Abstract

2D minerals are among key elements of advanced systems, but the need for understanding their interactions/reactions with materials and systems in which they are involved necessitates tracking their molecular and atomic monitoring. Zeolitic structures are microporous materials formed in the nature through volcanic activities or synthesis. Because of their outstanding physicochemical properties like cation exchange capacity and excellent adsorption properties, zeolites have found application in diverse chemical processes, e.g., gas adsorption, water purification, and wastewater treatment. Prediction of zeolite performance for a targeted application saves time and expense as such projection could lead to the synthesis of optimum zeolite with adjusted properties. This review paper aims at encapsulating the latest findings on the use of 2D zeolite adsorbents studying three eminent molecular simulation techniques, namely molecular dynamics simulation, density functional theory, and Monte Carlo. Zeolites with precision structures and cost-efficiency for adsorption together with their adsorption capacity were correspondingly discussed in this review. Information gleaned from published reports on simulating zeolites’ adsorption properties could bridge with a brief comparison between the techniques mentioned to pave the way for scientists and industries to find the ideal method to predict zeolites performance and select the appropriate zeolite structure for the on-demand application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

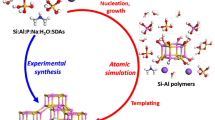

Zeolites, hydrated aluminosilicates of alkali elements such as Na and K and other elements like Ca, Li, and Mg, are mainly known as crystalline microporous materials obtained either naturally or synthetically (Bacakova et al. 2018; Servatan et al. 2020a, 2018). Zeolites are comprised of TO4 tetrahedral blocks that T (usually Si, Al, P) in the center is surrounded by four oxygen atoms, as depicted in Fig. 1 (Vinaches et al. 2017; Yazdi et al. 2020; Khalili et al. 2020; Servatan et al. 2020b). Such tetrahedral forms various types like 6-rings, 8-rings, or 12-rings as a secondary building unit of assorted cages or cylinders, which create a pore network in the zeolite crystal; ~ 250 different forms were produced, with similar chemical composition but different pore topologies (Fig. 1). Such pores are available from the outside, and such materials’ exceptional stability makes them ideal candidates for numerous applications (Beerdsen et al. 2006).

a Structures of four selected zeolites (from top to bottom: faujasite or zeolites X, Y; zeolite ZSM-12; zeolite ZSM-5 or silicalite-1; zeolite Theta-1 or ZSM-22) and their micropore systems and dimensions. Reprinted with permission from (Weitkamp 2000). b Examples of some zeolite structures: three-dimensional networks (top), one-dimensional channels (middle), and cage-like structures (bottom) reprinted with permission from (Beerdsen et al. 2006)

Equation (1) shows the chemical composition of the hydrated zeolite (Drioli and Giorno 2016):

In this formula, M is an extra-framework cation with n valence, the molar concentrations of Al and Si in the zeolite framework are stated by x, y, while z is the molar concentration of H2O. In the conventional building block of zeolite, T mainly denotes Al and Si, while in synthetic forms, the M element in Eq. (1) could be Na, K, or other cations from the periodic table of elements such as Li, Ca, and Ba (Byrappa and Yoshimura 2001). Zeolites of AlO4 or SiO4 possess an anionic structure. The cations in the channels are simply exchangeable, while Al or Si is not exchangeable under usual conditions.

The aluminum’s distribution in the zeolite framework generally obeys two rules: Loewenstein’s rule and Dempsey’s rule. Loewenstein’s rule states that no framework Al-O-Al linkages exist among the zeolites (Loewenstein 1954). According to the Dempsey’s rule, between two Al atoms of the structure of the zeolites, there must be at least three Si atoms because the presence of Al atoms in a shorter distance is unfavorable in terms of energy (Dempsey et al. 1969). Although there are a significant number of zeolites denying Dempsey’s rule, Loewenstein’s rule is acceptable for most of the discovered zeolites except a few like heulandite (HEU) zeolites (Slaughter and Yu 1991). Besides their high porosity, in terms of chemical structural position, zeolites are so variable that around 250 different types of zeolites have been identified so far (Mintova et al. 2013). From this perspective, zeolites are categorizable into three major groups: Si/Al ratio ≤ 2, 2 < Si/Al ratio ≤ 5, and Si/Al ratio ≥ 5, known as low silica, medium silica, and high silica, respectively. Furthermore, zeolites can be synthesized using natural elements found in the earth due to their abundance and negligible negative effects on the environment (Alver and Metin 2012). The zeolites formation process in nature, which is mainly the result of a reaction between volcanic ash and water, lasts for thousands of years. However, the synthesis process is shorter in laboratory conditions due to providing elevated pressure and temperature using natural raw materials. These materials mainly include those of silica sources like haolisite (Gualtieri 2001) and kaoline (Biel et al. 2020) as clay minerals, and pumice (Burriesci et al. 1983), diatomites (Garcia et al. 2016), and perlite (Dyer et al. 2004) as volcanic glasses. Zeolites are also synthesizable from the wastes of aluminosilicate materials like rice husk ash (Wang et al. 2020), fly ash (Czuma et al. 2019), paper sludge ash (Wajima et al. 2006), etc. There are different synthesis methods, namely hydrothermal synthesis, molten salt method, alkali activation, microwave-assisted synthesis, fusion method, etc., and the first method (hydrothermal synthesis) is the most commonly applied one (Król 2020). In this method, the Al and Si source components are mixed in the presence of an alkali solution having pH > 8.5. The reaction mixture is heated at an elevated temperature (above 100 °C); it will remain amorphous for a while after rising temperature to the synthesis temperature. The process parameters are then controlled for the formation of the crystalline zeolite, where the amorphous material is gradually replaced by a relatively equal mass of crystalline zeolites (Cundy and Cox 2005). From an economic point of view, using natural wastes for synthesizing zeolites is favorably cost-effective, taking into consideration that the costs of collecting and storing the waste will increase the final production cost to a limited extent. From an environmental point of view, it would significantly help to reduce the amount of natural waste polluting the environment. Moreover, more is that synthetic zeolites are advantageous compared to natural zeolites. Research proves that synthetic zeolites are more favorable in removing radioactive waste (Abdel Moamen et al. 2015), have higher adsorption capacity than natural zeolites especially in adsorbing heavy metal ions (Kozera-Sucharda et al. 2020), and have larger pores, which makes them potential candidates for a range of applications (Bandura et al. 2015; Nizami et al. 2016). For example, synthetic zeolites with big pores have been ideal for cleaning up petroleum spoils (Bandura et al. 2015), and those having large interconnected channels are more suitable for use as catalysts as they remain stable for a longer time compared to zeolites with smaller pore sizes (Nizami et al. 2016).

Adsorption is a chemical process by which the capability of a porous material in adsorbing one or more components within a gas or liquid flow is measured (Mashhadzadeh et al. 2016; Hamed Mashhadzadeh et al. 2018a, b; Ghorbanzadeh Ahangari and Hamed Mashhadzadeh 2020; Shahmoradi et al. 2020a,b; Karami et al. 2021a). In this process, a liquid or gas mixture is exposed to a porous material, and the separation process is carried out according to the affinity of different components within the mixture toward the porous material. Diverse industries apply the adsorption process such as the dehumidification of the air, water purification (Mahmodi et al. 2020a; Vatanpour et al. 2021), wastewater treatment (Karami et al. 2021b), gas separation like CO2 capturing, ion exchange, and catalysis (Fig. 2) (Sargazi et al. 2019; Treybal 1980). There have also been some other medicine and drug delivery applications, which have been comprehensively reviewed (Zarrintaj et al. 2020; Mahmodi et al. 2020b; Rahmati et al. 2020). One of the critical parameters for the adsorption process is selecting the appropriate porous material as the adsorbent (Bhattacharya et al. 2008). Several parameters have to be considered for this material, such as porosity, cost-efficiency, abundance, and ease of operation. Given the properties of zeolites, these materials are considered potential adsorbents.

