Abstract

Unexpected occurrence of uneven breakdowns and their consequences have a significant influence on the equipment life. Hence, there is a need to discover the motives for the happening of critical potential failures and required repair or replacement action to control. Reliability analysis is utilized to approximate the performance of the equipment. In this study, the performance of the underground mining machinery known as load haul dumper (LHD) has been estimated with reliability analysis. The best-fit distribution of the data sets was selected by testing the numerous statistical distributions using the Kolmogorov–Smirnov (K-S) test. The percentage of reliability of each subsystem of the LHD machine was computed based on the best-fit approximation. The overall system reliability of the equipment was estimated using a series configuration-based reliability block diagram (RBD) approach. The reliability-based preventive maintenance (PM) time intervals were also computed for estimated 90.00% reliability. To accomplish the desired level of reliability, a review on maintenance programs should be made. Possible recommendations were made to the maintenance department in the industry for improvement in equipment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The efficient usage of capital-intensive equipment in the work environment results in the accomplishment of the anticipated degree of production and productivity. In the present competitive business environment, every industry is regularly searching for improvement in their day-to-day production levels to survive with a noble reputation in society [1]. In the underground mining segment, utilized equipment for transportation purpose, i.e., load haul dumper (LHD), assumes an indispensable job in the accomplishment of the desired level of production rate. The recorded underground metal mine’s production in India is not at a satisfactory level from the last few decades. Unavailability of the equipment in the working phase is only the prominent reason for the fall of production levels in the industry [2]. The best probable utilization of equipment can be possible when the probability of equipment is readily available; the consequence of this should lead to an increase in the production levels of equipment. Enhancement of machinery availability can be possible through a reduction in the downtime hours.

Assessment and prediction of the reliability of intricate repairable assemblies play an important role in the estimation of overall performance. In general, complicated system performance usually relies on the usage of equipment, working ambiance, and adequacy of upkeep, operational techniques, and specialized expertise of the administrators. Dependability or reliability forecast helps to manage the activities of system operation and maintenance condition [3]. Dependability assessment is one of the key techniques to estimate the required outcomes. This assessment can be helpful to highlight the features of production flow in the industry and its reputation [4]. Untrustworthy components in the system assembly direct to unexpected stoppage of equipment operation. Restore as well as replacement activity provides a benchmark for disappointment segments to identify their leftover functional time [5, 6]. The enhancement of the required reliability level of percentage can be possible by undertaking suitable maintenance practices.

The activity of maintenance can be conducted in two different directions: One of the ways is performing maintenance activity in every scheduled time known as scheduled maintenance or preventive maintenance. In this activity, most of the failed parts/components can be repaired in the work environment as well as workshop premises and after successful completion of the repair action the parts can be restored in their original position. On the other hand, corrective maintenance (CM) can be performed to the parts or components that are unable to repair in the maintenance action. These parts can be replaced with new modified designs. The failures that cannot be possible to repair at the time of PM are called as censored failures. These failures can lead to an increase in both maintenance and operational costs. Statistical-based reliability methods can provide additional insight for the machinery during the estimation of the reliability, maintainability, and availability [7]. Keeping this in view, this research work mainly focuses on reorganization of frequent failures, identification of potential causes for the occurrence of these uncertainties, estimation of each subassembly reliability percentage, and identification remedial actions to control the influencing factors of reliability. The summary of the literature for the present research work is systematically arranged in Table 1.

Course of Action

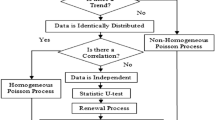

The required information/data can be gathered either from constant checking of tests or from the presence of previous chronicled disappointment information which was put away in the support records. The arrangement of the information should be possible as per the kind of disappointment (Table 2). This information is helpful to evaluate the time between disappointment (TBF) and time to fix (TTR) [8, 9]. In this present study, one financial year failure data of LHDs were collected during the operation of the vehicle. These are classified according to the type of failure mode. TBF and TTR were estimated corresponding to the failure and repair data. These data sets were validated for the identification of independent and identically distributed (IID) nature using the trend and serial correlation tests [10, 11]. After validation of the IID assumption, the data sets were considered for the estimation of best-fit approximation by Kolmogorov–Smirnov (K–S) test [12]. Best-fit approximation models are important in the reliability forecasting of each subcomponent [13]. The procedure of reliability analysis of a complex repairable system has explained in a flow chart (Fig. 1) as follows [14]:

Case Study

In this research, five numbers of LHD machines deployed in an Indian underground lead and zinc mine. The considered machines for the present analysis are made from M/s The Sandvick Company Limited with 17 tonne bucket capacity and named as LHD1, LHD2, LHD3, LHD4, and LHD5. The LHD is treated as the main workhorse intends for transportation in underground mining operations. The drilling and blasting approaches are utilized to extract the ore. The extracted ore is transported from the mined-out area to the primary belt conveyor point through an intermediate mechanized system called the LHD machine. A typical LHD machine at the workshop and during the repair action is shown in Fig. 2a and b.

