Abstract

This study aims to detect the effect of Desulfovibrio sp. on copper in terms of biofilm formation and corrosion in 722 h. In that way, appropriate strategies to inhibit microbiological corrosion in copper systems with Desulfovibrio sp. can be evaluated. For this purpose, experiments were performed in 1 L glass model system containing 28 copper coupons and pure culture of the sulfate-reducing bacteria (SRB) strain Desulfovibrio sp. in Postgate’s medium C. Also, a control system with copper coupons but without Desulfovibrio sp. containing sterile Postgate’s medium was studied concurrently with the test system. The test coupons were collected from systems at certain time intervals, namely 24, 168, 360, and 720 h. The samples were then subjected to several characterization analyses such as measurement of Desulfovibrio sp. numbers, corrosion resistance, EPS extraction, carbohydrate analysis, SEM, and EDS. During the experiments, the maximum Desulfovibrio sp. count in biofilm samples was found at 360 h. Carbohydrate and copper concentrations in biofilm were increased over time. EDS analysis revealed Cu, S, C, O, and Cl peaks on the surface of the samples. For the control coupons, only Cu peaks were observed. The results obtained from this study showed that copper was corroded by Desulfovibrio sp. in the model system under laboratory conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copper and copper alloys are known to be susceptible to microbiologically influenced corrosion (MIC) (Ref 1, 2). The usage of copper as an antimicrobial agent dates back to 1930s. Therefore, copper-based alloys such as brass and bronze have been used in several applications in hospitals to prevent spread of microbes. In the recent years, cases of MIC of copper have been reported. In spite of its toxicity, copper alloys are notably exposed to microbial corrosion in heating-cooling and pipelines for domestic and industrial water systems (Ref 3-5). Microbial corrosion has been estimated to account for 20% of annual corrosion damage of metals and non-metals, and the basic expense that needs to be spent for MIC is estimated to be $30-50 billion in total per year (Ref 6, 7).

Single or multiple bacterial species attached to a surface and embedded in an exopolysaccharide matrix (Ref 8) causes the disruption of a metal by corrosion processes which occurs directly or indirectly as a result of the metabolic activity of microorganisms (Ref 9). These microorganisms can be roughly classified as aerobic and anaerobic microbes. SRBs are anaerobic microorganisms and a heterogeneous group of organisms sharing the ability to reduce sulfate and are distributed within the domains of Bacteria and Archaea (Ref 10). SRBs have been regarded as the initial bacteria responsible for the corrosion of various metals (Ref 11). The best-known examples of SRB are Desulfovibrio and Desulfotomaculum which have been considered to be the most common stimulant of bio-corrosion (Ref 12). SRB use the sulfate ion as a terminal electron acceptor and generate H2S that is very toxic and an acidic product. On the other hand, extracellular polysaccharide substances (EPS) secreted by SRB are capable of binding metal ions and affect the electrochemical characteristics of metal surfaces, thus play an important role in the corrosion of metals (Ref 13, 14). There are also several different models of SRB-induced corrosion mechanisms. Some of them can be listed as cathodic depolarization by dehydrogenase enzymes, anodic depolarization, volatile phosphorous compounds, and generation of corrosive iron sulfide (Ref 15).

Microorganisms do not exist in the nature as one species. They, as mix culture, interact with each other and form biofilms on surfaces. Therefore, the kinds of microorganisms that can be present on the surface may vary, i.e., each biofilm is unique. Thus, the effect of microorganisms causing the corrosion can be reduced by the use of another kind of microorganism. That is to say, in order to inhibit microbiological corrosion in systems, it will be useful to determine the main bacteria that cause the corrosion and then use effective methods to eliminate it. The corrosive effects of SRB mix culture on copper surface are known (Ref 16); however, the effects of pure culture of Desulfovibrio sp. on copper surface have not been studied. Therefore, in this work, an anaerobic model system in laboratory conditions was used to determine the corrosion of copper surfaces which was exposed to sulfide-containing medium in a pure culture of Desulfovibrio sp. (which is a member of SRB) for 722 h. Thereby, the aim of this work was targeted to find appropriate strategies to inhibit microbiological corrosion in copper systems where Desulfovibrio sp. is present.

