Abstract

In this study, a nitrogen-doped multi-walled carbon nanotube (N-MWCNTs)/silver nanowire (AgNWs) nanocomposite electrode was prepared, using polydimethylsiloxane (PDMS) as a flexible substrate and N-MWCNTs and AgNWs as conductive materials. Trace Cu(II) in water was monitored by square wave stripping voltammetry (SWSV). Compared with commercial electrodes, the N-MWCNTs/AgNWs composite electrode generated much higher responsive peak current in detecting Cu(II), due to the enhanced conductivity of the composite electrode and the strong complexing ability of the N-MWCNTs for Cu(II). In the SWSV, this new electrode showed 0.06 μg/L (S/N = 3) limit of detection, a linear range from 0.500 to 100 μg/L, high resistance to interfering metals such as Ca(II), K(I), Zn(II), Na(I), Al(III), Fe(III), Hg(II), Cr(VI), Bi(III), Sb(III) and Sn(II), and stable response in natural water samples without sample pretreatment. This study established a new method for facile fabrication of high-performance flexible Cu(II) sensor with N-MWCNTs and AgNWs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metal ion pollution in water causes serious contamination to the environment (Hyder et al. 2022; Liu et al. 2019) and poses great threats to human health (Lee et al. 2016; Witkowska et al. 2021). In order to ensure the quality and safety of the water, real-time online monitoring of heavy metal ion content in the environmental water is highly meaningful. Compared with the conventional detection methods such as flame atomic absorption spectrometry (FAAS) (Molaei et al. 2017), inductively coupled plasma–mass spectrometry (ICP–MS) (Shyam et al. 2021) and flame emission spectroscopy (FES) (He et al. 2020), electrochemical methods have many advantages such as simple operation, low cost, high sensitivity and handiness (Li et al. 2024, 2022, 2023; Ramachandran et al. 2019; Wan et al. 2023; Zhu et al. 2015). Because of these advantages, electrochemistry is easy to realize real-time and online detection. However, conventional ITO, glassy carbon and other solid non-flexible electrodes have many disadvantages such as difficulties in shape customization, fragility and the dependence on polishing before use (Bagheri et al. 2021; Ding et al. 2021), which limit their applications in real-time heavy metal detection in water though conventional electrodes were applied in electrochemical sensing (Giacomino et al. 2021; Kokab et al. 2019). In recent years, flexible electrodes have attracted significant attention with the merits in bendability, stretchability, unnecessity for polishing, super-sensitivity and easy fabricability. They can overcome the shortcomings of the traditional solid non-flexible electrodes and are suitable for real-time detection in various conditions (Hui et al. 2020; Zhao et al. 2020). In addition, flexible electrodes allow for promising applications in wearable medical devices (Sun et al. 2022; Yao et al. 2020). Wang et al. prepared a flexible liquid crystal polymer (LCP) sensor by coating LCP with bismuth and Nafion for Cd(II) electrochemical detection with a detection limit of 0.06 μg/L. The low detection limit and the good flexibility of the LCP allowed the sensor to monitor Cd(II) in the actual environment (Nan Wang et al. 2018). Guan et al. prepared a flexible electrode by coating gold nanoparticles on carbon cloth and detected Hg(II) by square wave stripping voltammetry (SWSV) with good reproducibility (Guan et al. 2018).

Both silver nanowires (AgNWs) and carbon nanotubes (CNTs) are conductive materials with nanostructures that have excellent electrochemical properties. AgNWs have good electrical conductivity and nanoeffects (Sun and Du 2019). Our research group have coated AgNWs on the polydimethylsiloxane (PDMS) substrate to fabricate a new flexible silver nanowire electrode (Sun et al. 2020), which has a very sensitive response to metal ions. Using AgNWs coated PDMS as the working electrode, Cu(II) detection was performed with a limit of detection of 0.0927 μg/L and a linear range of 1.00 μg/L–100 μg/L (Yang et al. 2018). CNTs have large surface areas, good adsorption and stable electrochemical properties (Ferrier and Honeychurch 2021; Xia Zhang et al. 2018). Ouyang et al. modified Bi film on carboxylated single-walled CNTs to produce a nanomaterial composite electrode for trace Cr(VI) detection. With a linear range of 0 nM—25 nM and a detection limit of 0.036 nM, the electrode showed high sensitivity and selectivity (Ouyang et al. 2013). For Cu(II) detection, Hui et al. prepared flexible Ti3C2Tx/MWNTs/PET electrode for monitoring Cu(II) in human biofluids (Hui et al. 2020). Their results showed that Cu(II) could be detected in urine and sweat with linear rages of 10 μg/L − 500 μg/L and 300 μg/L—1500 μg/L, respectively. Although both AgNWs and CNTs have excellent electrochemical properties, there are few reports on using them together as combination nanomaterial electrodes. Furthermore, the field of flexible sensors undergoes fast development and flexible sensors for dynamic applications are highly demanded (Wen et al. 2020; Yuan et al. 2022). Therefore, the development of heavy metal sensors by AgNWs and CNTs on flexible substrate is worth investigation.

