Abstract

A new efficient method for the synthesis of isothiocyanates has been developed via the replacement reaction of phenyl isothiocyanate and the corresponding amines (the amino group of these amines was linked to tertiary carbon or secondary carbon) with dimethylbenzene as solvent. This reaction was carried out under the protection of nitrogen and mild condition. In addition, the yields of some products could be more than 90%. More importantly, this method has advantages with low toxicity, low cost, safety, less by-products and simple to operate. It has the potential to realize the industrial production of some complicated isothiocyanates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

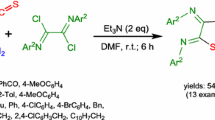

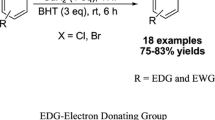

Isothiocyanates are considered to be the most biologically active degradation products of glucosinolates-secondary metabolites of some plants, mainly from Brassicaceae family (Pilipczuk et al. 2017; Fechner et al. 2018; Sarah et al. 2015). Meanwhile, isothiocyanates are a class of important organic synthetic intermediates and are widely applied as chemoselective electrophiles in bioconjugate chemistry due to their tolerance toward aqueous reaction conditions (Yella et al. 2010; Xiao et al. 2008; Márquez et al. 2008; Srisa et al. 2019). Therefore, various methods have been developed to synthesize isothiocyanates. There are three common methods for synthesis of isothiocyanates. The first method, isothiocyanates are prepared from amines and thiophosgene (Fig. 1) (Li et al. 2015; Banert et al. 2001). However, thiophosgene is an extremely poisonous and volatile liquid. Its production, transportation and storage will not be secure. The second method, isothiocyanates are synthesized from the corresponding amines with carbon disulfide using di-tert-butyl dicarbonate and DMAP or DABCO as catalyst (Fig. 2) (Zhang et al. 2019; Sun et al. 2012). Nevertheless, lots of isothiocyanates cannot be obtained by this method. In addition, carbon disulfide is volatile liquid and readily explosive. The third method, the synthesis of isothiocyanates is achieved through the reactions of phenyl chlorothionoformate with various primary amines (Fig. 3) (Zhang et al. 2000; Chen et al. 2011; Li et al. 2013). In our previous investigation, it was also found that isothiocyanate derivative of p-menth-3-en-1-amine could be synthesized via this reaction and the result had been published in Natural Product Research (Zhu et al. 2021). However, the price of phenyl chlorothionoformate is expensive and the production rate is low. Although the previous methods are efficient, we were eager to develop a synthetic method for isothiocyanates with low toxicity, safety, low cost and high output rate.

As we know that aromatic isothiocyanates can be easy to react with amines to give corresponding thioureas (Murata et al. 2018; Yildiz et al. 2017; Vagapova et al. 2015). However, in our investigation, it was found that thioureas could be broken down into isothiocyanates and amine at high temperatures. Based on the above points, thioureas were designed to synthesize from a highly reactive isothiocyanate (phenyl isothiocyanate) and amines, then thioureas are degraded to another isothiocyanate together with a less reactive amine. For this method, there were many advantages, such as inexpensive and commercially available material (phenyl isothiocyanate), mild reaction conditions and high security (normal pressure), simple work-up procedure and good potential of industrial application.

Experimental

Materials and instrumentation

All the chemicals were purchased from Shanghai Jingchun Biochemical Technology Co., Ltd (Shanghai, China) and were used without further purification. The NMR spectra were recorded on a Bruker AV-500 (Bruker, Switzerland) spectrometer with TMS as the internal reference and dimethylsulfoxide (DMSO-d6) as solvent. The IR spectra were carried out on a Thermo Nicolte IS10 spectrometer (Thermo, USA) connected to an OMNIC operating system. GC analysis was carried out on an Agilent 6890 N/5973 N spectrometer and used to confirm the purity of the compounds. The ESI+-MS were recorded on a TSQ Quantum Ultra AM mass spectrometer (Finnigan, USA). The element analysis was carried out on a Vario EL cube (Elemantar, Germany). Melting points were determined on a WRS-1B digital melting point apparatus. Column chromatography was carried out on silica gel (200–300 mesh).

General reaction procedure

16 mmol amine (except for entry 2, 8 mmol), 16 mmol phenyl isothiocyanate and 30 mL dimethylbenzene (the boiling point was 137–140 °C) were added into a flask. Then, the reaction mixture was heated to reflux for 5 h under the protection of nitrogen. After this, the solvent was removed by vacuum rotatory evaporator. The crude was purified by column chromatography on silica gel to afford the corresponding isothiocyanates. All of the product yields had been reported in molar units.

