Abstract

Mixtures of a cross-linked polyacrylic acid (Carbopol® 940) and two types of surfactants, namely anionic sodium dodecylsulfate (SDS) and nonionic Tween® 80, were investigated by viscometry, conductometry, tensiometry, spectrophotometry, fluorimetry and scanning electron microscopy (SEM). The addition of nonionic surfactant decreased the reduced viscosity and the transmittance of the Carbopol® polymer aqueous solutions. Furthermore, the interaction between Carbopol® 940 and SDS was characterized by two significant concentration values: the critical aggregation concentration of SDS was particularly independent of Carbopol® polymer concentration while the polymer saturation point of both surfactants increased with the increase in polymer content. The values of critical aggregation concentration and polymer saturation point obtained using various techniques confirmed the occurrence of Carbopol® polymer–surfactant associations. The effect of different SDS and Tween® 80 concentrations on the conformation of Carbopol® 940 in aqueous solution could be explained through hydrophobic association between surfactant micelles and Carbopol® polymer tails and through hydrogen bonding in the case of Tween® 80. Additionally, the surfactant-induced structural changes were confirmed in Carbopol® 940–SDS and Carbopol® 940–Tween® 80 aqueous solutions by SEM measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymers and surfactants represent major components of pharmaceutical formulations, personal care products, food products, etc. Besides other colloidal systems, polymers and surfactants are combined together in emulsions and suspensions. As a result of their widespread use, the interactions between polymer and surfactant are of huge scientific and commercial interest [1–4]. The development of new drugs and improvement of food formulations are highly dependent on the synergistic or antagonistic interactions in mixed surfactant–polymer solutions [5].

The addition of even a small amount of surfactant could change the physicochemical properties of polymer dispersions in terms of viscosity, solubilisation capacity, emulsification properties and stability of the system and, consequently, enlarge the possibilities for their application [6]. Depending on the molecular characteristics of a polymer and surfactant, interactions that might occur are mainly electrostatic and hydrophobic and could be detected by various techniques such as adsorption, fluorescence, dye solubilisation, surface tension, conductivity, etc. [7–11].

Polymers of cross-linked acrylic acid with polyalkenyl ethers or divinyl glycol, commercially known as Carbopol® polymer, are the major components of drug delivery systems for ocular, nasal, rectal, vaginal, buccal and transdermic applications. Depending on the molecular weight and manufacturing conditions, various grades of Carbopol® polymer are available and demonstrate different rheological properties and viscosity values, related to the particle size, molecular weight between cross-links, distribution of molecular cross-links and the fraction of the free chain ends [12]. The widespread use of this polymer is a result of its good rheological properties at low concentration, compatibility with many active ingredients, low toxicity profile, it is generally well tolerated and has the possibility to remain on the application area and resist physiological stress (caused by blinking, mucociliary movement, etc.) [13, 14]. As a result of its high molecular weight, it cannot penetrate into the skin and presents a good alternative to oil-based ointment formulations [15]. Similarly to other polymers, Carbopol® polymer enhances the stability of dispersed systems mainly by modifying the viscosity of the continuous phase. Therefore, in an emulsion system, Carbopol® polymer increases the aqueous phase viscosity and slows down the movement of surfactant-coated droplets. Compared with other Carbopol® polymer types, Carbopol® 940 has a high viscosity with an extremely short flow property, excellent appearance, clarity and good stability under various storage conditions [16]. Hence, this type of Carbopol® polymer is widely used as a gelling agent in topical commercial products, especially in those intended for ocular application.

Despite many publications that investigate interactions between neutral polymers and their complexes with ionic surfactants, especially interactions in aqueous solution of hydrophobically modified cellulose and sodium dodecylsulfate (SDS) [1, 6, 17] as well as polyethylene oxide (PEO) and SDS [2], only few studies have determined the interaction of water-soluble polyacrylic acid with surfactants. Considering the fact that Barreiro-Iglesisas et al. [18, 19] pointed out the physicochemical changes of Carbopol® 934 in the presence of different types of surfactants, the main purpose of this research was to get a deeper insight into the possible mechanism of interactions between widely used polymers, such as Carbopol® 940, and different surface-active molecules. Tween® 80 and SDS were used as nonionic and anionic surfactants, respectively. Tween® 80 is an ester of oleic acid and polyethoxylated sorbitan with significant application in the pharmaceutical and food industries owing to its appropriate stability and nontoxicity [20]. SDS is a low molecular weight surfactant, frequently applied in many cosmetic and pharmaceutical formulations [21]. The chemical structures of the studied compounds are presented in Fig. 1.

Therefore, in this research the interactions between Carbopol® 940 and ionic and nonionic surfactants were investigated using a combination of different techniques including viscometry, conductometry, tensiometry, spectrophotometry and fluorimetry. The microstructures of aqueous solutions of pure Carbopol® 940 and with the addition of surfactants were analysed.

