Abstract

In the present study, the effect of processing parameters like annealing temperature, excess of lead (Pb) content, and film thickness on the crystallographic orientation, dielectric and ferroelectric properties of PLZT (Pb/La/Zr/Ti: 92/8/52/48) films are investigated. For the investigation, PLZT films were prepared on Pt/Ti/SiO2/Si substrate by chemical solution deposition method and annealed at different temperatures (600, 625, 650, 675, and 700 °C). Diverse growth orientation was observed for different annealing temperatures that gave rise to modified electrical properties in the PLZT films. Comparative studies on processing temperature exhibited improved ferroelectric properties in 650 °C annealed PLZT film, which is attributed to its crystallinity (Full width at half maximum, FWHM101 = 0.49°) and texture coefficient (γ = 0.832). Excess Pb content (3 wt.%) yielded improved ferroelectric properties in PLZT film with a ~ 10% increment in domain switching. The PLZT film with 3 wt.% Pb-excess content showed an ASTM class 5B adhesion on Pt/Ti/SiO2/Si substrate, a nano-hardness value of 7894.43 MPa, and a Young’s modulus value of 143.05 GPa. To further study the effect of process control parameters on PLZT film, variation of thicknesses (492, 768, and 1500 nm) was studied for 3 wt.% Pb-excess film. The study showed considerable domain switching (switching current = 58.10 μA at 40 kV/cm), improved dielectric constant (~ 2750), higher polarization (Pmax = 71.4 μC/cm2) at a low electric field 334 kV/cm and low leakage current for 1500 nm thick PLZT film. A total energy storage density of ~ 26 J/cm3 at 1020 kV/cm and tunability of 68.46% at ~ 200 kV/cm was achieved for PLZT film with 3 wt.% excess Pb.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The lead-based ferroelectric systems have superior dielectric, piezoelectric, and energy storage properties (Ref 1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26). Among those, the lanthanum-modified lead zirconate titanate (PLZT) (Pb1−xLax)(Zr1−yTiy)O3 systems have been extensively studied in recent years for microelectronics, microelectromechanical systems (MEMS), pulsed power capacitors, electro-optic applications, ferroelectric non-volatile memories (NV-FeRAMs), high density dynamic random access memories, infrared pyroelectric detectors, decoupling capacitors, microsensors, etc., due to their exceptional dielectric, piezoelectric, and electro-optic characteristics (Ref 1, 27,28,29,30,31). The elementary operation of these ferroelectric devices is solely based on their polarization switching in response to external factors such as temperature, stress, and electric field (Ref 32). These switching studies are essential to understand the functionality of every ferroelectric system. For instance, the primary determinant of read/write operations in NV-FeRAMs is polarization switching (Ref 33).

Designing ferroelectric devices for specific applications requires careful consideration of process temperature (Ref 34) since it influences the ferroelectricity of the system. The study on the perovskite CH3NH3PbI3 film by F. Wang et al. reports altered crystallinity and crystal size, causing different domain behaviors at different annealing temperatures (Ref 35). In the HfO2:SiO2 thin films, a significant process temperature dependence of the remnant polarization, breakdown field, and leakage current densities was reported (Ref 36). In addition, a decrease and an increase in the remnant polarization and the coercive electric field, respectively, were observed in sol–gel deposited BFO thin films with increasing annealing temperature (550–650 °C) (Ref 37). Previous other studies have also shown that the presence of excess lead (Pb) content and annealing temperature can greatly change the electrical characteristics by changing the microstructural properties such as nucleation, perovskite growth, crystalline orientation, grain size, and shape of PLZT films (Ref 27, 38,39,40,41,42,43). Additionally, numerous researches confirm that the properties of films change with their thickness as well (Ref 30, 44,45,46,47,48,49,50,51). The phenomenological theory has been used to conceptually explain the switching kinetics in ferroelectrics (Ref 52,53,54). These kinetics have then been experimentally explored by measuring switching current transients or by analyzing domain motions (Ref 55,56,57).

Although the ferroelectric properties of PLZT system are well known, no literature reports the combined effect of various processing parameters on the crystallographic orientation causing the variation in dielectric and ferroelectric properties of PLZT films. As the Pb volatilization and/or Pb diffusion into the bottom substrate during the heat treatment disrupts the stoichiometry of the system and results in the formation of non-ferroelectric pyrochlore phase (Ref 38, 39, 41), the processing temperature is lowered/adjusted to minimize the Pb volatility (Ref 39). Furthermore, definite amount of Pb-excess contents are also added to the precursor solution to maintain its stoichiometry (Ref 40). Considering the above facts, the effect of process control parameters (like Pb-excess content in the composition, annealing temperature and thickness of the film) on physical (structure, microstructure, mechanical) and functional properties (ferroelectric properties and domain switching) of PLZT film (La/Zr/Ti = 8/52/48) is investigated thoroughly in the present study. The PLZT composition chosen for the study is the best composition reported by many for dielectric and ferroelectric properties (Ref 58,59,60,61). There are various film deposition techniques available for PLZT films; this paper reports the process control parameters associated with Chemical Solution Deposition (CSD) of the film considering its advantages of cost effectiveness, excellent control over stoichiometry and non-availability of such reports.

2 Experiments

The precursor solution for the PLZT composition of molecular formula (Pb0.92La0.08) (Zr0.52Ti0.48)O3 (PLZT) was prepared chemically as reported earlier with different Pb-excess content (0, 1, 2, 3, and 5 wt.%) (Ref 29, 62). The precursor solution was then spin-coated on Pt (111)/Ti/SiO2/Si substrates at an rpm of 6500 for 30 s, followed by two-step pyrolysis at 500 and 650 °C to remove the organics. In spite of the fact that Pt-coated Si substrates have more fatigue properties than oxide electrodes, Pt/Ti/SiO2/Si substrates were used in the study due to their high electrical conductivity, high chemical resistance, and wafer scalability (Ref 63). The spinning and pyrolysis process was repeated until the desired thickness is achieved. Three different thicknesses (492, 768, and 1500 nm) were prepared to study the thickness effect on the microstructure and electrical properties of the PLZT film. All the PLZT films of different Pb-excess contents were annealed at 600, 625, 650, 675, and 700 °C, for 30 min in the air atmosphere. The PLZT films with 0, 1, 2, 3, and 5 wt.% Pb-excess contents are named PLZT0, PLZT1, PLZT2, PLZT3, and PLZT5, respectively. Electrode layer (Ag) at the top of the film was deposited in a circular dot pattern of 0.3 mm diameter using a physical mask while thermal vapor deposition. A typical schematic representation of the thin film stack is given in Fig. 1. The XRD (X-pert, Copper_kα, λ = 1.54 Å) of the thin film samples were taken to investigate the phase formation and crystal structure. The microstructure of the films was studied through FESEM (SEM, Carl Zeiss supra 40 VP with Gemini column) images and thickness was measured by Dektak XT surface profilometer. The dielectric, piezoelectric and ferroelectric property measurements were carried out using thin-film analyzer (aixACCT FE 2000).

