Abstract

The aim of this work is the assessment of the corrosion resistance of NiCr-based casting alloys in oral environments. The variables considered were the chemical composition of the source (raw) material, the casting process used and the characteristics of the environment. The following materials were tested: NiCrV (Ni70-77, Cr11-14, Mo3.5-8 wt.%), NiCrW (Ni59.6, Cr24, Mo9.8) and NiCrTi (Ni60-76, Cr12-21, Mo4-14, Ti4-6). Corrosion resistance was investigated by using electrochemical methods, and the corrosion morphology was determined by surface analysis techniques (SEM and optical stereoscopy). Results showed that the chemical composition of the source material was the determining factor for corrosion resistance, while the casting route and environment modification with fluoride addition did not affect the corrosion behavior of NiCr alloys. The corrosion morphology was localized exhibiting a peculiar dissolution pattern as observed in scanning droplet cell microscopy analysis. Furthermore, it was concluded that titanium segregation in the alloy after casting process was responsible for the lower localized corrosion resistance observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nickel chromium (NiCr) alloys are commonly used in dentistry for manufacturing of prosthetic components, such as abutments and total crowns. The combination of adequate mechanical properties, including high strength and high modulus of elasticity, with biocompatibility, good adhesion of ceramics and reduced cost make them attractive as alloy replacement for more noble metal alloys, such as gold-based and palladium-based alloys (Ref 1,2,3).

Metals and metals alloys used as prosthetic components must have an adequate corrosion resistance in oral environments. Degradation of a metal or its alloys in the body due to corrosion has two major disadvantages: could result in integrity loss of the dental device and interfere in the material biocompatibility due to release of toxic and allergic ions into the body. The high nickel content of the alloy is a primary concern, since nickel allergy is the most prevalent metal allergy for patients (Ref 3, 4).

The formation of a Cr-rich oxide layer on NiCr alloys protects the metal from corrosion attack (Ref 5, 6). Although high corrosion resistance of NiCr in body fluid environments is expected (Ref 6, 7), many variables might interfere in such corrosion resistance. The oral cavity is a complex and dynamic environment representing a potential corrosive medium for metallic dental components, due to its high Cl− ion concentration. The oral environment can easily change, hence affecting its corrosiveness. Inflammation of the oral mucosa might result in decrease in saliva pH and oxygen content. A decrease in pH in simulated body fluids solutions has shown to alter the thickness of the passive film formed on the NiCr-based alloys (Ref 8) and increase the amount of Ni ion release (Ref 9). Additionally, the widespread use of fluoride in different forms, varying from mouthwashes to professional gel and varnish application also affects the oral medium properties.

Besides the environmental conditions, other factors may affect the corrosion resistance of a metal alloy, such as the composition of the source material, and the casting route adopted which can lead to different chemical compositions and microstructures. Casting process may also result in alteration of other properties, such as porosity and surface roughness (Ref 10). Moreover, the casting process by oxygen-gas flame may promote oxidation reactions in a non-controlled atmosphere that can influence the quality of the restoration compared to metal casted in an argon atmosphere (Ref 3). However, casting is an important processing method for the manufacturing of prosthetic components.

The aim of this work is to assess how the corrosion resistance of NiCr alloy is affected by chemical composition, casting route used and the characteristics of the simulated oral environment. The influence of three main variables was explored: (1) the presence of fluoride in the medium (artificial saliva), thus, modifying the environmental conditions; (2) alloying titanium (Ti) to the NiCr alloy, investigating the effect of chemical composition on the corrosion behavior in artificial saliva; and (3) the influence of the casting route used to shape the metal piece, namely electromagnetic induction and oxygen-gas direct flame. Electrochemical tests were carried out to quantify the in vitro corrosion resistance, using artificial saliva as electrolyte, as well as modified artificial saliva with different fluoride concentrations. It is important to point out that the comparison was made among different NiCr specimens obtained using different routes commonly used to produce prosthetic components. Surface analysis after corrosion tests were conducted using distinct techniques to determine the corrosion morphology.

Materials and Methods

Two commercial NiCr alloys VeraBond II (Aalbadent) and Wironia (Bego) and a NiCr with addition of titanium, NiCrTi (Tilite, Talladium) were used in this work. The NiCr alloys VeraBond II and Wironia will be referred in the text as NiCrV and NiCrW, respectively. The chemical compositions of the source materials are given in Table 1. These commercially available alloys were selected because they are widely used with the same function as dental casting alloys for prosthetic components.

