Abstract

At present, most of the research on lithium–air batteries (LABs) is carried out in a dry pure oxygen environment, and their working stability still needs to be further explored in the air environment. In this paper, the synergistic effect of perfluoronaphthane (PFDL) was added to the organic electrolyte (LiTFSI-TEGDME) of LABs. An oxygenating additive was systematically studied to improve the working stability of the battery in the air environment. The electrochemistry of LABs doped with PFDL electrolyte was studied by cyclic voltammetry, electrochemical impedance spectroscopy, a constant current and constant volume charge–discharge test, and deep charge–discharge test. At the same time, scanning electron microscopy and x-ray diffraction analysis were used to characterize the air cathode before and after the operation. The results showed that the best volume ratio of electrolyte to PFDL is 7:3. Under the condition of the charge–discharge current density of 100 mA cm−2, 136 cycles (1360 h) of lithium–air battery using PFDL mixed electrolyte in the air environment were achieved, which was about 5.5 times that of LABs with basic electrolyte, which is close to the cycle times of a battery in pure oxygen under the same conditions. At the same time, the specific capacity of the battery at first discharge reached 4730 mAh g−1. In addition, based on experiments, combined with simulation software, we established a mesoscopic mass transfer model to further verify the influence of adding PFDL into electrolytes on oxygen mass transfer and diffusion. Experimental and simulation results show that PFDL has excellent oxygen solubility and good hydrophobicity. It optimizes the oxygen transmission in the battery, makes the LABs more stable in air, and provides a wider space for the application of PFCs in LABs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Energy promotes social progress. Excessive use of fossil energy will lead to energy depletion and global warming. Therefore, finding new types of energy storage systems that are environmentally friendly, renewable, and sustainable has become an urgent problem to be solved.1,2,3 With the gradual popularity of the concept of “carbon neutrality”, it has evolved from the initial avant-garde idea to a common goal of countries all over the world. Some environmental protection energy sources such as wind energy, water energy, and solar energy have gradually entered people’s lives.4,5 However, due to their high manufacturing cost, these new energy sources cannot be mass-produced commercially. To better commercialize and apply clean energy, researchers have devoted increasing attention to non-aqueous electrolyte LABs with high theoretical energy density and environmental friendliness.6,7 Non-aqueous electrolyte LABs consist of a lithium negative electrode, electrolyte, and an air cathode. The positive electrode is air, so the theoretical energy density is similar to gasoline (11,430 Wh kg−1). Oxygen is the key reactive substance, and its transmission and diffusion inside the battery have an important impact on the battery’s capacity and efficiency.8 However, most of the current tests of LABs were in a dry pure oxygen environment, rather than in the air environment. Because impurity gases such as CO2 and N2 exist in the air environment, side reactions will occur with the batteries, resulting in the degradation of battery performance.9 At the same time, the lithium anode will be corroded by water evaporated in the air and electrolytes in the air environment. That makes the performance of the battery deteriorate in the air environment and even causes safety problems.10 To solve this problem and make LABs stable in the air environment, an oxygen-selective membrane (OSM) had become the most concerned and extensively researched method at present.11 By adding a thin film above the positive electrode, the researchers effectively reduced the entry of impurity gases and moisture from the air and also prevented the volatilization of electrolytes. The working stability and safety of the battery in the air environment are improved.12,13,14 Although the performance of the battery is optimized by OSM to some extent, the limited porosity of OSM makes the oxygen entering the battery much less than that of the LABs without OSM. At the same time, with the progress of the electrochemical reaction in the battery, a large amount of Li2O2 was formed and attached to the air electrode. As a result, the positive electrode pores of the battery are blocked, the oxygen inflow can not meet the internal electrochemical reaction requirements, and the overpotential increases, thus deteriorating the battery performance.

