Abstract

By utilizing the shear cell technique and achieving stable density layering with the addition of an alloying element Bi, the self-diffusion coefficients of liquid Sn were measured on the ground at 573 K, 773 K, and 973 K (300 °C, 500 °C, and 700 °C). Moreover, the impurity diffusion coefficients of Bi in the liquid Sn were simultaneously measured, to confirm the suppression of natural convection. From the experimental results, natural convection was confirmed to be suppressed, given that the impurity diffusion coefficients of Bi were in good agreement with the microgravity reference data. Upon changing the amounts of added Bi within 5 at. pct Bi, the self-diffusion coefficients of liquid Sn did not vary significantly. Moreover, the SnBi system within 5 at. pct Bi can be regarded as a dilute solution by calculating the activity of Sn in the SnBi system beforehand. The self-diffusion coefficients of the liquid Sn were in good agreement with the power law of temperature dependence from the microgravity reference data. After confirming the suppression of natural convection and that the SnBi system is a dilute solution, the self-diffusion coefficient of liquid Sn was determined as 5.00 ± 0.16 × 10−9 m2 s−1 at 773 K (500 °C). The effectiveness of the experimental method used in this study for the measurement of the self-diffusion coefficients was confirmed, under the condition that the liquid system could be regarded as a dilute solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Diffusion coefficients in liquid metals are essential to the understanding of metallurgical phenomena such as solute redistribution at solid–liquid interfaces during solidification processes. In particular, the self-diffusion coefficients in liquid metals are required for the modeling of diffusive theories in liquid metals, given that self-diffusion is the simplest diffusion phenomenon. The self-diffusion coefficients in liquid metals are widely used in diffusive theories[1,2,3,4,5,6]; namely, the Stokes–Einstein formula,[1] hard sphere model,[2] and molecular dynamics simulations.[3] The measurement of diffusion coefficients in liquid metals under microgravity conditions in space is significantly more reliable than that on the ground. However, prior to space experiments, several experiments were performed on the ground.[7,8] Due to the insufficient experimental data of reliable self-diffusion coefficients in liquid metals on the ground, it is unclear whether these diffusive theories can be demonstrated by the experimental results. On the ground, buoyancy causes natural convection in liquid metals, and the experimental results could be influenced by natural convection. Moreover, the methods using quasi-elastic incoherent neutron scattering are effective for the measurement of self-diffusion coefficients in liquid metals on the ground.[9] However, large equipment is required for experiments using quasi-elastic incoherent neutron scattering, and the number of experiments is limited.

It is common knowledge that microgravity conditions are effective in suppressing natural convection. Frohberg et al.[10] conducted diffusion experiments under microgravity conditions using a long capillary technique and measured the self-diffusion coefficients of liquid Sn. It was reported that the self-diffusion coefficients of liquid Sn under microgravity conditions were significantly lower than those measured on the ground. Moreover, the variation in the self-diffusion coefficients of liquid Sn under microgravity conditions was significantly smaller than that on the ground. Furthermore, Frohberg et al.[11] proposed the power law of temperature dependence D = ATn (A and n are fitting parameters; and the value of n is approximately 2). Itami et al.[12] also conducted a self-diffusion experiment on liquid Sn under microgravity conditions, using a long capillary technique. It was reported that the experimental results were in good agreement with those of Frohberg et al.,[11] and were represented as D = ATn with a maximum temperature value of up to 1622 K (1349 °C). Yoda et al.[13] conducted a self-diffusion experiment on liquid Sn using the shear cell technique under microgravity conditions, and reported good agreement between the experimental results at 1622 K (1349 °C) and those of Itami et al. The reproducibility of the self-diffusion coefficients of liquid Sn has therefore been confirmed by the results from previous experiments, under the microgravity conditions mentioned above. However, experiments under microgravity conditions are difficult to conduct, due to the high cost, preparation time, and the risk of damaging the devices due to the shock induced by the launching or re-entry of the spaceship. Thus, only a few self-diffusion experiments under microgravity conditions have been conducted on liquid Sn, despite the requirement of measuring the self-diffusion coefficients of other metals. The experimental method for the measurement of the self-diffusion coefficients on the ground is therefore required, in addition to the suppression of natural convection.