In this work, AgNWs and nitrogen-doped multi-walled carbon nanotubes (N-MWCNTs) were uniformly mixed and coated on a PDMS substrate for the preparation of a new flexible N-MWCNTs/AgNWs composite electrode. Nitrogen (N) stands out as an exceptional dopant for chemically enhancing carbon materials due to its comparable atomic dimensions and its five valence electrons, which facilitate robust bond formation with carbon atoms. As a result, N doping enhances the surface energy and reactivity of carbon nanomaterials, promoting charge polarization while minimizing damage to the carbon frameworks (Feng et al. 2011; Jeon et al. 2020; Li et al. 2023). Using the N-MWCNTs/AgNWs electrode as a working electrochemical electrode, trace Cu(II) was successfully detected by SWSV. The results showed that the peak current from the N-MWCNTs/AgNWs composite electrode was higher than that from the AgNWs electrode, which is much sensitive for Cu(II) detection than the AgNPs/RGO electrode and nanoporous gold electrode (Sang et al. 2017; Siepenkoetter et al. 2020), indicating the significant improvement on the sensitivity of the composite electrode by the addition of the N-MWCNTs. The Cu(II) levels in actual water samples were determined by the composite electrode and the recovery rate was 100.8%. Furthermore, our detection method required no pretreatment of the samples, such that real-time and on-site detection could be achieved more conveniently. This study combined two excellent nanomaterials on the flexible electrode by a simple method, which provides a new approach to the preparation of nanocomposite flexible electrodes with excellent performance.

Experimental

Materials and reagents

RTV615 polydimethylsiloxane (PDMS) was purchased from Momentiv (Chino, CA, USA). Silver nanowires (20 mg/mL in ethanol solution, 90 nm in diameter and 60 nm in length) were purchased from XFNANO (Nanjing, Jiangsu, China). Different types of carbon nanotubes, such as nitrogen-doped multi-walled carbon nanotubes (N-MWCNTs), hydroxylated multi-walled short carbon nanotubes (OH-MWCNTs-short), hydroxylated multi-walled long carbon nanotubes (OH-MWCNTs-long) and carboxylated multi-walled carbon nanotubes (COOH—MWCNTs), were also purchased from the XFNANO. Commercial Au (CHI101, diameter = 2 mm) and Ag (CHI103, diameter = 2 mm) electrodes were purchased from CHI (Shanghai, China). Polyvinyl alcohol (PVA) and glycerol (Gly) were obtained from MeilunBio (Dalian, Liaoning, China). Copper chloride, tartaric acid, acetic acid, citric acid and sodium hydroxide were purchased from Sinopharm (Beijing, China). The 4-inch single-side polished silicon wafer was purchased from Wanxiang Silicon Peak Electronics (Quzhou, Zhejiang, China).

Apparatus

A UV ozone cleaner (Jelight, Model 42 series, USA) was used to clean contaminants on the PDMS surface. Scanning electron microscope (SEM, Hitachi S-4800, Japan) was used to monitor the electrode morphology. SEM-EDS (energy dispersive spectroscopy) analysis was performed with X-MaxN (Horiba, Japan). A CNC router (Multicam, 7000 Series, USA) was used to cut the desired aluminum mold. All electrochemical measurements were taken by a CHI 660e electrochemical workstation (Chenhua Instruments, Shanghai, China).

Preparation of the PDMS substrate

A rectangle-shaped electrode was designed and drawn by the AutoCAD software (Letchumanan et al. 2020). By laser cutting, an aluminum mold with a hollow electrode structure was made. As shown in Fig. 1, a clean silicon wafer was placed under the mold and was tightly fixed by clips. The PDMS solution with a mass ratio of 10:1 was poured into the electrode mold (Xiao Min Zhang et al. 2022). After removing the bubbles, the solid PDMS electrode substrate was obtained by curing at 60 °C for 1.5 h.

Hydrophilic modification of PDMS

As described in our previous work (Jing Sun et al. 2020), the solid PDMS substrate was cleaned with 3 M tape and then by an UV Ozone cleaner. The cleaned PDMS was immersed in a solution of 2% (m/m) PVA and 5% (m/m) Gly for 20 min. After removing the excess liquid, it was vacuum-dried at 60 ℃ for 2 h. The above steps were repeated three times, and finally, the dried PDMS was vacuum heated at 100 ℃ for 20 min to obtain a stable hydrophilic surface.

Preparation of N-MWCNTs/AgNWs flexible electrode

1 mg/mL of N-MWCNTs was prepared using ultrapure water as the solvent. AgNWs solution of 2 mg/mL was prepared with a mixture of ethanol and water (1:1, v/v). 10 µL of the N-MWCNTs solution and 50 µL of the AgNWs solution were mixed evenly, and the mixture was coated on the hydrophilic-modified PDMS surface uniformly. The N-MWCNTs/AgNWs flexible electrode was ready to use after drying at room temperature for one day.

