Abstract

The effect of thiourea (TU) and N-methylthiourea (MTU) on the corrosion of mild steel in 0.5 M H3PO4 was examined using potentiodynamic polarization curve measurements, electrochemical impedance spectroscopy techniques and quantum chemical calculations. Results obtained revealed that MTU is more effective than TU in 0.5 M H3PO4. Theoretical fitting of different adsorption isotherms such as Langmuir, Flory–Huggins, Temkin, and the kinetic-thermodynamic models was tested. The thermodynamic activation parameters were calculated. Quantum chemical parameters were calculated and explained. The data explained that the inhibition of mild steel by TU in 0.5 M H3PO4 take place through chemical adsorption mechanism, while physicochemical adsorption mechanism is suggested for MTU.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many metals and alloys used in different human activities are susceptible to corrosion due to their exposure to different corrosive media. Among these, mild steel is very important since it is widely employed in industry because of its low cost and availability. Corrosion problems are usually connected with operating problems and equipment maintenance and failure resulting in severe economic losses. Corrosion of metals costs the U.S. economy almost $276 billion on an annual basis.

Although phosphoric acid (H3PO4) is classified as a medium-strong acid, it causes severe damage to ferrous alloys [1]. The protection of metals against corrosion by H3PO4 has been the subject of much study since it is widely used in the production of fertilizers. Ammonium phosphate fertilizers usually formed in a reaction between phosphoric acid and ammonia. Other fertilizer, namely, urea pellets was prepared by the addition of 0.45% methylurea or 2.44% thiourea + 13% asphalt-microcrystalline wax blend usually used for improving efficiency of urea fertilizers by inhibition of soil urease activity [2, 3]. H3PO4 is also used in surface treatment of steels such as chemical and electrolytic polishing or etching, chemical coloring, removal of oxide films, phosphating, passivating, and surface cleaning [4,5,6]. The use of inhibitors is one of the most practical methods of preventing corrosion, especially in acidic media [7]. Since the degree of protection of a metal is a function of adsorption, the investigation of the relation between corrosion inhibition and adsorption is of great importance [8]. The adsorption behavior of inhibitor molecules on metal surfaces would be affected by their molecular structure, surface state and surface excess charge of metal [9]. Most of the well-known acid inhibitors are organic compounds containing heteroatoms such as nitrogen, sulfur and oxygen atoms which act as better corrosion inhibitors [10]. Many studies have been carried out to examine the effect of thiourea and methylthiourea on the corrosion of mild steel in sulfuric [11,12,13,14,15,16]), hydrochloric [17, 18] and nitric [19] acid solutions since phosphoric acid is used for the synthesis of phosphate fertilizers. In addition, urea pellets fertilizers include thiourea (TU) and methylthiourea (MTU) as raw materials. Therefore, it is worth to investigate the effect of TU and MTU on the corrosion of mild steel in 0.5 M H3PO4.

Experimental

Solution Preparation

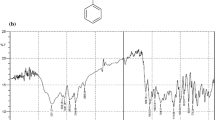

0.5 M H3PO4 solutions were prepared by the dilution of concentrated acids, purchased from Sigma-Aldrich, with distilled water. The inhibitors used were thiourea (TU) and N-methylthiourea (MTU) in the concentration range 8 × 10−5 to 1 × 10−3 M, Fig. 1.

Electrochemical Studies

Electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization curve measurements were achieved using a frequency response analyzer/potentiostat supplied from ACM Instruments (UK). The material used for constructing the working electrode was mild steel of the following composition (wt.%) C: 0.164, N: 0.019, Si: 0.260, S: 0.0005, Ni: 0.123, Cu: 0.173, Al: 0.116, Co: 0.012, Sn: 0.043, Zn: 0.024, Fe: 96.2. Details of the used experimental techniques were identical to those described previously [19].

Quantum Chemical Calculations

Quantum chemical calculation was utilized to investigate the corrosion inhibition mechanism using semi-empirical method PM3 within ‘‘Molecular Orbital Package’’ (MOPAC) program. The calculations were carried out by using CS ChemOffice 2004, CHEM 3D Ultra-Molecular modeling and analysis-Cambridge soft-version 8, supplied by Cambridge Software Company.

Results and Discussion

Potentiodynamic Polarization Data Measurements

Figure 2 shows that MTU behaves as a mixed type inhibitor since it shifts the anodic and cathodic parts of the polarization curves to a lower current values. Similar observations were recorded for TU.