The focus of this study is an experimental method using the shear cell technique and stable density layering proposed by Suzuki et al.[14] Stable density layering refers to the manner in which the diffusion axis is set parallel to the gravity vector, and the densities of the diffusion samples increase monotonically downward during the entire diffusion process. Suzuki et al.[14] reported that the results of diffusion experiments on the ground using the shear cell technique and stable density layering were in good agreement with those of diffusion experiments under microgravity conditions. However, in self-diffusion experiments, it is difficult to achieve stable density layering, given that the density gradient is insufficient for stability to be realized during the entire diffusion process.[15] Moreover, an experiment conducted to stabilize the density layering by the addition of a third element Bi to the binary alloy SnIn was reported.[16] The experimental results revealed that density layering can be stabilized by the addition of a third element. Based on the above experiment, it was suggested that stabilization could be achieved by the addition of an alloying element to a diffusion couple of a pure metal in a self-diffusion experiment. It is necessary to consider the influence of additive elements on the self-diffusion coefficient; however, no studies on the influence with respect to thermodynamics have been reported.

In this paper, the purpose is to propose an experimental method for the measurement of self-diffusion coefficients on the ground using the shear cell technique and stable density layering achieved by the addition of an alloying element. The samples used were Sn and SnBi alloy, due to the availability of the reference data from the space experiments. The diffusion experiments were conducted using a sample setting of SnBi that contained a tracer element 124Sn. The effect of the suppression of natural convection was discussed with respect to the comparison between the obtained impurity diffusion coefficients of Bi in liquid Sn and those of the reference data. In addition, it was investigated whether the SnBi system used in this study could be regarded as a dilute solution with respect to thermodynamics.

Experimental Procedure

Tin (99.999 at. pct purity; Kojundo Chemical Laboratory Co., Ltd.), bismuth (99.999 at. pct purity; Kojundo Chemical Laboratory Co., Ltd.), and a tin isotope 124Sn (99.90 at. pct purity; ISOFLEX USA) were used as diffusion samples to prepare designed alloys. The diffusion samples of Sn, Sn-1 at. pct Bi, Sn-3 at. pct Bi, Sn-5 at. pct Bi, and Sn*Bi were prepared as follows; and Sn*Bi, which contained 20 at. pct 124Sn higher than its natural abundance ratio, was prepared as Sn*-1 at. pct Bi, Sn*-3 at. pct Bi, and Sn*-5 at. pct Bi. First, each pure metal was weighed, placed into a graphite crucible, and heated at 873 K (600 °C). Second, the bulk samples were shaped into wires with diameters of 1.45 mm using wire drawing dies. Finally, the shaped samples were cut to suitable lengths that were able to fit into the diffusion device.

Figure 1 presents a schematic illustration of the shear cell technique. The design of the shear cell device was the same as that used in the Russian satellite mission FOTON-M2.[14] All four capillaries (A, B, C, and D) were filled with the samples of the Sn and SnBi alloys. An alloy sample Sn*Bi was set in capillary C. The samples of Sn were set in the upper part, and the samples of SnBi were set in the lower part, so as to achieve stable density layering. Each sample was weighed before insertion. The diffusion temperatures were 573 K (300 °C) (tdiff = 35,500 seconds), 773 K (500 °C) (tdiff = 18,000 seconds), and 973 K (700 °C) (tdiff = 12,200 seconds), and the samples used were Sn-3 at. pct Bi and Sn. At 773 K (500 °C) (tdiff = 18,000 seconds), the diffusion experiments which were changed with the concentration of samples used Sn-1 at. pct Bi and Sn-5 at. pct Bi were also conducted. Moreover, alloy samples Sn*-1 at. pct Bi and Sn*-5 at. pct Bi were set in capillary C. The diffusion experiment using Sn-1 at. pct Bi was conducted with three capillaries (A, B, and C).

