Abstract

The quantification of the role of alloying elements on interface migration during phase transformations in steels and selected non-ferrous alloys (e.g., Ti-based) remains an active area of research that was inspired by seminal contributions of Mats Hillert. In previous studies we had introduced atomistically informed solute drag models for simulation of grain growth and recrystallization. In the present study this approach is extended to diffusional phase transformations where a fast-diffusing species (e.g., C in Fe) redistributes between the parent and daughter phases. The proposed methodology is demonstrated with a conceptional analysis of nano- and mesoscale phase field simulations for model binary and ternary alloys. The approach is shown to be consistent with the formulations of the Hillert–Sundman solute drag model. The challenges in applying this simulation approach to experimental data are critically discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The study of austenite decomposition in steels, especially the interaction of alloying elements with the migrating austenite/ferrite interface remains a critical physical metallurgy research topic, particularly for designing steels with enhanced mechanical properties. Similar considerations are also relevant for the BCC-HCP transformations in titanium alloys. The early phase transformation models considered local equilibrium at the interface such that the bulk diffusion of solutes in the parent phase determines the interface migration rates.[1,2] This concept, also known as diffusion controlled transformation, can adequately describe the transformation rates in Fe-C alloys,[1,2] but falls short for Ti-Mo[3] and Fe-Mn[4] alloys.

In most steels, the complexity further increases due to the presence of substitutional elements such as Nb, Mo, Ti, Mn in addition to interstitial C, both of which have markedly different diffusivities. Para-equilibrium (PE) and no-partitioning local equilibrium (NPLE) have been proposed as thermodynamic limits for practical heat treatments to account for transformations that occur without partitioning of substitutional elements due to their low diffusivities.[5] In the former, the substitutional elements are considered immobile, whereas in the latter, a thin solute spike of the substitutional element is assumed to determine the local equilibrium at the interface. Mats Hillert had made seminal contributions to the introduction of these restricted equilibria. He was the first who proposed a spike of the substitutional alloying element at the interface which he initially called “false-para”-equilibrium[6] which is now the core assumption for the NPLE limit. While PE is criticized for ignoring the mobility of substitutional elements during reconstructive transformations, e.g., FCC to BCC transformations, the width of the solute spike in NPLE is often determined to be smaller than the interatomic distances raising concerns about the applicability of the NPLE model in determining phase transformation kinetics. Experimental studies have further revealed that the transformation rates for different alloys, e.g., Fe-Cr-C, Fe-Si-C, deviate strongly from both NPLE and PE models.[7] To overcome this, several theoretical and numerical models have been proposed,[8,9,10] all of which consider that the available chemical driving pressure is dissipated due to different interfacial processes such as interface friction, dissipation due to diffusion, and solute drag. Different phase transformation models were recently reviewed in detail by Goune et al.[11] and Militzer et al.[12]. These reviews highlighted also the seminal contributions of Mats Hillert in analysing solute drag, particularly the application of the Hillert–Sundman model[13] to rationalize the massive transformation in binary Fe alloys,[14] effective mobility of austenite-ferrite boundaries,[15] and deviation from local equilibrium in ternary alloys.[16]

Alloying elements are known to segregate to interfaces and retard the migration rates of interfaces due to solute drag. The first solute drag model was proposed by Cahn,[17] Lücke and Detert,[18] and Lücke and Stüwe[19] for grain boundaries, which was later extended to phase boundaries by Purdy and Bréchet,[20] as well as Hillert and Sundman.[13] The latter models were successful in predicting transition from PE to NPLE kinetics during phase transformations.[9] Two experimental approaches, i.e., ferrite growth during decarburization,[21] and cyclic phase transformations[22] were developed to quantify independently of the nucleation stage the migration rates in Fe-C-Z alloys, where Z is the substitutional element. Chen and Van der Zwaag[23] developed a Gibbs Energy Balance model and quantified the solute drag due to Mn using cyclic phase transformations experiments. On the other hand, Zurob and coworkers[7,21,24] introduced an atomistic description in the Hillert–Sundman model[13] and systematically investigated the solute drag due to various elements such as Si, Cr, Ni, Mn in ternary Fe alloys. In both approaches, segregation energy and trans-interface diffusivity are considered as fit parameters to describe experimental kinetics, and as a result, the predictive capabilities of solute drag models are limited to a narrow range of steel chemistries. In addition, the solute drag models assume steady state migration of interfaces and remain applicable to planar interfaces only.

The phase field method is a versatile approach which can overcome these limitations and simulate complex microstructure evolution at different length scales. Zhang et al.[25] utilized the phase field model proposed by Wheeler et al.[26] and explicitly considered solute segregation at the interface to describe the transformation rates in Fe-Mo and Fe-Mo-C alloys on the nanoscale. Technical alloys have, however, microstructural features in the order of few micrometers, and resolving solute segregation in these simulations requires extensive computational resources. Shahandeh et al.[27] proposed a friction pressure approach to account for the solute drag pressure on grain boundaries in mesoscale grain growth simulations. Using a systematic analysis, they found a variation in grain growth exponent consistent with experimental grain growth studies. Zhu et al.[28] extended the friction pressure approach to austenite-ferrite transformation in Fe-Mn-C alloys. In this study, the binding energy of Mn was selected based on the available literature data,[23] and the trans-interface diffusivity was considered to be a geometric mean of bulk diffusivities in ferrite and austenite, respectively. The solute drag pressure due to Mn was determined from the Purdy-Bréchet solute drag model[20] and the para-equilibrium limit was considered to determine the chemical driving pressure. The authors demonstrated a transition from PE to NPLE kinetics due to Mn solute drag. The Purdy-Bréchet model, however, has been criticized due to non-zero solute drag pressure even for static boundaries.[29] In addition, the solute drag parameters in phase field simulations, i.e., segregation energy and trans-interface diffusivity, are not known for common alloying elements in steels.

Atomistic simulations such as Density Functional Theory (DFT) can provide insights into the binding energies of solutes at interfacial sites. Jin et al.[30] calculated the binding energies at a special BCC-FCC interface in Fe for important substitutional alloying elements (Z) including Nb, Mo, Mn and Ni. Using these binding energies the interfacial concentrations were estimated for the phase transformation temperature range (773-1073 K). Based on this analysis, representative binding energies were concluded which are consistent with those obtained from the experimentally observed enrichments at BCC-FCC interfaces in Fe-C-Z model alloys.[31]

As a result, the atomistic calculations can be integrated with the phase field method to quantify solute drag of alloying elements during phase transformations. In recent work,[32,33,34] an atomistically informed approach has been developed and verified for recrystallization of gold with Bi and Fe impurities and austenite grain growth in binary Fe alloys. In this study, we aim to extend the atomistically informed approach to phase transformations in binary and ternary alloys. The emphasis here is to propose a conceptional approach that is subjected to a systematic parametric analysis for hypothetical alloying systems that are similar to Fe-C and Fe-C-Z alloys.

