Abstract

Large-sized rotating machines usually contain weak feature information of rub-impact fault, which is hard to extract. General scale transformation stochastic resonance (GSTSR) can match input signals with different frequencies by using the optimal barrier height and boost the weak fault feature in signals. The performance of GSTSR is determined by systemic parameters. When a rub-impact fault occurs between rotor and stator, vibration signals are often accompanied by an impact. Therefore, the paper takes advantage of sensibility of waveform factor to rub-impact fault information and margin factor to impact properties of signal and reconstructs a new signal evaluation index based on waveform and margin factors. The signal evaluation index is treated as the fitness function of grey wolf optimization (GWO) algorithm and combined with GSTSR to perform a comprehensive evaluation to rub-impact fault feature information. The result of comparison with conventional method (with signal to noise ratio (SNR) as fitness function) indicates that in case of extracting rub-impact fault features, the proposed method identifies a rotor-stator rub-impact fault more precisely than the classical method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rub-impact is a type of classical secondary fault present in large-sized rotating machines like aero-engines [1, 2]. The rub-impact fault can result in serious damage to the equipment, shorter service life and even huge economic loss and loss of life [3]. In the early stage of rub-impact fault, it is difficult to be precisely picked out because the fault feature information is rather weak in vibration signals and the influence of noise adds to the difficulty. At present, the study of denoising algorithm mainly includes two categories. One is to restrain or eliminate noise to further highlight fault feature information. For example, nonlinear signal denoising method [4] based on maximum variance and wavelet denoising method [5] is part of this category. The other is to highlight fault feature information from noise. Stochastic resonance (SR) is the representative of this kind of study. SR coordinates signal, nonlinear system and noise and transfers the energy of noise to signals to reduce the noise and enhance fault features [6,7,8].

Classical stochastic resonance theory requires manual parameter setting. To solve this matter, scholars have applied various optimization algorithms to stochastic resonance to adaptively determine system parameters, which is self-adaptive stochastic resonance. Meanwhile, as classical stochastic resonance is only applicable to the slow-change signals in the treatment of weak noise while fast-change signals in a strong noise environment should be treated in engineering practice most of the time, to expand the application of stochastic resonance, scholars have proposed various methods, such as normalized variable-scale stochastic resonance, double sampling stochastic resonance and general variable-scale stochastic resonance [9,10,11], etc. GSTSR relies on a large enough scale factor to change the scale of the signal, which converts the fast-change signals in strong noise background to slow-change signals in weak noise background which can be treated by stochastic resonance theory. High-frequency input signals can be matched with optimal potential barrier height to enhance the weak fault feature in the signals [11]. Because the SASR effect can overcome the drawback of traditional SR, in which manual parameter setting is required, scholars have integrated various intelligent optimization algorithms with GSTSR to implement self-adaptive stochastic resonance and precisely determine system parameters. In literature [12], quantum particle swarm algorithm and amplitude domain index were introduced to make self-adaptive option of systematic parameters of GSTSR and effectively detect a bearing fault. Literature [13] brought forward a combined method of particle swarm algorithm and GSTSR. The method treats SNR as a fitness function and realizes the extraction of rub-impact fault feature.

The effect of GSTSR is affected by systematic parameters. When system parameters are unreasonable, GSTSR will be hard to enhance weak fault feature information hidden in signals. Option of fitness function determines the systematic parameters determined by self-adaptive SR (SASR) and affects the overall performance of SASR. At present, the most common fitness function of SASR is SNR [14]. When the SNR of output signals of SASR reaches the maximum, the optimal value of stochastic resonance system parameters can be determined. For example, literature [15] combines particle swarm optimization algorithm (PSO) and SASR with SNR as fitness function, and implements the identification of faults in inner ring, outer ring and rolling element. Literature [16] includes a SASR method with SNR as the fitness function for whale optimization algorithm (WOA). The method accomplishes the identification of weak fault components in signals by giving a pre-treatment to breakdown signals of cracks on stator and that of inner ring. Nowadays, the application of SASR to fault feature enhancement of bearing is far more than to rub-impact fault.