It is necessary to have access to the adsorbents’ equilibrium data to design the equipment required for the industry’s adsorption process properly. The first data needed are the adsorption isotherm indicating the amount of the materials adsorbed by a specific amount of the applied adsorbent. The second is the heat of adsorption, indicative of the release of heat caused by the materials’ adsorption by a certain amount of the adsorbent (Calleja et al. 1998). Nevertheless, experimental methods may encounter some difficulties and restraints as there might be limitations to conduct the experiments in a particular range of operating conditions such as temperature and pressure due to the restricted capability of the experimental apparatus deployed (Rahmati and Modarress 2009a), or the method itself could be less cost-efficient. Therefore, to identify or substitute experimental methods with comparatively useful and accurate procedures, some theoretical models were improved to predict the adsorption process onto adsorbents, namely Langmuir, BET isotherms, and Kelvin equation (Sweatman and Quirke 2001; Lima et al. 2021). However, they were not sufficiently efficient and displayed limitations in predicting the adsorption process under some situations (Ungerer et al. 2005). Molecular simulation techniques have been developed as efficient, accurate, and expeditious methods to obtain the isotherms of adsorption (Tassel et al. 1991; Bates et al. 1996; Pillai et al. 2012), owing to modern statistical thermodynamics improvements. Density functional theory (DFT) (Hoffman et al. 2019; Salmankhani et al. 2020), Monte Carlo (MC) (Smit and Krishna 2001; Khorasani et al. 2014), and molecular dynamics simulation (MD) (Demontis et al. 2010; Khadem et al. 2021) are the most popular molecular simulation techniques which have been contributing to the science of zeolites. In this regard, enormous progress has been achieved with expanded accuracy, increased complexity, and improved integrity of modeling techniques. It is noteworthy to mention that MC and DFT are mainly applied to model zeolite structures and study their behavior while MD is used to investigate their mechanism of the process and to observe how molecules move through each other. Although the number of theoretical articles regarding zeolite structures has fluctuated over the last two decades, the future for the modeling techniques in zeolites industries is bright.

In scientific terms, zeolites are intriguing and challenging due to the activity inside the material, and molecular interactions are difficult to predict; thus, it is tough to perform experiments to achieve data at the level of molecules. Evaluating the pores’ interaction or reaction requires cognizance about the reactants’ adsorption, molecular diffusion, a chemical transition to an active site, and the products’ desorption from the active zeolite site. These steps could have an influence on the rates of reaction and in the formation of the products. It is more difficult to obtain information at the molecular level of the molecules of interest inside the material. Concerning this feature, the molecular simulations support the experiments for obtaining an accurate interpretation of the results. Herein, we have endeavored to provide a comprehensive overview of the importance of molecular simulation techniques’ in investigating the adsorption process using zeolites as adsorbents. The next section briefly explains the MD, followed by a discussion on the MD-based literature investigating zeolites’ adsorption process. Afterward, the philosophy of introducing the DFT method is expounded with the relevant literature simulating the adsorption process in zeolites using the DFT technique. Subsequently, the Monte Carlo method is discussed, and finally, the importance of these simulating techniques soon is deliberated.

Molecular dynamics (MD) simulation

The methodology of MD

The molecular dynamics simulation technique is based on the fundamental premise that every substance comprises atoms and molecules and the motion of the molecules is determined by the second Newton’s law (Abdelrasoul et al. 2017; Mohammadi et al. 2018; Saeb et al. 2015,2016). Furthermore, while a molecule moves within the studied system, other molecules in its surroundings might interact with it and exert different forces on the molecule, namely van der Waals force. As a result, to consider these significant interactions, force fields should be applied (Hussain and Titiloye 2005). Therefore, selecting the proper force field for the system under consideration and/or the development of an appropriate force field is the most challenging issue to predict the desired properties accurately. Another important point to consider is the time step of applying the force. Time step has to be very short to enhance the accuracy of the simulation and track the continuous movement of the molecule (such as 10−15 s). The forces exerted on each molecule are calculated during every time step. According to the forces and the velocity of each molecule at the current time, the local situation and the velocity of the molecule are predictable for the next time step. As time step is primarily short, it can be assumed that the forces exerted on each molecule are constant. Consequently, the movements of the molecules within the system are analyzed, and their local situation for the next time steps is obtained. Since the physical properties of every substances, such as temperature, are dependent on its molecules’ behavior, determining the molecules’ motion pattern leads to ascertaining the amount of the physical property of the substance (Maroo and Chung 2008). Moreover, the thermodynamic properties of every material are dependent on the movement of its atoms and molecules. Thus, the mentioned properties are obtainable after obtaining the behavior of the molecules of a system only. The structural simplicity of MD simulation compared to methods including atomic level interactions such as electrons and orbital has made it a favorable simulation technique for worldwide use. Nevertheless, this simulation technique brings about some limitations for selecting an appropriate force field among the existing ones or developing a new one as already stated. Furthermore, another issue restricting the applications of MD simulation is the CPU time.

Applications of MD

The uniform internal surface area of zeolites allows them to accomplish chemical transformations through their channels, thus enabling them to absorb, separate, and remove gases, hydrocarbons, and contaminants under different environments. Besides, introducing mesoporous channels to microporous structures has recently been an effective route to improve their diffusivity (Bai et al. 2016). Bai et al. (Bai et al. 2016) modeled a hierarchical SSP zeolite system, including MFI microporous zeolite and mesoporous channels, to probe cyclohexane diffusion under molecular dynamics simulation (MD). Using the GROMACS package and Einstein relation, they measured diffusion in this type of zeolite depending on motions in microporous regions. At higher temperatures only, mesoporous channels can sufficiently populate, and the diffusion exceeds that of conventional microporous zeolite. It has been shown that large free energies for escaping from the micro- to mesoporous region result in unusual transport behavior. Arya et al. carried out an MD-based study to investigate the effect of pore exit on the transportation of CH4 molecules through ALPO4−5 pores (Arya et al. 2001). They reported more surface barrier effects of pores at lower sorbate loadings even though they were less affected by other sorbents’ presence; their model could correctly predict the exit barrier effects as a function of temperature. Bora et al. used both MD simulations and quasielastic neutron scattering (QENS) to predict the diffusion of neopentane, isopentane, and n-pentane in NaY zeolite (Borah et al. 2010). Their results revealed higher self-diffusivity of iso- and neopentane compared to n-pentane at 300 K and higher activation energy (Ea) of n-pentane in contrast, (Ea(n-pentane) > Ea(isopentane) > Ea(neopentane)). Furthermore, their MD simulation showed existing energetic barriers at the bottleneck of n-pentane, while no such barriers were observed for the other two isomers. Figure 3 presents the pathway of different isomers through NaY zeolite provided by Bora et al.

Diffusion of n-pentane (blue, dark in black and white) and neopentane (red, gray) within NaY framework obtained from MD simulations at 200 K Ref. (Borah et al. 2010)

In another MD study, Bu et al. considered the diffusivity of various biomass pyrolysis vapors, including water, glycolaldehyde, methanol, and toluene and representative biofuel molecules, namely xylene isomers in H-ZSM-5 zeolite (Bu et al. 2017). They proved a good agreement of their results for the diffusion of biomass pyrolysis vapors compared to available NMR measures and the importance of molecular orientation on diffusivity. Furthermore, xylene isomers’ results revealed that the p-xylene molecule could diffuse along both zigzag and straight channels, while the o-xylene and the m-xylene were not able to switch between due to lower diffusion as depicted in Fig. 4.

