Abstract

The main purpose of this manuscript was to study the electropolymerization using cyclodextrin as a monomer for application as electrochemical sensors. This process was first studied by Morales et al. and will be discussed in this work using a systematic and descriptive approach. For that, the voltammetric behavior of a β-cyclodextrin electropolymerization on a carbon glassy electrode (CGE) surface and the mechanism involved was investigated. The electropolymerization exhibits two anode peaks at 0.61 V and 1.56 and two cathode peaks at − 0.58 V and − 1.05 that increases in successive cycles, indicating that a β-CD polymer film is being formed. The mechanism of β-CD electropolymerization occurs in two stages simultaneously: the monomer is deposited on the surface of the CGE by covalent bonds, while the monomer is coupled successively producing the polymer. The followed experimental conditions were optimized evaluating the voltammetric responses observed during the polymer formation: potential range (− 1.3 to 0.9 V), presence or absence of dissolved oxygen (presence) and stirring during the electropolymerization (with agitation), electrolyte pH (pH = 5.0), scan rate (100 mV s−1), and concentration of β-CD (6 mol L−1). The optimization promoted the development of a more efficiently synthesis.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Electrochemical polymerization provides a simple, clean, and efficient route for the synthesis of polymers. In this method, also known as electropolymerization, the synthesized polymers have no oxidant fragments or catalysts, and the chemical/physical properties of the polymer are dependent on the electrochemical conditions employed during the synthesis (Imisides et al. 1991). Electropolymerization is usually performed in aqueous media of monomer solution and supports electrolyte with a three-electrode electrochemical cell (Imisides et al. 1991, Sarac 2004). This process depends on several factors, such as monomer, electrode, supporting electrolyte, and electroanalytical methods. Despite this, the methodology is standard: an electrode is chosen, the monomer must be solubilized in a support electrolyte, and the technique may be galvanostatic or potentiostatic (Sarac 2004).

The galvanostatic method takes place through the application of constant current, allowing greater control of the thickness of the electropolymerized film. On the other hand, the potentiostatic method involves the application of a constant potential, usually using cyclic voltammetry (Cosnier and Karyaki 2010). The control of the scanning parameters such as speed, number of cycles, and potential range determinates the morphological characteristics of the film. When applying cyclic voltammetry, the anodic and cathodic current increase with the number of cycles, showing a typical behavior of the polymer being adsorbed on the surface of the electrode (Imisides et al. 1991; Golabi and Mirzazadeh 2003). The general mechanism for electropolymerization process is shown in Fig. 1 (Del Valle et al. 2003). The hydrogen atoms (H) shown are those in the position of the further bond formation (Cosnier and Karyaki 2010).

The electropolymerization is initiated by the oxidation of the monomer, to form a radical cation (1). In this case, it is possible to combine two monomers in the oxidized form to form an oligomer, in this case a dimer—two units of bonded monomers (Cosnier and Karyaki 2010). The oligomer formed can be oxidized to form a radical cation (3). This oxidized oligomer can couple with a previously oxidized monomer to form another oligomer, in this case a trimer—three units of bound monomers (4) (Del Valle et al. 2003). Finally, the monomer units add sequentially to this active site to form a growing polymer chain (5) (Cosnier and Karyaki 2010). This coupling between the radical cations can occur through carbon–carbon bonds; nitrogen–nitrogen, or carbon–nitrogen (Imisides et al. 1991).

In general, the oxidation potential decreases with increasing polymer chain length, since it involves a greater electronic delocalization (Cosnier and Karyaki 2010). Thus, the potential needed to oxidize the monomer is sufficient for oxidation of the dimer and higher oligomers (Cosnier and Karyaki 2010). In other words, when the monomer is oxidized to the corresponding radical cation, it can couple with a second radical cation or with another monomer to produce a oligomer (Del Valle et al. 2003). In addition, the radical cation of the oligomer can also couple with another oligomer (Cosnier and Karyaki 2010). By successive steps, polymeric chains grow up. Thus, the surface of the electrode will not be composed of only one type of oligomer, but a mixture of them (Del Valle et al. 2003). In principle, various polymers can be electrochemically synthesized. The only condition is that the monomer has an oxidation potential and can be oxidized in solution (Sarac 2004).

