,13)-diketones in a reverse Paal-Knorr reaction (see Scheme 7). Keto groups were identified in the NMR spectra of the reaction mixture, giving evidence to this hypothesis, although we do not have enough definitive evidence to determine what proportion was formed directly from an epoxy to keto rearrangement, and what was accounted for by a furan to diketo reaction.

Scope of the Reaction

Smaller-scale experiments between EMS and other alcohols (ethanol, isopropanol and benzyl alcohol) in the presence of Amberlyst 15 catalyst also yielded FFE products. Judging from the GC peak areas, the yields were 0.9 % for benzyl alcohol, 7 % for isopropanol and 1.6 % for ethanol after 24 h at 60 °C. This can be compared to the maximum of 13 % FFE yield, observed for the reaction of E2ES with 2-ethylhexanol. Possible variables for future study in this reaction are polarity, solvent, scale, and excess of alcohol. An additional observation is that the benzyl alcohol noticeably swelled the catalyst, possibly reducing yield. Control experiments showed no change when EMS and the above alcohols were placed together without catalyst for 24 h at 60 °C.

The sulfuric acid also promoted the formation of FFE. When ethanol, EMS, and sulfuric acid were mixed together, the yields were 6.5 % at 120 °C, 6.1 % at 60 °C, and 9.1 % at room temperature. With sulfuric acid, both the reaction of the epoxide rings and the FFE yields were faster than with Amberlyst 15 catalyst. This is probably due to the higher effective amount of sulfate groups in the sulfuric acid catalyst.

In our study, we observed that transesterification occurred in parallel to the reaction of the epoxy ring, differing from some literature reports, where the epoxy rings react faster and the transesterification takes place only after their depletion [5, 14, 15]. However, in our study, the methyl ester groups are more reactive than the higher alcohol or glycerol ester group used by the other authors. In our case, it was even an advantage as it allowed the de-convolution of GC–MS fragmentation of several esters from the furan fatty acids.

In conclusion, we report that ring-opening of fatty acid materials containing the bis-epoxy group can lead to products that cannot be predicted by using epoxidized methyl oleate as a model system. We identified a product—furan fatty acid ester—that has not been reported before in the synthesis of biobased materials, perhaps because only the composition of the ring opened epoxidized methyl oleate products has been investigated in sufficient detail. For example, 13C NMR of the product by Lathi and Mattiasson [8], where they react epoxidized soybean oil with 2-ethylhexanol in the presence of Amberlyst 15 catalyst, has a peak at ~105 ppm, indicating the presence of furan fatty acids. Nevertheless, the authors did not comment on this peak, and their schemes suggest that only ring-opening reactions according Scheme 2 took place. Such lack of knowledge of the actual composition of biobased lubricants can lead to a hindrance in understanding the real structure–property relationships.

References

Gast LE, Croston CB, Schneider WJ, Teeter HM (1954) Synthetic lubricants from polyhydroxystearic acids. Ind Eng Chem 46(10):2205–2208

Dahlke B, Hellbardt S, Paetow M, Zech WH (1995) Polyhydroxy fatty acids and their derivatives from plant oils. J Am Oil Chem Soc 72(3):349–353

Hwang H-S, Erhan SZ (2001) Modification of epoxidized soybean oil for lubricant formulations with improved oxidative stability and low pour point. J Am Oil Chem Soc 78(12):1179–1184

Harry-O’kuru RE, Holser RA, Abbott TP, Weisleder D (2002) Synthesis and Characteristics of Polyhydroxy Triglycerides from Milkweed Oil. Ind Crops Prod 15(1):51–58

Hwang HS, Adhvaryu A, Erhan SZ (2003) Preparation and properties of lubricant basestocks from epoxidized soybean oil and 2-ethylhexanol. J Am Oil Chem Soc 80(8):811–815

Hoelderich WF, Rios LA, Weckes PP, Schuster H (2004) Investigations into the epoxidation and alcoholysis of oleochemicals for use as lubricants. J Synth Lubr 20(4):289–301

Hwang H-S, Erhan SZ (2006) Synthetic lubricant basestocks from epoxidized soybean oil and guerbet alcohols. Ind Crop Prod 23(13):311–317

Lathi PS, Mattiasson B (2007) Green approach for the preparation of biodegradable lubricant base stock from epoxidized vegetable oil. Appl Catal B: Environ 69(304):207–212

Harry-O’kuru RE, Biresa WG, Cermak SC, Gordon SH, Vermillion KE (2011) Investigation of some characteristics of polyhydroxy milkweed triglycerides and their acylated derivatives in relation to lubricity. J Agric Food Chem 59(9):4725–4735

