Abstract

The potential impact of the liquid–liquid extraction technique for the removal and extraction of iron (III) metal ions has been investigated utilizing different basic extractants. In this respect, Octylamine and N,N-dimethylaniline as primary and tertiary amines were employed for the elimination of Fe(III) ions using benzine as a diluent and with the examination of various supportive parameters as solution pH, contact period, extractant concentration, metal ion concentration, diluent type and loading capacity. The solvent extraction results demonstrated that the maximum removal % of Fe(III) was found to be 96 and 92% for Octylamine and N, N-dimethylaniline, respectively, and it was fast, reached equilibrium after 30 min., and optimized at pH 2 with 0.05 M of the utilized extractants. According to the distribution coefficient calculations, two moles of Octylamine extractant are required for the extraction of a mole of Fe(III) ion, while for N,N-dimethylaniline one mole of it is for extraction of a mole of Fe(III) ion. Moreover, the maximum loading capacity of Fe(III) ions in the organic phase after 5 subsequent stages was 49.8 and 45.4 g/L for Octylamine and N,N-dimethylaniline, respectively. Therefore, the proposed system emphasizes and highlights the promising capability for future progress in the field of extraction techniques and wastewater management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrial wastewater is one of the significant sources of aquatic pollution, which possesses heavy metals that stand out because of their stability and toxicity. Moreover, heavy metal contamination is brought on by aqueous industrial wastes from a variety of processes, including tanning, mining, metal plating, etc. One of these heavy metals is iron which has a big challenge to decontaminate, as it plays a crucial role in ensuring that various enzymes in the human body function properly and make up 5% of the Earth's crust, making it the fourth most abundant element (Khatri et al. 2017). Further, iron is found in groundwater Fe2+ ions; the existence of iron in water is likely the most frequent issue that both consumers and water treatment experts encounter after hardness. The secondary maximum contaminant level (MCL) for iron is 0.3 mg/l, which, if it comes into contact with and stays in the tissues, may result in conjunctivitis, choroiditis, and retinitis (Nieto et al. 2010). On the other hand, the appearance of iron with a relatively considerable amount as a blotch during the recovery of valuable metals from ores by the hydrometallurgical method represents a huge problem. Therefore, it is an inevitable task to eliminate iron ions from samples of real and synthetic solutions. So, over the years, numerous techniques have been developed for wastewater management that contains ions of heavy metal, including ion exchange, solvent extraction, reverse osmosis, chemical precipitation, membrane separation, electroflotation, coagulation, etc. (Maes et al. 2017). A successful method for the recovery and enrichment of metal ions is solvent extraction. The primary benefits of this method are its ease of automatic control, low cost, effective separation, and continuous operation (Maes et al. 2017; Su et al. 2016). The solvent extraction procedures commonly studied are systems of phosphates (ASANO et al. 2001; Mishra et al. 2010), amines (Alguacil and Amer 1986a, 1986b; Alguacil et al. 1987; Saji and Reddy 2001), and carboxylic acids (Pouillon and Doyle 1988). However, the phosphate extraction process lacks selectivity, and it is challenging to strip the iron-loaded organic phase. Because carboxylic acids dissolve so easily in water in the carboxylic acid extraction system, extractant loss is significant. Therefore, these two extractants cannot be used for iron elimination. Otherwise, the extraction of iron with an amine extraction system has a higher extraction percent and preferable selectivity. Amine systems with iron are simpler to strip rather than phosphate systems (Luo et al. 2004a, b; Sun and O’Keefe 2002). Moreover, the removal of Fe(III) was examined utilizing various extractants like neodecanoic acid (Stefanakis and Monhemius 1987), tributyl phosphate (TBP) (Saji and Reddy 2001), 2-EPAMEE (PC-88A) (Jayachandran and Dhadke 1997), Bis(2-ethylhexyl) hydrogen phosphate (DEHPA)(El-Nadi and El-Hefny 2010). Dioctyl phenyl phosphate (Ismael and Carvalho 2003). Further, a Primene JMT as a primary amine was applied for Fe(III) elimination from neutral and sulfuric acid solutions (Li et al. 2011). Also, Cyanex 923 (a mixture of R3PO (14%), R2R'PO (42%), RR'2PO (31%), and R3'PO(8%)) (Deep et al. 2006), tetraalkylated malonamides (Paiva and Costa 2005), 3-phenyl-4-benzoyl-5-isoxazolone (HPBI) (Remya et al. 2004), Phosphinothioic acid, bis(2,4,4-trimethylpentyl) with fiber membrane (Luo et al. 2004a, b), 1-hydroxy-1-phosphono-hexadecyl phosphinic acid (Biswas and Singha 2006). and an aliphatic tertiary amine (Adogen 364) (de San Miguel et al. 2000), were checked for iron separation. At lower pH values, Cyanex 272 (soluble in Isopar-H as a diluent) was reported for Fe(III) extraction from nitrate medium and showed a decrease in extraction % with changing the aqueous phase anion composition (Zhao et al. 2022). The aim of this work will be oriented for the removal of Fe(III) from aqueous solutions that may be produced as industrial wastewater or produced during the hydrometallurgical process for the recovery of valuable metals from ores, at highly acidic medium using basic organic extractants to avoid the drawbacks of other neutral and acidic extractants as well as different effective parameters will be investigated and optimized.

