Abstract

We have investigated the thermal stability of Co/Au and Ni/Au Schottky contacts to Sn-doped (\(\overline{2 }\)01) β-Ga2O3 substrates. Current–voltage (I–V) and capacitance–voltage (C–V) measurements were conducted after sequential annealing treatments totaling > 400 h at 300°C and > 150 h at 500°C in vacuum. For both sets of contacts, the average Schottky barrier heights (SBHs) calculated from the I–V measurements displayed no significant changes and remained within a narrow range throughout the anneals at 300°C. The SBHs calculated from the C–V measurements also remained largely constant for 300°C anneals, except for a modest increase for both contacts for anneal times > 350 h. For 500°C anneals, the I–V characteristics for Ni/Au and Co/Au contacts displayed continual degradation in the electrical behavior after 12 h and 24 h, respectively. Characterizations using scanning transmission electron microscopy, energy dispersive x-ray spectroscopy, and scanning electron microscopy of the samples annealed at 500°C revealed considerable changes in film morphology, interdiffusion, and phase segregation within the contacts. The results suggest the potential for Co/Au or Ni/Au Schottky contacts to be used in Ga2O3 devices at temperatures below, or possibly up to, 300°C, whereas higher temperatures will require modified metallization schemes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Silicon-based semiconductors have been the dominant semiconductor platform for decades. However, wide band gap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are replacing silicon in applications in which devices need to operate at elevated temperatures, high voltages, and/or higher powers.1 Beta-gallium oxide (β-Ga2O3) is an emerging ultra-wide band gap (EG ∼ 4.8 eV) semiconductor that has attracted much interest due to its high Baliga’s figure of merit for power devices and the availability of melt-grown bulk single crystals. Schottky barrier diodes (SBDs), which can operate at higher switching speeds than p–n junctions, are of particular interest for power devices.2 For stable operation of Ga2O3 SBDs, there is a need for Schottky contacts to Ga2O3 that operate at high temperatures for long periods of time, since the devices can generate heat or become hot from the surrounding environment.

To date, there have been limited studies of the long-term thermal stability of Schottky contacts to Ga2O3. Most reports on the effects of temperature on Ga2O3 Schottky contacts describe the electrical characteristics as a function of temperature taken from current–voltage–temperature measurements3 for short heating exposures (e.g., long enough to reach a stable temperature and to conduct the measurements). For example, metal oxides, such as PtOx and IrOx, displayed high Schottky barrier heights (SBHs) on Ga2O3 and stable electrical characteristics for limited times at operating temperatures up to 180°C.4 Lyle et al.5 investigated the short-term annealing effect of Au/Ti contacts annealed for 10 min from 50°C to 250°C on different orientations. With regard to elemental metals, Fares et al.6 measured vertical Ga2O3 diodes with W/Au and Ni/Au Schottky contacts as a function of temperatures between 25°C and 500°C. The W contacts were more stable than the Ni/Au contacts, but showed evidence of Ga migration through the contact after 500°C device operation. Hong et al.7 studied the effects of low-temperature post-annealing performed in N2 gas on Ni/Au Schottky contacts at 100°C and 200°C for 5 min, resulting in the SBH increasing from 1.07 eV to 1.14 eV after 200°C annealing. Ahn et al.8 explored the temperature-dependent characteristics of Ni/Au and Pt/Au Schottky diodes. They noted that the ideality factor decreased and the SBH increased with an increase in temperature.

In this study, we investigated the electrical properties of Co/Au and Ni/Au Schottky contacts on single-crystal n-type β-Ga2O3 substrates as a function of extended annealing time at 300°C and 500°C in air. Co and Ni were chosen because of their high work functions (5 eV and 5.25 eV, respectively), and previous work by our group that showed near-ideal Schottky diode characteristics with an ideality factor (n) of ~ 1.05 for these metals on (100) \(\beta \)-Ga2O3.3 In addition, positive free energies of reaction to form metal oxides (NiO, Co3O4, and CoO) from Ga2O3 were calculated at 25–500°C using the FactSage Database.9 This analysis indicates that Ni or Co should not reduce Ga2O3 to form Ni-oxide or Co-oxide at the interface, although it does not preclude the possibility of other reactions and reaction products. Electrical properties of the contacts were determined from current–voltage (I–V) and capacitance–voltage (C–V) measurements conducted after sequential annealing treatments. Selected samples were characterized using high-resolution transmission electron microscopy (TEM), energy dispersive x-ray (EDX) spectroscopy, and scanning electron microscopy (SEM) to investigate changes in the morphology, microstructure, and chemical composition of the contacts after annealing.

