Abstract

Microbial colonization of metal surfaces or adhesion of bacteria on metal surfaces is a crucial step in initiating microbiologically influenced corrosion. As the substrate is essential in the development of a biofilm, an understanding of how substrate properties affect adhesion of bacterial cells, including the mechanism of bacterial adhesion, may assist in designing or modifying substrates to inhibit bacterial adhesion and prevent the corrosion of materials. A study was carried out to investigate the effect of nickel on the adhesion and corrosion ability of stainless steels with the same chromium content in nutrient-rich simulated seawater containing Pseudomonas aeruginosa. These stainless steels were 201, 316, 304 and 430 stainless steels. In addition, a carbon steel sample with fully nickel coated was included for comparison. The hydrophobicity of different materials was evaluated by measuring the contact angles made by the water, glycerol and formaldehyde. The number of bacteria adhering to the material surface after short-term immersion was counted by fluorescence microscopy. For corrosion study, the corrosion rates and pitting morphology were studied after 42 days of immersion. The corrosion behavior of the samples was also observed by scanning electron microscope (SEM) coupled with energy-dispersive x-ray spectroscopy (EDX) and inductively coupled plasma mass spectrometry (ICPMS). It was found that the nickel-coated sample had the highest level of bacteria attachment and offered poor corrosion resistance under artificial seawater with Pseudomonas aeruginosa strain. Higher nickel content in stainless steel resulted in a higher level of bacteria attachment. It was found that stainless steel with molybdenum exhibited better corrosion resistance in artificial seawater containing bacteria.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbiologically influenced corrosion (MIC) refers to the involvement of microorganisms in deteriorating metallic and nonmetallic materials. It is an electrochemical process that can increase the corrosion rates of metals up to 2-3 times (Ref 1). Microorganisms can initiate, facilitate or accelerate corrosion of metal and mostly result in the formation of localized and crevice corrosion on metal surfaces (Ref 2). MIC causes numerous problems in many industries including marine industries (Ref 3). It has been evaluated that 20% of the corrosion cost is caused by microbial corrosion and degradation (Ref 3).

Pseudomonas aeruginosa is a Gram-negative motile rod bacterium and ubiquitous in nature. This organism gains energy by transferring electrons from glucose in the environment to oxygen, producing gluconate in the periplasm. Then, gluconate is then transferred through the inner membrane by a specific energy-dependent gluconate uptake system (Ref 4). P. aeruginosa is also a dominant bacterium in marine environments and one of the aerobic slime-forming bacteria (SFBs) (Ref 5) which forms a biofilm layer on metal surfaces. The biofilm becomes larger, thicker and more heterogeneous with exposure time, which then generates differential aeration and concentration cells, thus promoting local differences in pH, corrosion products and dissolved oxygen (Ref 5), and this results in the initiation and acceleration of the corrosion process of steel (Ref 5 and 6).

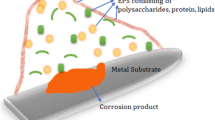

Adhesion of microorganisms and the consequent formation of biofilm on metal surfaces have played an essential role in initiating MIC (Ref 7). First, organic molecules from bulk solutions including those produced by bacteria immobilize at the substrate metal and form a conditioning film. The substrate then determines the composition and orientation of the molecules in the conditioning film, and with time, the composition of the adsorbed material becomes substrate independent (Ref 8). Those molecules are small and polymeric compounds such as lipids, proteins, complex polysaccharides and humic substances (Ref 9). Bacteria have the potential to produce molecules, such as biosurfactants, amphiphilic polymers and polyphilic polymers, which are likely to interact with interfaces (Ref 10) and have an effect on the adhesion process of bacteria on the metal surfaces.

There are many factors that affect the adhesion process, including bacteria characteristics, material surface and environmental factors (Ref 11). It has been reported that both physical characteristics including surface roughness, surface tension and hydrophobicity and chemical composition properties of the material have influence on bacterial adhesion (Ref 12). Additionally, the alloying elements such as nickel, chromium, nitrogen added to steel could significantly affect the attachment of bacteria and biofilm development (Ref 13). Felipe A. Lopes reported that nickel ions had increased bacterial growth and proved that pure nickel had higher adhered cells than 304 SS (stainless steel) (Ref 12). It was explained that the formation of passive film containing high level of chromium oxide (Cr2O3) on 304 SS prevents the dissolution of metal species. However, there is lack of the literature to show if nickel has an effect on microbial adhesion of SSs which contain similar level of chromium.