When it is impossible to determine the frequency of target signals, SNR usually cannot guide the parameter adjustment and optimization of the SR system [14]. Therefore, scholars have studied the fitness function of SASR. For example, in literature [14], they built a new index parameter through back propagation network using six indexes, such as root-mean-square error, smoothness and so on, and conducted SR of vibration signals with genetic algorithm based on the new index, and successfully identified the fault of bearing. Literature [17] presented a SASR method grounded on comprehensive quantitative index. This method took advantage of kurtosis, margin index and others to set up a new index which was blended with cuckoo search algorithm to optimize parameters of underdamping SR system and identify bearing faults.

SNR is the ratio of signal power and noise power. According to the above studies, when SNR is chosen as a fitness function, it is required to calculate the energy contained in fault feature frequency and compare the result with noise energy. Therefore, before it guides parameter tuning of stochastic resonance system, it is necessary to determine the fault feature frequency of target signals [11].

To simplify the operation and think of the feature of signals in rub-impact faults, this paper has established a new signal evaluation index without the necessity to determine the frequency of target signals. The proposed method starts with the wear degree and impact feature of the system in a rub-impact fault, and blends waveform factor and margin factor into a new index. The new signal evaluation index is treated as the fitness function of grey wolf optimization algorithm and system parameters are adaptively determined based on general scale transformation stochastic resonance. When the signal evaluation index constructed in the paper reaches the maximum, the optimum value of GSTSR system parameter can be obtained and stator-rotor rub-impact fault can be identified based on that.

Theoretical Basis

GSTSR

Stochastic resonance transfers the energy of noise to weak signals by obtaining the best match of noise, non-linear system, and signal, and plays an important role in the feature extraction of weak signals [11]. Statistical mechanics model can be used to explain stochastic resonance. When a Brownian particle unit moves in potential field, its motion equation is shown as follow [11]:

In the formula (1), \(k\) represents damping ratio, \(U\left( x \right)\) potential function, \(\ddot{x}\) inertial item, \(k\dot{x}\) damping term, \(s\left( t \right)\) weak feature signal and \(n\left( t \right)\) white gaussian noise. Potential function has direct influence on the output signals of stochastic resonance system. The typical potential function in stochastic resonance system is a bistable potential function [11] and can be expressed as follow:

In the formula (2), parameter \(a\), \(b\) (\(a > 0\), \(b > 0)\) is the parameter of stochastic resonance system and can determine the potential barrier height of potential function and affect the output signals of stochastic resonance [11]. The \(x\) in the formula represents system output.

When inertial force is far smaller than damping force, \(\ddot{x}\) can be neglected. Let damping coefficient \(k{ } = 1\) [11] and \(s\left( t \right) = A\cos \left( {2\pi ft} \right)\) in which \(A\) is the amplitude of signal and \(f\) is the signal frequency far smaller than 1; \(n\left( t \right) = \sqrt {2D} \varepsilon \left( t \right)\), in which \(D\) is noise intensity, \(\varepsilon \left( t \right)\) standard white gaussian noise with mean value as zero and variance 1; the values of system parameters \(a\) and \(b\) are smaller. A classical bistable stochastic resonance can be obtained by bringing formula (2) to (1). Its expression is as follow:

Classical SR is only applicable to slow-change signals in weak noise background while a great number of engineering practices need to deal with fast-change signals under strong noise background. To parallel signals to requirements of SR, a large enough scale coefficient is introduced. Let \(x\left( t \right) = z\left( \tau \right)\) and \(\tau = mt\), GSTSR model can be expressed as [13]:

Formula (4) is the mathematical model of GSTSR. After scale transformation, the signal amplitude, noise intensity, signal frequency and amplitude in the formula (4) have been reduced to the \(1/m\) of original, implementing the transition from fast-change signals in strong noise background to the slow-change signals in weak noise context, which can be analyzed with stochastic resonance theory.

GSTSR can be implemented by 4-order Rung-Kutta algorithm, in which \(h\) is the step size for calculation. As the system parameter a and b of GSTSR has great influence on output signals, they are optimized by grey wolf optimization algorithm and the result is m times of original system parameters [13].

Grey Wolf Optimization

GWO is an intelligent group optimization algorithm and works by simulating the hierarchy and hunting activity of grey wolf to implement optimization [18]. The algorithm is characterized by strong convergence ability and high precision [19]. The mathematical expression of hunting activity of grey wolf is shown as follow [20]:

(1) The phase of surrounding

During hunting, grey wolf will evaluate the distance from a prey and update their own position by iteration:

In the formula, \(D\) represents the distance between grey wolf and prey, \(h\) current number of iterations, \(X_{p} \left( h \right)\) estimated prey position vector when \(h\) iterations, \(X\left( h \right)\) grey wolf position vector when \(h\) iterations, \(X\left( {h + 1} \right)\) grey wolf position vector when \(h + 1\) iterations, \(A\) and \(C\) coefficient vector.