Two different casting methods were used to produce the specimens: electromagnetic induction and direct oxygen-gas flame. Electromagnetic induction was done by heating the alloy in an argon atmosphere and injecting of the liquid metal into the mold by vacuum-pressure. In the case of direct flame, the alloy was melted with oxygen/gas and an automatic centrifugal machine was used to inject the alloy into the mold. The test specimens were casted with 5 mm diameter and 10 mm height, resulting in an electrode surface exposed area of 0.196 cm2. For the investigation of the influence of the casting route, NiCrV alloy was selected for the corrosion tests. Thus, both casting methods were applied. On the other hand, NiCrW was exclusively casted by direct flame.

Before each corrosion experiment, the electrodes surfaces were mechanically ground gradually with SiC emery paper up to grit 600, washed with distilled water, cleaned ultrasonically in ethyl alcohol and air-dried. Using this procedure, the surface roughness of the specimens was equalized. For microstructure characterization, the specimens were chemically etched with Kroll’s reagent (100 mL H2O + 4 mL HNO3 + 22 mL HF).

Electrochemical Tests

Fusayama modified by Meyer artificial saliva maintained at 37°C was used as test solution. The saliva detailed composition consisted of NaCl (0.4 g/L), KCl (0.4 g/L), CaCl2·H2O (0.6 g/L), NaH2PO4·H2O (0.58 g/L) and urea (1 g/L). For assessment of influence of fluoride on the corrosion behavior of NiCr alloys, sodium fluoride was added to the electrolyte in the following concentrations: 0, 227, 454 and 12,300 ppm.

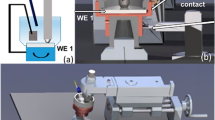

The electrochemical experiments were carried out in a three-electrode cell. Saturated calomel electrode (sce) and platinum were used as reference and counter electrode, respectively. Before potentiodynamic and potentiostatic polarizations the specimens were immersed for potential stabilization until they reached a steady-state value. Potentiostatic polarizations were performed using an Omnimetra potentiostat (model PG-/05). The potential amplitude was from the open circuit potential (OCP) up to + 800 mV above OCP, and the steady-state current density was recorded at each potential. Potentiodynamic polarizations were carried out using a PGA 302N MAC 90015 multipotentiostat (Metrohm Autolab). The potential scan rate was 1 mV/s, from the open circuit potential (OCP) to + 800 mV above OCP. Using these same parameters, localized anodic polarization of NiCrW alloy was performed with scanning droplet cell microscope (SDCM) technique. The droplet cell was a three-electrode cell containing a reference and a counter electrode on the tip electrode, being the working electrode, the wetted area delimited by the droplet electrolyte filled in contact with the tip. The analyzed contact surface was approximately 1 mm diameter. The electrolyte was renewed during SDCM measurements with a constant flow rate.

Current density with time curves was ascertained by potentiostatic polarization using a constant potential of + 200 mV (sce) above corrosion potential (Ecorr) for a total time of 1440 min. All electrochemical experiments were performed in triplicate.

Surface Analysis

The metallic surfaces were analyzed using scanning electron microscope (SEM), JEOL JXA 840. The microscope is equipped with an energy-dispersive x-ray (EDX) unit. Surfaces analyses after corrosion tests using SDCM technique were done with an optical stereoscopy Stemi 508 Zeiss.

Results

SEM surface analyses before corrosion tests are shown in Fig. 1. The photomicrographs of NiCrV (Fig. 1a) and NiCrW (Fig. 1b) reveal a dendritic two-phase microstructure, consisting of gamma (γ) and gamma-prime (γ′) phases, characteristic of NiCr alloys metallography (Ref 11). The γ is the primary phase (matrix) and y′ is the second phase. For the NiCrTi alloy, micrographs also evidence the existence of precipitates, which are more frequently observed within the dendritic cores. The corresponding EDX analyses of SEM photomicrographs are shown in Fig. 2. The NiCrV and NiCrW EDX spectra reveal predominant peaks of Ni and Cr. Similar Ni and Cr peaks were observed for NiCrTi, with only a discrete Ti peak in its spectrum.