Experimental

Copper Coupon

Copper coupons (99.9% purity) (20 × 20 × 1 mm) were prepared according to ASTM G1-72 standards (Ref 17). The surfaces of the copper coupons were prepared by grinding with abrasive paper (400-1200 gradation) and then washing with distilled water. The coupons were rinsed in acetone and dried at room temperature. The total surface area of each coupon was determined and subsequently they were stored in a vacuum desiccator.

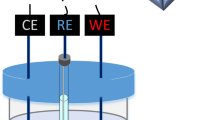

Experimental Setup

Experiments were carried out in 1 L glass model system containing copper coupons and pure culture of the strain Desulfovibrio sp. (25.106 ml−1) in Postgate’s medium C at 28 °C (Ref 18). Postgate’s medium C consists of C3H5O3Na (6.0 g/L), KH2PO4 (0.5 g/L), NH4Cl (1.0 g/L), Na2SO4 (4.5 g/L), CaCl2 × 6H2O (0.06 g/L), MgSO4 (0.06 g/L), yeast extract (1.0 g/L), FeSO4 (0.004 g/L), C6H5O7Na3 (0.3 g/L) (Ref 19), pH adjusted to 7.2. A control set of copper coupons exposed to sterilized Postgate’s medium was also investigated for the same period of time. Anaerobic conditions were established with the AnaeroGen anaerobic system (Oxoid) in a standard anaerobic jar. The medium in the test system was magnetically stirred with a Teflon bar throughout the experiment. Test coupons were removed from system at 24, 168, 360, and 720 h time intervals. Determination of the Desulfovibrio sp. numbers, corrosion analysis, EPS extraction, carbohydrate analysis, copper measurement, and SEM and EDS analyses were performed.

Enumeration of Desulfovibrio sp.

Desulfovibrio sp. enumeration was performed after 24, 168, 360, and 720 h of incubation. To estimate the number of sessile Desulfovibrio sp., biofilm on the surfaces was scraped by a sterile cotton swab and suspended according to Gagnon and Slawson (Ref 20). The biofilm suspension and bulk samples were serially diluted from 10−1 to 10−7 for sessile and planktonic Desulfovibrio sp., respectively.

Desulfovibrio sp. counts were determined by the most probable number (MPN) technique using Postgate’s medium B. Postgate medium B consists of C3H5O3Na (3.5 g/L), KH2PO4 (0.5 g/L), NH4Cl (1.0 g/L), Ca2SO4 (1 g/L), MgSO4·7H2O (2 g/L), yeast extract (1.0 g/L), C6H7O6Na (0.1 g/L), C2H3O2SNa (0.1 g/L), FeSO4.7H2O (0.5 g/L), and C6H5O7Na3 (0.3 g/L) (Ref 19, 20). All diluted samples were inoculated tubes and then incubated for one month at 28 °C. The tubes exhibiting a black FeS precipitate were recorded as positive for sulfate-reducing bacterial growth (Ref 21, 22).

Copper Measurement

Scraped biofilm from coupon was suspended in deionized water and vortexed for 4 min. Then, the pH of biofilms and EPS extracts was adjusted to 3 with 3 N nitric acid (Ref 23). After that, the samples were filtered through a 0.45 μm membrane filter (Millipore) to extract insoluble suspended particles. The copper amount in the filtered samples was analyzed by an inductively coupled plasma.

EPS Extraction and Carbohydrate Analysis

For EPS extraction, four copper coupons were removed from experimental system after 24, 168, 360, and 720 h of incubation. Biofilms were removed from the surfaces of copper coupons with a sterile cotton swab and suspended in 10 mL sterile distilled water. The suspension was centrifuged at 6000×g for 10 min, and the supernatant was collected. The biofilm pellet was re-suspended with 10 ml 8.5% NaCl solution containing 0.22% formaldehyde, and the contents were mixed in a vortex blender at high speed for 1 min. Finally, liquids from the previous two steps were combined and centrifuged at 11,227×g for 30 min at room temperature using Eppendorf centrifuge 5804R. The supernatants were filtered through a 0.22 μm membrane. The filtrates were used as EPS samples (Ref 24). Polysaccharide content in the EPS was analyzed using the phenol/sulfuric acid method (Ref 25). Glucose was used as a standard (10-100 mg L−1), and the absorbance was measured at 490 nm.