Experimental

Materials and method

Analytical reagent-grade materials were utilized for this study. Sigma Aldrich provided iron (III) chloride (99.9%). Merck provided the N,N-dimethylaniline and octylamine. Xylene, benzene, benzine, hexane, and ammonium thiocyanate were bought from the Misr Petroleum Company in Egypt. The solutions' pH was adapted with 0.1 M HCl and 0.1 M NH4OH.

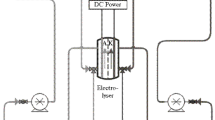

Instrumentation

Fe(III) metal ions concentration was recorded by Shimadzu UV–Visible Spectrophotometer (UV-160A, Shimadzu Kyoto, Japan) through thiocyanate method at the wavelength (λmax) of 495 ± 2 nm (Marczenko 1975).

Experimental procedure

Two different amines Octylamine (primary) and N,N-dimethylaniline (tertiary) were utilized for the extraction procedures which were separately solubilized in benzine. For practical and economic purposes, benzine was employed as a diluent in this study. The influence of contact time, pH, initial metal ion concentration, extractant concentration, diluent type, and loading capacity on the removal of Fe(III) ions by the investigated amines was tested. To avoid the hydrolysis of Fe(III) metal ions, the initial pH values of the prepared samples were performed at 1.5; 2 and 2.5 pH values by contacting 5 mL of Fe(III) solution (100 mg/L) with 5 mL of 0.075 M from the two investigated amines extractant for 1 h at 25 ± 1 °C in a thermostatic shaker. Further, the contact time parameter was conducted at (5, 10, 15, 30, 45, 60, 90, 120 min) by contacting 5 mL of Fe(III) solution (100 mg/L) with 5 mL of 0.075 M from the two investigated amines extractant at 25 ± 1 °C and sample's pH 2. The impact of the extractant concentration was examined in the range (0.005, 0.01, 0.025, 0.05, 0.075, 0.1 M) by contacting 5 mL of Fe(III) solution (100 mg/L) with 5 mL from the two investigated amines(different concentration) for 30 min and sample's pH 2. Moreover, the diluent type effect was checked by using different diluents as benzene, hexane and xylene, in which 5 mL of Fe(III) ion solution (100 mg/L) with 5 mL of 0.05 M from the two investigated amines extractant dissolved in the different diluents at 25 ± 1 °C, pH value of 2 for 30 min. Different Fe(III) ion (5 mL) concentrations (50, 100, 200, 300, 400, 500 mg/L) were tested to evaluate the removal process efficiency through mixing with 5 mL of 0.05 M from the two investigated amines extractant (dissolved in benzine) at 25 ± 1 °C, pH value of 2 for 30 min. The maximum loading capacity of the organic extractant was investigated in different cycles by contacting 5 mL of Fe(III) solution (100 mg/L) with 5 mL of 0.05 M from the two investigated amines extractant at 25 ± 1 °C, optimum pH value of 2 for 30 min., after the separation of the 2 phases, the organic phase was used in the second cycle with a new metal ion sample, and thus for multicycles until reaching the organic phase saturation. Note that the organic/aqueous phase ratio in all the previous experiments was 1:1.

The removal percentage was calculated by the following equation (Mingyu et al. 2011):

where Co and Ce are the initial and final Fe(III) metal ions concentration in the aqueous solution after the removal process, respectively.

The value of the extraction or distribution ratio was calculated by the following equation (Agrawal et al. 2011):

Results and discussion

This study's primary goal is to introduce a new procedure for iron removal as one of the critical heavy metals utilizing solvent extraction techniques.