Once the process parameters are optimized for the improved ferroelectric properties, the mechanical properties of the film were also studied by nano-hardness test and cross-hatch adhesion test. Nano-hardness measurements of PLZT film (1500 nm thick) was carried out using a diamond indenter in NHT S/N: 04-00,114 instrument. The data acquired under linear loading mode, with a maximum applied load of 3.00mN. The provided loading and unloading rate was 6.00 mN/min with a pause time of 2 s. Five indents were made on each samples to measure the average hardness and Young’s modulus values. For the ASTM D3359 adhesion test, a cross-hatch cutter (Elcometer 107) having 11 metal blades of 1 mm apart was chosen. Even cuts of 1 mm apart were made on the samples by scraping the cutter through the samples with sufficient pressure, ensuring the cutting edge hits the substrate. The film was then softly brushed to remove the possible detached flakes. Additional cuts were made at 90° to the previous cuts, followed by soft brushing. A pressure-sensitive tape was then placed over the engraved grid region, ensuring not to entrap air under the tape. The tape was then smoothly rubbed using fingers to establish uniform and firm contact between the tape and coating. The tape was then removed at an angle of 180° and the grid area is inspected under an optical microscope (Unitron) at 5X magnification.

3 Experimental Results

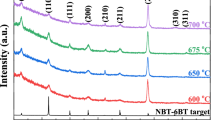

3.1 XRD Pattern Analysis

Figure 2(a)-(e) shows the low glancing angle (1 °C) XRD θ-2θ scans of the PLZT films having different Pb-excess content and annealed at different temperatures. All the PLZT films exhibited the tetragonal perovskite phase of PLZT crystal with no secondary phase and are in good agreement with the JCPDS card no: 00-046-0504. To compare the growth orientation in each films, the texture coefficient (γ) is calculated using the equation below (Ref 64, 65).

where Ihkl represents the intensity of XRD peak measured from the plot, I0 hkl represents the standard intensity value of PLZT powder sample, taken from JCPDS card number 00-046-0504 for particular (hkl) plane, and N represents the number of diffraction peaks. The calculated texture coefficient value of each film is compared with their corresponding full-width half maximum (FWHM) value in Fig. 3(a)-(e).

FWHM & texture coefficient of PLZT film as calculated from XRD pattern (Fig. 1) (a) PLZT0, (b) PLZT1, (c) PLZT2, (d) PLZT3, and (e) PLZT5 film, and (k) lattice parameter & c/a ratio of PLZT films plotted against excess Pb content

From the above figures, it is observed that the films annealed at 650 °C shows higher γ value and lower FWHM which is desirable for directional orientation and better crystallinity (Ref 66,67,68). In PLZT film with no Pb-excess content, the γ value increased with increase in annealing temperature indicating maximum orientation along (101) direction, when the film is annealed at 650 °C (Fig. 3a). The 650 °C annealed PLZT0 film is the best because of its low full-width-half-maximum (FWHM = 0.49°) and high texture coefficient (γ = 0.83) values. All the PLZT1 films show low γ values, between 0.1 and 0.2 (Fig. 3b). It implies lack in particular orientation, which is desired. This leads to the lower functional properties of these films. Furthermore, all PLZT1 films showed high FWHM values. Hence, this set of films were not considered for further study. The PLZT2 films (Fig. 3c) show low FWHM and high γ. But due to the presence of the extra peak (at 2θ = ~ 52°), the XRD pattern does not match with the reported literature. Therefore, this set of films were discarded from further studies. From Fig. 3(d), it is verified that the 650 and 700 °C annealed PLZT3 films show low FWHM and high γ values. Therefore, these film samples were further studied for electrical property measurements. For PLZT5 films, the 700 °C annealed film shows highest γ and lowest FWHM value (Fig. 3e). But due to the presence of the extra peak (at 2θ = ~ 52°), the XRD pattern does not match with the reported literature. The same extra peak is also observed for 625, and 675 °C annealed films. Among this batch, the 650 °C annealed film was considered for further electrical studies due to its higher γ and low FWHM values compared to 600 °C annealed film.

The XRD spectra are further studied to calculate the intensity ratio of (111) peak to the maximum intensity peak (101) in PLZT0, PLZT3, and PLZT5 films, using the following expression:

The I/Imax ratio for (111) peak in PLZT0 films annealed at 600, 650, and 700 °C is 25, 16.5, 18.5%, respectively. This shows that the growth is more uniform towards (101) direction in PLZT0 film annealed at 650 °C and is consistent with the highly crystalline nature of the film obtained from the XRD results. However, as the Pb-excess content is raised to 5 wt.% (PLZT5_650), the I/Imax ratio for (111) peak is increased to ~ 52%, indicating mixed orientation. Such a mixed orientation in PLZT5_650 film can adversely affect the electrical properties (Ref 50, 69). To gain a deeper understanding on the crystallographic orientation of the films, Rietveld refinement is carried out using the tetragonal phase of P4mm space group (CIF file no: 1521044). The obtained lattice parameters are listed in Table 1. No peak shift is observed in the XRD patterns of prepared PLZT films. Here, the residual stress is insignificant on the films as they are much thicker (~ 1500 nm) than the critical thickness (Ref 70).

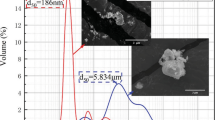

3.2 FESEM Image Analysis

The surface morphology of PLZT_650, PLZT3_650, and PLZT5_650 films was investigated using FESEM (Fig. 4a-c). All films exhibited a dense crack-free microstructure. The film thickness obtained from cross-sectional view is 1.5 µm for the cumulative layers (Fig. 4d). Further, the grain size and percentage of porosity of all the films were calculated using ImageJ software from the FESEM images and plotted against the Pb-excess content (Fig. 4e). The least percentage of porosity is observed in the PLZT3_650 film and might have contributed to the improvement in ferroelectric properties (Ref 27, 42, 43, 71).