Electrochemical detection of Cu(II)

A three-electrode system consisting of N-MWCNTs/AgNWs working electrode, Ag/AgCl reference electrode (3 mol/L KCl) and Pt counter electrode was used for Cu(II) detection. Different concentrations of Cu(II) solution were prepared with 0.5 mg/L Bi(III) and 0.1 mol/L tartaric acid–sodium tartrate buffer solution. The final pH of each Cu(II) solution was adjusted to 3.8 by the addition of sodium hydroxide. SWSV was used to record the current response of Cu(II) in a potential range of − 0.3 V–0.25 V with deposition potential of − 1.0 V and deposition time of 300 s. Standard curves of the current responses by the N-MWCNTs/AgNWs electrode against the Cu(II) concentrations were calculated by Origin 2019b (OriginLab, Northampton, MA, USA). Water samples from a lake on our campus and tap water were measured under the optimized conditions.

Electrochemical active surface area (ECSA) was calculated using the following equation (Jing Sun et al. 2019).

where Q is the coulombic charge of the AgO reduction peak, s is the proportional constant (280 μC cm−2) of the area dependent charge and l (g cm−2) is the loading of the electrocatalyst Ag.

Results and discussion

Morphological and conductivity characterization

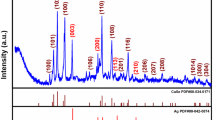

The morphology of the N-MWCNTs/AgNWs composite electrode was characterized by SEM (Fig. 2a). N-MWCNTs and AgNWs were evenly distributed on the surface of the flexible electrode, and a 3D network was formed. The AgNWs connected to each other and the N-MWCNTs scattered in the network. The SEM image of the AgNWs electrode is shown in Fig. 2b for comparison. EDS analysis demonstrated the element compositions of the composite electrode, mainly by C and Ag, reflecting the contribution of N-MWCNTs and AgNWs, respectively, while the Si and O in the EDS were from the substrate PDMS (Fig. 2c). The average sheet resistance of the N-MWCNTs/AgNWs composite electrode was 0.457 Ω/sq. In comparison, the average sheet resistance of the AgNWs electrode was 0.753 Ω/sq. The improvement of the conductivity for the N-MWCNTs/AgNWs composite electrode could be attributed to the addition of the N-MWCNTs (Choi 2023).

Electrochemical performance

The N-MWCNTs/AgNWs composite electrode was used to detect Cu(II) in water by SWSV. Bi(III) was added to facilitate the detection of Cu(II), as Bi(III) can form a film with Cu(II) on the surface of the N-MWCNTs/AgNWs electrode to increase the detection sensitivity (Ngoensawat et al. 2022). As shown in Fig. 3a, a significant stripping peak current was generated by the SWSV of the N-MWCNTs/AgNWs electrode in a solution containing 100 μg/L of Cu(II) (black line), while in the blank solution without any Cu(II) (red line) no peak was elicited. The result indicated that the N-MWCNTs/AgNWs composite electrode showed a high and specific voltammetric response to Cu(II). Under the same detection condition, the SWSV results of 100 μg/L Cu(II) by the AgNWs electrode, an N-MWCNTs electrode, a commercial Ag electrode and a commercial Au electrode were also recorded (Fig. 3b). The peak current of the N-MWCNTs/AgNWs electrode was approximately 70% higher than that of the AgNWs electrode and much higher than those of the N-MWCNTs, commercial Ag and commercial Au electrodes. Our laboratory showed previously that the AgNWs electrode was much sensitive than the commercial electrodes due to its nanowire structure (Sun et al. 2020; Sun and Du 2019). However, the structures of the N-MWCNTs/AgNWs electrode and the AgNWs electrode were the same and the only difference was the addition of N-MWCNTs in the composite electrode. Therefore, it was obvious that the N-MWCNTs improved the current signals from the composite electrode. These implied that coordination reaction was the main reason for the signal improvement since the nitrogen group of the N-MWCNTs caused Cu(II) to interact effectively with the N-MWCNTs/AgNWs composite electrode (Wang and Yue 2017). In addition, the 3D network of the N-MWCNTs and AgNWs allowed significantly effective charge transportation along the nanowire structure as well as sufficient and quick electrolyte diffusion to the conductor layer, which accelerated the charge transportation on the electrode surface and improved its sensitivity (Cui et al. 2014).

a SWSV of the N-MWCNTs/AgNWs electrode in the absence (blank) or presence of 100 μg/L Cu(II) (Cu(II)). b SWSV of the N-MWCNTs/AgNWs electrode and other types of electrodes. c SWSV of different CNTs/AgNWs electrodes for the detection of Cu(II). d SWSV of the N-MWCNTs/AgNWs electrode with different ratios of N-MWCNTs to AgNWs for the detection of Cu(II). All the Cu(II) detection by the SWSV was performed in 0.1 M tartaric acid buffer solution (pH = 3.8) containing 100 μg/L of Cu(II)

