Abstract

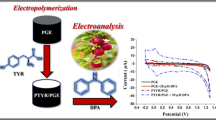

For the first time in this work, 4-amino-3-hydrazino-5-mercapto-1,2,4-triazole (Purpald®) polymer film on the surfaces of disposable pencil graphite electrodes (PGEs) were successfully electrosynthesized. The optimized conditions of electropolymerization of Purpald® film were also investigated. Electrochemical deposition was carried out by cyclic voltammetry (CV) in a potential range of 0.0–1.0 V at a scan rate of 25 mV s−1 in 10 cycles. Polymer growth conditions were systematically investigated for determining optimal settings in developing the sensor. The recommended Purpald®-modified pencil graphite electrodes were used for the determination of fenitrothion. Under appropriate working conditions, the differential pulse voltammetric (DPV) current response of fenitrothion (FNT) oxidation was linear in the range of 25–200 µM (R2: 0.993) with a detection limit of 17.39 µM (S/N: 5). The recommended Purpald®-modified pencil graphite electrode was successfully applied to the detection of fenitrothion in apple juice and tap water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pesticides are chemicals that are used against the target living organisms in agricultural struggle, and which are effective in destroying, blocking, removing from the environment and reducing (Yan et al. 2018). Today, pesticides have supported the increase in product quality and yield in agriculture by controlling agricultural pests and diseases caused by them. The use of pesticides is a necessity in getting food products that will meet the world population. Therefore, they are also vital for use not only for farmers but also for consumers. In addition, pesticides are used not only in the production but also in the post-harvest storage period, to prevent yield penalty (Pundir and Chauhan 2012; Songa and Okonkwo 2016; Eddleston et al. 2008).

On the one hand, the use of agricultural chemicals increases agricultural production; while on the other hand, the unconscious and wrong use of the end user can directly or indirectly threaten human and environmental health (Kumar et al. 2015; Long and Krupke 2016). In addition, pesticides used in controlled quantities have the adverse effect on living organisms by causing accumulation in the tissues of plants in the food chain (Zhang et al. 2017; Xia et al. 2018).

Organophosphate compounds are the most widely used pesticide group in the world. Organophosphate insecticides with high insecticidal and acaricidal effects are mainly phosphoric, thiophosphoric and dithiophosphoric acid esters. Organophosphate insecticides are absorbed by the respiratory and digestive systems as well as by the skin. The main toxic mechanisms of action are due to the inactivity of the two very important enzymes, cholinesterase, and acetylcholinesterase. Thus, the breakdown of acetylcholinesterase in synapses is halted and acetylcholine, which is continuously synthesized in the organism, accumulates. As a result, endogenous acetylcholine poisoning occurs (Xia et al. 2018; Uniyal and Sharma 2018; Sgobbi and Machado 2018).

Fenitrothion, which we use in our work, is an organophosphate-derived insecticide that is no longer approved for use in the EU but in the current MRL values of European Union pesticide database indicates at a rate of 0.01–7.0 mg kg−1 in some vegetables and fruits as the lower limit of analytical determination to fenitrothion. Fenitrothion has a low potential for leaching to groundwater and is not expected to be persistent in soil or water systems. It is highly toxic to birds, aquatic invertebrates and honeybees, but moderately toxic to fish, algae, earthworms, and mammals. Studies in the literature on this subject are mostly chromatographic and electrochemical studies, and these insecticides and fungicides have been shown to have adverse effects on humans and many experimental animals (Shamili et al. 2017, 2018; Park et al. 2018; Mahugija et al. 2018; Sun et al. 2018; Zhu et al. 2017; Takayasu et al. 2017; Kumar et al. 2018; Ensafi et al. 2017a, b; Surucu et al. 2016; Akyuz et al. 2017; Salehzadeh et al. 2016; Khan et al. 2017).

Due to the limited use of voltammetric electrodes, the working conditions have been improved by changing the chemical or electrochemical properties of the electrodes. The modifying by chemical may be prepared by chemical bonding to the electrode surface or by chemical adsorption. Polymer films based on modified electrodes have received extensive interest due to their broad scope of application in the chemical and biological sensor (Mantione et al. 2017; Gu et al. 2017). Such electrodes can also be prepared by electropolymerization at the surface of the electrode or by forming a polymer film directly on the electrode surface. Electropolymerization is a facile and rather of the effective approach for preparing polymer film-based electrodes. Electropolymerization process conditions (concentration, scan rate, the range of potential, etc.) can be easily changed and thus conductive films having different properties and functions are obtained (Dunst et al. 2017; Kim and Palmore, 2012; Chen et al. 2013; Correa et al. 2016). In this way, the electrochemical parameters can control thickness of film, interpenetration and charge transport characteristic. Due to their various electrochemical properties, conductive polymers have a wide range of applications when they showed electrical conductivity close to metals and can be easily processed. Especially, they are used in the construction of sensors, chargeable batteries, photochemical cells, electrochromic devices and ion selective electrode (Mangione et al. 2018; Castaneda et al. 2017; Boursicot et al. 2017; Wolfart et al. 2017; Devasurendra et al. 2017).