Experimental

A single-crystalline, Sn-doped (ND = 2 × 1018 cm−3), (\(\overline{2 }\)01) n-type β-Ga2O3 wafer grown by the edge-defined film-fed method, purchased from Novel Crystal Technology, Japan, was used in this study. Two 10 mm × 10 mm pieces were cut using a dicing saw and used as substrates. The substrates were ultrasonicated in acetone, isopropyl alcohol, and deionized (DI) water for 10 min each followed by a 10% hydrochloric acid clean for 5 min, rinsed in deionized water, and immersed for 5 min in boiling H2O2 at 85°C; this process follows the recipe described in Ref.10. The samples were blown dry in nitrogen after each step. All the metals were deposited onto unheated substrates by electron-beam evaporation via a Kurt Lesker PVD 75 deposition system with a base pressure of ~ 2.0 × 10–7 Torr. Ohmic contacts were formed using Ti/Au (20 nm/100 nm) on the backside of the substrate; a gap separating the contacts into two halves allowed the ohmic contacts to be tested electrically during the annealing series. The contacts were then annealed at 475°C for 1 min in N2 in an AG Heat Pulse rapid thermal annealer. Schottky contacts were deposited through a shadow mask on the frontside of the substrates to form circular Schottky contacts with diameters of 125 μm, 250 μm, and 500 μm, and 20-nm-thick Co on one half and 20-nm-thick Ni on the other half. The Schottky contacts were then coated with 80 nm of Au to serve as a capping layer.11 Cross-section and top-view schematics of the diode structure are shown in Fig. 1.

A resistively heated furnace with a mullite tube was used for the experimental anneals (as opposed to the processing anneals for the ohmic contacts). After loading the samples onto a quartz boat and inserting them into the furnace, the tube was evacuated to a pressure of 4.1 × 10–5 Torr for anneals at either 300°C or 500°C. Initial anneal times were 6 h, and then the times were increased to 12 h, 24 h, or 48 h. I–V measurements were conducted at room temperature using an Agilent 4155C semiconductor parameter analyzer with a Signatone S-1160-4 N probe station. C–V measurements were taken using an HP 4284A LCR meter at 1 MHz and a bias voltage range from − 5 V to 0 V. Before each use, a zero-correction calibration was performed on an open and closed circuit using two probes. The 125-μm-diameter contacts were selected for electrical measurements, since they were generally found to exhibit less noise in the C–V measurements than other contact diameters.

To understand the chemical, microstructural, and morphological changes that may occur during annealing, the samples were investigated using a variety of techniques. The focused ion beam-assisted lift-out using a Nova 600 and a Helios 650 was used to prepare the samples for subsequent characterization in a Themis 200 S/TEM. Pt was deposited as a capping layer to mitigate damage during TEM sample preparation. Plan view and cross-sections of the as-deposited and post-annealed samples were analyzed with SEM and STEM imaging, respectively. The SEM images were collected with an Everhart–Thornley detector and a backscattered electron detector in a Quanta 600. Cross-section images and elemental maps were characterized in STEM using high-angle annular dark-field (HAADF) imaging and energy-dispersive x-ray spectroscopy (EDX) on the as-deposited (i.e., pre-annealed) and post-annealed (at 500°C) Co/Au and Ni/Au contacts.

Results and Discussion

For moderately doped semiconductors, current transport is expected to be due to thermionic emission over the Schottky barrier. The I–V relationship can then be expressed by:

with

where Is is the saturation current, A is the area of the diode, A** is the Richardson constant, q is the electronic charge, k is the Boltzmann constant, T is temperature, Rs is the series resistance, n is the ideality factor (determines the departure from the ideal diode characteristic), and \({\Phi }_{\mathrm{B}}\) is the SBH. The Richardson constant for β-Ga2O3 has been calculated to be 33.65 A/cm2 K2.2 The SBHs (ΦBI−V) were calculated from the I–V measurements using the method of Cheung and Cheung,12 as described in our previous study.3