In the formula, \(o_{1}\) and \(o_{2}\) is the random number within the interval [0, 1] and \(l\) is convergence factor.

(2) The phase of tracking

When a prey is positioned, grey wolf updates its own position:

The \(X_{1}\), \(X_{2}\) and \(X_{3}\) represents the position and step size grey wolf takes toward wolf \(\alpha\), \(\beta\) and \(\delta\). Wolf \(\alpha\) is the first optimal solution of fitness, \(\beta\) secondary and \(\delta\) thirdly.

(3) The phase of attacking

When prey stops moving, a grey wolf initiates an attack and finishes the hunting. The establishment of this mathematical model is achieved by convergence factor \(l\):

The \(h_{{{\text{max}}}}\) in the formula is the maximum number of iterations.

Propose the Method

Establish a New Signal Evaluation Index

Signal evaluation index can direct the adjustment and optimization of parameters as the fitness function of SASR. At present, SNR is one of the most common signal evaluation indexes for SASR. It is necessary to determine a target signal frequency before having SNR direct the adjustment and optimization of parameters of SASR. As the friction caused by rub-impact is non-linear, and higher harmonics (2x and 3x of rotation frequency) and subharmonics (1/2 and 1/3 of rotation frequency) may exist in vibration frequency, this will cause abundant fault feature frequencies along with rub-impact faults. The operation of parameter adjustment and optimization directed by SNR as fitness function will be very complicated.

When a rub-impact fault occurs, there is friction between rotor and stator and the signals often contain impact features. Self-adaptive stochastic resonance can transfer the energy of high-frequency section to low-frequency.

Waveform factor is the ratio of root-mean-square value and absolute mean value and reflects strongly toward low-frequency signals. Meanwhile, it is sensitive to wearing nature [18, 21]. The larger waveform factor is, the more abundant wearing features contained in low-frequency signals will be, as well as rub-impact fault feature information. Given SR output signal is \(x_{k}\), \(x_{k} = \left[ {x_{1} ,x_{2} \ldots x_{N} } \right]\) and N represents the length of signal, the waveform factor \(S_{f}\) of output signal \(x_{k}\) can be expressed as:

Margin factor is the ratio of signal peak value and root mean, sensitive to impact feature of signal and can be used to measure the wearing extent of equipment [21]. When margin factor is larger, the signal can reflect more abundant information of wearing and impact features, and there is more possibility to contain more abundant rub-impact fault information [21]. Given the output signal of SASR is \(x_{k}\), the margin factor \(C_{f}\) of output signal \(x_{k}\) can be expressed as:

It can be found that when waveform and margin factors are larger, it is more possible to contain more abundant rub-impact fault information. Based on the above analysis, to simplify the calculation of stochastic resonance system parameter tuning, this paper has constructed a new signal evaluation index \(N_{f}\) in the form of waveform and margin factors, which has no need to determine target signal frequency. \(N_{f}\) can embody wearing and impact characteristics of rub-impact fault and measure it more comprehensively. Larger \(N_{f}\) indicates more possibility to contain more abundant rub-impact fault feature information.

In the formula, \(S_{f}\) is waveform factor and \(C_{f}\) margin factor. Given SASR output signal is \(x_{k}\), \(x_{k} = \left[ {x_{1} ,x_{2} \ldots x_{N} } \right]\), in which N represents signal length, then the new signal evaluation index \(N_{f}\) of output signal \(x_{k}\) can be represented as:

When the new signal evaluation index (sum of margin and waveform factor) is treated as the fitness function for grey wolf optimization algorithm, optimal values of GSTSR system parameters are self-adaptively determined by the maximum of signal evaluation index value. Therefore, there is no need to determine the fault feature frequency of signal.

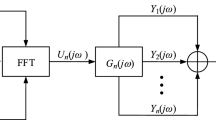

Block Diagram of Thought

To realize the accurate identification of rub-impact fault, the paper introduces the new signal evaluation index (in place of SNR) as the fitness function of GWO for SASR. Specific flow is shown in Fig. 1 in which \(a\) and \(b\) are the systematic parameters of variable scale SR.

