Abstract

Composite coating techniques are becoming increasingly popular owing to their peculiar performances. In this study, the wear resistance of thermally sprayed Ni-MoS2 composite coatings on an AISI 1020 steel substrate was investigated. Ni-MoS2 composite powder (size: 60-90 μm) containing 25 wt.% of dispersed MoS2 was prepared by electroless plating. Ni-MoS2 composite coatings were then prepared by HVOF thermal spraying. The coatings were characterized by structural, surface morphological, and compositional analyses by means of microhardness tests, SEM/EDS, XRD, and ICP-AES. For the evaluation of their anti-wear properties, the composites were subjected to ball-on-disk dry wear tests based on the ASTM G99 standard at room temperature. Experimental results showed that some of the MoS2 content dispersed in the Ni-based composite coating burnt away during the high-temperature spraying process, thereby reducing the MoS2 concentration in the coating. In the wear test, the weight loss in the Ni-MoS2 composite coating was minimal under a low load (<15 N) but increased rapidly with increasing load (>30 N). The average wear rate of the coatings was found to be ~1/40 times that of a Ni coating, showing that the wear resistance of the composite coatings was significantly improved by MoS2 addition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The 1020 carbon steel is widely used in the iron and steel material industry owing to its advantages of low price and high strength. It is commonly used for fabricating structural and mechanical components. The use of this steel can be further increased by subjecting it to suitable surface treatments. Iron and steel components are subjected to bending, wearing, rotating, or sliding loads at various sites. These components are not coated for maintaining their dimensional accuracy but are often plated with chromium at the loading sites to enhance their wear resistance. The use of chromium poses serious threats to human health and environment; thus, research is being conducted for finding alternatives to chromium plating.

Tribology is the study of friction, wear, and lubrication of interacting surfaces between two moving objects. Friction is a major problem for almost all types of industries, as it causes wear, heat, and unnecessary energy consumption. The energy used to overcome friction turns into heat, and it is estimated that about 30-50% of the cost is that spent on replacing worn components. It is therefore very important to minimize the friction between moving parts. Frictional force is a resistant force that occurs when two contacting surfaces slide against each other, and it needs to be maintained at an optimum level to achieve a smooth and efficient operation of the machinery.

The wear resistance of a coating can be improved by increasing the hardness, changing the chemical composition, reducing roughness and friction coefficient, and adding an appropriate lubricant. The wear resistance of a coating can be improved by chemical and physical methods. The physical ones include adding a solid lubricant at the interface between the two contacting surfaces to act as a buffer, and the lubricant will avoid direct friction between the two surfaces.

The term “self-lubricating” indicates that characteristics can be reduced from the friction coefficient of a frictional surface without adding lubricant. The results of the wear test in this study indicate that the wear rate of Ni-MoS2 composite coatings reduced significantly without the addition of lubricant. This evidence suggests that HVOF Ni-MoS2 composite coatings are self-lubricating.

Shawki et al. study the wear resistance of Ni-based composite coatings prepared by electroplating. Ni-P-SiC coatings have the highest hardness and wear resistance of all commercial coatings, as wear resistance increases with the SiC concentration (>4 wt.%) (Ref 1).

Cardinala et al. used pulsed electroplating to prepare Ni-W-MoS2 composite coatings, and added sodium dodecyl sulfate (SDS) as a surface active agent for achieving an even dispersion of MoS2 particles in the solution. As the MoS2 concentration increased, the tungsten content in the solution and microhardness reduced. When the MoS2 concentration in the solution was low (<0.5 g/L), the friction coefficient of the coating reduced; however, if the concentration was increased beyond a limit (>1.0 g/L), the coating became soft like sponge and its surface became irregular, thus reducing the binding force and wear resistance (Ref 2).