Materials and Methods

Materials

Polyacrylic acid (Carbopol® 940) was provided by Lubrizol Advanced Materials, USA. Polyoxyethylene (20) sorbitan monoleate (Tween® 80) and sodium dodecylsulfate (SDS) were obtained from J.T. Baker (Holland), while pyrene was purchased from Sigma Aldrich (USA).

Preparation of Solutions

Carbopol® 940 stock solution was prepared by gradually dissolving the required mass of polymer in doubly distilled water under mild stirring (300 rpm) at 25 °C. After 1 h of stirring (500 rpm), the system was left to swell at room temperature for 24 h before characterization. According to the Lubrizol specification, unneutralized Carbopol® polymers have a pH in the range 2.5–3.5 [22] and pK a around 6.0 ± 0.5 [23]. The pH value of the prepared Carbopol® 940 solutions was little bit higher (around pH 4). Acidic carboxyl groups of Carbopol® polymers partially dissociate in water which results in a flexible coil structure [22]. Surfactant stock solutions were prepared by dissolving accurately weighed quantities of Tween® 80 or SDS in doubly distilled water. Binary mixtures of polymer and surfactant were prepared by mixing required volumes of stock solutions at the appropriate ratio and diluting with water to obtain a constant polymer concentration with a wide range of surfactant concentrations. Mixtures were stored at room temperature for at least 24 h prior to further analysis.

Methods

The critical micelle concentration (CMC) of surfactants and their interactions with Carbopol® polymer were studied by comparing the six techniques mentioned below.

Viscosity Measurements

The viscosity of aqueous dispersions was measured by an Ubbelohde capillary viscometer (SCOTT, Germany) immersed in a water bath at 25 ± 0.1 °C. The eflux time for doubly distilled water was 284.73 s at 25 °C. Three measurements for each solution were taken and average values were calculated.

Conductivity Measurements

Conductivity measurements were carried out in aqueous solutions of pure SDS or its binary mixture with Carbopol® polymer. Analyses were done at 25 °C by adding portions (0.5 mL) of 25 mM SDS solution in a glass cell with 40 mL doubly distilled water or Carbopol® polymers solution using a Consort C860 conductometer (Belgium) with a cell constant of 1 cm−1, which is appropriate for samples having a conductivity range 0.01–2 mS/cm [24]. The cell, containing solutions, was immersed in a water bath, controlling the temperature variation at ±0.1 °C. After adding each portion of the surfactant, the solution was gently stirred (300 rpm) until a steady value of conductivity was achieved. The specific conductance of doubly distilled water was between 2 and 3 µS/cm at 25 °C.

Surface Tension Measurements

Surface tension measurements were carried out in aqueous solutions of Tween® 80 and SDS as well as in polymer–surfactant mixture, in order to determine the individual CMC of surfactants and to examine the occurrence of interaction. All measurements were done on a digital Krüss Easy Dyne tensiometer (Germany) using the du Noüy ring method. The correction of surface tension values was done with the method of Harkins and Jordan, which is integrated into the electronic Krüss tensiometer. Prior to each measurement the ring was immersed in the liquid and the surface was left for 10 min to equilibrate. The reported values of the surface tension were the average values of five measurements at constant temperature of 25 °C ± 0.1. Surface tension of the water used for the preparation of solutions was 71.6 mN/m.

Spectrofluorimetric Measurements

The fluorescence experiments were performed on an Agilent Cary Eclipse fluorescence spectrophotometer (USA) equipped with a Peltier thermostated cell holder. Pyrene (solution concentration 0.6 µM) was used as a probe molecule. The excitation wavelength was 334 nm. The intensity ratio of the first (I 1, 373 nm) and the third (I 3, 384 nm) vibrational band of pyrene emission spectrum was monitored at 25 °C ± 0.1.

Spectrophotometric Measurements

The optical transmittance measurements of the polymer–surfactant mixtures were done using a UV/Vis Pye Unicam spectrophotometer (UK). The absorption spectra (200–850 nm) confirmed no UV-absorbing moieties. The transmittance was measured at 450 nm in a 1-cm-path-length cell at room temperature using doubly distilled water as a reference.

Microstructure

A drop of each sample was spin-coated on an aluminium stub and frozen with liquid nitrogen. Afterwards, the samples were dried and sputter-coated with gold in vacuum by a BAL-TEC-SCD 005 instrument (180 s/30 mA/50 mm distance) (BAL-TEC AG, Principality of Liechtenstein). Scanning electron microscopy (SEM) images were taken with the Jeol JSM 6460LV scanning electron microscope (Japan) with a 25-kV acceleration voltage.

Results and Discussion

Viscosity measurements were performed in order to obtain information about the conformation changes of Carbopol® polymer in dilute aqueous solution, in the presence of anionic or nonionic surfactant. The results were expressed in the terms of relative η rel and reduced viscosity η red:

where c is the concentration of the solution and

where η sp is the specific viscosity, while t and t 0 are the flow times of the solution and pure solvent, respectively.