Influence of aqueous solution pH value

The hydrogen ion concentration (pH) of the influent affects the extraction yield of metals ion. Based on the obtained results in Fig. 1, the Fe(III) metal ion removal % increased with increasing pH value from 87 to 98% for Octylamine and from 76 to 93% for N,N-dimethylaniline (Li et al. 2011). In this regard, the value of pH 2 was chosen in the next experiment to avoid the probability of metal hydrolysis.

Impact of equilibration time

The removal of Fe(III) metal ions was examined as a function of time. According to the obtained results in Fig. 2, the removal efficiency grew up with contact time and reached equilibrium after 30 min with removal efficiency 96 and 92% for Octylamine and N,N-dimethylaniline, respectively. Faster mass transfer rates between the two phases of the extraction process result from shorter contact times (Agrawal et al. 2011). Hence, the shaking time was fixed at 30 min in all the experiments performed.

The extractant concentration impact

The amine extractants concentration in the organic phase is one of them is crucial factors that significantly influence the final removal process of Fe(III) ions. According to Fig. 3, it was observed that the removal efficiency is directly proportional to the investigated extractants concentration and reached equilibrium at 0.05 M (Li et al. 2011).

The concentration of Fe(III) in the two immiscible organic and aqueous phases was investigated in term of the distribution coefficient (KD) of to elucidate how many number of the utilized organic solvent molecules are required for the extraction of Fe(III) ions.

. Therefore, the plot of log D vs log [extractant] for extraction of iron as shown in Fig. 4 illustrates the slope of 1.52 for Octylamine which indicates the association of two moles of it for extraction of a mole of Fe(III) ion; on the other hand, for N,N-dimethylaniline, the slope value was 1.27 that clarify the association of a mole of it for extraction of a mole of the metal ion (Mishra et al. 2010, 2011).

Mechanism for extraction of iron

The extraction mechanism of metal ions using the hydrophobic basic organic extractant (amines) is usually called liquid anion exchangers in which a negatively charged metal complex present in the aqueous phase is exchanged for anions in the organic phase. In this regard, the primary, secondary and tertiary amines are not the active form for the extraction of metals. They first must be protonated (Lommelen 2021):

where r is 1 (primary amine), 2 (secondary amine) or 3 (tertiary amine).

On the other hand, the extraction of Fe(III) from HCl medium can be represented by the following equation (Mishra et al. 2010):

where ‘S’ is the organic extractant (Octylamine, N,N-dimethylaniline).

Therefore and based on the above experimental results the proposed extraction mechanism of iron utilizing the investigated amines may be represented by the following Eq. (5) for Octylamine and Eq. (6) for N,N-dimethylaniline extractants:

The effect of diluent type

Due to their aggregation in the organic phase, diluents have an impact on the extraction of metals by amines and acids (Ritcey and Ashbrook 1984). As a result, as shown in Table 1, different aliphatic and aromatic solvents with various dielectric constants were examined as diluents for the extraction of Fe(III) metal ions. According to the findings in Fig. 5, benzine and hexane are both preferred for Fe(III) ions removal process. According to a report by Desouky et al. (2009), there is a strong correlation between a diluent's effect and its dielectric constant. The weak hydrogen bonding capacity and low dielectric constant of the diluents are desirable. Therefore, aliphatic benzine was chosen as the diluent for all experimental work due to a number of reasons, including cost, environmental and safety considerations, and maximum extraction efficiency.

Influence of metal ion concentration

The impact of the initial concentration of Fe(III) metal ions in the range of 50–500 mg/L was tested on its removal process with 0.05 M of the investigated amines and at an organic/aqueous phase ratio equal to 1. It was noticed that increasing the initial Fe(III) concentration decreased the extraction efficiency from 96 to 49% in the case of Octylamine, and decreased from 93 to 42% with N,N-dimethylaniline, Fig. 6 (Agrawal et al. 2011).

The effect of loading capacity

The loading capacity is an important variable for the applicability of an extractant and is defined as the amount of metal ion extracted in the pure extractant (Ali et al. 2011). In this respect, the loading capacity of Octylamine, and N,N-dimethylaniline extractants in benzine was studied by shaking 100 mg/L Fe(III) in aqueous solution with 0.05 M from both extractants individually at constant organic/aqueous phase ratio of 1:1; the two phases were separated, and Fe(III) metal ions concentration was determined, then again the same organic phase was utilized for the extraction of a fresh Fe(III) sample, Fig. 7. This procedure was repeated till no extraction of Fe(III) was obtained with the organic solvent. After 5 extraction stages, the concentration of Fe(III) in the organic phase of the Octylamine extractant was found to be 240 mg/5 mL (49.8 g/L), and 227 mg/5 mL (45.4 g/L) with N,N-dimethylaniline.