Specific steps:

-

(1)

With the new signal evaluation index \(N_{f}\) as the fitness function of grey wolf optimization algorithm, implement SASR for parameters of SR system. By seeking for the maximum value of fitness function \(N_{f}\), a group of SR system parameters a1 and b1 can be acquired.

-

(2)

Based on a1 and b1 and scale coefficient m (m = 100 [13]), calculate variable scale parameter of the GSTSR system a and b.

-

(3)

Based on the variable scale parameters a and b, give SASR to original vibration acceleration signals and obtain the resulted signals.

-

(4)

To extract the characteristics of rub-impact fault, the frequency spectrum of SASR output signal is analyzed and fault is estimated and identified.

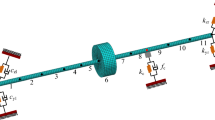

Rub-Impact Fault Experiment

The data included in this paper originates from the test of an aero-engine, rotor and rolling bearing shown in Fig. 2. The testing machine has similar shape as the core of an aeroengine, but its size is only one third; inside is a 0-2-0 support structure whose rigidity can be adjusted according to dynamic properties; multi-stage compressor is replaced by single-stage disk structure and the overall structure of the system consists of rotor—support—blade disk—casing. During the experiment, a bolt set in the casing was rotated to squeeze a ring until it was out of shape and the deformed ring rubbed against rotating blades. The tester supports single-spot rub-impact experiments on multiple locations. The paper has documented the rub-impact experiment on four spots, including left, right, top and bottom. Vibration signals were collected by model 4508 acceleration sensors provided by Denmark B&K corporation. Acceleration sensors were installed on the left and right, top and bottom of turbine casing. Installation positions of sensors and rubbing locations are included in Fig. 2. Figure 2a shows installation positions of sensors and rubbing locations, the top and right of casing while Fig. 2b the bottom and left.

Verification and Analysis of Presented Method

The analysis starts with the data from the sensor installed on the right of turbine casing with rubbing position on the left, randomly. This state includes rotation speed \(f_{n}\) = 1734.0 r/min, rotation frequency \(f_{r}\) = 28.90 Hz and rubbing extent slight. The step size of GSTSR is h = 0.3 [22] and proportionality coefficient m = 100 [13].

Proposed New Method

Fault features were extracted based on the proposed method with the data randomly chosen and the result is shown in Fig. 3. Figure 3a and b is the time-domain diagram and frequency spectrum diagram of the original vibration signal. This vibration signal was processed based on grey wolf optimization algorithm with the new signal evaluation index \(N_{f}\) as fitness function. When \(N_{f}\) is maximum, system parameter is a1 = 0.0011 and b1 = 1.9766. According to proportionality coefficient, optimal parameter of variable scale is a = 1.11*10−5 and b = 1.98*10−2. Signals were subjected to SASR according to system optimal parameters a and b. Figure 3c is the time domain diagram of output signals after SASR, and Fig. 3d is the frequency spectrum diagram of Fig. 3c. Figure 3e is a partial enlarged drawing of Fig. 3d.

Real-time monitoring frequency of equipment is usually in the mid and low sections. Therefore, the analysis of low and mid frequencies is more favorable to detection and identification of faults. By the comparison between spectra of original signals in Fig. 3b and that of acquired signals based on proposed method in Fig. 3(d, e), what can be found is that the spectrum diagram produced by the proposed method has the following features:

-

(1)

Due to the function of SR, the high-frequency noise components of original signals had part of energy passed on to low-frequency feature information and the amplitude of low-frequency section has been improved significantly.

-

(2)

The intensity of noise components has been dramatically reduced.

-

(3)

There are prominent and highlighted feature frequencies of rub-impact fault in low-frequency section, including the following component multiples of rotation frequency (\(f_{r}\) = 28.90 Hz): \(\frac{1}{4}\)x of fr, 7.324 Hz (7.324*4 = 29.30); \(\text{1}\)x of fr, 29.30 Hz; \(\text {1}\frac{1}{4}\)x of fr, 36.62 Hz (36.62/1.25 = 29.30); \(\text {1}\frac{5}{8}\) x of fr, 47.61 Hz (47.61*8/13 = 29.30); \(\text {2}\) x of fr, 57.37 Hz (57.37/2 = 28.69); \(\text {3}\) x of fr, 86.67 Hz (86.67/3 = 28.89).