In recent years, researchers have proposed a new method, using perfluorocarbons (PFCs) to improve the oxygen dissolution and diffusion coefficient in batteries. Since 1966, PFCs have been proven to increase oxygen content, and were widely used in artificial blood.15 At the same time, the solubility of oxygen, as a nonpolar molecule, is 3–10 times higher in PFCs than in water and hydrocarbons. In addition, a large number of C–F bonds and C–C bonds in PFCs also ensure high chemical stability in the air environment. That creates a new way to improve the dynamic performance of LABs.16,17,18 Wang et al.19 used phacoemulsification to disperse perfluorotributylamine (PFTBA) into the LiPF6, which effectively increased the oxygen content in the electrolyte and improved the rate performance of the gas diffusion electrode (GDE). The internal redox ability of the battery is also significantly improved, and the battery has a good discharge capacity. PFTBA can be dissolved in the electrolyte to a certain extent after being emulsified. However, the system cannot maintain stability in the air environment for a long time, and there is still a long way to go before complete miscibility. Subsequently, Nishikami et al.20 used lithium perfluorooctane sulfonate (LiPFOS) as a PFC surfactant to better combine PFCs with electrolytes. High fluorine organic electrolytes for lithium–oxygen batteries (LOBs) were prepared, which broke the previous constraint that PFCs and electrolytes could not be miscible. Experiments show that this method can make PFCs highly compatible with tetramethylene glycol dimethyl ether (TEGDME), which provides a new solution for the application of PFCs in the electrolyte.

To find out the real reason that PFCs improve battery performance, Wang et al.21 took PFTBA as an example, systematically studied the influence of PFCs on battery performance by adding PFCs into Li-O2 battery electrolyte, and analyzed its synergistic effects. After adding a small amount of PFTBA into the electrolyte, the battery showed good discharge capacity and cycle times. The main reason is that the growth morphology of Li2O2 is changed with the addition of PFTBA, and the optimized morphology is more conducive to the transmission and diffusion of oxygen in the battery. The discharge capacity reaches 9548.7 mAg−1, and it is stable for 200 cycles in the dry pure oxygen environment. Although it has been proved that PFCs have an impact on the morphology of main products, since its test environment is the pure oxygen environment, the impact of PFTBA on battery performance in the presence of moisture and other impurity gases in the air has not been considered. At the same time, most of the materials used in PFC research are PFTBA. At present, it is necessary to find new PFCs to replace PFTBA, which can increase oxygen content and reduce side effects in the air environment. At the same time, the dissolved amount of other gases such as H2O and CO2 in PFTBA is much higher than that in other PFCs. That the introduction of PFTBA in the air environment is more likely to cause side reactions in the battery, thus affecting the battery performance.

To increase the amount of oxygen dissolved in the electrolyte, overcome the influence of side reactions in the air environment, and realize the LABs in the true sense without the pure oxygen environment. We are inspired by modern medicine showing that perfluoronaphthane (PFDL) is more suitable for artificial blood than PFTBA for its high molecular stability.22 At the same time, the oxygen dissolution amount of PFDL is second only to PFTBA at 1 standard atmospheric pressure, and the dissolution amount of water and other impurity gases is far less than PFTBA, which is more conducive to the stability of the battery in the air environment. As shown in Fig. 1, this paper attempts to add PFDL as an oxygenation additive into the electrolyte of LABs and improve the stability of the battery in the air environment by optimizing the products at the positive electrode. The presence of PFDL can increase the O2 content in the battery, further promote the ORR reaction, and prevent the products from accumulating at the air cathode and blocking the pores. In addition, a positive mesoscopic mass transfer was established by Material Studios (MS) simulation software. It was used to study the diffusion of oxygen in LABs after adding PFDL into electrolytes. That provides some help for the application of PFDL in LABs.

Experimental

Materials

Multi-walled CNTs (95%) were obtained from Beijing Deke Island Gold Technology. Manganese dioxide (AR) was obtained from Tianjin Hengxing Chemical Reagent Co. Polytetrafluoroethylene reagent (60%) was purchased from Shenzhen Tianchenghe Technology; 1M TEGDME-LiTFSI was purchased from Shenzhen Beijie New Energy, and PFDL (95%) was purchased from Aladdin Reagent.

Preparation of PFDL Mixed Electrolyte

The PFDL and 1M LiTFSI-TEGDME were proportioned in a glove box filled with argon (Super (1220/750/900)). After the electrolyte was sealed, it was taken out from the glove box and put into the oscillator for repeated oscillation mixing, and then ultrasonic oscillation treatment is carried out (Fig. 2). To compare the influence of different mixing ratios on battery performance, this experiment used five different ratios of electrolyte for the control experiment. Conventional electrolyte without PFDL was used as the basic control group. On this basis, the optimum volume of PFDL was determined. The preparation process is shown in Fig. 3.