2 Methodology

2.1 Effective Binding Energy

Jin et al.[30] utilized DFT calculations at T = 0 K and reported the binding energies for microalloying elements such as Nb, Mo, Ni at a special BCC–FCC interface in Fe. Assuming a linear interpolation between the bulk energies from FCC to BCC at the interface as a reference, the binding energies were determined by calculating the difference between the interpolated and calculated energies at each interface site.[30] The corresponding binding energies of Nb, Mo and Ni are used in the White–Coghlan model[35] to determine the occupancy, i.e., concentration (\({c}_{b,l})\), at each interfacial site l,such that,

Here \({E}_{seg, l}\) is the binding energy at interfacial site l, \({c}_{0}\) is the bulk composition and T is the absolute temperature in Kelvin. Similar to grain boundaries, the total enrichment \(({\Gamma }_{int})\) in atoms/nm2 is calculated using,[32]

where \({A}_{int}\) is the interface area for the unit cell in DFT calculations. Considering interfacial enrichment at equilibrium to be independent of the bulk energies of individual phases, the solute drag model with identical bulk energies across the interface is used to approximate the segregation energy by equating the interfacial enrichment from atomistic simulations to that obtained from the solute drag model.[32,36] Using our methodology proposed for grain boundaries,[32] the effective segregation energies (E) for Nb, Mo, and Ni are determined as − 23 kJ/mol, − 13 kJ/mol, and − 6 kJ/mol for 0.1 at.% bulk composition at T = 800 °C. A temperature variation from 700 to 800 °C, and a bulk composition variation from 0.1 to 0.2 at.% result in a negligible change (< 2 kJ/mol ≈ 20 meV) in the segregation energy. In addition, fast diffusing species such C and P are also found to segregate to austenite-ferrite interfaces in Fe-Mn-C[37] and Fe-P[38] alloys, respectively, and may retard the austenite-to-ferrite transformation kinetics. In the present investigation, we use E = − 6, − 12, − 24 kJ/mol with arbitrary diffusivity in phase field simulations to investigate the solute drag effect in hypothetical binary and ternary alloys that in a first approximation replicate Fe-based alloys.

2.2 Binary and Ternary Phase Diagram

Phase transformation is simulated by considering two phases, \(\alpha\) (product) and \(\beta\) (parent), where the free energy of both phases is defined using an ideal solution model as,

where p is the phase, \({N}_{c}\) is the total number of components, \({c}_{i}\) is the composition of solute i, \({B}_{i}^{p}\) and \({T}_{i}^{p}\) are coefficents that are used to determine the standard state energies of different components in a given phase. These coefficients are taken to be 0 for the \(\alpha\) phase and values for the \(\beta\) phase are included in Table 1 for both binary M-X and ternary M-X-Z systems. Here, M is the matrix element (e.g., Fe or Ti) whereas X and Z are hypothetical alloying components where X is the fast diffusing species and Z is a slow diffusing species, i.e., similar to C and substitutional elements (Nb, Mn, Cr) in industrially relevant ternary Fe alloys, respectively.

Figure 1(a) shows the binary phase diagram for the dilute M-X system, and Fig. 1(b) shows the ternary M-X-Z isotherm at 800 °C. Note that two independent sets of parameters (\({B}_{i}^{p}\),\({T}_{i}^{p}\)) are used for binary and ternary systems which corresponds to separate phase diagrams for each system. For the ternary system, the two phase fields corresponding to equilibrium and constrained equilibria (para-equilibrium and no-partition local equilibrium) are shown in Fig. 1(b).

2.3 Phase Field Model in Nanoscale

A single phase field model, proposed by Wheeler, Boettinger, McFadden (WBM model)[26] is used to explicitly simulate the solute segregation and drag during phase transformation for nanoscale simulations. The model assumes an interface between \(\alpha\) and \(\beta\) phases such that \(\phi\)=1 corresponds to the \(\alpha\) phase and \(\phi\)=0 to the \(\beta\) phase. The total energy (\({G}_{total})\) is composed of interface energy density (\({G}_{int}\)), chemical energy density (\({G}_{chem}\)) and segregation energy density (\({G}_{seg}\)) given as,

such that,

Here \(\epsilon\) and \(\omega\) are phase field coefficents that are related to the interface width (\(2\delta\)) and interface energy (\(\sigma\))[25,26] such that \(\epsilon = \sqrt {\left( {2\delta } \right)\sigma }\) and \(\omega =1.125\sigma /(2\delta )\) whereas \(g\left(\phi \right)=16{\phi }^{2}{\left(1-\phi \right)}^{2}\) is a double well function. \({G}^{\alpha }\) and \({G}^{\beta }\) are free energy densities of \(\alpha\) and \(\beta\) phases, respectively, and \(h\left(\phi \right)=3{\phi }^{2}-2{\phi }^{3}\) is an interpolation function that takes a value of 1 at \(\phi =1\) and 0 at \(\phi =0\). \(E\) is the effective segregation energy, and \({c}_{i}\) is the composition of solute i. According to Zhang et al.[25], \(p\left(\phi \right)=g\left(\phi \right)\) is considered in the present study to simulate interfacial segregation.

The WBM model assumes that the composition at each point (\({c}_{i})\) is a mixture of \(\alpha\) and \(\beta\) phases with identical composition, i.e., \({c}_{i}={c}_{i}^{\alpha }={c}_{i}^{\beta }\) where \({c}_{i}^{j}\) is the composition of solute i in phase j. The phase field evolution under this assumption can be determined using the Allen-Cahn equation[39] as,

where \({L}_{\phi }={M}_{int}/(2\delta )\) is the kinetic coefficent related to the effective interface mobility (\({M}_{int}\)) in the absence of segregation and \(g^{\prime } \left( \phi \right)\), \(p^{\prime } \left( \phi \right)\), \(h^{\prime } \left( \phi \right)\) are partial derivatives with respect to \(\phi\). Note that the addition of segregation energy in the total free energy density modifies the interface energy and interface width. Grönhagen and Ågren,[40] and later Li and Yang[41] utilized a similar model for grain boundary segregation and numerically determined ~ 10% increase and decrease in interface width and interface energy, respectively, for an increase in composition at the grain boundary by a factor of 10. In this study, the variations in interface energy and interface width due to segregation are neglected for small enrichment factors (< 10) at the interface.

