Abstract

This work describes a simple and straightforward magnetic solid phase extraction (MSPE) approach based on benzalkonium chloride-modified silica-coated magnetite nanoparticles (Fe3O4@SiO2@BZC). The developed extraction method was employed for extracting doxycycline hyclate (DOX) from water and urine samples after derivatization with procaine benzylpenicillin (PP) as a color reagent. An orange azo dye with a maximum adsorption wavelength (λmax) of 440 nm was produced by the azo-coupling of DOX with the color reagent in the alkaline medium. The analytical conditions were optimized carefully, including the reagent and surfactant volumes, the amount of sorbent, the extraction time, and the pH of the solution. The developed extraction approach achieved pre-concentration and enrichment factors of 47 and 25, respectively. UV–vis spectroscopy was utilized to determine the target analyte after the extraction step. A good linearity (R2 > 0.99) in the concentration range of 0.08–3.00 μg/mL was achieved. Detection and quantification limits of DOX were found to be 0.01 and 0.04 μg/mL, respectively. The suggested method was successfully applied to the extraction and determination of DOX spiked in urine and various water samples, with excellent recoveries of 97.00–98.30% and 98.00–102.00%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The global worry about the poisoning of water resources with a range of organic pollutants, particularly new pharmaceutical compounds, rises daily (Ortúzar et al. 2022). Pollution from pharmaceutical compounds creates severe hazards to the health of humans, animals, and the environment (Al-Toriahi et al. 2023). Antibiotics are a class of extensively used medicines in bacterial infection treatment of people, animals, and plants whose residues in the environment, even in low quantities, are considered dangerous contaminants (Ben et al. 2019; Zaher et al. 2021). Antibiotic remnants in aquatic environments can lead to the emergence of antibiotic-resistant genes and bacteria (Ben et al. 2019).

Doxycycline (DOX) is a tetracycline-group antibiotic with high effectiveness and anti-infective properties versus both gram-positive and negative bacteria (Rabeie et al. 2022). The low cost of DOX made it famous in animal husbandry as an anti-infection drug and feed additive (Li et al. 2023). Nevertheless, only a limited amount of the prescribed DOX is destroyed by the body, with the majority excreted into the environment via urine and feces (Rahman and Raheem 2022). DOX can stay in the environment long and enter the food chain (Li et al. 2023). The maximum residue limit for DOX in poultry muscle and fish has been reported as 100 μg kg−1 by the European Union (Xu et al. 2020; Zhuang et al. 2021). The foodstuffs that have relatively high quantities of DOX residue may cause unpleasant effects such as gastrointestinal upset, allergic responses, liver damage, and tooth yellowing (Feng et al. 2018). As a result, creating sensitive and rapid methods for detecting DOX in environmental, food, and biological samples is an important research topic.

The literature includes numerous analytical methods for quantification of DOX in diverse biological, food, pharmaceutical, and environmental water samples (Alipanahpour Dil et al. 2020; Cherkashina et al. 2020; Ding et al. 2022; Han et al. 2022; Tang et al. 2020; Yang et al. 2021). Due to the low concentrations of DOX and the complexity of the sample matrices, the majority of these methods include a pre-treatment step (Camızcı Aran and Bayraç 2023; Hadjiioannou et al. 1993; Cherkashina et al. 2020). Till now, various techniques have been developed for pre-concentration and extraction of DOX, including cloud point extraction (CPE) (Saridal and Ulusoy 2019), liquid–liquid microextraction (Alipanahpour Dil et al. 2020; Saghafi et al. 2022), solid-phase extraction (SPE) (Cherkashina et al. 2020; Tang et al. 2020; Yang et al. 2021).

Based on the literature, SPE is one of the most frequent pre-treatment methods for extracting antibiotics from different samples (Suseela et al. 2023). The popularity of SPE is due to its simplicity, high extraction factor, minimal solvent usage, and time-saving features (Ramezani and Yamini 2020; Soylak et al. 2021; Suseela et al. 2023). There are various varieties of SPE, the most prevalent being traditional SPE, dispersive SPE, and magnetic SPE (MSPE) (D. Sun et al. 2021). Using a magnetic adsorbent that can be easily separated from the solutions by an external magnetic field is a distinguishing and attractive characteristic of the MSPE technique (Arain et al. 2019; Camızcı Aran and Bayraç 2023; Zhao et al. 2008). Magnetite nanoparticles (Fe3O4 MNPs) are the magnetic material that is most commonly utilized for MSPE (Zhang et al. 2023). The Fe3O4 MNPs have unique features, including superparamagnetic properties, large surface area, low toxicity, and convenience of surface functionalization (Abed and Hadi 2020; Simamora et al. 2018). Nonetheless, bare MNPs have limited dispersibility, chemical stability, and selectivity. Modifying the surface with appropriate chemical compounds can readily overcome these limits (Hassan and Hadi 2022, 2023). In this context, numerous surface modification techniques were utilized, including salination, polymer coating, and surfactant adsorption (Hamidi 2023). The silica (SiO2) modification of the Fe3O4 MNPs surface can enhance their surface area and stability in aqueous media (Soylak et al. 2023). Surfactant-modified Fe3O4 MNPs often exhibit better extraction efficiency than bare Fe3O4 MNPs, which is due to the electrostatic and hydrophobic interactions of the surfactants (Treder et al. 2023).