The SBHs \((\Phi_{B}^{CV} )\) were also calculated from the C–V measurements using the method outlined by Sze.13 The depletion-layer capacitance in a Schottky diode is given by:

where \(\varepsilon_{{\text{s}}}\) is the semiconductor permittivity and \(N_{{\text{c}}}\) is the conduction band density of states:

where \(m^{*} = 0.28m_{o}\) is the electron effective mass in β-Ga2O3 and \(m_{o}\) is the free electron mass. For β-Ga2O3 at room temperature, the conduction band density of states was calculated to be Nc = 2.67 × 1018 cm−3.2 By plotting 1/C2 versus V, the net donor density ND can be calculated from the slope and \(\Phi_{B}^{CV}\) can be calculated from the x-intercept.14 Plots of 1/C2 versus V for the 300°C annealing series for Co/Au and Ni/Au contacts are shown in Fig. 2b and d, respectively. These plots remain linear, implying a constant distribution of ND through the depth of the sample after each annealing cycle. The slopes of these curves tended to increase with annealing time, indicating a slight decrease in the doping concentration from the initial value of 1.66 × 1018 cm−3 to a final value of 3.67 × 1017 cm−3.

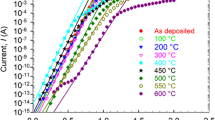

Figure 2a and c shows representative current–density (J) versus V characteristics of Co/Au and Ni/Au SBDs on β-Ga2O3 after different annealing times at 300°C. For forward bias, Co/Au and Ni/Au display linearity over several decades of current before being limited by series resistance. Relatively high reverse leakage currents are not surprising due to the high doping level in the Ga2O3 substrate. For the purposes of this study, changes in the electrical characteristics as a result of annealing are more important than the absolute values of characteristics like the reverse-bias current. No significant changes were observed in the J–V characteristics of the Co/Au diodes throughout the 300°C annealing series for a total of 432 h. The J–V characteristics of the Ni/Au contacts displayed a little more variability between the contacts, but also did not show significant signs of electrical degradation during the 300°C annealing series. The annealing experiments at 300°C were terminated after 432 h due to a furnace controller malfunction.

Figure 3a shows the barrier heights calculated from the I–V and C–V measurements plotted as a function of annealing time at 300°C. It should be noted that the ideality factors were 1.17 eV for both Co/Au and Ni/Au. These moderately high ideality factors are again attributed to the high doping level in the Ga2O3 substrate, and suggest that the ΦBI−V values are underestimated. Again, for the purposes of this research study, the changes in the electrical properties as a result of annealing are considered more important than the absolute values. The ΦBI−V values remained essentially constant throughout the annealing series, with average values of ΦBI−V (Co/Au) = 1.05 eV and ΦBI−V (Ni/Au) = 1.13 eV. The ΦBC−V values also remained relatively constant for at least 300 h, with average values of ΦBC−V (Co/Au) = 1.33 eV and ΦBC−V (Ni/Au) = 1.45 eV. It is noted that the ΦBC−V values are higher (~ 0.3 eV) than the ΦBI−V values. The ΦBC−V values are generally expected to be less affected by the high doping in the Ga2O3 substrate. Spatially inhomogeneous Schottky barriers at the M–S interface could also account for part of the difference in the ΦBI−V and ΦBC−V values.13 Beyond 350 h, the ΦBC−V values increased to 1.46 eV and 1.62 eV, respectively. It is unknown why the ΦBC−V values for both contacts increased for anneal times of 384 h, while the ΦBI−V values remained essentially unchanged. Overall, the electrical characteristics for the Co/Au and Ni/Au Schottky contacts on β-Ga2O3 remained largely stable through 300°C annealing for up to ~ 350–450 h.

After completing the annealing series at 300°C, a separate sample with Co/Au and Ni/Au contacts was characterized electrically, and then used for an annealing study at 500°C. In contrast to the results for the 300°C annealing (Fig. 3a), significant degradation in the electrical characteristics was observed during the 500°C annealing series (Figs. 3b, 4). The Ni/Au contacts had degraded to the extent that they could not be measured after 156 h, and the Co/Au could not be measured after 204 h. After the first (6 h) anneal at 500°C, the ΦBI−V and ΦBC−V values for both contacts tended to show gradual increases through ~ 40–60 h of annealing time (Fig. 3b). Increases in barrier height have been previously reported in Ni Schottky diodes on n-type epitaxial layers on conducting bulk Ga2O3 substrates at temperatures up to 200°C, attributed to interfacial reactions post-annealing.5

It should also be noted that the electrical behavior of the ohmic contacts was monitored throughout the 300°C and 500°C annealing series by placing one probe on each of the two backside ohmic contacts. Modest increases in resistance were observed with increasing annealing time (see insets in Figs. 2b and 4b).