-

(4)

Fault feature information in the low-frequency section has been significantly enhanced and the maximum amplitude rises from 0.05 to 0.57.

These obvious fault feature frequency components can be used to precisely identify a rubbing fault.

Classical Methods

To verify the accuracy of the presented method, the presented method is compared with the conventional method based on the same data and optimization algorithm (GWO), which is with SNR as fitness function. The result of comparison is shown in Fig. 4. As original data is completely consistent with section "Proposed new method", the time domain and frequency spectrum of the raw signal is displayed in Fig. 3a and b, respectively. Based on grey wolf optimization algorithm, signals are exposed to SASR with SNR as fitness function (step size and proportionality coefficient is the same with that in the proposed method). The result is system parameter a1 = 4.0367 and b1 = 0.6926. According to proportionality coefficient m = 100, system variable scale parameter a = 4.04*10-2 and b = 6.93*10-3. Vibration signals are subjected to SASR based on the optimal value of a and b. Fig. 4a is the time domain of output signals of SASR, and Fig. 4b keeps the frequency spectrum of Fig. 4a. Figure 4c represents the partial enlarged drawing of Fig. 4b.

After analyzing Fig. 4b and c and comparing with the proposed method (Fig. 3d and e), it can be concluded that:

(1) When SNR is treated as the fitness function of grey wolf optimization algorithm, the frequency components in low-frequency segment are basically the same as the proposed method. According to classical methods, it is possible to effectively extract rub-impact faults.

(2) Compared with the proposed method, there is no \(\frac{1}{4}\) x of rotation frequency (\(f_{r}\) = 28.90 Hz) in frequency spectrum, a component of classical frequency which can be used to identify a rub-impact fault. Meanwhile, the amplitude of low frequency segment of signals obtained by classical method is lower than that obtained by proposed method. For example, the amplitude of 1x of rotation frequency is 0.41 in classical scheme while it is 0.57 with the proposed method. This has further illustrated that based on the signal evaluation index rebuilt based on waveform and margin factors, it is feasible to highlight the fault feature information in low-frequency segment and feature information extracted will be more comprehensive. Furthermore, the operation of parameter adjustment and optimization directed by index constructed as fitness function will be simpler than SNR.

Analysis of the Effectiveness of the Proposed Method in Different Situations

Different Fixed Positions of Sensors

To verify if the effect of the proposed method is affected by the installation positions of sensors, the data for analysis is collected at the same time with section "Proposed new method" by the sensor fixed at the bottom of the turbine casing. The result is displayed in Fig. 5. Figure 5a and b shows the time domain and frequency spectrum of an original vibration signal. Based on grey wolf optimization algorithm, with the new signal evaluation index \(N_{f}\) as fitness function, signals are exposed to SASR. When \(N_{f}\) is maximum, system parameter a1 = 0.0012 and b1 = 4.2300 can be obtained. According to proportionality coefficient m, optimal parameter of variable scale a = 1.21*10-5 and b = 4.23*10-2 can be obtained. According to a and b, vibration signals are subjected to SASR. Fig. 5c is the time-domain of output signals of SASR; Fig. 5d is the frequency spectrum of Fig. 5c, e is relative to partial enlarged drawing of Fig. 5d.

By analyzing of Fig. 5b, d and e, it can be revealed the frequency spectrum obtained by the proposed method has the following features:

-

(1)

Noise intensity is still dramatically lower.

-

(2)

There is a remarkable frequency of rub-impact faults with higher amplitude. It includes 1x of rotation frequency \(f_{r}\) (28.90 Hz), 29.3 Hz; \({2}\)x of fr, 57.37 Hz (57.37/2 = 28.69); \({5}\frac{1}{2}{\text{x of }}f_{r} \), 157. 5 Hz (157.5/5.5 = 28.64).

-

(3)

Fault feature information in low-frequency segment has been substantially enhanced.

For example, the amplitude of 2x of rotation frequency \(f_{r}\) rises from the 0.11 to 0.82.

Thus, it is shown that the signal evaluation index, which is built based on waveform and margin factors starting with wear degree of rub-impact fault and signal impact feature, can still give prominence to the rub-impact fault feature information in the low-frequency segment of signal and thereby precisely recognize a rub-impact fault when fixed positions of sensors are different. That is, the proposed method is not affected by fixed positions of sensors.