This work combines the advantages of surface modification of the Fe3O4 MNPs with silica and surfactant. In this regard, an MSPE approach based on benzalkonium chloride-modified silica-coated Fe3O4 MNPs (Fe3O4@SiO2@BZC) was designed for the efficient extraction of DOX from water and urine samples after derivatization with the diazotized reagent. Procaine benzylpenicillin (PP) was utilized as a cost-efficient, available, and non-toxic derivatization reagent. The UV–vis spectrophotometric determination of DOX followed the extraction process.

Experimental

Apparatus

All aqueous solutions were prepared using bi-distilled water, and all reagents utilized were of analytical quality. All spectra measurements were carried out by a UV–vis spectrophotometer (Shimadzu 1260, Japan, https://www.shimadzu.com). The pH of solutions was adjusted using a pH meter model 827 Metrohm (Switzerland, https://www.metrohm.com) with a glass electrode. A magnetic stir bar (IKA, USA, https://www.ika.com) was used to agitate the liquids. A powerful Nd-Fe-B magnet (1 × 5 × 4 cm, 1.4 T) was utilized to gather MNPs. The FTIR spectra of prepared MNPs were obtained in the 400–4000 cm−1 range using an FTIR spectrophotometer (Shimadzu Prestige-21, Japan, https://www.shimadzu.com). A scanning electron microscope (SEM, ZEISS LEO 1430VP, https://www.zeiss.com) was used to characterize the structure of the produced nanoparticles.

Chemicals and materials

DOX and PP (99.0%) were supplied by the Samarra company for the drugs industry and medical appliances (Samarra, Iraq, https://www.sdi.industry.gov.iq). Hydrochloric acid (36% w/w) was obtained from Merck (Darmstadt, Germany, www. merckmillipore.com). Benzalkonium chloride (50% w/v) was purchased from Sigma-Aldrich (St. Louis, Missouri, USA, https://www.sigmaaldrich.com). FeCl3.6H2O, FeCl2.2H2O, sodium nitrite, sodium hydroxide, and sodium silicate were purchased from BDH (Poole, United. Kingdom, https://www.copens-sci.com). A standard stock solution of 100.0 μg/mL of DOX was prepared by dissolving 0.0100 g in 100.0 mL of bi-distilled water. The diazotized procaine benzylpenicillin (DPP, 1.0 mM) stock solution was prepared by dissolving 0.0589 g of PP in 20.0 mL of bi-distilled water in a 100.0 mL volumetric flask. After the flask was placed in the ice bath, the PP solution was acidified with 3 mL of hydrochloric acid (1.0 M), then 0.0069 g of sodium nitrite was added, and the solution was brought up to the mark with bi-distilled water. A solution of sodium silicate (100.0 mL, 1.0 M) was prepared by dissolving 12.2060 g of Na2SiO3 in a 100.0 mL of bi-distilled water. A 2% v/v BZC surfactant solution was made by diluting 2.0 mL of its concentrated solution (50% w/v) with bi-distilled water in a 100.0-mL volumetric flask. A solution of sodium hydroxide (2.0 M) was made by dissolving the precise weight of the base in bi-distilled water and then standardized.

Preparation of the spiked samples

Urine samples were collected from volunteer healthy males and females and stored in the refrigerator without preservatives. Before the extraction operation, the urine samples were kept in ambient conditions until reaching the ambient temperature. After that, 5.0 mL of the clear supernatant was spiked with various amounts of the DOX stock solution, then centrifuged (15 min at 2500 rpm), and filtered through a cellulose membrane filter (Millipore, 0.45 μm pore size). Finally, the samples were diluted to 50.0 mL with bi-distilled water. The spiked samples were achieved by adding different amounts of the DOX stock solution to the diluted urine samples.

Two environmental water samples were analyzed, including river water collected from the Tigris River (Iraq) and surface water from Al-Karrada (Baghdad, Iraq). The water samples were kept in polyethylene bottles. Before analysis, water samples were filtered using Millipore cellulose membrane filters (0.45 μm pore size) and pH adjusted to 7.0 with NaOH solution. The spiked samples were achieved by adding different amounts of the DOX stock solution to the water samples.

Synthesis of Fe3O4@SiO2 MNPs

The co-precipitation method that was previously described was used to prepare iron oxide (Fe3O4) MNPs (Sun et al. 2007). Concisely, FeCl3.6H2O (10.40 g), FeCl2.2H2O (3.27 g), and 1.7 mL of HCl (12.0 M) were dissolved in 50.0 mL of bi-distilled water to make the stock solution of ferrous/ferric chloride. The prepared stock solution was gradually added dropwise into the 500.0 mL of sodium hydroxide solution (1.5 M) within 30 min. Throughout the process, the temperature of the solution was kept at 80 °C with vigorous stirring (1000 rpm). The produced Fe3O4 MNPs were then dried at 40°C for 24 h after being washed several times with bi-distilled water. The procedure described earlier (Zhao et al. 2015) was followed to cover the prepared Fe3O4 MNPs with SiO2. Briefly, 1.00 g of Fe3O4 MNPs was dispersed in 100.0 mL of bi-distilled water at 80 °C. After that, the Fe3O4 MNPs solution was vigorously stirred while the sodium silicate solution (10.0 mL, 1.0 M) was added dropwise. The solution's pH was adjusted to 6.0, and it was vigorously agitated for three hours. After being washed with bi-distilled water several times, the generated Fe3O4@SiO2 MNPs were resuspended in 50.0 mL of water and stored for further use. The obtained Fe3O4@SiO2 suspension has a concentration of about 20.0 mg/mL.