Physical Characterization and Electrochemical Test

X-ray diffraction (XRD) measurement was implemented on a D8 ADVANCE (Bruker AXS GmbH) with Cu Kα (λ = 0.15405 nm). The scanning range was 10°–80°, and the scanning rate was 10° min−1. Scanning electron microscopy (SEM) images with patterns were obtained from ZEISS scanning. Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) were measured in the electrochemical workstation (PARSTAT 4000+). The voltage range of the cyclic volt-ampere characteristic test was 2–5 V, and the scanning rate was 5 mVs−1. The frequency range of electrochemical impedance spectroscopy was 105 to 10−2 Hz, and the amplitude of the AC potential wave was 5 mV s−1. Constant current and constant volume charge and discharge test and deep charge and discharge tests were carried out in the blue electric test system (5V10mA8CT). The limited capacity of constant current and constant volume charge and discharge was 500 mAh g−2, the protection voltage was 2–5 V, and the current density was 100 mA cm−2. The voltage range of deep charge and discharge was 2–4.5 V. All tests were carried out in the air environment.

Results and Discussion

Measurement and Analysis of Dissolved Oxygen Content in the Electrolyte

To further verify the effect of PFDL on the oxygen solubility of batteries’ electrolytes, the oxygen content in electrolytes was measured by a dissolved oxygen meter. The prepared electrolyte was taken out of the glove box and exposed to the air environment for 10 min to ensure sufficient oxygen was dissolved in the electrolyte, and the oxygen content in the electrolyte was measured at this time. Then, five groups of electrolytes were sealed, and pure oxygen was introduced into the sealed electrolyte to detect the influence of electrolyte-containing PFDL on oxygen dissolution ability in an oxygen-enriched state. The dissolved oxygen content was recorded in the electrolyte every 5 min until the oxygen content in the electrolyte did not change.

As shown in Fig. 4, when the electrolyte was in the air environment, the oxygen content in the electrolyte added with PFDL is higher than that in the electrolyte without PFDL. When the volume ratio reaches 7:3, the oxygen content increases by about 1.67 times relative to the basic electrolyte. However, when the ratio exceeds 7:3, the increased oxygen content in the electrolyte was small. The reason is that the amount of oxygen dissolved at this time reaches saturation, and it is impossible to dissolve more oxygen by continuing to add PFDL. As can be seen from the figure, with the introduction of oxygen, the oxygen content in the five electrolytes has increased to a certain extent. When oxygen is introduced into the electrolyte for 15 minutes, the oxygen content in the electrolyte tends to be stable. It shows that the oxygen content in the electrolyte reaches saturation at this time. At the same time, looking at the curve in Fig. 4, we can find that when oxygen is introduced for 15 minutes, comparing the curves of 6:4 and 5:5, it is close to coincident with the curves of 7:3, and there is no great change. This means that when oxygen is introduced for a while, the oxygen content in the electrolyte reaches saturation, and it is impossible to continue to increase the oxygen content by increasing the PFDL content in the electrolyte. This shows that adding a small amount of PFDL into the electrolyte can greatly increase the oxygen content in the electrolyte, which is more conducive to accelerating the electrochemical reaction in the battery and improving the battery performance.

LABs Electrochemical Test and Analysis of Electrolyte Containing PFDL

Cyclic Charge and Discharge Test and Analysis of LABs

Figure 5 shows the cyclic charge–discharge curves of lithium–air batteries with different electrolyte ratios in the air environment at a fixed capacity of 500 mAh g−2 and a current density of 100 mAg−1. As can be seen from the figure, in the absence of PFDL in the electrolyte, the battery only circulates 25 times in the air environment due to the existence of moisture and impurity gas (Fig. 5a). With the addition of PFDL in the electrolyte, the charge–discharge cycle times of the battery increase continuously. The improvement of cycle performance is mainly due to the excellent oxygen solubility of PFDL, which makes more oxygen enter the battery. This promotes the transmission and diffusion of oxygen in the electrolyte so that more oxygen can be quickly transported to the three-phase interface of the battery. Decomposition of Li2O2 at the positive electrode was promoted at the same time. Oxygen can normally enter the battery through the porous positive electrode. In addition, as can be seen from Fig. 6, PFDL is immiscible with the electrolyte in the untreated state, and its density is higher than that of the electrolyte. PFDL will transfer under the electrolyte. Because perfluorocarbons have excellent waterproof properties, PFDL transferred to the lower part will form a hydrophobic film on the anode surface, that reduces the influence of moisture on the Li anode. The residual PFDL in the electrolyte can also reduce the influence of moisture on the electrolyte to a certain extent, and ensure the stable operation of the battery in the air environment. When the volume ratio of PFDL to the electrolyte is 7:3, the cycle performance of the battery in the air environment reaches the best, and the cycle times are increased by about 6 times compared with the battery with basic electrolyte. However, with the addition of PFDL, the cycle performance of the battery gradually decreases. Combined with the test results of oxygen content in the electrolyte, the main reason for the poor cycle performance is that with the addition of PFDL, the oxygen content in the electrolyte gradually reaches saturation. Adding PFDL will dissolve more water and other gas impurities in the environment, and more water will erode the Li anode, while the side reaction products will block the porous positive electrode. Eventually, oxygen cannot enter the battery to maintain the electrochemical reaction. At the same time, ether electrolyte is used in this experiment, as it is easy to decompose and produce water. The water produced by decomposition will also erode the negative electrode of Li, which will also cause the battery to fail to continue its normal electrical reaction. It also can be seen from Fig. 5 that LABs with PFDL electrolytes have smaller overpotential during the cycle. This is beneficial to the working stability of the battery in the air environment.