Different Rubbing Extent

Next discussion will be switched to whether the effect of the proposed method is affected by rubbing extent. Rubbing position is consistent with section "Verification and analysis of presented method" and "Different fixed positions of sensors." and left side of turbine remains, and rubbing extent is serious. As seen from the previous section, the proposed method was not affected by fixed positions of sensors. Therefore, the data randomly taken for analysis were collected by the sensor at the bottom of turbine casing. The result is shown in Fig. 6. This state is relative to rotation speed \(f_{n}\) = 1731.0 r/min and rotation frequency \(f_{r}\) = 28.85 Hz.

Figure 6a and b displays the time domain and frequency spectrum of raw vibration signal which is explored to SASR by grey wolf optimization algorithm with the new signal evaluation index \(N_{f}\) as fitness function. When \(N_{f}\) is maximum, according to proportionality coefficient m, variable scale optimal parameters can be acquired, a = 1.56*10-5 and b = 1.47*10-2. Vibration signals are treated with SASR with system optimal parameters a, and b. Figure 6c shows the time domain diagram of output signals of SASR; Fig. 6d, frequency spectrum diagram of Fig. 6c, e, the partial enlarged drawing of Fig. 6d.

After analyzing Fig. 6b, d and e, it can be found that when rubbing extent is serious, there are the following characteristics of frequency of the proposed method:

-

(1)

Noise intensity is significantly lower.

-

(2)

There are outstanding frequency components in low-frequency segment, which corresponds to rub-impact faults, including \(\frac{1}{8}\) x of rotation frequency (\(f_{r} = {28}.{\text{85Hz}}\)), 3.662 Hz (3.662*8 = 29.30); \({1}\)x of fr, 29.3 Hz; \({2}\)x of fr, 57.37 Hz (57.37/2 = 28.69); \({3}\frac{9}{10} \)x of fr, 113.5 Hz (116/3.9 = 29.10); \({4}\frac{1}{2}\)x of fr, 128.2 Hz (128.2/4.5 = 28.49); \({4}\frac{3}{4} \)x of fr, 139.2 Hz(139.2/4.75 = 29.31); \({5}\frac{1}{2} \)x of fr, 157.5 Hz (157.5/5.5 = 28.64).

-

(3)

Compared with the spectrum of raw signals, the rub-impact fault feature information in low-frequency segment is substantially strengthened, for example, maximum amplitude from 0.04 to 0.35.

Thus, it can be observed that the presented method can still comprehensively extract the feature frequency corresponding to rub-impact fault when rubbing extent varies (including slight and serious) and thereby correctly recognize a rub-impact fault.

Different Rubbing Positions

This section will analyze if the change of rub-impact position affects the effect of the proposed method. It can be known from section "Different fixed positions of sensors." and "Different rubbing extent" that the proposed method is not affected by installation locations of sensors and rubbing extent. Therefore, the data of rubbing above turbine casing randomly taken for analysis was collected by the sensor above. The result is shown in Fig. 7. This state is relative to rotation speed \(f_{n}\) = 1738r/min and frequency 28.97 Hz and rubbing extent is serious.

Figure 7a and b is respectively relative to the time domain and frequency spectrum of raw signal. Based on scale coefficient m, when \(N_{f}\) is maximum, variable-scale optimal parameter a = 5.16*10-5 and b = 7.49*10-2. Subject vibration signals to SASR according to the optimal parameter a, and b. Fig. 7c and d respectively corresponds to the time domain and frequency spectrum diagram of output signals of SASR. Figure 7e proves the partial enlarged drawing of Fig. 7d.

After analyzing Fig. 7b, d and e, what can be observed is that when rubbing positions is different, the frequency spectrum acquired by the proposed method has the following characteristics:

-

(1)

High-frequency noise intensity is significantly reduced.

-

(2)

There are prominent characteristic frequencies of rub-impact fault. Classical feature frequencies relative to rubbing fault include \({1} \)x of fr, 29.30 Hz; \({2}\)x of fr, 57.37 Hz (57.37/2 = 28.69); \({4} \)x of fr, 116 Hz (116/4 = 29); \({5}\frac{1}{2}\)x of fr, 157.5 Hz (157.5/5.5 = 28.64).