To verify the effect of coordination, other different carbon nanotubes were tested, such as hydroxylated multi-walled short carbon nanotubes (OH-MWCNTs-short), hydroxylated multi-walled long carbon nanotubes (OH-MWCNTs-long) and carboxylated multi-walled carbon nanotubes (COOH-MWCNTs) (Fig. 3c). Different CNTs/AgNWs electrodes with the weight ratio of MWCNTs/AgNWs at 1:10 were produced, and 100 μg/L Cu(II) solution was measured by these electrodes. The SWSV results showed that the N-MWCNTs/AgNWs electrode had the highest current among all the MWCNTs/AgNWs electrodes. This could be ascribed to the differences in the coordination because it has been reported that the complexing ability of N groups to Cu(II) was stronger than those of the COOH and OH groups (Wei et al. 2019). Thus, the experimental results of the different MWCNTs/AgNWs electrodes confirmed our hypothesis that the addition of N-MWCNTs into AgNWs improved the sensitivity of the electrode to Cu(II) through the coordination interaction of the nitrogen group on the N-MWCNTs with Cu(II).

The ratio of N-MWCNTs to AgNWs was also an important impact factor on the electrochemical performance of the composite electrode. Four N-MWCNTs/AgNWs electrodes were prepared with the weight ratios of N-MWCNTs/AgNWs at 1:20, 1:10, 2:10 and 3:10 (Fig. 3d). The stripping peak currents suggested that the N-MWCNTs amount should be critical to the sensitivity of the electrode and the electrode with 1:10 of N-MWCNTs to AgNWs showed the highest current response. The conductivity of the AgNWs should be much higher than that of the N-MWCNTs; therefore, more amount of AgNWs had positive influence on the performance of the electrode. Furthermore, the N-MWCNTs tended to aggregate at higher concentrations that might affect the charge transportation. However, too small amount of the N-MWCNTs would impair the coordination of the electrode with Cu(II). Thus, the coordination and the ratio effects discussed above both contributed to the improved sensitivity and the faster charge transportation by the N-MWCNTs/AgNWs composite electrode (Figure S1). As a result, the N-MWCNTs/AgNWs electrode exhibited large estimated ECSA of 700 cm2 mg−1. ECSA reflects the active sites that are available for catalytic reactions. The large ECSA of the N-MWCNTs/AgNWs electrode benefited greatly from the above-mentioned complex 3D network of AgNWs and N-MWCNTs, in addition to the coordination by nitrogen doping of the MWCNTs.

Mechanical performance, repeatability and reproducibility

Compared with the traditional solid non-flexible electrodes, the novel N-MWCNTs/AgNWs electrode exhibited extraordinary flexibility, such as bendability and stretchability. It could be bent up to one hundred times and stretched up to 150% of the original length, yet retaining stable electrochemical properties. Figure 4a shows the electrochemical current variation of the N-MWCNTs/AgNWs electrode on the measurements of Cu(II) by SWSV before and after 20, 40, 60, 80 and 100 times of 180̊ bending. The current variation was indicated by I/I˳ (ratio of the peak current after bending (I) versus that before bending (I˳)), which was slightly decreased but still at 0.9 after 100 times of bending. The electrochemical current variation of the electrode after stretching 110%, 120%, 130%, 140% and 150% was also studied by SWSV on the measurement of Cu(II), and the ratio of I/I˳ is compared in Fig. 4b. It was demonstrated that the electrochemical property of the N-MWCNTs/AgNWs composite electrode kept stable even after 150% of stretching. In brief, the above results proved that the composite electrode showed both favorable tensile and bending properties.

a Peak current ratios of the N-MWCNTs/AgNWs electrode for the measurement of Cu(II) after and before bending for up to 100 cycles at 180 °. b Peak current ratios of the N-MWCNTs/AgNWs electrode for the measurement of Cu(II) solution after and before stretching for up to 50% strain. Repeatability (c) and reproducibility (d) of the N-MWCNTs/AgNWs composite electrode were tested in the measurement of Cu(II). All the Cu(II) measurements by the SWSV were taken in 0.1 M tartaric acid buffer solution (pH 3.8) containing 100 μg/L of Cu(II)

Repeatability and reproducibility are important indices to evaluate electrode performance. The same N-MWCNTs/AgNWs composite electrode was used for the successive determination of 100 μg/L Cu(II) for six times. The relative standard deviation (RSD) was 1.62% (n = 6, Fig. 4c), indicating that the N-MWCNTs/AgNWs electrode showed excellent repeatability. Five different N-MWCNTs/AgNWs composite electrodes prepared under the same conditions were used to detect the SWSV of 100 μg/L Cu(II) solution (Fig. 4d). The RSD for stripping peak current of the measurements was 1.83% (n = 5), demonstrating a good reproducibility among the electrodes.