Intrinsic viscosity is calculated as the limiting value of the reduced viscosity at zero concentration from the Huggins equation:

where [η] is the intrinsic viscosity, k is the Huggins constant and c is the concentration of the polymer. The intrinsic viscosity of pure Carbopol® 940 in water was calculated to be 6.24 (dL/g). This value is influenced by hydrodynamic volume, size and conformation of a single Carbopol® 940 polymer chain [25]. Appropriate linearity of the Huggins plot, which is a characteristic of neutral polymers, indicated that the dissociation of carboxyl groups of Carbopol® polymer chain was negligible in diluted solution at a certain pH value (pH ca. 4).

CMC is the minimum concentration of surfactant above which the micelles are formed, causing physicochemical changes of the system [21, 26]. The influence of surfactants and polymer concentration on the relative viscosity of the mixtures is presented in Fig. 2. For higher concentrations of polymer, minimums were noticed for both of the surfactants used. For concentrations above the minimum, relative viscosity values changed differently for SDS and Tween® 80 as seen from the different shape of the curves presented in Fig. 2a (SDS) and Fig. 2b (Tween® 80). The minimum in relative viscosity value occurred around the CMC for SDS. Above the CMC of SDS (around 0.2 g/dL), as micelles were formed in the mixture, the relative viscosity of the mixture increased up to an SDS concentration of 0.4 g/dL. Above this concentration repulsive forces between micelles and polymer associates dominate and cause polymer shrinkage which resulted in a constant or slight decrease in relative viscosity for the highest polymer concentration (0.06 % w/v).

On the contrary, above the concentration of Tween® 80 at which the minimum in relative viscosity occurs, relative viscosity constantly increases with increasing Tween® 80 concentration, at all polymer concentrations. The CMC of Tween® 80 is very low and could not be detected precisely on the presented curve. The minimum in relative viscosity value probably occurred around the polymer saturation point for Tween® 80. The interactions for nonionic surfactant and polymer exist, but are only visible for lower concentrations of Tween® 80. In the case of relative viscosity, calculated from the efflux time of the measured solution, the increase in concentration of both polymer and Tween® 80 resulted in increased relative viscosity values. Concentration increase effects dominates over the interactions present.

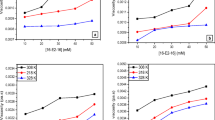

In order to determine the existence of interactions, the concentration effect was eliminated by calculating reduced viscosity. The reduced viscosity changes for mixtures of Carbopol 940®–SDS and Carbopol 940®–Tween 80 vs concentration of Carbopol® polymer are presented in Fig. 3. The curve shapes indicate that the interactions in the system are governed by the concentrations of surfactant. In the presence of anionic surfactant, SDS, at concentrations lower than the CMC, reduced viscosity values decreased as the concentration of Carbopol® 940 increased (Fig. 3a). Probably, the reduced viscosity decrease is the result of the smaller hydrodynamic volume of Carbopol® polymer due to the presence of SDS hydrophobic groups. As a result of interactions between hydrophobic SDS chains and Carbopol® molecules, curling and shrinkage of the macromolecule occurred and resulted in lower values of reduced viscosity compared to those of pure macromolecule at the same concentration. In the presence of SDS at concentrations above the CMC, the increase of Carbopol® polymer concentration caused an increase in the reduced viscosity. The difference in behaviour of the mixtures below and above the CMC is influenced by the presence of SDS micelles. Likewise, higher charge density of the Carbopol® 940–SDS complex and the presence of micelles in the solution caused electrostatic repulsion which expanded the polymer and increased the reduced viscosity.

The impact of different surfactant concentrations on reduced viscosity of a SDS–Carbopol® 940 and b Tween® 80––Carbopol® 940 mixtures: a squares no SDS, circles 0.15 % SDS, triangles 0.3 % SDS, inverted triangles 0.7 % SDS; b squares no Tween® 80, circles 0.05 % Tween® 80, triangles 0.5 % Tween® 80, inverted triangles 0.8 % Tween® 80

On the contrary, interactions with nonionic surfactant were of lower intensity (Fig. 3b). At the lower concentration of Carbopol® 940, changes in reduced viscosity were clearly noticed. Interactions between the polymer and surfactant at low polymer concentrations caused uncurling of the Carbopol® polymer chain as a result of interactions with the oxyethylene groups of Tween® 80. Since these interactions result from rather weak hydrogen bridges, at higher concentrations of polymer (above 0.06 % w/v) these are negligible and intramolecular bonds of Carbopol® 940 molecules dominate. That is the reason why the changes in the reduced viscosity were negligible.

The electrical conductivity is a widely used technique for the investigation of phenomena in systems containing ionic surfactants [27–29]. Accordingly, conductivity measurements were performed to determine the CMC of anionic surfactant and, moreover, to provide valuable information about the association between SDS and Carbopol® 940. The addition of anionic surfactant into the water caused a linear increase in the specific conductance until the CMC was reached. After reaching the CMC, SDS was present in the form of micelles and, therefore, further addition of SDS led to less progressive increase in conductance (the slope of the curve was lower). The break in the linear conductivity behaviour, which represents the CMC value, was observed at 8.2 mM for SDS at 25 °C. The measured CMC was in agreement with previously published data [28–30].