There are only few studies that have compared MIC of different SSs having similar levels of chromium contents. Therefore, this study focused on the mechanism of MIC with varying nickel contents and similar levels of chromium contents in SS. A nickel-coated carbon steel with 40 µm in coating thickness was used for comparison. Assays used to determine the extent of MIC were adhesion assays, surface tension, hydrophobicity, metal ion concentration analysis, scanning electron microscope (SEM), inductively coupled plasma mass spectrometry (ICPMS) and weight loss measurement.

Experimental Methods

Four SSs including 201, 304, 316, 430 and a nickel-coated sample with typical chemical composition as given in Table 1 were investigated in the study. They were cut into 10 mm × 10 mm for corrosion study and round samples of diameter 15 mm for adhesion assays. The SS coupons were finish polished to 1 µm. All coupons were ultrasonically washed with acetone for 10 min and then followed by immersion in ethanol 80% for 2 h, rinsed with high purity water and finally dried in a biohazard cabinet.

Culturing of Bacteria

The bacterium used in this study was Pseudomonas aeruginosa. The strain was stored at − 80°C in glycerol 20%. First, the bacteria were streaked to cell culture dishes and grown overnight. The bacteria were then transferred to a 500-mL culture medium for experiments under shaking and incubated at 37°C. The cell culture dish was prepared by adding 6 g tryptic soy agar (TSA) to 200 mL high purity water, stirred and autoclaved and then distributed to sterilized empty cell culture dish, cooled down and stored at 4°C. The culture growth medium used was nutrient-rich artificial seawater which was prepared according to ASTM 114-98 (g L−1): NaCl 24.53; MgCl2 5.2; Na2SO4 4.09; CaCl2 1.16; KCl 0.695; NaHCO3 0.201; KBr 0.101; H3BO3 0.027; SrCl2 0.0025; NaF 0.003; high purity water; nutrient TSA 3 g L−1 (Ref 14). The pH of the medium was adjusted to 7.4 ± 0.2 and stirred for 10 min and then autoclaved at 121°C for 15 min. Additionally, phosphate-buffered saline (PBS) 1X and formaldehyde 4% in PBS solution were prepared for staining bacteria with 4′,6-diamidino-2-phenylindole (DAPI).

Adhesion Experiment

After approximately 48 h of bacteria growth, 10 mL of bacteria culture medium was taken out for determining bacterial concentration. The bacterial cells were harvested by centrifugation (5000 rpm, 10 min) and resuspended in 10 mL high purity water for enumerating bacteria cells by staining with trypan blue 0.4% and using hemocytometer. The result showed that after 2 days of incubation, the bacterial concentration was 1.5 × 107 cells mL−1. Two coupons of each material (201, 304, 310 and 430 SSs, as well as nickel-coated sample) were used in the adhesion assays. The coupons were placed in sterilized 50-mL Scott bottles, and 45 mL of the test medium was added aseptically. Those bottles were incubated at 37°C for 60 min. During the test, the coupons were fully immersed in the test medium with the polished sides facing upward. After incubation, coupons were gently rinsed with 1 × PBS 3 times to remove any poorly adhered bacteria and then 350 µL of 4% formaldehyde was added to fix the cells for 20 min, rinsed with 1 × PBS for 3 times, stained with 350 µL of 300 nM DAPI in PBS solution and incubated without light for 5 min. These coupons were rinsed with 1X PBS for 3 times before microscopic observation. Attached cells were enumerated by fluorescence microscopy, and around 15-20 different fields were randomly selected and counted for each surface. To ensure reproducibility, the tests were repeated 6 times.

Contact Angle Experiment

Contact angle is the angle formed by a liquid at the phase boundary where a liquid, gas and solid intersect as shown in Table 2. The contact angles of materials were measured according to a smartphone-based contact angle measurement method (Ref 15). The measurements were carried at room temperature using 2 µL high purity water, formamide and glycerol on material surfaces, the tests were repeated 10 times for each material with each liquid used, and the averaged contact angles were determined. The images were recorded by phone camera, and the contact angels were determined using ImageJ software with DropSnake plugin. The data of surface free energy of the liquids used are given in Table 2 (Ref 16).