After evacuating the chamber containing the shear cell device, the furnace was heated to the diffusion temperature, and the samples were homogenized, as shown in Figure 1(a). The reservoirs were then pressurized under P = 20 kPa using graphite felts, to prevent the formation of a free surface on the capillaries. After homogenization for 2 hours, the intermediate cell inserted the capillaries at a shear speed v0 of 0.5 mm s−1, and the diffusion process began, as shown in Figures 1(b) and (c). The temperature was measured at three points (x = 0 mm, x = 30 mm, and x = 60 mm). The temperature at the center (x = 30 mm) was the highest, that at each edge (x = 0 and x = 60 mm) was the lowest in the shear cell device, and the absolute value of the temperature gradient was smaller than 40 K m−1. Moreover, the atmosphere was 5.0 × 10−4 Pa during the diffusion experiments. At the end of the diffusion process, which was followed by cooling, each sample piece was mechanically pressed out of the 20 cells at a shear speed v0 of 0.5 mm s−1, as shown in Figure 1(d). The cells were then weighed and dissolved in nitric acid. The concentration of 124Sn in each cell was analyzed using inductively coupled plasma mass spectroscopy (ICP-MS; Agilent 7700), and the concentration of Bi in each cell was analyzed using inductively coupled plasma optical emission spectroscopy (ICP-OES; Agilent 5100).

Results

Self-diffusion

Figure 2 presents the concentration profiles of 124Sn at temperatures of 573 K, 773 K, and 973 K (300 °C, 500 °C, and 700 °C). Figure 3 presents the concentration profiles of 124Sn with added amounts of 1 at. pct Bi, 3 at. pct Bi, and 5 at. pct Bi. The concentration curves c(x,t) for the diffusion experiments were fitted with the thick layer solution, and can be expressed as

where c2, x, and t are set at the constant parameters; and X2meas, h0, and c1 are set at the fitting parameters. There were slight variations in the h0 values of the samples, due to the variations in the weights of the alloying samples.

Figure 2 reveals that each obtained concentration profile was in good agreement with Eq. [1] (R2 > 0.99). Figure 3 presents the obtained concentration profiles and the normalized concentration profile, using the following equation:

These profiles were also in good agreement with Eq. [1] (R2 > 0.99), as shown in Figure 3(a). Although the same sample was used, the values of c1 differed, due to the systematic error from the ICP analysis. However, Figure 3(b) reveals that all the profiles nearly overlap. Therefore, the difference in the values of c1 did not affect the calculation of the diffusion coefficients.

Figures 4 and 5 are linearized representations of the 124Sn concentration profiles presented in Figures 2 and 3, respectively. Figures 4 and 5 can be used to determine the influence of the convection rolls. The profiles can also be approximately modeled using a thin layer solution, and can be expressed as

where h 20 /6 is due to the step of the start profile.[14] Moreover, Eq. [4] is the logarithm of Eq. [3], and Eq. [4] reveals the linear relationship between ln(c(x,t) − c1) and x2.

The mean-square diffusion depth and diffusion coefficient are related to the Einstein–Smoluchowski equation presented in Eq. [5]. In this study, the value of X2meas in the case of the shear cell technique contains two systematic error sources of additional mass transport, which can be interpreted as X2shear and X2aver. It is necessary to correct these additional values when calculating the diffusion coefficients, to determine the pure diffusion coefficients. Here, X2shear is the additional value resulting from the shearing processes shown in Figure 1(d) and is considered to cause shear-induced convection in each cell (X2shear = 2.0 × 10−7 m2).[17] Moreover, X2aver is an additional value obtained from the plot of the average concentration value for each cell. The gradient of the concentration within each cell was eliminated using analyses such as ICP, due to the process of dissolving in nitric acid. However, this averaging effect can be described geometrically as H2/12 (X2aver = H2/12 = 7.5 × 10−7 m2, where H = 3 mm).[14] The diffusion coefficient under each condition could therefore be calculated using

The measured self-diffusion coefficients of 124Sn and the errors are listed in Table I for each condition.