Switching trajectory of p-xylene between channels against the trajectory of the o- and m-xylene only through the original channels Ref. (Bu et al. 2017)

Adsorption of methane using Si-LTA zeolite was investigated by Combariza et al. under the MD framework (Combariza and Sastre 2011). Using energy profiles, 2D occupational densities, and the adsorption process along the z-direction, they could show the preferential zones of interaction, according to van der Waals interactions. Moreover, they revealed an increase in surface permeability as a function of loading using both the MD results and Schuring’s analytical equation. CO2 adsorption on the modified AU NaY siliceous, Na88(SiO4)44, zeolite by sodium dodecyl sulfate surfactant (SDS) was investigated by Ortega et al. (Valencia-Ortega et al. 2019), where the principle adsorption of CO2 was due to the free ions in the zeolite. Since the sodium ions are mainly deposited close to the surface, adsorption occurred near the surface. In the absence of surfactant, zeolite could not adsorb all the CO2 itself, and its adsorption capacity decreased. The simulation results elucidated that in the absence of a surfactant, zeolite could partially adsorb the CO2 even in a highly populated CO2 atmosphere. A similar trend was the case for zeolite surfaces rich in surfactant, while at an optimal amount of CO2 complete adsorption was gained. It is concluded that CO2 adsorption onto zeolite is improved by surface modification using a surfactant at low CO2 concentrations. A summary of MD-based articles regarding the adsorption/diffusion properties of zeolites is provided in Table. 1.

Besides the applications above, zeolites can be considered a significant candidate for water purification and water treatment due to their advantages over conventional treatment processes such as reverse osmosis (RO) (Shannon et al. 2010; Gupta et al. 2016). Accordingly, the zeolites’ influences have been investigated on the water treatment processes in the last few years, both theoretically and experimentally. Cohen et al. modeled an LTA-type zeolite membrane capped with hydrophobic and hydrophilic moieties by MD simulations to evaluate the water transport under varying pressure of 50–400 MPa (Turgman-Cohen et al. 2013). A 15 ns monitoring of simulation showed a higher water adsorption rate on the membrane’s surface for the hydrophilic membrane. Water flux was independent of the pressure drop in both types and was also lower than the bulk form membranes of the same zeolite. The authors also proposed that applying a periodic pressure difference between the inlet and outlet could direct the water to flow toward the low-pressure cages. Mousavi et al. used MFI zeolite nanosheets to remove chemical contaminants, including mercury chloride (HgCl2) and copper chloride (CuCl2) from water in an MD-based study (Rassoulinejad-Mousavi et al. 2020). They modeled a simulation box including a zeolite membrane and a mixture of the hazardous elements with water, as shown in Fig. 5. MFI zeolite could effectively confine mercury, copper, and chlorine permeation ions without affecting water flux rate and employing non-equilibrium MD simulations. Jamali et al. considered the salt separation capacity of 27 types of zeolites (Jamali et al. 2017) by modeling zeolites with orthorhombic unit cells and the pore-limit diameters (PLDs) of more than 2.8 Å (the minimum diameter of water molecules). They established that the zeolites with PLDs smaller than 5.5 Å would show higher separation properties, while those with greater PLDs must be more adjudicated in terms of their channels shape or cross-sectional area.

Schematic of the simulation box including MFI zeolite and contaminated water Ref. (Rassoulinejad-Mousavi et al. 2020)

Hu et al. selected ZIF-8 zeolite to model new RO membranes for water purification using MD simulations (Hu et al. 2011). They selected this type of zeolite due to its high thermal and chemical stability and high mechanical strength, making it strong enough to withstand high external pressures during the desalination process. The designed membrane successfully rejects Na + and CL− ions, while it did not confine water flux. Their proposed membrane also showed strong fouling resistance and large water permeation. In a combined MD-experimental article, Nagar et al. designed a novel membrane of zeolite MFI/hydrophobic polyvinylchloride (PVC) matrix to purify kitchen wastewater using microbial fuel cell (MFC)-based treatment method as shown in the schematic of Fig. 6 (Nagar et al. 2019).

Schematic for the MFC setup, including zeolite/PVC membrane in the middle for kitchen wastewater treatment (Nagar et al. 2019)

MD was used to model the zeolite/PVC, pristine PVC, and Nafion membranes, which indicated that the zeolite membrane had high ion exchange capability and water sorption and is a better membrane for wastewater treatment compared to pristine PVC or Nafion membranes. Their experimental results also demonstrated a considerably lower cost of producing this membrane than the Nafion type (3$ against 7$). The exciting outcomes obtained from molecular dynamics investigation of zeolites in the context of water purification applications widened the horizons of using zeolite materials for developing water treatment membranes.

In conclusion, we can see that a wide variety of zeolites, especially those having Si4+ and Al3+ in their structure, together with different pollutants due to providing distinctive electrostatic and van der Waals forces, have been considered in atomic and molecular simulations. The simulation could provide very high pressures as high as 500 MPa, which are not obtainable in the laboratory. Various factors such as water flux, radial distribution function (RDF), mean squared displacement (MSD), and water and ions density have been predicted to give valuable insights into its effects on zeolite structure and pollutants for experimental analyzes. The inherent simplicity of the molecular dynamics simulation due to the lack of electrons and orbitals as well as its fast character due to the use of fewer equations have been the main reasons for its worldwide use (Laaksonen and Tu 1999).

Density functional theory (DFT)

The methodology of DFT

Quantum mechanics (QM) has been developed to describe electrons and individual molecules’ behavior, which cannot be carried out using classical mechanics. Schrodinger equation, the central equation of QM, describes electrons’ behaviors within the atoms and molecules (Nakatsuji et al. 2007).

where H is the Hamiltonian operator, E is the energy, and Ψ is the wave function. Ψ describes the electron based on probability, so it does not show the exact position of electrons in the atoms and molecules yet show how probable it is to find the electron somewhere. In general, the following equation describes the H parameter in the Schrodinger equation (Abdelrasoul et al. 2017):

where i and j are electron counters, and k and l are nuclei counters. h is Planck’s constant, me and mk are the masses of electrons and nuclei, respectively, r is the distance between two particles, e is the charge of the electron, Z is the atomic number of nuclei, and \(\nabla\) is the Laplacian operator. The first and second terms of the above equation indicate the kinetic energy of the electrons and nuclei. The rest of the terms represent the electric potential energy of the electrons and nuclei. The complexity of the equation, as mentioned above, can be reduced using the Born–Oppenheimer approximation. According to this approximation, the nuclei’s mass is so high that they move very slowly when they have exerted an equal force on the electrons. Thereby, one can assume that the nuclei are static. Therefore, it can be stated that the Schrodinger equation contains variables dealing with electrons. Although the Schrodinger equation can theoretically predict atoms and molecules’ properties, it can be solved analytically for the atoms with only one electron, such as H, He+, Li2+, and C+5 in practical terms. Different solutions have been suggested, such as density functional theory (DFT), to enable the Schrodinger equation to investigate other atoms and molecules. This technique adapted from the Hohenberg-Cohen theorem expounds that an atom or molecule’s energy can be calculated via electron density instead of Ψ. The number of electrons and the atomic number of atoms are obtainable using electron density. Subsequently, this information can be applied to calculate the Hamiltonian operator and to calculate the Schrodinger equation. Since DFT considers the atoms’ electrons, it is expected that the data acquired using this method are comparatively accurate. On the other hand, the calculations carried out via this method are heavier and more complex than MD. Consequently, for systems including high numbers of atoms, the DFT method is not cost-efficient.

The applications of DFT

Researchers have used the DFT technique to investigate zeolites’ adsorption processes in many research studies for MD. In this regard, Bensiradj et al. applied DFT to consider the adsorption properties of ZIF-4 and ZIf-6 toward SF6, CH4, and H2O. They considered different binding sites, as shown in Fig. 7, and reported that the co-adsorption of three gases was impossible due to the unavailability of enough pore space. The capture of the gases individually was favored in ZIF-6, and the maximum adsorbed content of CH4 was observed in the same zeolite at high pressure (Bensiradj et al. 2019).