Comparison study for iron removal with other systems

The removal of Fe(III) ions using Octylamine and N,N-dimethylaniline extractants compared with some previous studies are briefed in Table 2. It was remarkable that the current work demonstrates higher removal efficiency rather than the others and in consequence, is considered a promising outcome for Fe(III) ions elimination.

Conclusion

Fast, effective and promising study was performed for the removal of Fe(III) ions by solvent extraction technique using different organic extractants at highly acidic medium that can be applied for the decontamination process whatever from industrial wastewater or hydrometallurgical aqueous solutions. This investigation clarified the optimized parameters for the extraction process at pH value 2, 0.05 M concentration of the extractant, and equilibration time 30 min at organic/aqueous ratio = 1. Otherwise, two moles of Octylamine extractant or one mole of N,N-dimethylaniline, respectively, are required for the extraction of a mole of Fe(III) ion. Further, a very high loading capacity for Fe(III) ions was observed to be 49.8 and 45.4 g/L for Octylamine and N,N-dimethylaniline, respectively. In this regard, the presented extraction system is highly recommended for the extraction of iron metal ions.

References

Agrawal A, Kumari S, Sahu K (2011) Studies on solvent extraction of iron (III) as a step for conversion of a waste effluent to a value added product. J Environ Manag 92(12):3105–3111

Alguacil FJ, Amer S (1986a) Extraction equilibrium between primary amine primene 81R and iron (III) sulphate. Polyhedron 5(11):1747–1753

Alguacil FJ, Amer S (1986b) The extraction of iron (III) from aqueous sulphate solutions by primene sulphate. Hydrometallurgy 15(3):337–350

Alguacil FJ, Amer S, Luis A (1987) The application of Primene 81R for the purification of concentrated aluminium sulphate solutions from leaching of clay minerals. Hydrometallurgy 18(1):75–92

Ali M, Biswas R, Salam S, Akhter A, Karmakar A, Ullah M (2011) Cyanex 302: an extractant for Fe3+ from chloride medium. Bangladesh J Sci Ind Res 46(4):407–414

Asano H, Itabashi H, Kawamoto H (2001) Separation of iron (III) by di (2-ethylhexyl) phosphate/4-methyl-2-pentanone extraction. Tetsu-to-Hagane 87(9):623–625

Biswas R, Singha H (2006) Purified Cyanex 272: Its interfacial adsorption and extraction characteristics towards iron (III). Hydrometallurgy 82(1–2):63–74

de San Miguel ER, Aguilar JC, Rodrı́guez MT, De Gyves J (2000) Solvent extraction of Ga (III), Cd (II), Fe (III), Zn (II), Cu (II), and Pb (II) with ADOGEN 364 dissolved in kerosene from 1–4 mol dm−3 HCl media. Hydrometallurgy 57(2):151–165

Deep A, Correia PF, Carvalho JM (2006) Selective recoveries of Fe (III) and Cr (III) from a tannery filtrate using Cyanex 923. Anal Chim Acta 558(1–2):254–260

Desouky O, Daher A, Abdel-Monem Y, Galhoum A (2009) Liquid–liquid extraction of yttrium using primene-JMT from acidic sulfate solutions. Hydrometallurgy 96(4):313–317

El-Nadi Y, El-Hefny N (2010) Removal of iron from Cr-electroplating solution by extraction with di (2-ethylhexyl) phosphoric acid in kerosene. Chem Eng Process 49(2):159–164

Ismael M, Carvalho J (2003) Iron recovery from sulphate leach liquors in zinc hydrometallurgy. Miner Eng 16(1):31–39

Jayachandran J, Dhadke P (1997) Liquid-liquid extraction separation of iron (III) with 2-ethyl hexyl phosphonic acid mono 2-ethyl hexyl ester. Talanta 44(7):1285–1290

Khatri N, Tyagi S, Rawtani D (2017) Recent strategies for the removal of iron from water: a review. J Water Process Eng 19:291–304

Li M, He Z, Zhou L (2011) Removal of iron from industrial grade aluminum sulfate by primary amine extraction system. Hydrometallurgy 106(3–4):170–174