Impurity Diffusion

Figure 6 presents the concentration profiles of 3 at. pct Bi at a temperature of 773 K (500 °C). Figure 6 reveals that each obtained concentration profile was in good agreement with Eq. [1] (R2 > 0.9999). Similarly, Figure 7 is a linearized representation of the concentration profiles of 3 at. pct Bi presented in Figure 6. Other results of impurity diffusion were also obtained with the same profiles presented in Figures 6 and 7. Table II presents the obtained impurity diffusion coefficients of Bi in liquid Sn and the error ΔD at each temperature and concentration, calculated using Eqs. [1] and [5].

Discussion

Investigation of Suppressing Natural Convection

Figure 7 reveals that the influence of large convection rolls was small, given that the linear plots of Bi lncBi was in good agreement with Eq. [4], in the form of a linear relationship. With respect to δ in Table II, the reproducibility of DBi at each temperature was appropriate. Figure 8 presents the temperature dependence of DBi. The DBi values were in good agreement with the reference data,[18,19,20,21] and were obtained under convection-free conditions. The average DBi value (DBi_ave) at 773 K (500 °C) was in good agreement with the result of Dµ = 4.36 × 10−9 m2 s−1, which was obtained from the Russian satellite mission FOTON-M2[21] at 773 K (500 °C) with a small relative error of (DBi_773 K − Dµ)/Dµ × 100 = 0.14 pct, where DBi_773 K is the average value of DBi_ave at 773 K (500 °C). Considering that the estimated measurement error in the previous study[22] was approximately 6 pct, this relative error was small. It was therefore concluded that natural convection was sufficiently suppressed in the experiments.

The Relationship Between Self-diffusion and Intrinsic Diffusion

Figure 9 presents the activity of Sn in the SnBi system at 773 K (500 °C), using a quasi-chemical theory.[23] The calculations based on the quasi-chemical theory are presented in Appendix A. The SnBi system was then assumed to be the regular solution.[24] The activity of Sn can be expressed as

Based on Figure 9 and Raoul’s law, the activity is considered for an ideal solution of Sn within the range of the measured concentrations of Bi in the experiments, given that the activities indicated by the solid line and the dashed line cannot be distinguished. Therefore, the SnBi system in the experiments was considered as a dilute solution in liquid Sn.

In this study, \( D_{{^{124} {\text{Sn}}}} \) refers to an intrinsic diffusion coefficient of liquid Sn in the SnBi system, given that the solvent was Sn with a very small amount of Bi. Moreover, the influence of the solute element Bi on \( D_{{^{124} {\text{Sn}}}} \) was previously estimated using the thermodynamic theoretical formula. According to the thermodynamic theoretical formula, \( D_{{^{124} {\text{Sn}}}} \) can be expressed as

The thermodynamic factor was calculated from Figure 9. Figure 10 presents the relationship between \( \varPhi_{\text{Sn}} \) and NSn. At the experiments, \( \varPhi_{\text{Sn}} \) was included within the error range of σ = 3.14 pct, which was calculated considering the error of measurement from the ICP-MS (Appendix B). Thus, the estimated influence of Bi on \( D_{{^{124} {\text{Sn}}}} \) was sufficiently smaller than that of the error of measurement from the ICP-MS.

Figure 11 presents the relationship between the results of \( D_{{^{124} {\text{Sn}}}} \) and the amounts of added Bi in the experiments at 773 K (500 °C). There was a slight decrease in the value of \( D_{{^{124} {\text{Sn}}}} \) in accordance with a decrease in the amount of Bi. On the other hand, there was a slight increase in the value of \( \varPhi_{\text{Sn}} \) in accordance with a decrease in the amount of Bi, as shown in Figure 10. The trends of \( D_{{^{124} {\text{Sn}}}} \) and \( \varPhi_{\text{Sn}} \) were initially the same as that expressed by Eq. [7]. However, the trend of \( D_{{^{124} {\text{Sn}}}} \) with a decrease in the amount of Bi did not match that of \( \varPhi_{\text{Sn}} \). In addition, the values of \( D_{{^{124} {\text{Sn}}}} \) and \( D^{*}{_{{^{124} {\text{Sn}}}}} \) were included within the same error range, as shown in Figure 11. The trend of \( D_{{^{124} {\text{Sn}}}} \) was therefore considered as experimental error.