Initially, the influence of casting route on the corrosion resistance of NiCrV was investigated in two mediums: artificial saliva with and without addition of 454 ppm of fluoride. Anodic polarization was carried out for NiCr casted by oxygen-gas direct flame (DF) and electromagnetic induction (I) (Fig. 3). As expected for biomaterials, all specimens presented a passive range, with low current densities, attributed to the formation of a passive film on the surface. Passive film formation occurred regardless of the casting process and fluoride addition protecting the NiCr alloy of rapid deterioration in an aggressive environment.

However, with the increasing of potential during polarization, there is a breakdown of the passive film and an abrupt increase in the current density is observed, characterizing a localized corrosion process. The potential in which breakdown of the oxide layer occurs is the pitting potential (Epit). The collected data from the curves (Table 2) show no significant variation in the passive range of NiCr alloys casted by distinct routes, both in saliva and saliva with fluoride medium. The average passive range, i.e., ΔE (ΔE = Epit − Ecorr) varied from 759 to 796 mV, indicating that the casting route does not affect the corrosion resistance of NiCr alloy.

Since no influence of the casting route on the corrosion resistance of NiCr alloys was observed, the subsequent tests were done only with NiCr alloys casted by gas-oxygen direct flame. The influence of chemical composition of NiCr alloys was investigated.

Electrochemical tests were conducted in NiCrV and NiCrW alloys, and in NiCrTi alloy in artificial saliva. Polarization is shown in Fig. 4, and respective obtained parameters in Table 3. The lowest average corrosion potential (Ecorr) was obtained for NiCrTi alloy, with an average value of − 220 mV. Usually, lower Ecorr indicates that the metal or metal alloy has more tendency to oxidize. Polarization curves show the presence of a protective passive film formed on both NiCrV and NiCrW and NiCrTi metal alloys surface. The average pitting potential for NiCrV and NiCrW alloys were 585 mV and 520 mV, respectively. Thus, for both NiCr alloys, Epit is around 400 mV higher than the one from NiCrTi alloy, indicating a significant better corrosion resistance of NiCr alloys in saliva environment. The average passive range, i.e., ΔE of NiCr (NiCrV and NiCrW), is almost two times higher than the NiCrTi alloy, confirming that addition of Ti in NiCr alloy results in much lower corrosion resistance, independent on the NiCr basic compositions (NiCrV and NiCrW).

In order to investigate the response of the passive film formed on NiCrW and NiCrTi, current vs time values were recorded under anodic potentiostatic polarization, by applying a constant potential of + 200 mV above Ecorr, i.e., approximately +25 mV for the NiCr alloy and − 20 mV for NiCrTi alloy. This potential corresponds to a potential value within the passive range of the alloys. The current with time registered is shown in Fig. 5. For the NiCr alloy, the anodic current values are very low, near zero, and remain stable during the 24 h test period. This indicates the formation of a stable passive film, which maintains its integrity during the test. A different behavior is observed for the NiCrTi alloy. From the beginning of the test, fluctuations of the current densities are detected, varying from 0.5 to 3.2 µA. A rapid increase in the current density is observed before reaching 9 h, indicating the breakdown of the passive film due to onset of localized corrosion. SEM analysis after corrosion tests revealed the presence of pits near the precipitates of NiCrTi (Fig. 6a). The EDX analysis of the precipitate showed a high titanium peak (Fig. 6b).

Scanning droplet cell microscope measurements were taken. For this test, anodic potentiodynamic polarizations were carried using a microcell containing tip electrodes and a drop of the artificial saliva solution in contact with the surface of the NiCrV alloy. The anodic polarization curves obtained exhibited similarity, regarding Ecorr, Epit and ΔE, to the curves obtained with macroscopic cell experiments, as shown in Fig. 7. Figure 8a shows the area where the electrochemical tests were carried out, limited by a drop of the artificial saliva. Degradation due corrosion follows one peculiar dissolution pattern (Fig. 8b and c).

To assess the influence of different concentrations of fluoride on the corrosion behavior of NiCr alloys, anodic polarizations were carried out on the present work. The following fluoride concentrations were used: 0, 227 and 12,300 ppm.

Data obtained from the polarization curves (Fig. 9) are shown in Table 4. Although a more negative Ecorr values were obtained on higher fluoride concentrations, the passive range (ΔE) was similar in 0, 227 and 12,300 ppm fluoride concentrations. In the environments tested, ΔE ranged from 830 to 868 mV, suggesting that the localized corrosion resistance was not affected by the addition of fluoride. The anodic current densities slightly increased with higher fluoride concentration. The median current densities of the passive range were 4.5 μA/cm (Ref 2) for 0 ppm, 6.5 μA/cm2 for 227 ppm and 7.8 μA/cm2 for 12,300 ppm of fluoride. Despite the increase in the current density, the median current densities remained between 1 and 10 μA/cm2 for all fluoride addition, confirming that the corrosion resistance was not affected by the presence of fluoride.