-

(3)

Compared with the spectrum of raw signals, rubbing fault feature information in low-frequency segment is significantly improved. For example, the amplitude of 2x of \(f_{r}\) rises from 0.08 to 0.53.

Thus, the new signal evaluation index established in the paper can strengthen the feature of rubbing fault and precisely identify a fault no matter where a rubbing fault occurs. That means the proposed method in this paper is insensitive to rubbing positions.

Conclusion

To realize the accurate identification of rub-impact fault and simplify the optimizing process of system parameter of SR, the paper takes advantage of sensitivity of waveform factor to rubbing fault signal and margin factor to signal impact feature to establish a new signal evaluation index without the necessity to determine target signal frequency. The new signal evaluation index is in place of SNR as the fitness function of GWO in the optimization of parameters of GSTSR system. The following conclusions can be drawn through data analysis of multiple statuses.

-

(1)

Compared with the scheme of taking SNR as fitness function, the proposed method does not have to determine the frequency of target signal to determine optimal parameter of system, which is more beneficial to the accurate identification of faults. The proposed method can further highlight feature information of rub-impact fault and the fault frequency extracted will be more complete.

-

(2)

The proposed method is insensitive to fixed locations of sensors. No matter the sensors are fixed horizontal or vertical of the turbine casing, the presented method can still implement accurate identification of a rub-impact fault.

-

(3)

The effect of the proposed method is not affected by rubbing extent. No matter rubbing extent is slight or serious, the method can equally extract the rub-impact faults.

-

(4)

The effect of the proposed method is not affected by rubbing locations. No matter rubbing position is horizontal or vertical to turbine casing, the proposed method can still correctly identify a rub-impact fault.

Based on the signal of the tester, the effectiveness of the proposed method is verified. However, the signals from real aeroengines have more interference and are more difficult to analyze, so that the method proposed requires more pretreatments in actual engineering applications.

References

P.C. Yu, Y.H. Ma, J. Hong, G. Chen, Application of complex nonlinear modes to determine dry whip motion in a rubbing rotor system. Chin. J. Aeronaut. 34(01), 209–225 (2021). https://doi.org/10.1016/j.cja.2020.09.049

Z. Meng, M. Lv, Z.H. Liu, F.J. Fan, General synchroextracting chirplet transform: Application to the rotor rub-impact fault diagnosis. Measurement. 169, 108523 (2021). https://doi.org/10.1016/j.measurement.2020.108523

M.Y. Yu, A novel intrinsic time-scale decomposition-graph signal processing-based characteristic extraction method for rotor-stator rubbing of aeroengine. J. VIB CONTROL. 28, 902–914 (2022). https://doi.org/10.1177/1077546320985968

Y. Zhang, B.W. Li, Noise reduction method for nonlinear signal based on maximum variance unfolding and its application to fault diagnosis. Sci. China Technol. Sci. 53(08), 2122–2128 (2010). https://doi.org/10.1007/s11431-009-3172-8

F. Miao, R.Z. Zhao, A new method of vibration signal denoising based on improved wavelet. J. LOW FREQ NOISE V A. 41(02), 637–645 (2022). https://doi.org/10.1177/14613484211051857

N.Q. Hu, M. Chen, X.S. Wen, The application of stochastic resonance theory for early detecting rub-impact fault or rotor system. Mech. Syst. Signal Process. 17(04), 883–895 (2003). https://doi.org/10.1006/mssp.2002.1470

X.J. Gu, C.Z. Chen, Adaptive parameter-matching method of SR algorithm for fault diagnosis of wind turbine bearing. J. Mech. Sci. Technol. 33, 1007–1018 (2019). https://doi.org/10.1007/s12206-019-0202-8

B.M. Xu, J.C. Shi, M. Zhong, J. Zhang, Incipient fault diagnosis of planetary gearboxes based on an adaptive parameter-induced stochastic resonance method. Appl. Acoust. (2022). https://doi.org/10.1016/j.apacoust.2021.108587

T.Y. Wang, Y.G. Leng, Numerical research of twice sampling stochastic resonance for the detection of a weak signal submerged in a heavy Noise. Acta Phys. Sin. 10, 2432–2437 (2003)