The binding sites of SF6, CH4, and H2O in a ZIF-4 and b ZIF-6 Ref. (Bensiradj et al. 2019)

Ag and Cu ion-exchanged faujasites have been used in a combined DFT-experimental study provided by Kumar et al. to remove H2S from dilute streams including He, N2, CO2, CO, and H2O (Ungerer et al. 2005). Ag–X and Ag–Y could adsorb H2S in the presence of all other existing elements, while Cu–X and Cu–Y failed to remove H2S in the presence of 2% CO (Kumar et al. 2011). In another DFT-based study, Fellah et al. investigated the adsorption of H2 molecules using Mg-, Ca-, and Be- modified 24 T ERI zeolite clusters as depicted in Fig. 8 (Fellah 2017). Their findings demonstrated higher adsorption energy and better chemical potential for the Be-ERI cluster compared to Mg-ERI or Ca-ERI. However, these two clusters showed better electronegativity and chemical reactivity than Be-ERI. Furthermore, they reported that the hydrogen adsorption enthalpy values for Mg-ERI and Ca-ERI clusters were equal to − 3.6 kJ/mole and − 3.9 kJ/mole, respectively (Fellah 2017). Table. 2 provides a summary of the literature on the adsorption in zeolites using the DFT technique.

Schematic for a 24 T ERI zeolite modeled using DFT with the location of Ca, Mg, and Be metal atoms on 6 T membered ring Ref. (Fellah 2017)

In DFT simulation, fewer atoms are considered, which enhances the performance of calculations. For instance, diffusion can be more accurately visualized, leading to a more realistic outcome with a comprehensive image provided for interaction determination. Moreover, functional groups’ effect in removing contaminants and their interactions with the sorbent can be detected. On the other hand, considering fewer atoms can be a drawback of these systems, such that results would be of lower reliability for practical cases in which adsorption and removal of contaminants are on a large scale (Aliano et al. 2012; Gomes et al. 2019).

Monte Carlo (MC) simulation

The methodology of MC

MC is yet another technique to determine the arrangement of the molecules in a system. Here, the arrangement of molecules in each configuration is entirely random, dependent on the last configuration, unlike the MD technique by which the motion and the position of the molecules are obtainable using Newton’s law. There are several criteria for generating a new configuration from the last one. To find a pattern for determining the distribution of the system’s molecules, Metropolis et al. (Metropolis et al. 1953) developed a method through which the distribution of the molecules is determined based on the Boltzmann distribution function. To determine the physical properties of a system via the MC method, the amount of the desired property is calculated for each configuration, and finally, the property is obtained by averaging the amount of the property in all configurations (Abdelrasoul et al. 2017). According to the system simulation using MC, some properties are kept constant to calculate the amounts of others. As a result, the MC technique can be carried out in different ensembles (Papadopoulou et al. 1993). In this section, several of them are briefly explained.

Canonical ensemble MC (CMC)

In this ensemble, temperature (T), pressure (P), and the number (N) of atoms are kept constant. This ensemble provides this opportunity to calculate the system’s pressure and other properties using the equation of state (McQuarrie 2000), ensemble being mainly applied for studying single-phase systems.

Isothermal–isobaric canonical MC

In this method, temperature, pressure, and number of atoms are fixed, which is possible by allowing the system to exchange energy with its surrounding. This mode is appropriate to investigate inhomogeneous systems such as phase equilibrium systems. Therefore, this method is appropriate to study adsorption processes (Abdelrasoul et al. 2017).

Grand canonical MC (GCMC)

In the simulation method, the properties of the system are determined while the chemical potential, temperature, and volume are kept constant. Likewise, this method is applied to study inhomogeneous systems such as phase equilibrium systems. Therefore, it can investigate the adsorption process as isothermal–isobaric canonical MC does. In comparison with the last ensemble, this one is more cost-efficient; hence, it is preferable (Abdelrasoul et al. 2017).

The applications of MC

In this section, we have provided a few investigations studying the adsorption process in zeolites using MC. Liu et al. applied GCMC to study the adsorption of CO2 by ZIF-8, ZIF-8-NH2, and ZIF-8-(NH2)2 zeolites as the crystalline structures (Fig. 9) (Liu et al. 2013). Zeolitic imidazolate frameworks (ZIFs) belong to the big family of metal–organic frameworks (MOFs). They are a structure in which Fe, Co, Cu, Zn tetrahedrally coordinated transition metal ions are covalently linked with the aid of imidazolate as a bridging agent Figs. 10 and 11. Their topology resembles zeolite because of the angle between two metal–imidazole bonds with imidazole, which is almost equal to the 145° Si–O–Si angle in the zeolite structure. ZIF-8 is methyl-imidazolate-based zeolite with 1.16 nm cages connected in a hexagonal arrangement appear as the most widely used zeolite in adsorption and storage applications (Phan et al. 2010).

The crystalline structures of ZIFs modeled by Liu et al. a ZIF-8, b ZIF-8-NH2, and c ZIF-8-(NH2)2 (Zn in purple, C in gray, N in blue, and H in white) Ref. (Liu et al. 2013)

The amount of CO2 uptake into NaX zeolite at 305 K and a 0.01 b c 7.5 MPa (Liu and Yang 2006)

The results indicated that at the low pressure, the order of increasing CO2 adsorption capacity by zeolites was ZIF-8 < ZIF-8-NH2 < ZIF-8-(NH2)2, while at the high pressure, it was: ZIF-8 < ZIF-8-(NH2)2 < ZIF-8-NH2. DFT calculations were also applied to calculate CO2 adsorption sites and binding energies of unmodified and amino-modified ZIF-8, which showed a significant enhancement in the CO2 adsorption capacity of the amino-functionalized ZIF-8 (Liu et al. 2013). More studies using the MC technique to model and investigate the adsorption process in zeolites are provided in Table 3 (Also see Fig. 11).

Location of n-alkanes in the cages of CHA type zeolite (Krishna and Baten 2008)

Comparing zeolitic structures proves how the interaction between zeolite and a given ion or contaminant occurs and how functional groups improve their adsorption efficiency. So far, a variety of combinations of a contaminant and a zeolite have been theoretically analyzed. Monte Carlo simulation has some advantages, e.g., user-friendly after a relevant computer program has been developed for simulation. Moreover, there are various software commercially developed and available for the MC simulation. Unlike analytical approaches providing closed solutions, a generic Monte Carlo simulation’s generic feature is that it is not path dependent and can consider complicated stochastic processes compared with Brownian geometric motion.

Moreover, to a large extent, Monte Carlo simulation methods can be refined to increase the accuracy or reduce the computation time. The Monte Carlo simulation can also identify and provide indicators of the results’ accuracy by increasing the number of iterations from generation to generation. On the other hand, there are also some disadvantages of using MC methodologies, e.g., the large number of calculations required. It is also noticeable that in dealing with the limitations of small dimensions, MC appears less efficient than the analytical methods. They are also challenging to understand and often require programming skills (Wu and Buyya 2015).

Conclusion and future perspectives

The first step for the simulation of the adsorption process is choosing an appropriate method among the available techniques explained in this review paper. There would be some reasons behind choosing one technique to carry out the simulation process over another one. For instance, since the MD is dependent on the consumed time, it is possible to estimate the required time for simulation of the adsorption process carried out by MD. On the other hand, it is not possible to estimate the needed time to perform the simulation in the MC technique. Moreover, because MD considers the effect of time, it is possible to simulate the adsorption process as a function of the time. Inevitably, for instance, as mentioned in the main text, MD ignores the influence of the electrons on the adsorption process. Compared to DFT, MD simulation provides the user with an opportunity to simulate the adsorption process in a shorter time interval. Nevertheless, since the DFT method considers more details than the other methods, the results are more precise and trustable and the experimental data can be more closely fit the DFT outcome. Therefore, when accuracy is the matter of concern, DFT would be a preferred method.