Analysis of LAB Deep Charge and Discharge Test

Figure 7 shows the deep charge–discharge curves of batteries with different electrolyte ratios in the air environment and a current density of 100 mAg−1. As shown in the figure, LABs without PFDL discharged only 5.19 mAh (about 2591 mAh g−1) in the air environment. After a small amount of PFDL was added, the discharge capacity of the battery improved. The main reason for the improvement of battery capacity is that PFDL has excellent oxygen solubility. Through the porous positive electrode, more oxygen is dissolved in the electrolyte. Due to the increase of oxygen, the oxygen reduction reaction ORR is promoted, which makes Li2O2 accumulate in the discharge process at the positive electrode decompose rapidly, and effectively prevents the reaction products from blocking the porous positive electrode. In addition, PFDL, as a nonpolar molecule, is insoluble in organic electrolytes of polar molecules and has a higher density. Incompletely miscible PFDL is deposited on the surface of the Li anode to form a hydrophobic film. The moisture in the air and the moisture evaporated from the electrolyte can not erode the Li-negative electrode, which fully ensures the stability of the battery in the air environment. When the addition ratio exceeds 7:3, the charge and discharge capacity of the battery decreases. The main reason for the performance degradation is that too much PFDL is added, which leads to a decrease in electrolyte content. The contact area between the electrolyte and medium and the transport carrier of Li+ is reduced, which cannot maintain normal electrochemical reaction, and finally reduces the capacity of the battery. At the same time, the excessive addition of PFDL dissolves more impurity gas, which leads to more side reactions in the battery. Irreversible side reaction products block the porous air electrode, leading to a decrease in surface porosity. Oxygen cannot enter the battery to maintain an electrochemical reaction, and the overall discharge capacity of the battery will also decrease.

LAB Cyclic Voltammetry Test

To verify their redox performance, five kinds of lithium–air batteries were tested by cyclic voltammetry. As shown in the Fig. 8, the battery without PFDL in the electrolyte had no obvious oxidation peak and reduction peak after testing, and the curve fluctuates greatly, which indicates that the OER (oxygen evolution) and ORR (oxygen reduction) ability of the battery was poor at this time. With the addition of PFDL, an obvious oxidation peak and reduction peak gradually appeared in the battery, which means that the OER (oxygen evolution) and ORR (oxygen reduction) ability of the battery was improved after PFDL was added to the electrolyte. This is due to the excellent oxygen-dissolving ability of PFDL, which causes more oxygen to dissolve in electrolytes and promotes the redox reaction of the battery. When the volume ratio of PFDL to electrolyte reaches 7:3, the voltammetric cyclic test curve shows the best symmetry (the ratio of oxidation peak to reduction peak to peak is close to 1). Under this ratio, the battery has the best redox performance and reversibility, and the redox performance ensures the working stability of the battery in the air environment, which is also consistent with the previous test results of cycling charge and discharge of the battery. A large amount of Li2O2 and side reaction products block the porous positive electrode, which eventually leads to a decrease in the working stability of the batteries in the air environment and a decrease in the cycle life and discharge capacity performance of the batteries (Table I).

LABs Electrochemical Impedance Test

In this study, the equivalent circuit method is used, and the equivalent circuit can be obtained by fitting electrochemical impedance spectroscopy (EIS). The fitting circuit is shown in Fig. 9, where Rs represents the electrolyte solution resistance, which is determined by the high-frequency value of the semicircle intercept on the real axis. Rct represents charge transfer resistance, which is controlled by electrochemical reaction kinetics. Cdl denotes the capacitance between the electrode and the electrolyte. ZW represents diffusion impedance, the impedance of reactant diffusion from the electrolyte to the electrode reaction interface. The EIS spectrum consists of semicircles in the high-frequency regions and slashes in the low-frequency regions. The semicircle in the high-frequency region corresponds to Rct in the equivalent circuit diagram, and the larger the semicircle diameter, the larger the Rct. The diagonal line in the low-frequency region corresponds to ZW in the equivalent circuit diagram, and the larger the slope of the diagonal line, the smaller the ZW.