FESEM images of (a) PLZT0_650, (b) PLZT3_650, and (c) PLZT5_650 film. Figure 3(d) is the cross-sectional view of PLZT3_650, and (e) plots the grain size and porosity of the PLZT films with Pb-excess content

3.3 Hysteresis Loops

Figure 5a represents the room temperature bipolar PE loops (frequency 100 Hz) of PLZT0 films annealed at different temperatures. PLZT0_650 film shows maximum polarization (Pmax) 65.8 μC/cm2 at 334 kV/cm. This is in good agreement with the enhanced crystallinity of the film verified using the XRD results (Fig. 3a). Similar enhancement in the polarization value is noted in PLZT3 film, when annealed at 650 °C (Fig. 5b). Therefore, PE-loop parameters of different Pb-excess films annealed at 650 °C are studied (Fig. 5c). In addition, the effect of annealing temperature, Pb-content, and thickness on the coercive field (Ec), remnant polarization (Pr), maximum polarization (Pmax), and hysteresis loss (Wloss) are shown in Fig. 6.

Figure 6(a) and (b) depicts the Pr, Pmax, Ec, and Wloss of PLZT0 film as a function of annealing temperature. The PLZT0 film annealed at 650 °C showed optimum Pmax value, lower Ec, and reduced Wloss. The reduced Ec value in the film indicates better domain switching at lower electric fields. The Pmax value reduction in the film annealed at 700 °C is due to the reduced crystalline quality of the film, as verified in the XRD analysis. In fact, the enhanced Pmax in PLZT0__650 film arises from the highly crystalline nature, which is consistent with the XRD results (Fig. 3a). The PLZT0_650 film, which exhibited the best ferroelectric properties, is then compared with other Pb-excess films (PLZT3_650 & PLZT5_650) to find the optimum composition (Fig. 6c, d). This comparison shows a higher Pmax of 71.4 μC/cm2 for PLZT3_650 film, which is attributed to the improved density and crystallinity of this film, as discussed before (Fig. 4e, 3d). It is reported that higher density increases the volume fraction of polarization domains (Ref 72). The variation of Pr value with different Pb-excess content (Fig. 6c) may also be associated with c/a ratio variation (Fig. 3f) (Ref 73). Furthermore, there is a gradual reduction in the Ec values as the Pb content increases. This can be attributed to the backfield effects that act on domain walls during domain switching (Ref 74). In an externally applied electric field, the backfields may work against the switching of domains. In contrast, the backfield favors domain switching in the absence of an external electric field. This can be further explained with the help of surface morphology. The grain size in the films increases with an increase in Pb-excess content and, thereby, reduces both grain boundary density and domain wall density (Ref 75,76,77). Consequently, backfield intensity reduces. This, in turn, creates a weaker clamping effect on domain walls (Ref 78, 79). Therefore, the ferroelectric/ferroelastic domain wall switching becomes easier with the increase in grain size in an applied electric field, yielding low Ec values (Ref 75). Since PLZT3_650 film showed improved ferroelectric performance with the variation of process control parameters like annealing temperature and excess Pb, the effect of film thickness was finally studied for same the film on its ferroelectric properties. The improvement in polarization value is observed with increased film thickness with the reduction in Ec and Wloss value in the film (Fig. 6e, f), which is desired for a device quality film.

3.4 Room Temperature Switching Current Plot

Figure 7(a) shows the switching current-electric field (I-E) plots of PLZT films. The absence of four switching peaks in the I-E plot suggests the high ferroelectric nature of PLZT films and is in good agreement with the P-E studies. The I-E plot further confirms the Ec values acquired from PE-loops. That is, at lower electric fields, the developed current is due to the dielectric response of the film. However, as the applied electric field increases, the current value peaks due to domain switching. The current contribution due to domain switching becomes prominent when the domain starts switching after crossing the threshold field. So the electric field corresponding to the maximum switching current in the I-E plot is the film’s coercive field (Ec) (Ref 80).

Relatively sharp and intense peaks are obtained for PLZT0_650 film (switching current = 51.5 μA at 45 kV/cm, Fig. 6a). Similar trend is observed in PLZT3 film, showing highest switching current when annealed at 650 °C (Fig. 7b). Among different Pb-excess samples, the sharpest and highly intense switching current peak is obtained for PLZT3_650 film (switching current = 58.10 μA at 40 kV/cm, Fig. 7c). It indicates the highest domain switching at a slightly lower electric field in PLZT3_650 film, with ~ 10% increment in its switching current value (Fig. 7e). This optimum film is prepared in different thickness and their switching current properties are plotted in Fig. 7d. The 768 nm thick PLZT film showed improved domain switching, at a slightly higher electric field of 70 kV/cm.

3.5 Room Temperature CV Plots

The room temperature C-V plots of PLZT films, measured at an applied voltage of 30 V and an input frequency of 1 kHz, are given in Fig. 8. The corresponding capacitance and dielectric constant values are tabulated in Table 2. The slight difference observed between the two peaks of each film is due to the difference in the top (Ag) and bottom (Pt) electrodes.

The room temperature capacitance value of the films initially increases with an increase in Pb-excess content (Fig. 8c). It corresponds to a very high dielectric value of ~ 2750 in the PLZT3_650 film, which is significantly higher than the previously reported values in other PLZT films (Ref 8, 58, 80,81,82,83,84,85,86,87,88,89,90). This can be correlated with its increased density, larger grain size, and lower percentage of porosity. As the Pb-excess content is further increased to 5 wt.% (PLZT5_650), the capacitance value is reduced. This variation in the capacitance (and dielectric constant) value depending on the Pb-content is associated with the microstructural changes in the film. Along with a higher percentage of porosity in this film, the domain switching current is also verified to be lower in PLZT5_650 film (Sect. 3.4, Fig. 7c). It indicates higher aggregation of point defects at the grain boundaries/domain boundaries, causing domain wall pinning (Ref 91,92,93,94). Consequently, the domain wall mobility reduces and correspondingly deteriorates the domain switching current. This pinning of domain walls by point defects causes low permittivity with increasing grain size (Ref 75).