In the literature, there are many studies for electropolymerization of five- or six-membered heterocyclic compounds, such as pyrrole, o-phenylenediamine and thiophene (Si and Song, 2018; Azak et al. 2018; Shamsipur et al. 2018; Rao et al. 2018). At the same time, a restricted number of studies involving electropolymerization processes with thiadiazole and triazole-based monomers are existing.

Purpald® is a chemical material acting as a pigment and/or a color-exchanger agent used in the detection of aldehyde and aldehyde derivatives. Due to the S, C and N atoms present in the Purpald® structure, it shows an ideal ligand effect for metal complexes (Chu et al. 2018; do Carmo et al. 2015; Wondracek et al. 2016; Hill et al. 2009).

In this study, for the first time in the literature, the voltammetric detection of fenitrothion insecticide was performed using disposable pencil graphite electrodes modified by Purpald®. Characterization of these polymer films was carried out using cyclic voltammetry. Working conditions are optimized for best voltammetric performance. The developed disposable Purpald®-modified pencil graphite electrodes were tested in apple juices as a real sample.

Materials and methods

Reagents and instruments

Purpald® ( ≥ 99%), sodium hydroxide ( ≥ 98%), glacial acetic acid (100%), boric acid ( ≥ 99.5%), phosphoric acid ( ≥ 85%), dimethyl sulfoxide ( ≥ 99.9%) and fenitrothion (HPLC and GC grade) were purchased from Sigma–Aldrich. Britton–Robinson buffer solutions (BR) were prepared with H3BO3, CH3COOH and H3PO4, and NaOH was added until the desired pH was reached. All used chemicals are of analytical purity and have not been subjected to any purification process. The chemical solutions used in the experiments were prepared with ultrapure water. All pH buffer solutions were stored at 4 oC. The analyte and monomer solutions were newly prepared each day. Tombow (HB, 0.5 mm) pencil graphite was purchased from stationery shop.

An IVIUM Compact Stat Plus Model electrochemical analyzer (The Netherlands) was used for cyclic voltammetry (CV), differential pulse voltammetry (DPV). The three-electrode system consisted of a pencil graphite electrode (PGE) as working (geometric area is 15 mm2), an Ag/AgCl (3.0 M KCl) electrode (BAS, Model RE-5B, W. Lafayette, USA) as reference, and a platinum wire (geometric area is 15 mm2) as auxiliary. Thermo Scientific Orion 4-Star plus pH/Conductivity Meter with combined glass electrode was used to determine the pH of buffer solutions. Ultrapure water was obtained from a LABCONCO WaterPro Water Purification Systems (Kansas City, USA).

Preparation of Purpald®-PGE

Electropolymerization of Purpald® onto the pencil graphite electrode was executed using cyclic voltammetry technique. For the fabrication of electrode, PGE was coated with the electrochemically synthesized polymer of Purpald®. Any pre-treatment procedure was not performed prior to modification to the PG electrode. Electrosynthesis solution consisted of 1 × 10−4 M Purpald® in 0.1 M H2SO4 and the potential of the PGE working electrode was cycled ten times between 0.0 and 1.0 V at scan rate of 25 mV s−1. Then, PGE was removed from the synthesis solution and washed several times with ultrapure water to remove any residual compound left with the polymer matrix.

Results and discussion

Electrochemical behavior of Purpald®

The formation of poly(Purpald®) film on the electrode surface is demonstrated in Fig. 1a. The cyclic voltammogram was obtained during the electropolymerization of Purpald® performed using Britton–Robinson (BR) buffer pH 8. The figure indicates one irreversible oxidation peak, which is responsible from the electrochemical polymerization, at 0.280 V vs. Ag/AgCl (3.0 M KCl). As shown in Fig. 1a, Purpald® can easily be polymerized via potentiodynamic polymerization between (0.0) and ( + 0.6) V. After the first cycle, the oxidation peak current tended to decrease. This can be interpreted as:

a Electropolymerization of Purpald® (5 cycles) on the pencil graphite electrode. 0.1 mM Purpald® containing 0.1 M pH 8 BR. The potential sweeps applied between (0.0 V) and ( + 0.6 V) with the scan rate of 25 mV s−1. b The Nyquist plots of bare PGE and Purpald®-PGE in the 2.5 mM [Fe(CN)6]3−/4− in 0.1 M KCl solution

The electroactivity of monomeric species is higher than that of the polymeric ones. The concentration of monomeric species decreases during the CV cycles. Furthermore, the redox reactions at the electrode surface where a new polymeric species is formed in each CV cycle are more difficult than the redox reactions on the bare electrode surface, and, therefore, a reduction in the peak current occurs in each CV cycle.