It is obligatory to examine the capability of the applied adsorbents for adsorption in order to be able to develop the adsorption process at an industrial scales. Due to the lack of cost-efficiency of the experimental methods, predictive tools such as molecular simulations categorized into different groups, including MD, DFT, and MC, can be interchangeably used to give a more precise picture of the process. It is notable that, in contrast to what an experimentalist may imagine, theoretical simulations are complements to the experimental data. It has been proven that the molecular simulation techniques can bring about profound information about the structure of zeolite adsorbents on a molecular and atomic scale, which is not experimentally possible to detect. Furthermore, the capacity of adsorbents can be anticipated using molecular simulation techniques with an acceptable accuracy level. According to the enhanced development of the capability of the computer systems, it is expected that molecular simulation techniques will achieve a unique position for investigating the chemical process, including adsorption processes. For instance, there is a need to implement simulation when different sorts of pollutants are expected to be adsorbed on zeolites, like dyes, heavy metal ions, proteins found in biomedical wastewater, COx, SOx, and NOx. To date, some challenging aspects of molecular simulation of adsorption of pollutants by the zeolitic structures, to name: (1) the lack of experimental data on newly developed or sometimes theoretically born structures to validate models; (2) the number of hypotheses in simulations, mainly arising from the complexity of structures; (3) the size and distribution of pores and involvement of the porosity in simulations, which make computations timely and sometimes impossible; (4) the need for finding model parameters (coefficients of model and potential functions); and (5) more particularly, the inability of explaining the underlying mechanisms behind adsorption of pollutants by complex and hybrid zeolitic structures.

Availability of data and material

Available by the corresponding author per request through the email (amin.hamed.m@gmail.com)

References

Abdel Moamen OA, Ismail IM, Abdelmonem N, Abdel Rahman RO (2015) Factorial design analysis for optimizing the removal of cesium and strontium ions on synthetic nano-sized zeolite. J Taiwan Inst Chem Eng 55:133–144

Abdelrasoul A, Zhang H, Cheng C-H, Doan H (2017) Applications of molecular simulations for separation and adsorption in zeolites. Microporous Mesoporous Mater 242:294–348

Akten ED, Siriwardane R, Sholl DS (2003) Monte Carlo simulation of single-and binary-component adsorption of CO2, N2, and H2 in zeolite Na-4A. Energy Fuels 17:977–983

Alexopoulos K, Lee M-S, Liu Y, Zhi Y, Liu Y, Reyniers M-FO et al (2016) Anharmonicity and confinement in zeolites: structure, spectroscopy, and adsorption free energy of ethanol in. J Phys Chem C 120:7172–82

Aliano A, Cicero G (2012) Ab Initio DFT simulations of nanostructures. In: Bhushan B (ed) Encyclopedia of nanotechnology. Springer, Netherlands, Dordrecht, pp 11–17

Alver E, Metin AÜ (2012) Anionic dye removal from aqueous solutions using modified zeolite: adsorption kinetics and isotherm studies. Chem Eng J 200:59–67

Arya G, Maginn EJ, Chang H-C (2001) Effect of the surface energy barrier on sorbate diffusion in AlPO4-5. J Phys Chem B 105:2725–2735

Bacakova L, Vandrovcova M, Kopova I, Jirka I (2018) Applications of zeolites in biotechnology and medicine–a review. Biomaterials Science 6:974–989

Bai P, Haldoupis E, Dauenhauer PJ, Tsapatsis M, Siepmann JI (2016) Understanding diffusion in hierarchical zeolites with house-of-cards nanosheets. ACS Nano 10:7612–7618

Bandura L, Franus M, Józefaciuk G, Franus W (2015) Synthetic zeolites from fly ash as effective mineral sorbents for land-based petroleum spills cleanup. Fuel 147:100–107

Bates SP, van Well WJ, van Santen RA, Smit B (1996) Location and conformation of n-alkanes in zeolites: an analysis of configurational-bias Monte Carlo calculations. J Phys Chem 100:17573–17581

Beerdsen E, Dubbeldam D, Smit B (2006) Loading dependence of the diffusion coefficient of methane in nanoporous materials. J Phys Chem B 110:22754–22772

Bensiradj NEH, Timón V, Boussessi R, Dalbouha S, Senent ML (2019) DFT studies of single and multiple molecular adsorption of CH4, SF6 and H2O in Zeolitic-Imidazolate Framework (ZIF-4 and ZIF-6). Inorg Chim Acta 490:272–281

Bhattacharya A, Naiya T, Mandal S, Das S (2008) Adsorption, kinetics and equilibrium studies on removal of Cr (VI) from aqueous solutions using different low-cost adsorbents. Chem Eng J 137:529–541

Biel O, Rożek P, Florek P, Mozgawa W, Król M (2020) Alkaline activation of kaolin group minerals. Crystals 10:268

Borah BJ, Jobic H, Yashonath S (2010) Levitation effect in zeolites: quasielastic neutron scattering and molecular dynamics study of pentane isomers in zeolite NaY. J Chem Phys 132:144507

Bu L, Nimlos MR, Robichaud DJ, Kim S (2017) Diffusion of biomass pyrolysis products in H-ZSM-5 by molecular dynamics simulations. J Phys Chem C 121:500–510

Burriesci N, Crisafulli ML, Saija LM, Polizzotti G (1983) Hydrothermal synthesis of zeolites from rhyolitic pumice of different geological origins. Mater Lett 2:74–78

Byrappa K, Yoshimura, M (2001) Hydrothermal synthesis and growth of zeolites. In: handbook of hydrothermal technology. University of Mysore Manasagangotri Mysore, India and Tokyo Institute of Technology, Elsevier, pp 315–414

Calleja G, Pau J, Calles J (1998) Pure and multicomponent adsorption equilibrium of carbon dioxide, ethylene, and propane on ZSM-5 zeolites with different Si/Al ratios. J Chem Eng Data 43:994–1003

Castillo J, Vlugt T, Dubbeldam D, Hamad S, Calero S (2010) Performance of chiral zeolites for enantiomeric separation revealed by molecular simulation. J Phys Chem C 114:22207–22213

Chanajaree R, Bopp PA, Fritzsche S, Kärger J (2011) Water dynamics in chabazite. Microporous Mesoporous Mater 146:106–118

Chandrakumar K, Pal S (2002) DFT and local reactivity descriptor studies on the nitrogen sorption selectivity from air by sodium and calcium exchanged zeolite-A. Colloids Surf A: Physicochem Eng Asp 205:127–38

Chatterjee A, Iwasaki T (1999) A novel approach using DFT to explain the selective permeation of small gaseous molecules through Y-type zeolite membrane. J Phys Chem A 103:9857–9863

Chebbi M, Chibani S, Paul J-F, Cantrel L, Badawi M (2017) Evaluation of volatile iodine trapping in presence of contaminants: a periodic DFT study on cation exchanged-faujasite. Microporous Mesoporous Mater 239:111–122

Chen X, Shen B, Sun H (2018) Ion-exchange modified zeolites X for selective adsorption desulfurization from Claus tail gas: experimental and computational investigations. Microporous Mesoporous Mater 261:227–236

Combariza AF, Sastre G (2011) Influence of zeolite surface in the sorption of methane from molecular dynamics. J Phys Chem C 115:13751–13758

Cosoli P, Ferrone M, Pricl S, Fermeglia M (2007) Grand canonical Monte-Carlo simulations for VOCs adsorption in non-polar zeolites. Int J Environ Technol Manage 7:228–243