The interactions between polymer and surfactant could be characterized by two significant concentrations. The critical aggregation concentration (CAC) represents the minimum concentration of a surfactant required for the beginning of the interaction with polymer. At the polymer saturation point (PSP) polymer chains are saturated with surfactant [29, 31]. In order to determine CAC and PSP values at different polymer concentrations, the following Carbopol® polymer concentrations were titrated with SDS: 0.01, 0.02, 0.03, 0.04, 0.05 and 0.06 % (w/v). In the presence of Carbopol® polymer, two break points could be observed from the titration curve (Fig. 4). Firstly, addition of SDS caused a linear increase in the conductivity. After reaching the CAC, the interaction between Carbopol® polymer and SDS led to a decrease in the slope of the conductivity curve. The nonlinear conductivity profile was a result of the formation of polymer-surfactant aggregates and self-associaton process. Further addition of SDS caused the saturation of Carbopol® 940 and the appearance of the second break point, which represents the PSP. Above the PSP, the dependence of specific conductivity on surfactant concentration was linear again. The association of Carbopol® 940 with SDS started at the concentration of surfactant below the CMC, since it is a more favourable process than micelle formation. This is in good accordance with the CAC values published for other polymer–ionic surfactant systems [26, 29]. It was found that the CAC value remained approximately constant (2.10 mM) and independent of Carbopol® polymer concentration. Similar results for CAC and PSP dependence on polymer concentration were reported for hydroxypropylmethyl cellulose–SDS systems [6, 29]. On the contrary, while PSP increased linearly with increasing concentration of cellulose, an exponential increase in PSP was noticed in the case of Carbopol® 940 (Fig. 5).

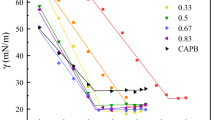

Since the tensiometric technique could be applied to both ionic and nonionic surfactants, this method was also used for the examination of surfactant micellarization and the possible Carbopol® 940–surfactant interaction (Figs. 6, 7). Below the CMC, the surface tension of the surfactant solution decreased rapidly with increasing surfactant concentration. After reaching the CMC value, further addition of surfactant resulted in new micelle formation, while the free surfactant concentration remained almost unchanged, which resulted in surface tension that remained constant. The CMC of Tween® 80 was determined by measuring the surface tension as a function of concentration and the obtained value was 0.013 mM (Fig. 7). This result is in good agreement with other reported values obtained by surface tension [8, 21, 32, 33], although Barreiro-Iglesisas and co-authors [18] reported a value more than ten times higher (0.153 mM).

On the other hand, some surface-active impurities could make the surface tension unchanged even below the CMC [34]. Moreover, the presence of impurities could reflect on the occurrence of a minimum of a surface tension around the CMC, which makes its determination difficult. As it could be seen in Fig. 6, the surface tension of SDS firstly decreased, then reached minimum and, after slight increment, finally stayed relatively unchanged. The minimum in the surface tension curve could be explained by the presence of impurities, such as dodecanol, which have higher affinity for the surface in comparison to SDS [35]. Auto-hydrolysis of SDS to dodecanol could not be prevented and even if it is present in a very low concentration, dodecanol preferentially adsorbs at the surface and decreases the surface tension of the solution at concentrations below the CMC. When the concentration of surfactant was high enough to form micelles, dodecanol became solubilised and desorbed from the surface, which resulted in a slight increase in the surface tension. Since this increase in surface tension obtained for SDS containing impurities corresponds to that of theoretically ideally pure SDS, it could be designated as the CMC of SDS. The CMC determined by tensiometric measurements (7.98 mM) was a little lower than that obtained by conductometric titration. Previously, Katona et al. [35] reported the same value using this technique.

In the case of pure Carbopol® 940 aqueous solutions, the increase in concentration from 0.01 to 0.06 % (w/v) led to a slight decrease in the surface tension from 70.9 to 65 mN/m. This is because Carbopol® 940 possesses certain surface activity due to the presence of hydrophobic parts in the macromolecule. The surface tension of polymer–surfactant mixtures was measured at constant polymer concentration (0.01, 0.03, 0.06 % w/v) and the obtained curves showed a similar trend. In the presence of Carbopol® 940, the addition of SDS led to a decrease in the surface tension. Firstly, addition of SDS to the Carbopol® 940 aqueous solution caused a decrease in the surface tension having the same tendency as for the pure surfactant solution. After reaching the CAC, the surface tension strongly decreased with increasing surfactant concentration, as a result of Carbopol® 940–SDS complex formation (Fig. 6). Finally, after saturation of polymer chains with SDS molecules, further addition of SDS caused no variation in the surface tension compared to the pure surfactant solution. As a result of the absorption of polymer and surfactant molecules on the surface, the values of surface tension of Carbopol® 940–SDS mixtures were lower than those of the pure surfactant solution. The CAC and PSP values obtained by tensiometry were in good agreement with the results obtained using conductivity measurements.