To investigate whether the β-Ga2O3 diode performance degradation may be associated with changes in the interfacial chemistry and/or morphology, we characterized samples before and after annealing at 500°C using STEM, EDX, and SEM. As points of reference, cross-section bright field STEM images of the as-deposited Co/Au and Ni/Au contacts (Fig. 5a and c) display relatively sharp interfaces and comprise continuous layers having uniform thicknesses. A difference in image contrast can be observed between the top and bottom layers of the bilayer film, with the Co (or Ni) layer having a brighter contrast than the Au layer, indicating no detectable interdiffusion has occurred between Au and Co or Ni before annealing. There is a noticeable delineation between the Au and Co (or Ni) layers.

In contrast, after annealing at 500°C for 204 h (Co/Au) or 156 h (Ni/Au), the TEM cross-sections show a dramatic difference in morphology, and a redistribution of the metals is observed throughout the contacts, such that separate Au, Co and Ni layers no longer exist (Fig. 5b and d). The films became semi-continuous with distinct Co-rich, Ni-rich, and Au-rich regions.

HAADF images and EDX elemental maps of the as-deposited Co/Au and Ni/Au contacts, shown in Figs. 6a and 7a, respectively, indicate sharp and abrupt interfaces, in agreement with the STEM images in Fig. 5. No detectable interdiffusion has occurred between or within the layers. There is a well-defined indication of where each metal layer starts and stops. The EDX results confirm that the as-deposited samples do not display any interdiffusion of Co or Ni with the surrounding layers (Ga2O3 and Au).

However, EDX maps of samples annealed at 500°C reveal substantial changes in film morphology and chemical distribution. Au and Co (or Ni) formed segregated Au-rich and Co-rich (or Ni-rich) regions across the interface (Figs. 6b and 7b, respectively). The observed phase segregation agrees with the phase diagrams, which indicate that Co and Au do not form solid solutions or compounds with each other; this is also true for Ni and Au at the temperatures of interest here.

Solid films are usually metastable or unstable in the as-deposited state, and can agglomerate to form islands when heated to sufficiently high temperatures. This is driven by surface energy minimization and can occur via surface diffusion well below a film's melting temperature, especially when the film is very thin.15 The Co/Au contact shows the presence of a large void at the interface with Ga2O3 (Fig. 6b), which could be a precursor for agglomeration, otherwise known as solid-state dewetting.16 Dewetting proceeds in several stages, including void initiation, void growth. and void coalescence.17 Once a hole in the film has formed, it can grow subsequently by continuous diffusion, exposing the surface of the underlying substrate.

SEM was used as a complementary tool to characterize the top surfaces of the contacts. Before annealing, the SEM images (not shown) showed smooth, uniform surfaces of the contacts. Figure 8 shows representative secondary electron and backscattered electron images of Co/Au contacts annealed at 500°C for 204 h and Ni/Au contacts annealed at 500°C for 156 h. All the images show clear evidence of phase segregation, with Co-rich or Ni-rich regions embedded in a matrix of polycrystalline Au. EDX spectra (not shown) confirmed that the regions that appear light gray are the Au-rich areas, whereas the dark areas correspond with Co-rich or Ni- rich phases.

Conclusions

We have investigated changes in the electrical characteristics of Ni/Au and Co/Au SBDs on \((\overline{2 }\)01) β-Ga2O3 substrates as a function of annealing time at 300°C and 500°C in vacuum. The I–V and C–V characteristics remained largely stable throughout the annealing series at 300°C for > 400 h. However, for 500°C anneals, continual changes were observed, with significant degradation evident in the I–V characteristics after 156 h for the Ni/Au contacts and after 204 h for the Co/Au contacts. Characterization of the samples annealed at 500°C using STEM, EDX, and SEM revealed substantial interdiffusion and phase segregation within the contacts. The results point to the potential use of these pure-metal (Co/Au or Ni/Au) contacts in Ga2O3 Schottky diodes at temperatures below, or possibly up to, 300°C, whereas alternative contact metallization schemes, possibly incorporating metal oxides,4 will be necessary for Ga2O3-based device operation at temperatures at or above 300°C.