Solid phase extraction process

The extraction process of DOX by Fe3O4@SiO2@BZC NPs was performed as follows: (1) The aqueous solutions of DOX with different concentrations (50.0 mL, 0.08–3.00 µg/mL) were prepared in a 50.0 mL volumetric flask; (2) 2.0 mL of the DPP solution (1.0 mM) was added to the aqueous solutions of DOX, and then, the pH of the solutions was adjusted to 11.3 by adding 2.0 mL of NaOH solution (0.1 M); (3) an orange azo dye (λmax = 440 nm) was generated after incubation for two minutes; (4) the mixture was mixed with 3.0 mL of Fe3O4@SiO2 MNPs suspension and 3.0 mL of benzalkonium solution (2% v/v); (5) the mixture was stirred at 1250 rpm for 10 min to increase the adsorption of the azo dye onto the MNPs; (6) MNPs were separated from the solution by a powerful magnet, and the supernatant was then poured away; (7) the adsorbed dye was desorbed by agitating of the MNPs in 2.0 mL ethanol for 2.0 min; and (8) finally, an external magnet was used to separate the MNPs again, and spectrophotometric analysis was performed on the eluate solution. Figure 1 displays digital photos of the solution at every stage of the MSPE process.

Results and discussion

The current study used an MSPE method based on Fe3O4@SiO2@BZC MNPs for the effective pre-concentration of DOX in urine and water samples, followed by spectrophotometric analysis. The previously published research supports using pharmaceutical compounds as economical and safe reagents for color development or derivatization (Al-Uzri et al. 2023; Muhammed and Abed 2022). Prior to extraction, a diazotization coupling reaction between diazotized PP (a medicinal compound) and DOX was carried out in an alkaline medium to produce an orange azo dye with a maximum absorption wavelength of 440 nm.

The PP with an aromatic amino group is diazotized and then coupled with the o- or p-position of the phenolic groups of the DOX molecule in alkaline media. The coupling process requires the alkaline medium because it changes the DOX (phenolic compound) into a more reactive ionic form (phenoxide anion) (Hassan and Hadi 2022). The ratio of DOX to DPP was predicted to be 1:1 using the continuous variation method (Chatzēiōannou n.d.). Electrostatic adsorption of the azo dye with negative charge groups is possible on the surface of Fe3O4@SiO2@BZC MNPs. The pH zero point of charge of the Fe3O4@SiO2 MNPs is 6.5, so it has a negative surface charge in the alkaline medium. The BZC is a cationic surfactant that can easily electrostatically adsorbed on the negatively charged surface of the Fe3O4@SiO2 MNPs and produces an admicelle layer (Scheme 1). The azo dye can quickly establish electrostatic contact with the BZC cationic head that is present on the Fe3O4@SiO2@BZC MNPs surface. The absorption spectra of the generated azo dye before and after extraction are presented in Fig. 2. The stability of the azo dye λmax before and after the extraction process confirms the existence of electrostatic interaction and the absence of chemical interaction between the azo dye and the adsorbent (Fe3O4@SiO2@BZC MNPs). Scheme 1 depicts the proposed mechanism for the coupling reaction between DOX and DPP and the azo dye adsorption mechanism on the Fe3O4@SiO2@BZC MNP surface.

Characterization of the adsorbent

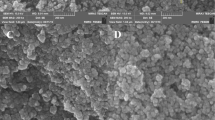

The synthesized MNPs were investigated using SEM and FTIR analysis. The FTIR spectrogram of the bare Fe3O4, Fe3O4@SiO2, and Fe3O4@SiO2@BZC MNPs were recorded to investigate their surface functional groups (Fig. 3A). The distinctive absorption band of Fe–O is recognizable in the spectra of Fe3O4 (at 570 cm−1), Fe3O4@SiO2 (at 572.8 cm−1) and Fe3O4@SiO2@BZC MNPs (at 588 and 597.9 cm−1) (Faraji et al. 2010). The stretching and bending vibrational bands of O–H are responsible for the absorption bands at approximately 3420 and 1627 cm−1, respectively. The FTIR spectra of Fe3O4@SiO2 and Fe3O4@SiO2@BZC MNPs clearly show the distinctive bands of asymmetry bending (at 1002–1022 cm−1), symmetry bending (at 879 cm−1), and stretching bending (at 489 cm−1) of Si–O–Si (LEE et al. 2012). These findings validate the SiO2 coating on the Fe3O4 MNPs. The adsorption of BZC on the Fe3O4@SiO2 MNPs surface was confirmed by the characteristic peaks of N+–CH3 (at 2937 cm−1), C–H stretching vibrations (at 2852 cm−1), and C–H bending (at 1469 cm−1) in the spectrum of Fe3O4@SiO2@BZC NPs (Hassan and Hadi 2022). Figure 3B–D shows the SEM images of the Fe3O4, Fe3O4@SiO2, and Fe3O4@SiO2@BZC MNPs, respectively. The SEM images display the agglomerated Fe3O4 MNPs with a diameter of about 17–30 nm, Fe3O4@SiO2 MNPs with a diameter of about 28 − 40 nm, and Fe3O4@SiO2@BZC MNPs with a diameter of about 40 − 56 nm.

Magnetic solid phase extraction optimization

The effects of several factors, including the solution pH, the amount of MNPs, surfactant, and reagents, eluent type and volume, and the time of adsorption and desorption, were examined to achieve the highest extraction efficiency. The aqueous solutions containing 2 µg/mL of DOX were used in the optimization step. The absorbance intensity of the azo dye (λmax = 440 nm) after desorption was utilized as the analytical signal. All the optimization experiments were replicated three times.