Z.H. Jiang, F. Xie, H.N. Wang, Condition monitoring of tools with normalized variable-scale stochastic resonance. Mech. Sci. Technol Aerosp Eng. 39, 1520–1525 (2020). https://doi.org/10.13433/j.cnki.1003-8728.20190266

Yang, J.H. Zhou, D.J. (Re-scaled Resonance Theory and Application in Fault Diagnosis), Science Press, Beijing 2020, p. 10

D.W. Huang, J.H. Yang, D.J. Zhou, G. Litak, Novel adaptive search method for bearing fault frequency using stochastic resonance quantified by amplitude-domain index. IEEE Trans. Instrum. Meas. 69(01), 109–121 (2020). https://doi.org/10.1109/TIM.2019.2890933

H.N. Cong, M.Y. Yu, Y.H. Gao, M.H. Fang, A new method for rubbing fault identification based on the combination of improved particle swarm optimization with self-adaptive stochastic resonance. J. Fail. Anal. Prev. 22, 690–703 (2022). https://doi.org/10.1007/s11668-022-01365-1

P. Zhou, S.L. Lu, F. Liu, Y.B. Liu, G.H. Li, J. Zhao, Novel synthetic index-based adaptive stochastic resonance method and its application in bearing fault diagnosis. J. Sound Vib. 391, 194–210 (2017). https://doi.org/10.1016/j.jsv.2016.12.017

Z.H. Lai, S.B. Wang, G.Q. Zhang, C.L. Zhang, J.W. Zhang, Rolling bearing fault diagnosis based on adaptive multiparameter-adjusting bistable stochastic resonance. Shock Vib. (2020). https://doi.org/10.1155/2020/6096024

B. He, Y. Huang, D.Y. Wang, B. Yan, D.W. Dong, A parameter-adaptive stochastic resonance based on whale optimization algorithm for weak signal detection for rotating machinery. Measurement. 136, 658–667 (2019). https://doi.org/10.1016/j.measurement.2019.01.017

B.C. Li, R. Tong, J.S. Kang, K. Chi, Bearing fault diagnosis using synthetic quantitative index-based adaptive underdamped stochastic resonance. Math. Probl. Eng. (2021). https://doi.org/10.1155/2021/8888079

X.D. Sun, Y. Zhang, X. Tian, J.H. Cao, J.G. Zhu, Speed sensorless control for IPMSMs using a modified MRAS with gray wolf optimization algorithm. IEEE Trans. Transp. Electrif. 8, 1326–1337 (2022). https://doi.org/10.1109/TTE.2021.3093580

W.L. Fu, J.W. Tan, X.Y. Zhang, T. Chen, K. Wang, Blind parameter identification of MAR model and mutation hybrid GWO-SCA optimized SVM for fault diagnosis of rotating machinery. Complexity. (2019). https://doi.org/10.1155/2019/3264969

Y.Z. Hou, S.M. Li, S.Q. Gong, J.G. Huang, J.B. Zhang, Hybrid algorithm of filter and improved gray wolf optimization for fault feature selection of rolling bearing. Comp. Integr. Manuf. 29, 1452–1461 (2022). https://doi.org/10.13196/j.cims.2023.05.004

J.T. Lu, T. Yao, S.M. Li, R.Q. Cui, An intelligent fault diagnosis method for rolling bearings based on hybrid characteristics. J. Shock. Vib. 41, 7984176 (2022). https://doi.org/10.13465/j.cnki.jvs.2022.16.011

S.L. Lu, Y.S. Su, J.W. Zhao, Q.B. He, F. Liu, Y.B. Liu, Bearings fault diagnosis based on two-dimensional complementary stochastic resonance. J. Shock. Vib. 37, 71227 (2018). https://doi.org/10.13465/j.cnki.jvs.2018.4.002

Acknowledgments

This work was supported by National Natural Science Foundation of China [grant number: 51605309], Natural Science Foundation of Liaoning Province [grant number: 2022-MS-299], Aeronautical Science Foundation of China [grant number: 201933054002] and Department of Education of Liaoning Province [grant number: LJKMZ20220529].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest in preparing this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, M., Wang, P., Su, J. et al. Self-Adaptive Stochastic Resonance Rub-Impact Fault Identification Grounded on a New Signal Evaluation Index. J Fail. Anal. and Preven. 23, 2118–2130 (2023). https://doi.org/10.1007/s11668-023-01745-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01745-1