Cyclodextrins (CD) are cyclic oligosaccharides formed by glucose molecules, joined by glycosidic linkages (Kurkov and Loftsson 2013). The CD is shaped like a truncated cone, as shown in Fig. 2b (Mannakker et al. 2009; Moriwaki et al. 2009). The secondary hydroxyl groups (–OH) at carbons C2 and C3 are located on the wider edge of the cone, and primary hydroxyls at C6 are located on the narrow side of the cone shape. The positions of the carbon atoms in the glucose unit can be seen in Fig. 2b. The hydroxyls at C3 and C6 are sterically oriented the outside of the ring, while the hydroxyl at C2 points into the cavity (Del Valle et al. 2003). The interior of the cavity is composed of hydrogen atoms of C3 and C5 and oxygen atoms of the glycosidic linkage at C1 and C4 (Del Valle et al. 2003).

The use of CDs as a monomer in electropolymerization is a recent technique with few published works (Alarcón-Ángeles et al. 2010; Jiang et al. 2016; Zhang et al. 2013; Morales et al. 2003). Furthermore, most of these works do not present the electrochemical behavior of electropolymerization. Thus, the study of the electropolymerization of CDs is a key for a better understanding of the process.

Materials and methods

Chemicals and reagents

Dimethyl sulfoxide (DMSO), hydrochloric acid (HCl), sodium phosphate dibasic heptahydrate (Na2HPO4·7H2O), and sodium phosphate monobasic monohydrate (NaH2PO4·H2O) were obtained from Synth (Brazil); nitric acid (HNO3) from dynamics (Brazil); β-cyclodextrin (β-CD) purchased from Sigma-Aldrich (Brazil); and liquid alumina polish obtained from Fortel (Brazil). All the reagents used were analytical or higher purity grade. All solutions were prepared from water purified in Millipore Milli-Q system.

Pretreatment of glassy carbon electrode

The glassy carbon electrode (CGE) was pretreated by mechanical polishing with alumina and thoroughly rinsed with deionized water. Subsequently, an electrochemical pretreatment of glassy carbon electrode was performed by cyclic voltammetry in a potential range of – 0.2–1.6 V at 100 mV s−1 (20 scans). The activation solution was H2SO4 0.5 mol L−1.

β-Cyclodextrin electropolymerization on a glassy carbon electrode

The electropolymerization solution was 6.0 mmol L−1 β-CD in phosphate buffer 0.05 mol L−1 (pH 5.0). To ensure a homogeneous distribution of particles, the solution was ultrasonicated for 10 min. The CGE was immersed in this solution and the potential was scanned from − 2.0 to + 2.2 V during 5 consecutive cycles at 100 mV s−1 (Alarcón-Ángeles et al. 2010; Jiang et al. 2016; Zhang et al. 2013; Morales et al. 2003). After, the β-CD monomer was electropolymerized onto CGE surface. The working electrode was named CGE/β-CD. After the electropolymerization, the proposed sensor was carefully washed with deionized water to remove adsorbed materials on the surface. A schematic illustration of the working electrode modification during electropolymerization is shown in Fig. 3.

Experimental conditions such as potential range, presence of dissolved oxygen and stirring during the electropolymerization, scan rate, electrolyte Ph, and concentration of β-CD were previously optimized. The chosen initial conditions of synthesis were based on some articles as Ref. [9-12].

Experimental measurements

Electrochemical measurements were carried out using an Autolab PGSTAT12 (Ecochemie) in combination with the NOVA 1.11 software with a conventional a three-electrode cell (Fig. 4). The system includes a CGE/β-CD as working electrode, a Pt wire counter electrode, and a Ag/AgCl reference electrode. The experiments were carried out in a phosphate buffer solution (0.05 mol L−1, pH 5.0). After the electrochemical measurements, the working electrode cleaning was performed. The CGE surface was polished using alumina as an abrasive and thoroughly rinsed with deionized water. Then, it was ultrasonicated in in HNO3 solution (5% v/v) for 3 min, followed by washing with deionized water.

Results and discussion

Electrochemical behavior of electropolymerized β-CD on a glassy carbon electrode

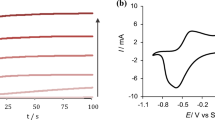

Initially, studies were conducted to better understand the voltammetric behavior of β-CD electropolymerized on the glassy carbon electrode (CGE) surface. The electropolymerization was performed scanning the potential between − 2.0 and + 2.2 V (50 successive cycles) by cyclic voltammetry experiments. The cyclic voltammograms obtained in the β-CD electropolymerization process on CGE are shown in Fig. 4.