Influence of the reagent concentration and the solution pH

This study utilized PP as a safe and affordable color development reagent instead of hazardous and costly chemical substances. Furthermore, the current colorimetric reaction may be utilized to simultaneously determine both drugs (PP and DOX) by employing each drug as a reagent for the other drug. Before the extraction process, a diazotization coupling reaction between DPP and DOX was used to create a sensitive orange azo dye with a maximum absorption peak at 440 nm. The effect of the reagent concentration in the range of 1.0–5.0 mL (1.0 mM) on the analytical signal was examined, and the corresponding results are shown in Fig. 4A. Based on the findings, the volume of 2 mL was chosen as the optimal amount for the diazotized reagent solution (1.0 mM). According to preliminary investigations, an alkaline medium was necessary for the diazotization coupling reaction. Additionally, the pH of the extracted solution is a critical factor that can influence the solution's chemistry and the MNPs surface charge (Bagheri et al. 2024). Therefore, the solution pH was optimized as an essential analytical factor. The solution pH was adjusted by adding a varied amount of NaOH solution (0.1 M). The effect of NaOH solution (0.1 M) volume in the 0.5–4.0 mL range on the analytical signal was evaluated (Fig. 4B). The maximum adsorption efficiency (98.9%) and absorbance value of the desorbed dye were reached with pH = 11.25 (2 mL of NaOH solution). Therefore, 2 mL was selected as the optimum volume of the NaOH solution.

Influence of BZC amount

The impact of changing the amount of BZC solution (2% v/v) volume from 1.0 to 5.0 mL on the analytical signal was investigated, and the corresponding results are displayed in Fig. 4C. The extraction procedure yielded the best analytical signal when 3.0 mL of BZC solution was used. By increasing the BZC solution amount, the admicelle layer gradually forms on the surface of the Fe3O4@SiO2 MNPs. These findings suggest that the absorbent surface can be saturated with 3.0 mL of BZC solution. By further increasing the volume of the BZC solution, micelle production in the bulk solution could distribute the analyte into the solution, reducing analyte adsorption. Therefore, 3.0 mL of surfactant volume was selected for further use.

Influence of MNPs amount

The amount of Fe3O4@SiO2 MNPs is a significant factor influencing the extraction efficiency. Different volumes of the Fe3O4@SiO2 MNPs suspension (20.0 mg/mL) were added to the sample to vary the mass of the MNPs from 20 to 100 mg (Fig. 4D). By increasing the amount of sorbent to 60 mg, the extraction efficiency of azo dye was improved since more extraction sites were available. The extraction efficiencies remained almost constant by further increasing the sorbent concentrations. So, 60 mg of magnetic sorbent was selected as the optimal condition.

Influence of extraction time

The extraction time is the time required to completely transfer the analyte to the adsorbent after bringing the solution and adsorbent into contact. The impact of extraction time on azo dye extraction efficiency was examined over a duration of 4–16 min. The results demonstrated that the maximum analytical signal and removal efficiency were achieved for 10 min. For extraction time above 10 min, the adsorption efficiency approximately stayed constant. Therefore, 10 min was chosen as the optimal extraction time (Fig. 4E). The rapid extraction process was achieved due to the fast dynamic process, the large surface area of the MNPs, and uniform sorbent dispersion throughout the sample (Bagheri et al. 2024; Khalid et al. 2023).

Desorption conditions

The azo dye can be desorbed using a suitable organic solvent by disrupting the BZC admicelle structure on the adsorbed (Fe3O4@SiO2@BZC MNPs) surface. The desorption conditions were optimized by studying the impact of different parameters, including the type and volume of eluent, desorption time, and sample volume, on the analytical signal.

Influence of type and volume of eluent

The admicelle can be rapidly and completely disrupted by the organic solvents. By the admicelle disruption, the adsorbent dye can be desorbed. This study examined various organic solvent (eluent) types, including methanol, ethanol, acetone, chloroform, acetic acid, and cyclohexanol, for the desorption of the azo dye from the Fe3O4@SiO2@BZC MNPs. Based on the findings, it was concluded that ethanol was the best solvent since it produced the strongest signal (Fig. 5A). The influence of the ethanol volume on the analytical signal was also monitored in the range of 1.0 to 5.0 mL (Fig. 5B). As demonstrated in Fig. 5B, the analytical signal increased by increasing the ethanol volume up to 2.0 mL and then decreased. This decrease can be due to the dilution effect.

Influence of sample volume and desorption time

In addition, the influence of the sample amount and the desorption time on the analytical signal were also examined in the range of 10.0–100.0 mL and 1–5 min, respectively. As can be observed in Fig. 5C, the best analytical signal was achieved for the sample volume of 50.0 mL. Additionally, the analytical signal rose with an increase in the desorption time from 1 to 2 min and then started to level off at the higher time (Fig. 5D). Based on these obtained results (Fig. 5C, D), 2.0 mL of the sample volume with a desorption time of 2 min was selected as the optimal conditions. Table 1 summarizes the final optimum experimental parameters.