(a) & (b). A typical LHD machine at the workshop and during the repair action. Before performing the reliability analysis, each machinery must be categorized into several subsystems for identifying potential failure modes [15]. Theses categorizations were made based on past historical records like day-to-day worksheets maintained by maintenance personnel about the breakdowns. In the current study, LHD was classified into seven subsystems/subassemblies (Table 2)

The two years (2015–2016 and 2016–2017) of the breakdown were collected for all the LHD systems of LHD1 to LHD5 to carry out the required analysis. This breakdown information is in the form of spreadsheets prepared by maintenance personnel and computerized soft copies of day-to-day failures. This information was comprised of three metrics such as the failure frequency (FF), the time between failure (TBF), and the time to repair (TTR). Collected data of various LHDs from a field visit are given in Table 3, and the failure frequency of each subsystem is shown in Fig. 3.

Results and Discussion

Key Performance Indicators (KPIs)

The reorganization of the status of the equipment can be helpful as a guideline for carrying out further analysis. The performance of the equipment can be projected by computing the key performance indicators (KPI) such as availability percentage (AP) and utilization percentage (UP). The AP is defined as the percentage of equipment which is readily available to perform the specified task in its work environment known as AP. It can be computed with the ratio of machine available hours (MAH) to the scheduled working hours (SWH) (Eq 1). The idle time of equipment with less than 15 min is need not be considered while calculating the percentage of available time.

UP can be defined as the ratio of available machine working hours or utilized hours to the shift scheduled hours. Depending upon the denominator value, the quantity of UP can be varied. In a study, available machine hours (AMH) are all the time smaller than the scheduled shift hours (SSH) (Eq 2). The computed values of AP and UP are given in Table 4, and the percentage difference is shown in Fig. 4.

Trend as Well as Serial Correlation Checking

These examinations are utilized to check the breakdown information of every individual subsystem; to decide the IID attributes. The graphical analysis between cumulative failure frequencies (CTFF) in opposition to cumulative time between failures (CTBF) determines the trend of existence or not in the collected field failure data. The statement data sets are free from the presence of a trend that can be said when the failure data set points are not in a straight line manner [16, 17]. The presence of correlation between the data sets was determined by performing the graphical analysis with the ith estimation of TBF and (i − 1)th estimation of TBF. Scatter plots of informational indexes between the ith estimation of TBF and (i − 1)th estimation of TBF show the connection among the two qualities [18]. From the graphical analysis (Figs. 5, 6, 7, 8 and 9), it was observed that the data set points are not passing through the straight line and conclude that there is no existence of a trend in the data sets. Because of the serial correlation test, the focuses are dissipated haphazardly, which displayed no relationship. The aftereffect of these tests demonstrates that the informational collections of the considerable number of subsystems were found as pattern-free and the focuses are indistinguishably dispersed. Consequently, the IID supposition for the informational collections was not denied for every subsystem.

The Best-Fit Approximation

The estimation of best-fit approximation of the data sets is necessary for identification of the maximum likelihood estimation (MLE) parameters such as scale, shape, and location parameters. These parameters are estimated using ‘Isograph Reliability Workbench 13.0 (IRW)’ software and are used at the time of reliability percentage estimation. The theoretical probability distribution functions of exponential, 1-parameter Weibull, 2-parameter Weibull, and 3-parameter Weibull, were considered for comparison of best-fit distribution functions. From the outcomes (Table 5) of best-fit approximations, it was found the 3-parameter Weibull distribution function was best fitted for the data sets of LHDs. Distinguishing proof of the best fit for the informational indexes has made using the Kolmogorov–Smirnov (K–S) test. Least estimation of the degree of significance (ε) in the K–S test was treated as a better fitment. The assessed parameters for best-fit circulation work with MLE are introduced in Table 6.

Reliability and Maintainability Analysis

The term reliability is stated as the likelihood of an item or product to perform its intended task before undergoing a failure. The reliability function of a 3-parameter Weibull distribution (Eq 3) is given as

The failure rate is (FR) an important measure in system performance and is defined as the number of failures happened in a product for a particular period. FR can also be called as the hazard function of a system (Eq 4).

The probability density function of 3-parameter Weibull distribution (Eq 5) is given as

The mean time to failure (MTTF) or mean time between failure (MTBF) is defined as the average life of failure-free operation of equipment up to a consequent occurrence of a failure. The Weibull PDF function of MTTF or MTBF is specified as

where \(\lambda = h(t)\) and λ = failure rate.