Figure 10 shows the electrochemical impedance curves of five kinds of LABs. It can be seen from the figure that when a small amount of PFDL was added, the resistance Rs of the electrolyte solution was not much different. When the ratio was more than 7:3, the curve clearly changed, which indicates that under the condition of constant volume, excessive addition of PFDL leads to the decrease of Li+ content in the electrolyte and the increase of electrolyte impedance. At the same time, it can be seen from the figure that the specific change of impedance appears in the charge-transfer impedance. However, when the volume ratio was 7:3, the battery shows the smallest charge-transfer impedance. The main reason for the decrease in charge-transfer impedance is that PFDL dissolves more oxygen in the electrolyte and promotes the electrochemical reaction. At the same time, the existence of PFDL in the electrolyte reduces the influence of moisture on the electrolyte and Li-negative electrode, which is more conducive to charge transmission and transfer. When the ratio of PFDL to electrolyte exceeds 7:3 the electrolyte impedance and charge transfer impedance in the battery increase. The main reason is that the volume of electrolytes decreases, which makes Li+ transport carriers reduce and cannot maintain the normal electrochemical reaction. Excessive addition of PFDL will also introduce more water in the solvent, that will lead to the side reaction of the Li anode being eroded by water and increase the internal resistance of the battery (Table II).

Material Characterization Analysis

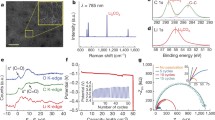

Scanning Electron Microscope Analysis and Test (SEM)

Figure 11 is an SEM image of LABs containing different electrolytes before and after 20 cycles of the test. It can be seen from Fig. 11a that before the test, manganese dioxide and carbon nanotubes have a large number of connected pore structures, which was convenient for the transmission and diffusion of oxygen in the external environment and provides enough space for the discharge products to attach. Figure 11b and c present porous air-positive SEM images of LABs assembled with the original electrolyte and LABs with a mixed electrolyte ratio of 8:2 after charging and discharging for 20 cycles, respectively. It can be seen that when a small amount of PFDL is added to the electrolyte, compared with the air electrode without PFDL in the electrolyte, the structure of the product in the SEM images obviously changes. Larger pores are produced that are more conducive to the transmission and diffusion of oxygen in the positive electrode and ensures the normal electrochemical reaction of the battery. The stability of the battery in the air environment improved, which is also consistent with the results of the electrochemical test of the battery. When the volume ratio of PFDL to electrolyte reaches 3:7 (Fig. 11d), the shape of discharge products is more orderly, and a larger pore structure is formed between them. At this time, LABs maximize the utilization rate of oxygen in the air, and oxygen enters the battery to the maximum extent, which makes LABs show the best performance in both cycle life and discharge capacity. However, when the volume ratio of PFDL to electrolyte exceeds 7:3, the positive electrode surface is covered by a large number of reaction products (Fig. 11e and f). A large number of irreversible reaction products block the gap structure on the electrode surface, which makes O2 in the air environment unable to normally enter the battery to continue to participate in chemical reactions, and finally leads to the decline of the stable working ability of the battery.

X-Ray Diffraction Analysis (XRD)

To further study the specific reasons for the influence of PFDL on the electrochemical performance of LABs after 20 cycles, XRD analysis was carried out for the products on the negative electrode surface of the battery. As shown in the Fig. 12, when PFDL is not added to the electrolyte after the battery is circulated in the air environment for 20 cycles, a large number of irreversible products LiOH and LiOH·H2O are generated on the negative electrode surface due to the erosion of water in the air and water evaporating from the ether electrolyte in the air environment. A large amount of LiOH and LiOH·H2O increases the internal impedance of the battery, which affects the working stability of the battery in the air environment, and finally leads to the decrease of the cycle life of the battery in the air environment. After adding PFDL into the electrolyte, it is obvious that there is no large amount of LiOH in XRD images because PFDL has excellent waterproof performance. This effectively prevents the erosion of the Li negative electrode surface by the water evaporating from the electrolyte in the air environment and effectively ensures the working stability of the Li negative electrode in the air environment. In addition, a small amount of Li2O appeared in XRD images after adding PFDL into the electrolyte. The appearance of Li2O is mainly due to the excellent oxygen solubility of PFDL. Due to the existence of PFDL, more O2 was dissolved in the electrolyte, and excess oxygen reacted with the lithium anode to form part of Li2O attached to the surface of the Li anode. Li2O formed a protective film that further protects the negative electrode from erosion, protects the electrochemical reaction from normal progress, and improves the working stability of the battery in the air environment. The reason for the appearance of Li2CO3 is that PFDL not only can dissolve more O2 but also dissolved more CO2. It reacts with LiO formed on the negative electrode surface to form Li2CO3.