After completion of the electropolymerization process, the modified electrode was washed five times in the 0.1 BR (pH 8) buffer solution and left to dry.

The interfacial charge transfer resistance (Rct) is related to interfacial processes of charge/ion transfer through the electrode/electrolyte interface. If the chemical system is kinetically slow going, it will show a large semicircle (Rct), indicating that mass transfer, which is an important factor, is only effective in a very limited frequency range. The smaller semicircle (Rct) indicates the rapid transfer capability of the charge/ions.

According to Fig. 1b, the Rct value of Purpald®-PGE is much higher than that of the bare electrode. This result shows that a polymeric structure that causes mass transfer on the electrode surface is formed, i.e., the Purpald® molecule is coated on the electrode surface by the electropolymerization process.

Determination of optimal electrochemical conditions for an effective Purpald® modification

Electrochemically prepared film properties depend on preparation parameters such as potential, temperature, concentrations, electrode materials, supporting electrolyte, current density, and the nature of anions incorporated into the polymer during the electrosynthesis. In electrochemical studies, the pH of the media performs a significant effect of the peak current, potential, and shape of the voltammograms. It is also useful in the assessment of proton–electron ratio related to electrode reaction. To produce fine and stable poly(Purpald®) films, it is necessary to first determine the electrosynthesis potential and the pH values of each solution in each electrolyte.

At first, 1 × 10−4 M Purpald® was inserted in different electrolyte solutions to deposit Purpald® on the PGE surface with cyclic voltammetry. The obtained voltammograms are shown in Fig. 2. As shown in Fig. 2, the voltammetric signals of the Purpald®, at different pH (between 2 and 8) BR buffer solutions and 0.1 M H2SO4 were examined by cyclic voltammetry between (0.0) and ( + 1.0) V.

pH of electrolyte and redox potential are important chemical parameters that could alter the reduction/oxidation potential of target compounds; since protons are involved in many reactions, and electrolyte redox images the existence of oxidizing/reducing substances. These conditions affect the morphology of the electrode materials and their redox mechanisms. It is of utmost importance to study the changing behaviors of materials to variable factors to optimize experimental conditions and obtain accurate results. The pH value is an important variable in buffer systems, which can be easily manipulated to optimize experimental conditions, as compared to other factors. The electrode surface has to be relatively stable to such changes and not affect the voltammetric signals. In addition, the presence of H+ in the electrosynthesis media promotes the growth of Purpald® either when using CV. In the same vein, the amount of charge passed in each situation indicates that low pH values promote the formation of more conducting films than those acquired from neutral pH. In this regard, buffer solutions and H2SO4 were used in this paper. When Fig. 2 is scrutinized, the magnitude of the faradaic current composed by the magnification of with 0.1 M H2SO4 is higher. As a result, on the surface of the disposable pencil graphite electrode, it will have a higher amount of Purpald® deposited.

When cyclic voltammetry is used in electrochemical polymerization for the modification of voltammetric electrodes, it is well known that the thickness of resultant polymer film is somehow related to cycle number. Therefore, it may not be wrong to assume that the number of the cycles not only has a significant effect on the polymer film thickness and morphology but also on its resistivity and charge transfer characteristics. For this reason, the scan rate is one of the important factors affecting the limit of detection of analytes at a given concentration and pH value.

Therefore, 1 × 10−4 M Purpald® was inserted in 0.1 M H2SO4 electrolyte solution to deposit Purpald® on the PGE surface with different number of cycle. Then, the prepared electrodes were measured by differential pulse voltammetry (DPV) with containing 1 × 10–4 M fenitrothion (FNT) in pH 2 BR buffer solution. The obtained voltammogram and histogram are shown in Fig. 3.

As seen in Fig. 3, it is seen that the peak current value obtained by FNT analysis with Purpald®-coated PG electrode is increased as the number of cycle is increased until the number of cycle 10. After 10 cycles of electropolymerization, the FNT peak currents have approached approximately to the almost steady-state value.