The CV plots of different thickness PLZT films are shown in Fig. 8(d). The zero bias field dielectric constant values of 1500, 768, and 492 nm thick films are ~ 2750, ~ 1680, and ~ 1065, respectively. A similar decrease in dielectric constant value with decreasing film thickness is reported elsewhere (Ref 44, 47, 51, 95). Previous studies suggest that the decrease in the dielectric constant with the decrease in film thickness is due to the formation of a thin layer with a lower dielectric constant, caused by a concentration of space charge carriers such as oxygen vacancies and/or an imperfection induced during film growth, near the film/electrode interfaces (Ref 47,48,49, 96, 97). However, the current study does not confirm the presence of such a lower dielectric constant layer at the interface. The optimum film, PLZT3_650, showed a dielectric tunability value of 68.46% at an electric field of ~ 200 kV/cm when calculated using the equation below.

where τ is the tunability, εr(E) is the dielectric constant at an electric field, and εr(0) is the dielectric constant at zero field.

3.6 Room Temperature Leakage Current Plots

The leakage current density of PLZT films increases gradually with the applied voltage. The lowest leakage current density is obtained in PLZT0_650 film (Fig. 9a). Similarly, the 650 °C annealed PLZT3 film shows the lowest leakage current compared to the PLZT3 films annealed at other temperatures (Fig. 9b). The comparatively lower leakage current in the PLZT3_650 film (Fig. 9c) is attributed to its reduced porosity (Ref 98,99,100,101). In addition, as verified from FESEM images, the PLZT3_650 film has a slightly larger grain size than the PLZT0_650 film. Therefore, the grain boundary density is less in PLZT3_650 film. As a result, defect aggregation at the boundaries is less in PLZT3_650 compared to the PLZT0_ 650 film. This results in less percolating pathways for leakage current. Hence the leakage current is less in the PLZT3_650 film at lower applied voltages (Ref 102,103,104,105). Figure 9(d) confirms the reduction in the leakage current density with film thickness. This thickness-dependent arrest in leakage current is responsible for high polarization values in thicker films.

3.7 Room Temperature Energy Storage Plots

The room temperature energy storage density plots of PLZT films are given in Fig. 10. The recoverable energy storage density (Wrec), total energy storage density (Wtotal), and energy storage efficiency (η) of the system are calculated using the below equations.

where E is the applied electric field. The above calculations are based on the polarization response of the metal/ferroelectric/metal system when an input voltage of 50 V is applied. The annealing temperature study confirmed a maximum Wrec value (4.47 J/cm3 under an electric field of ~ 330 kV/cm) in PLZT0_650 film (Fig. 10a). This can be attributed to the improved crystalline quality and enhanced polarization in the film, which is verified through XRD and hysteresis loop analysis. Figure 10(b) verifies the highest energy storage density in 650 °C annealed PLZT3 film. Figure 10(c) compares the energy storage values of 650 °C annealed PLZT films with different Pb-excess contents. An improved Wtotal (9.45 J/cm3) and Wrec (4.84 J/cm3) value is observed in the PLZT3_650 film, with the same electric field (~ 330 kV/cm). This is caused by the dense microstructure of PLZT3_650 film, which resulted in lower leakage current density and improved polarization values, as discussed in Sects. 3.2, 3.3, and 3.6.

From Fig. 10(d), it is verified that the energy storage properties improve as the film thickness reduces. It is due to the higher values of the electric field experienced by thinner films. The highest value of Wtotal and Wrec obtained are ~ 26 J/cm3 and ~ 10.50 J/cm3, respectively, for 492-nm-thick PLZT film under an applied field of ~ 1020 kV/cm.

3.8 Nano-Hardness Test

The nano-indentation test results for the PLZT3 film, annealed at 650 °C are given in Fig. 11 and Table 3. Figure 11 shows the force versus penetration depth plot, obtained from nano-indentation test.

A high Young’s modulus value of 143.054 GPa is achieved for PLZT3 film, which is attributed to its good microstructural properties, as discussed in Sect. 3.2 (Fig. 4e).

3.9 Cross-Hatch Adhesion Test

The optical microscope image of cross-hatch adhesion test result revealed totally smooth cutting edges with zero detached square lattices (Fig. 12). It demonstrates the 5B class adherence of the PLZT3 film on Pt/Ti/SiO2/Si substrate.

4 Conclusions

Effect of process parameters (annealing temperature, Pb-excess content, and film thickness) on structure, microstructure, dielectric and ferroelectric properties of PLZT film, prepared by chemical solution deposition was investigated in the present study. At first, the effect of annealing temperature (600, 625, 650, 675, and 700 °C) and Pb-excess (0, 1, 2, 3, and 5 wt.%) content in the structural properties of PLZT films were studied. Results showed high crystallinity and orientation for 650 °C annealed films, which resulted in improved ferroelectric properties like better domain switching, low leakage current densities, and improved energy storage densities compared to the other PLZT films annealed at 600, 625, 675, and 700 °C. The 3 wt.% Pb-excess composition (PLZT3_650 film) yielded the highest domain switching (~ 10% increment), low leakage current density, high dielectric constant (~ 2750), and improved energy storage density (Wtotal = 0.9.45 J/cm3 under ~ 330 kV/cm). In addition, the film exhibited strong polarization (Pmax = 71.4 μC/cm2 at 334 kV/cm) as a result of its improved microstructural density and larger volume fraction of polarization domains. The optimum film, PLZT3_650 showed a hardness value of 7894.43 MPa, Young’s modulus value of 143.05GPa, and an ASTM class 5B adhesion on the substrate. Finally, the thickness study (492 nm, 768 nm, and 1500 nm) on the optimum composition PLZT3_650 showed better ferroelectric and dielectric properties due to the reduction in leakage current. The maximum energy storage density (Wtotal = ~ 26 J/cm3 at 1020 kV/cm) was obtained for PLZT3_650 film.

References

C. Huang et al., Large Quadratic Electro-Optic Effect of the PLZT Thin Films for Optical Communication Integrated Devices, ACS Photonics, 2020, 7(11), p 3166–3176.

X. Niu et al., High-Performance PZT-Based Stretchable Piezoelectric Nanogenerator, ACS Sustain. Chem. Eng., 2018, 7(1), p 979–985.

W.Y. Pan, C.Q. Dam, Q.M. Zhang, and L.E. Cross, Large Displacement Transducers Based on Electric Field Forced Phase Transitions in the Tetragonal (Pb0.97La0.02(Ti.Zr.Sn)O3 Family of Ceramics, J. Appl. Phys., 1989, 66, p 6014–6023.

M.D. Nguyen, E.P. Houwman, M.T. Do, and G. Rijnders, Relaxor-Ferroelectric Thin Film Heterostructure with Large Imprint for High energy-Storage Performance at Low Operating Voltage, Energy Storage Mater., 2020, 25, p 193–201.