Cosoli P, Ferrone M, Pricl S, Fermeglia M (2008) Hydrogen sulphide removal from biogas by zeolite adsorption: part I GCMC molecular simulations. Chem Eng J 145:86–92

Cundy CS, Cox PA (2005) The hydrothermal synthesis of zeolites: precursors, intermediates and reaction mechanism. Microporous Mesoporous Mater 82:1–78

Czuma N, Baran P, Franus W, Zabierowski P, Zas bska KJAS Technology (2019) Synthesis of zeolites from fly ash with the use of modified two-step hydrothermal method and preliminary SO2 sorption tests. Adsorp Sci Technol 37:61–76

De Wispelaere K, Ensing B, Ghysels A, Meijer EJ, Van Speybroeck V (2015) Complex reaction environments and competing reaction mechanisms in zeolite catalysis: insights from advanced molecular dynamics. Chem-A Eur J 21:9385–9396

Demontis P, Gulín-González J, Masia M, Suffritti GB (2010) The behaviour of water confined in zeolites: molecular dynamics simulations versus experiment. J Phys: Cond Matter 22:284106

Dempsey E, Kühl G, Olson DH (1969) Variation of the lattice parameter with aluminum content in synthetic sodium faujasites. Evidence for ordering of the framework ions. J Phys Chem 73:387–90

DING J, HU Y, YANG X, YANG J (2008) Monte Carlo simulation of water adsorption in ZSM-5 zeolite [J]. J Chem Indus Eng (China) 9

Drioli E, Giorno L (2016) Encyclopedia of Membranes [electronic resource]/edited by Enrico Drioli, Lidietta Giorno, Berlin, Heidelberg: Springer Berlin Heidelberg: Imprint: Springer.

Dyer A, Tangkawanit S, Rangsriwatananon K (2004) Exchange diffusion of Cu2+, Ni2+, Pb2+ and Zn2+ into analcime synthesized from perlite. Microporous Mesoporous Mater 75:273–279

Fellah MF (2017) A DFT study of hydrogen adsorption on Be, Mg and Ca frameworks in erionite zeolite. Appl Surf Sci 394:9–15

Ferreira ML, Al-Bogami SA, de Lasa HI (2016) Self diffusivity of n-dodecane and benzothiophene in ZSM-5 zeolites. its significance for a new catalytic light diesel desulfurization process. Int J Chem Reactor Eng 14:737–48

Fischer M, Bell RG (2014) Cation-exchanged SAPO-34 for adsorption-based hydrocarbon separations: predictions from dispersion-corrected DFT calculations. Phys Chem Chem Phys 16:21062–21072

Fu J, Feng X, Liu Y, Yang C (2017) Effect of pore confinement on the adsorption of mono-branched alkanes of naphtha in ZSM-5 and Y zeolites. Appl Surf Sci 423:131–138

Garcia G, Cardenas E, Cabrera S, Hedlund J, Mouzon J (2016) Synthesis of zeolite Y from diatomite as silica source. Microporous Mesoporous Mater 219:29–37

Gee JA, Chung J, Nair S, Sholl DS (2013) Adsorption and diffusion of small alcohols in zeolitic imidazolate frameworks ZIF-8 and ZIF-90. J Phys Chem C 117:3169–3176

Ghorbanzadeh Ahangari M, Hamed Mashhadzadeh A (2020) Density functional theory based molecular dynamics study on hydrogen storage capacity of C24, B12N12, Al12 N12, Be12O12, Mg12O12, and Zn12O12 nanocages. Int J Hydrogen Energy 45:6745–6756

Ghysels A, Moors SL, Hemelsoet K, De Wispelaere K, Waroquier M, Sastre G et al (2015) Shape-selective diffusion of olefins in 8-ring solid acid microporous zeolites. J Phys Chem C 119:23721–23734

Gomes EO, Fabris GSL, Ferrer MM, Motta FV, Bomio MRD, Andres J et al (2019) Computational procedure to an accurate DFT simulation to solid state systems. Comput Mater Sci 170:109176

Granato MA, Vlugt TJ, Rodrigues AE (2007) Molecular simulation of propane− propylene binary adsorption equilibrium in zeolite 4A. Ind Eng Chem Res 46:321–328

Gualtieri AF (2001) Synthesis of sodium zeolites from a natural halloysite. Phys Chem Miner 28:719–728

Gupta KM, Qiao Z, Zhang K, Jiang J (2016) Seawater pervaporation through zeolitic imidazolate framework membranes: atomistic simulation study. ACS Appl Mater Interfaces 8:13392–13399

Hamed Mashhadzadeh A, Fathalian M, Ghorbanzadeh Ahangari M, Shahavi MHDFT (2018a) Study of Ni, Cu, Cd and Ag heavy metal atom adsorption onto the surface of the zinc-oxide nanotube and zinc-oxide graphene-like structure. Mater Chem Phys 220:366–373

Hamed Mashhadzadeh A, Ghorbanzadeh Ahangari M, Salmankhani A, Fataliyan M (2018b) Density functional theory study of adsorption properties of non-carbon, carbon and functionalized graphene surfaces towards the zinc and lead atoms. Physica E 104:275–285

Hoffman A, DeLuca M, Hibbitts D (2019) Restructuring of MFI framework zeolite models and their associated artifacts in density functional theory calculations. J Phys Chem C 123:6572–6585

Hu Z, Chen Y, Jiang J (2011) Zeolitic imidazolate framework-8 as a reverse osmosis membrane for water desalination: insight from molecular simulation. J Chem Phys 134:134705

Hussain I, Titiloye J (2005) Molecular dynamics simulations of the adsorption and diffusion behavior of pure and mixed alkanes in silicalite. Microporous Mesoporous Mater 85:143–156

Jabraoui H, Hessou E, Chibani S, Cantrel L, Lebègue S, Badawi M (2019) Adsorption of volatile organic and iodine compounds over silver-exchanged mordenites: a comparative periodic DFT study for several silver loadings. Appl Surf Sci 485:56–63

Jafari L, Moradi H, Tavan Y (2020) A theoretical and industrial study of component co-adsorption on 3A zeolite: an industrial case. Chem Pap 74:651–661

Jamali SH, Vlugt TJ, Lin L-C (2017) Atomistic understanding of zeolite nanosheets for water desalination. J Phys Chem C 121:11273–11280

Karami Z, Mashhadzadeh AH, Habibzadeh S, Ganjali MR, Ghardi EM, Hasnaoui A et al (2021b) Atomic simulation of adsorption of SO 2 pollutant by metal (Zn, Be)-oxide and Ni-decorated graphene: a first-principles study. J Mol Model 27:1–10

Karami Z, Hamed Mashhadzadeh A, Shahmoradi A, Ganjali MR, Vatanpour V, Esmaeili A et al (2021) Lead adsorption onto Ni- and Pt-decorated nano γ-alumina: a first-principles study. J Molecul Liquids 337:116349

Khadem SSM, Mashhadzadeh AH, Habibzadeh S, Munir MT, Lima EC, Saeb MR (2021) A theoretical probe into the effects of material and operational variables on water purification with zeolite membranes. Microporous Mesoporous Mater 320:111070

Khalili R, Zarrintaj P, Jafari SH, Vahabi H, Saeb MR (2020) Electroactive poly (p-phenylene sulfide)/r-Graphene Oxide/Chitosan as a novel potential candidate for tissue engineering. Int J Biol Macromol 154:18–24

Khorasani MM, Saeb MR, Mohammadi Y, Ahmadi M (2014) The evolutionary development of chain microstructure during tandem polymerization of ethylene: a Monte Carlo simulation study. Chem Eng Sci 111:211–219

Kozera-Sucharda B, Gworek B, Kondzielski I (2020) The simultaneous removal of zinc and cadmium from multicomponent aqueous solutions by their sorption onto selected natural and synthetic zeolites. Minerals 10:343

Krishna R, van Baten J (2008) Separating n-alkane mixtures by exploiting differences in the adsorption capacity within cages of CHA, AFX and ERI zeolites. Sep Purif Technol 60:315–320

Król M (2020) Natural vs. synthetic zeolites. Crystals 10:622

Kumar P, Sung C-Y, Muraza O, Cococcioni M, Al Hashimi S, McCormick A et al (2011) H2S adsorption by Ag and Cu ion exchanged faujasites. Microporous Mesoporous Mater 146:127–133

Laaksonen A, Tu Y (1999) Chapter 1—Methods of incorporating quantum mechanical calculations into molecular dynamics simulations. In: Theoretical and Computational Chemistry, Balbuena PB, Seminario JM (Eds), Elsevier, Vol. 7, pp. 1–29.