During electropolymerization, the mass transfer mechanism is effective in the formation and growth of the film on the electrode surface of the monomer. To provide this diffusion–controlled condition, it is also necessary to determine the scan rate in the electropolymerization process. To find the optimal value of the scan rate to be used in this electropolymerization process:

Six various scan rates (10, 20, 25, 50, 75 and 100 mV s−1) have been tried by depositing Purpald® polymer film on the surface of the PGE using 1 × 10−4 M Purpald® solution in 0.1 M H2SO4. The obtained voltammograms and histogram drawn with these DPV data are shown in Fig. 4. As seen in Fig. 4, electrodes formed at six different scan rates show quite close values in the FNT test. Although there are close results, there are minor differences between them. Taking these into consideration, it has been decided to use a scan rate of 25 mV s−1 at the next film growth of the polymer film.

Electrochemical behavior of fenitrothion and determination of optimal electrochemical conditions for fenitrothion

The electrochemical response of fenitrothion begins with the formation of an irreversible reduction peak. The mechanism of this peak is explained by the conversion of the nitro group in the fenitrothion molecule to the hyroxylamine in the presence of four hydrogen and four electrons as described in the literature (Bolat et al. 2018; Ensafi et al. 2017a, b; Salehzadeh et al. 2016; Khan et al. 2017; Wang et al. 2016).

The impression of solution pH on the electrochemical behavior of 1 × 10−4 M FNT at the surface of Purpald®-modified PGE was examined in the pH range of 1.3–10 utilization on 0.1 M BR with a scan rate of 50 mV s−1. According to the results gained, it is observed that the solution media in the electrochemical cell in which Purpald®-modified PGE is used as an increase in the current signal amplitude from FNT up to pH 5.0, almost stabilizing between pH 5.0 and 8.0 and decreasing after pH 8.0. For this reason, it was decided to use pH 8.0 for all subsequent measurements. The oxidation peak current of fenitrothion was a considerable extent affected by the pH of the media. As the pH of the electrolytic solution raised, the position of oxidation peak obtained from FNT proceeded to negative zone. The pH effect on the oxidation peak current of FNT was examined in the range of pH 1.3–10.0 BR solution. The maximum peak current response was beheld at pH 8.0 BR (as shown in Fig. 5). Hence, pH 8.0 BR was chosen as the optimal electrolyte pH for subsequent measurements.

The following results are achieved when Fig. 5 is interpreted.

-

1.

At the pH values below pH 5, it is observed that the chemical structure of fenitrothion insecticide is demethylation to structure of demethylated fenitrothion as stated in the literature (Lal 1984), thus decreasing the peak current value obtained from FNT.

-

2.

It can be concluded that the pH value should be between 5 and 8 to show the maximum capacity of fenitrothion.

-

3.

The media of pH values above 8, as stated in the literature (Lal 1984), as a result of the hydrolysis of fenitrothion transformed to the structure of 3-methyl-4-nitrophenol due to the peak current values obtained from FNT are seen to be decreasing.

The influence of potential scan rate on the peak current of FNT was tested with DPV in pH 8.0 BR at FNT-PGE in the range 10–200 mV s−1 at pulse amplitude of 25 mV with pulse time of 25 ms, and E step of 25 mV. Figure 6 indicates the differential pulse voltammograms of FNT saved at various scan rates. Cathodic peak currents increased linearly between 10 and 50 mV s−1. The resulting FNT values of DPV measurements at scan rates above 50 mV s−1 are close to each other. For this reason, in the subsequent steps, a scan rate of 50 mV s−1 was used.

The DPV characteristics of FNT on the Purpald®-modified PGE availed as an efficacious electrochemical quantitative method to detect FNT. Implementation of Purpald®-modified PGE for the determination of FNT has been prospected using differential pulse voltammetry (DPV). DPV used as an analytical tool offers some of the advantages when compared to other electrochemical techniques. DPV is very sensitive, mostly using directly the determination of the innumerable electroactive molecules. As seen in Fig. 7, the typical differential pulse voltammetric responses of FNT in pH 8.0 BR buffer showed a sharp and well-defined peak (– 0.14) V (vs. Ag/AgCl) at the potential range from (– 0.7) to ( + 1.3) V. Five sets of modified that optimized in terms of film growth were prepared. Each set contained five electrodes. Each one of five sets was intended to study the effect of concentration (25, 50, 75, 100, and 200 µM) of the FNT. As revealed in Fig. 7, a linear relationship was observed in the concentration range of 25–200 µM with linear equation of I (µA) = 0.152 × C (µM) + 9.131 with a regression coefficient of 0.993 (n:5) for the optimized modified electrodes. The LOD and LOQ were obtained as 17.39 µM and 52.17 µM, respectively. Five replicate measurements of peak current of 25 µM FNT showed a relative standard deviation (RSD) of 2.6%. As seen in Fig. 7, bare PGE showed lower sensitivity when compared with that Purpald®-modified PGE.