However, the presence of Carbopol® 940 increased the surface tension of Tween® 80 compared to the pure surfactant solution. This phenomenon usually implies the presence of a weak interaction between polymer and nonionic surfactant [17]. The difference in the shape of curves with and without constant polymer concentration could be ascribed to Carbopol® 940–Tween 80® associations (Fig. 7). The CAC values of Carbopol® 940–Tween 80® mixtures could not be precisely determined because of the low CMC of Tween® 80 (0.013 mM). Similar to SDS, PSP values for Tween® 80 increased with Carbopol® polymer concentrations (Table 1).

The fluorescence probe technique has proven to be a successful tool for studying micelles, mixed-surfactant systems as well as polymer–surfactant interactions [36–40]. The aggregation behaviour of SDS and Tween® 80 in aqueous solution as well as in the presence of Carbopol® 940 was analysed using pyrene as a hydrophobic probe. Pyrene is highly sensitive to changes in the polarity and could be successfully used to monitor the micropolarity in polymer–surfactant mixtures. In order to analyse this phenomenon, experiments were carried out at constant pyrene concentration (0.6 µM), with no disrupting effects, as suggested in previously published papers [41, 42]. The differences in the ratio of the intensities of the first to third peak of the probe as a function of surfactant concentration was used to interpret the behaviour of surfactants and polymer solutions. If micelles or hydrophobic regions are formed in water solution, molecules of pyrene will have the tendency to penetrate into them, which will result in the decrease of the I 1/I 3 ratio.

As it could be seen in Fig. 8, there is a clear difference between nonionic and ionic surfactant behaviour. Addition of Tween® 80 caused a sharp decrease in I 1/I 3 ratio, while in the case of SDS slight changes in I 1/I 3 ratio were observed, followed by an abrupt decrease as a consequence of the beginning of the surfactant self-assembly process. It could be assumed that pyrene has the tendency to associate with some kind of premicellar aggregates of Tween® 80. Further surfactant addition, above the CMC, did not influence the value of the I 1/I 3 ratio, which was constant owing to the incorporation of pyrene molecules into the hydrophobic region of the micelles. Accordingly, the CMC of pure anionic and nonionic surfactant was calculated from the interception of the rapidly varying and constant part of the curve. The obtained CMC values of Tween® 80 and SDS were 0.018 and 7.21 mM, respectively. These concentrations were in good agreement with the previously published data obtained using the same method [36, 43]. From Fig. 8b, it is evident that there are more hydrophobic regions in the case of sodium dodecyl chain compared to Tween® 80, which indicates that the micelles of SDS are more compact having negligible amounts of water.

Pyrene fluorescence intensity was measured in a series of solutions of different Carbopol® 940 concentration (0.01, 0.03, 0.06 % w/v) as a function of total surfactant concentration. In the case of Tween® 80, the addition of surfactant slightly increased the hydrophobicity of the system. Higher concentration of polymer (0.06 %) increased the hydrophobicity of the system by introducing larger amounts of hydrophobic groups into the Tween® 80 solution at lower concentration (Fig. 9). The constant value of I 1/I 3 ratio, observed below the CMC of pure Tween® 80, confirmed the occurrence of Carbopol® 940–Tween® 80 associations. The presence of hydrophobic parts in the Carbopol® 940 chains together with the formation of polymer–surfactant aggregates increased the hydrophobicity of the system.

According to results presented in Fig. 10, the addition of SDS into the Carbopol® polymer solutions caused noticeable changes in the polarity of the microenvironment. The I 1/I 3 values were significantly different from those of pure SDS, even when the polymer concentration was 0.01 % (data not presented), indicating the formation of aggregates. At constant polymer concentration, there was a gradual decrease in I 1/I 3 value of SDS–Carbopol® 940 mixtures at low SDS concentration. In the presence of Carbopol® 940, SDS began to form aggregates below the CMC (7.21 mM) which resulted in a less polar microenvironment around pyrene. A comparison with tensimoteric results revealed that polymer started to form aggregates via hydrophobic chains at low surfactant concentration which influenced the surface tension decrease. With the increase of polymer concentration, hydrophobic aggregates were formed easily and at lower SDS concentrations.

Although during the preparation of samples only Carbopol® 940–Tween® 80 mixtures expressed visually noticeable turbidity, transmittance tests were also carried out for various SDS concentrations. Mixtures of Carbopol® 940–SDS showed a slight decrease in transmittance above the CMC. Above PSP values, the polymer chain was saturated with SDS and further addition of surfactant caused the electrostatic repulsion of the Carbopol® 940–SDS complex which led to compaction of the polymer. This resulted in lower transmittance of the system.