1-isopropyl-4-isothiocyanato-4-methylcyclohex-1-ene, 3a (a racemate), was recovered in 90.0% yield as a colorless transparent liquid, b.p. : 245.6–247.3 °C. Purity, 99.2%. 1H NMR (DMSO-d6, 500 MHz), δH 5.34 (1H, t, 3-Ha), 2.30–2.35 (1H, m, 5-Ha), 2.17–2.27 (3H, m, 2-Ha, 5-He, 8-H), 2.05–2.09 (1H, m, 2-He), 1.95–2.00 (1H, m, 6-Ha), 1.69–1.75 (1H, m, 6-He), 1.41 (3H, s, 7-H), 1.04 (6H, d, J = 7.5, 9-H, 10-H). 13C NMR (DMSO-d6, 125 MHz), δC 142.8 (4-C), 130.9 (1-N = C = S), 114.9 (3-C), 59.9 (1-C), 38.9 (6-C), 35.3 (2-C), 34.8 (8-C), 28.0 (7-C), 23.4 (5-C), 21.89 (10-C), 21.5 (9-C). FT-IR (cm−1): 3060 (w, ν=C–H); 2961, 2931 (s, νC-H); 2095, 2067 (s, ν-N=C=S); 1661 (w, νC=C); 1381 (m, δC-H); 813 (m, ν-C=CH). GC–MS, m/z 195.1, 162.1, 136.1, 107.1, 81.1, 53.1. Elem. Anal. calcd. for C11H17NS: C, 67.64; H, 8.77; N, 7.17; S,16.42. Found: C, 67.68; H, 8.80; N, 7.13; S, 16.39. Spectroscopic data are according to the literature (Zhu et al. 2021).

1-isothiocyanato-4-(2-isothiocyanatopropan-2-yl)-1-methylcyclohexane, 3b (a new compound), was recovered in 94.6% yield as a white solid, m.p. 85.7–86.2 °C. Purity, 99.0%. 1H NMR (DMSO-d6, 500 MHz), δH 2.00 (2H, d, J = 12.8 Hz, 3-Ha, 5-Ha), 1.80 (2H, d, J = 12.2 Hz, 2-Ha, 6-Ha), 1.53–1.60 (3H, m, 2-He, 4-H, 6-He), 1.42 (6H, s, 9-H, 10-H), 1.41 (3H, s, 7-H), 1.31–1.39 (2H, m, 3-He, 5-He). 13C NMR (DMSO-d6, 125 MHz), δC 130.8 (1-N=C=S), 130.0 (8-N=C=S), 64.7 (8-C), 62.0 (1-C), 46.2 (4-C), 38.2 (2-C, 6-C), 29.4 (7-C), 26.9 (9-C, 10-C), 23.4 (3-C, 5-C). FT-IR (cm−1): 2978, 2937 (s, νC-H); 2127, 2095 (s, ν-N=C=S); 1386 (m, δC-H). GC–MS, m/z 254.1, 195.1, 137.2, 112.0, 81.1, 55.1. Elem. Anal. calcd. for C12H18N2S2: C, 56.65; H, 7.13; N, 11.01; S, 25.1. Found: C, 56.62; H, 7.17; N, 10.98; S, 24.99.

Isothiocyanatocyclohexane, 3c, was recovered in 53.6% yield as a colorless transparent liquid, b.p. 217.7–218.8 °C. Purity, 99.1%. 1H NMR (DMSO-d6, 500 MHz), δH 3.58 (1H, m, 1-H), 3.29 (s, H2O), 1.87–1.92 (2H, m, 2-Ha, 6-Ha), 1.59–1.64 (4H, m, 2-He, 3-Ha, 5-Ha, 6-He), 1.36–1.48 (4H, m, 3-He, 4-Ha, 4-He, 5-He). 13C NMR (DMSO-d6, 125 MHz), δC 129.11 (1-N=C=S), 55.5 (1-C), 33.0 (2-C, 6-C), 25.0 (3-C, 5-C), 23.2 (4-C). FT-IR (cm−1): 2936, 2857 (s, νC-H); 2178, 2102 (s, ν-N=C=S); 1361 (m, δC-H). GC–MS, m/z 141.1, 113.0, 98.0, 83.1, 55.1. Elem. Anal. calcd. for C7H11NS: C, 59.53; H, 7.85; N, 9.92; S, 22.70. Found: C, 59.56; H, 7.89; N, 9.88; S, 22.67. Spectroscopic data are according to the literature (Li et al. 2015).