Discussion

Corrosion is a complex phenomenon and it is influenced by several factors, including physical and chemical properties of the environment and metal alloys. Although a good corrosion resistance of NiCr alloys in saliva is expected, there are some variables that affect their corrosion behavior which are not fully understood.

Casting is one of the most widely used methods for fabrication of metallic restorations. Influence of casting technique, i.e., direct flame or electromagnetic induction, on the corrosion resistance of NiCr alloys was not evidenced in this work. Other authors (Ref 12) did not find any influence in the casting route on the biocompatibility of NiCr alloys. Metallic ion release from NiCr alloys using distinct casting route was quantified after corrosion tests in artificial saliva. Ni and Cr ions content in the medium was measured for NiCr alloys casted by induction and oxygen-gas flame. Regardless of the different casting methods, the amount of ion release in artificial saliva was similar. Rather than the casting route, the recasting effect on the corrosion resistance of dental alloys is important to highlight. Making use of sprues from the previous casting is a normal practice in dental prosthetic laboratories. However, recasting can incorporate defects and result in inferior corrosion performance of the NiCr dental alloys (Ref 10).

NiCr alloys when in contact with oral environment tend to form oxide layer on the metal surface, protecting the alloy from oxidation in the aggressive medium. Chemical composition might have an influence on the formation and composition of the oxide layer, also called passive film. Chromium is responsible for the growth of this oxide layer and the oxide layer is mainly composed by Cr2O3 (Ref 5, 13). XPS analysis conducted during potentiostatic passivation in NaCl environment showed that Ni and Cr-rich films are formed during the early stages of passivation in chloride (Ref 8). For the passive film formation, Cr content must be at least 12 wt.% (Ref 6), and NiCrV and NiCrW alloys exhibited equivalent performance, despite the higher Cr content of NiCrW alloy. The detrimental effect of Ti was clearly demonstrated from the experimental results.

Titanium and titanium-based alloys are widely used in biomedical applications. One of the main advantages of titanium-based alloys is an expected higher corrosion resistance in physiological environments, as has been extensively documented in the literature (Ref 2, 14, 15). The passive film formed on titanium alloys surfaces is mainly titanium dioxide TiO2 (Ref 16) and provides protection against aggressive environments. Despite their potentially higher corrosion resistance, the results obtained on the present work indicate that alloying titanium to NiCr does not result in improvement of the corrosion resistance. On contrary, the NiCrTi alloy is significantly less corrosion resistant than the NiCr alloy. NiCrTi (4–6 wt.% titanium) has also shown to increase the Ni release in artificial saliva when compared to NiCr alloy (Ref 12). The EDX analysis reveals that the NiCrTi two-phase microstructure was depleted of Ti (Fig. 2c). Subsequently, EDX was performed in the precipitate region (Fig. 6b), showing a pronounced titanium peak. This suggests a low solubility of Ti in the NiCr matrix. Hence, titanium does not remain in the solid solution matrix, but rather segregates forming Ti-based precipitates. As a consequence, the composition of NiCrTi does not significantly differ from the composition of NiCr alloy, except for the precipitate regions. Those precipitates might belong to titanium carbides (TiC), as reported in the literature (Ref 17). Previous researchers (Ref 3) found the presence of titanium nitride compounds (TiN) in the microstructure of a commercially available NiCrTi alloy. SEM images revealed the presence of pits near the precipitates, indicating that localized corrosion has started on the vicinity of a Ti-rich precipitate. This confirms the effect of chemical composition homogeneity on the corrosion resistance of NiCr-based alloys, with inferior corrosion performance observed for NiCrTi alloy.

To achieve a better understanding of the corrosion morphology of NiCr alloys, scanning droplet cell microscope measurements were taken. The advantages of the SDCM technique are the possible investigation of small areas with local resolution, allowing the analysis of welding zones, single grains and heterogeneous microstructure, abstain the bulk alloy interference (Ref 18). The most relevant conclusion was derived from the surface analysis after the local anodic polarization. The loss of material corresponds to one corrosion morphology following a particular dissolution pattern. Early investigations (Ref 9, 19) associated the localized dissolution of NiCr to the different compositions of the two phases observed in the microstructure. Preferential dissolution occurred in the second phase, which is a Ni-rich phase and has lower Cr and Mo content, when compared to the matrix.