In addition, long-term stability was tested when five N-MWCNTs/AgNWs composite electrodes were stored for 35 days and tested for the detection of Cu(II) by SWSV on different days (Figure S4). Compared with the stripping peak current on day 1, the peak currents on days 7, 14, 21, 28 and 35 remained constant with less than 1% variation, demonstrating high long-term stability of the N-MWCNTs/AgNWs composite electrodes.

Linear range and detection limit

The SWSV of different concentrations of Cu(II) solutions were determined under the optimized experimental conditions with the N-MWCNTs/AgNWs electrode. The stripping peak current of Cu(II) increased with the increase of Cu(II) concentrations (Fig. 5a). When the Cu(II) concentrations were in the range of 0.500 μg/L—100 μg/L, linear relationship was established between the concentrations of Cu(II) and the current responses of the N-MWCNTs/AgNWs electrode (Fig. 5b). The equation of linear regression was ip(µA) = 2.864C(µg/L) + 148.808(µA) (R2 = 0.9984) and the detection limit (LOD) was 0.06 µg/L (S/N = 3). The detection performance of the method was compared with other methods shown in Table 1, which showed that the detection range of the method was wider and the detection limit was lower than those in most publications were.

a SWSV for different concentrations of Cu(II) (0, 0.5, 1, 10, 20, 40, 60, 80, 100 μg/L) in 0.1 mol/L tartarate–sodium tartarate buffer solution (pH = 3.8). b Linear 20 fitting curve of Cu(II) concentrations and stripping peak currents. Error bars = SD (n = 3). c SWSV peak current variations (% interference) of the N-MWCNTs/AgNWs composite electrode for the measurements of 100 μg/L Cu(II) in the presence of 1000 μg/L of Ca(II), K(I), Zn(II), Na(I), Al(III), Fe(III), Hg(II), Cr(VI), Bi(III), Sb(III) and Sn(II), respectively

The influence of interfering metal ions on the detection of Cu(II) was investigated (Fig. 5c). The SWSV peak current of Cu(II) was measured by adding 1000 μg/L of Ca(II), K(I), Zn(II), Na(I), Al(III), Fe(III), Hg(II), Cr(VI), Bi(III), Sb(III) and Sn(II), in 100 μg/L Cu(II) solution, respectively. The Cu(II) was determined by SWSV, and the relative errors (n = 5) were all less than 5.0%. Therefore, the interference ions had little influence on the Cu(II) peak current, indicating that the N-MWCNTs/AgNWs composite electrode had strong anti-interference ability.

Determination of Cu(II) in actual water samples

Cu(II) contents in the tap and lake water samples were determined with the composite electrode by the method developed in this study and by ICP–MS (Table 2). As summarized in Table 2, the comparative results between our and the ICP–MS methods suggest that the flexible N-MWCNTs/AgNWs composite electrode is suitable for analysis of trace Cu(II) in real samples. Among them, the tap water met the Hygiene Standard for Water Used in Daily Life (GB5749-2006), and the river and lake located on the campus of the Dalian University met the class III Environmental Quality Standards for Surface Water (GB3838-2002) (Lin et al. 2021).

Conclusions

In this study, a new flexible N-MWCNTs/AgNWs electrode was developed with high electrical conductivity, owing to the addition of N-MWCNTs into the AgNWs. The controlled addition of N-MWCNTs into the AgNWs also resulted in improved electrolyte penetration, adsorption and coordination reaction. The flexible N-MWCNTs/AgNWs electrode exhibited an excellent performance in Cu(II) detection in terms of limit of detection, linear range, flexibility, anti-interference, repeatability and reproducibility. Moreover, the electrode has successfully been utilized for detecting Cu(II) in real natural water samples. Due to its excellent performance and flexibility, this PDMS-based flexible composite electrode may aid in the future development of novel environmental monitoring and wearable devices.

References

Bagheri HM, Siavash MR, Sharifi AP, Zargarnezhad H, Shone M, Rahmani SA, Moradi N, Niksefat V, Shayar BK, Dolati A (2021) Facile and ultra-sensitive voltammetric electrodetection of Hg2+ in aqueous media using electrodeposited auptnps/ito. Anal Methods 13(24):2688–2700. https://doi.org/10.1039/D1AY00361E

Choi HY (2023) Study on the microstructure, electrical properties, and electric-heating performance of mwcnt/agnw/cellulose hybrid fibers. J Text Inst 114(4):613–621. https://doi.org/10.1080/00405000.2022.2057639

Cui L, Du Z, Zou W, Li H, Zhang C (2014) The in situ growth of silver nanowires on multi-walled carbon nanotubes and their application in transparent conductive thin films. RSC Adv 4(52):27591–27596. https://doi.org/10.1039/C4RA02691H

