Abstract

We evaluated the potential use of amino silane coupling agent (SiNH) to improve physical and mechanical properties of UF-bonded wheat straw (Triticum aestivum L.) poplar wood particleboard. We examined the effects of varied content of silane coupling agent content and ratios of straw to poplar wood particles on particleboard properties. The ratios of straw to poplar wood particles were 100:0, 85:15, 70:30 and 55:45. Silane coupling agent content was tested at three levels, 0, 5 and 10 %. The experimental panels were tested for their mechanical strength, including modulus of elasticity (MOE), modulus of rupture (MOR), internal bonding (IB) and physical properties according to procedures specified in DIN 68763 (Chipboard for special purposes in building construction: concepts, requirements, testing, 1982–03, 1982). All board properties were improved by the addition of silane coupling agent. The use of poplar wood particles had a positive effect on the mechanical properties of wheat straw particleboard but had a negative effect on physical properties (thickness swelling and water absorption).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Approximately 95 % of the lignocellulosic material available in large volumes in many regions of world. Worldwide production of cereal straw is estimated at 1.5 billion mt annually (Grigoriou 2000). Traditionally, farmers harvest grain and then burn or otherwise dispose the residues (stalks, husk, etc.). Burning wheat straw causes environmental problems such as air pollution, soil erosion, and reduced soil biological activity.

In the last two decades, the use of straw has gained research attention as a fibrous raw material potentially suitable as a substitute for wood in particleboard manufacturing (Azizi et al. 2011). But some problems remain due to seasonality, storage, scattered sources, and bondability. Among these problems, bondability remains a major unsolved technical problem, especially when urea-based resins are applied (Han et al. 1998).

Morphologically, straw is more complicated than wood. Straw contains a relatively large number of elements, including the actual fibers, parenchyma cells, vessel elements, and epiderma cells, which contain large amounts of ash and silica. The epidermal cells of straw, the outermost surface cells, are covered by a thin wax layer. This reduces moisture absorbance by straw from water-based adhesives such as urea–formaldehyde (UF) resin (Markessini et al. 1997). It therefore acts as a barrier to the gluing of straw with UF resin. Removing this bonding barrier layer from straw materials has been a technical obstacle to performance enhancement of straw panels (Markessini et al. 1997; Han et al. 1999). Isocyanate is an alternative resin that can be used to improve the properties of strawboards but the use of isocyanate is hindered by its high cost; hence, it is not commonly utilized, especially in developing countries (Han et al. 1999). Silane coupling agents are generally applied for improving the adhesion between organic and inorganic materials (Han et al. 1998). Silane coupling agents are used to modify the characteristics of the inorganic surface by fixing some organic functional groups onto it (Han et al. 1998). The objective of this study was to evaluate the effects of varied content of silane coupling agent on the physical and mechanical properties of UF-bonded wheat straw (Triticum aestivum L.)/poplar wood particleboards.

Materials and methods

Materials

Wheat straw and poplar wood particles

Poplar logs were harvested from the forest in northern Iran. The agricultural lignocellulosic fiber used in this study was wheat straw (Triticum aestivum L.) obtained from Karaj city near Tehran. Straw and poplar particles were prepared using Pallmann knife ring flakers. All particles were oven-dried to about 3 % moisture content. Subsequently, they were screened by handle sieve and oversize and undersize particles were removed. The average size of straw particles was 34 mm by 2.56 mm by 0.33 mm and poplar particles averaged 23 mm by 5.6 mm by 0.85 mm. Slenderness ratios for wheat straw particles were calculated as 80 and 27, respectively. Table 1 presents the fraction analysis of straw particles in comparison to poplar particles.

Silane coupling agent

Amino silane coupling agent NH2-C3H6-Si(OC2H5)3, was used for improving the properties of the straw/poplar wood particleboards. Properties of the silane coupling agents (Merck Chemistry Company, Germany) are listed in Table 2.

UF resin

The commercial UF resin used in this study was supplied by Tiran Chemistry Company, Iran. This resin was water dispersed with solid content of 62 %, viscosity of 125 cp, gelation time of 54 s, pH of 7.5, and density of 1.28 g cm−3.

Board manufacturing

UF resin was sprayed onto the particles in a blender at 10 % resin content based on the oven-dried weight of particles. Silane coupling agent was mixed with the UF resin prior to blending, based on the weight of the resin solid. One percent of NH4CL based on the weight of the resin solid, was added as the curing catalyst. Hand-formed mats were pressed into 14 mm thick boards using distance bars at 180 °C for 5 min. The mats were pressed under a pressure of 35 kg cm−2. The board size was 400 mm × 400 mm × 14 mm with targeted density of 0.70 g cm−3. We tested the following four ratios of straw to poplar particles: 100/0, 85/15, 70/30, and 55/45. The proportion of coupling agent was tested at three levels of 0, 5 and 10 %. Our experimental schedule is shown in Table 3.

Physical and mechanical properties tests

Prior to testing the physical and mechanical properties, the boards were conditioned at (20 ± 1) °C and (65 ± 5) % relative humidity (RH) until they reached constant weight. The modulus of rupture (MOR), modulus of elasticity (MOE), internal bonding strength (IB), water absorption (WA), and thickness swelling (TS) after soaking for 2 and 24 h in water were measured according to DIN 68763 (1982) (DIN 68763 1982). Based on these variables 12 board formulations were manufactured with three boards of each type resulting in 36 boards in total.

Statistical analysis

The experiment was designed as a factorial using completely randomized design. Duncan method was used to compare means at P < 0.05. Statistical analysis was conducted in SPSS.