The influence of the oral environment composition was also investigated. The concentrations of 227 and 12,300 ppm correspond to the concentration used in daily fluoride mouth rinses and fluoride gel for dental professional application, respectively (Ref 20). Fluorides are effective to prevent dental caries by inhibiting demineralization and promoting dental remineralization. However, fluoride ions can have a detrimental effect on the passive film and decrease the corrosion resistance of some dental alloys, as previously reported for nickel titanium (NiTi) (Ref 15), titanium alloys (Ref 2) and stainless-steel alloys (Ref 21). Regarding the effect of fluoride on the corrosion behavior of NiCr alloys, few researches results have been reported. Carranzas et al. (Ref 22), mentioned that the presence of fluoride results in lower crevice corrosion caused by chlorides and suggested that fluoride could act as a weak crevice corrosion inhibitor for a NiCrMoW alloy. On the other hand, other authors reported that the passive film formed on the NiCr surface is more porous when in the presence of fluoride, contributing to the breakdown of the passive films (Ref 6).

Considering the anodic current densities values within the passive potential range (median), the uniform corrosion rates estimated would be 1.92 · 10−4 mm/year for NiCrW, 7.84 · 10−4 mm/year for NiCrV and 0.9 · 10−4 mm/year for NiCrTi. These values are negligible and not detectable by weight loss measurements, as expected from passive alloys without the incidence of localized corrosion. This simulation was carried out assuming that the passive electrochemical process is totally faradaic and considering stoichiometric dissolution and the composition of the alloys.

Conclusions

The influence of chemical composition, exposed environment and casting process on the corrosion resistance of NiCr-based alloys were investigated. The results showed that the most relevant parameter affecting the corrosion resistance of NiCr was the alloy chemical composition homogeneity. The corrosion behavior of NiCr-based alloys was not significantly affected by the casting route and addition of fluoride to the environment. It was concluded that titanium addition to NiCr alloy has detrimental effect, since NiCrTi alloy presented a significant reduction of the corrosion resistance in saliva environment. The narrow passive interval and lower Epit values obtained for NiCrTi are probably due to titanium segregation in the alloy. Fluoride addition to saliva and the casting method did not influence the corrosion resistance, since no significant differences were observed in the passive range. Even the highest concentration of fluoride used in the dental practice (12,300 ppm) was not able to alter the susceptibility to localized corrosion of NiCr alloys. The morphology of corrosion was localized, and the dissolution follows a particular pattern defined by the microstructure.

References

K.J. Anusavice, C. Shen, and H.R. Rawls, Phillips’ Science of Dental Materials, 12th ed., Elsevier Health Sciences, St. Louis, 2012, p 69–91

C.D.R. Barros, J.C. Rocha, B.F. Braz, R.E. Santelli, and J.A.C. Ponciano Gomes, Galvanic corrosion of Ti6Al4V Coupled with NiCr as a Dental Implant Alloy in Fluoride Solutions, Int. J. Electrochem. Sci., 2020, 15, p 394–411

J. Bauer, J.F. Costa, C.N. Carvalho, R.H.M. Grande, A.D. Loguercio, and A. Reis, Characterization of Two Ni–Cr Dental Alloys and the Influence of Casting Mode on Mechanical Properties, J. Prosthodont. Res., 2012, 56, p 264–271

S.F. Haddad, M.M. Helm, B. Meath, C. Adams, N. Packianathan, and R. Uhl, Exploring the Incidence, Implications, and Relevance of Metal Allergy to Orthopaedic Surgeons, J. Am. Acad. Orthop. Surg. Glob. Res. Rev., 2019, 3, p 023

H. Huang, Surface Characterization of Passive film on NiCr-Based Dental Casting Alloys, Biomaterials, 2003, 24, p 1575–1582

N.A. Sampaio, J.W. Silva, H.A. Acciari, R.Z. Nakazato, E.N. Codaro, H. de Felipe, Influence of Ni and Cr Content on Corrosion Resistance of Ni-Cr-Mo Alloys for Fixed Dental Prostheses in 0.05% NaF Aqueous Solution. Mater. Sci. Appl., 2010, p 369–372.