M.S. Mirshekarioo, K. Yao, and T. Sirtharan, Large Strain and High Energy Storage Density in Orthorhombic Perovskite (Pb0.97La0.02) (Zr1−x−ySnxTiy)O3 Antiferroelectric Thin Films, Appl. Phys. Lett., 2010, 97, p 142902.

B. Peng et al., Large Energy Storage Density and High Thermal Stability in a Highly Textured (111)-Oriented Pb0.8Ba0.2ZrO3 Relaxor Thin Film with the Coexistence of Antiferroelectric and ferroelecTric Phases, ACS Appl. Mater. Interfaces, 2015, 7(24), p 13512–13517.

K. Yao et al., Nonlinear Dielectric Thin Films for High-Power Electric Storage with Energy Density Comparable with Electrochemical Supercapacitors, IEEE Trans. Ultrason. Ferroelectr. Freq. Control, 2011, 58(9), p 1968–1974.

X. Hao, Y. Wang, J. Yang, S. An, and J. Xu, High Energy-Storage Performance in Pb0.91La0.09(Ti0.65Zr0.35)O3 Relaxor Ferroelectric Thin Films, J. Appl. Phys., 2012, 112(11), p 114111.

B.P. Bruno, A.R. Fahmy, M. Stürmer, U. Wallrabe, and M.C. Wapler, Properties of Piezoceramic Materials in High Electric Field Actuator Applications, Smart Mater. Struct., 2018, 28(1), p 015029.

X. Wang, J. Shen, T. Yang, Y. Dong, and Y. Liu, High Energy-Storage Performance and Dielectric Properties of Antiferroelectric (Pb0.97La0.02)(Zr0.5Sn0.5−xTix)O3 Ceramic, J. Alloys Compd., 2016, 655, p 309–313.

G. Zhang et al., High-Energy Storage Performance of (Pb0.87Ba0.1La0.02)(Zr0.68Sn0.24Ti0.08)O3 Antiferroelectric Ceramics Fabricated by the Hot-Press Sintering Method, J. Am. Ceram. Soc., 2015, 98, p 1175–1181.

X.L. Wang, L. Zhang, X.H. Hao, and S.L. An, High Energy-Storage Performance of 0.9Pb (Mg1/3Nb2/3)O3-0.1PbTiO3 Relaxor Ferroelectric Thin Films Prepared by RF Mag- Netron Sputtering, Mater. Res. Bull., 2015, 65, p 73–79.

C.T. Nguyen, H.N. Vu, and M.D. Nguyen, High-Performance Energy Storage and Breakdown Strength of Low-Temperature Laser-Deposited Relaxor PLZT Thin Films on Flexible Ti-Foils, J. Alloys Compd., 2019, 802, p 422–429.

H. Tang, Y. Lin, C. Andrews, and H.A. Sodano, Nanocomposites with Increased Energy Density Through High Aspect Ratio PZT Nanowires, Nanotechnology, 2011, 22, p 015702–015711.

Q. Zhang et al., High Recoverable Energy Density over a Wide Temperature Range in Sr Modified (Pb.La)(Zr.Sn.Ti)O3 Antiferroelectric Ceramics with an Orthorhombic Phase, Appl. Phys. Lett., 2016, 109, p 262901.

L. Zhang, S. Jiang, B. Fan, and G. Zhang, High Energy Storage Performance in (Pb0.858Ba0.1La0.02Y0.008)(Zr0.65Sn0.3Ti0.05)O3-(Pb0.97La0.02)(Zr0.9Sn0.05Ti0.05)O3 Anti-Ferroelectric Composite Ceramics, Ceram. Int., 2015, 41(1), p 1139–1144.

Y.Z. Li, Z.J. Wang, Y. Bai, and Z.D. Zhang, High Energy Storage Performance in Ca-doped PbZrO3 Antiferroelectric Films, J. Eur. Ceram. Soc., 2020, 40(4), p 1285–1292.

D. Oliveira, M.A.A.V. Monteiro, and J.V. Filho, A New Structural Health Monitoring Strategy Based on PZT Sensors and Convolutional Neural Network, Sensors., 2018, 18(9), p 2955.

J. Li et al., A Walking Type Piezoelectric Actuator Based on the Parasitic Motion of Obliquely Assembled PZT Stacks, Smart Mater. Struct., 2021, 30(8), p 085030.

G. Lu, Y. Li, M. Zhou, Q. Feng, and G. Song, Detecting Damage Size and Shape in a Plate Structure Using PZT Transducer Array, J. Aerosp. Eng., 2018, 31(5), p 04018075.

Y. Zhang et al., Enhanced Pyroelectric and Piezoelectric Properties of PZT with Aligned Porosity for Energy Harvesting Applications, J. Mater. Chem. A, 2017, 5(14), p 6569–6580.

Y. Li et al., Flexible PLZT Antiferroelectric Film Capacitor for Energy Storage in Wide Temperature Range, J. Alloys Compd., 2021, 868, p 159129.

P. Qiao, Y. Zhang, X. Chen, M. Zhou, G. Wang, and X. Dong, Effect of Mn-doping on Dielectric and Energy Storage Properties of (Pb0.91La0.06)(Zr0.96Ti0.04)O3 Antiferroelectric Ceramics, J. Alloys Compd., 2019, 780, p 581–587.

H. Wu et al., Effect of Holding Time on Microstructure Ferroelectric and Energy-Storage Properties of Pb0.925La0.05Zr0.95Ti0.05O3@SiO2 Ceramics, J. Alloys Compd., 2022, 896, p 162932.

X. Qin et al., Enhanced Energy-Storage Performance of Pb0.925La0.05Zr0.95Ti0.05@ x wt.%SiO2 Composite Ceramics, J. Alloys Compd., 2022, 890, p 161869.

M. Kumar, G. Sharma, S.D. Kaushik, A.K. Singh, and S. Kumar, Critical Behavior of Relaxor Pb0.91La0.09Zr0.65Ti0.35O3: Interplay Between Polar Nano Regions, Electrocaloric and Energy Storage Response, J. Alloys Compd., 2021, 884, p 161067.

J. Wang, Z.G. Wu, X.M. Yuan, S.R. Jiang, and P.X. Yan, The Effect of Heat-Treatment on the Structure and Chemical Homogeneity of Ferroelectrics PLZT Thin Films Deposited by RF Sputtering, Mater. Chem. Phys., 2004, 88(1), p 77–83.