In the inset cycle, a cathode peak 1 is noticed at − 0.58 V. From the second cycle onwards, anode peak appears at 0.61 V (peak 2) and 1.56 V (peak 3). From the 27th cycle, a new cathodic peak 4 appears in − 1.05 V. The peak currents increase in successive cycles indicating that a β-CD polymer film is being formed on the surface of the CGE. The current increases rapidly until the 12 cycles and with less intensity in the following cycles, indicating that possibly the film reached the maximum thickness (Páramo-García et al. 2011).

The experimental studies show that the cathode peak 1 is directly related to the success of the synthesis. Therefore, when the cathode peak 1 is well-defined and with high intensity, it is probable that the electropolymerization has been successful. Thus, for optimization of experimental variables, the current of this peak was important criteria. The first cycle of the electropolymerization usually presents a voltammetric behavior distinct from the others (Cosnier and Karyakin 2010). This cycle corresponds to the start of the electropolymerization and usually shows no signs of polymer growth. In fact, the monomer begins to be oxidized on the surface of the electrode in the first cycle, electropolymerization only occurs in subsequent cycles (Eftrkhari and Yazdani 2010). Therefore, the first cycle shows a behavior different from the others. The mechanism involved in the electropolymerization of β-CD will be discussed below.

The mechanisms of β-CD electropolymerization

Compounds having two or more units of CD, covalently bonded, are called polymeric cyclodextrins (CDP). The CDPs, as the CDs, have several binding sites and present ability to form inclusion complexes (Qin et al. 2016). The most widely known CDP synthesis include the cross-linking with a polyfunctional compound, such as epichlorohydrin (Szejtli 2013). Electropolymerization is another way to synthesize CDP. This method provides a simple, clean, and efficient route for polymer synthesis (Mannakker et al. 2009). Morales et al. was the first one to report the electrochemical polymerization of β-cyclodextrin and its mechanism (Morales et al. 2003). This mechanism will be explored below using a systematic and descriptive approach.

Each CD unit behaves as a monomer. The potential is applied to the electropolymerization solution by oxidizing the CD to the radical cation. The mechanism of electropolymerization of β-CD on the surface of an electrode occurs in two stages (Morales et al. 2003). These stages occur simultaneously and are responsible for the formation of the polymer film. The following two stages will be considered:

- Stage 1:

-

According the literature, by applying an electrochemical potential, it is possible to partially oxidize β-CD (Jarazabek 1990). This oxidation not only causes the polarization of the molecule, but also generates a radical cation on the carbon bearing the hydroxyl group (Cosnier and Karyakin 2010). This active center interacts with the CGE surface through a covalent bond, producing a ketone. Therefore, the β-CD monomer is deposited on the surface of the CGE (Morales et al. 2003). This stage 1 is represented in Fig. 5

- Stage 2:

-

As the β-CD is oxidized, the primary hydroxyls become more susceptible to oxidation. According to the literature, oxidation of a primary hydroxyl generates a carboxylic acid and/or aldehyde (Clayden et al. 2012). The radical cations formed in the process may react with each other to form a dimer. One hypothesis is that the reaction, known as esterification, occurs between the primary hydroxyl (–OH) and the carboxylic acid (–COOH), forming a dimer (Bruice 2006). Thus, the coupling of the monomers goes on successively leading to a growing chain (Del Valle et al. 2003). The proposed mechanism for this electropolymerization stage is shown in Fig. 6

In summary, during the electropolymerization of β-CD, the active center generated in the oxidation interacts with the CGE being deposited on the surface by covalent bonds, while the monomer is coupled successively producing the polymer. Therefore, an electroactive polymer film is formed on the surface of the CGE. This film is exemplified in Fig. 7. Several approaches have been made to improve the chemical and electrochemical properties of polymers. Considering that this mechanism can undergo changes according to the conditions used in the electropolymerization, some experimental parameters were studied. These factors will be discussed in the next section.

Optimization of experimental conditions

The main purpose of this manuscript was to study the β-cyclodextrin electropolymerization for application as electrochemical sensors. Therefore, the optimization parameters will be evaluated comparing the voltammetric responses observed during the polymer formation. For the construction of a sensitive β-CD polymer film, to be applied as electrochemical sensor, it is necessary that a certain quantity of polymers be deposited on the surface of the electrode. This is because the amount of binding sites present in the polymer structure influences the sensitivity of the sensor. For that reason, the parameter exhibiting higher peak current is the optimized value.