The potentiodynamic polarization parameters together with the inhibition efficiency (%η) are presented in Table 1. %η was calculated using the relation:

where io and iinh represent the corrosion current density values in the absence and the presence of the inhibitor, respectively.

Table 1 illustrates that %η increases with increasing TU or MTU concentrations. Moreover, the %η of MTU is higher that of TU, reaching 91 and 72% at 1 × 10−3 M of MTU and TU, respectively. The cathodic and anodic Tafel lines slope, βa and βc, show slight variations confirming that the inhibition occurs by simple geometric blocking of the active sites, and the anodic and cathodic reaction mechanisms are not affected [20, 21].

Electrochemical Impedance Spectroscopy Results

Figure 3 shows that the impedance response consisted of depressed capacitive semicircles indicating that the corrosion process occurs under activation control [22]. The depression of the semicircles is attributed to the roughness and inhomogeneous nature of the electrode surface [23].

The diameter of the capacitive loop increases with increasing MTU concentrations, indicating that MTU is adsorbed on the electrode surface and thereby produces a barrier, which inhibits corrosion [24].

The analysis of the impedance plots was made by fitting to the equivalent circuit shown in Fig. 4. The constant phase element, CPE, is composed of a non-ideal double layer capacitance component Qdl and a coefficient “n”. The parameter “n” quantifies different physical phenomena like surface inhomogeneity resulting from surface roughness [25].

The electrochemical impedance parameters of Rs, Rct, Qdl together with %η were obtained and are presented in Table 2. The inhibition efficiency (%η) was calculated using the relation:

where Rcto and Rct represent the charge transfer resistance in the absence and the presence of inhibitor, respectively.

Table 2 shows that the values of Rct increase, while the Qdl values decrease with increasing the concentration of TU and MTU. The decrease in Qdl values is due to the decrease in the local dielectric constant or an increase in the thickness of the electrical double layer, indicating that inhibitor molecules act by adsorption at the solution interface [26]. The high value of the solution resistance, Rs, is due to the formation of iron phosphate film. The %η values are in good agreement with that obtained from polarization curve measurements.

Adsorption Considerations

To discuss adsorption isotherms, the degrees of surface coverage values were obtained from AC impedance measurements using equation (θ = %η/100). Langmuir, Kinetic-Thermodynamic model, Florry–Huggins, and Temkin isotherms were used to test the adsorption behavior of TU and MTU [27,28,29]. The parameters obtained from the fitting are depicted in Table 3.

It was found that for TU, the experimental data do not fit the Langmuir adsorption isotherm. Such observation indicates the non-ideal adsorption behavior of TU at mild steel surface. However, the experimental data for MTU fit all the applied isotherms.

The values of correlation coefficient (R2) were used to judge the best-fit isotherm. In the present study, the strong correlation (R2 > 0.98) suggests that the adsorption of TU and MTU obeyed kinetic-thermodynamic model, Florry–Huggins, and Temkin isotherm.

Different information is obtained from each isotherm. In the case of MTU, the number of active sites occupied by a single inhibitor molecule, 1/y, was nearly equal to the size parameter x, number of absorbed water molecules substituted by a given MTU molecule. This indicates that the MTU inhibitor and water molecules are of similar size [30]. However, TU with 1/y < 1 indicating that TU does not occupy a complete active site. It is also evident from the Temkin isotherm that positive values of the adsorption parameter (f) suggest the occurrence of mutual repulsion of molecules [31, 32]. This is confirmed by the values of attractive parameter (a) of Temkin which are negative in both inhibitors, indicating that repulsion exists in the adsorption layers [33]. The larger magnitude of binding constant K for MTU (obtained from the three models) indicates a stronger interaction between the metal surface and MTU in phosphoric acid media than that of TU [30]. Such improvement of K value of MTU compared to that of TU is attributed to its molecular structure and geometry.

Thermodynamics and Activation Parameters

The thermodynamic parameters for dissolution of mild steel in 0.5 M H3PO4 in the absence and presence of 1 × 10−3 M of TU and MTU were obtained from the Arrhenius equation and the transition state equation [34]. The corrosion rates were taken as the corrosion currents (icorr) which were obtained from the potentiodynamic polarization curves of steel in 0.5 M phosphoric acid at different temperatures. Figure 5 indicates that increasing temperature affects both cathodic and anodic parts of the polarization curves in 0.5 M H3PO4 in the presence of MTU.