Lachet V, Boutin A, Tavitian B, Fuchs AH (1998) Computational study of p-xylene/m-xylene mixtures adsorbed in NaY zeolite. J Phys Chem B 102:9224–9233

Lachet V, Buttefey S, Boutin A, Fuchs AH (2001) Molecular simulation of adsorption equilibria of xylene isomer mixtures in faujasite zeolites. A study of the cation exchange effect on adsorption selectivity. Phys Chem Chem Phys 3:80–6

Lima EC, Sher F, Guleria A, Saeb MR, Anastopoulos I, Tran HN et al (2021) Is one performing the treatment data of adsorption kinetics correctly? J Environ Chem Eng 9:104813

Liu D, Wu Y, Xia Q, Li Z, Xi H (2013) Experimental and molecular simulation studies of CO 2 adsorption on zeolitic imidazolate frameworks: ZIF-8 and amine-modified ZIF-8. Adsorption 19:25–37

Liu S, Yang X (2006) Gibbs ensemble Monte Carlo simulation of supercritical CO 2 adsorption on Na A and Na X zeolites. J Chem Phys 124:244705

Loewenstein W (1954) The distribution of aluminum in the tetrahedra of silicates and aluminates. Am Mineralogist: J Earth Planetary Mater 39:92–96

Mahmodi G, Dangwal S, Zarrintaj P, Zhu M, Mao Y, McLlroy DN et al (2020) NaA zeolite-coated meshes with tunable hydrophilicity for oil-water separation. Sep Purif Technol 240:116630

Mahmodi G, Zarrintaj P, Taghizadeh A, Taghizadeh M, Manouchehri S, Dangwal S et al (2020) From microporous to mesoporous mineral frameworks: an alliance between zeolite and chitosan. Carbohydr Res 489:107930

Maroo SC, Chung J (2008) Molecular dynamic simulation of platinum heater and associated nano-scale liquid argon film evaporation and colloidal adsorption characteristics. J Colloid Interface Sci 328:134–146

Mashhadzadeh AH, Vahedi AM, Ardjmand M, Ahangari MG (2016) Investigation of heavy metal atoms adsorption onto graphene and graphdiyne surface: a density functional theory study. Superlattices Microstruct 100:1094–1102

McQuarrie D (2000) Statistical mechanics university science books. CA, Sausalito, pp 222–3

Metropolis N, Rosenbluth AW, Rosenbluth MN, Teller AH, Teller E (1953) Equation of state calculations by fast computing machines. J Chem Phys 21:1087–1092

Mintova S, Gilson J-P, Valtchev V (2013) Advances in nanosized zeolites. Nanoscale 5:6693–6703

Mohammadi Y, Saeb MR, Penlidis A, Jabbari E, Zinck P, Stadler FJ et al (2018) Intelligent monte carlo: a new paradigm for inverse polymerization engineering. Macromol Theory Simul 27:1700106

Nagar H, Badhrachalam N, Rao VB, Sridhar S (2019) A novel microbial fuel cell incorporated with polyvinylchloride/4A zeolite composite membrane for kitchen wastewater reclamation and power generation. Mater Chem Phys 224:175–185

Nakatsuji H, Nakashima H, Kurokawa Y, Ishikawa A (2007) Solving the Schrödinger equation of atoms and molecules without analytical integration based on the free iterative-complement-interaction wave function. Phys Rev Lett 99:240402

Narasimhan L, Boulet P, Kuchta B, Schaef O, Denoyel R, Brunet P (2009) Molecular simulations of water and paracresol in MFI zeolite-a Monte Carlo study. Langmuir 25:11598–11607

Newsome D, Gunawan S, Baron G, Denayer J, Coppens M-O (2014) Adsorption of CO 2 and N 2 in Na–ZSM-5: effects of Na+ and Al content studied by Grand Canonical Monte Carlo simulations and experiments. Adsorption 20:157–171

Nguyen CM, Reyniers M-F, Marin GB (2010) Theoretical study of the adsorption of C1–C4 primary alcohols in H-ZSM-5. Phys Chem Chem Phys 12:9481–9493

Nizami AS, Ouda OKM, Rehan M, El-Maghraby AMO, Gardy J, Hassanpour A et al (2016) The potential of Saudi Arabian natural zeolites in energy recovery technologies. Energy 108:162–171

O’Malley AJ, Catlow CRA (2013) Molecular dynamics simulations of longer n-alkanes in silicalite: a comparison of framework and hydrocarbon models. Phys Chem Chem Phys 15:19024–19030

Papadopoulou A, Becker ED, Lupkowski M, van Swol F (1993) Molecular dynamics and Monte Carlo simulations in the grand canonical ensemble: local versus global control. J Chem Phys 98:4897–4908

Pascual P, Ungerer P, Tavitian B, Pernot P, Boutin A (2003) Development of a transferable guest–host force field for adsorption of hydrocarbons in zeolites I. Reinvestigation of alkane adsorption in silicalite by grand canonical Monte Carlo simulation. Phys Chem Chem Phys 5:3684–93

Phan A, Doonan CJ, Uribe-Romo FJ, Knobler CB, O’Keeffe M, Yaghi OM (2010) Synthesis, structure, and carbon dioxide capture properties of zeolitic imidazolate frameworks. Acc Chem Res 43:58–67

Pillai RS, Sebastian J, Jasra RV (2012) Grand canonical Monte Carlo simulation and volumetric equilibrium studies for adsorption of nitrogen, oxygen, and argon in cadmium (II) exchanged zeolite A. J Porous Mater 19:683–693

Prakash M, Sakhavand N, Shahsavari R (2013) H2, N2, and CH4 gas adsorption in zeolitic imidazolate framework-95 and-100: Ab initio based grand canonical Monte Carlo simulations. J Phys Chem C 117:24407–24416

Prasanth K, Pillai RS, Peter SA, Bajaj H, Jasra R, Chung H et al (2008) Hydrogen uptake in palladium and ruthenium exchanged zeolite X. J Alloy Compd 466:439–446

Rahmati M, Mills D, Urbanska A, Saeb M, Venugopal J, Ramakrishna S et al (2020) Electrospinning for tissue engineering applications. Prog Mater Sci 117:100721

Rahmati M, Modarress H (2009a) Nitrogen adsorption on nanoporous zeolites studied by Grand Canonical Monte Carlo simulation. J Mol Struct (thoechem) 901:110–116

Rahmati M, Modarress H (2009b) Grand canonical Monte Carlo simulation of isotherm for hydrogen adsorption on nanoporous siliceous zeolites at room temperature. Appl Surf Sci 255:4773–4778

Rassoulinejad-Mousavi SM, Azamat J, Khataee A, Zhang Y (2020) Molecular dynamics simulation of water purification using zeolite MFI nanosheets. Sep Purif Technol 234:116080

Razmus DM, Hall CK (1991) Prediction of gas adsorption in 5A zeolites using Monte Carlo simulation. AIChE J 37:769–779