The surface tension of each material was calculated by three-liquid method developed by Van Oss (Ref 17) using the contact angles values obtained by high purity water, formamide and glycerol. The surface tension of each material is calculated using Eq 1.

where θ is the contact angle of each material in each liquid; γ totL is the total surface tension of each liquid; γLW is the Lifschitz–van der Waals (LW) (nonpolar) component; γAB is the polar component; γ+ is the electron-acceptor (+) component; γ− is the electron-donor (−) component. The terms L and S represent liquid and solid, respectively. The subscript is for each liquid use (i = high purity water, formamide and glycerol).

The hydrophobicity of each material was estimated by following equations (Ref 18):

where ΔG totSWS is the interfacial free energy of each material in the presence of water. ΔG LWSWS is the nonpolar component; ΔG ABSWS is the polar component. The terms S and W denote the solid and high purity water. It has been reported that if ΔG totSWS is negative, the surfaces of solid samples have less affinity for water than the water molecules have for themselves, and then, they are hydrophobic (Ref 18). If ΔG totSWS is positive, they are hydrophilic. The more negative the ΔG totSWS , the more hydrophobic the surface, and the more positive the ΔG totSWS , the more hydrophilic the surface.

Corrosion Behavior Experiment

The corrosion study was performed in duplicate, each time using three coupon samples. The 10 mm × 10 mm coupons were hung by nylon string and aseptically introduced to individual sterilized 500-mL Scott bottles containing 400-mL nutrient-rich medium. Then, 10 mL of solution with bacteria was transferred aseptically to culture medium in these bottles and incubated at 37°C for 42 days. To maintain the bacterial density and the resultant metabolic activity in the steady-state growth phase during immersed time, 75% of the medium was drained and replaced by an equal amount of fresh nutrient-rich medium every 7 days. The study was conducted in the laboratory under the optimum conditions for bacteria growth (nutrient-rich solution, incubation at 37°C), and this maintained the bacteria density during the 42 days of exposure. Forty-two days are sufficient for biofilm to form and produce corrosion. Other researchers have conducted MIC studies in laboratory from 14 days to 42 days (Ref 19 and 20). Furthermore, 10 mL solution from each bottle was collected after 42 days and filtered with 4-µm filter to remove bacteria, and then, they were acidified using ultrapure nitric acid to 0.13%. Finally, the solution was analyzed for metal concentrations by Agilent 7500ce inductively coupled plasma mass spectrometry (ICPMS) which is octopole reaction system using a standard addition calibration method for seawater. The reporting limit for Cr, Mn, Fe, Ni and Mo is 0.20, 0.20, 4.20, 0.10 and 0.30 ppb, respectively.

The metal coupons were then subjected to surface analysis. They were retrieved from the biotic medium and washed gently three times with PBS 1X and then fixed with glutaraldehyde 4.5% in PBS in 30 min. The glutaraldehyde was removed, and the coupons were washed three times with high purity water. The coupons were dehydrated with ethanol 25, 50, 75, 90 and 100% for 10 min for each, dried in biohazard cabinet for 30 min and mounted for SEM imaging to observe biofilm and corrosion product on the surface of samples. Chemical analysis of the biofilm and/or corrosion products on the surface of the coupons was carried out using energy-dispersive x-ray spectroscopy (EDX). To observe corrosion attack and pitting formation on coupon surfaces, the biofilm and corrosion products were removed immediately after taking the samples out of the media. At first, the samples from the solution were washed three times with 100 mL high purity water and then cleaned with ultrasonic bath for 2 min. The coupons were then immersed in Clarke’s solution according to the ASTM standard G1-03 (Ref 21). Finally, all coupons were rinsed in high purity water followed by ethanol 80% and dried in a biohazard cabinet. The cleaned samples were then weighed and analyzed using SEM. The corrosion rate of the coupons was measured according to the ASTM standard G1-03 from weight loss measurement (Ref 21):

Results

Figure 1 shows the concentration of bacteria adhering on various metallic surfaces. There were significant differences of bacteria colonization between the Ni-coated sample and SS samples. Within SS samples, the greatest adhesion of cells was observed on 430 SS, followed by 316, 304 and 201 SSs. This can be explained by the hydrophobicity of the materials. After measuring contact angles of the coupons by using high purity water, formamide and glycerol, surface tension of the coupons was calculated using Eq 1 and 2. The calculation of the surface tension of metal coupons requires three unknown components: Lifschitz–van der Waals (LW) (nonpolar) component (γLW), electron-acceptor (+) component (γ+) and electron-donor (−) component (γ−). These three unknown components were solved by the system of three equations using Eq 1 for three types of liquid testing. Table 3 shows the contact angles and surface tension of 201, 304, 316, 430 SSs and nickel-coated coupons.