Result and discussion

Mechanical properties

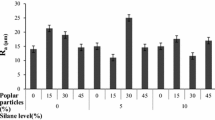

Mechanical properties of particleboard samples in terms of MOR, MOE and IB were significantly influenced by the ratio of fibrous materials and content of silane coupling agent (Fig. 1, 2, 3). All mechanical properties of the boards were improved when silane coupling agent was added. The boards made with 10 % content of silane coupling agent yielded the highest values. Similar results were also reported by Han et al. (1998, 2001). Addition of 5 % silane increase the MOE and MOR of particleboard by about 25 and 33 %, respectively, in comparison with the control samples.

We attribute the improvement in IB to the removal of wax-like substances from the straw surface. Higher IB strength might also contribute to the reduction in water penetration with addition of silane coupling agent by facilitating the adherence of UF resin to the active hydroxyl sites of the cellulose. Reduced water penetration could also be attributed to improved wettability of the straw surfaces as a result of adding silane coupling agent. Increased content of poplar particles substantially improved the MOR and MOE of the produced boards. Similar results were reported by Yang et al. (2003). Replacement of wood particles with rice straw resulted in decreased MOR. This result can be explained by the weak interfacial interaction between wheat straw and UF resin. Boquillon et al. (2004) reported that wheat straw has an outer silica and waxy layer with very low porosity, which disrupts resin penetration and consequently reduces the bondability between UF resin and the particles (Boquillon et al. 2004). Adding 30 % poplar particles increased the IB of boards by about 63 % in comparison with control samples. The significant positive influence of poplar particles on IB can be explained by the increased bonding ability due to the greater thickness of poplar particles than wheat straw particles. In addition, wheat straw particles have greater surface area than poplar particles, thus the resin coverage and consequently the bond is less.

Physical properties

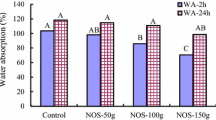

Generally, the thickness swelling of boards decreased with addition of 5 % silane coupling agent. No further reduction in thickness swelling resulted from addition of SCA at levels >5 %. A similar result was reported by Han et al. (2001). Mean TS of sample particleboards ranged from 24 to 58 % and 34 to 72 % for 2 and 24 h immersion, respectively. The thickness swelling of boards increased with increasing content of poplar particles and sample boards with 15 % poplar particles had the lowest thickness swelling. This is related to the greater water-resistance of wheat straw than poplar due to the higher silica content of wheat straw. Wheat straw particles are also longer and thinner than wood particles, and this also contributes to reduced swelling (Grigoriou 2000). Average water absorption of the samples ranged from 68 to 106 % and 94 to 130 % for 2 and 24 h immersion, respectively (Fig. 4, 5, 6, 7).

Conclusion

In this research work, the potential use of amino silane coupling agent (SiNH) was evaluated to improve physical and mechanical properties of UF-bonded wheat straw/poplar wood particleboard. Overall, results showed that the both wheat straw/poplar particle ratio and the addition of silane influenced the physical and mechanical properties of the boards. Adding silane coupling agents significantly improved the MOR, MOE, WA and TS of sample boards. However, no sample boards met the TS requirement of EN standards for general use. According to EN 312-4 standard (EN 312-4 1996), particleboard should have a maximum TS value of 8 and 15 % for 2 h and 24 h immersion, respectively. Thus, it is recommended to use suitable hydrophobic additives during particleboard manufacturing. On the whole, wheat straw particleboard with 5 % silane coupling agent and 30 % poplar particles gave superior physical and mechanical performance.

References

Azizi KH, Tabarsa T, Ashori A (2011) Performance characterizations of particleboards made with wheat straw and waste veneer splinters. J Compos Part B 42:2085–2089

Boquillon N, Elbez G, Schonfeld U (2004) Properties of wheat straw particleboards bonded with different type of resin. J Wood Sci 50(3):230–235

DIN 68763 (1982) Chipboard for special purposes in building construction: concepts, requirements, testing. 1982–03

EN 312-4 (1996) Particleboards-specifications. Part 4. Requirements for load-bearing boards for use in dry conditions. European committee for standardization, Brussels

Grigoriou AH (2000) Straw-wood composites bonded with various adhesive systems. J Wood Sci Technol 34:355–365

Han G, Zhang C, Zhang D, Umemura K, Kawai S (1998) Upgrading of urea formaldehyde-bonded reed and wheat straw particle boards using silane coupling agents. J Wood Sci 44(4):282–286

Han G, Umemura K, Kawai S, Kajita H (1999) Improvement mechanism of bond ability in UF bonded reed and wheat straw boards by silan coupling agent and extraction treatments. J Wood Sci 45(4):299–305

Han G, Umemura K, Wong ED, Zhang M, Kawai S (2001) Effect of silan coupling agent level and extraction treatment on properties of UF bonded reed and wheat straw particleboard. J Wood Sci 47(1):18–23

Markessini E, Roffael E, Rigal L (1997) Panels from annual plant fibers bonded with urea-formaldehyde resins. Proceedings 31st international particleboard composite materials symposium, April 8-10. Washington State University, Pullman, pp 147–160

Yang HS, Kim DJ, Kim HJ (2003) Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour Technol 86:117–121

Author information

Authors and Affiliations

Corresponding author

Additional information

The online version is available at http://www.springerlink.com

Corresponding editor: Yu Lei

Rights and permissions

About this article

Cite this article

Hafezi, S.M., Enayati, A., Hosseini, K.D. et al. Use of amino silane coupling agent to improve physical and mechanical properties of UF-bonded wheat straw (Triticum aestivum L.) poplar wood particleboard. J. For. Res. 27, 427–431 (2016). https://doi.org/10.1007/s11676-015-0135-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11676-015-0135-8