Dalmasso PR, Pedano ML, Rivas GA (2015) Electrochemical determination of Cu(II) using a glassy carbon electrode modified with multiwall carbon nanotubes dispersed in polyhistidine. Electroanal 27(9):2164–2170

Ding Q, Li C, Wang H, Xu C, Kuang H (2021) Electrochemical detection of heavy metal ions in water. Chem Commun 57(59):7215–7231. https://doi.org/10.1039/D1CC00983D

El Tall O, Jaffrezic-Renault N, Sigaud M, Vittori O (2007) Anodic stripping voltammetry of heavy metals at nanocrystalline boron-doped diamond electrode. Electroanal 19(11):1152–1159. https://doi.org/10.1002/elan.200603834

Feng X, Li R, Ma Y, Chen R, Mei Q, Fan Q, Huang W (2011) Nitrogen-doped carbon nanotube/polyaniline composite: synthesis, characterization, and its application to the detection of dopamine. Sci China Chem 54(10):1615–1621. https://doi.org/10.1007/s11426-011-4330-y

Ferrier DC, Honeychurch KC (2021) Carbon nanotube (cnt)-based biosensors. Biosensors 11(12):486

Giacomino A, Ruo Redda A, Caligiuri R, Inaudi P, Squadrone S, Abete MC, Abollino O, Morandi S, Conca E, Malandrino M (2021) Development of an easy portable procedure for on-site determination of mercury and methylmercury. Food Chem 342:128347. https://doi.org/10.1016/j.foodchem.2020.128347

Guan P, Guo P-R, Liu N, Zhang F, Lei Y-Q (2018) The preparation of a flexible aunp modified carbon cloth electrode and its application in electrochemical detection of Hg(II) by continuous flow in environmental water. Analyst 143(18):4436–4441. https://doi.org/10.1039/C8AN01284A

Guo E (2015) Simultaneous electrochemical determination of lead and copper based on graphenated multi-walled carbon nanotubes. Int J Electrochem Sci 10(9):7341–7348. https://doi.org/10.1016/S1452-3981(23)17353-6

He X, Lou C, Qiao Y, Lim M (2020) In-situ measurement of temperature and alkali metal concentration in municipal solid waste incinerators using flame emission spectroscopy. Waste Manag 102:486–491. https://doi.org/10.1016/j.wasman.2019.11.015

Hui X, Sharifuzzaman M, Sharma S, Xuan X, Zhang S, Ko SG, Yoon SH, Park JY (2020) High-performance flexible electrochemical heavy metal sensor based on layer-by-layer assembly of Ti3C2tx/mwnts nanocomposites for noninvasive detection of copper and zinc ions in human biofluids. ACS Appl Mater Interfaces 12(43):48928–48937. https://doi.org/10.1021/acsami.0c12239

Hyder A, Buledi JA, Nawaz M, Rajpar DB, Shah Z-U-H, Orooji Y, Yola ML, Karimi-Maleh H, Lin H, Solangi AR (2022) Identification of heavy metal ions from aqueous environment through gold, silver and copper nanoparticles: an excellent colorimetric approach. Environ Res 205:112475. https://doi.org/10.1016/j.envres.2021.112475

Jeon IY, Noh HJ, Baek JB (2020) Nitrogen doped carbon nanomaterials synthesis, characteristics and applications. Chem an Asian J 15(15):2282–2293

Kokab T, Shah A, Iftikhar FJ, Nisar J, Akhter MS, Khan SB (2019) Amino acid-fabricated glassy carbon electrode for efficient simultaneous sensing of zinc(II), cadmium(II), copper(II), and mercury(II) ions. ACS Omega 4(26):22057–22068. https://doi.org/10.1021/acsomega.9b03189

Lee S, Oh J, Kim D, Piao Y (2016) A sensitive electrochemical sensor using an iron oxide/graphene composite for the simultaneous detection of heavy metal ions. Talanta 160:528–536. https://doi.org/10.1016/j.talanta.2016.07.034

Letchumanan I, Md Arshad MK, Gopinath SCB, Rajapaksha RDAA, Balakrishnan SR (2020) Comparative analysis on dielectric gold and aluminium triangular junctions: impact of ionic strength and background electrolyte by ph variations. Sci Rep 10(1):6783. https://doi.org/10.1038/s41598-020-63831-w

Li G, Qi X, Zhang G, Wang S, Li K, Wu J, Wan X, Liu Y, Li Q (2022) Low-cost voltammetric sensors for robust determination of toxic Cd(II) and Pb(II) in environment and food based on shuttle-like α-Fe2O3 nanoparticles decorated β-Bi2O3 microspheres. Microchem J 179:107515. https://doi.org/10.1016/j.microc.2022.107515