Evaluation of factors affecting the electropolymerization such as potential range, influence of electrolyte agitation, and the presence of oxygen during electropolymerization was investigated. The film thickness was optimized by controlling the number of scans. In the pH, the electrolyte and the concentration of the monomer were also studied. These conditions and their response will be evaluated in the next topics.

Effect of the applied potential range

The potential range consists of the difference between the initial and final potentials applied in the electrochemical system. The deposition potential of the polymer varies according to the monomer used, since the functional groups present in the structure directly influence this potential (Imisides et al. 1991). Hoever, in general, the deposition potential is equal to the oxidation potential of the monomer and should be able to oxidize all the monomers and oligomers (Cosnier and Karyaki 2010). Thus, this range influences the film thickness and the degree of oxidation of the polymer matrix. Therefore, the effect of potential range was studied according to the voltammetric behavior.

Studies that report electropolymerization of β-CD employ the range − 2.0 to + 2.5 or − 1.3 to + 0.9 (Alarcón-Ángeles et al. 2010, Jiang et al. 2016, Hernandez-Jiménez et al. 2016). The two ranges were tested and the results are shown in Fig. 8a. In the range of − 1.3 to +0.9 V, the cyclic voltammogram shows no peaks with high noise levels, indicating that the polymeric film was not formed effectively on the surface of the CGE. Probably, in this potential range, the oxidation was not complete. In contrast, in the range of − 2.0 to + 2.2 V, the voltammogram exhibited the two anodic peaks and a cathode peak, showing the formation of the polymer film on the electrode was successful and the oxidation was complete. Therefore, from the two conditions tested, the potential range of − 2.0 to +2.2 V was the most suitable to conduct the electropolymerization of β-CD.

Cyclic voltammograms for the electropolymerization of β-CD on CGE surface, 5th scan a in different ranges of potential; b in the absence and presence of dissolved oxygen in the electropolymerization solution; c with and without agitation of electropolymerization solution; d in different pHs of electropolymerization solution; e in different scan rates; and f in different monomer concentrations. Insets: zoom of dashed area

Influence of dissolved oxygen on electropolymerization solution

Oxygen (O2) is electroactive and capable of dissolving in aqueous solutions in millimolar levels, which can interfere in the electrochemical measurement. It is often necessary to remove dissolved oxygen from the electrolyte solution while working in the cathodic region (Aleixo 2003). Oxygen is typically removed by bubbling an inert gas through the solution for a few minutes. The gases have to be inert both chemically and electrochemically and heavy enough to easily displace oxygen. The most commonly used gas is nitrogen (N2), because it is easily obtained with high purity and is cheaper than others.

While some studies remove dissolved oxygen in the electrolyte solution prior to electropolymerization (Hernandez-Jiménez et al. 2016), others synthesize in the presence of oxygen (Morales et al. 2003). These two conditions were tested and the results of the voltammetric behavior in the presence and absence of oxygen, after bubbling the solution with N2 gas for 15 min, are shown in Fig. 8b. In the presence of oxygen, the voltammogram exhibits three well-defined characteristic peaks at 0.51, 1.38, and − 0.75 V. In the absence of oxygen, the peak at 0.44 V is not defined and exhibits a lower current. This fact is explained by analyzing the electropolymerization mechanism. In stage 1, oxidation generates a radical cation on the carbon bearing the hydroxyl group and that active center interacts with the CGE through a covalent bond, producing a ketone. The oxygen involved in mechanism is probably obtained from the electropolymerization solution. Therefore, for the mechanism to occur effectively, it is necessary that the electropolymerization be performed in the presence of oxygen. Thus, it is recommended that the electropolymerization of β-CD be performed in the presence of oxygen.

Effect of electrolyte agitation

Electropolymerization is usually carried out in a three-electrode electrochemical cell with aqueous solution of a monomer and a supporting electrolyte (Imisides 1991). During electropolymerization, this solution may be under stirring or not. The agitation promotes an increase in the number of molecules that collide on the surface of the electrode and accelerates the dissolution of the monomer (Alarcón-Ángeles 2010). However, polymer films formed in a static system tend to exhibit greater stability (McCarley et al. 1990).