Zhang et al. prepared self-lubricating composite coatings of Ni-CaF2-WS2 by high-velocity oxygen fuel (HVOF) spraying, and investigated the wear resistance of Ni45-10%CaF2-5%WS2 and Ni45-5%CaF2-10%WS2. The friction coefficient of Ni45-10%CaF2-5%WS2 was low (0.31-0.41) under a load of 40 N and a speed of 2 m/s in the wear test. When the speed was reduced to 1 m/s, the friction coefficient was still low (0.35-0.46) but was greater than that at 2 m/s (Ref 3).The development of thermal-sprayed coatings is essential for increasing the wear and corrosion resistances of materials employed in numerous applications such as power generation and in the steel, chemical, and aerospace industries. Thermal-sprayed composite coatings are generally classified into four types: metal matrix composites, ceramic matrix composites, polymer matrix composites, and intermetallic composites. These composite coatings are usually sprayed from a pre-prepared powder by various methods such as blending, spray drying agglomeration, mechanical alloying, self-propagating high-temperature synthesis, electroplating, and electroless plating. The HVOF process is a potential coating method for developing adherent and uniform coatings with low porosities and oxide contents; it can even be employed in high temperature, severely corrosive, and erosive environments. In addition, thermal spraying is also a novel process for the preparation of intermetallic compounds, metal matrix composite coatings, ceramic matrix composite coatings, functional gradient coatings, and duplex layers (Ref 4, 5) using composite wires or composite powders such as premixed powder (Ref 6), mechanically alloyed powder (Ref 7, 8), cored powder (Ref 9), or agglomerated nanopowder. Some composite coatings have been prepared by pseudo-arc spraying, in which two dissimilar wires are fed synchronously (Ref 10, 11).

The discussion in the previous paragraph shows that only a few studies have been focused on thermally sprayed self-lubricated coatings, and most of the feedstock powders for thermal spraying are prepared by pre-blend or mechanical alloys from which it is hard to form a uniformly dispersed composite coating. In this study, the wear resistance of thermally sprayed Ni-MoS2 composite coatings was investigated. The feedstock powders used in this study were Ni-MoS2 core-shell composite powders containing 25 wt.% dispersed MoS2. The powders were prepared by electroless Ni-plating technology, and the powder sizes were in the range 60-90 μm. The Ni-MoS2 composite coatings were subsequently fabricated by the HVOF process and were characterized by structural, surface morphological, and compositional analyses using microhardness tests, scanning electron microscopy/energy-dispersive spectroscopy (SEM/EDS), x-ray diffraction (XRD), and inductively coupled plasma atomic emission spectroscopy (ICP-AES). Ball-on-disk dry wear tests based on the ASTM G99 standard were performed at room temperature to evaluate the anti-wear properties of the coatings.

We hope to use this composition for preparing metal and solid lubricant particles for spray coating to create a uniform coating. This can reduce the friction coefficient of the frictional surface on steel. Common types of solid lubricants are polymer or ceramic, which are nonconductive. Several processes are used to form composite powder containing metal and solid lubricants. The most common, simple process is electroless plating. Nickel is a kind of electroless plating solution; it is suitable for coating copper and steel. Its corrosion resistance is better than copper and more active than iron. The Ni-MoS2 core-shell composite powders used in this study were prepared by electroless plating; the Ni-MoS2 composite coatings were subsequently fabricated by the HVOF process. The results of this study indicate that the Ni-MoS2 composite coatings are uniform.

Experimental Apparatus and Procedure

Preparations of Ni-MoS2 Composite Powders and Coatings

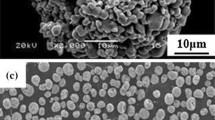

The Ni-MoS2 composite powders were prepared by subjecting MoS2 powders to Ni electroless plating. The particle size of the MoS2 powders before plating was about 20-50 μm. The plating temperature was controlled between 65 and 80 °C, and the pH value of the solution ranged from 6.1 to 6.4. The ratio of powder to plating solution was 10 g MoS2 powder for 3 L plating solution. The ICP-AES analysis results showed that the Ni-MoS2 powders were composed of 72.2 wt.% Ni and 27.8 wt.% MoS2. SEM images of the Ni-MoS2 powders are shown in Fig. 1. The geometry of the Ni-MoS2 powders was irregular after electroless plating, and the particle size ranged from 60 to 90 µm.