While all metal coupons had higher electron donor than electron acceptor (\(\gamma^{ - } > \gamma^{ + }\)) which could create positive metallic substrates, 430 SS and Ni-coated coupon seemed to have much greater electron donor than electron acceptor (\(\gamma^{ - } > > \gamma^{ + }\)). Hydrophobicity of test samples was calculated by using Eq 3, 4, and 5 as given in Table 3. By using hydrophobicity results (\(\Delta G_{\text{SWS}}^{\text{tot}} )\) of metal coupons, it is possible to determine the degree of hydrophobicity. According to Van Oss (Ref 18), the more negative the \(\Delta G_{\text{SWS}}^{\text{tot}}\), the more hydrophobic the sample is and vice versa. Table 3 indicates that Ni-coated sample had the lowest value or the highest hydrophobicity and 430 SS had the lowest hydrophobic ability. 201, 304 and 316 SSs had lesser differences in hydrophobicity.

Figure 2 shows the concentration of iron ion, and Table 4 shows the concentration of other metal ions including nickel ion, chromium ion, manganese ion and molybdenum ion in solution after 42 days of immersion of metal coupons in a P. aeruginosa environment. Results showed a statistically significant higher concentration of dissolved iron ion and nickel ion in solution in the Ni-coated sample compared to the SS coupons. 201 SS seemed to have the highest iron ion dissolved in the SS group, followed by 304, 430 and 316 SSs, respectively. Manganese ion release from 201 SS was more than that from other samples (Table 1). There appeared no molybdenum ion in solution or it is very low (under report limit of 0.30 ppm). This may indicate that molybdenum had formed a stable compound form on stainless steel surface.

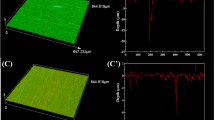

Figure 3-7 shows SEM images of test materials: (a) as-received, (b) after 42 days of immersion, (c) following biofilm removal and (d) EDX analysis of (b) samples. There was little difference in biofilm formation among 201, 304 and 316 SS specimens. The biofilm formation on 430 SS and Ni-coated samples was thicker than that on other samples. However, the Ni-coated sample showed very deep and large pits on the surface, while 430 SS sample showed few small and narrow pits. Moreover, 201 SS appeared to be more corroded than 304, 316 and 430 SS specimens by presenting more larger pits on the surface. EDX results indicate the possible formation of metal oxide on the surface of samples. Furthermore, all stainless steel samples contain manganese (Table 1); however, Fig. 3-7(d) shows very low concentration of manganese on test samples surface. Table 4 shows a high concentration of manganese in solution which indicates the high solubility of manganese in the test solution. This may indicate poorer corrosion resistance of 201 SS.

Figure 8 illustrates the corrosion rate of test samples following 42 days of immersion in artificial seawater with P. aeruginosa. Ni-coated sample had the highest corrosion rate (mm year−1) compared to other samples. Furthermore, 430 SS had low corrosion rate, while it had very high density of bacteria attachment. Within SS, 201 SS showed the highest corrosion rate, while it had the lowest adhesion of cells on the surface.

Discussion

P. aeruginosa is a SFBs type bacterium which forms a dense slime layer on substrates. During biofilm formation, it excretes an acidic exopolymeric substance (EPS). EPS contains mostly polysaccharide (alginate) on substrates (Ref 22), and this consists of anionic carboxylic groups with metal-binding ability. The corrosion process can happen through four main reactions: First, when there is not enough iron which is essential for P. aeruginosa growth in the environment, the bacterium synthesizes two siderophores: pyochelin and pyoverdin (Ref 23). These siderophores are low molecular weight compounds with a high affinity for iron, which solubilize iron from insoluble ferric compounds (in passive film compounds) and transport these ions into the bacterial cell for their growth and activity. The metabolism of P. aeruginosa transfers electron from glucose which is available in environment to oxygen to form gluconate and release oxygen ion (Ref 4). These ions probably combine with water to form (OH)− ion which interact with iron ions to form compound [Fe(OH)2+]. The EPS releases protons from the carboxylic group to gain energy for bacterial growth by the reaction with the iron compound, resulting in corrosion product [(RCOO)2(FeOH)] followed by reaction 7. The resulting protons are likely to be dissolving oxides in passive film of SS, resulting in the breakdown of the passive film.