The activation parameters were calculated and presented in Table 4. The change in the free energy of activation (ΔG*) of the corrosion process is calculated at 303 K by applying the equation:

The binding constant of adsorption, K, is related to the free energy of adsorption (ΔGads), with the following equation [31]:

where R is the molar gas constant, T is the absolute temperature in Kelvin, and 55.5 is the concentration of water at the metal/solution interface expressed in molar. ΔGads values were obtained by using the values of K obtained from the kinetic—thermodynamic model.

Table 4 illustrates that the values of apparent activation energy, Ea, enthalpy of activation, ΔH*, and ΔG* for MTU are larger than that of TU. The positive values of ΔH* indicate that the formation of the activated complex is an endothermic process. The negative value of ΔS* implies that the activated complex represents an association rather than a dissociation step. However, the values of ΔS* were found to decrease upon the addition of the TU or MTU. This means that an increase in disordering takes place on going from reactants to the activated complex in the presence of the inhibitor [35,36,37]. The negative values of the ΔGads reflect the spontaneity of the adsorption process of both TU and MTU and the stability of the adsorbed layer on the mild steel surface.

Generally, values of ΔGads up to − 20 kJ mol−1 are consistent with electrostatic interactions between the charged molecules and the metal (physisorption), while those around − 40 kJ mol−1 or higher are associated with chemisorption [38]. The ΔGads value of TU is − 40 kJ mol−1 indicates chemisorption as a result of sharing or transfer of electron pair or π electrons from TU molecules to the metal surface to form a coordinate type of bond (chemisorption) The ΔGads value of MTU is − 34 kJ mol−1 indicates that the adsorption is not merely physisorption or chemisorption but obeying a comprehensive adsorption mechanism (physicochemical adsorption).

Chemical Quantum Studies

Quantum chemical calculations have been proven to be useful in studying the relationship between the molecular structure of the corrosion inhibitor and its inhibition effect. The chemical quantum parameters of TU and MTU were calculated and are given in Table 5 [39, 40].

The absolute electronegativities (χ) of TU and MTU are lower than that obtained from Lukovits’s study for iron (7 eV) [41]. Therefore, electrons move from the TU or MTU toward the steel surface until the equilibrium in chemical potential is obtained. This favors chemical adsorption of the inhibitors on the electrode surface.

The ionization potential (I) and energy of higher occupied molecular orbital, EHOMO is often associated with the capacity of a molecule to donate electrons (I = − EHOMO). High values of (I) indicate a tendency of the molecule to donate electrons to appropriate acceptor molecules with low energy unoccupied molecular orbital, ELUMO [42, 43]. The value of ΔE provides a measure for the stability of the formed complex on the metal surface [44]. The lower ΔE value of MTU than that of TU indicates that MTU is more stable than TU since it adsorbed through physicochemical mechanism, whereas TU adsorbed via a chemical mechanism only.

Conclusion

TU and MTU inhibit the corrosion of the mild steel in 0.5 M H3PO4. The efficiencies of the inhibitors in phosphoric acid are dependent on the concentration of the inhibitors and temperature. With the same concentration of the inhibitors, MTU was found to be more efficient than TU, showing 95% at 1 × 10−3 M. The success of MTU as inhibitor in similar industrial applications, and its cost, safety, and environmental advantages could be a subject of a further study.

References

L. Malki Alaoui, B. Hammouti, A. Bellaouchou, A. Benbachir, A. Guenbour, S. Kertit, Corrosion inhibition and adsorption properties of 3-amino-1,2,3- triazole on mild steel in H3PO4. Pharma Chem. 3(4), 353–360 (2011)

M.B. Geeson, C.C. Cummins, Phosphoric acid as a precursor to chemicals traditionally synthesized from white phosphorus. Science 359(6382), 1383–1385 (2018)

S. Kiss, M. Simihaian, Improving Efficiency of Urea Fertilizers by Inhibition of Soil Urease Activity (Kluwer Academic Publishers, Dardrecht, 2002), p. 48

L. Wang, Inhibition of mild steel corrosion in phosphoric acid solution by triazole derivatives. Corros. Sci. 48(3), 608–616 (2006)

M. Benabdellah, M. Benkaddour, B. Hammouti, M. Bendahhou, A. Aouniti, Inhibition of steel corrosion in 2 M H3PO4 by artemisia oil. Appl. Surf. Sci. 252(18), 6212–6217 (2006)

M. Benabdellah, A. Aouniti, A. Dafali, B. Hammouti, M. Benkaddour, A. Yahyi, A. Ettouhami, Investigation of the inhibitive effect of triphenyltin 2-thiophene carboxylate on corrosion of steel in 2 M H3PO4 solutions. Appl. Surf. Sci. 252(23), 8341–8347 (2006)