Li G, Wan X, Xia Y, Tuo D, Qi X, Wang T, Mehmandoust M, Erk N, He Q, Li Q (2023) Lamellar α-zirconium phosphate nanoparticles supported on n-doped graphene nanosheets as electrocatalysts for the detection of levofloxacin. ACS Appl Nano Mater 6(18):17040–17052. https://doi.org/10.1021/acsanm.3c03162

Li G, Qi X, Wu J, Wan X, Wang T, Liu Y, Chen Y, Xia Y (2024) Highly stable electrochemical sensing platform for the selective determination of pefloxacin in food samples based on a molecularly imprinted-polymer-coated gold nanoparticle/black phosphorus nanocomposite. Food Chem 436:137753. https://doi.org/10.1016/j.foodchem.2023.137753

Lin T, Yu H, Wang Q, Hu L, Yin J (2021) Surface water quality assessment based on the integrated water quality index in the Maozhou River Basin, Guangdong, China. Environ Earth Sci 80(10):368. https://doi.org/10.1007/s12665-021-09670-y

Liu X, Yao Y, Ying Y, Ping J (2019) Recent advances in nanomaterial-enabled screen-printed electrochemical sensors for heavy metal detection. TrAC Trends Anal Chem 115:187–202. https://doi.org/10.1016/j.trac.2019.03.021

Mashhadizadeh MH, Talemi RP (2011) Used gold nano-particles as an on/off switch for response of a potentiometric sensor to Al(III) or Cu(II) metal ions. Anal Chim Acta 692(1–2):109–115. https://doi.org/10.1016/j.aca.2011.02.028

Molaei K, Bagheri H, Asgharinezhad AA, Ebrahimzadeh H, Shamsipur M (2017) SiO2-coated magnetic graphene oxide modified with polypyrrole–polythiophene: a novel and efficient nanocomposite for solid phase extraction of trace amounts of heavy metals. Talanta 167:607–616. https://doi.org/10.1016/j.talanta.2017.02.066

Ngoensawat U, Pisuchpen T, Sritana-Anant Y, Rodthongkum N, Hoven VP (2022) Conductive electrospun composite fibers based on solid-state polymerized poly(3,4-ethylenedioxythiophene) for simultaneous electrochemical detection of metal ions. Talanta 241:123253. https://doi.org/10.1016/j.talanta.2022.123253

Nodehi M, Baghayeri M, Veisi H (2021) Preparation of GO/Fe3O4@pmda/aunps nanocomposite for simultaneous determination of As3+ and Cu2+ by stripping voltammetry. Talanta 230:122288. https://doi.org/10.1016/j.talanta.2021.122288

Ouyang R, Zhang W, Zhou S, Xue ZL, Xu L, Gu Y, Miao Y (2013) Improved bi film wrapped single walled carbon nanotubes for ultrasensitive electrochemical detection of trace Cr(VI). Electrochim Acta 113:686–693. https://doi.org/10.1016/j.electacta.2013.09.110

Ramachandran R, Chen T-W, Chen S-M, Baskar T, Kannan R, Elumalai P, Raja P, Jeyapragasam T, Dinakaran K, Kumar GPG (2019) A review of the advanced developments of electrochemical sensors for the detection of toxic and bioactive molecules. Inorg Chem Front 6(12):3418–3439. https://doi.org/10.1039/C9QI00602H

Sang S, Li D, Zhang H, Sun Y, Jian A, Zhang Q, Zhang W (2017) Facile synthesis of agnps on reduced graphene oxide for highly sensitive simultaneous detection of heavy metal ions. RSC Adv 7(35):21618–21624. https://doi.org/10.1039/C7RA02267K

Shyam Sunder GS, Rohanifar A, Alipourasiabi N, Lawrence JG, Kirchhoff JR (2021) Synthesis and characterization of poly(pyrrole-1-carboxylic acid) for preconcentration and determination of rare earth elements and heavy metals in water matrices. ACS Appl Mater Interfaces 13(29):34782–34792. https://doi.org/10.1021/acsami.1c05061

Siepenkoetter T, Mastin H, Salaj-Kosla U, Magner E (2020) Benzene diazonium sulfonate modified nanoporous gold electrodes for the direct detection of copper(II) ions. ChemElectroChem 7(22):4625–4632. https://doi.org/10.1002/celc.202001158

Sullivan C, Lu D, Brack E, Drew C, Kurup P (2020) Voltammetric codetection of arsenic(III) and copper(II) in alkaline buffering system with gold nanostar modified electrodes. Anal Chim Acta 1107:63–73. https://doi.org/10.1016/j.aca.2020.02.015

Sun Y, Du Z (2019) A flexible and highly sensitive pressure sensor based on agnws/nrlf for hand motion monitoring. Nanomaterials 9(7):945

Sun J, Li Y, Liu Y, Zhou W, Zhen X, Lang M-F (2019) Facile fabrication of a flexible electrode by electrodeposition of palladium on silver nanowires for ethanol oxidation. Int J Hydrogen Energy 44(12):5990–5996. https://doi.org/10.1016/j.ijhydene.2019.01.138