Due to the presence of the biofilm layer on the metal surface, aeration cells are created in different areas, resulting in pitting corrosion. The anode is located beneath the biofilm layer and lacks oxygen, whereas the cathode is placed on the surface of the steel substrate and is enriched with oxygen (Ref 24). The anode reaction is the dissolving of iron, and the cathode reaction is the dissolving of oxygen to oxygen ion. Additionally, the presence of chloride (Cl−) in artificial seawater increases the acidity of electrolyte water (reaction 8), resulting in severe pitting corrosion.

According to Table 2, this study found that 304 and 316 SSs had a similar surface tension (\(\gamma^{\text{tot}}\)) and hydrophobicity (\(\Delta G_{\text{SWS}}^{\text{tot}}\)), which indicates similar physical properties. However, SS types vary in nickel content with 316 SS > 304 SS > 201 SS as shown in Table 1. Figure 1 shows the highest bacteria density on 316 SS, followed by 304 and 201 SSs, indicating that SS with higher nickel content had greater bacterial adhesion on the surface as has been reported previously (Ref 12). Additionally, nickel is essential for bacteria in a variety of cellular process (Ref 25). P. aeruginosa can accumulate nickel ion as phosphide (Ni5P4, NiP2, Ni12P5) and carbide crystal (Ni3C) mostly in the cell envelope region (Ref 26). It is possible that when the passive film is dissolved during corrosion process and Ni2+ ion is released attracting bacterium to metal surface. Although 316 SS had the highest bacteria density, it appeared to be less corroded than other test samples. 201 SS which had the lowest bacteria adhesion appeared to be the most corroded as the most iron concentration in solution in Fig. 2 and the highest corrosion rate in Fig. 8 among 201 SS, 304 SS and 316 SS. 201 SS is same as 304 SS, but nickel is replaced by manganese which lowers corrosion resistance of 201 SS as explained above. Gou-dong Bao (Ref 27) reported that the passive film of 304 SS was much stronger than that of 201 SS and the corrosion rate of 201 SS was much higher than that of 304 SS. Thus, although 201 SS had less bacteria density than 304 SS, it is still corroded more. Although Fig. 5 shows the presence of molybdenum for 316 SS, there was no molybdenum ion in corrosive solution as shown in Table 4. A previous study also shows the formation of MoO2 in the passive film, remaining passive at lower pH value (Ref 28). Hence, the higher corrosion resistance of 316 SS may be attributed to the more stable passive film due to the presence of molybdenum in the passive film.

P. aeruginosa are Gram-negative bacteria, and their cell walls are negatively charged (Ref 29). Therefore, they have a tendency to adhere to positively charged substratum, specifically metallic substrates, and initiate biofilm formation (Ref 30). According to Table 3, 430 SS and Ni-coated coupons are dominant electron donors and minor electron acceptors \((\gamma^{ - } > > \gamma^{ + }\)). However, 201, 304 and 316 SSs had nearly the same values as electron donors and electron acceptors. Therefore, 430 SS and Ni-coated coupons were a more positive metallic substrate than 201, 304 and 316 SSs, and this is probably one of the reasons that 430 SS and Ni-coated coupons had higher bacteria colonization than others. On the other hand, 430 SS had the highest hydrophilic ability as the hydrophobicity value \(\left( {\Delta G_{\text{SWS}}^{\text{tot}} } \right)\) as shown in Table 3 was least negative. P. aeruginosa strains have been shown to have hydrophilic properties in the recent research (Ref 31, 32). Moreover, hydrophilic cells interact more easily with hydrophilic interfaces than hydrophobic interfaces (Ref 10). The more hydrophilic the metallic substrate, the more bacteria adhere on surface. 430 SS surface had the highest hydrophilic ability; therefore, this is a possible explanation for why it had higher bacterial adhesion compared to the other SS samples even though it has low nickel content as given in Table 1. However, its corrosion rate was low, which can be explained by the passive film of 430 SS and its dense biofilm. Microorganism settled down and formed biofilm on SS surface. Due to the formation of passive film on the surface, the corrosion process happened slowly. While 430 SS had a greater number of adhered bacteria, this may have acted as a layer to inhibit corrosion (Ref 33), resulting in a lower corrosion rate.