Surface Characterisation

The surfaces of copper coupons were examined to observe biofilms and corrosion products by scanning electron microscopy (SEM). The coupons containing biofilm were immersed for 1 h in a 2.5% glutaraldehyde solution at 4 °C in order to fix the biofilm to the copper surface and then biofilm was dehydrated using four ethanol solutions (10 min each): 30, 50, 80, and 95% successively. After that, the coupons were dried in a critical point dryer (EMITECH K850). The dried samples were coated with a palladium layer (15 nm) and then analyzed using the Jeol JSM-6335 field emission electron microscope. The chemical composition of corrosion products was detected by an energy dispersive X-ray spectroscopy (EDS).

Statistical Analysis of Data

Spearman’s correlation coefficient test was used to examine the relationship between Desulfovibrio sp. counts measured on the copper surfaces and copper amount using SPSS for Windows Version 11.5. The Mann-Whitney U test was employed to detect statistically significant changes in the bacteria counts. Statistical significance for all analyses was accepted at a P < 0.05.

Results and Discussion

Biofilm Formation and Bacterial Counts

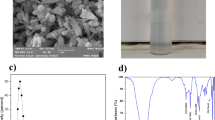

Desulfovibrio sp. cells formed a biofilm layer on copper coupons within 24, 168, 360, and 720 h of incubation. Desulfovibrio sp. cells were presented on copper coupons surface after 720 h are shown in Fig. 1. The SEM analysis shows that Desulfovibrio sp. was present on copper surface to form biofilm in Postgate C medium under anaerobic condition, although copper can be toxic to a variety of microorganisms. Chen et al. (Ref 16) and Onan (Ref 26) conducted surface analyses and demonstrated in their studies that SRB held on to copper surfaces and form biofilm. These were in good agreement with the current study.

Planktonic and sessile Desulfovibrio sp. cell numbers were presented in Fig. 2. During the experiment, the maximum Desulfovibrio sp. counts were found as 8.45 ± 0.1 at 24 h and 6.87 ± 0.04 at 360 h in bulk and biofilm samples, respectively. Although in this study, the count of the planktonic Desulfovibrio sp. was higher than that of the sessile Desulfovibrio sp. except in the 360th hour, there was no significant difference between the planktonic and sessile Desulfovibrio sp. counts according to the result of Mann-Whitney U test analysis. In their studies where similar conditions were used, Özüölmez and Çotuk (Ref 27) also indicated that there was no significant difference between the planktonic and sessile SRB counts according to their statistical analysis.

Copper Measurement

Copper concentrations in biofilm and EPS increased over time (P < 0.01), and a positive correlation between the copper concentrations in the biofilms and EPS (P < 0.01) was determined. As seen in Fig. 3, the maximum copper concentrations were 0.46 and 0.34 µg cm−2 at 720 h for biofilm and EPS, respectively. The fact that the copper concentrations in the biofilm and EPS increased over time and that the biofilm and EPS had a positive correlation between them show that biofilm and EPS play a significant role in copper corrosion. Similarly, Doğruöz Güngör et al. (Ref 5) also found that there was a positive correlation between the copper concentrations in the biofilm and EPS.

It was also detected that the concentration of copper in the control film layer (P < 0.01) increased over time, and the copper concentrations in biofilm were statistically higher than in the control film layer (P < 0.01). This result indicates that the effect of microorganisms accelerates the dissolution of copper and gives way to microbiological corrosion. Doğruöz Güngör et al. (Ref 5) also reported that the copper concentration was higher in the biofilm than in the control samples.