Thus, \( D_{{^{124} {\text{Sn}}}} \) could be distinguished between a self-diffusion coefficient and an intrinsic diffusion coefficient within 5 at. pct Bi. The value of \( D_{{^{124} {\text{Sn}}}} \) was 5.00 ± 0.16 × 10−9 m2 s−1 at 773 K (500 °C), and the error σ was 3.14 pct. However, the results of \( D_{{^{124} {\text{Sn}}}} \) had a sufficiently small relative standard deviation (RSD) of 0.62 pct for use in discussions on diffusive theories and the temperature dependence of diffusion coefficients. Consequently, the measured intrinsic diffusion coefficient could be considered as the self-diffusion coefficient in these experiments. It was assumed that the influence of a solute element Bi on \( D_{{^{124} {\text{Sn}}}} \) was sufficiently small in the SnBi system, which was regarded as a dilute solution in liquid Sn.

Self-diffusion Coefficient of Liquid Sn

Figures 4 and 5 reveal that the influence of the large convection rolls was small, given that the linear plots of \( ^{124} {\text{Sn ln}}\left( {c_{{^{124} {\text{Sn}}}} - c_{ 1} } \right) \) was in good agreement with Eq. [4], in the form of a linear relationship. Figure 12 presents the temperature dependence of \( D_{{^{124} {\text{Sn}}}} \). All the data of \( D_{{^{124} {\text{Sn}}}} \) in the study were included within the calculated curves of the microgravity reference data.[11,12,13] Thus, the data of \( D_{{^{124} {\text{Sn}}}} \) in the study were in good agreement with the microgravity reference data[11,12,13] of \( D_{{^{124} {\text{Sn}}}} \), due to the suppression of natural convection. Moreover, it was concluded that the influence of the solute element Bi on \( D_{{^{124} {\text{Sn}}}} \) was sufficiently small, due to the correspondence between the \( D_{{^{124} {\text{Sn}}}} \) data in this study and the microgravity reference data.

The experimental results therefore highlight two points. First, the addition of a high-density alloying element facilitated the suppression of natural convection. This effect can be explained as an “anchor.” Second, the influence of a solute element on the self-diffusion coefficient of liquid metal is sufficiently small in a liquid system that is regarded as a dilute solution. In other words, the addition of an adequate amount of a high-density alloying element (the anchor) provides stable density layering that is effective in the suppression of natural convection, under the condition that the liquid system can be regarded as a dilute solution.

Conclusion

The results of the self-diffusion experiments of Sn were in good agreement with the concentration curves and fitting functions. There was good agreement in the temperature dependencies of the self-diffusion coefficients of liquid Sn between the experimental results and the curves obtained from the space experiments. Moreover, from the results of the impurity diffusion, it was clear that natural convection was suppressed in the experiments, due to the effect of stable density layering achieved by the addition of an alloying element. With respect to the thermodynamics, the SnBi alloys could be considered as dilute solutions in liquid Sn within the range of concentration of the added amount of Bi. The influence of a solute element Bi on \( D_{{^{124} {\text{Sn}}}} \) was therefore assumed to be sufficiently small, given that the intrinsic diffusion coefficient was considered as the self-diffusion coefficient in the SnBi system, which was regarded as a dilute solution in liquid Sn. It was concluded that the self-diffusion coefficients could be measured on the ground using the shear cell technique and a stable density layering achieved by the addition of an alloying element, under the condition that the liquid system can be regarded as a dilute solution.