On the contrary, the progressive decrease in the transmittance with the addition of nonionic surfactant was observed (Fig. 11). The percentage of transmittance was also influenced by the polymer concentration and it decreased with increasing polymer concentration. The variation of transmittance at 0.5 mM of Tween® 80 suggested the appearance of aggregates or coacervates which modified the optical properties of the system. Probably, intrapolymeric interactions were favoured by Tween® 80 binding which resulted in polymer shrinkage. The observed decrement in the transmittance was in agreement with the previously observed decrease in viscosity.

The studies of transmittance and pyrene fluorescence emission were done to gain additional insight into the Carbopol® 940–surfactant associations. However, the SEM measurements were performed in order to observe the microscopic differences between pure Carbopol® 940 and that with the addition of surfactants.

The SEM analysis of untreated and neutralized Carbopol® 940 confirmed the conformational changes of the polymer with the addition of sodium hydroxide. Unneutralized polymer was in a coiled form while the addition of base led to chain uncoiling toward a more extended structure as a result of the presence of repulsive forces. The effect of SDS and Tween® 80, below and above the CMC, on the Carbopol® polymer structure was also examined. In Carbopol® 940–surfactant mixtures, different structural changes occurred compared to the pure polymer. Figure 12 reveals Carbopol® 940 associations with anionic and nonionic surfactant as a function of SDS/Tween® 80 concentration. Additionally, the surfactant-induced changes in the polymer conformation at the microstructural level confirmed previously observed interactions determined by different analytical techniques.

SEM micrographs of freeze-dried aqueous solution of 0.06 % Carbopol® 940 with the addition of a 0 % NaOH, magnification ×10,000, b 0 % NaOH, magnification ×20,000, c 0.15 % NaOH, magnification ×5,000, d 6 mM SDS, magnification ×10,000, e 12 mM SDS, magnification ×10,000, f 12 mM SDS, magnification ×20,000, g 0.008 mM Tween® 80, magnification ×10,000, h 0.03 mM Tween® 80, magnification ×5,000, i 0.03 mM Tween® 80, magnification ×20,000

Conclusions

In this study, the interactions between Carbopol® 940 and two types of surfactants, SDS and Tween® 80, in aqueous solution were investigated using six different experimental methods. The relative and reduced viscosities of Carbopol® 940 in the presence of SDS indicate formation of mixed micelles mainly through hydrophobic interaction. Although the interactions between polymer and nonionic surfactant are usually weak, at lower concentrations of Carbopol® 940 changes in reduced viscosity were clearly noticed. Furthermore, the CMC of anionic (SDS) and nonionic (Tween® 80) surfactants was determined and the applied techniques provided comparable results. The values of CAC and PSP, obtained using various techniques, confirmed the assumption about the occurrence of associations between Carbopol® 940 and surfactants. The CAC of SDS was particularly independent of Carbopol® polymer concentration, while PSP exponentially increased with polymer concentration, as revealed by conductivity measurements. Additionally, the PSP values of Tween® 80 increased with the increase in polymer content. The obtained results concerning surfactant-induced conformational changes of Carbopol® 940 in the aqueous solution were confirmed at the microscopic level by SEM micrographs.

References

Dal-Bó AG, Laus R, Felippe AC, Zanette D, Minatti E (2011) Association of anionic surfactant mixed micelles with hydrophobically modified ethyl(hydroxyethyl) cellulose. Colloids Surf A 380:100–106. doi:10.1016/j.colsurfa.2011.02.028

Zanette D, Soldi V, Romani AP, Gehlen MH (2002) The role of the carboxylate head group in the interaction of sodium dodecanoate with poly(ethylene oxide) investigated by electrical conductivity, viscosity, and aggregation number measurements. J Colloid Interface Sci 246:387–392. doi:10.1006/jcis.2001.8088

Bakshi MS, Kaur R, Kaur I, Mahajan RK, Sehgal P, Doe H (2003) Unlike surfactant–polymer interactions of sodium dodecyl sulfate and sodium dodecylbenzene sulfonate with water-soluble polymers. Colloid Polym Sci 281:716–726. doi:10.1007/s00396-002-0822-9

Krstonošić V, Dokić L, Dokić P, Dapčević T (2009) Effects of xanthan gum on physicochemical properties and stability of corn oil-in-water emulsions stabilized by polyoxyethylene (20) sorbitan monooleate. Food Hydrocolloid 23:2212–2218. doi:10.1016/j.foodhyd.2009.05.003

Somasundaran P (2002) Simple colloids in simple environments explored in the past, complex nanoids in dynamic systems to be conquered next: some enigmas, challenges, and strategies. J Colloid Interface Sci 256:3–15. doi:10.1006/jcis.2002.8597

Sovilj VJ, Petrović LB (2006) Influence of hydroxypropylmethyl cellulose-sodium dodecylsulfate interaction on the solution conductivity and viscosity and emulsion stability. Carbohydr Polym 64:41–49. doi:10.1016/j.carbpol.2005.10.030