G. Trabanelli, 1991 Whitney award lecture: inhibitors—an old remedy for a new challenge. Corrosion 47(6), 410–419 (1991)

O.K. Abiola, Adsorption of 3-(4-amino-2-methyl-5-pyrimidyl methyl)-4-methyl thiazolium chloride on mild steel. Corros. Sci. 48(10), 3078–3090 (2006)

J.Z. Ali, X.P. Guo, J.E. Qu, Z.Y. Chen, J.S. Zheng, Adsorption behavior and synergistic mechanism of a cationic inhibitor and KI on the galvanic electrode. Colloids Surf. A Physicochem. Eng. Asp. 281(1–3), 147–155 (2006)

A. Chetouani, B. Hammouti, A. Aouniti, N. Benchat, T. Benhadda, New synthesised pyridazine derivatives as effective inhibitors for the corrosion of pure iron in HCl medium. Prog. Org. Coat. 45(4), 373–378 (2002)

B.G. Ateya, B.E. El-Anadouli, F.M. El-Nizamy, The effect of thiourea on the corrosion kinetics of mild steel in H2SO4. Corros. Sci. 24(6), 497–507 (1984)

B.G. Ateya, B.E. El-Anadouli, F.M. El-Nizamy, The adsorption of thiourea on mild steel. Corros. Sci. 24(6), 509–515 (1984)

M. Metikoš-Hukovič, R. Babić, Z. Grubač, S. Brinić, Impedance investigation of corrosion inhibition of armco iron by thiourea. J. Appl. Electrochem. 26(4), 443–449 (1996)

T.P. Hoar, R.D. Holliday, The inhibition by quinolines and thioureas of the acid dissolution of mild steel. J. Chem. Technol. Biotechnol. 3(11), 502–513 (1953)

M. Özcan, I. Dehri, The effect of temperature on the corrosion of mild steel in acidic media in the presence of some sulphur-containing organic compounds. Mater. Chem. Phys. 98(2–3), 316–323 (2006)

F.M. Mahgoub, Effect of protonation on the inhibition efficiency of thiourea and its derivatives as corrosion inhibitors. Anti-Corros. Methods Mater. 55(6), 324–328 (2008)

K. Chandrasekhara Pillai, R. Narayan, Inhibition of corrosion of iron in acids by thiourea and derivatives. J. Electrochem. Soc. 125(9), 1393–1397 (1978)

G. Oakes, J.M. West, Influence of thiourea on the dissolution of mild steel in strong hydrochloric acid. Br. Corros. J. 4(2), 66–73 (1969)

H.T. Rahal, A.M. Abdel-Gaber, G.O. Younes, Inhibition of steel corrosion in nitric acid by sulfur containing compounds. Chem. Eng. Commun. 203(4), 435–445 (2016)

C. Cao, On electrochemical techniques for interface inhibitor research. Corros. Sci. 38(12), 2073–2082 (1996)

L. Tang, X. Li, Y. Si, G. Mu, G. Liu, The synergistic inhibition between 8-hydroxyquinoline and chloride ion for the corrosion of cold rolled steel in 0.5 M sulfuric acid. Mater. Chem. Phys. 95(1), 29–38 (2006)

A.M. Abdel-Gaber, M.S. Masoud, E.A. Khalil, E.E. Shehata, Electrochemical study on the effect of Schiff base and its cobalt complex on the acid corrosion of steel. Corros. Sci. 51(12), 3021–3024 (2009)

M. Lebrini, M. Lagrenée, H. Vezin, M. Traisnel, F. Bentiss, Experimental and theoretical study for corrosion inhibition of mild steel in normal hydrochloric acid solution by some new macrocyclic polyether compounds. Corros. Sci. 49(5), 2254–2269 (2007)

A.K. Satpati, P.V. Ravindran, Electrochemical study of the inhibition of corrosion of stainless steel by 1, 2, 3-benzotriazole in acidic media. Mater. Chem. Phys. 109(2–3), 352–359 (2008)

P. Bommersbach, C. Alemany-Dumont, J.P. Millet, B. Normand, Hydrodynamic effect on the behaviour of a corrosion inhibitor film: characterization by electrochemical impedance spectroscopy. Electrochim. Acta 51(19), 4011–4018 (2006)

M. Lagrenee, B. Mernari, M. Bouanis, M. Traisnel, F. Bentiss, Study of the mechanism and inhibiting efficiency of 3, 5-bis (4-methylthiophenyl)-4H-1, 2, 4-triazole on mild steel corrosion in acidic media. Corros. Sci. 44(3), 573–588 (2002)