Saeb MR, Mohammadi Y, Ahmadi M, Khorasani MM, Stadler FJ (2015) A Monte Carlo-based feeding policy for tailoring microstructure of copolymer chains: reconsidering the conventional metallocene catalyzed polymerization of α-olefins. Chem Eng J 274:169–180

Saeb MR, Mohammadi Y, Pakdel AS, Penlidis A (2016) Molecular architecture manipulation in free radical copolymerization: an advanced monte carlo approach to screening copolymer chains with various comonomer sequence arrangements. Macromol Theory Simul 25:369–382

Salmankhani A, Karami Z, Mashhadzadeh AH, Ganjali MR, Vatanpour V, Esmaeili A, et al. (2020) New insights into H2S adsorption on graphene and graphene-like structures: a comparative DFT study. C 6:74

Sargazi G, Afzali D, Mostafavi A, Shadman A, Rezaee B, Zarrintaj P et al (2019) Chitosan/polyvinyl alcohol nanofibrous membranes: towards green super-adsorbents for toxic gases. Heliyon 5:e01527

Servatan M, Ghadiri M, Damanabi AT, Bahadori F, Zarrintaj P, Ahmadi Z et al (2018) Zeolite-based catalysts for exergy efficiency enhancement: the insights gained from nanotechnology. Mater Today Proc 5:15868–15876

Servatan M, Zarrintaj P, Mahmodi G, Kim S-J, Ganjali MR, Saeb MR et al (2020b) Zeolites in drug delivery: progress, challenges and opportunities. Drug Discov Today 25:642–656

Servatan M, Ghadiri M, Yazdi MK, Jouyandeh M, Mahmodi G, Samadi A et al (2020) Synthesis of cost-effective hierarchical MFI-type mesoporous zeolite: introducing diatomite as silica source. Silicon. https://doi.org/10.1007/s12633-020-00786-7

Shah MS, Tsapatsis M, Siepmann JI (2015) Monte Carlo simulations probing the adsorptive separation of hydrogen sulfide/methane mixtures using all-silica zeolites. Langmuir 31:12268–12278

Shahmoradi A, Ghorbanzadeh Ahangari M, Jahanshahi M, Hamed Mashhadzadeh A (2020a) Adsorption of hazardous atoms on the surface of TON zeolite and bilayer silica: a DFT study. J Mol Model 26:119

Shahmoradi A, Ghorbanzadeh Ahangari M, Jahanshahi M, Mirghoreishi M, Fathi E, Hamed Mashhadzadeh A (2020b) Removal of methylmercaptan pollution using Ni and Pt-decorated graphene: an ab-initio DFT study. J Sulfur Chem 41:593–604

Shannon MA, Bohn PW, Elimelech M, Georgiadis JG, Marinas BJ, Mayes AM (2010) Science and technology for water purification in the coming decades. In: Nanoscience and technology: a collection of reviews from nature Journals, World Scientific pp. 337–46

Slaughter M, Yu J-Y (1991) Partial binding energies and structural properties of the heulandite/clinoptilolite series. In: Clay Minerals Society 28th Annual Meeting, Vol. 773, p. 145

Smit B, Krishna R (2001) Monte Carlo simulations in zeolites. Curr Opin Solid State Mater Sci 5:455–461

Song MK, No KT (2007) Molecular simulation of hydrogen adsorption in organic zeolite. Catal Today 120:374–382

Sweatman M, Quirke N (2001) Modelling gas adsorption in slit-pores using Monte Carlo simulation. Mol Simul 27:295–321

Thomas AM, Subramanian Y (2017) Hexane isomers in faujasite: anomalous diffusion and kinetic separation. J Phys Chem C 121:14745–14756

Thomas AM, Subramanian Y (2019) Bridging the gap between diffusivities from experiment and molecular dynamics: n-hexane and 2, 2-dimethyl butane in zeolite BEA. Microporous Mesoporous Mater 287:124–134

Timón V, Senent ML, Hochlaf M (2015) Structural single and multiple molecular adsorption of CO2 and H2O in zeolitic imidazolate framework (ZIF) crystals. Microporous Mesoporous Mater 218:33–41

Treybal RE (1980) Mass transfer operations. New York, p. 466

Turgman-Cohen S, Araque JC, Hoek EM, Escobedo FA (2013) Molecular dynamics of equilibrium and pressure-driven transport properties of water through LTA-type zeolites. Langmuir 29:12389–12399

Ungerer P, Tavitian B, Boutin A (2005) Applications of molecular simulation in the oil and gas industry: Monte Carlo methods, Editions Technip.

Valencia-Ortega M, Fuentes-Azcatl R, Dominguez H (2019) Carbon dioxide adsorption on a modified zeolite with sodium dodecyl sulfate surfactants: a molecular dynamics study. J Mol Graph Model 92:243–248

Van Tassel P, Davis H, McCormick A (1991) Monte Carlo calculations of adsorbate placement and thermodynamics in a micropore: Xe in NaA. Mol Phys 73:1107–1125

Vatanpour V, Khadem SSM, Dehqan A, Al-Naqshabandi MA, Ganjali MR, Hassani SS et al (2021) Efficient removal of dyes and proteins by nitrogen-doped porous graphene blended polyethersulfone nanocomposite membranes. Chemosphere 263:127892

Vinaches P, Bernardo-Gusmão K, Pergher SB (2017) An introduction to zeolite synthesis using imidazolium-based cations as organic structure-directing agents. Molecules 22:1307

Wajima T, Haga M, Kuzawa K, Ishimoto H, Tamada O, Ito K et al. (2006) Zeolite synthesis from paper sludge ash at low temperature (90Eæ C) with addition of diatomite 132: 244–52

Wang Y, Jia H, Chen P, Fang X, Du T (2020) Synthesis of La and Ce modified X zeolite from rice husk ash for carbon dioxide capture. J Market Res 9:4368–4378

Weitkamp J (2000) Zeolites and Catalysis. Solid State Ionics 131:175–188

Wu C, Buyya R (2015) Chapter 18—real option theory and monte carlo simulation. In: Wu C, Buyya R (eds) Cloud data centers and cost modeling. Morgan Kaufmann, Elsevier, pp 707–72

Yazdi MK, Zarrintaj P, Hosseiniamoli H, Mashhadzadeh AH, Saeb MR, Ramsey JD et al (2020) Zeolites for theranostic applications. J Mater Chem B 8:5992–6012

Zarrintaj P, Mahmodi G, Manouchehri S, Mashhadzadeh AH, Khodadadi M, Servatan M et al (2020) Zeolite in tissue engineering: Opportunities and challenges. MedComm 1:5–34

Zhang J, Burke N, Zhang S, Liu K, Pervukhina M (2014) Thermodynamic analysis of molecular simulations of CO2 and CH4 adsorption in FAU zeolites. Chem Eng Sci 113:54–61

Acknowledgements

The authors thank CAPES, FAPERGS, and CNPq for funds. They also thank Dr. Bruno Azambre from Laboratoire de Chimie et Physique-Approche Multi-Echelle des Milieux Complexes, Université de Lorraine, for useful comments and discussions.

Funding

N/A

Author information

Authors and Affiliations

Contributions

AS wrote the original draft of article, SSMK wrote the original draft of article, FS generated formal analysis, AHM did conceptualization, PZ generated formal analysis, SH generated formal analysis, AM generated formal analysis, NR generated formal analysis, ECL, MS, and RSV were involved in writing, reviewing, and editing to give the review its final form, , , MRS helped in visualization and final checking of the whole manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflicts of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salmankhani, A., Mousavi Khadem, S.S., Seidi, F. et al. Adsorption onto zeolites: molecular perspective. Chem. Pap. 75, 6217–6239 (2021). https://doi.org/10.1007/s11696-021-01817-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01817-2