Abstract

By means of the diffusion couple technique, electron probe micro-analyzer measurement and diffusion controlled transformation simulation, the interdiffusion behavior of ternary fcc Ni-Co-W alloys has been investigated. In the present work, the concentration profiles of fcc Ni-Co-W diffusion couples annealed at the temperatures of 1273, 1373 and 1523 K for the whole Ni-Co edge (i.e. W-poor) region of the fcc phase were measured. Based on the concentration profiles, the interdiffusion coefficients were deduced and used to assess the diffusion mobilities in conjunction with the thermodynamic description. The calculated diffusivities and experimental diffusion coefficients agree well. In addition, validation of the diffusion mobilities have been performed by further comparing the calculated concentration profiles and diffusion paths with the experiment data obtained in the present work.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High-temperature superalloys, such as Co-based alloys and Ni-based alloys, possess excellent performance on high-temperature strength and toughness, corrosion resistance, and fatigue properties. Tungsten, a common alloying element for superalloys, plays an important role in solid solution strengthening.[1,2] Studies on the thermodynamics and diffusion in the Ni-Co-W system are of notable value for the development of the Ni-based alloys, Co-based alloys, W-based high-density alloys and refraction metals.[3]

It is known that the diffusion process has much to do with not only the homogenization and solidification of metal castings but also the forming and dissolving process of precipitated phase, high-temperature creep and various surface treatments.[4,5,6] However, there is no thorough study on the diffusion behavior of the Ni-Co-W system up to now, although there is an increasing need for understanding the interdiffusion behavior in the Ni-Co-W system. This is the focus of the present work, to assess the diffusion mobilities for the fcc Ni-Co-W alloys experimentally and theoretically.

Diffusion research for three binary sub-systems of the ternary, including the Ni-Co, Ni-W and Co-W systems, has already been conducted. Cui et al.[7] assessed the self-diffusion of fcc-Co and established the diffusion mobility of the Co–Ni system considering the self-diffusion of fcc-Ni taken from the work by Jönsson.[8] Subsequently, Campbell and Rukhin[9] adopted the DL consensus estimators to compare the experimental data and assessment of fcc-Ni self-diffusion from Neumann and Tölle[10] with those from Jönsson[8] and Zhang et al.[11] It has been found that the experimental analysis by Neumann and Tölle has the best agreement with most experimental data. Several groups have investigated the Ni-W system. Karunaratne et al.[12] and Campbell et al.[13] both adopted the experimental data measured by Karunaratne et al.[14] which apparently shows deviation from other data to assess the Ni-W system. Therefore, by employing the diffusion mobility for the fcc-Ni self-diffusion from Zhang et al.[11] and the bcc-W self-diffusion from Campbell et al.,[13] Chen et al.[15] analyzed the experimental diffusivities from different sources and optimized the Ni-W system. Using the diffusion-couple method combined with the electron probe micro-analyzer (EPMA) technique, Cui et al.[16] determined the interdiffusion coefficients of the fcc Co-W system in a temperature range from 1273 to 1573 K. Moreover, the assessment of the binary Co-W fitted well with the experiment data.

In view of the fact that the interdiffusion of the ternary fcc Ni-Co-W system cannot be described by a simple extrapolation of its sub-binaries, in the present work, the diffusion couples of fcc Ni-Co-W alloys were designed and measured at 1273, 1373 and 1523 K by EPMA. As a result, the interdiffusion coefficients were obtained and the diffusion mobilities of the fcc Ni-Co-W system were assessed by means of the PARROT module in the DICTRA[17,18] software. The concentration profiles and diffusion paths were simulated to validate the diffusion mobility database.

2 Experiments

To ensure an accurate assessment of the diffusion coefficient and mobility, totally 25 pairs of diffusion couples distributed in the whole fcc Ni-Co-W region were assembled. All diffusion couples are schematically presented in Fig. 1 and listed in Table 1.