A 3-mm-thick AISI 1020 low-carbon steel plate was cut into smaller plates of 100 × 100 mm; the cut-out plates were used as specimens in this experiment. All the specimens were pretreated by grit blasting to a white metal finish to meet the Swedish standard (SIS 05 59 00 Sa3) prior to spraying. The prepared specimens were subsequently sprayed with the Ni-MoS2 composite powders using the HVOF process, with two passes of cross spray for each specimen. The Sulzer Metco DJ 2600 HVOF spray system consisting of a powder feeder, programmable logic control (PLC) panel, and a spray torch that were used in our experiments; the operating parameters for the spraying process are listed in Table 1.

Ni coatings were prepared using dual Ni wires (99.9% pure) by the arc spraying process, carried out at an arc current of 200 A, an arc voltage of 28 V, and an atomizing pressure of 60 psi. The thicknesses of the Ni coatings ranged from 250 to 300 μm. The Sulzer Metco SmartArc spray system consisting of a power supply, a PLC panel, and an arc spray torch that were used in this process.

Analysis of Coating Characteristics

Numerous analyses and measurements, including microhardness tests (Matsuzawa MXT70), XRD analyses (Philips PW1840), friction coefficient tests (Oakland FX-7000), and ICP-AES and SEM observations (Philips SL40), were carried out to determine the characteristics of the composite coatings.

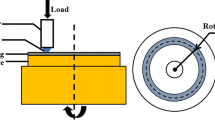

Ball-on-Disk Wear Test

Ball-on-disk wear tests were performed at room temperature according to the ASTM G99 standard. An AISI E52100 chromium steel ball with a diameter of 6.35 mm and average hardness of HRC 60 ± 2 was used in this study. The wear-test conditions are listed in Table 2. A constant load of 56 N was applied, and the test ball was slid at three different sliding velocities: 6, 8, and 10 m/min. The sliding distances were set at 50, 100, and 200 m. The weight loss in both the coatings and steel ball before and after the wear test was measured using an electronic analytical balance (Mettler AT261; Mettler) with a minimum reading of 0.01 mg. The anti-wear performance of the test specimens was defined by their wear rate, which is defined as the weight loss (mg) per unit of distance traveled (m).

Results and Discussion

Coating Characteristics

SEM Analysis Results

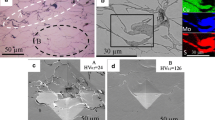

Surface and cross-sectional SEM photographs of the HVOF Ni-MoS2 composite coatings are shown in Fig. 2. Figure 3 shows the surface morphologies of the HVOF Ni-MoS2 composite coatings prepared using electroless-plated Ni-MoS2 composite powders. It is clear from the figure that the coatings are composed of white, gray, and black regions, and the EDS analysis shown in Fig. 4 reveals that these white and gray regions correspond to Ni and MoS2, respectively. As seen in Fig. 2, the surface SEM image exhibits a uniform mixture of Ni and MoS2. The black region is composed of porosity voids that were formed during the spray process as a result of trapped gases or shrinkage during solidification; however, only a few porosity voids are observed inside the HVOF Ni-MoS2 coating. The cross-sectional SEM photograph of the HVOF-sprayed Ni-MoS2 coating shown in Fig. 3 exhibits a dense and uniform structure, with no significant defects or voids observed in the coating.

XRD Analysis Results

The XRD analysis results for both Ni-MoS2 powders and coatings are shown in Fig. 5. The diffraction profile indicates that the Ni-MoS2 powder is composed of only Ni and MoS2. The compositions of the Ni-MoS2 coatings are more complicated than that of the raw powder; the coatings are mainly composed of Ni, MoS2, and Ni3S2. A lot of research (Ref 12, 13) has been focused on the high-temperature synthesis behavior of the HVOF process, as this process is always conducted at high temperatures and with a high impact speed of molten droplets. The XRD pattern reveals that some sulfur atoms are decomposed from MoS2 and are subsequently synthesized with Ni during molten droplet flying, flattening, and cooling.