1-isothiocyanato-4-methylbenzene, 3d, was recovered in 45.6% yield as a colorless transparent, liquid b.p. 235.7–236.9 °C. Purity, 99.1%. 1H NMR (DMSO-d6, 500 MHz), δH 7.28 (2H, d, J = 8.5 Hz, 3-H, 5-H), 7.24 (2H, d, J = 8.4 Hz, 2-H, 6-H), 2.33 (3H, s, 4-CH3). 13C NMR (DMSO-d6, 125 MHz), δC 138.19 (4-C), 133.57 (1-N=C=S), 130.7 (3-C, 5-C), 127.8 (1-C), 126.1 (2-C, 6-C), 21.2 (4-CH3). FT-IR (cm−1): 3032 (w, ν=C-H); 2922, 2854 (m, νC-H); 2175, 2092 (s, ν-N=C=S); 1607, 1578 (w, νC=C); 1503 (s, νC=C); 813 (m, ν-C–CH). GC–MS, m/z 149.0, 121.0, 91.1, 65.0. Elem. Anal. calcd. for C8H7NS: C, 64.39; H, 4.73; N, 9.39; S, 21.49. Found: C, 64.42; H, 4.77; N, 9.35; S, 21.47. Spectroscopic data are according to the literature (Li et al. 2015).

Results and discussion

Phenyl isothiocyanate was a good electrophilic reagent due to the fact that the electrons of the group (N=C=S) could be spread over the benzene, and it was highly reactive with various amines. Furthermore, it was very cheap comparing with phenyl chlorothionoformate. So phenyl isothiocyanate was selected as the reaction substrate in this investigation. A competitive experiment in which 16 mmol phenyl isothiocyanate was reacted with 16 mmol amine (except for cis-1,8-p-menthane-diamine) was undertaken in our experiment (Fig. 4). Dimethylbenzene or methylbenzene was used as solvent and nitrogen was used to prevent oxidization of the amine. The result is listed in Table 1. It was found that most of the aliphatic amines were easy to react with phenyl isothiocyanate to provide relevant aliphatic isothiocyanates (53.6–94.6% yield) and aniline (entries 1–4). However, some aromatic isothiocyanates could not be obtained from the reaction between the corresponding aromatic amines and phenyl isothiocyanate, and the main product of the reaction was thiourea. The reason we speculated is that the electron of the group (N=C=S) of aromatic isothiocyanate could be dispersed to the benzene, making the electrophilic ability of the isothiocyanate stronger. As a result, the isothiocyanate was easier to react with nucleophilic reagent (amine) and the direction of the reaction moved toward the intermediate (thiourea). Based on the above consideration, we planned to introduce an electron-donating group into aniline as the reaction substrate. It was found that 1-isothiocyanato-4-methoxybenzene and 1-isothiocyanato-4-trifluoromethoxybenzene could not be acquired from the reaction between the corresponding amines and phenyl isothiocyanate due to the fact that the steric hindrance of the groups (methoxy and trifluoromethoxy) was not enough low (entries 8 and 9). To our delight, 1-isothiocyanato-4-methylbenzene (compound 3d) could be obtained from the reaction between 4-Methylaniline (introduction of a strong electron-donating group into aniline, entry 4) and phenyl isothiocyanate in 45.6% yield. 4-Methylaniline had not been converted to other materials except for compound 3d and the corresponding thiourea. The thiourea could be degraded continuously to give the product compound 3d.

Conclusions

In conclusion, it was speculated that isothiocyanates could be synthesized from phenyl isothiocyanate and various amines (the amino group of these amines was linked to tertiary carbon or secondary carbon) via replacement reaction. Although some aromatic isothiocyanates could not be prepared through this reaction, the characteristics (low toxicity, safety, low cost, less by-products and simple to operate) of this method are still attractive for isothiocyanate preparation in many cases.

References

Banert K, Hagedorn M, Muller A (2001) Synthesis of new vinyl thiocyanates by [3,3] sigmatropic rearrangement of isothiocyanates. Eur J Org Chem 2001:1089–1103. https://doi.org/10.1002/1099-0690(200103)2001:6%3c1089::AID-EJOC1089%3e3.0.CO;2-N

Chen X, Li Z, Sun X, Ma HZ (2011) New method for the synthesis of sulforaphane and related isothiocyanates. Synthesis 2011:3991–3996. https://doi.org/10.1055/s-0031-1289601

Fechner J, Kaufmann M, Herz C, Eisenschmidt D, Lamy E, Kroh LW, Hanschen FS (2018) The major glucosinolate hydrolysis product in rocket (Eruca sativa L.), sativin, is 1,3-thiazepane-2-thione: elucidation of structure, bioactivity, and stability compared to other rocket isothiocyanates. Food Chem 261:57–65. https://doi.org/10.1016/j.foodchem.2018.04.023

Li ZY, Ma HZ, Han C, Xi H, Meng Q, Chen X, Sun X (2013) Synthesis of isothiocyanates by reaction of amines with phenyl chlorothionoformate via one-pot or two-step process. Synthesis 45:1667–1674. https://doi.org/10.1055/s-0033-1338744

Li ZY, Shi S, Zhuang Y, Zheng CQ, Zhang JL, Sun XQ (2015) Improvement of the synthesis of isothiocyanates. Chin J Org Chem 35:1999–2003. https://doi.org/10.6023/cjoc201503026