It has been reported that organic acids produced by SRB in biofilm damage the protective layer on the metal surface (Ref 28) and bind to copper (Ref 29). On the other hand, high-level copper concentration can be toxic for SRB. Jin et al. (Ref 30) found that the sulfate reduction decreased with 8 mg L−1 and inhibited with 30 mg L−1 dissolved copper concentration completely. Indeed, in this study, 47 µg cm−2 (11.6 mg L−1) copper concentration was measured at 720th h which shows a decrease in the number of SRBs because of the adverse effect of copper concentration.

Carbohydrate Analysis

In EPS samples, carbohydrate amount was increased over time (P < 0.01), and the maximum carbohydrate amount was found to be 47.01 µg cm−2 after the 720th h as seen in Fig. 4. This result points to the fact that the Desulfovibrio sp. could not degrade EPS for the experimental conditions used in this work (i.e., Postgate medium). Contrary to what was found, Ilhan-Sungun et al. (Ref 18) also conducted an experiment in Postgate’s medium using Desulfovibrio sp. and demonstrated that Desulfovibrio sp. degraded EPS. In addition, Zhang et al. (Ref 24) reported that the microorganisms existing in mix-culture biofilm degraded EPS in the starved state.

Furthermore, a positive correlation was observed between quantities of carbohydrate and copper concentrations in biofilm (P < 0.01). This finding suggests that there was a direct correlation between the corrosion of copper and the quantities of carbohydrate. Minnos et al. (Ref 31) also reported that there was a relation between the amount of carbohydrate and corrosion.

SEM and EDS Analyses

SEM analysis was carried out on the surface of the test coupons for both incubated and control sample surfaces. The SEM images and EDS analysis of all the samples are given in Fig. 5, 6, 7 and 8.

(a) The corroded surface of the samples after 720 h of incubation, (b) EDS analysis of needle-like flaky structure in Fig. 8(a)

As can be seen in Fig. 5, there are no apparent corrosion on the surface of the control sample (Fig. 5a) which is supported by the EDS analysis that only reveals Cu peaks (Fig. 5b). On the other hand, deterioration on the surface was observed after 24 h of incubation (Fig. 5c). This visual examination was confirmed by the oxygen and sulfur peaks in EDS analysis as shown in Fig. 5(d).

After 168 h of incubation, the control sample started to show some signs of corrosion on the surface (Fig. 6a) with a small intensity of oxygen peak in EDS (Fig. 6b). The bacteria-subjected samples again show small regions of corroded areas (Fig. 6c) with oxygen and strong sulfur peaks (Fig. 6d).

It can be clearly seen from Fig. 5(d), 6(d), and 7(d) that the intensity of sulfur peak was increased with increased incubation duration for 24, 168, and 369 h, respectively. Figures 5(c), 6(c), and 7(c) show that corrosion had begun locally in small regions for 24 and 168 h, but progressively spread along the whole surface after 360 h.

It can be seen from the EDS analysis (Fig. 8b) that chloride, carbon, oxygen, and strong sulfur peaks were detected which indicated that the copper substrate was deteriorated. Cu2S can be generated in SRB medium as follows (Ref 32):

After 24 h of incubation, approximately 25 μm2 area of pitting corrosion began on the surface of copper. Rest of the surface appeared to exhibit no signs of corrosion. After 168 h of incubation, the fractional area of corrosion was not changed; however, whole surface of the copper started to degrade. After 369 h of incubation, the corrosion was more visible and clearly observed even at lower magnifications. After 720 h of incubation, CuS phases were formed and the surface was almost completely covered with this phase.

Conclusion

In order to inhibit microbiological corrosion in systems, it will be useful to determine the main bacteria that cause the corrosion and then use effective methods to eliminate it. For example, sulfate-containing mediums are typically present in oil production sites where copper surfaces are exposed to Desulfovibrio sp. Thus, the findings in this work are aimed to enlighten the potential fundamental corrosive effects of Desulfovibrio sp. in copper. In general, it can be concluded that under the laboratory conditions that was studied in this work, H2S, the acidic product of the pure culture Desulfovibrio sp., can be produced. EPS has the ability to bind to metal, and the carbohydrate that EPS involves could accelerate the corrosion of copper.