Influence of sample volume and reusability of the adsorbent

A large pre-concentration factor is usually obtained with a considerable volume of the sample. To examine the impact of sample volume, the azo dye product was extracted from a sample volume ranging from 10.0 to 100.0 mL, which contained 2.0 µg/mL of DOX under optimum conditions. As demonstrated in Fig. 5D, the absorbance value of desorbed azo dye increased up to a 50 mL volume before decreasing at higher test volumes. Thus, it was determined that under the given experimental conditions, the sorbent is unable to quantitatively adsorb the dye from solutions with volumes greater than 50.0 mL. With the sample volume of 50 mL and the final elution volume of 2.0 mL (described previously), a pre-concentration factor of 25 was easily attained. The reusability of prepared nanoparticles was evaluated (Al-Jabari et al. 2019). Six times, 60.00 mg of the NPs were utilized repetitively (Fig. 5E). Before being reused, the nanoparticles were twice cleaned for 30 s using ethanol and water and then dried. Subsequent investigations have demonstrated that the adsorption efficiency of the reused silica coated-Fe3O4 MNPs was sustained at around 90% and RSD% < than 4.4% after at least five recycles. All of the optimal studied variables are listed in Table 1.

Analytical characteristics of the method

To evaluate the current method, several figures of merit, including the limits of detection (LOD) and quantification (LOQ), linearity ranges, regression equations, the correlation of determinations (R2), and the accuracy and repeatability of the suggested method, were studied with and without MSPE at the optimal investigational variables (Table 2). The calibration plot was obtained by plotting the absorption intensity of the azo dye (at λmax) against the DOX concentration in the sample solutions. A good linear range of 0.08–3.0 µg/mL with a correlation coefficient 0.9977 was achieved. The LOD 0.01 µg/mL and the LOQ 0.04 µg/mL were estimated for the target analyte. The influence of the pre-treatment step on the sensitivity of the developed MSPE approach was confirmed by evaluating all analytical parameters without the extraction step. The obtained results are summarized in Table 2. The appropriate pre-concentration factor of 47 and enrichment factor of 25 were estimated. The pre-concentration factor is defined as the ratio of the sample volume to the eluent volume. Moreover, the accuracy and precision of the established extraction technique were assessed. In this regard, three spiked samples containing various amounts of DOX were prepared. Each of the prepared solutions was analyzed five times, and then, the error percentage, recovery percentages (Re%), and relative standard deviation percentages (RSD%) parameters were calculated (Table 3). These findings validate the excellent accuracy and precision of the developed method.

The reusability of the prepared sorbent was evaluated. In this regard, 6.00 mg of the Fe3O4@SiO2 MNPs were repeatedly used six times (Fig. 6). At every turn, the MNPs were washed twice for 30 s using ethanol and water and then dried. The findings have demonstrated that the adsorption efficiency of the Fe3O4@SiO2 MNPs was sustained at around 90% after at least five recycles. All of the optimal studied variables are listed in Table 1.

Analysis of the spiked samples

To check the reliability of the proposed MSPE approach in real sample analysis, the DOX was measured in urine samples and various types of water (surface and river water). In this regard, the real samples were spiked with different amounts of DOX, and after doing the MSPE process, the recovery values were calculated. The averages of five independent assessments are shown in Table 4. The obtained recovery percentage values for the urine and water samples analysis were 98–102% and 97–98.3%, respectively. The findings values in Table 4 validate the excellent accuracy and precision of the developed method.

Comparison with other documented methods

The performance features of the current method in comparison with previously described methods for DOX analysis in Table 5. The current spectrophotometric method is simple and cost-effective and can be substituted with many costly and sophisticated techniques, such as HPLC, LC/MS, and flow injection analysis (Al Abachi and Hadi 2014; Belal et al. 2019). Compared to the other given approaches in Table 5, the recommended strategy has good sensitivity and precision. Additionally, in the developed method, the MNPs can be easily synthesized using a minimal organic solvent and a safe colorimetric reagent that is a medicinal compound.

Conclusion

A quick, easy, and inexpensive magnetic solid-phase extraction (MSPE) approach based on benzalkonium chloride-modified silica-coated magnetite nanoparticles (Fe3O4@SiO2@BZC) was developed for the extraction and pre-concentration of doxycycline hyclate (DOX) from environmental and biological samples. Prior to extraction, DOX was coupled with procaine benzylpenicillin (PP) as a cost-efficient, available, and non-toxic color reagent using the azo-coupling procedure. The coupling of DOX with PP caused the generation of an orange azo dye with a λmax of 440 nm. Following the pre-treatment step, the target analyte was determined spectrophotometrically. Under optimal conditions, the developed technique demonstrated good analytical properties and was effectively utilized for the extraction and detection of DOX in the different water and urine samples. The developed approach in the present study outperforms most previous studies in terms of LOD. Another benefit of this study is the utilization of a straightforward, easily accessible, and user-friendly UV–vis spectroscopy to quantify the target analytes. The existing extraction method is expandable to pre-concentrate and quantify various phenolic compounds.

References

Abed RI, Hadi H (2020) Determination of vancomycin hydrochloride in pharmaceutical forms and urine samples using modified magnetic iron oxide nanoparticles. Arab J Sci Eng 45(6):4751–4763. https://doi.org/10.1007/s13369-020-04517-3

Al Abachi MQ, Hadi H (2014) Simple, rapid and sensitive method for the determination of mefenamic acid in pharmaceutical preparations. J Anal Chem 69(8):769–776. https://doi.org/10.1134/S106193481408005X/METRICS

Alipanahpour Dil E, Ghaedi M, Asfaram A, Tayebi L, Mehrabi F (2020) A ferrofluidic hydrophobic deep eutectic solvent for the extraction of doxycycline from urine, blood plasma and milk samples prior to its determination by high-performance liquid chromatography-ultraviolet. J Chromatogr A 1613:460695. https://doi.org/10.1016/j.chroma.2019.460695