To examine the feasibility of the sensor, interferences study was performed. Imidacloprid (neonicotionid insecticide), Na+, Ca2+, Mg2+, PO43−, K+, SO42−, NH4+, NO3−, CO32− and Cl− (common inorganic acid) were selected for the interference studies of sensor. Even in the presence of these interferences, there was no influence the peak current values obtained from fenitrothion. The reproducibility of Purpald®-modified PG electrode was achieved by five times repeated 25 µM FNT measurements using the modified electrode. The RSD was calculated as 4.7%. The stability of Purpald®-modified PG electrode was good because the electrochemical activity of the electrode was 95% after dark storage for 7 days.

To further prove the usability of the recommended electrochemical modified electrode, fenitrothion was studied in real samples. Apple juice and tap water were selected as the real samples. Analysis of these sample solutions with the recommended electrochemical modified electrode founded that none of the samples involved FNT. Therefore, the known quantity concentration of FNT was added into the samples and recoveries of the added values were determined. These analytical results can be seen in Fig. 7d. The results were admissible showing that the proposed modified electrode could be successfully used for the detection of FNT in real samples.

The published studies shown in Table 1 include electrode modifications developed for the determination of fenitrothion. The obtained LOD values of the studies shown in Table 1 are seen to be lower than the LOD calculated by the FNT determination using the electrode modification proposed. This result shows that the limitation of our study is the LOD value obtained. It can easily be said that the modifiers used in the studies given in the table should have specific, expensive, and complicated processes and the surface areas are quite large. The proposed modifier is a chemical that can be smoothly attached to the electrode surface using a simple electrochemical technique as well as being cheap. In addition, the proposed modifier can be easily combined with other modifiers, and the LOD value to be obtained with the electrode/sensor is undoubtedly lower.

Conclusions

For the first time in this work, Purpald® polymer film on the surfaces of pencil graphite electrodes was successfully electrosynthesized. The optimized conditions of electropolymerization of Purpald® film were also investigated.

The electrochemical behavior of the Purpald®-modified disposable pencil graphite electrode under several pH conditions was studied. Differential pulse voltammetric technique has displayed fenitrothion oxidation in the linear range of 25–200 µM with a detection limit 17.39 µM.

According to the results obtained, the recommended Purpald®-modified electrode can be used for real samples. A successful recovery was obtained from real samples.

References

Akyuz D, Keleş T, Bıyıklıoğlu Z, Koca A (2017) Electrochemical pesticide sensors based on electropolymerized metallophtalocyanines. J Electroanal Chem 804:53–63. https://doi.org/10.1016/j.jelechem.2017.09.044

Azak H, Yıldız HB, Carbas BB (2018) Synthesis and characterization of a new poly(dithieno(3,2-b:2',3'-d) pyrrole) derivative conjugated polymer: Its electrochromic and biosensing applications. Polymer 134:44–52. https://doi.org/10.1016/j.polymer.2017.11.044

Bolat G, Abaci S, Vural T, Bozdogan B, Denkbas EB (2018) Sensitive electrochemical detection of fenitrothion pesticide based on self-assembled peptide-nanotubes modified disposable pencil graphite electrode. J Electroanal Chem 809:88–95. https://doi.org/10.1016/j.jelechem.2017.12.060

Boursicot S, Bouquet V, Bombard A, Langer M, Boulanger C, Viry MG (2017) Electrochemical behaviour of CuxMo6S8 thin film synthesized by CSD. Electrochim Acta 257:436–443. https://doi.org/10.1016/j.electacta.2017.10.039

Canevari C, Prado M, Cincotto H, Machado AS (2016) Immobilization of ruthenium phthalocyanine on silica-coated multi-walled partially oriented carbon nanotubes: electrochemical detection of fenitrothion pesticide. Mater Res Bull 76:41–47. https://doi.org/10.1016/j.materresbull.2015.12.007

Castaneda LF, Walsh FC, Nava JL, de Leon CP (2017) Graphite felt as a versatile electrode material: Properties, reaction environment, performance and applications. Electrochim Acta 258:1115–1139. https://doi.org/10.1016/j.electacta.2017.11.165

Chen X, Shen L, Yuan CA, Wong CKY, Zhang G (2013) Molecular model for the charge carrier density dependence of conductivity of polyaniline as chemical sensing materials. Sens Actuators B 177:856–861. https://doi.org/10.1016/j.snb.2012.12.009