GuoA ChoY, Petrovic ZS (2000) Structure and properties of halogenated and nonhalogenated soy-based polyols. J Polym Sci A Polym Chem 38(21):3900–3910

Zlatanic A, Lava C, Zhang W, Petrovic ZS (2004) Effect of structure on properties of polyols and polyurethanes based on different vegetable oils. J Polym Sci B Polym Phys 42(5):809–819

Petrovic ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155

Bailosky LC, Bender LM, Bode D, Choudhery RA, Craun GP, Gardner KJ, Michalski CR, Rademacher JT, Stella GJ, Telford DJ (2013) Synthesis of polyether polyols with epoxidized soybean oil. Prog Org Coatings 76(12):1712–1719

Moser BR, Erhan SZ (2006) Synthesis and evaluation of a series of α-hydroxy ethers derived from isopropyl oleate. J Am Oil Chem Soc 83(11):959–963

Moser BR, Erhan SZ (2007) Preparation and evaluation of a series of α-hydroxy ethers from 9,10-epoxystearates. Eur J Lipid Sci Technol 109(3):206–213

Rios LA, Weckes PP, Schuster H, Hoelderich WF (2005) Resin catalyzed alcoholysis of epoxidized fatty esters: Effect of the alcohol and the resin structures. Appl Catal A General 284(1–2):155–161

Weber N, Vosmann K, Fehling E, Mukherjee KD, Bergenthal D (1995) Analysis of hydroxylated fatty acids from plant oils. J Am Oil Chem Soc 72(3):361–368

Capon RJ, Barrow RA, Skene C, Rochfort S (1997) The biomimetic synthesis of marine epoxy lipids: bisepoxides to tetrahydrofurans. Tetrahedron Lett 38(43):7609–7612

Capon RJ, Barrow RA (1998) Acid-mediated conversion of methylene-interrupted bisepoxides to tetrahydrofurans: a biomimetic transformation. J Org Chem 63:75–83

Piazza GJ, Nuñez A, Foglia TA (2003) Hydrolysis of mono- and di-epoxyoctadecanoates by alumina. J Am Oil Chem Soc 80(9):901–904

Glueck SM, Fabian WM, Faber K, Mayer SF (2004) Biocatalytic asymmetric rearrangement of a methylene-interrupted bis-epoxide: simultaneous control of four asymmetric centers through a biomimetic reaction cascade. Chem Eur J 10(14):3467–3478

Kodali DR, Stolp LJ, Bhattacharya M (2013) Bio-renewable plasticizers derived from vegetable oil. US Patent App 2013/0228097 A1

Morten CJ, Byers JA, Jamison TF (2011) Evidence that epoxide-opening cascades promoted by water are stepwise and become faster and more selective after the first cyclization. J Am Chem Soc 133(6):1902–1908

Rios LA, Llano BA, Hoelderich WF (2012) Fatty ketones from the rearrangement of epoxidized vegetable oils. Appl Catal A General 445–446:346–350

Lie Ken Jie MSF, Bus J, Groenewegen A, Sies I (1986) Fatty acids, Part 28. 1H-and 13C-nuclear magnetic resonance studies of 2,5-disubstituted C18furanoid ester isomers. J Chem Soc Perkin Trans 2(8):1275–1278

Abbot GG, Gunstone FD (1971) Fatty acids, Part 31. The formation of some substituted vic-epoxyoctadecanoates and their conversion to 1,4-epoxides and other compounds. Chem Phys Lipids 7(4):290–302

White DC, Geyer R, Aaron D, Peacock AD, David B, Hedrick DB, Stephen S, Koenigsberg SS, Youlboong Sung Y, He J, Loffler FE (2005) Phospholipid furan fatty acids and ubiquinone-8: Lipid biomarkers that may protect Dehalococcoides strains from free radicals. Appl Env Microbiol 71(12):8426–8433

Foglia TA, Sonnet PE, Nuñez A, Dudley RL (1998) Selective oxidations of methyl ricinoleate: Diastereo selective epoxidation with titaniumIV catalysts. J Am Oil Chem Soc 75:601–607

Acknowledgments

The authors acknowledge the help of Benjamin Lowery with the GC–MS. This work was a part of the in-house research of the Agricultural Research Service of the United States Department of Agriculture.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

About this article

Cite this article

Bantchev, G.B., Doll, K.M., Biresaw, G. et al. Formation of Furan Fatty Alkyl Esters from their Bis-Epoxide Fatty Esters. J Am Oil Chem Soc 91, 2117–2123 (2014). https://doi.org/10.1007/s11746-014-2560-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-014-2560-9