Aliu M, Junaid A, Ibraheem A, Ishaq A, Lawal A, Ayeni K et al (2023) Dispersive liquid-liquid microextraction/HPLC techniques for determination of oxytetracycline and doxycycline residues in beef samples: method developments and statistical analysis. Afr Sci Rep 2:87–87. https://doi.org/10.46481/ASR.2023.2.1.87

Al-Jabari MH, Sulaiman S, Ali S, Barakat R, Mubarak A, Khan SA (2019) Adsorption study of levofloxacin on reusable magnetic nanoparticles: kinetics and antibacterial activity. J Mol Liq 291:111249. https://doi.org/10.1016/J.MOLLIQ.2019.111249

Al-Toriahi AKM, Azooz EA, Al-Mulla EAJ (2023) Metal nanoparticles and nano-filters for the disposal of hospital waste: a review. Nano Biomed Eng 15(2):179–190. https://doi.org/10.26599/NBE.2023.9290017

Al-Uzri WA, Jamal M, Hadi H (2023) Colorimetric determination of salbutamol sulfate using spectrophotometry-continuous flow injection technique in pure and pharmaceutical forms. Iraqi Journal of Pharmaceutical Sciences (p-ISSN 1683-3597 E-ISSN 2521-3512) 32(1):45–52. https://doi.org/10.31351/VOL32ISS1PP45-52

Arain MB, Yilmaz E, Hoda N, Kazi TG, Soylak M (2019) Magnetic solid-phase extraction of quercetin on magnetic-activated carbon cloth (MACC). J Iran Chem Soc 16(7):1365–1372. https://doi.org/10.1007/S13738-019-01622-5/METRICS

Bagheri V, Naseri A, Sajedi-Amin S, Soylak M, Zhang Z (2024) Using Fe3O4-graphene oxide-modified chitosan with melamine magnetic nanocomposite in the removal and magnetic dispersive solid-phase microextraction of Cr (VI) ion in aquatic samples. Chem Pap 78(1):381–396. https://doi.org/10.1007/S11696-023-03096-5/METRICS

Belal F, Hadi H, Jamal M (2019) Reversed flow-injection method for estimation of chlorpromazine in pharmaceuticals and urine samples using charge-transfer complexation. Bull Chem Soc Ethiop 33(1):11–20. https://doi.org/10.4314/BCSE.V33I1.2

Ben Y, Fu C, Hu M, Liu L, Wong MH, Zheng C (2019) Human health risk assessment of antibiotic resistance associated with antibiotic residues in the environment: a review. Environ Res 169:483–493. https://doi.org/10.1016/j.envres.2018.11.040

Camızcı Aran G, Bayraç C (2023) Magnetic solid-phase extraction of fipronil from aqueous solution and eggshells using amine-coated iron oxide nanoparticles. ChemPlusChem 88(5):e202300055. https://doi.org/10.1002/CPLU.202300055

Cherkashina K, Voznesenskiy M, Osmolovskaya O, Vakh C, Bulatov A (2020) Effect of surfactant coating of Fe3O4 nanoparticles on magnetic dispersive micro-solid phase extraction of tetracyclines from human serum. Talanta 214:120861. https://doi.org/10.1016/j.talanta.2020.120861

Ding L, Cao Y, Li H, Wang F, Guo DY, Yang W, Pan Q (2022) A ratiometric fluorescence-scattering sensor for rapid, sensitive and selective detection of doxycycline in animal foodstuffs. Food Chem 373:131669. https://doi.org/10.1016/J.FOODCHEM.2021.131669

Faraji M, Yamini Y, Tahmasebi E, Saleh A, Nourmohammadian F (2010) Cetyltrimethylammonium bromide-coated magnetite nanoparticles as highly efficient adsorbent for rapid removal of reactive dyes from the textile companies’ wastewaters. J Iran Chem Soc 7(2):S130–S144. https://doi.org/10.1007/BF03246192/METRICS

Feng X, Ashley J, Zhou T, Sun Y (2018) Fluorometric determination of doxycycline based on the use of carbon quantum dots incorporated into a molecularly imprinted polymer. Microchim Acta 185(11):1–9. https://doi.org/10.1007/s00604-018-2999-8

Ghaemi M, Absalan G (2015) Fast removal and determination of doxycycline in water samples and honey by Fe3O4 magnetic nanoparticles. J Iran Chem Soc 12(1):1–7. https://doi.org/10.1007/S13738-014-0450-6/METRICS

Hadjiioannou TP, Christian GD, Koupparis MA, Macheras PE (1993) Quantitative calculations in pharmaceutical practice and research. VCH, New York, pp 345–348. https://cir.nii.ac.jp/crid/1130000793842821888. Accessed 8 Mar 2024

Hamidi S (2023) Recent advances in solid-phase extraction as a platform for sample preparation in biomarker assay. Crit Rev Anal Chem 53(1):199–210. https://doi.org/10.1080/10408347.2021.1947771

Han S, Zhang X, Sun H, Wei J, Wang H, Wang S et al (2022) Electrochemical behavior and voltammetric determination of chloramphenicol and doxycycline using a glassy carbon electrode modified with single-walled carbon nanohorns. Electroanalysis 34(4):735–742. https://doi.org/10.1002/ELAN.202100354