Pure Ni (99.995 wt.%), Co (99.999 wt.%) blocks and W (99.99 wt.%) thin filaments used as raw materials were prepared for melting in an arc furnace under a high-purity argon atmosphere. The ingots were re-melted five times to obtain the homogeneous alloys. To keep the high-temperature microstructure of the fcc phase and reduce the effect of grain boundary diffusion, the ingots were encapsulated in quartz tubes at 1473 K for 72 h before water-quenching. Then, the ingots were cut into pieces of size 4 × 4 × 6 mm3. After grinding, polishing and alcohol-cleaning process, the smooth faces of the samples were tightly knitted by a specially fabricated Mo clamp which has two Mo disks bound together with screws. To prevent the contamination by oxygen, the diffusion couples were re-sealed in quartz tubes filled with argon. Heat treatments were performed in an electric resistance furnace for various times, as listed in Table 1. With thermocouples, the temperature fluctuation of the furnace can be kept to less than 6 K. Subsequently, the diffusion couples were quenched and executed to inlaying, grinding, and polishing according to the standard metallographic techniques. The concentration profiles were characterized in the direction perpendicular to the original contact interface by EPMA in the back-scattering condition. Then, a fitting procedure using the error function expansion (ERFEX) method was applied. The smoothed composition data obtained from the ERFEX agree well with the experimental EPMA data. This procedure can reduce the noise and smooth local fluctuations of the measured data; therefore improving the accuracy of the resulting interdiffusivities. Finally, the interdiffusion coefficients were deduced for each intersecting composition of two diffusion couples by the Whittle–Green method.[19] The details of the analysis of the measured EPMA composition data and the interdiffusion coefficient deduction are described in Ref 20.

3 Modeling of Diffusion Mobility

The diffusion mobility M i of component i (i = Ni, Co, or W) can be expressed as a function of temperature according to Andersson and Ågren’s suggestion.[21]

where mg Ω, the ferromagnetic factor, equals unity, as the ferromagnetic contribution to the diffusion is ignored for the fcc phase. M 0 i is the frequency factor, Q S i is the activation energy, and R is the gas constant.

The parameter, Q i = −Q S i + RTlnM 0 i , combines the activation energy and the frequency factor, and it is treated as composition-dependent. For the fcc Ni-Co-W system, Q i can be expressed as:

where x Co, x Ni and x W are the mole fractions of Co, Ni and W, respectively. Q Co i , Q Ni i and Q W i represent the mobility end-members describing the component i diffusing in pure components Co, Ni and W, respectively. Q Ni,Co i , Q Ni,W i and Q Co,W i denote the binary interaction parameters. 0 Q Co,Ni,W i , 1 Q Co,Ni,W i and 2 Q Co,Ni,W i stand for the ternary interaction parameters for the component i. In the present work, only the binary interaction parameter was employed to optimize the diffusion mobility and fit the experimental data well.

The interdiffusion coefficient \( \tilde{D}_{pq}^{n} \) with n as the dependent component (the superscript ‘n’ denotes Ni or Co in the present work) can be expressed by

where the Kronecker delta δ ip = 1 when i = p and 0 otherwise, and μ i is the chemical potential of component i calculated by using the thermodynamic database.

x i is the mole fraction. When Q i is evaluated based on various experimental diffusivity data, the diffusion mobility M i can be combined with thermodynamic data μ i and its derivatives to calculate the interdiffusion coefficients. For detailed modeling, refer to Ref 21 and 22.

4 Result and Discussion

4.1 Experimental Results

The measured interdiffusion coefficient for each intersecting composition for the fcc Ni-Co-W alloys at the temperatures of 1273, 1373 and 1523 K are listed in Table 2.

The upper part and the lower part of Table 2 denote the interdiffusion coefficients in the rich-Ni region and rich-Co region, respectively. All the main interdiffusion coefficients, \( \tilde{D}_{\text{WW}}^{\text{Ni}} \), \( \tilde{D}_{\text{CoCo}}^{\text{Ni}} \), \( \tilde{D}_{\text{WW}}^{\text{Co}} \) and \( \tilde{D}_{\text{NiNi}}^{\text{Co}} \), are positive, while some cross interdiffusion coefficients, \( \tilde{D}_{\text{WCo}}^{\text{Ni}} \), \( \tilde{D}_{\text{CoW}}^{\text{Ni}} \), \( \tilde{D}_{\text{WNi}}^{\text{Co}} \) and \( \tilde{D}_{\text{NiW}}^{\text{Co}} \), are negative. It is obvious from Table 2 that the main interdiffusion coefficients increase with increasing temperature. The main diffusion coefficients show a noticeable trend, i.e. \( \tilde{D}_{\text{CoCo}}^{\text{Ni}} > \tilde{D}_{\text{WW}}^{\text{Ni}} \) in the Ni-rich region and \( \tilde{D}_{\text{NiNi}}^{\text{Co}} > \tilde{D}_{\text{WW}}^{\text{Co}} \) in the Co-rich region. This diffusion behavior demonstrates that Co and Ni diffuse faster than W under the same condition, contributing to the fact that the diffusion distances of Co and Ni are longer than that of W as shown in Fig. 3, 4, and 5. In addition, all the interdiffusion coefficients fulfill the thermodynamic constrains,[23] such as in the Ni-rich region of fcc Ni-Co-W alloys:

4.2 Assessment of Diffusion Mobility

In conjunction with the thermodynamic description which provides the thermodynamic factor and chemical potential, the database of the diffusion mobilities for the fcc Ni-Co-W system was established. The thermodynamic parameters for the ternary Ni-Co-W system were taken from Zhu et al.[24] Figure 1 presents the calculated isothermal sections at 1273, 1373 and 1523 K together with the designed diffusion couples. The diffusion mobility of self-diffusion for Ni, Co, W utilized in the present work were from Neumann and Tölle,[10] Cui et al.[7] and Campbelle et al.,[13] respectively. In the first step, with proper weights and using a least-squares method to minimize the error between the experimental and calculated diffusion coefficients, the diffusion mobilities for the fcc Ni-Co-W were initially obtained in the PARROT module in the DICTRA software. More specifically, the weights for the main diffusion coefficients were set to 1, while the cross diffusivities were not used. The optimized results of diffusivities agree with most experimental data but a few validations which predict the concentration profiles and diffusion paths were not satisfactory. Therefore, in the second step, the mobility parameters were manually adjusted based on the diffusion mobilities derived from the PARROT module in the first step. A reasonable agreement was finally reached between the calculated and experimental data including diffusion coefficients, concentration profiles and diffusion paths. All the mobility parameters obtained in the present work for the fcc Ni-Co-W are listed in Table 3.

4.2.1 Binary Systems

The mobility parameters of Co-W system were directly employed from the work by Cui et al.[16] In addition, the mobility parameters for the Ni-Co system based on Cui et al.[7] were modified slightly in this work by adopting the mobility for Ni self-diffusion from Neumann and Tölle[10] instead of Jönsson.[8] In order to unify the mobility of Ni self-diffusion, it is necessary to reassess the Ni-W system based on the assessment from Chen et al.[15] The results are satisfactory as the original assessments. Thereafter, the diffusion mobilities corresponding to three binary systems were fixed.

4.2.2 Ternary System

Figure 2 presents the calculated main interdiffusion coefficients compared with the experimental data for the fcc Ni-Co-W alloys at 1273, 1373 and 1523 K. It is presented in logarithmic values so the cross-coefficients with some negative data are not plotted. The calculated logarithmic values of the interdiffusion coefficients equal to the experimental ones along the diagonal line. The dotted lines represent a factor of 2 or 0.5, which is a generally accepted experimental error for measurements of diffusion coefficients from the diagonal line, and almost all of the main interdiffusion coefficients fall within the reasonable error range showing a good agreement has been reached.

4.3 Diffusion Simulation

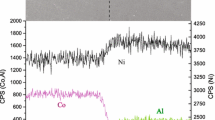

Simulation using the assessed diffusion mobilities together with the reasonable thermodynamic data is a common means to predict a variety of diffusion behaviors including the concentration profiles and diffusion paths. The concentration profiles of diffusion couples at the temperatures of 1273, 1373 and 1523 K are shown in Fig. 3, 4, and 5, respectively. In particular, the diffusion couples of B8, B9, B10 and B11 at 1373 K confirm that the diffusion mobility can describe the diffusion behavior in a wide composition range. Generally, the calculated concentration profiles fit the experiment data well. Figure 6, 7, and 8 illustrate the comparisons of the calculated diffusion paths and the experimental data from this work. It can be observed that the diffusion paths at 1273, 1373 and 1523 K agree well with the corresponding experimental data except for the diffusion couple of B1 at the temperature of 1373 K. As the diffusion paths of A1 and C1 with the same composition as B1 can be well reproduced, the diffusion data for B1 are suspicious and may be checked experimentally.