According to the allocation of best-fit distribution, the renewal process was implemented as a reliability modeling technique for the estimation of each subsystem’s reliability. The percentage of reliability was computed for TBF data sets of each system using Eq 3 and is illustrated in Table 7. The maintainability (Eq 8) and failure rate (Eq 9) metrics were estimated with a mean time between failure (MTBF) and mean time to repair (MTTR) values. The value of MTBF was computed with the ratio of CTBF and the total number of failures. Similarly, MTTR was computed with the ratio of CTTR with a total number of failures.

Estimation of Overall System Reliability

Reliability is a statement of probability, so complex systems are analyzed with logical statements and logical arithmetic. The reliability-wise relationship of components in a system can be represented graphically with a reliability block diagram (RBD) [19]. Reliability block diagram (RBD) is a deductive method utilized to estimate the overall system reliability. Keep in mind that the RBD is not the same as connectivity, system, or physical configuration diagram. It is also important to note that the value of reliability mainly depends upon the variation in the periods, that is, reliability of 0.1 means a component has a 90% probability of failure during a specified operational period. The estimation of overall system reliability is only possible by performing the analysis either in series or parallel configuration system dependency, that is, if one component fails, does it affect the reliability of the others.

In this analysis, reliability-wise relationship of the components was identified as all the subsystems were connected in the series configuration for all the equipment (Table 8). An example of RBD for the LHD1 system is shown in Fig. 10. Therefore, the reliability of each system was estimated with series configuration calculations (Table 9). The following empirical Eq 12 was utilized to estimate the overall system reliability:

where Rs denotes the overall system reliability, i indicates the number of subsystems, i.e., 1,2,3… n, and R indicates the reliability of each subsystem. The variation in predicted values from ‘Isograph Reliability Workbench 13.0’ of the percentage of reliability of each subsystem and system is shown in Figs. 11 and 12.

Reliability-Based Preventive Maintenance (PM) Time Schedules

Forecasting of preventive maintenance (PM) time intervals is very essential for the improvement in the reliability as well as reducing the failure rate of any kind of system or subsystem [20]. The calculated results of reliability-based preventive maintenance time intervals for the expected rate of reliability levels are presented in Table 10. It was understood that if the desired reliability for LHD is 90%, then PM must perform for every 538 h. Similarly, for LHD2 to LHD5 it is 367, 349, 620, and 288 h, respectively. PM can be also be defined as the actions executed to hold the machinery in an indicated state by giving the well-organized evaluation, reorganization, and furthermore avoidance from claiming early failure [21].

Conclusion

Reliability assessment techniques have been gradually accepted as standard tools during the planning and operation of simple to complex engineering systems for the past six decades. In this paper, a case study describing the reliability investigation for a fleet of LHDs in the underground mining industry was performed. Primarily, the performance of equipment was calculated, and it is noticed that from the results of Table 5, the least value of AP has identified for LHD3 (70.10%) and the highest value is for LHD1 (79.23%). Availability is the measure of maintainability and reliability. The required levels of a generation of productivity can be possible only when the equipment is readily available to perform its intended task. From the corresponding values of UP, it was found that the utilization of all the equipment is unsatisfactory. The utilization percentage can be improved by minimizing the idle times of the machine. This includes insufficient availability of ore to transport, shift changing of the personnel, harsh environmental conditions, and traffic in the underground. This can be controlled by undertaking better managerial and operational practices.

As the reliability investigation is one of the well-sophisticated techniques to forecast the life of the machinery, the present study has drawn the results of the reliability percentage of each subsystem and system of every LHD machine. From the results of reliability (Table 9), the very least value of the reliability was noticed for SSEl (16.00%), SSTy (20.56%), and SSE (21.73%). It was concluded that these subsystems are the most critical as compared with the others and assessed that more concentration needs to be kept improving their life. Similarly, overall system reliability (Rs) of each LHD machine was performed by considering all the subsystems as connected in series (RBD). The highest level of Rs was obtained for LHD1 (69.11%) and level obtained for LHD3 (56.77%) as compared with other systems. The achievement of (Fig. 12) least percentage of Rs is due to happening of frequent failures with fewer TBFs. Therefore, it is suggested that the poor efficiency equipment must be maintained at an adequate level by designing the optimal maintenance practices.