On the basis of the experimental results obtained from this study, it can be stated that

-

(i)

The SEM analysis showed that Desulfovibrio sp. can be attached on copper surfaces and form biofilm.

-

(ii)

The copper concentrations in biofilm and EPS increased over time (P < 0.01), and a positive correlation between the copper concentrations in the biofilms and EPS (P < 0.01) was determined. Thus, the important role of biofilm and EPS on corrosion was supported.

-

(iii)

The copper concentrations in biofilm were statistically higher than the control film layer (P < 0.01). This result indicated that copper was corroded by Desulfovibrio sp.

-

(iv)

The amount of carbohydrate was positively correlated with copper concentration in biofilm (P < 0.01). This result showed that there was a correlation between corrosion of copper and carbohydrate amount.

-

(v)

EDS analysis was carried out on the surface of the test coupons and Cu, S, C, O, and Cl peaks were observed. On the other hand, the control coupons revealed only Cu peaks. These results clearly indicate that Desulfovibrio sp. caused the corrosion on the surface of copper.

References

P.J. Bremer and G.G. Geesey, Laboratory Based Model of Microbiologically Induced Corrosion of Copper, Appl. Environ. Microbiol., 1991, 57, p 1956–1962

D. Wagner and B. Little, Impact of Alloying on Microbiologically Influenced Corrosion—A review, Mater. Performance, 1993, 32, p 65–68

P.J. Bremer, B.J. Webster, and D.B. Well, Biocorrosion of Copper in Potable Water, J. Am. Water Works Assoc., 2001, 93, p 82–91

T. Burleigh et al., Copper Tube Pitting in Santa Fe Municipal Water Caused by Microbial Induced Corrosion, Materials, 2014, 7(6), p 4321–4334

N. Doğruöz Güngör, A. Çotuk, E. Ilhan-Sungur, N. Cansever, Effect of Mixed-Species Biofilm on Copper Surfaces in Cooling Water System, J. Mater. Eng. Perform., 2014. doi:10.1007/s11665-014-1332-x

H.C. Flemming, Biofouling and Microbiologically Influenced Corrosion (MIC)-an Economic and Technical Overview, Microbial Deterioration of Materials, ed. E. Heitz., W. Sand, and H.C. Flemming. 1996, New York: Springer

R. Javaherdashti, A Review of Some Characteristics of MIC Caused by Sulfate-Reducing Bacteria: Past, Present and Future, Anti-Corros. Methods Mater., 1999, 46(3), p 173–180

R.M. Donlan and J.W. Costerton, Biofilms: Survival Mechanisms of Clinically Relevant Microorganisms, Clin. Microbiol. Rev., 2002, 15(2), p 167–193

W. Lee et al., Role of Sulfate-Reducing Bacteria in Corrosion of Mild Steel: A Review, Biofouling, 1995, 8(3), p 165–194

I.B. Beech, Sulfate-Reducing Bacteria in Biofilms on Metallic Materials and Corrosion, Microbiol. Today, 2003, 30, p 115–117

W.A. Hamilton, Sulphate-Reducing Bacteria and Anaerobic Corrosion, Annu. Rev. Microbiol., 1985, 39(1), p 195–217

Y.J. Chang, Y.T. Chang, C.H. Hung, J.W. Lee, H.M. Liao, and H.L. Chou, Microbial Community Analysis of Anaerobic Bio-Corrosion in Different ORP Profiles, Int. Biodeterior. Biodegrad., 2014, 95, p 93–101

Z.H. Dong, T. Liu, and H.F. Liu, Influence of EPS Isolated from Thermophilic Sulphate-Reducing Bacteria on Carbon Steel Corrosion, Biofouling, 2011, 27(5), p 487–495

D.R. Lovley and E.J.P. Phillips, Novel Processes for Anaerobic Sulfate Production from Elemental Sulfur by Sulfate-Reducing Bacteria, Appl. Environ. Microbiol., 1994, 60, p 2394–2399

S. Kakooei and M.C. Ismail, Mechanisms of Microbiologically Influenced Corrosion: A Review, Worl Appl. Sci., 2012, 17, p 524–531