References

C.-T. Ma and Z.-H. Gu, Review on driving circuits for wide-bandgap semiconductor switching devices for mid- to high-power applications. Micromachines 12, 65 (2021).

S.J. Pearton, J. Yang, P.H. Cary, F. Ren, J. Kim, M.J. Tadjer, and M.A. Mastro, A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 5, 011301 (2018).

L.A.M. Lyle, K. Jiang, E.V. Favela, K. Das, A. Popp, Z. Galazka, G. Wagner, and L.M. Porter, Effect of metal contacts on (100) β-Ga2O3 Schottky barriers. J. Vac. Sci. Technol. A 39, 033202 (2021).

C. Hou, R.M. Gazoni, R.J. Reeves, and M.W. Allen, Direct comparison of plain and oxidized metal Schottky contacts on β-Ga2O3. Appl. Phys. Lett. 114, 033502 (2019).

L. A. M. Lyle, T. C. Back, C. T. Bowers, A. J. Green, K. D. Chabak, D. L. Dorsey, E. R. Heller, and L. M. Porter, Electrical and chemical analysis of Ti/Au contacts to β-Ga2O3. APL Mater. 9, 061104 (2021).

C. Fares, F. Ren, and S.J. Pearton, Temperature-dependent electrical characteristics of β-Ga2O3 diodes with W Schottky contacts up to 500°C. ECS J. Solid State Sci. Technol. 8, Q3007 (2019).

Y.-H. Hong, X.F. Zheng, Y.L. He, F. Zhang, X.Y. Zhang, X.C. Wang, J.N. Li, D.P. Wang, X.L. Lu, H.B. Han, and X.H. Ma, The optimized interface characteristics of β-Ga2O3 Schottky barrier diode with low temperature annealing. Appl. Phys. Lett. 119, 132103 (2021).

S. Ahn, F. Ren, L. Yuan, S.J. Pearton, and A. Kuramata, Temperature-dependent characteristics of Ni/Au and Pt/Au Schottky diodes on β-Ga2O3. ECS J. Solid State Sci. Technol. 6, P68 (2017).

C.W. Bale and P. Chartrand, FactSage Thermochemical Software and Database, (2002).

Y. Yao, R.F. Davis, and L.M. Porter, Investigation of different metals as ohmic contacts to β-Ga2O3: comparison and analysis of electrical behavior, morphology, and other physical properties. J. Electron. Mater. 46, 2053 (2017).

M.-H. Lee and R.L. Peterson, Process and characterization of ohmic contacts for beta-phase gallium oxide. J. Mater. Res. 36, 4771 (2021).

S.K. Cheung and N.W. Cheung, Extraction of Schottky diode parameters from forward current–voltage characteristics. Appl. Phys. Lett. 49, 85 (1986).

C.R. Crowell and S.M. Sze, Current transport in metal-semiconductor barriers. Solid-State Electron. 9, 1035 (1966).

M.K. Yadav, A. Mondal, S.K. Sharma, and A. Bag, Probing interface trapping characteristics of Au/β-Ga2O3 Schottky barrier diode on Si (100). IEEE Trans. Device Mater. Reliab. 21, 613 (2021).

D. Deduytsche, C. Detavernier, R.L. Van Meirhaeghe, and C. Lavoie, High-temperature degradation of NiSi films: agglomeration versus NiSi2 nucleation. J. Appl. Phys. 98, 033526 (2005).

X. Cen, X. Zhang, A.M. Thron, and K. van Benthem, agglomeration and long-range edge retraction for Au/Ni bilayer films during thermal annealing. Acta Mater. 119, 167 (2016).

X. Cen, A.M. Thron, X. Zhang, and K. van Benthem, Cross-sectional characterization of the dewetting of a Au/Ni bilayer film. Ultramicroscopy 178, 131 (2017).

Acknowledgments

This material is based upon work supported by the Air Force Office of Scientific Research under award numbers FA9550-18-1-0387 and FA9550-21-1-0360 (Program Manager Ali Sayir). The use of the Materials Characterization Facility at Carnegie Mellon University was supported by Grant No. MCF-677785.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Favela, E.V., Zhang, K., Cabral, M.J. et al. Effects of Annealing on Co/Au and Ni/Au Schottky Contacts on β-Ga2O3. J. Electron. Mater. 52, 1927–1936 (2023). https://doi.org/10.1007/s11664-022-10151-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-10151-6