The evolution of the concentration field is determined using the Cahn–Hillard equation[42] as,

where \({M}_{c}= {D}_{i}(\phi )/{\partial }_{{c}_{i}{c}_{i}}G\) is the diffusion mobility of solute, \(G\) is the total free energy density, \({\partial }_{{c}_{i}{c}_{i}}\) is the second derivative with respect to composition of solute i and \({D}_{i}\left(\phi \right)={D}_{i}^{\alpha }h\left(\phi \right)+{D}_{i}^{\beta }\left(1-h\left(\phi \right)\right)\) is the effective diffusion coefficent of solute i interpolated between the diffusion coefficents in \(\alpha\) (\({D}_{i}^{\alpha }\)) and \(\beta\) (\({D}_{i}^{\beta }\)), respectively.

In the WBM model, the solute concentration (\({c}_{i}\)) at equilibrium varies continuously from \({c}_{i, eq}^{\alpha }\) to \({c}_{i, eq}^{\beta }\) from \(\phi =1\) to \(\phi =0\) such that the chemical energy at each interfacial point is higher than the minimum energy determined from the common tangent construction.[43] The excess energy is negligible in comparison to the interface potential, i.e., \(\omega g(\phi )\), for thin interfaces or for small differences in equilibrium composition.[44] As a result, the WBM model is applicable for nanoscale simulations but leads to numerical artifacts for artificially wide interfaces in mesoscale simulations.

2.4 Friction Pressure Model

Kim, Kim and Suzuki (KKS model)[43,45] proposed an alternative approach which preserves the interface kinetics for artificially wide interfaces and thus for mesoscale simulations. In this model, the total free energy is composed of the interface energy density and chemical energy density in the absence of segregation. In contrast to the WBM model, the KKS model considers the concentration to be composed of a weighted fraction composition with respect to the mixture of phases \(\alpha\) and \(\beta\), such that \({c}_{i}={c}_{i}^{\alpha }h\left(\phi \right)+ {c}_{i}^{\beta }\left(1-h\left(\phi \right)\right)\). A unique solution to individual concentration fields, \({c}_{i}^{\alpha }\) and \({c}_{i}^{\beta }\), at each interfacial point is determined by considering the equal diffusion potential, i.e., \({\mu }_{i}^{\beta }-{\mu }_{M}^{\beta }= {\mu }_{i}^{\alpha }- {\mu }_{M}^{\alpha }\), where \({\mu }_{i}^{j}\) is the chemical potential of i in phase \(j\). For dilute systems, this further simplifies to \({c}_{i}^{\beta }/{c}_{i}^{\alpha }={c}_{i, eq}^{\beta }/{c}_{i, eq}^{\alpha }={k}_{i}\) where \({k}_{i}\) is the equilibrium partition coefficent for a given temperature.[46]

The equal diffusion potential condition ensures that the chemical free energy is independent of the interface potential, and as a result, the width of the interface can be increased artificially to perform thermodynamically consistent mesoscale simulations.[45] The inclusion of segregation energy density in the total free energy, however, results in two challenges: (1) inability to correctly resolve solute segregation spike in artificially wide interfaces, (2) violation of equal diffusion potential at the interface leading to incorrect equilibrium condition. Note that Kadambi et al.[47] considered the interface as a separate phase and introduced a modified interpolation function, \(h(\phi )\), to simulate solute segregation in the KKS model which is, however, still limited to nanoscale simulations.

Here, we introduce a friction pressure in the KKS model to account for solute drag in mesoscale simulations without explicitly resolving the solute segregation spike at the interface. Accordingly, the phase field evolution under the assumption of equal diffusion potential is determined from,

Here, \(\Delta {G}_{eff}\) is the effective driving pressure at an interfacial grid point. In the absence of solute drag, \(\Delta {G}_{eff}=\Delta {G}_{chem,pf}\) is given as,

In a dilute binary M-X system, \(\Delta {G}_{chem,pf}\) is further simplified as \({\mu }_{M}^{\beta }-{\mu }_{M}^{\alpha },\) whereas for ternary M-X-Z systems with X as a fast diffusing species, \(\Delta {G}_{chem,pf}\) for no partitioning of Z (para-equilibrium) is determined as \({c}_{M}^{\beta }\left({\mu }_{M}^{\beta }-{\mu }_{M}^{\alpha }\right)+{c}_{Z}^{\beta }({\mu }_{Z}^{\beta }-{\mu }_{Z}^{\alpha })\), where \({c}_{i}^{\beta }\) is the concentration of solute i. In the presence of solute segregation and solute drag, the chemical driving pressure is modified with a retarding friction pressure such that \(\Delta {G}_{eff}=\Delta {G}_{chem,pf}-\Delta {G}_{SD}\), where \(\Delta {G}_{SD}\) is the parameterized solute drag pressure determined from either nanoscale phase field simulations or an analytical solute drag model. In these simulations, the chemical driving pressure and the solute drag pressure are averaged across the interface to promote interface stability.

The concentration evolves according to Eq. 9 where the denominator in the diffusion mobility \({M}_{c}\) is defined as \({\partial }_{{c}_{i}{c}_{i}}G=[h\left(\phi \right)/{\partial }_{{c}_{i}^{\alpha }{c}_{i}^{\alpha }}{G}^{\alpha }+(1-h\left(\phi \right))/{\partial }_{{c}_{i}^{\beta }{c}_{i}^{\beta }}{G}^{\beta }]^{-1}\). In the present work, a single phase field model is used in both the nanoscale simulations with the WBM model and in the mesoscale simulations with the KKS model. A more sophisticated model that utilizes double obstacle potential and multi-phase field formulation developed by Steinbach and co-workers[46,48] can also be coupled with an appropriate solute drag (friction) pressure for mesoscale simulations of phase transformations.[28]

2.5 Chemical Driving Pressure

In the WBM phase field model, the driving pressure is evaluated at each interfacial point. The solute drag pressure (\(\Delta {G}_{SD}\)) can be determined from nanoscale simulations that explicitly consider solute segregation at the interface by monitoring the interface velocities (\(v\)) and chemical driving pressure across the interface \(\Delta {G}_{chem, int}\) analogous to the sharp interface approach as,[49]

where

Here \({x}_{i, int}^{\beta /\alpha }\) is the concentration of solute i in front of the interface and \({\mu }_{i,int}^{\beta /\alpha }\), \({\mu }_{i,int}^{\alpha /\beta }\) are the chemical potentials of solute i on the \(\alpha\) and \(\beta\) side of the interface, respectively. Note that \({c}_{i}^{\alpha }\) and \({c}_{i}^{\beta }\) in the phase field model are defined at each grid point and are different from \({x}_{i,int}^{\beta /\alpha }\) and \({x}_{i,int}^{\alpha /\beta }\), respectively. Further, the fast diffusing species is assumed to be in local equilibrium at the interface in the ternary alloy, and the chemical driving pressure is due to the difference in the chemical potentials of the slow diffusing species.