Although the nickel-coated sample had the lowest hydrophilic ability (\(\Delta G_{\text{SWS}}^{\text{tot}}\) was the most negative in Table 3), its bacterial adhesion was highest and was more than three times than that on 430 SS. The corrosion rate was highest compared to other test samples as shown in Fig. 8, producing deep and large pits on the surface after removing biofilm as given in Fig. 7. This may be explained as follows: The presence of chloride ions in solution formed acidic chloride via reaction 8 which dissolved nickel oxide and nickel in nickel-coated sample to form nickel ion. P. aeruginosa was attracted to nickel ions released from the nickel-coated sample. The nickel-coated sample was carbon steel coated with nickel; therefore, when differential aeration cells form, the nickel layer was dissolved. The corrosion reaction would have occurred quickly and released plenty of metallic ions as shown in Fig. 2. Moreover, the lipopolysaccharide in EPS, a highly anionic structure, has been identified as the main binding site for metals (Ref 34). When the cell wall is in direct contact with the environment, negatively charged groups are able to attract and bind metallic cations based on electrostatic forces without cellular energy consumption (Ref 35), resulting in high enhancement of bacteria attachment on nickel-coated sample.

Conclusion

Nickel-coated samples had the weakest corrosion resistance and resulted in the highest corrosion rate compared to other SSs samples in artificial seawater containing P. aeruginosa strain. Electron donor and hydrophobicity abilities of a metal will have a significant effect on bacteria adhesion which leads to higher bacteria attachment density as seen on 430 SS compared to other SS samples. Besides passive film with chromium has high corrosion resistance, passive film with molybdenum also played a positive role in microbial corrosion resistance. 316 SS despite having high bacterial adhesion showed to be less corroded than 201 and 304 SSs due to the stability of molybdenum compound on the passive film. 201 SS had the lowest bacteria adhesion, but showed to be the most corroded compared to other SS samples due to the vulnerable manganese compound in the passive film in low-pH environment.

References

R. Javaherdashti, A Brief Review of General Patterns of MIC of Carbon Steel and Biodegradation of Concrete, Istanbul Univ. Fac. Sci. J., 2009, 68, p 65–73

J. Stott, What Progress in the Understanding of Microbially Induced Corrosion has been Made in the Last 25 Years? A Personal Viewpoint, Corros. Sci., 1993, 35, p 667–673

E. Heitz and W. Sand, Microbially Influenced Corrosion of Materials, Springer, Berlin, 1996

K. Rabaey and W. Verstraete, Microbial Fuel Cells: Novel Biotechnology for Energy Generation, Trends Biotechnol., 2005, 23, p 291–298

S. Yuan and S. Pehkonen, Microbiologically Influenced Corrosion of 304 Stainless Steel by Aerobic Pseudomonas NCIMB 2021 Bacteria: AFM and XPS Study, Colloids Surf., 2007, 59, p 87–99

J. Morales, The Role of Pseudomonas aeruginosa on the Localized Corrosion of 304 Stainless Steel, Corros. Sci., 1993, 34, p 1531–1540

H. Fleming and G. Geesey, Biofouling and Biocorrosion in Industrial Water Systems, Springer, Berlin, 1991

G.I. Loeb and R.A. Neihof, Marine Conditioning Films, ACS Publications, Washington, DC, 1975

A. Chamberlain, The role of adsorbed layers in bacterial adhesion, in Biofilms—Science and Technology 1992, p. 59–67.

T.R. Neu, Significance of Bacterial Surface-Active Compounds in Interaction of Bacteria with Interface, Microbiol. Rev., 1996, 60, p 151

Y.H. An and R.J. Friedman, Concise Review of Mechanisms of Bacterial Adhesion to Biomaterial Surfaces, J. Biomed. Mater. Res., 1998, 43, p 338–348

F. Lopes, The Influence of Nickel on the Adhesion Ability of Desulfovibrio desulfuricans, Colloids Surf B, 2005, 46, p 127–133

D. Feron, Attachment of Desulfovibrio vulgaris to steels: influence of alloying elements, in Microbial Corrosion: Proceedings of the 3 rd International EFC Workshop 1994.

“Standard practice for the preparation of substitute ocean water”, D1141-98, ASTM International, 2008.