ICP-AES Analysis Results

The ICP-AES analysis results show that the Ni-MoS2 powders are composed of 72.2 wt.% Ni and 27.8 wt.% MoS2, and the HVOF Ni-MoS2 composite coatings are composed of 81.4 wt.% Ni and 18.6 wt.% MoS2. This evidence indicates that some of the MoS2 content is burnt away during the thermal-spraying process. From the viewpoint of thermodynamics, the Mo element is more easily combined with oxygen than sulfur. MoS2 may react with oxygen to cause the gaseous formation of MoO2 and SO2. Therefore, the content of MoS2 decreases in the HVOF Ni-MoS2 composite coatings. The ICP-AES analysis results are consistent with the XRD analysis results discussed in section 3.1.2, in that some sulfur atoms are decomposed from MoS2 and are subsequently synthesized with Ni, resulting in a decrease in the MoS2 content.

Microhardness Measurements

The microhardness results show that the average microhardness of the arc-sprayed Ni coatings is Hv 0.1 = 228.6 after five tests with the test load fixed at 100 gf. The microhardness values of the arc-sprayed Ni coatings are slightly higher than that of pure Ni wire, which has an average microhardness of Rb58.

Extensive research (Ref 12, 13) has focused on the high-temperature synthesis behavior of the HVOF process because this process is always conducted at high temperatures and with a high impact speed of molten droplets. The effects of high temperature and high impact speed of molten droplets on the Ni-based matrix may form the reaction of Ni and S that results from the decomposition of MoS2. The connection between the Ni3S2 phase and the Ni-based matrix may represent an excellent coherence that is resistant to deformation. Consequently, the distribution of Ni3S2 phases may improve the strength of the Ni-based matrix and increase microhardness in the HVOF Ni-MoS2 composite coatings.

Friction Coefficient Measurements

The friction coefficients of the Ni and Ni-MoS2 coatings were evaluated using an Oakland FX-7000 film coefficient-of-friction tester, which meets the specifications of the ASTM D1894 standard. A 3-mm-thick specimen was cut into smaller plates of dimensions 50 × 50 mm, and the net weight of the specimen was 60 g. Prior to the friction coefficient test, both the Ni and Ni-MoS2 coatings were polished to obtain an average surface roughness (R a) of less than 1.6 μm. The coated specimen was connected to a 250 g load cell with a minimum reading of 0.1 g, and then placed on a screw-driven, stainless steel slide sled at a constant traveling speed of 150 mm/min. The frictional force was measured while the sled was moving backward, and the coefficient of friction was obtained by dividing the value of the frictional force needed to move the specimen over the sled at a constant speed by the normal force equal to the self-weight of the specimen. The average friction coefficients for the Ni and Ni-MoS2 coatings against the stainless steel sled as obtained from the test results were 0.55 and 0.32, respectively, after five tests. Thus, it can be concluded that the addition of MoS2 powders significantly reduced the friction coefficient of the Ni coating and led to a decrease in wear loss.

Ball-on-Disk Test Results

The results of the ball-on-disk tests are presented in Table 2 and are illustrated in Fig. 6, 7, 8, and 9. The optical micrographs of the coating and steel-ball surface morphologies after the wear tests are shown in Fig. 8. The wear resistance properties of the composite coatings were evaluated from their wear rate, which is defined as the ratio of weight loss to distance traveled. The average wear rates of the HVOF Ni-MoS2 coating and arc-sprayed Ni coating after a traveling distance of 200 m were 0.164 and 7.225 mg/m, respectively. The HVOF Ni-MoS2 coating exhibited better wear resistance than the Ni coating; the wear resistance of the HVOF Ni-MoS2 coating was 40 times better than that of the Ni coating. By comparing the wear-test results for coatings subjected to a constant traveling distance but under different loads, we inferred that the weight loss in the coatings was proportional to the normal load: the heavier the load, the greater the wear loss.

By comparing the wear-test results under constant loads but at different traveling speeds, it was found that at both low (6 m/min) and high (10 m/min) traveling speeds, the weight loss in the HVOF Ni-MoS2 coatings was very low. Severe wear was observed at a medium traveling speed (8 m/min). The phenomenon of friction is associated with stress and temperature. At low speeds, stress is extensive at the same loads; the phenomenon of friction is abrasion, so we inferred that the load was proportional to the wear rate. When the speed increases gradually, the effect of temperature on frictional surface is more obvious, the stress is lessened, and the phenomenon of friction is transformed to adhesion. In summary, the additional effects of stress and temperature are maximized at the speed of 8 m/min.