Hassan B, Hadi H (2022) Magnetic solid-phase extraction based on benzalkonium chloride-coated Fe3O4@SiO2 nanoparticles for spectrophotometric determination of ritodrine hydrochloride and salbutamol sulfate in water and urine samples. Microchem J 181:107805. https://doi.org/10.1016/J.MICROC.2022.107805

Hassan B, Hadi H (2023) Magnetic nanoparticles and cationic surfactants for the extraction and determination of phenolic compounds in environmental and biological samples. Green Analyt Chem 6:100064. https://doi.org/10.1016/J.GREEAC.2023.100064

Khalid A, Ahmed RM, Taha M, Soliman TS (2023) Fe3O4 nanoparticles and Fe3O4 @SiO2 core-shell: synthesize, structural, morphological, linear, and nonlinear optical properties. J Alloy Compd 947:169639. https://doi.org/10.1016/J.JALLCOM.2023.169639

Kogawa AC, Salgado HRN (2013) Quantification of doxycycline hyclate in tablets by HPLC–UV method. J Chromatogr Sci 51(10):919–925. https://doi.org/10.1093/CHROMSCI/BMS190

Lee JS, Lee EJ, Hwang HJ (2012) Synthesis of Fe3O4-coated silica aerogel nanocomposites. Trans Nonferrous Metals Soc China 22(SUPPl 3):702–706. https://doi.org/10.1016/S1003-6326(12)61790-7

Li Z, Li S, Li Y, Liu M, Jiang L, Niu J et al (2023) Highly selective and sensitive determination of doxycycline integrating enrichment with thermosensitive magnetic molecular imprinting nanomaterial and carbon dots based fluorescence probe. Sci Total Environ 896:165257. https://doi.org/10.1016/j.scitotenv.2023.165257

Liu M, Li Y, Lin S, Dong X (2014) Determination of tetracycline residues in lake water by on-line coupling of molecularly imprinted solid-phase extraction with high performance liquid chromatography. Anal Methods 6(23):9446–9452. https://doi.org/10.1039/C4AY02009J

Mileva R (2019) Determination of free doxycycline concentrations in the plasma and milk of sheep and in the plasma of rabbits by using the HPLC method. Maced Vet Rev. https://doi.org/10.2478/macvetrev-2019-0016

Muhammed FF, Abed SS (2022) Flow injection spectrophotometric technique for determining of genistein in pure and supplements formulations through diazotization coupling reaction. Iraqi J Pharm Sci (p-ISSN 1683-3597 E-ISSN 2521-3512) 31(1):278–284. https://doi.org/10.31351/VOL31ISS1PP278-284

Opriş O, Coman V, Copaciu F, Vlassa M (2012) Solid phase extraction and high-performance thin-layer chromatography quantification of some antibiotics from surface waters. JPC—J Planar Chromatogr—Mod TLC 25(6):516–522. https://doi.org/10.1556/JPC.25.2012.6.5

Ortúzar M, Esterhuizen M, Olicón-Hernández DR, González-López J, Aranda E (2022) Pharmaceutical pollution in aquatic environments: a concise review of environmental impacts and bioremediation systems. Front Microbiol 13:869332. https://doi.org/10.3389/FMICB.2022.869332/BIBTEX

Rabeie B, Mahmoodi NM, Mahkam M (2022) Morphological diversity effect of graphene quantum dot/MIL88A(Fe) composites on dye and pharmaceuticals (tetracycline and doxycycline) removal. J Environ Chem Eng 10(5):108321. https://doi.org/10.1016/J.JECE.2022.108321

Rahman N, Raheem A (2022) Graphene oxide/Mg-Zn-Al layered double hydroxide for efficient removal of doxycycline from water: Taguchi approach for optimization. J Mol Liq 354:118899. https://doi.org/10.1016/J.MOLLIQ.2022.118899

Ramesh PJ, Basavaiah K, Tharpa K, Kanakapura B, Vinay H, Doddarevanna R (2010) Development and validation of RP-HPLC method for the determination of doxycycline hyclate in spiked human urine and pharmaceuticals. J Pre-Clin Clinl Res 4(2):101–107. https://www.jpccr.eu. Accessed 8 Mar 2024

Ramezani AM, Yamini Y (2020) Electrodeposition of poly-ethylenedioxythiophene-graphene oxide nanocomposite in a stainless steel tube for solid-phase microextraction of letrozole in plasma samples. J Sep Sci 43(23):4338–4346. https://doi.org/10.1002/jssc.202000838

Saghafi A, Sanavi Khoshnood R, Sanavi Khoshnoud D, Eshaghi Z (2022) Preconcentration and determination of four antibiotics in biological samples using nanofluid-assisted magnetic dispersive micro-solid-phase extraction coupled with high-performance liquid chromatography. Chem Pap 76(2):901–911. https://doi.org/10.1007/S11696-021-01903-5/METRICS

Sancho E, Granados-Chinchilla F, Barquero-Calvo E (2022) Determination of streptomycin and doxycycline using LC/MS towards an effective treatment against an experimental Brucella abortus infection in mice. J Microbiol Methods 194:106436. https://doi.org/10.1016/J.MIMET.2022.106436

Saridal K, Ulusoy Hİ (2019) A simple methodology based on cloud point extraction prior to HPLC-PDA analysis for tetracycline residues in food samples. Microchem J 150:104170. https://doi.org/10.1016/J.MICROC.2019.104170

Šatínský D, Dos Santos LML, Sklenářová H, Solich P, Montenegro MCBSM, Araújo AN (2005) Sequential injection chromatographic determination of ambroxol hydrochloride and doxycycline in pharmaceutical preparations. Talanta 68(2):214–218. https://doi.org/10.1016/J.TALANTA.2005.06.059