Thummar AD, Sastry NV, Verma G, Hassan PA (2011) Aqueous block copolymer-surfactant mixtures-surface tension, DLS and viscosity measurements and their utility in solubilization of hydrophobic drug and its controlled release. Colloids Surf A 386:54–64. doi:10.1016/j.colsurfa.2011.06.027

Sovilj V, Milanovic J, Petrovic L (2013) Viscosimetric and tensiometric investigations of interactions between gelatin and surface active molecules of various structures. Food Hydrocolloid 32:20–27. doi:10.1016/j.foodhyd.2012.12.003

Craig DQM, Tamburic S, Buckton G, Newton JM (1994) An investigation into the structure and properties of Carbopol® 934 gels using dielectric spectroscopy and oscillatory rheometry. J Control Release 30:213–223. doi:10.1016/0168-3659(94)90027-2

Manglik RM, Wasekar VM, Zhang J (2001) Dynamic and equilibrium surface tension of aqueous surfactant and polymeric solutions. Exp Therm Fluid Sci 25:55–64. doi:10.1016/S0894-1777(01)00060-7

Taylor DJF, Thomas RK, Penfold J (2007) Polymer/surfactant interactions at the air/water interface. Adv Colloid Interface Sci 132:69–110. doi:10.1016/j.cis.2007.01.002

Lubrizol Advanced Materials (2008) TDS-222: molecular weight of Carbopol® and Pemulen™ polymers. Lubrizol, Cleveland

Barreiro-Iglesisas R, Alvarez-Lorenzo C, Concheiro A (2001) Incorporation of small quantities of surfactants as a way to improve the rheological and diffusional behavior of carbopol gels. J Control Release 77:59–75. doi:10.1016/S0168-3659(01)00458-8

Das B, Nayak AK, Nanda U (2013) Topical gels of lidocaine HCl using cashew gum and Carbopol 940: preparation and in vitro skin permeation. Int J Bio Macromol 62:514–517. doi:10.1016/j.ijbiomac.2013.09.049

Liu W, Hu M, Liu W, Xue C, Xu H, Yang X (2008) Investigation of the carbopol gel of solid lipid nanoparticles for the transdermal iontophoretic delivery of triamcinolone acetonide acetate. Int J Pharm 364:135–141. doi:10.1016/j.ijpharm.2008.08.013

Dumitriu S (2002) Polymeric biomaterials, revised and expanded. Dekker, New York

Hansson P, Lindman B (1996) Surfactant-polymer interactions. Curr Opin Colloid Interface Sci 1:604–613. doi:10.1016/S1359-0294(96)80098-7

Barreiro-Iglesisas R, Alvarez-Lorenzo C, Concheiro A (2003) Poly(acrylic acid) microgels (Carbopol® 934)/surfactant interactions in aqueous media Part I: nonionic surfactants. Int J Pharm 258:165–177. doi:10.1016/S0378-5173(03)00181-9

Barreiro-Iglesisas R, Alvarez-Lorenzo C, Concheiro A (2003) Poly(acrylic acid) microgels (Carbopol® 934)/surfactant interactions in aqueous media Part II: ionic surfactants. Int J Pharm 258:179–191. doi:10.1016/S0378-5173(03)00182-0

Liu T, Guo R (2007) Investigation of PEG 6000/Tween 80/Span 80/H2O niosome microstructure. Colloid Polym Sci 285:711–713. doi:10.1007/s00396-006-1627-z

Ćirin DM, Poša MM, Krstonišić VS, Milanović ML (2012) Conductometric study of sodium dodecyl sulfate-nonionic surfactant (Triton X-100, Tween 20, Tween 60, Tween 80 or Tween 85) mixed micelles in aqueous solution. Chem Ind 66:21–28. doi:10.2298/HEMIND110612059C

Lubrizol Advanced Materials (2009) TDS-237: neutralizing Carbopol® and Pemulen™ polymers in aqueous and hydroalcoholic systems. Lubrizol, Cleveland

Lubrizol Advanced Materials (2013) LSP-PS-PHPROP-BRC: pharmaceutical polymers typical properties and specifications. Lubrizol, Cleveland

Consort bvba. Conductivity cell instruction guide. Turnhout, Belgium

Genest S, Schwarz S, Petzold-Welcke K, Heinze T, Voit B (2013) Characterization of highly substituted, cationic amphiphilic starch derivatives: dynamic surface tension and intrinsic viscosity. Starch 65:999–1010. doi:10.1002/star.201200295

Krstonošić V, Dokić L, Milanović J (2011) Micellar properties of OSA starch and interaction with xantan gum in aqueous solution. Food Hydrocolloid 25:361–367. doi:10.1016/j.foodhyd.2010.06.014

Sovilj VJ, Petrović LB (2005) Influence of molecular characteristics of nonionic cellulose ethers on their interaction with ionic surfactant investigated by conductometry. Colloid Polym Sci 284:334–339. doi:10.1007/s00396-005-1376-4