The comparison between measured and calculated concentration profiles for diffusion couples of (a) A1: Ni-8at.%W/Ni-8at.%Co, (b) A2: Ni-14at.%W/Ni-14at.%Co, (c) A3: Ni/Ni-10at.%Co-12at.%W, (d) A4: Ni/Ni-16at.%Co-7at.%W, (e) A5: Co-9at.%W/Co-9at.%Ni, (f) A6: Co/Co-7at.%Ni -8at.%W, (g) A7: Co/Co-13at.%Ni-5at.%W annealed at 1273 K for 360 h

The comparison between measured and calculated concentration profiles for diffusion couples of (a) B1: Ni-8at.%W/Ni-8at.%Co, (b) B2: Ni-14at.%W/Ni-14at.%Co, (c) B3: Ni/Ni-10at.%Co-12at.%W, (d) B4: Ni/Ni-16at.%Co-7at.%W, (e) B5: Co-9at.%W/Co-9at.%Ni, (f) B6: Co/Co-7at.%Ni -8at.%W, (g) B7: Co/Co-13at.%Ni-5at.%W, (h) B8: Ni-46at.%Co/Ni-40at.%Co-13at.%W, (i) B9: Ni-56at.%Co/Ni-50at.%Co-12.5at.%W, (j) B10: Ni-16at.%Co-7at.%W/Co-13at.%Ni-5at.%W, (k) B11: Ni-10at.%Co-12at.%W/Co-7at.%Ni-8at.%W annealed at 1373 K for 216 h

The comparison between measured and calculated concentration profiles for diffusion couples of (a) C1: Ni-8at.%W/Ni-8at.%Co, (b) C2: Ni-14at.%W/Ni-14at.%Co, (c) C3: Ni/Ni-10at.%Co-12at.%W, (d) C4: Ni/Ni-16at.%Co-7at.%W, (e) C5: Co-9at.%W/Co-9at.%Ni, (f) C6: Co/Co-7at.%Ni -8at.%W, (g) C7: Co/Co-13at.%Ni-5at.%W annealed at 1523 K for 24 h

5 Conclusion

The measured concentration profiles of all diffusion couples annealed at 1273, 1373 and 1523 K for fcc Ni-Co-W alloys contribute to deduce the interdiffusion coefficients. Based on the thermodynamic data and experimentally determined diffusivities, the diffusion mobilities have been critically assessed. By adopting the established mobility database, the calculated diffusion coefficients agree well with the measured ones. Moreover, a further validation, which predicts the concentration profiles and diffusion paths by means of the DICTRA software and compares them with the experimental data, was satisfactorily conducted in this work. It provides a basis for a diffusion mobility database for multi-component Ni-Co-based alloys.

References

R. Darolia, D.F. Lahrman, and R.D. Field, Formation of Topologically Closed Packed Phases in Nickel Base Single Crystal Superalloys, Superalloys, 1988, 1988, p 255-264

P. Caron and T. Khan, Evolution of Ni-Based Superalloys for Single Crystal Gas Turbine Blade Applications, Aerosol Sci. Technol., 1999, 3(8), p 513-523

Z.P. Jin, W.P. Gong, and C.A. Qiu, A Study of the Isothermal Section of the W-Ni-Co System at 1300°C, Mater. Sci. Eng., A, 1990, 124(2), p 211-213

T. Kraft, M. Rettenmayr, and H.E. Exner, An Extended Numerical Procedure for Predicting Microstructure and Microsegregation of Multicomponent Alloys, Modell. Simul. Mater. Sci. Eng., 1996, 4(2), p 161

J. Agren, Kinetics of Carbide Dissolution, Scand. J. Metall., 1990, 19(1), p 2-8

A. Engström, L. Höglund, and J. Ågren, Computer Simulation of Diffusion in Multiphase Systems, Metall. Mater. Trans. A, 1994, 25(6), p 1127-1134

Y.W. Cui, M. Jiang, I. Ohnuma, K. Oikawa, R. Kainuma, and K. Ishida, Computational Study of Atomic Mobility for fcc Phase of Co-Fe and Co-Ni Binaries, J. Phase Equilibria Diffus., 2008, 29(1), p 2-10

B. Jönsson, Ferromagnetic Ordering and Diffusion of Carbon and Nitrogen in bcc Cr-Fe-Ni Alloys, Z. Metallkd., 1994, 85(7), p 498-501