M.D. Nguyen, C.T. Nguyen, H.N. Vu, and G. Rijnders, Controlling Microstructure and Film Growth of Relaxor-Ferroelectric Thin Films for High Break-Down Strength and Energy-Storage Performance, J. Eur. Ceramic Soc., 2018, 38(1), p 95–103.

A.A. Jeyaseelan and S. Dutta, Improvement in Piezoelectric Properties of PLZT Thin Film with Large Cation Doping at A-Site, J. Alloys Compd., 2020, 826, p 153956.

G. Chen et al., Effects of the Film Thickness and Poling Electric Field on Photovoltaic Performances of (Pb.La)(Zr.Ti)O3 Ferroelectric Thin Film-Based Devices, Ceram. Int., 2020, 46(4), p 4148–4153.

A. Anju Balaraman and S. Dutta, Inorganic Dielectric Materials for Energy Storage Applications: A Review, J. Phys. D Appl. Phys., 2022, 55(18), p 183002.

B. Ma, Z. Hu, S. Liu, M. Narayanan, and U. Balachandran, Temperature Dependent Polarization Switching Properties of Ferroelectric Pb0.92La0.08Zr0.52Ti0.48Oδ Films Grown on Nickel Foils, Appl. Phys. Lett., 2013, 102(7), p 072901.

S. Hong. Nanoscale phenomena in ferroelectric thin films. 2004.

G.H. Haertling, Ferroelectric Thin Films for Electronic Applications, J. Vac. Sci. Technol. A: Vac. Surfaces Films, 1991, 9(3), p 414–420.

F. Wang, D. Meng, X. Li, Z. Zhu, Z. Fu, and Y. Lu, Influence of Annealing Temperature on the Crystallization and Ferroelectricity of Perovskite CH3NH3PbI3 Film, Appl. Surface Sci., 2015, 357, p 391–396.

P.D. Lomenzo, Q. Takmeel, S. Moghaddam, and T. Nishida, Annealing Behavior of Ferroelectric Si-Doped HfO2 Thin Films, Thin Solid Films., 2016, 615, p 139–144.

Z. Lin, W. Cai, W. Jiang, C. Fu, C. Li, and Y. Song, Effects of Annealing Temperature on the Microstructure, Optical, Ferroelectric and Photovoltaic Properties of BiFeO3 Thin Films Prepared by Sol–Gel Method, Ceram. Int., 2013, 39(8), p 8729–8736.

E. R. Myers and A. I. Kingon Ferroelectric Thin Films, in Materials Research Society Symposium Proceedings. 1990. p. Volume 200.

E.B. Araujo et al., Processing and Structural Properties of Random Oriented Lead Lanthanum Zirconate Titanate Thin Films, Mater. Res. Bull., 2015, 61, p 26–31.

G.L. Brennecka and B.A. Tuttle, Fabrication of Ultrathin Film Capacitors by Chemical Solution Deposition, J. Mater. Res., 2007, 22(10), p 2868–2874.

A.P. Wilkinson, J.S. Speck, A.K. Cheetham, S. Natarajan, and J.M. Thomas, In Situ X-Ray Diffraction Study of Crystallization Kinetics in PbZr1−xTixO3,(PZT, x = 0, 055, 1.0), Chem. Mater., 1994, 6(6), p 750–754.

A.Z. Simoes, A.H.M. Gonzalez, M.A. Zaghete, J.A. Varela, and B.D. Stojanovic, Effects of Annealing on the Crystallization and Roughness of PLZT Thin Films, Thin Solid Films., 2001, 384(1), p 132–137.

S. Kandasamy et al., Heat Treatment Effects on the Formation of Lanthanum-Modified Lead Zirconate Titanate Thin Films, Mater. Lett., 2008, 62(3), p 370–373.

G.H. Haertling, Thickness Dependent Properties of Acetate-Derived PLZT Films, Integr. Ferroelectr., 1997, 14(1–4), p 219–228.

H. Pan, Y. Zeng, Y. Shen, Y.-H. Lin, and C.-W. Nan, Thickness-Dependent Dielectric and Energy Storage Properties of (Pb0.96La0.04)(Zr0.98Ti0.02)O3 Antiferroelectric Thin Films, J. Appl. Phys., 2016, 119(12), p 124106.

C. Neusel, H. Jelitto, D. Schmidt, R. Janßen, F. Felten, and G.A. Schneider, Thickness-Dependence of the Breakdown Strength: Analysis of the Dielectric and Mechanical Failure, J. Eur. Ceram. Soc., 2015, 35(1), p 113–123.

M.D. Nguyen, D.T. Tran, H.T. Dang, C.T. Nguyen, G. Rijnders, and H.N. Vu, Relaxor-Ferroelectric Films for Dielectric Tunable Applications: Effect of Film Thickness and Applied Electric Field, Materials, 2021, 14(21), p 6448.

J. Oh et al., The Dependence of Dielectric Properties on the Thickness of (Ba.Sr) TiO3 Thin Films, Curr. Appl. Phys., 2007, 7(2), p 168–171.

J. Pérez De La Cruz, E. Joanni, P.M. Vilarinho, and A.L. Kholkin, Thickness Effect on the Dielectric, Ferroelectric, and Piezoelectric Properties of Ferroelectric Lead Zirconate Titanate Thin Films, J. Appl. Phys., 2010, 108(11), p 114106.

X. Hao, J. Zhai, F. Zhou, X. Song, and S. An, Thickness and Frequency Dependence of Electric-Field-Induced Strains of Sol-Gel Derived (Pb0.97La0.02)(Zr0.95Ti0.05)O3 Antiferroelectric Films, J. Sol-gel Sci. Technol., 2010, 53(2), p 366–371.

K. Natori, D. Otani, and N. Sano, Thickness Dependence of the Effective Dielectric Constant in a Thin Film Capacitor, Appl. Phys. Lett., 1998, 73(5), p 632–634.

M. Avrami, Granulation, Phase change, and Microstructure Kinetics of Phase Change. III, J. Chem. Phys., 1941, 9(2), p 177–184.

E. Fatuzzo, Theoretical Considerations on the Switching Transient in Ferroelectrics, Phys. Rev., 1962, 127(6), p 1999.

Y. Ishibashi and Y. Takagi, Note on ferroelectric domain switching, J. Phys. Soc. Jpn., 1971, 31(2), p 506–510.

V. Gopalan and T.E. Mitchell, In Situ Video Observation of 180 Domain Switching in LiTaO3 by Electro-Optic Imaging Microscopy, J. Appl. Phys., 1991, 85(4), p 2304–2311.