In the diffuse interface approach, the interfacial compositions, \({x}_{i,int}^{\beta /\alpha }\) and \({x}_{i,int}^{\alpha /\beta }\), are defined from either end of the interface.[50] The composition at \(\phi =0.01\) and \(\phi =0.99\) with additional five points outside the interface are used to linearly extrapolate the composition to \(\phi =0.5\) that are considered as \({x}_{i,int}^{\beta /\alpha }\) and \({x}_{i,int}^{\alpha /\beta }\), respectively. The interfacial compositions determined this way represent the outer points of the interface such that the chemical driving pressure determined from Eq. (13) is independent of the solute segregation at the interface.

2.6 Computational Details

A one-dimensional domain is initialized with 500 grid points with a grid spacing of 0.1 nm for nanoscale simulations and 0.1 µm for microscale simulations in both binary and ternary systems. The free energy density described in Eqs. (4,5 and 6) results in a wedge shaped potential well in nanoscale simulations similar to Purdy and Bréchet’s treatment of the chemical potential well.[25] The interface is discretized in 12 points to resolve gradients in concentration due to solute segregation. The interface energy is taken as 0.5 J/m2. The intrinsic mobility is assumed to follow an Arrhenius relationship with \(5 \times 10^{ - 5} { }\;{\text{m}}^{4} /{\text{Js}}\) as pre-exponential factor and 140 kJ/mol as the activation energy. Two different cases are considered for solute diffusivity, i.e., equal solute diffusivities are considered in \(\alpha\) and \(\beta\) for simulations in the binary system, and unequal diffusivities such that the solute diffusivity is higher in the \(\alpha\) phase (similar to BCC-Fe) are considered for simulations in ternary systems as shown in Table 2. An explicit finite difference method with a forward Euler scheme in space and time is implemented to solve for phase field and concentration fields. Accordingly, the time step is defined as \(\Delta t=\Delta {x}^{2}/10{D}_{max}\) where \({D}_{max}\) is the maximum diffusivity among all components in the simulation.

The WBM model is used to simulate solute segregation and solute drag in nanoscale simulations. Figure 2 shows the simulation domain for a binary M-0.18 X (at.%) alloy. An initial \(\alpha\) fraction of 0.2 is considered such that the \(\alpha\) phase is in equilibrium with the \(\beta\) phase at 800 °C without segregation of X. No flux boundary condition is considered for both phase field and concentration variables. The composition profiles are allowed to initially equilibriate for effective segregation energies of \(E\) = 0, − 6, − 12, − 24 kJ/mol. Due to mass conservation and domain size, the modified equilibrium \(\alpha\) fractions are obtained as 0.2, 0.21, 0.22 and 0.33, respectively. These equilibrium composition profiles are shown in Fig. 2 which are considered as the initial condition for subsequent phase field simulations. An undercooling of 50 °C, as indicated in Fig. 1(a), is applied such that the equilibrium compositions in the \(\alpha\) and \(\beta\) phases are 0.149 at.% and 0.298 at.%, respectively. For simulations in the ternary system, an M-0.01X-0.01Z (at. fr.) alloy is considered with an initial \(\alpha\) fraction of 0.05 such that the initial composition in the \(\alpha\) phase is determined from the para-equilibrium tie line. In these simulations, Z is considered as the segregating element with no pre-existing segregation at the interface. This leads to a buildup of a solute spike at the interface differing from the steady state assumption in classical solute drag models.

In mesoscale simulations, the KKS model is used with an appropriate solute drag pressure as a friction pressure. The interface mobility is selected to be identical to the kinetic coefficent, \({L}_{\phi }\Delta t\), from nanoscale simulations. The solute drag pressure is a function of interface velocity \(({v}_{PF})\), where \({v}_{PF}={-\partial }_{t}\phi /|\nabla \phi |\), and Eq. 10 is solved iteratively until convergence in interface velocity is achieved.

3 Results

3.1 Binary M-X System

3.1.1 Nanoscale Simulations and Solute Drag

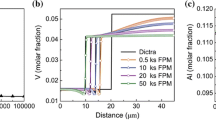

Figure 3 shows the composition profiles of solute X for nanoscale simulations using the WBM model for two cases, i.e., \(E\) = 0 and − 12 kJ/mol, respectively. The interface position corresponding to \(\phi =0.5\), and the interfacial compositions, \({x}_{X,int}^{\alpha /\beta }\) and \({x}_{X,int}^{\beta /\alpha }\), are highlighted along with the equilibrium compositions of the \(\alpha\) and \(\beta\) phases at 750 °C. The slower phase transformation rates are evident for the latter case, and the interfacial concentrations differ from the equilibrium concentrations indicating deviation from local equilibrium. For \(E\) = − 12 kJ/mol solute segregation increases with time due to the increase in the equilibrium \(\alpha\) concentration, as well as an increase in the segregation tendency at 750 °C as compared to the initial condition at 800 °C. Figure 4(a) shows the interface velocity as a function of chemical driving pressure for different segregation energies. Here, the chemical driving pressure is obtained from Eq. (13) with interfacial concentrations extracted from phase field simulations. It is evident that higher segregation energies lead to slower transformation rates which can also be interpreted as decrease in effective mobilities such that \({M}_{eff}=\partial v/\partial\Delta {G}_{chem, int}\). The solute drag pressure is determined using Eq. (12) and is shown in Fig. 4b. The solute drag pressure increases with increase in velocity and segregation energy, indicating that the diffusional transformation is in the low velocity regime of solute drag. The interfacial concentration of the product phase, \({x}_{X,int}^{\alpha /\beta }\), interface velocity from phase field simulations, solute diffusivity, and segregation energy are used to determine the solute drag pressure from the analytical Hillert–Sundman model.[13] As shown in Fig. 4(b), the solute drag pressure from phase field simulations is consistent with the analytical solute drag model.