Wear occurs when two surfaces slide against each other, and it depends on various factors such as hardness, size of wear debris, loading force, and sliding speed. In sliding contact, the harder surface (e.g., a counter steel ball) is immersed into and plows the softer surface (e.g., Ni and Ni-MoS2 coatings). Plowing increases the friction force and generally produces wear debris, which is trapped at the interface, resulting in more friction and more serious wear. High contact stresses in small areas cause a localized bonding phenomenon (cold welding); the coating material is broken away and sticks on the harder surface, exhibiting adhesive wear.

As shown in Fig. 10, the widths of the wear traces of the coatings under loads of 15, 30, and 60 N are 371.09, 559.34, and 1189.6 μm, respectively. Under low normal loading, the counter ball only slides on the coating surface, leading to a low weight loss and small wear trace width. In the case of heavy normal loading, the steel ball is stuck deeply into the coating, resulting in a larger wear trace.

Conclusions

In this study, Ni-MoS2 composite coatings containing a Ni matrix and a MoS2-dispersed phase were prepared. Tests performed to determine the coating characteristics revealed that MoS2 was uniformly distributed in the composite coating but some of the MoS2 content was burnt away during the thermal-spraying process. MoS2 addition reduced the friction coefficient of the Ni coating from 0.55 to 0.32.

Further, the wear resistance of the Ni coating was enhanced upon the addition of MoS2: the wear resistance of the HVOF Ni-MoS2 composite coating was 40 times better than that of the Ni coating.

References

S. Shawki and Z.A. Hamid, Deposition of High Wear Resistance of Ni-Composite Coatings, Aircr. Eng. Aerosp. Technol., 1997, 69(5), p 432-439

M.F. Cardinala, P.A. Castroa, J. Baxic, H. Liangc, and F.J. Williams, Characterization and Frictional Behavior of Nanostructured Ni-W-MoS2 Composite Coatings, Surf. Coat. Technol., 2009, 204(1-2), p 85-90

X. Zhang, X. Zhang, A. Wang, and Z. Huang, Microstructure and Properties of HVOF Sprayed Ni-based Submicron WS2/CaF2 Self-lubricating Composite Coating, Trans. Nonferrous Met. Soc. China, 2009, 19(1), p 70-85

X.J. Liu, B.C. Xu, S.I. Ma, and Z.G. Chen, Wear, 1997, 211, p 151-155

P. Jokinen, K. Korpiola, and A. Mahiout, J. Therm. Spray Technol., 2002, 9, p 241-244

J.H. Ahn, B.C. Hwang, and S.H. Lee, J. Therm. Spray Technol., 2005, 14, p 251-257

B. Wielage, J. Wilden, T. Schnick, A. Wank, J. Beczkowiak, R. Schülein, H. Zoz, and H. Ren, Mechanically Alloyed SiC Composite Powders for HVOF Applications, Proc. Int. Therm. Spraying Conf., E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Verlag, 2002, p 1047-1051

J.B. Zhou and K.P. Rao, J. Alloys Compd., 2004, 384, p 125-130

B.S. Xu, Z.X. Zhu, S.N. Ma, W. Zhang, and W.M. Liu, Wear, 2004, 257, p 1089-1095

N. Sakoda, M. Hida, Y. Takemoto, A. Sakakibara, and T. Tajiri, J. Jpn. Inst. Met., 2002, 66, p 1304-1310

T. Sato, A. Nezu, and T. Watanabe, Trans. Mater. Res. Soc. Jpn., 2000, 25, p 302

R. Goswami, S. Sampath, H. Herman, and J.B. Parise, J. Mater. Res., 2000, 14, p 25-28

R. Goswami, S. Sampath, H. Herman, and J.B. Parise, J. Mater. Res., 1999, 14, p 3489-3492

Acknowledgments

This study was supported by a National Science Council grant for project publication (project number: NSC99-2221-E-008-020-MY2).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y.L., Jeng, M.C., Hwang, J.R. et al. A Study on Wear Resistance of HVOF-Sprayed Ni-MoS2 Self-Lubricating Composite Coatings. J Therm Spray Tech 24, 489–495 (2015). https://doi.org/10.1007/s11666-014-0208-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0208-9