Márquez JM, López O, Maya L, Fuentes J, Fernández-Bolaños JG (2008) Fernández-Bolaños. Taurine isothiocyanate: a versatile intermediate for the preparation of ureas, thioureas, and guanidines. Taur Deriv Cyclodext Tetrahedron Lett 49:3912–3915. https://doi.org/10.1016/j.tetlet.2008.04.053

Murata Y, Matsumoto N, Miyata M, Kitamura Y, Kakusawa N, Matsumura M, Yasuike S (2018) One-pot reaction for the synthesis of N-substituted 2-aminobenzoxazoles using triphenylbismuth dichloride as cyclodesulfurization reagent. J Organomet Chem 859:18–23. https://doi.org/10.1016/j.jorganchem.2018.01.041

Pilipczuk T, Kusznierewicz B, Chmiel T, Przychodzen W, Bartoszek A (2017) Simultaneous determination of individual isothiocyanates in plant samples by HPLC-DAD-MS following SPE and derivatization with N-acetyl-l-cysteine. Food Chem 214:587–596. https://doi.org/10.1016/j.foodchem.2016.07.125

Sarah ML, Ya L, Michael JC, Laciak AR, Singh H, Seiner DR, Reilly TJ, Tanner JJ, Gates KS (2015) Inactivation of protein tyrosine phosphatases by dietary isothiocyanates. Bioorg Med Chem Lett 25:4549–4552. https://doi.org/10.1016/j.bmcl.2015.08.065

Srisa J, Tankam T, Sukwattanasinitt M, Wacharasindhu S (2019) Micelle-enabled one-pot guanidine synthesis in water directly from isothiocyanate using hypervalent iodine(III) reagents under mild conditions. Chem Asian J 14:3335–3343. https://doi.org/10.1002/asia.201900982

Sun N, Li B, Shao J, Mo W, Hu B, Shen Z, Hu X (2012) A general and facile one-pot process of isothiocyanates from amines under aqueous conditions. Beilstein J Org Chem 8:61–70. https://doi.org/10.3762/bjoc.8.6

Vagapova LI, Sharafutdinova DR, Burilov AR, Mustafina AR, Babaev VM, Rizvanov IK, Pudovik M (2015) A Synthesis and properties of new thiophosphorylated thioureas containing a trialkoxysilyl group. Russ J Org Chem 51:309–312. https://doi.org/10.1134/s1070428015030033

Xiao D, Powolny AA, Singh SV (2008) Benzyl isothiocyanate targets mitochondrial respiratory chain to trigger reactive oxygen species-dependent apoptosis in human breast cancer cells. J Biol Chem 283:30151–30163. https://doi.org/10.1074/jbc.m802529200

Yella R, Ghosh H, Murru S, Sahoo SK, Patel BK (2010) Efficient preparation of isothiocyanates from dithiocarbamates using bromineless brominating reagent. Synth Commun 40:2083–2096. https://doi.org/10.1080/00397910903219476

Yildiz IN, Orucemre EE, Tasdemir D, Karakucukiyidogan A, Ulasli M, Bayram H (2017) Design and synthesis of novel thioureas derived from 4-(4-Fluorophenoxy)aniline as anticancer agents: novel thiourea derivatives from 4-(4-Fluorophenoxy) aniline. J Chin Chem Soc 64:321–330. https://doi.org/10.1002/jccs.201600193

Zhang B, Shi L (2019) One-pot synthesis of isothiocyanates. Chin J Appl Chem 36:892–896

Zhang X, Lee YK, Kelley JA, Burke TR (2000) Preparation of aryl isothiocyanates via protected phenylthiocarbamates and application to the synthesis of caffeic acid (4-isothiocyanato) phenyl ester. J Org Chem 65:6237–6240. https://doi.org/10.1002/chin.200105085

Zhu SJ, Li JF (2021) Design, synthesis and herbicidal activities of p-menth-3-en-1-amine thiourea derivatives. Nat Prod Res 51:1–8. https://doi.org/10.1080/14786419.2021.1880407

Acknowledgements

This work was supported by Science and Technology Project of Chaozhou (grant No. 2019ZC01), PhD Startup Project of Hanshan Normal University (grant No. QD20181008), and The Program of Basic Capability Improvement Project of Young and Middle-aged Teachers in GuangXi Colleges and Universities (grant No. 2018KY0697).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

A patent filing on the practice of this reaction [Faming Zhuanli Shenqing (2020), CN 111635345 A 20200908] has been initiated by Shouji Zhu.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Sj., Li, Jf. A novel synthesis of isothiocyanates from amines and phenyl isothiocyanate via replacement reaction. Chem. Pap. 75, 4543–4547 (2021). https://doi.org/10.1007/s11696-021-01692-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01692-x