R. Gaynutdinov, S. Yudin, S. Ducharme, and V. Fridkin, Homogeneous Switching in Ultrathin Ferroelectric Films, J. Phys. Condens. Matter, 2011, 24(1), p 015902.

M.J. Zou, Y.L. Tang, Y.P. Feng, W.R. Geng, X.L. Ma, and Y.L. Zhu, Influence of Flexoelectric Effects on Domain Switching in Ferroelectric Films, J. Appl. Phys., 2021, 129(18), p 184103.

Z. Hu, B. Ma, S. Liu, M. Narayanan, and U. Balachandran, Relaxor Behavior and Energy Storage Performance of Ferroelectric PLZT Thin Films with Different Zr/Ti Ratios, Ceram. Int., 2014, 40(1), p 557–562.

B. Ma, S. Liu, S. Tong, M. Narayanan, and U. Balachandran, Enhanced Dielectric Properties of Pb0.92La0.08Zr0.52Ti0.48O3 Films with Compressive Stress, J. Appl. Phys., 2012, 112(11), p 114117.

S. Tong et al., Effect of Lanthanum Content and Substrate Strain on Structural and Electrical Properties of Lead Lanthanum Zirconate Titanate thin Films, Mater. Chem. Phys., 2013, 140(2–3), p 427–430.

W. Xu, Q. Li, Z. Yin, X. Wang, and H. Zou, Effect of La Doping on Crystalline Orientation, Microstructure and Dielectric Properties of PZT Thin Films, Mater. Test., 2017, 59(10), p 885–889.

A. Antony Jeyaseelan and S. Dutta, Effect of Ligand Concentration on Microstructure, Ferroelectric and Piezoelectric Properties of PLZT Film, Mater. Chem. Phys., 2015, 162, p 487–490.

N. Md, Impact of Fatigue Behavior on Energy Storage Performance in Dielectric Thin-Film Capacitors, J. Eur. Ceram. Soc., 2020, 40(5), p 1886–1895.

A. Pandey, S. Dalal, S. Dutta, and A. Dixit, Structural Characterization of Polycrystalline Thin Films by X-ray Diffraction Techniques, J. Mater. Sci.: Mater. Electron., 2021, 32, p 1341–1368.

F. Vassenden, G. Linker, and J. Geerk, Growth Direction Control YBCO Thin Films, Physica C, 1991, 175(5–6), p 566–572.

T. Nakamura, Y. Yamada, T. Kusumori, H. Minoura, and H. Muto, Improvement in the Crystallinity of ZnO Thin Films by Introduction of a Buffer Layer, Thin Solid Films, 2002, 411(1), p 60–64.

N. Jackson, F. Stam, J. O’Brien, L. Kailas, A. Mathewson, and C. O’Murchu, Crystallinity and Mechanical Effects From Annealing Parylene Thin Films, Thin Solid Films, 2016, 603, p 371–376.

M. Toyoda, Y. Nanbu, Y. Nakazawa, M. Hirano, and M. Inagaki, Effect of Crystallinity of Anatase on Photoactivity for Methyleneblue Decomposition in Water, Appl. Catal. B Environ., 2004, 49(4), p 227–232.

X. Hao, J. Zhou, and S. An, Effects of PbO Content on the Dielectric Properties and Energy Storage Performance of (Pb0.97La0.02)(Zr0.97Ti0.03)O3 Antiferroelectric Thin Films, J. Am. Ceram. Soc., 2011, 94(6), p 1647–1650.

S. Gariglio, N. Stucki, J.-M. Triscone, and G. Triscone, Strain relaxation and critical temperature in epitaxial ferroelectric Pb (Zr0.20Ti0.80)O3 thin films, Appl. Phys. Lett., 2007, 90(20), p 202905.

Z. Zhao et al., Grain-Size Effects on the Ferroelectric Behavior of Dense Nanocrystalline BaTiO3 Ceramics, Phys. Rev. B, 2004, 70(2), p 024107.

M.D. Nguyen, Tuning the Energy Storage Performance, Piezoelectric Strain and Strain Hysteresis of Relaxor PLZT Thin Films Through Controlled Microstructure by Changing the Ablation Rate, J. Eur. Ceram. Soc., 2019, 39(6), p 2076–2081.

S.J. Kang and Y.H. Joung, Fatigue, Retention and Switching Properties of PLZT (x/30/70) Thin Films with Various La Concentrations, J. Mater. Sci., 2007, 42(18), p 7899–7905.

G. Viola, K. Boon Chong, F. Guiu, and M. John Reece, Role of Internal Field and Exhaustion in Ferroelectric Switching, J. Appl. Phys., 2014, 115(3), p 034106.

Y. Tan et al., Unfolding Grain Size Effects in Barium Titanate Ferroelectric Ceramics, Sci. Rep., 2015, 5(1), p 1–9.

M. Eriksson et al., Ferroelectric Domain Structures and Electrical properties of Fine-Grained Lead-Free Sodium potassium Niobate Ceramics, J. Am. Ceram. Soc., 2011, 94(10), p 3391–3396.

J.-F. Chou, M.-H. Lin, and H.-Y. Lu, Ferroelectric Domains in Pressureless-Sintered Barium Titanate, Acta Mater., 2000, 48(13), p 3569–3579.

W. Cao, The Strain Limits on Switching, Nat. Mater., 2005, 4(10), p 727–728.

H.T. Martirena and J.C. Burfoot, Grain-Size Effects on Properties of Some Ferroelectric Ceramics, J. Phys. C Solid State Phys., 1974, 7(17), p 3182.

A. Kumar, S.R. Emani, K.C.J. Raju, J. Ryu, and A.R. James, Investigation of the Effects of Reduced Sintering Temperature on Dielectric, Ferroelectric and Energy Storage Properties of Microwave-Sintered PLZT 8/60/40 Ceramics, Energies, 2020, 13(23), p 6457.

M.D. Nguyen, C.T. Nguyen, H.N. Vu, and G. Rijnders, Experimental Evidence of Breakdown Strength and its Effect on Energy-Storage Performance in Normal and Relaxor Ferroelectric Films, Curr. Appl. Phys., 2019, 19(9), p 1040–1045.

M.D. Nguyen, E.P. Houwman, and G. Rijnders, Energy Storage Performance and Electric Breakdown Field of Thin Relaxor Ferroelectric PLZT Films Using Microstructure and Growth Orientation Control, J. Phys. Chem. C, 2018, 122(27), p 15171–15179.