Chu H, Yang H, Huan S, Lin W, Shen G, Yu R (2018) Adsorption of Purpald® SAMs on silver and gold electrodes: a Raman mapping study. J Raman Spectrosc 38:295–300. https://doi.org/10.1002/jrs.1642

Correa AA, Gonçalves R, Pereira R, Pereira EC (2016) The electropolymerization of several poly(3–methylthiophene) films in the same used solution and its consequence in their properties. J Appl Polym Sci 134:44368–44375. https://doi.org/10.1002/app.44368

Devasurendra AM, Zhang C, Young JA, Tillekeratne LMV, Anderson JL, Kirchhoff JR (2017) Electropolymerized pyrrole-based conductive polymeric ionic liquids and their application for solid-phase microextraction. ACS Appl Mater Interfaces 9:24955–24963. https://doi.org/10.1021/acsami.7b05793

Diaz TG, Cabanillas AG, Mansilla AE, Soto MDL (2008) Adsorptive stripping square wave voltammetry (Ad-SSWV) accomplished with second-order multivariate calibration determination of fenitrothion and its metabolites in river water. Anal Chim Acta 618:131–139. https://doi.org/10.1016/j.aca.2008.04.058

do Carmo DR, Silvestrini DR, da Silveira TFS, Cumba LR, Filho NLD, Soares LA (2015) Silsesquioxane organofunctionalized with 4-amino-3-hydrazino-5-mercapto-1,2,4-triazole: Preparation and subsequent reaction with silver and potassium hexacyanoferrate(III) for detection of L-cysteine. Mater Sci Eng C 57:24–30. https://doi.org/10.1016/j.msec.2015.07.023

Dunst K, Karczewski J, Jasinki P (2017) Nitrogen dioxide sensing properties of PEDOT polymer films. Sens Actuators B 247:108–113. https://doi.org/10.1016/j.snb.2017.03.003

Eddleston M, Buckley NA, Eyer P, Dawson AH (2008) Management of acute organophosphorous pesticide poisoning. Lancet 371:597–607. https://doi.org/10.1016/S0140-6736(07)61202-1

Ensafi AA, Noroozi R, Atashbar NZ, Rezaei B (2017) Cerium(IV) oxide decorated on reduced graphene oxide, a selective and sensitive electrochemical sensor for fenitrothion determination. Sens Actuators B 245:980–987. https://doi.org/10.1016/j.snb.2017.01.186

Ensafi AA, Rezaloo F, Rezaei B (2017) Electrochemical determination of fenitrothion organophosphorous pesticide using polyzincon modified-glassy carbon electrode. Electroanalysis 29:2839–2846. https://doi.org/10.1002/elan.201700406

Geremedhin W, Amare M, Admassie S (2013) Electrochemically pretreated glassy carbon electrode for electrochemical detection of fenitrothion in tap water and human urine. Electrochim Acta 87:749–755. https://doi.org/10.1016/j.electacta.2012.09.046

Gu H, Lin K, Jian N, Qu K, Yu H, Wei J, Chen S, Xu J (2017) Synthesis and electropolymerization of furan end-capped dibenzothiophene/dibenzofuran and electrochromic properties of their polymers. Int J Electrochem Sci 12:5000–5011. https://doi.org/10.20964/2017.06.29

Hill AA, Lipert RJ, Fritz JS, Porter MD (2009) A rapid, simple method for determining formaldehyde in drinking water using colorimetric-solid phase extraction. Talanta 77:1405–1408. https://doi.org/10.1016/j.talanta.2008.09.025

Khan I, Pandit UJ, Wankar S, Das R, Limaye SN (2017) Fabrication of electrochemical nanosensor based on polyaniline film-coated AgNP-MWCNT-modified GCE and its application for trace analysis of fenitrothion. Ionics 23:1293–1308. https://doi.org/10.1007/s11581-016-1939-z

Kim SY, Palmore GTR (2012) Electropolymerization vs. electrocrystallization: Electrosynthesis of poly(3,4-ethylenedioxythiophene) in the presence of 2,2'-azino-bis(3-ethylbenzothiaxoline-6-sulfonic acid). Electrochim Acta 77:184–188. https://doi.org/10.1016/j.electacta.2012.05.107

Kumar P, Kim KH, Deep A (2015) Recent advancements in sensing techniques based on functional materials for organophosphate pesticides. Biosens Bioelectron 70:469–481. https://doi.org/10.1016/j.bios.2015.03.066

Kumar JV, Karthik R, Chen SM, Natarajan K, Karuppiah C, Yang CC, Muthuraj V (2018) 3D flower-Like gadolinium moybdate catalyst for efficient detection and degradation of organophosphate pesticide (fenitrothion). ACS Appl Mater Interfaces 10:15625–15664. https://doi.org/10.1021/acsami.8b00625