These two conditions were tested, the synthesis in solution under agitation and in static system, and the results are in Fig. 8c. It is observed that in the system without stirring the peaks at 0.48 V and 1.44 V are less defined than those presented in the system with agitation. It is possible that in the systems under agitation the polymerization reactions are favored in relation to the secondary reactions, making the synthesis more efficient. Furthermore, the agitation promotes the formation of oligomers, favoring the formation of the film, that is, increasing the efficiency of electropolymerization (McCarley et al. 1990). Therefore, the agitation promoted an improvement in the surface uniformity of the formed polymer films. Therefore, the higher efficiency of electropolymerization was achieved with the synthesis made under agitation.

Influence of pH

An important experimental condition to be controlled in an electrochemical process is the electrolyte pH. The pH variation affects the structure of the monomer and directly influences the electropolymerization. Thus, the electrolyte pH plays effective role in polymer synthesis. The electropolymerization was carried out in solution with different pHs and the results are in Fig. 8d. This result shows that the basic medium is not favoring the electropolymerization of β-CD. In contrast, the highly acidic medium also compromised the synthesis. In the voltammogram exhibited at pH = 5.0, despite the definition loss at the peak of 0.55 V, all other peaks showed higher current. According to Kulandaivalu, et al., the increase of the monomer concentration promotes the increase of the current. Thus, the result shows that electropolymerization at pH = 5.0 has a polymer with more active binding sites (Kulandaicalu et al. 2016).

Usually, when the monomer is less protonated, it facilitates the oxidation, because it leaves pairs of electrons more available for reaction. As discussed in the literature (Kurkov and Loftsson 2013; Gaidamauskas et al. 2009), in the β-CD structure, in basic media, there is deprotonation of three hydroxyl groups. Therefore, β-CD was expected to be electropolymerized more effectively in basic medium. However, the study showed that electropolymerization was favored in acid medium (pH = 5). Souto et al. associated highly basic medium to uncontrolled reaction rates, resulting in more amorphous polymers. This occurred, because a high concentration of hydroxyl ions increased the rate of initiation of the reaction. On the other hand, the slightly acidic medium gave rise to polymers with lower molar mass (Souto et al. 2012). Considering this hypothesis, the electropolymerization of β-CD at pH = 5 led to the formation of a more homogeneous polymer film. Therefore, the current peak at this pH was higher.

Effect of scan rate

The rate of potential variation in time is called scan rate. The higher the scan speed, the faster the cycle is completed. As a general rule, low scan rates generate polymer films more organized, and high scan rates, a ticker and less organized (Shin and Hak-Sunk 1996).

These assumptions are in accordance with the voltammetric behavior at different scan rates, as shown in Fig. 8e. The voltammogram of 50 mV s−1 exhibits a lower peak current, possibly because there is a smaller amount of monomers deposited on the surface of the electrode, reducing the number of binding sites and the sensitivity of the sensor. The 0.5 V and 1.55 V peaks in the voltammogram of 150 mV s−1 are less defined, despite a higher current peak. High scan rates directly interfere in the monomer diffusion kinetics, restricting the mass transport of the monomers to the conducting surface and, consequently, a decrease in the amount of the formed film (Li et al. 2010). Possibly, the film formed at this rate is not homogeneous or stable. Therefore, the rate of 100 mV s−1 was the most indicated to conduct the electropolymerization.

Influence of monomer concentration

The monomer concentration affects the properties of the formed film. The higher the concentration of the monomer, the faster the film is formed and a greater amount of polymers deposited on the electrode (Cosnier and Karyakin 2010). The behavior shown in Fig. 8f shows that the electropolymerization of 6 mmol L−1 of β-CD exhibits greater current peak compared to the others. These results show that the amount of film deposited could limit the synthesis. In the voltammogram of 2 mmol L−1, three well-defined peaks are observed, indicating that the electropolymerization was successful. However, at this concentration of the monomer, it is possible that the amount of monomers deposited on the surface of the electrode is not enough to form a homogeneous film (Razola et al. 2002).