P.J. Flory, Inhibitive action of some plant extracts on the corrosion of steel in acidic media. J. Chem. Phys. 10, 51 (1942)

A.A. El-Awady, B.A. Abd-El-Nabey, S.G. Aziz, Kinetic-thermodynamic and adsorption isotherms analyses for the inhibition of the acid corrosion of steel by cyclic and open-chain amines. J. Electrochem. Soc. 139(8), 2149–2154 (1992)

M.I. Temkin, Kinetics of heterogeneous catalysis. J. Phys. Chem. (USSR) 14, 1153–1158 (1940)

B.A. Abd-El-Nabey, A.M. Abdel-Gaber, G.Y. Elawady, S. El-Houssein, Inhibitive action of some plant extracts on the alkaline corrosion of aluminum. Int. J. Electrochem. Sci. 7, 7823–7839 (2012)

N.O. Eddy, E.E. Ebenso, Inhibitive and adsorption properties of Musa sapientum for the corrosion of mild steel in acid medium. Afr. J. Pure Appl. Chem. 2, 46–54 (2008)

H. Ashassi-Sorkhabi, B. Shaabani, B. Aligholipour, D. Seifzadeh, The effect of some Schiff bases on the corrosion of aluminum in hydrochloric acid solution. Appl. Surf. Sci. 252(12), 4039–4047 (2006)

J.T. Nwabanne, V.N. Okafor, Adsorption and thermodynamics study of the inhibition of corrosion of mild steel in H2SO4 medium using vernonia amygdalina. J. Miner. Mater. Charact. Eng. 11(9), 885–890 (2012)

O.R. Khalifa, S.M. Abdallah, Corrosion inhibition of some organic compounds on low carbon steel in hydrochloric acid solution. PEA 29(1), 47–56 (2011)

I.B. Obot, Synergistic effect of nizoral and iodide ions on the corrosion inhibition of mild steel in sulphuric acid solution. Port. Electrochim. Acta 27, 539–553 (2009)

R.Y. Khaled, A.M. Abdel-Gaber, H.M. Holail, Electrochemical studies of the inhibition effect of 4,6-dichloro-2-(methylthio) pyrimidine on the corrosion of AISI type 321 stainless steel in 1.0 M hydrochloric acid. Int. J. Electrochem. Sci. 11, 2790–2798 (2016)

G. Cristofari, M. Znini, L. Majidi, A. Bouyanzer, S. Al-Deyab, J. Paolini, B. Hammouti, J. Costa, Chemical composition and anti-corrosive activity of Pulicaria mauritanica essential oil against the corrosion of mild steel in 0.5 M H2SO4. Int. J. Electrochem. Sci. 6, 6699–6717 (2011)

S. Saravanamoorthy, S. Velmathi, Physiochemical interactions of chiral Schiff bases on high carbon steel surface: Corrosion inhibition in acidic media. Prog. Org. Coat. 76(11), 1527–1535 (2013)

T. Koopmans, Ordering of wave functions and eigen values to the individual electrons of an atom. Physica 1(1–6), 104–113 (1934)

R.G. Pearson, Absolute electronegativity and hardness: applications to organic chemistry. J. Org. Chem. 54(6), 1423–1430 (1989)

I. Lukovits, E. Kalman, F. Zucchi, Corrosion inhibitors—correlation between electronic structure and efficiency. Corrosion (NACE) 57(1), 3–8 (2001)

M. Bouklah, N. Benchat, B. Hammouti, A. Aouniti, S. Kertit, Thermodynamic characterisation of steel corrosion and inhibitor adsorption of pyridazine compounds in 0.5 M H2SO4. Mater. Lett. 60(15), 1901–1905 (2006)

N. Khalil, Quantum chemical approach of corrosion inhibition. Electrochim. Acta 48(18), 2635–2640 (2003)

H. Zarrok, A. Zarrouk, R. Salghi, H. Oudda, B. Hammouti, M.E. Touhami, M. Bouachrine, S. Boukhris, A combined experimental and theoretical study on the corrosion inhibition and adsorption behaviour of quinoxaline derivative during carbon steel corrosion in hydrochloric acid. PEA 30(6), 405–417 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saad, I.R., Abdel-Gaber, A.M., Younes, G.O. et al. Thiourea and N-Methylthiourea as Corrosion Inhibitors for Steel in Phosphoric Acid. J Fail. Anal. and Preven. 18, 1293–1299 (2018). https://doi.org/10.1007/s11668-018-0522-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0522-5