Composition as a function of time for (a) E = 0 kJ/mol and (b) E = − 12 kJ/mol. The horizontal dashed lines correspond to the equilibrium composition in α (bottom) and β (top) phases and the solid circles indicate the interface compositions relevant for the chemical driving pressure. The vertical dashed line represents the interface position

3.1.2 Mesoscale Simulations with Friction Pressure

The KKS model with the friction pressure model is used to conduct mesoscale simulations. The solute drag pressure determined from the Hillert–Sundman model[13] is parameterized with a simplified function,

with \(a\) and \(b\) as fitting parameters. The solute drag pressures for \(E\) = − 12 kJ/mol and − 24 kJ/mol and the corresponding fits according to Eq. (13) are shown in Fig. 5 as a function of interface velocity. In the absence of segregation, both KKS and WBM models are verified to yield identical phase transformation kinetics for nanoscale simulations. Figure 6(a) shows the comparison of transformation kinetics for nanoscale simulations considering explicitly solute segregation at the interface (WBM model) and using the friction pressure approach (KKS model), respectively. As highlighted earlier, mass conservation in the WBM model results in different initial \(\alpha\) fractions for varying segregation energies. The change in \(\alpha\) fraction (\(\Delta f\)) during simulation remains insensitive to the segregation energies, and is chosen to quantify the transformation kinetics. A delay in transformation kinetics due to solute segregation is evident from both models, but the friction pressure model results in faster transformation rates in comparison to the WBM model. This deviation can be attributed to the differences in the fit function and the Hillert–Sundman solute drag model in Fig. 5 where the fit function results in lower solute drag pressure, i.e., faster transformation, in comparison to the exact Hillert–Sundman model for the same velocity in the low-velocity regime.

The friction pressure model is extended to mesoscale simulations. Figure 6(b) shows the transformation kinetics for cases where the initial \(\alpha\) film thickness is 10 µm and the initial grain size of the \(\beta\) phase is 40 µm. The transformation kinetics is identical in the absence and presence of solute segregation. For nanoscale simulations, the diffusion distance in the parent phase, i.e., \(\sqrt{{D}_{X}t}\) = 10 nm at 100 µ\(\text{s}\), is comparable to the interface width resulting in non-negligible solute drag pressure, whereas in microcrystalline simulations, the long-range diffusion in the parent phase is rate limiting and solute segregation at the interface occurs de facto instantaneously resulting in no solute drag for binary alloys.

3.2 Ternary M-X-Z System

3.2.1 Nanoscale Simulations and Solute Drag

In ternary alloys, the interface velocity is controlled by the long-range diffusion of the fast diffusing species and solute drag due to the slower diffusing element may lead to a decrease in the transformation rates. For an M-0.01 X-0.01 Z (at. fr.) alloy, phase field simulations with the WBM model were performed to quantify solute drag due to the slow diffusing species, i.e., Z in this case. As a benchmark, a simulation representing para-equilibrium kinetics was conducted by considering negligible diffusion of Z in both \(\alpha\) and \(\beta\) phases such that the transformation kinetics is only controlled by X diffusion. To quantify the role of solute segregation, simulations were performed with finite diffusion of Z and segregation energies of 0, −6, and −12 kJ/mol. Figure 7 shows the composition evolution of X and Z in the absence (\(E\)=0 kJ/mol) and presence of Z segregation (\(E\)= −12 kJ/mol). The interfacial concentrations on the \(\beta\) side, i.e. \({x}_{X,int}^{\beta /\alpha },\) and \({x}_{Z,int}^{\beta /\alpha }\), are indicated by the solid circle symbols in the respective composition profiles. Clearly, the transformation rates are decreased when segregation is present. When comparing the two cases in detail a rapid gradual build up of a spike of the substitutional solute Z is seen in the absence of segregation which essentially reflects the transition from para-equilibrium to a transformation regime that is close to no-partition local equilibrium. On the other hand, when segregation is present this initial transformation period is used to build up the segregation profile inside the interface but the system remains in the para-equilbrium limit from the phase transformation perspective. Additional holding time is required for reaching the transformation limit close to NPLE, as shown in Fig. 8 that also includes the intermediate segregation case with a segregation energy of −6 kJ/mol.

(a, c) Composition of fast-diffusing solute X and (b, d) Composition of slow-moving solute Z in M-X-Z system without Z segregation, E = 0 kJ/mol, (a, b) and with Z segregation, E = − 12 kJ/mol, (c, d). The solid circles correspond to interfacial composition of X in (a, c) and Z in (b, d), respectively, relevant for the chemical driving pressure

The limiting \(\alpha\) fraction for the case of no segregation and no Z diffusion (PE limit) is higher than the cases considering Z diffusion, as in the para-equilibrium limit the equilibrium α fraction is about 0.1 larger than in the NPLE limit. Interestingly, for the considered faster transformation case without segregation the complete transition towards the NPLE limit occurs after an α fraction has already been formed that is above the NPLE limit, as indicated by the maximum in the fraction transformed curve. In the case of Z segregation, the delay in transformation kinetics increases with segregation energy but the final \(\alpha\) fraction is independent of segregation consistent with the transformation limit close to NPLE.

Similar to the binary system, the interface velocity determined by monitoring the interface displacement, and the chemical driving force calculated using interfacial compositions in Eq. (13), is shown in Fig. 9(a). A linear relationship between velocity and chemical driving pressure is observed for the case with negligible Z segregation and diffusion which corresponds to no energy dissipation due to solute diffusion at the interface and is considered as a reference for solute drag calculations. The solute drag pressure is determined for the case with finite Z diffusion and segregation using Eq. (12) and is shown in Fig. 9(b). For unequal diffusivities of Z in the parent and product phases, the geometric mean of solute diffusion in the \(\alpha\) and \(\beta\) phase is considered as the trans-interface diffusivity in the Hillert–Sundman model.[13] It can be observed that the phase field simulations indicate a transition from high to low velocity regimes consistent with the solute drag model. Hillert[51] suggested that the dissipation due to diffusion is included in solute drag calculations such that a finite dissipation for no solute segregation and finite solute diffusion is determined at intermediate velocities from both the Hillert–Sundman model and the phase field simulations. The solute drag pressures concluded from phase field simulations are at least semi-quantitatively consistent with the solute drag model. There are some deviations with the maximum deviations occuring during the transition for E = − 6 kJ/mol, i.e., simulation and solute drag model predict a maximum drag pressure of 50 J/mol and 32 J/mol, respectively. These deviations can be attributed to the build-up of the segregation spike of Z in phase field simulations in comparison to pre-existing segregation in the solute drag model. Solute build-up during interface migration may lead to increased asymmetry in the composition profile and, therefore, result in higher solute drag pressures in comparison to classical solute drag models.

3.2.2 Mesoscale Simulations and Solute Drag

The solute drag pressure according to the Hillert–Sundman model is included in the mesoscale simulations since the build-up times of the segregation spike occur on much smaller time scales as compared to mesoscale transformation times. Similar to the binary system, the friction pressure is parameterized with the solute drag model given in Eq. (14) using \(a\)= 0.39, b = 0.23 for E = − 6 kJ/mol, and \(a\)= 0.94, b = 0.15 for E = − 12 kJ/mol.