Selvadurai M, Meyyanathan SN (2010) Determination of doxycycline in human plasma by liquid chromatography-mass spectrometry after liquid-liquid extraction and its application in human pharmacokinetics studies. J Bioequiv Bioavailab. https://doi.org/10.4172/jbb.1000038

Simamora P, Manullang M, Munthe J, Rajagukguk J (2018) The structural and morphology properties of Fe3O4/Ppy nanocomposite. In: Journal of physics: conference series, vol 1120. Institute of Physics Publishing. https://doi.org/10.1088/1742-6596/1120/1/012063

Soylak M, Ozalp O, Uzcan F (2021) Magnetic nanomaterials for the removal, separation and preconcentration of organic and inorganic pollutants at trace levels and their practical applications: a review. Trends Environ Analyt Chem 29:e00109. https://doi.org/10.1016/J.TEAC.2020.E00109

Soylak M, Uzcan F, Goktas O, Gumus ZP (2023) Fe3O4-SiO2-MIL-53 (Fe) nanocomposite for magnetic dispersive micro-solid phase extraction of cadmium (II) at trace levels prior to HR-CS-FAAS detection. Food Chem 429:136855. https://doi.org/10.1016/J.FOODCHEM.2023.136855

Sun J, Zhou S, Hou P, Yang Y, Weng J, Li X, Li M (2007) Synthesis and characterization of biocompatible Fe3O4 nanoparticles. J Biomed Mater Res, Part A 80A(2):333–341. https://doi.org/10.1002/JBM.A.30909

Sun D, Song Z, Zhang Y, Wang Y, Lv M, Liu H et al (2021) Recent advances in molecular-imprinting-based solid-phase extraction of antibiotics residues coupled with chromatographic analysis. Front Environ Chem. https://doi.org/10.3389/fenvc.2021.703961

Suseela MNL, Viswanadh MK, Mehata AK, Priya V, Vikas S, A et al (2023) Advances in solid-phase extraction techniques: Role of nanosorbents for the enrichment of antibiotics for analytical quantification. J Chromatogr A 1695:463937. https://doi.org/10.1016/J.CHROMA.2023.463937

Tang HZ, Wang YH, Li S, Wu J, Gao ZX, Zhou HY (2020) Development and application of magnetic solid phase extraction in tandem with liquid–liquid extraction method for determination of four tetracyclines by HPLC with UV detection. J Food Sci Technol 57(8):2884–2893. https://doi.org/10.1007/S13197-020-04320-W/METRICS

Treder N, Szuszczewicz N, Roszkowska A, Olędzka I, Bączek T, Bień E et al (2023) Magnetic solid-phase microextraction protocol based on didodecyldimethylammonium bromide-functionalized nanoparticles for the quantification of epirubicin in biological matrices. Pharmaceutics 15(4):1227. https://doi.org/10.3390/PHARMACEUTICS15041227/S1

Xu N, Li M, Chou WC, Lin Z (2020) A physiologically based pharmacokinetic model of doxycycline for predicting tissue residues and withdrawal intervals in grass carp (Ctenopharyngodon idella). Food Chem Toxicol 137:111127. https://doi.org/10.1016/J.FCT.2020.111127

Yang Y, Zhang J, Li Y, Yin S, Jiang Y, Sun C (2021) Determination of seven tetracyclines in milk by dissolvable layered double hydroxide-based solid-phase extraction coupled with high-performance liquid chromatography. Anal Methods 13(13):1618–1624. https://doi.org/10.1039/D1AY00154J

Zaher A, Taha M, Mahmoud RK (2021) Possible adsorption mechanisms of the removal of tetracycline from water by La-doped Zn-Fe-layered double hydroxide. J Mol Liq 322:114546. https://doi.org/10.1016/J.MOLLIQ.2020.114546

Zhang D, Yang X, an, Jin, C. zhao, & Zhang, W. bing. (2023) Ultrasonic assisted magnetic solid phase extraction of ultra-trace mercury with ionic liquid functionalized materials. Anal Chim Acta 1245:340865. https://doi.org/10.1016/J.ACA.2023.340865

Zhao X, Shi Y, Cai Y, Mou S (2008) Cetyltrimethylammonium bromide-coated magnetic nanoparticles for the preconcentration of phenolic compounds from environmental water samples. Environ Sci Technol 42(4):1201–1206. https://doi.org/10.1021/ES071817W/SUPPL_FILE/ES071817W-FILE002.PDF

Zhao J, Liao W, Yang Y (2015) Magnetic solid-phase extraction for determination of sulpiride in human urine and blood using high-performance liquid chromatography. Biomed Chromatogr 29(12):1871–1877. https://doi.org/10.1002/BMC.3509

Zhuang Y, Lin B, Yu Y, Wang Y, Zhang L, Cao Y, Guo M (2021) A ratiometric fluorescent probe based on sulfur quantum dots and calcium ion for sensitive and visual detection of doxycycline in food. Food Chem 356:129720. https://doi.org/10.1016/J.FOODCHEM.2021.129720

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no competing or conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammed, T., Hadi, H. Magnetic solid phase extraction based on Fe3O4@SiO2@BZC as adsorbent for the extraction and pre-concentration of doxycycline hyclate from water and urine samples prior to UV–vis spectrophotometric analysis. Chem. Pap. 78, 5071–5084 (2024). https://doi.org/10.1007/s11696-024-03453-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-024-03453-y