In “Electrochemical behavior of electropolymerized β-CD on a glassy carbon electrode” section, it was discussed that from the 27th cycle, a new cathodic peak 4 appears in at − 1.05 V. Therefore, high concentrations of β-CD are probably associated with this new cathode peak. This peak was observed in the voltammogram of 8 mmol L−1 at − 0.95 V, indicating that there was saturation of the polymer sites, compromising sensor sensitivity (Razola et al. 2002). In addition, the monomer may not completely solubilize limiting the synthesis (Kulandaivalu et al. 2016). The voltammogram of 6 mmol L−1 has three peaks with high current, but the peak of 0.47 V has some loss of resolution, thus suggesting that the electropolymerization in 6 mol L−1 was successful. In conclusion, the electropolymerization of the β-CD carried out at the concentration of 6 mmol L−1 represented the best synthesis condition.

Conclusions

The electropolymerization of β-CD on the CGE surface by cyclic voltammetry was studied and it was observed the appearance of two anode peaks at 0.61 V and 1.56 and two cathode peaks at − 0.58 V and − 1.05, The peak currents increase in successive cycles indicating that a β-CD polymer film is being formed on the surface of the CGE. As presented by Morales et al. and discussed systematically in this work, the electropolymerization mechanism of β-CD on the surface of an electrode occurs in two stages: the monomer is deposited on the surface of the CGE by covalent bonds, while the monomer is coupled successively producing the polymer. These stages happen simultaneously and are responsible for the formation of the film.

For the construction of a sensitive β-CD polymer film, it was necessary that a certain quantity of polymers be deposited on the surface of the electrode. This is because the amount of binding sites present in the polymer structure influences the sensitivity of the sensor. In addition, the formed film must be stable and well deposited on the surface of the sensor. Finally, the optimization of the experimental conditions of electropolymerization promoted the development of a more efficiently methodology.

References

Alarcón-Ángeles G, Guix M, Silva WC, Ramírez-Silva MT, Palomar-Padavé M, Romero-Romo M, Merkoçi A (2010) Enzyme entrapment by β-cyclodextrin electropolymerization onto a carbon nanotubes-modified screen-printed electrode. Biosens Bioeletron 26:1768–1773. https://doi.org/10.1016/j.bios.2010.08.058

Aleixo LM (2003) Voltametria: conceitos e Técnicas. ChemKeys 1:1–40

Bruice PY (2006) Química Orgânica, vol 2. Pearson, New York

Clayden J, Greeves N, Warren S (2012) Organic chemistry. Oxford University, Oxford

Cosnier C, Karyakin A (2010) Electropolymerization: Concepts materials and applications. Wiley, Weinheim

Del Valle MA, Diaz FR, Bustos FE, Guerra L (2003) Electropolymerization of carbazole using tempo as radical trapping. J Chil Chem Soc 48:23–25. https://doi.org/10.4067/S0717-97072003000400004

Eftekhari A, Yazdani B (2010) Initiating electropolymerization on graphene sheets in graphite oxide structure. J Polym Sci Part A 48:2204–2213. https://doi.org/10.1002/pola.23990

Gaidamauskas E, Norkus E, Butkus E, Crans DC, Grinciene G (2009) Deprotonation of b-cyclodextrin in alkaline solutions. Carbohyd Res 344:250–254. https://doi.org/10.1016/j.carres.2008.10.025

Golabi S, Mirzazadeh J (2003) Electrocatalytic oxidation of hydrazine at epinephrine modified glassy carbon electrode. Chem Eng 22:1–14

Hernandez-Jiménez A, Roa-Morales G, Oeyes-Pérez H, Balderas-Hernández P, Barrera-Díaz BM (2016) Voltammetric determination of metronidazole using a sensor based on electropolymerization of a-cyclodextrin over a carbon paste electrode. Electroanalysis 28:704–710. https://doi.org/10.1002/elan.201500452

Imisides MD, John R, Riley PJ, Wallace GG (1991) The use of electropolymerization to produce new sensing surfaces: a review emphasizing electrodeposition of heteroaromatic compounds. Elechoanalysis 3:879–889. https://doi.org/10.1002/elan.1140030903

Jarazabek G (1990) Adsorption of β-cyclodextrin at the polycrystalline gold electrode-aqueous solution interface. J Electroan Chem 294:253–265. https://doi.org/10.1016/0022-0728(90)87149-E

Jiang Z, Li G, Zhang M (2016) Electrochemical sensor based on electro-polymerization of β-cyclodextrin and reduced-graphene oxide on glassy carbon electrode for determination of gatifloxacin. Sens Actuat B Chem 228:59–65. https://doi.org/10.1016/j.snb.2016.01.013