N.R.S.R.M. Jonas, K.K. Ole-Andreas, H.G. Armend, H. Bruusb, and B.T. Stokkea, Simple and Low-Cost Contact Angle Measurements Using a Smartphone with a PDMS-Lens, Royal Society of Chemistry, London, 2016

B. Jańczuk, T. Białopiotrowicz, and A. Zdziennicka, Some Remarks on the Components of the Liquid Surface Free Energy, J. Colloid Interface Sci., 1999, 211, p 96–103

C.J. Van Oss, M. Chaudhury, and R. Good, Monopolar surfaces, Adv. Colloid Interface Sci., 1987, 28, p 35–64

C.J. Van Oss and R. Giese, The Hydrophilicity and Hydrophobicity of Clay Minerals, Clays Clay Miner., 1995, 43, p 474–477

J. Xia et al., Laboratory Investigation of the Microbiologically Influenced Corrosion (MIC) Resistance of a Novel Cu-Bearing 2205 Duplex Stainless Steel in the Presence of an Aerobic Marine Pseudomonas aeruginosa Biofilm, Biofouling, 2015, 31(6), p 481–492

M. Javed, P. Stoddart, and S. Wade, Corrosion of Carbon Steel by Sulphate Reducing Bacteria: Initial Attachment and the Role of Ferrous Ions, Corros. Sci., 2015, 93, p 48–57

“Standard Practice for preparing, cleaning, and evaluating corrosion test specimens”, A Standard G1-03, Annual Book of ASTM Standards 3, 2003, pp. 17–25.

A. Boyd and A. Chakrabarty, Pseudomonas aeruginosa Biofilms: Role of the Alginate Exopolysaccharide, J. Ind. Microbiol., 1995, 15, p 162–168

J. Brandel, Pyochelin, a Siderophore of Pseudomonas aeruginosa: Physicochemical Characterization of the Iron(III), Copper(II) and Zinc(II) Complexes, Dalton Trans., 2012, 49, p 2820–2834

B. Little, P. Wagner, and F. Mansfeld, An Overview of Microbiologically Influenced Corrosion, Electrochim. Acta, 1992, 37, p 2185–2194

S.B. Mulrooney and R.P. Hausinger, Nickel Uptake and Utilization by Microorganisms, FEMS Microbiol. Rev., 2003, 27, p 239–261

P. Sar, P, Nickel Uptake by Pseudomonas aeruginosa: Role of Modifying Factors, Curr. Microbiol., 1998, 37, p 306–311

G. Bao, Corrosion of Stainless Steel 201, 304 and 316L in the Simulated Sewage Pipes Reactor, Huanjing Kexue, 2014, 35, p 3002–3006

K. Hashimoto, The Role of Corrosion-Resistant Alloying Elements in Passivity, Corros. Sci., 2007, 49, p 42–52

F.R.B. Frankel and D.A. Bazylinski, Biologically Induced Mineralization by Bacteria, Rev. Mineral. Geochem., 2003, 54, p 95–114

J. Palmer, S. Flint, and J. Brooks, Bacterial Cell Attachment, the Beginning of a Biofilm, J. Ind. Microbiol. Biotechnol., 2007, 34, p 577–588

A. Deptuła, A. Mikucka, and E. Gospodarek, Influence of Growth Conditions on Cell Surface Hydrophobicity of Multiresistant Pseudomonas aeruginosa Strains, Medycyna Doświadczalna, 2004, 56, p 364

D. Allison et al., Surface Hydrophobicity and Dispersal of Pseudomonas aeruginosa from Biofilms, FEMS Microbiol. Lett., 1990, 71, p 101–104

A. Jayaraman, Axenic Aerobic Biofilms Inhibit Corrosion of SAE 1018 Steel Through Oxygen Depletion, Appl. Microbiol. Biotechnol., 1997, 48, p 11–17

S. Langley and T. Beveridge, Effect of O-Side-Chain-Lipopolysaccharide Chemistry on Metal Binding, Appl. Environ. Microbiol., 1999, 65, p 489–498

B. Atkinson, F. Bux, and H. Kasan, Considerations for Application of Biosorption Technology to Remediate Metal-Contaminated Industrial Effluents, Water S. A., 1998, 24, p 129–135

Acknowledgments

Tien’s Ph.D. candidature is funded by Charles Darwin University RTP scholarship funding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tran Thi Thuy, T., Kannoorpatti, K., Padovan, A. et al. Effect of Nickel on the Adhesion and Corrosion Ability of Pseudomonas aeruginosa on Stainless Steel. J. of Materi Eng and Perform 28, 5797–5805 (2019). https://doi.org/10.1007/s11665-019-04283-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04283-w