Abbreviations

- a Sn :

-

Activity of Sn

- c 1 :

-

Initial concentration of 124Sn or Bi in the semi-infinite layer (at. pct)

- c 2 :

-

Initial concentration of 124Sn or Bi in the thick layer (at. pct)

- \( c_{{^{124} {\text{Sn}}}} \) :

-

Concentration of 124Sn (at. pct)

- c Bi :

-

Concentration of Bi (at. pct)

- c norm :

-

Normalized concentration of 124Sn by c1

- D :

-

Diffusion coefficient (m2 s−1)

- \( D_{{^{124} {\text{Sn}}}} \) :

-

Self-diffusion coefficient of 124Sn (m2 s−1)

- \( D^{*}{_{{^{124} {\text{Sn}}}}} \) :

-

Self-diffusion coefficient of 124Sn without the addition of Bi (m2 s−1)

- \( D_{{^{124} {\text{Sn}}_{\text{ave}}}} \) :

-

Average value of \( D_{{^{124} {\text{Sn}}}} \) at each temperature (m2 s−1)

- D Bi :

-

Impurity diffusion coefficient of Bi in liquid Sn (m2 s−1)

- D Bi_ave :

-

Average value of DBi for each experimental condition (m2 s−1)

- \( G_{\text{m}}^{\text{ex}} \) :

-

Excess free energy of mixing (J)

- h 0 :

-

Initial thickness of a sample (m)

- H :

-

Height of a cell (m)

- k B :

-

Boltzmann’s constant (J K−1)

- N Sn :

-

Molar fraction of Sn

- R :

-

Molar gas constant (J K−1 mol−1)

- R 2 :

-

Coefficient of determination

- RSD:

-

Relative standard deviation (pct)

- t :

-

Time (s)

- t diff :

-

Diffusion time (s)

- T :

-

Temperature (K)

- x :

-

Position (m)

- X 2 aver :

-

Mean-square diffusion depth of additional value resulting from the plot of the average value for each cell (m2)

- X 2 meas :

-

Measured mean-square diffusion depth (m2)

- X 2 sim :

-

Mean-square diffusion depth of simulated concentration profile (m2)

- X 2 shear :

-

Mean-square diffusion depth of additional value resulting from the shearing process (m2)

- z :

-

Coordination number

- γ Bi :

-

Activity coefficient of Bi

- γ Sn :

-

Activity coefficient of Sn

- σ :

-

Calculated error, considering the error of measurement from the ICP-MS (pct)

- \( \varPhi_{\text{Sn}} \) :

-

Thermodynamic factor of Sn in the SnBi system

- ω :

-

Interchange energy (J)

References

1. G.B.B.M. Sutherland: Phil. Mag., 1905, vol. 9, pp. 781-85.

2. P. Protopapas, H.C. Andersen, and N. A. D. Parlee: J. Chem. Phys, 1973, vol. 59, pp. 15-25.

3. M. Mouas, J.G. Gasser, S. Hellal, B. Grosdidier, A. Makradi, and S. Belouettar: J. Chem. Phys., 2012, vol. 136, 094501.

4. T. Iida, R.I.L. Guthrie, and N. Tripathi: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 559-64.

5. G. Kaptay: Int. J. Mat. Res., 2008, vol. 99, pp. 14-17.

6. I. Yokoyama: Physica B, 2000, vol. 291, pp. 145-51.

7. C.H. Ma and R.A. Swalin: J. Chem. Phys., 1962, vol. 36, pp. 3014-18.

8. J.P. Foster and R.J. Reynik: Metall. Trans., 1973, vol. 4, pp. 207-16.

9. A. Meyer: EPJ Web of Conferences, 2015, vol. 83, 01002.

G. Frohberg, K.H. Kraatz, and H. Wever: ESA-SP-222, 1984, pp. 201–05.

11. Y. Malmejac and G. Frohberg: Fluid Sciences and Materials Science in Space, 1st ed., Springer-Verlag, Berlin, 1987, pp. 158-90.