Lommelen R, Binnemans K (2021) Hard–Soft Interactions in Solvent Extraction with Basic Extractants: Comparing Zinc and Cadmium Halides. Acs Omega 6(42):27924–27935

Luo F, Li D, Wei P (2004a) Synergistic extraction of zinc (II) and cadmium (II) with mixtures of primary amine N1923 and neutral organophosphorous derivatives. Hydrometallurgy 73(1–2):31–40

Luo F, Li D, Wu Y (2004b) Extraction and separation of cadmium (II), iron (III), zinc (II), and europium (III) by Cyanex302 solutions using hollow fiber membrane modules. Solvent Extr Ion Exch 22(1):105–120

Maes S, Zhuang W-Q, Rabaey K, Alvarez-Cohen L, Hennebel T (2017) Concomitant leaching and electrochemical extraction of rare earth elements from monazite. Environ Sci Technol 51(3):1654–1661

Mao X (2015) Solvent extraction of iron (III) from chloride acid solutions by decanol. In: 3rd international conference on material, mechanical and manufacturing engineering (IC3ME 2015)

Marczenko Z (1975) Spectrophotometric determination of elements. E. Horwood

Mingyu L, Zhimei H, Li Z (2011) Extraction of iron by primary amine N1923 from industrial aluminium sulfate. In: 2011 international conference on computer distributed control and intelligent environmental monitoring

Mishra R, Rout P, Sarangi K, Nathsarma K (2010) A comparative study on extraction of Fe (III) from chloride leach liquor using TBP, Cyanex 921 and Cyanex 923. Hydrometallurgy 104(2):298–303

Mishra R, Rout P, Sarangi K, Nathsarma K (2011) Solvent extraction of Fe (III) from the chloride leach liquor of low grade iron ore tailings using Aliquat 336. Hydrometallurgy 108(1–2):93–99

Nieto LM, Alami SBD, Hodaifa G, Faur C, Rodríguez S, Giménez JA, Ochando J (2010) Adsorption of iron on crude olive stones. Ind Crops Prod 32(3):467–471

Paiva A, Costa M (2005) Application of N, N′-tetrasubstituted malonamides to the recovery of iron (III) from chloride solutions. Hydrometallurgy 77(1–2):103–108

Pośpiech B, Walkowiak W (2010) Studies on iron (III) removal from chloride aqueous solutions by solvent extraction and transport through polymer inclusion membranes with D2EHPA. Physicochem Probl Miner Process 44:195–204

Pouillon D, Doyle F (1988) Solvent extraction of metals with carboxylic acids—Theoretical analysis of extraction behaviour. Hydrometallurgy 19(3):269–288

Remya P, Pavithran R, Reddy M (2004) 3-Phenyl-4-acyl-5-isoxazolones as reagents for the solvent extraction separation of titanium (IV) and iron (III) from multivalent metal chloride solutions. Solvent Extr Ion Exch 22(3):473–490

Ritcey GM, Ashbrook A (1984) Solvent extraction. principles and applications to process metallurgy. Part I

Saji J, Reddy M (2001) Liquid–liquid extraction separation of iron (III) from titania wastes using TBP–MIBK mixed solvent system. Hydrometallurgy 61(2):81–87

Sokolov A, Valeev D, Kasikov A (2021) Solvent extraction of iron (III) from Al chloride solution of bauxite HCl leaching by mixture of aliphatic alcohol and Ketone. Metals 11(2):321

Stefanakis M, Monhemius A (1987) Computer modelling of the solvent extraction of iron by versatic acid from aluminium nitrate solutions. Hydrometallurgy 19(2):187–198

Su W, Chen J, Jing Y (2016) Aqueous partition mechanism of organophosphorus extractants in rare earths extraction. Ind Eng Chem Res 55(30):8424–8431

Sun J, O’Keefe T (2002) An evaluation of steel scrap as a reducing agent in the galvanic stripping of iron from D2EHPA. Miner Eng 15(3):177–185

Zhao X, Cui K, Huang K (2022) Enhanced interfacial salt effect on extraction and separation of Er (III) from Mg (II), Al (III), Fe (III) sulfate aqueous solutions using bubble-supported organic liquid membrane. Sep Purif Technol 285:120344

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest with any ethical problems.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Bagawi, A.H., Alanazi, T.Y.A. Prospective investigation for iron (III) removal from aqueous solutions with solvent extraction technique using Octylamine and N,N-dimethylaniline extractant. Chem. Pap. 77, 6739–6745 (2023). https://doi.org/10.1007/s11696-023-02973-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-02973-3