T. Hirano, H. Kawai, H. Suzuki, S. Kaneko, and A. Wada, Effect of Excess Lead Addition on Processing of Sol-Gel Derived Lanthanum-Modified Lead Zirconate Titanate Thin Film, Jpn. J. Appl. Phys., 1999, 38(9S), p 5354.

S. Tong et al., Lead Lanthanum Zirconate Titanate Ceramic Thin Films for Energy Storage, ACS Appl. Mater. Interfaces, 2013, 5(4), p 1474–1480.

B. Ma et al., Residual Stress of (Pb0.92La0.08)(Zr0.52Ti0.48)O3 Films Grown by a Sol–Gel Process, Smart Mater. Struct., 2013, 22(5), p 055019.

C. Vijayaraghavan, T.C. Goel, and R.G. Mendiratta, Structural and Electrical Properties of Sol-Gel Synthesized PLZT Thin Films, IEEE Trans. Dielectr. Electr. Insul., 1999, 6(1), p 69–72.

Y. Zhao, X. Hao, and Q. Zhang, Energy-Storage Properties and Electrocaloric Effect of Pb (1–3 x/2) La x Zr0.85Ti0.15O3 Antiferroelectric Thick Films, ACS Appl. Mater. Interfaces, 2014, 6(14), p 11633–11639.

M.D. Nguyen, E.P. Houwman, M. Dekkers, C.T. Nguyen, H.N. Vu, and G. Rijnders, Research Update: Enhanced Energy Storage Density and Energy Efficiency of Epitaxial Pb0.9La0.1(Zr0.52Ti0.48)O3 Relaxor-Ferroelectric Thin-Films Deposited on Silicon by Pulsed Laser Deposition, APL Mater., 2016, 4(8), p 080701.

E. Brown, C. Ma, J. Acharya, B. Ma, J. Wu, and J. Li, Controlling Dielectric and Relaxor-Ferroelectric Properties for Energy Storage by tuning Pb0.92La0.08Zr0.52Ti0.48O3 Film Thickness, ACS Appl. Mater. Interfaces, 2014, 6(24), p 22417–22422.

B. Ma, D.-K. Kwon, M. Narayanan, and U. Balachandran, Dielectric Properties and Energy Storage Capability of Antiferroelectric Pb0.92La0.08Zr0.95Ti0.05O3 Film-on-Foil Capacitors, J. Mater. Res., 2009, 24, p 2993.

I. K. Yoo and S. B. Desu., “Fatigue parameters of lead zirconate titanate thin films, in MRS Online Proceedings Library (OPL), 1991, p. 243.

J.F. Scott and C.A.P. de Araujo, Ferroelectric Memories, Science, 1989, 246(4936), p 1400–1405.

L. He and D. Vanderbilt, First-Principles Study of Oxygen-Vacancy Pinning of Domain Walls in PbTiO3, Phys. Rev. B, 2003, 68(13), p 134103.

Y.-K. Choi, T. Hoshina, H. Takeda, and T. Tsurumi, Effect of Oxygen Vacancy and Oxygen Vacancy Migration on Dielectric Response of BaTiO3-Based Ceramics, Jpn. J. Appl. Phys., 2011, 50, p 031504.

C.S. Hwang, Thickness-Dependent Dielectric Constants of (Ba, Sr) TiO3 Thin Films with Pt or Conducting Oxide Electrodes, J. Appl. Phys., 2002, 92(1), p 432–437.

T.M. Doan, L. Lu, and M.O. Lai, Thickness Dependence of Structure, Tunable and Pyroelectric Properties of Laser-Ablated Ba (Zr0.25Ti0.75)O3 Thin Films, J. Phys. D. Appl. Phys., 2010, 43(3), p 035402.

S. Song, J. Zhai, L. Gao, X. Yao, S. Lu, and Z. Xu, Thickness-Dependent Dielectric and Tunable Properties of Barium stannate Titanate Thin Films, J. Appl. Phys., 2009, 106(2), p 024104.

H. Yang, F. Yan, Y. Lin, T. Wang, L. He, and F. Wang, A Lead Free Relaxation and High Energy Storage Efficiency Ceramics for Energy Storage Applications, J. Alloys Compd., 2017, 710, p 436.

Y. Podgorny, K. Vorotilov, P. Lavrov, and A. Sigov, Leakage Currents in Porous PZT Films, Ferroelectrics, 2016, 503(1), p 77–84.

P. Shi et al., Study on the Properties of Pb (Zr, Ti)O3 Thin Films Grown Alternately by Pulsed Laser Deposition and Sol-Gel Method, Phys. Lett. A, 2020, 384(11), p 126232.

C.M. Raghavan, J.W. Kim, and S.S. Kim, Effects of Ho and Ti Doping on Structural and Electrical Properties of BiFeO3 Thin Films, J. Am. Ceram. Soc., 2014, 97(1), p 235–240.

J. Narayan, R.A. Weeks, and E. Sonder, Aggregation of Defects and Thermal-Electric Breakdown in MgO, J. Appl. Phys., 1978, 49(12), p 5977–5981.

K. Kukli et al., Properties of Hafnium Oxide Films Grown by Atomic Layer Deposition from Hafnium Tetraiodide and Oxygen, J. Appl. Phys., 2002, 92(10), p 5698–5703.

K. McKenna et al., Grain Boundary Mediated Leakage Current in Polycrystalline HfO2 Films, Microelectron. Eng., 2011, 88(7), p 1272–1275.

K. Murakami, M. Rommel, V. Yanev, A.J. Bauer, and L. Frey, Current Voltage Characteristics through Grains and Grain Boundaries of High-k Dielectric Thin Films Measured by Tunneling Atomic Force Microscopy, AIP Conf. Proc., 2011, 1395, p 134–138.

Acknowledgment

The authors acknowledge the research facilities and infrastructure from CSIR-National Aerospace Laboratories. A.A.B acknowledges the doctoral fellowship from CSIR, India, and AcSIR, Ghaziabad, for the Ph.D. position to carry out the research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balaraman, A.A., Jeyaseelan, A.A. & Dutta, S. Process-Controlled Domain Switching and Improved Ferroelectric Properties in Lanthanum-Modified Lead Zirconate Titanate Films. J. of Materi Eng and Perform 33, 2585–2598 (2024). https://doi.org/10.1007/s11665-023-08163-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08163-2