In ternary alloys, the interfacial concentrations of both X and Z determine the chemical driving pressure. As indicated in the nanoscale simulations, Z segregation at the interface as well as diffusion in the parent phase occur in small distances of less than 5 nm. As a result, resolving of these Z concentration changes is not practical in mesoscale simulations. Different assumptions such as NPLE and PE can be made to constrain X and Z concentrations in mesoscale simulations. In the current scenario, Z diffusion in the parent phase is approximately 5 orders of magnitude smaller than that of X such that bulk diffusion of Z can be neglected.

Thus, as a proof of concept, phase field simulations with friction pressure are performed using the KKS model assuming the chemical driving pressure due to para-equilibrium. Figure 10 shows the transformation kinetics confirming the retardation of the phase transformation kinetics with increasing segregation energy and the associated increased friction pressure.

4 Discussion

This study demonstrates a methodology to integrate atomistic information into mesoscale phase transformation models. For the most widely considered cases of austenite-ferrite transformation in steels, the discussed model cases confirm the delay due to interfacial segregation of slowly diffusing substitutional alloying elements as well as a fraction transformed that approaches the NPLE limit for practical heat treatments with negligible diffusion of substitutional elements. The nanoscale simulations provide insight into the transition from PE to NPLE but the incorporation of this transition into mesoscale models requires further considerations. In addition, there remain a number of other challenges to adapt the proposed methodology to actual phase transformations in steels and similarly in Ti alloys.

The binding energies of elements such as Nb, Mo, Ni in Fe from atomistic simulations are determined at T = 0 K. While simplistic assumptions are made to determine an approximate segregation energy for solute drag models, the interfacial enrichment in the Hillert–Sundman model[13] is also a function of the difference in the standard state free energies of phases at either end of the interface, especially for solutes with large partition coefficients.[52] DFT simulations used in the present study only consider the standard enthalpy at 0 K and the temperature dependence of free energies is required to determine more accurate segregation energies for solutes. In addition, C is present in most Fe alloys, and the binding energies of solutes in the presence of C need to be considered with the present methodology to determine transformation rates that can be compared with experimental data. For example, DFT simulations of binding energies of C and Mn at an incoherent Σ3 grain boundary in BCC-Fe suggest an attraction between C and Mn, i.e., co-segregation.[53]

The present analysis emphasizes atomistically informed segregation energies and is based on simplified assumptions for the trans-interface diffusivity of the segregating species. Such diffusivity assumption may be useful for trend predictions as previously demonstrated for austenite grain growth[34] but for a more detailed comparison with experimental transformation data interfacial saddle point energies for diffusion would have to be determined from DFT simulations as previously shown for the case of recrystallization in Au.[32] In addition, the so-called intrinsic mobility of the interface needs to be quantified and appears to be given in steels by the interface migration with a carbon segregation spike rather than that in ultra-pure Fe without carbon segregation. It is expected that molecular dynamic simulations can provide insight into these mobilities, in particular with DFT augmented potentials through machine learning approaches.

5 Conclusion

In this study, atomistically informed binding energies of solutes are included in a phase field model to simulate phase transformation kinetics in binary and ternary alloys. The phase field simulations for binary alloys suggest solute drag on the nanoscale when the diffusion distances in the bulk phases are comparable to the interface width. Extending the simulations to the mesoscale indicates no solute drag effect due to significantly different length scales at the interface as compared to long-range bulk diffusion of the solute as long as partitioning between the parent and daughter phases are required for the transformation to proceed.

In ternary alloys with fast and slow diffusing alloying elements, e.g., Fe-C-Z (Z = Nb, Mo etc.) the interface velocity is controlled by the long range diffusion of the fast diffusing element (i.e., C in Fe) but modified by the solute drag due to the slow diffusing species. Nanoscale simulations confirm the transition between para-equilibrium and no-partition local equilibrium and can be used to evalute the transition stages as long as the diffusivities of the two solutes are sufficiently different. Further, these simulations may also be useful to describe the transition from transformation rates being controlled by the fast diffusing species to the slow diffusing species which will be of particular relevance when the latter is non-negligible on the mesoscale, e.g., for austenite formation at higher temperatures. Mesoscale simulations assuming para-equilibrium can be used to make trend predictions for the reduction in transformation rates due to slow-diffusing alloying elements, e.g., substitutional alloying elements in steels.

In future work it is envisioned that the current methodology will be extended to multi-phase field simulations for microstructural evolutions during phase transformations in steels and titanium alloys. In addition, solute binding energies from atomistic simulations that account for the presence of fast diffusing species (e.g., C in Fe, O in Ti) at interfaces will be useful to compare the transformation kinetics in ternary alloys with experiments.

References

S. Crusius, L. Höglund, U. Knoop, G. Inden, and J. Ågren, On the Growth of Ferrite Allotriomorphs in Fe-C Alloys, Int. J. Mater. Res., 1992, 83, p 729–738. https://doi.org/10.1515/ijmr-1992-831004

A. Béché, H.S. Zurob, and C.R. Hutchinson, Quantifying the Solute Drag Effect of Cr on Ferrite Growth Using Controlled Decarburization Experiments, Metall. Mater. Trans. A, 2007, 38, p 2950–2955. https://doi.org/10.1007/s11661-007-9353-9

M.C.M. Rodrigues, and M. Militzer, Laser Ultrasonic Measurements of Phase Transformation Kinetics in Lean Ti–Mo Alloys, Metall. Mater. Trans. A, 2022, 53, p 3893–3905. https://doi.org/10.1007/s11661-022-06792-1

T. Jia, and M. Militzer, Modelling Phase Transformation Kinetics in Fe–Mn Alloys, ISIJ Int., 2012, 52, p 644–649. https://doi.org/10.2355/isijinternational.52.644

M. Hillert, Nature of Local Equilibrium at the Interface in the Growth of Ferrite from Alloyed Austenite, Scr. Mater., 2002, 46, p 447–453. https://doi.org/10.1016/S1359-6462(01)01257-X

M. Hillert, and J. Ågren, On the Definitions of Paraequilibrium and Orthoequilibrium, Scr. Mater., 2004, 50, p 697–699. https://doi.org/10.1016/j.scriptamat.2003.11.020

C. Qiu, H.S. Zurob, D. Panahi, Y.J.M. Bréchet, G.R. Purdy, and C.R. Hutchinson, Quantifying the Solute Drag Effect on Ferrite Growth in Fe-C-X Alloys Using Controlled Decarburization Experiments, Metall. Mater. Trans. A, 2013, 44, p 3472–3483. https://doi.org/10.1007/s11661-012-1547-0

C. Hutchinson, A Novel Experimental Approach to Identifying Kinetic Transitions in Solid State Phase Transformations, Scr. Mater., 2004, 50, p 285–290. https://doi.org/10.1016/j.scriptamat.2003.09.051