Sun J, Wang Q, Luo G, Meng W, Cao M, Li Y, Masterman-Smith MD, Yang H, Sun X, Lang M-F (2020) A novel flexible ag/agcl quasi-reference electrode based on silver nanowires toward ultracomfortable electrophysiology and sensitive electrochemical glucose detection. J Mater Res Technol 9(6):13425–13433. https://doi.org/10.1016/j.jmrt.2020.09.041

Sun JZ, Sun R, Jia P, Ma MD, Song YL (2022) Fabricating flexible conductive structures by printing techniques and printable conductive materials. J Mater Chem C 10(25):9441–9464. https://doi.org/10.1039/d2tc01168a

Wan X, Du H, Tuo D, Qi X, Wang T, Wu J, Li G (2023) Uio-66/carboxylated multiwalled carbon nanotube composites for highly efficient and stable voltammetric sensors for gatifloxacin. ACS Appl Nano Mater 6(20):19403–19413. https://doi.org/10.1021/acsanm.3c03874

Wang T, Yue W (2017) Carbon nanotubes heavy metal detection with stripping voltammetry: a review paper. Electroanal 29(10):2178–2189. https://doi.org/10.1002/elan.201700276

Wang N, Kanhere E, Miao J, Triantafyllou MS (2018) Nanoparticles-modified chemical sensor fabricated on a flexible polymer substrate for cadmium(II) detection. Polymers 10(7):694

Wei P, Zhu Z, Song R, Li Z, Chen C (2019) An ion-imprinted sensor based on chitosan-graphene oxide composite polymer modified glassy carbon electrode for environmental sensing application. Electrochim Acta 317:93–101. https://doi.org/10.1016/j.electacta.2019.05.136

Wen N, Zhang L, Jiang D, Wu Z, Li B, Sun C, Guo Z (2020) Emerging flexible sensors based on nanomaterials: Recent status and applications. J Mater Chem A 8(48):25499–25527. https://doi.org/10.1039/D0TA09556G

Witkowska D, Słowik J, Chilicka K (2021) Heavy metals and human health: possible exposure pathways and the competition for protein binding sites. Molecules 26(19):6060

Yang H-B, Zhou W-H, Zhen X, Ma L-F, Shen G-J, Sun J (2018) Preparation of silver nanowires flexible electrode for electrochemical detection of trace copper in water. Chin J Anal Chem 46(3):446–453. https://doi.org/10.11895/j.issn.0253-3820.171280

Yao S, Ren P, Song R, Liu Y, Huang Q, Dong J, O’Connor BT, Zhu Y (2020) Nanomaterial-enabled flexible and stretchable sensing systems: processing, integration, and applications. Adv Mater 32(15):1902343. https://doi.org/10.1002/adma.201902343

Yuan F, Xia Y, Lu Q, Xu Q, Shu Y, Hu X (2022) Recent advances in inorganic functional nanomaterials based flexible electrochemical sensors. Talanta 244:123419. https://doi.org/10.1016/j.talanta.2022.123419

Zhang X, Xu Y, Ye B (2018) An efficient electrochemical glucose sensor based on porous nickel based metal organic framework/carbon nanotubes composite (ni mof/cnts). J Alloy Compd 767:651–656. https://doi.org/10.1016/j.jallcom.2018.07.175

Zhang XM, Yang X-L, Wang B (2022) Highly stretchable, sensitive, and flexible strain sensors based on Ag@Cu/PdMs composites. J Mater Sci: Mater Electron 33(10):8104–8113. https://doi.org/10.1007/s10854-022-07960-0

Zhao Y, Yang X, Pan P, Liu J, Yang Z, Wei J, Xu W, Bao Q, Zhang H, Liao Z (2020) All-printed flexible electrochemical sensor based on polyaniline electronic ink for copper (II), lead (II) and mercury (II) ion determination. J Electron Mater 49(11):6695–6705. https://doi.org/10.1007/s11664-020-08418-x

Zhu C, Yang G, Li H, Du D, Lin Y (2015) Electrochemical sensors and biosensors based on nanomaterials and nanostructures. Anal Chem 87(1):230–249. https://doi.org/10.1021/ac5039863

Acknowledgements

This research was funded by the grant from the Liaoning Province-Shenyang National Laboratory for Materials Science Joint Research and Development Fund (No. 2019010274-JH3/301).

Funding

Funding for this study was received from the Natural Science Foundation of Liaoning Province, 2019010274-JH3/301, by Jing Sun.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Liu, Y., Mei, Y. et al. A novel flexible carbon nanotube/silver nanowire electrode toward trace Cu(II) detection in water. Chem. Pap. (2024). https://doi.org/10.1007/s11696-024-03639-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11696-024-03639-4