Simulation Analysis of Mesoscopic Mass Transfer

We have established a mesoscopic mass transfer model for LABs. The influence of PFDL on LABs and on the mass transfer and diffusion of O2 in electrolytes was investigated based on the simulation.

Mesoscopic Mass-Transfer Model Force Field

To further validate the effect of PFDL in the electrolyte on the battery performance, we used the Mesocite module of Materials Studio (MS) software and used coarse-grained molecular dynamics and other methods to simulate the battery performance. The advantage of this method is that some groups or particles in the simulation system are coarse-grained mesoscopic particles. This greatly improves the operation speed without sacrificing certain accuracy, and it also can carry out dynamic operations with larger mass on a larger scale. The coarse-grained force field is the Martini force field, which is used to study the interaction between CNTs, O2, LITFSI-TEGDME, and PFDL particles in the cathode of the battery.

Based on the Martini force field, Leonard–Jones (L-J) 12-6 potential energy was used to express van der Waals interaction potential energy, and the Lorentz–Berthelot combination rule was used to express the interaction between different particles. The expressions of effective particle size and potential well depth are as follows: (1) and (2).

where \(\sigma_{11}\) represents the effective distance of 1 particle;\(\sigma_{22}\) represents the effective distance of 2 particles;\(\sigma_{12}\) represents the effective distance between 1 particle and 2 particles;\(\varepsilon_{11}\) represents the potential well depth of 1 particle;\(\varepsilon_{22}\) represents the potential well depth of 2 particles;\(\varepsilon_{12}\) represents the depth of the potential well between particle 1 and particle 2.

The electrostatic force interaction between particles with different dots is expressed by the universal Coulomb law and the expression is as Eq. 3.

where \(q_{i}\) represents the charge carried by i particles; \(q_{j}\) represents the charge carried by the jth particle; \(\varepsilon_{0}\) represents the vacuum dielectric constant; \(\varepsilon_{r}\) denotes the relative dielectric constant.

To prevent the energy discontinuity of the system at the truncated radius in the mesoscopic dynamics calculation, it is necessary to constrain the condition function of this simulation. Rc represents the preset truncation radius, and Rs is the initial point of the conditional function, which is expressed as follows.

When \(r \le r_{{^{s} }}\):

when \(r \ge r_{{^{c} }}\):

when \(r_{{^{s} }} \le r \le r_{{^{c} }}\):

The transfer properties of matter are expressed by diffusion coefficient D. According to Einstein’s diffusion law, the expression of the diffusion coefficient of particles is shown in (7). If time is sufficient, the diffusion coefficient D is approximately equal to one-sixth of the derivative of mean square displacement (MSD) concerning time, that is, Eq. 8. In the model, the diffusion coefficient of particles can be obtained by truncating the linear part of the MSD curve and calculating its slope.

Parameter Setting and Simulation Process

The electrolyte used in this simulation is 1M/L LiTFSI-TEGDME LABs organic electrolyte. CNTs are the positive electrode of the battery, and the initial density of the Mesocite module system was set to 0.25 gcm−3. As shown in Fig. 13, the CNTs, O2, Li+, TFSI−, TEGDME, and PFDL particles in the model were coarse at first. The effective size and potential well depth of each particle is adjusted and each particle is put into a mesoscopic box with a size of 150 Å × 150 Å × 150 Å to construct a mesoscopic mass transfer model (Fig. 14).

After modeling, structural optimization and dynamic optimization are carried out to reduce the energy of the solution system and make it reach the equilibrium state. The Smart algorithm is used for structural optimization, The NPT ensemble is used for dynamic optimization, and a reliability analysis of the optimized model is carried out.