C.E. Campbell and A.L. Rukhin, Evaluation of Self-diffusion Data Using Weighted Means Statistics, Acta Mater., 2011, 59(13), p 5194-5201

G. Neumann and V. Tölle, Monovacancy and Divacancy Contributions to Self-diffusion in Face-centred Cubic Metals Reanalysis for Copper, Silver, Gold, Nickel and Platinum, Philos. Mag. A, 1986, 54(5), p 619-629

L. Zhang, Y. Du, Q. Chen, I. Steinbach, and B. Huang, Atomic Mobilities and Diffusivities in the fcc, L12 and B2 Phases of the Ni-Al System, Int. J. Mater. Res., 2010, 101(12), p 1461-1475

M.S.A. Karunaratne, D.C. Cox, P. Carter, and R.C. Reed, Modelling of the Microsegregation in CMSX-4 Superalloy and Its Homogenisation During Heat Treatment, Superalloys, 2000, 2000, p 263-272

C.E. Campbell, W.J. Boettinger, and U.R. Kattner, Development of a Diffusion Mobility Database for Ni-base Superalloys, Acta Mater., 2002, 50(4), p 775-792

M.S.A. Karunaratne, P. Carter, and R.C. Reed, Interdiffusion in the Face-Centred Cubic Phase of the Ni-Re, Ni-Ta and Ni-W systems between 900 and 1300°C, Mater. Sci. Eng., A, 2000, 281(1), p 229-233

C. Chen, L. Zhang, J. Xin, Y. Wang, Y. Du, F. Luo, Z. Zhang, T. Xu, and J. Long, Diffusivities and atomic mobilities in disordered fcc and ordered L12 Ni-Al-W alloys, J. Alloys Compd., 2015, 645, p 259-268

Y.W. Cui, G. Xu, R. Kato, X.G. Lu, R. Kainuma, and K. Ishida, Interdiffusion and Atomic Mobility for Face-Centered Cubic (FCC) Co-W Alloys, Metal. Mater. Trans. A, 2013, 44(4), p 1621-1625

A. Borgenstam, L. Höglund, J. Ågren, and A. Engström, DICTRA, a Tool for Simulation of Diffusional Transformations in Alloys, J. Phase Equilib., 2000, 21(3), p 269-280

J.O. Andersson, T. Helander, L. Höglund, P. Shi, and B. Sundman, Thermo-Calc & DICTRA, Computational Tools for Materials Science, Calphad, 2002, 26(2), p 273-312

D.P. Whittle and A. Green, The Measurement of Diffusion Coefficients in Ternary Systems, Scr. Metal., 1974, 8(7), p 883-884

X.J. Xu, N.Q. Zhu, W.S. Zheng, and X.-G. Lu, Experimental and Computational Study of Interdiffusion for fcc Ni-Cu-Cr Alloys, Calphad, 2016, 52, p 78-87

J.O. Andersson and J. Ågren, Models for Numerical Treatment of Multicomponent Diffusion in Simple Phases, J. Appl. Phys., 1992, 72(4), p 1350-1355

N. Zhu, J. Li, X.-G. Lu, Y. He, and J. Zhang, Experimental and Computational Study of Diffusion Mobilities for fcc Ni-Cr-Mo Alloys, Metall. Mater. Trans. A, 2015, 46(11), p 5444-5455

J.S. Kirkaldy, D. Weichert, and Z.U. Haq, Diffusion in Multicomponent Metallic Systems: VI. Some Thermodynamic Properties of the D Matrix and the Corresponding Solutions of the Diffusion Equations, Can. J. Phys., 1963, 41(12), p 2166-2173

J. Zhu, M.S. Titus, and T.M. Pollock, Experimental Investigation and Thermodynamic Modeling of the Co-rich Region in the Co-Al-Ni-W Quaternary System, J. Phase Equilib. Diffus., 2014, 35(5), p 595-611

Acknowledgment

The financial support from the Shanghai Municipal Science and Technology Commission Project (Grant Number: 14521100603) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Wang, Y., Zhu, N. et al. Experimental and Computational Study of Interdiffusion for fcc Ni-Co-W Alloys. J. Phase Equilib. Diffus. 38, 37–50 (2017). https://doi.org/10.1007/s11669-016-0513-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-016-0513-8