J. Odqvist, M. Hillert, and J. Ågren, Effect of Alloying Elements on the γ to α Transformation in Steel, I, Acta Mater., 2002, 50, p 3213–3227. https://doi.org/10.1016/S1359-6454(02)00143-X

M. Enomoto, Influence of Solute Drag on the Growth of Proeutectoid Ferrite in Fe–C–Mn Alloy, Acta Mater., 1999, 47, p 3533–3540. https://doi.org/10.1016/S1359-6454(99)00232-3

M. Gouné, F. Danoix, J. Ågren, Y. Bréchet, C.R. Hutchinson, M. Militzer, G. Purdy, S. van der Zwaag, and H. Zurob, Overview of the Current Issues in Austenite to Ferrite Transformation and the Role of Migrating Interfaces Therein for Low Alloyed Steels, Mater. Sci. Eng. R. Rep., 2015, 92, p 1–38. https://doi.org/10.1016/j.mser.2015.03.001

M. Militzer, C. Hutchinson, H. Zurob, and G. Miyamoto, Modelling of the Diffusional Austenite-Ferrite Transformation, Int. Mater. Rev., 2022. https://doi.org/10.1080/09506608.2022.2126257

M. Hillert, and B. Sundman, A Treatment of the Solute Drag on Moving Grain Boundaries and Phase Interfaces in Binary Alloys, Acta Metall., 1976, 24, p 731–743. https://doi.org/10.1016/0001-6160(76)90108-5

M. Hillert, and M. Schalin, Modeling of Solute Drag in the Massive Phase Transformation, Acta Mater., 2000, 48, p 461–468. https://doi.org/10.1016/S1359-6454(99)00361-4

M. Hillert, and L. Höglund, Mobility of α/γ Phase Interfaces in Fe Alloys, Scr. Mater., 2006, 54, p 1259–1263. https://doi.org/10.1016/j.scriptamat.2005.12.023

J. Odqvist, B. Sundman, and J. Ågren, A General Method for Calculating Deviation from Local Equilibrium at Phase Interfaces, Acta Mater., 2003, 51, p 1035–1043. https://doi.org/10.1016/S1359-6454(02)00507-4

J.W. Cahn, The Impurity-Drag Effect in Grain Boundary Motion, Acta Metall., 1962, 10, p 789–798. https://doi.org/10.1016/0001-6160(62)90092-5

K. Lücke, and K. Detert, A Quantitative Theory of Grain-Boundary Motion and Recrystallization in Metals in the Presence of Impurities, Acta Metall., 1957, 5, p 628–637. https://doi.org/10.1016/0001-6160(57)90109-8

K. Lücke, and H.P. Stüwe, On the Theory of Impurity-controlled Grain Boundary Motion, Acta Metall., 1971, 19, p 1087–1099. https://doi.org/10.1016/0001-6160(71)90041-1

G.R. Purdy, and Y.J.M. Bréchet, A Solute Drag Treatment of the Effects of Alloying Elements on the Rate of the Proeutectoid Ferrite Transformation in Steels, Acta Metall. Mater., 1995, 43, p 3763–3774. https://doi.org/10.1016/0956-7151(95)90160-4

H.S. Zurob, D. Panahi, C.R. Hutchinson, Y. Bréchet, and G.R. Purdy, Self-Consistent Model for Planar Ferrite Growth in Fe-C-X Alloys, Metall. Mater. Trans. A, 2013, 44, p 3456–3471. https://doi.org/10.1007/s11661-012-1479-8

H. Chen, and S. van der Zwaag, An Overview of the Cyclic Partial Austenite-Ferrite Transformation Concept and Its Potential, Metall. Mater. Trans. A, 2017, 48, p 2720–2729. https://doi.org/10.1007/s11661-016-3826-7

H. Chen, K. Zhu, L. Zhao, and S. van der Zwaag, Analysis of Transformation Stasis During the Isothermal Bainitic Ferrite Formation in Fe–C–Mn and Fe–C–Mn–Si Alloys, Acta Mater., 2013, 61, p 5458–5468. https://doi.org/10.1016/j.actamat.2013.05.034

D. Panahi, H. Van Landeghem, C.R. Hutchinson, G. Purdy, and H.S. Zurob, New Insights into the Limit for Non-partitioning Ferrite Growth, Acta Mater., 2015, 86, p 286–294. https://doi.org/10.1016/j.actamat.2014.12.018

C.-Y. Zhang, H. Chen, J.-N. Zhu, W.-B. Liu, G. Liu, C. Zhang, and Z.-G. Yang, A New Treatment of Alloying Effects on Migrating Interfaces in Fe-X Alloys, Scr. Mater., 2019, 162, p 44–48. https://doi.org/10.1016/j.scriptamat.2018.10.034

A.A. Wheeler, W.J. Boettinger, and G.B. McFadden, Phase-Field Model for Isothermal Phase Transitions in Binary Alloys, Phys. Rev. A, 1992, 45, p 7424–7439. https://doi.org/10.1103/PhysRevA.45.7424

S. Shahandeh, M. Greenwood, and M. Militzer, Friction Pressure Method for Simulating Solute Drag and Particle Pinning in a Multiphase-Field Model, Model. Simul. Mater. Sci. Eng., 2012, 20, 065008. https://doi.org/10.1088/0965-0393/20/6/065008

B. Zhu, H. Chen, and M. Militzer, Phase-Field Modeling of Cyclic Phase Transformations in Low-Carbon Steels, Comput. Mater. Sci., 2015, 108, p 333–341. https://doi.org/10.1016/j.commatsci.2015.01.023

F. Fazeli, and M. Militzer, Application of Solute Drag Theory to Model Ferrite Formation in Multiphase Steels, Metall. Mater. Trans. A, 2005, 36, p 1395–1405. https://doi.org/10.1007/s11661-005-0232-y

H. Jin, I. Elfimov, and M. Militzer, First-Principles Simulations of Binding Energies of Alloying Elements to the Ferrite-Austenite Interface in Iron, J. Appl. Phys., 2018, 123, 085303. https://doi.org/10.1063/1.5020166

M. Militzer, J.J. Hoyt, N. Provatas, J. Rottler, C.W. Sinclair, and H.S. Zurob, Multiscale Modeling of Phase Transformations in Steels, JOM, 2014, 66, p 740–746. https://doi.org/10.1007/s11837-014-0919-x

A. Suhane, D. Scheiber, M. Popov, V.I. Razumovskiy, L. Romaner, and M. Militzer, Solute Drag Assessment of Grain Boundary Migration in Au, Acta Mater., 2022, 224, 117473. https://doi.org/10.1016/j.actamat.2021.117473