Analysis of Simulation Results

Diffusion Coefficient Analysis

Figure 15 is the mean square displacement curve of O2 in five electrolytes. It can be seen from the figure that when the time reaches about 400 ps, the internal chemical reaction of the battery tends to be stable, so the stable diffusion coefficient is selected to compare it. The slope of the mean square displacement curve increases with the increase of PFDL content, indicating that the corresponding diffusion coefficient is increasing. However, The slopes all decrease when the ratio exceeds 7:3. Table III shows the diffusion coefficient of O2 in PFDL-mixed electrolytes at different proportions. It can be seen from the table that with the increase of PFDL content, the diffusion coefficient of O2 in electrolytes gradually increases. However, Its diffusion coefficient decreases when too much PFDL is added. Based on the oxygen content values shown above, it is speculated that too large a proportion can improve the oxygen diffusion rate in the battery, but at the same time, PFDL absorbs more water into the battery. Based on the oxygen content values shown above, it is speculated that too large a proportion can improve the oxygen diffusion rate in the battery, but at the same time, PFDL absorbs more water into the battery. More side reactions occur on the positive surface of the battery, which leads to the weakening of the working stability of the battery in the air environment but does not greatly improve the performance of the battery. The diffusion coefficient of O2 in the electrolyte is the largest when the ratio of electrolytes is 7:3. This is also similar to the results of electrochemical tests.

Radial Distribution Function Analysis

The influence of PFDL on the distribution of O2 in the electrolyte was studied by RDF. Figure 16 shows the radial distribution function of O2 and TEGDME, and the main peak reflects the positional relationship between TEGMDE beads and O2 due to intermolecular forces. It can be seen from the figure that with the increase of PFDL content, the peak value of the O2-TEGDME radial distribution function gradually increases. It is confirmed that the probability of oxygen molecules appearing around electrolyte molecules becomes larger, which shows that the distribution of O2 in the equilibrium position of solvent molecules in electrolyte gradually increases, which distributes O2 in the electrolyte in a more orderly manner, thus improving the diffusion of oxygen in the electrolyte.

Conclusion

To sum up, the effect of PFDL on improving the electrochemical performance of Li-air cells was demonstrated in this paper. When PFDL was added to 1M/L LiTFSI-TEGDME in different proportions under a constant volume of organic electrolyte for lithium–air battery, the oxygen content in the electrolyte was significantly increased compared with that of ordinary LiTFSI-TEGDME, which was about 0.7 times that of basic electrolyte. Under the condition of charge and discharge current density of 100 mAh g−1, the performance of LABs using PFDL mixed electrolyte is more stable in the air environment. The cycle times reached 136 (about 1360 h), which was about 6 times longer than that of the basic electrolyte battery. The specific discharge capacity increased to 4730 mAh g−1. The enhancement of electrochemical performance is attributed to the excellent oxygen solubility of PFDL, which dissolves more oxygen in electrolytes and promotes the electrochemical reaction. Related characterization tests show that the excellent hydrophobic properties of perfluorocarbons can also effectively protect the Li anode from water erosion in the air environment and electrolyte evaporation and decomposition. Due to the addition of PFDL, the growth morphology of reaction products attached to porous cathode was effectively improved. Larger pores were formed, which rendered the structure more conducive to the normal entry of oxygen to participate in the electrochemical reaction. This study will provide a new method for the application of PFDL in LABs.

References

E. Alhajji, F. Zhang, and H.N. Alshareef, Status and prospects of laser-induced graphene for battery applications. Energ. Technol. 9(10), 2100454 (2021).

F.J. Günter, S. Rössler, M. Schulz, W. Braunwarth, R. Gilles, and G. Reinhart, Influence of the cell format on the electrolyte filling process of lithium-ion cells. Energ. Technol. 8(2), 1801108 (2020).

M. Nava, A.E. Thorarinsdottir, N. Lopez, C.C. Cummins, and D.G. Nocera, Chemical challenges that the peroxide dianion presents to rechargeable lithium-air batteries. Chem. Mater. 34(9), 3883 (2022).

J.H. Williams, R.A. Jones, B. Haley, G. Kwok, J. Hargreaves, J. Farbes, and M.S. Torn, Carbon-neutral pathways for the United States. AGU Adv. 2(1), e2020AV000284 (2021).

Z.O.U. Caineng, B. Xiong, X.U.E. Huaqing, D. Zheng, G.E. Zhixin, W.A.N.G. Ying, J. Luyang, P.A.N. Songqi, and W.U. Songtao, The role of new energy in carbon neutral. Pet. Explor. Dev. 48(2), 480 (2021).