Felippe AC, Schweitzer B, Dal-Bó AG, Eising R, Minatti E, Zanette D (2007) Self-association of sodium cholate with poly(ethylene oxide) cooperatively induced by sodium dodecyl sulfate. Colloids Surf A 294:247–253. doi:10.1016/j.colsurfa.2006.08.019

Silva SMC, Antunes FE, Sousa JJS, Valente AJM, Pais AACC (2011) New insights on the interaction between hydroxypropylmethyl cellulose and sodium dodecyl sulfate. Carbohydr Polym 86:35–44. doi:10.1016/j.carbpol.2011.03.053

Prasad M, Palepu R, Moulik SP (2006) Interaction between sodium dodecyl sulfate (SDS) and polyvinylpyrrolidone (PVP) investigated with forward and reverse component addition protocols employing tensiometric, conductometric, microcalorimetric, electrokinetic, and DLS techniques. Colloid Polym Sci 284:871–878. doi:10.1007/s00396-005-1453-8

Gouveia LM, Grassl B, Müller AJ (2009) Synthesis and rheological properties of hydrophobically modified polyacrylamides with lateral chains of poly(propylene oxide) oligomers. J Colloid Interface Sci 333:152–163. doi:10.1016/j.jcis.2009.01.064

Hait SK, Moulik SP (2001) Determination of critical micelle concentration (CMC) of nonionic surfactants by donor-acceptor interaction with iodine and correlation of CMC with hydrophile-lipophile balance and other parameters of the surfactants. J Surfactants Deterg 4:303–309. doi:10.1007/s11743-001-0184-2

Haque ME, Das AR, Moulik SP (1999) Mixed micelles of sodium deoxycholate and polyoxyethylene sorbitan monooleate (Tween 80). J Colloid Interface Sci 217:1–7. doi:10.1006/jcis.1999.6267

Patist A, Bhagwat SS, Penfield KW, Aikens P, Shah DO (2000) On the measurement of the critical micelle concentrations of pure and technical-grade nonionic surfactants. J Surfactants Deterg 3:53–58. doi:10.1007/s11743-000-0113-4

Katona JM, Sovilj VJ, Petrović LB, Mucić NZ (2010) Tensiometric investigation of the interaction and phase separation in a polymer mixture-ionic surfactant ternary system. J Serb Chem Soc 75:823–831. doi:10.2298/JSC100112056K

Poša M, Vapa I, Ćirin D (2014) Influence of surfactant hydrophobic segment length on the thermodynamic parameters of binary mixed micelles of homologues polysorbates and Triton X-100. Fluid Phase Equilib 376:124–131. doi:10.1016/j.fluid.2014.06.003

Torrens F, Abad C, Codoñer A, García-Lopera R, Campos A (2005) Interaction of polyelectrolytes with oppositely charged micelles studied by fluorescence and liquid chromatography. Eur Polym J 41:1439–1452. doi:10.1016/j.eurpolymj.2005.01.004

Turro NJ, Baretz BH, Kuo P-L (1984) Photoluminescence probes for the investigation of interactions between sodium dodecyl sulfate and water-soluble polymers. Macromolecules 17:1321–1324. doi:10.1021/ma00137a005

Kamboj R, Singh S, Chauhan V (2014) Synthesis, characterization and surface properties of N-(2-hydroxyalkyl)-N′-(2-hydroxyethyl)imidazolium surfactants. Colloids Surf A441:233–241. doi:10.1016/j.colsurfa.2013.08.063

Panmai S, Prud’homme RK, Peiffer DG, Jockusch S, Turro NJ (1984) Interactions between hydrophobically modified polymers and surfactants: a fluorescence study. Langmuir 18:3860–3864. doi:10.1021/la020165g

Wilhelm M, Zhao C-L, Wang Y, Xu R, Winnik MA, Mura J-L, Riess G, Croucher MD (1991) Poly(styrene-ethylene oxide) block copolymer micelle formation in water: a fluorescence probe study. Macromolecules 24:1033–1040. doi:10.1021/ma00005a010

Gao J, Guo Y, Gu Z, Zhang X (2009) Micellization and controlled release properties of methoxy poly(ethylene glycol)-b-poly(d,l-lactide-co-trimethylene carbonate). Front Chem China 4:104–109. doi:10.1007/s11458-009-0006-y

de Martins RM, da Silva CA, Becker CM, Samios D, Christoff M, Bica CID (2006) Interaction of (hydroxypropyl) cellulose with anionic surfactants in dilute regime. Colloid Polym Sci 284:1353–1361. doi:10.1007/s00396-006-1497-4

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Milanović, M., Krstonošić, V., Dokić, L. et al. Insight into the Interaction Between Carbopol® 940 and Ionic/Nonionic Surfactant. J Surfact Deterg 18, 505–516 (2015). https://doi.org/10.1007/s11743-015-1677-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-015-1677-7