A. Suhane, and M. Militzer, Representative Grain Boundaries during Anisotropic Grain Growth, Comput. Mater. Sci., 2023, 220, 112048. https://doi.org/10.1016/j.commatsci.2023.112048

A. Suhane, D. Scheiber, V.I. Razumovskiy, and M. Militzer, Atomistically Informed Phase Field Study of Austenite Grain Growth, Comput. Mater. Sci., 2023, 228, 112300. https://doi.org/10.1016/j.commatsci.2023.112300

C.L. White, and W.A. Coghlan, The Spectrum of Binding Energies Approach to Grain Boundary Segregation, Metall. Trans. A, 1977, 8, p 1403–1412. https://doi.org/10.1007/BF02642853

N. Maruyama, G.D.W. Smith, and A. Cerezo, Interaction of the Solute Niobium or Molybdenum with Grain Boundaries in α-Iron, Mater. Sci. Eng. A, 2003, 353, p 126–132. https://doi.org/10.1016/S0921-5093(02)00678-0

F. Danoix, X. Sauvage, D. Huin, L. Germain, and M. Gouné, A Direct Evidence of Solute Interactions with a Moving Ferrite/Austenite Interface in a Model Fe-C-Mn Alloy, Scr. Mater., 2016, 121, p 61–65. https://doi.org/10.1016/j.scriptamat.2016.04.038

J.I. Kim, J.H. Pak, K.-S. Park, J.H. Jang, D.-W. Suh, and H.K.D.H. Bhadeshia, Segregation of Phosphorus to Ferrite Grain Boundaries during Transformation in an Fe–P Alloy, Int. J. Mater. Res., 2014, 105, p 1166–1172. https://doi.org/10.3139/146.111129

S.M. Allen, and J.W. Cahn, A Microscopic Theory for Antiphase Boundary Motion and its Application to Antiphase Domain Coarsening, Acta Metall., 1979, 27, p 1085–1095. https://doi.org/10.1016/0001-6160(79)90196-2

K. Grönhagen, and J. Ågren, Grain-Boundary Segregation and Dynamic Solute Drag Theory—A Phase-Field Approach, Acta Mater., 2007, 55, p 955–960. https://doi.org/10.1016/j.actamat.2006.09.017

J. Li, J. Wang, and G. Yang, Phase Field Modeling of Grain Boundary Migration with Solute Drag, Acta Mater., 2009, 57, p 2108–2120. https://doi.org/10.1016/j.actamat.2009.01.003

J.W. Cahn, and J.E. Hilliard, Free Energy of a Nonuniform System. I. Interfacial Free Energy, J. Chem. Phys., 1958, 28, p 258–267. https://doi.org/10.1063/1.1744102

S.G. Kim, W.T. Kim, and T. Suzuki, Phase-Field Model for Binary Alloys, Phys. Rev. E, 1999, 60, p 7186–7197. https://doi.org/10.1103/physreve.60.7186

A.M. Jokisaari, P.W. Voorhees, J.E. Guyer, J. Warren, and O.G. Heinonen, Benchmark Problems for Numerical Implementations of Phase Field Models, Comput. Mater. Sci., 2017, 126, p 139–151. https://doi.org/10.1016/j.commatsci.2016.09.022

S.G. Kim, W.T. Kim, T. Suzuki, and M. Ode, Phase-Field Modeling of Eutectic Solidification, J. Cryst. Growth, 2004, 261, p 135–158. https://doi.org/10.1016/j.jcrysgro.2003.08.078

J. Eiken, B. Böttger, and I. Steinbach, Multiphase-Field Approach for Multicomponent Alloys with Extrapolation Scheme for Numerical Application, Phys. Rev. E, 2006, 73, 066122. https://doi.org/10.1103/PhysRevE.73.066122

S.B. Kadambi, F. Abdeljawad, and S. Patala, Interphase Boundary Segregation and Precipitate Coarsening Resistance in Ternary Alloys: An Analytic Phase-Field Model Describing Chemical Effects, Acta Mater., 2020, 197, p 283–299. https://doi.org/10.1016/j.actamat.2020.06.052

I. Steinbach, Phase-Field Model for Microstructure Evolution at the Mesoscopic Scale, Annu. Rev. Mater. Res., 2013, 43, p 89–107. https://doi.org/10.1146/annurev-matsci-071312-121703

J. Ågren, and Q. Chen, Simplified Growth Model for Multicomponent Systems—Inclusion of PARA and NPLE Conditions, J. Phase Equilibria Diffus., 2022, 43, p 738–744. https://doi.org/10.1007/s11669-022-00969-2

N. Perevoshchikova, B. Appolaire, J. Teixeira, E. Aeby-Gautier, and S. Denis, Investigation of the Growth Kinetics of γ→α in Fe–C–X Alloys with a Thick Interface Model, Comput. Mater. Sci., 2014, 82, p 151–158. https://doi.org/10.1016/j.commatsci.2013.09.047

M. Hillert, Solute Drag in Grain Boundary Migration and Phase Transformations, Acta Mater., 2004, 52, p 5289–5293. https://doi.org/10.1016/j.actamat.2004.07.032

H.P. Van Landeghem, B. Langelier, B. Gault, D. Panahi, A. Korinek, G.R. Purdy, and H.S. Zurob, Investigation of Solute/Interphase Interaction During Ferrite Growth, Acta Mater., 2017, 124, p 536–543. https://doi.org/10.1016/j.actamat.2016.11.035

A.T. Wicaksono, and M. Militzer, Interaction of C and Mn in a ∑3 Grain Boundary of bcc Iron, IOP Conf. Ser. Mater. Sci. Eng., 2017, 219, 012044. https://doi.org/10.1088/1757-899X/219/1/012044

Acknowledgments

The authors gratefully acknowledge the financial support under the scope of the COMET program within the K2 Center ‘‘Integrated Computational Material, Process and Product Engineering (IC-MPPE)’’ (Project No 859480). This program is supported by the Austrian Federal Ministries for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK) and for Digital and Economic Affairs (BMDW), represented by the Austrian research funding association (FFG), and the federal states of Styria, Upper Austria and Tyrol.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of Mats Hillert on the 100th anniversary of his birth. The issue was organized by Malin Selleby, John Ågren, and Greta Lindwall, KTH Royal Institute of Technology; Qing Chen, Thermo-Calc Software AB; Wei Xiong, University of Pittsburgh; and JPED Editor-in-Chief Ursula Kattner, National Institute of Standards and Technology (NIST).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suhane, A., Militzer, M. Atomistically Informed Phase Field Modeling of Solid-Solid Phase Transformations. J. Phase Equilib. Diffus. (2024). https://doi.org/10.1007/s11669-024-01146-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11669-024-01146-3