O.F. Benatti, W.G. Miranda, Jr., and A. Muench, In Vitro and In Vivo Corrosion Evaluation of Nickel-Chromium-and Copper-Aluminum-Based Alloys, J. Prosthet. Dent., 2000, 84, p 360–363

K.L. Cwalina, H.M. Ha, N. Ott, P. Reinke, N. Birbilis, and J.R. Scully, In Operando Analysis of Passive Film Growth on Ni-Cr and Ni-Cr-Mo Alloys in Chloride Solutions, J. Electrochem. Soc., 2019, 166(11), p 3241–3253

E. Moslehifard, S. Ghasemzadeh, F. Nasirpouri, Influence of pH Level of Artificial Saliva on Corrosion Behavior and Nickel Ion Release of a Ni-Cr-Mo Alloy: An In Vitro Study, Anti Corros. Method. Mater., 2019, 66, p 746–756

S. Viennot, M. Lissac, G. Malquarti, F. Dalard, and B. Grosgogeat, Influence of Casting Procedures on the Corrosion Resistance of Clinical Dental Alloys Containing Palladium, Acta Biomater., 2006, 2, p 321–330

A.J. Lewis, The Metallography of a Nickel Base Casting Alloy, Aust. Dental J., 1975, 20, p 298–303

R.R. Galo, L.A. Rocha, A.C. Faria, R.R. Silveira, R.F. Ribeiro, and M.D.G.C. de Mattos, Influence of the Casting Processing Route on the Corrosion Behavior of Dental Alloys, Mater. Sci. Eng. C Mater. Biol. Appl., 2014, 45, p 519–523

C. Jang, D. Kim, D. Kim, I. Sah, W. Ryu, and Y. Yoo, Oxidation Behaviors of Wrought Nickel-Based Superalloys in Various High Temperature Environments, Trans. Nonferrous Met. Soc. China, 2011, 21, p 1524–1531

R. Bailey and Y. Sun, Corrosion and Tribocorrosion Performance of Thermally Oxidized Commercially Pure Titanium in a 09% NaCl Solution, J. Mater. Eng. Perform., 2015, 24(4), p 1669–1678

E.J. Kassab and J.P. Gomes, Assessment of Nickel Titanium and Beta Titanium Corrosion Resistance Behavior in Fluoride and Chloride Environments, Angle Orthod., 2013, 83, p 864–869

S. Bahl, P.L. Nithilaksh, S. Suwas, S.V. Kailas, and K. Chatterjee, Processing–Microstructure–Crystallographic Texture–Surface Property Relationships in Friction Stir Processing of Titanium, J. Mater. Eng. Perform., 2017, 26(9), p 4206–4216

B. Piekarski, Effect of Nb and Ti Additions on Microstructure, and Identification of Precipitates in Stabilized Ni-Cr Cast Austenitic Steels, Mater. Charact., 2001, 47, p 181–186

M. Lohrengel, A. Moehring, and M. Pilaski, Capillary-Based Droplet Cells: Limits and New Aspects, Electrochim. Acta, 2001, 47, p 137–141

V.S. Saji and H. Choe, Electrochemical Behavior of Co-Cr and Ni-Cr Dental Cast Alloys, Trans. Nonferr. Metal. Soc., 2009, 19(4), p 785–790

E. Newbrun, Topical Fluorides in Caries Prevention and Management: A North American Perspective, J. Dent. Educ., 2001, 65, p 1078–1083

I. Mutlu and E. Oktay, Influence of Fluoride Content of Artificial Saliva on Metal Release from 17-4 PH Stainless Steel Foam for Dental Implant Applications, J. Mater. Sci. Technol., 2013, 29, p 582–588

R.M. Carranza, M.A. Rodríguez, and R.B. Rebak, Effect of Fluoride Ions on Crevice Corrosion and Passive Behavior of Alloy 22 in Hot Chloride Solutions, Corrosion, 2007, 63, p 480–490

Acknowledgements

This work was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES); Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) [141177/2014-4]; Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (Faperj) and Fundação COPPETEC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kassab, E.J., Barros, C.D.d., Silva, P.G. et al. Corrosion of NiCr Alloys for Dental Applications: Effects of Environment, Chemical Composition and Casting Route. J. of Materi Eng and Perform 30, 994–1000 (2021). https://doi.org/10.1007/s11665-020-05409-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05409-1