Kumaravel A, Chandradekaran M (2011) A biocompatible nano TiO2/Nafion composite modified glassy carbon electrode for the detection of fenitrothion. Electroanal Chem 650:163–170. https://doi.org/10.1016/j.jelechem.2010.10.013

Lal R (1984) Insecticide microbiology. Springer-Verlag, Berlin

Li C, Wang C, Ma Y, Hu S (2004) Voltammetric determination of trace amounts of fenitrothion on a novel nano-TiO2 polymer film electrode. Microchim Acta 148:27–33. https://doi.org/10.1007/s00604-004-0257-8

Long EY, Krupke CH (2016) Non-cultivated plants present a season-long route of pesticide exposure for honey bees. Nat Commun 7:11629. https://doi.org/10.1038/ncomms11629

Mahugija JAM, Chibura PE, Lugwisha EHJ (2018) Residues of pesticides and metabolites in chicken kidney, liver and muscle samples from poultry farms in Dar es Salaam and Pwani, Tanzania. Chemosphere 193:869–874. https://doi.org/10.1016/j.chemosphere.2017.11.094

Mangione MI, Spanevello RA, Minudri D, Cavallo P, Otero L, Fungo F (2018) Electrochemical films deposition and electro-optical properties of bis-carbazol-triphenylamine end-caped dendrimeric polymers. Electrochim Acta 263:585–595. https://doi.org/10.1016/j.electacta.2017.12.137

Mantione D, del Agua I, Sanchez AS, Mecerreyes D (2017) Poly(3,4–ethylenedioxythiophene) (PEDOT) derivatives: innovative conductive polymers for bioelectronics. Polymers 9:354–375. https://doi.org/10.3390/polym9080354

Park KY, Shin JC, Pyo D (2018) Simultaneous determination of carbaryl & organophosphorous pesticides in water by liquid chromatograhy-tandem mass spectrometry. Anal Sci Technol 31:39–46. https://doi.org/10.5806/AST.2018.31.1.39

Pellicer C, Caballero AG, Unceta N, Goicolea M, Barrio R (2010) Using a portable device based on a screen printed sensor modified with a molecularly imprinted polymer for the determination of the insecticide fenitrothion in forest samples. Anal Methods 2:1280–1285. https://doi.org/10.1039/C0AY00329H

Pundir CS, Chauhan N (2012) Acetylcholinesterase inhibition-based biosensors for pesticide determination: a review. Anal Biochem 429:19–31. https://doi.org/10.1016/j.ab.2012.06.025

Rao H, Zhao X, Liu X, Zhong J, Zhang Z, Zou P, Jiang Y, Wang X, Wang Y (2018) A novel molecularly imprinted electrochemical sensor based on graphene quantum dots coated on hollow nickel nanospheres with high sensitivity and selectivity for the rapid determination of bisphenol S. Biosens Bioelectron 100:341–347. https://doi.org/10.1016/j.bios.2017.09.016

Salehzadeh H, Ebrahimi M, Nematollahi D, Salarian AA (2016) Electrochemical study of fenitrothion and bifenox and their simultaneous determination using multiwalled carbon nanotube modified glassy carbon electrode. J Electroanal Chem 767:188–194. https://doi.org/10.1016/j.jelechem.2016.02.011

Sgobbi LF, Machado SAS (2018) Functionalized polyacrylamide as an acetylcholinesterase-inspired biomimetic device for electrochemical sensing of organophosphorous pesticides. Biosens Bioelectron 100:290–297. https://doi.org/10.1016/j.bios.2017.09.019

Shamili AB, Dadfarnia S, Shabani AMH, Moghadam MR, Saeidi M (2017) Temperature-controlled liquid-liquid microextraction combined with high-performance liquid chromatography for the simultaneous determination of diazinon and fenitrothion in water and fruit juice samples. J Sep Sci 41:2411–2418. https://doi.org/10.1002/jssc.201701427

Shamili AB, Dadfarnia S, Shabani AMH, Moghadam MR, Saeidi M (2018) MultiSimplex optimization of the dispersive solid-phase microextraction and determination of fenitrothion by magnetic molecularly imprinted polymer and high-performance liquid chromatography. J Iran Chem Soc 15:1181–1189. https://doi.org/10.1007/s13738-018-1316-0

Shamsipur M, Moradi N, Pashabadi A (2018) Coupled electrochemical-chemical procedure used in construction of molecularly imprinted polymer-based electrode: a highly sensitive impedimetric melamine sensor. J Solid State Electrochem 22:169–180. https://doi.org/10.1007/s10008-017-3731-z