S. Chen, P. Wang, and D. Zhang, Corrosion Behavior of Copper Under Biofilm of Sulfate-Reducing Bacteria, Corros. Sci., 2014, 87, p 407–415

A.S.f.T. Materials, Standard Recommended Practice for Preparing, Cleaning and Evaluating Corrosion Test Specimens. 1975, Annual Book of ASTM Standards, Philadelphia p. 626–629

E. Ilhan-Sungur, N. Cansever, and A. Cotuk, Microbial Corrosion of Galvanized Steel by a Freshwater Strain of Sulphate Reducing Bacteria (Desulfovibrio sp.), Corros. Sci., 2007, 49(3), p 1097–1109

J.R. Postgate, The Sulphate-Reducing Bacteria, Cambridge University Press, Cambridge 1979

G.A. Gagnon and R.M. Slawson, An Efficient Biofilm Removal Method for Bacterial Cells Exposed to Drinking Water, J. Microbiol. Methods, 1999, 34(3), p 203–214

Determination of the Viable Aerobic Microbial Content of Fuels and Fuel Components Boiling Below 390 °C-Filtration and Culture Method. 1995

M.A. López et al., Phylogenetic Analysis of a Biofilm Bacterial Population in a Water Pipeline in the Gulf of Mexico, FEMS Microbiol. Ecol., 2006, 58(1), p 145–154

Y.M. Nelson et al., Lead Distribution in a Simulated Aquatic Environment: Effects of Bacterial Biofilms and Iron Oxide, Water Res., 1995, 29, p 1934–1944

X. Zhang, P.L. Bishop, and B.K. Kinkle, Comparison of Extraction Methods for Quantifying Extracellular Polymers in Biofilms, Water Sci. Technol., 1999, 39(7), p 211–218

M. DuBois et al., Colorimetric Method for Determination of Sugars and Related Substances, Anal. Chem., 1956, 28(3), p 350–356

M. Onan, An Investigation of Microbiological Influenced Corrosion on Copper Metal by Using Electrochemical Techniques, in Metallurgical and Materials Engineering, Yildiz Technical University, Istanbul, 2010

D. Özüölmez and A. Çotuk, Biofilm Formation on Galvanized Steel by SRB Isolate Obtained from Cooling Tower Water, IUFS J. Biol., 2011, 70(2), p 35–42

H. Liu, L. Xu, and J. Zeng, Role of Corrosion Products in Biofilms in Microbiologically Induced Corrosion of Carbon Steel, Br. Corros. J., 2000, 35(2), p 131–135

T.A.M. Bridge, C. White, and G.M. Gadd, Extracellular Metal-Binding Activity of the Sulphate-Reducing Bacterium Desulfococcus multivorans, Microbiology, 1999, 145(10), p 2987–2995

S. Jin, J.I. Drever, and P.J. Colberg, Effects of Copper on Sulfate Reduction in Bacterial Consortia Enriched from Metal-Contaminated and Uncontaminated Sediments, Environ. Toxicol. Chem., 2007, 26(2), p 225–230

B. Minnoş et al., The Corrosion Behaviour of Galvanized Steel in Cooling Tower Water Containing a Biocide and a Corrosion Inhibitor, Biofouling, 2013, 29, p 223–235

J. Chen, Z. Qin, and D.W. Shoesmith, Long-Term Corrosion of Copper in a Dilute Anaerobic Sulfide Solution, Electrochim. Acta, 2011, 56(23), p 7854–7861

Acknowledgments

The author wishes to thank Esra İlhan Sungur for help with isolate acquisition. We are grateful to Prof. Dr. Nurhan Cansever who shared her opinions and provided us with copper coupons. The support by Gülriz Bayçu in copper measurement for encouragement is gratefully acknowledged. This study was supported by the Research fund of Istanbul University (Project No: 6677).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Güngör, N.D., Çotuk, A. & Dışpınar, D. The Effect of Desulfovibrio sp. Biofilms on Corrosion Behavior of Copper in Sulfide-Containing Solutions. J. of Materi Eng and Perform 24, 1357–1364 (2015). https://doi.org/10.1007/s11665-015-1388-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1388-2