G. Girishkumar, B. McCloskey, A.C. Luntz, S. Swanson, and W. Wilcke, Lithium-air battery: promise and challenges. J. Phys. Chem. Lett. 1(14), 2193 (2010).

M. Balaish, A. Kraytsberg, and Y. Ein-Eli, A critical review on lithium-air battery electrolytes. Phys. Chem. Chem. Phys. 16(7), 2801 (2014).

A. Suryatna, I. Raya, L. Thangavelu, F.R. Alhachami, M.M. Kadhim, U.S. Altimari, Z.H. Mahmoud, Y.F. Mustafa, and E. Kianfar, A review of high-energy density lithium-air battery technology: investigating the effect of oxides and nanocatalysts. J. Chem. 2022, 1–32 (2022).

Y. Liu, L. Wang, L. Cao, C. Shang, Z. Wang, H. Wang, L. He, J. Yang, H. Cheng, J. Li, and Z. Lu, Understanding and suppressing side reactions in Li-air batteries. Mater. Chem. Front. 1(12), 2495 (2017).

J.H. Kang, J. Lee, J.W. Jung, J. Park, T. Jang, H.S. Kim, J.S. Nam, H. Lim, K.R. Yoon, W.H. Ryu, I.D. Kim, and H.R. Byon, Lithium-air batteries: air-breathing challenges and perspective. ACS Nano 14(11), 14549 (2020).

J. Li, L. Hou, M. Yu, Q. Li, T. Zhang, and H. Sun, Review and recent advances of oxygen transfer in Li-air batteries. ChemElectroChem 8(19), 3588 (2021).

L. Wang, J. Pan, Y. Zhang, X. Cheng, L. Liu, and H. Peng, A Li-air battery with ultralong cycle life in ambient air. Adv. Mater. 30(3), 3375 (2018).

X. Zou, K. Liao, D. Wang, Q. Lu, C. Zhou, P. He, R. Ran, W. Zhou, W. Jin, and Z. Shao, Water-proof, electrolyte-nonvolatile, and flexible Li-air batteries via O2-permeable silica-aerogel-reinforced polydimethylsiloxane external membranes. Energy Storage Mater. 27, 297 (2020).

U. Sahapatsombut, H. Cheng, and K. Scott, Modelling of operation of a lithium-air battery with ambient air and oxygen-selective membrane. J. Power Sources 249, 418 (2014).

S. Moradi, A. Jahanian-Najafabadi, and M.H. Roudkenar, Artificial blood substitutes: first steps on the long route to clinical utility. Clin. Med. Insights Blood Disord. 9, S38461 (2016).

R. Schmid, Recent advances in the description of the structure of water, the hydrophobic effect, and the like-dissolves-like rule. Chem. Mon. 132(11), 1295 (2001).

J. Madan, S.R. Gundala, B. Baruah, M. Nagaraju, C. Yates, T. Turner, V. Rangari, D. Hamelberg, M.D. Reid, and R. Aneja, Cyclodextrin complexes of reduced bromonoscapine in guar gum microspheres enhance colonic drug delivery. Mol. Pharm. 11(12), 4339 (2014).

J. Deschamps, M.C. Gomes, and A.A. Pádua, Solubility of oxygen, carbon dioxide and water in semifluorinated alkanes and in perfluorooctylbromide by molecular simulation. J. Fluor. Chem. 125(3), 409 (2004).

Y. Wang, D. Zheng, X.Q. Yang, and D. Qu, High rate oxygen reduction in non-aqueous electrolytes with the addition of perfluorinated additives. Energy Environ. Sci. 4(9), 3697 (2011).

Y. Nishikami, T. Konishi, R. Omoda, Y. Aihara, K. Oyaizu, and H. Nishide, Oxygen-enriched electrolytes based on perfluorochemicals for high-capacity lithium–oxygen batteries. J. Mater. Chem. A 3(20), 10845 (2015).

Y. Wang, F. Bai, A. Wang, Z. Cui, D. Wang, S. Shi, and T. Zhang, Perfluorinated organics regulating Li2O2 formation and improving stability for Li-oxygen batteries. Chem. Commun. 57(24), 3030 (2021).

S.I. Vorobev, First-and second-generation perfluorocarbon emulsions. Pharm. Chem. J. 43, 209 (2009).

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51906166).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Wang, X., Zhang, T. et al. A High-Stability Lithium–Air Battery Using Electrolyte Doped with PFDL. J. Electron. Mater. 52, 6378–6390 (2023). https://doi.org/10.1007/s11664-023-10584-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10584-7