Si B, Song E (2018) Molecularly imprinted polymers for the selective detection of multi analyte neurotransmitters. Microelectron Eng 187–188:58–65. https://doi.org/10.1016/j.mee.2017.11.016

Songa EA, Okonkwo JO (2016) Recent approaches to improving selectivity and sensitivity of enzyme-based biosensors for organophosphorous pesticides: a review. Talanta 155:289–304. https://doi.org/10.1016/j.talanta.2016.04.046

Sreedhar NY, Reddy P, Reddy CN, Prasad KS (2011) Electrochemical analysis of fenitrothion in human urine samples using polyaniline nanosensor based electrode. Nanosci Nanotechnol Int J I:6–11

Sun P, Gao YL, Xu C, Lian YF (2018) Determination of six organophosphorous pesticides in water samples by three-dimensional grapheme aerogel-based solid-phase extraction combined with gas chromatography/mass spectrometry. RSC Adv 8:10277–10283. https://doi.org/10.1039/c7ra13316b

Surucu O, Bolat G, Abacı S (2016) Electrochemical behavior and voltammetric detection of fenitrothion based on a pencil graphite electrode modified with reduced graphene oxide (RGO)/poly(E)-1-(4-((4-(phenylamino)phenyl)diazenyl)phenyl)ethanone (DPA) composite film. Talanta 168:113–120. https://doi.org/10.1016/j.talanta.2017.03.033

Takayasu T, Yamamoto H, Ishida Y, Nosaka M, Kawaguchi M, Kuninaka Y, Kimura A, Kondo T (2017) Postmortem distribution of chlorpyrifos-methyl, fenitrothion, and their metabolites in body fluids and organ tissues of an intoxication case. Leg Med 29:44–50. https://doi.org/10.1016/j.legalmed.2017.10.002

Uniyal S, Sharma RK (2018) Technological advancement in electrochemical biosensor based detection of organophosphate pesticide chlorpyrifos in the environment: A review of status and prospects. Biosens Bioelectron 116:37–50. https://doi.org/10.1016/j.bios.2018.05.039

Wang L, Dong J, Wang Y, Cheng Q, Yang M, Cai J, Liu F (2016) Novel signal-amplified fenitrothion electrochemical assay, based on glassy carbon electrode modified with dispersed graphene oxide. Sci Rep 6:23409

Wolfart F, Hryniewicz BM, Marchesi LF, Orth ES, Dubal DP, Romero PG, Vidotti M (2017) Direct electrodeposition of imidazole modified poly(pyrrole) copolymers: synthesis, characterization and supercapacitive properties. Electrochim Acta 243:260–269. https://doi.org/10.1016/j.electacta.2017.05.082

Wondracek MHP, Jorgetto AO, Silva ACP, Ivassechen JR, Schneider JF, Saeki MJ, Pedrosa VA, Yoshito WK, Colauto F, Ortiz WA et al (2016) Synthesis of mesoporous silica-coated magnetic nanoparticles modified with 4-amino-3-hydrazino-5-mercapto-1,2,4-triazole and its applications Cu(II) adsorbent from aqueous samples. Appl Surf Sci 367:533–541. https://doi.org/10.1016/j.apsusc.2016.01.172

Xia N, Wang QL, Liu L (2018) Nanomaterials-based optical techniques for the detection of acetylcholinesterase and pesticides. Sensors 15:499–514. https://doi.org/10.3390/s150100499

Yan X, Li H, Su X (2018) Review of optical sensors for pesticides. TrAC 103:1–20. https://doi.org/10.1016/j.trac.2018.03.004

Zhang WY, Asiri AM, Liu DL, Du D, Lin YH (2017) Nanomaterial-based biosensors for environmental and biological monitoring of organophosphorous pesticides and nerve agents. TrAC 54:1–10. https://doi.org/10.1016/j.trac.2013.10.007

Zhao L, Zhao F, Zeng B (2014) Synthesis of water-compatible surface-imprinted polymer via click chemistry and RAFT precipitation polymerization for highly selective and sensitive electrochemical assay of fenitrothion. Biosens Bioelectron 62:19–24. https://doi.org/10.1016/j.bios.2014.06.022

Zhu YZ, Fu M, Jeong IH, Kim JH, Zhang CJ (2017) Metabolism of insectide fenitrothion by Cunninghamella elegans ATCC36112. J Agric Food Chem 65:10711–10718. https://doi.org/10.1021/acs.jafc.7b04273

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soysal, M. Voltammetric determination of fenitrothion based on pencil graphite electrode modified with poly(Purpald®). Chem. Pap. 73, 1785–1794 (2019). https://doi.org/10.1007/s11696-019-00731-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00731-y