Kulandaivalu S, Zainal Z, Sulaiman Y (2016) Influence of monomer concentration on the morphologies and electrochemical properties of PEDOT, PANI, and PPy prepared from aqueous solution. Int J Polym Sci 1:1–12. https://doi.org/10.1155/2016/8518293

Kurkov SV, Loftsson T (2013) Cyclodextrins. Int J Pharm 453:167–180

Li JL, Gao F, Zhang YK, He LZ, Han GM, Wang XD (2010) Electropolymerization of nickel complexes with schiff bases: effect of sweep rate on anodic polymerization. Acta Phys Chim Sin 26:2647–2652. https://doi.org/10.3866/PKU.WHXB20100940

Mannakker FV, Vermonden T, Nostrym CF, Wim E (2009) Cyclodextrin-based polymeric materials: synthesis, properties, and pharmaceutical/biomedical applications. Biomacromol 10:3157–3161. https://doi.org/10.1021/bm901065f

Mccarley RL, Thomas RE, Irene EA, Murray RW (1990) Optical, electrical, and electrochemical characteristics of ultrathin poly(phenyl oxide) films. Organic dielectrics less than 10 nm thick. J Electroanal Chem 290:79–87. https://doi.org/10.1016/0022-0728(90)87421-F

Morales GR, Silva TR, Galicia L (2003) Carbon paste electrodes electrochemically modified with cyclodextrins. J Solid State Electrochem 7:355–360. https://doi.org/10.1007/s10008-002-0325-0

Moriwaki C, Ferreira LR, Rodella JRT, Matioli G (2009) A novel cyclodextrin glycosyltransferase from Bacillus sphaericus strain 41: production, characterization and catalytic properties. Biochem Eng J 48:124–131. https://doi.org/10.1016/j.bej.2009.09.001

Páramo-García U, Ibanez JG, Batina N (2011) Electrochemical modulation of the thickness of polypyrrole films by using different anionic dopants. Int J Electrochem Sci 6:5172–5188

Qin Q, Bai X, Hua Z (2016) Electropolymerization of a conductive β-cyclodextrin polymer on reduced graphene oxide modified screen-printed electrode for simultaneous determination of ascorbic acid, dopamine and uric acid. J Electroanal Chem 782:50–58. https://doi.org/10.1016/j.jelechem.2016.10.004

Razola SS, Diez NM, Ruiz BL, Kauffmann JM (2002) Hydrogen peroxide sensitive amperometric biosensor based on horseradish peroxidase entrapped in a polypyrrole electrode. Biosens Bioelectron 17:921–928. https://doi.org/10.1016/S0956-5663(02)00083-0

Sarac AS (2004) Electropolymerization. Encycl Polym Sci Technol 1:1–25. https://doi.org/10.1002/0471440264.pst512

Shin M, Hak-Sung K (1996) Electrochemical characterization of polypyrrole/glucose oxidade biosensor: part I. Influence of enzyme concentration on the growth and properties of the film. Biosens Bioelectron 11:161–169. https://doi.org/10.1016/0956-5663(96)83723-7

Souto EB, Santana S, Helena M (2012) Preparação de nanopartículas poliméricas a partir da polimerização de monômeros: parte I. Polímeros 22:96–100. https://doi.org/10.1590/S0104-14282012005000006

Szejtli J (2013) Cyclodextrins in analytical chemistry: utility of host-guest type molecular recognition. ACS Paragon Plus Environ 1:1–19. https://doi.org/10.1021/ac400639y

Zhang F, Gu S, Ding Y, Zhang Z, Li L (2013) A novel sensor based on electropolymerization of β-cyclodextrin and l-arginine on carbon paste electrode for determination of fluoroquinolones. Anal Chim Acta 770:53–61. https://doi.org/10.1016/j.aca.2013.01.052

Acknowledgements

We thank FAPEMIG, CAPES, CNPQ, and Rede Mineira de Química for the continuous support of our research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pereira, A.C., Oliveira, A.E.F. & Bettio, G.B. β-Cyclodextrin electropolymerization: mechanism, electrochemical behavior, and optimization. Chem. Pap. 73, 1795–1804 (2019). https://doi.org/10.1007/s11696-019-00732-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00732-x