Anticipating of reliability-based PM time intervals will be used as a technical base for performing scheduled maintenance activity. The remaining useful life of the machine can be accomplished by performing the PM from time to time. From the determined consequences of PM time intervals, if the prerequisite of reliability is 90%, at that point the PM should conduct in every 539 h for LHD1, and others are given in Table 10. This examination observed that because of divergent operational and environmental conditions, diverse LHD machines ought to require distinctive maintenance strategies. For efficient maintenance planning and organization, each equipment’s reliability requirements are estimated individually. The present analysis provides a base for maintenance personnel in the industry to mitigate or control the uncertainties present in the equipment for the enhancement of equipment reliability.

References

Military Handbook., 2003. MIL-HDBK-5H Metallic Materials and Elements for Aerospace Vehicle Structures, (Knovel Interactive Edition) U.S. Department of Defense, Pp.6-55

B.S. Dhillon, Mining equipment reliability maintainability and safety (Springer, London, 2008)

T.O. Oyebisi, On reliability and maintenance management of electronic equipment in the tropics. Technovision 20(9), 517–522 (2000)

A.K.S. Jardine, Maintenance replacement and reliability (Preney Print and Litho Inc, Ontario, 1998)

S.M. Ross, Applied probability models with optimization applications (Holden-Day, San Francisco, 1970)

P.D.T. O’Connor, Practical reliability engineering, 3rd edn. (Wiley, New York, 1991)

N. Vagenas, N. Runciman, S.R. Clement, A methodology for maintenance analysis of mining equipment. Int J Surface Min Reclamat Environ 11, 33–40 (1997)

R.S. Sinha, A.K. Mukhopadhyay, Reliability centered maintenance of cone crusher- a case study. Int J Syst Assurance Eng Manag 6(1), 32–35 (2015)

J.B. Raju, R.M. Govinda, C.S.N. Murthy, Reliability analysis and failure rate evaluation of load haul dump machines using Weibull distribution analysis. J Math Model Eng Probl 5(2), 116–122 (2018)

J. Barabady, U. Kumar, Reliability and maintainability analysis of crushing plants in jajarm bauxite mine of Iran, in proceedings of the annual reliability and maintainability symposium, pp. 109–115 (2005)

J. Barabady, U. Kumar, Reliability analysis of mining equipment- a case study of a crushing plant at jajarm bauxite mine in Iran. Reliab Eng Syst Saf 93(4), 647–653 (2008)

R.S. Ahluwalia, A software tool for reliability estimation. Quality Eng 15(4), 593–608 (2003)

J. Balaraju, R.M. Govinda, C.S.N. Murthy, Estimation of Reliability-based maintenance time intervals of Load Haul Dumper in an underground coal mine. Int J Min Environ 9(3), 761–770 (2018)

H. Ascher, H. Feingold, Repairable systems reliability modeling inference misconceptions and their causes, Vol. 45, No.4 (Marcel Dekker, New York, 1984), pp. 222–232

N. Vagenas, V. Kazakidis, M. Scoble, S. Espley, Applying a maintenance methodology for excavation reliability. J Surface Min Reclamation Environ 17, 4–19 (2003)

U. Kumar, B. Klefsjo, S. Granholm, Reliability investigation for a fleet of load haul dump machines in a Swedish mine. Reliab Eng Syst Saf 26(4), 341–361 (1989)

M. Mohammadi, P. Rai, S. Gupta, Improving productivity of dragline through enhancement of reliability inherent availability and maintainability. Acta Montanistica Slovaca 21(1), 1–8 (2016)

M. Kostina, T. Karaulova, J. Sahno, M. Maleki, Reliability estimation for manufacturing processes. J Achi Mater Manufact Engineering (AMME) 51(1), 7–13 (2012)

K.N.S. Harish, R.P. Choudhary, C.S.N. Murthy, Failure rate and reliability of the KOMATSU hydraulic excavator in surface limestone mine. AIP Conf. Proc. 1943(1), 020007 (2018)

Q. Fan, H. Fan, Reliability analysis and failure prediction of construction equipment with time series models. J Adv Manag Sci 3(3) 2015

Z. Allahkarami, A.R. Sayadi, A. Lanka, Reliability Analysis of Motor System of Dump Truck for Maintenance Management, Springer International Publishing, Current Trends in Reliability Availability Maintainability and Safety: Lecture Notes in Mechanical Engineering (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

As being a corresponding author and on behalf of all the co-authors, I am providing the information that we do not have any conflict of interest to publish our original research work in The International Journal of Reliable Intelligent Environment. Authorized data sets were used to carry out the present reliability investigation, and no other relationships of personnel and finances of the third party have existed. We are very much interested to publish my manuscript with you.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Balaraju, J., Govinda Raj, M. & Murthy, C.S.N. Performance Evaluation of Underground Mining Machinery: A Case Study. J Fail. Anal. and Preven. 20, 1726–1737 (2020). https://doi.org/10.1007/s11668-020-00980-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00980-0