12. T. Itami, H. Aoki, M. Kaneko, M. Uchida, A. Shisa, S. Amano, O. Odawara, T. Masaki, H. Oda, T. Ooida, and S. Yoda: J. Jpn. Soc. Microgravity Appl., 1998, vol. 15, pp. 225-32.

13. S. Yoda, H. Oda, T. Oida, T. Masaki, M. Kaneko, and K. Higashino: J. Jpn. Soc. Microgravity Appl., 1999, vol. 16, pp. 111-18.

14. S. Suzuki, K.H. Kraatz, and G. Frohberg: Ann. N.Y. Acad. Sci., 2004, vol. 1027, pp. 169-81.

15. S. Suzuki, K.H. Kraatz, and G. Frohberg: J. Jpn. Soc. Microgravity Appl., 2005, vol. 22, pp. 165-75.

16. S. Suzuki, K.H. Kraatz, and G. Frohberg: J. Jpn. Soc. Microgravity Appl., 2011, vol. 28, pp. S100-04.

S. Suzuki, K.H. Kraatz and G. Frohberg: Microgravity Sci. Technol., 2005, XVI-1, pp. 127-32.

18. S. Suzuki, K.H. Kraatz, G. Frohberg, R. Roşu-Pflumm, and G. Müller-Vogt: J. Non-Cryst. Solids., 2007, vol. 353, pp. 3300-04.

19. V. Botton, P. Lehmann, R. Bolcato, and R. Moreau: Int. J. Heat Mass Transf., 2004, vol. 47, pp. 2457-67.

20. R. Roşu-Pflumm, W. Wendl, G. Müller-Vogt, S. Suzuki, K.H. Kraatz, and G. Frohberg: Int. J. Heat Mass Trans., 2009, vol. 52, pp. 6042-49.

S. Suzuki, K.H. Kraatz, and G. Frohberg: Microgravity Sci. Technol., 2006, 4, pp. 155-59.

22. J.P. Garandet, G. Mathiak, V. Botton, P. Lehmann, and A. Griesche: Int. J. Thermophys., 2004, vol. 25, pp. 249-72.

23. R. N. Singh: Can. J. Phys, 1987, vol. 65, pp. 309-25.

24. Y. Tiba, T. Matsushima, and K. Ono: Tohoku Daigaku Senko Seiren Kenkyusho Iho, 1964, vol. 20, pp. 41-49 (in Japanese).

25. T. Itami, S. Munejiri, T. Masaki, H. Aoki, Y. Ishii, T. Kamiyama, Y. Senda, F. Shimoji, and K. Hoshino: Phys. Rev. B, 2003, vol. 67, 064201.

26. R. Hultgren, P. D. Desai, D. T. Hawkins, M. Gleiser, and K. K. Kelley: Selected Values of the Thermodynamic Properties of Binary Alloys, American Society for Metals, Metals Park, Ohio, 1973, pp. 451-55.

Acknowledgments

This work was supported by a grant-in-aid from the Mitsubishi Materials Corporation in the 2017 fiscal year, and the diffusion phenomena in melts working group of the Japan Aerospace Exploration Agency. Furthermore, we would like to thank the Environmental Safety Center, Waseda University, for the sample analysis; and Kimura Foundry Co., Ltd. for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 30, 2018.

Appendices

Appendix A

The quasi-chemical theory is a theoretical model that assumes the existence of chemical complexes in a liquid binary alloy. In this study, the SnBi system was assumed to be the regular solution. Thus, the excess free energy of mixing \( G_{\text{m}}^{\text{ex}} \) in the SnBi system, using the quasi-chemical theory, can be expressed as

where \( \gamma_{\text{Sn}} \) is given by the following expressions:

Therefore, using Eq. [6], \( \varPhi_{\text{Sn}} \) is given by the following expressions:

where the value of z was set as 10.2 at 773 K (500 °C) in liquid Sn.[25] The value of ω/kB was calculated from the reference of the activity at 600 K (327 °C)[26] and was set as 126.6.

Appendix B

In diffusion experiments, it is important to obtain a concentration profile with a small variation. An increase in the concentration step (c2 − c1) of the diffusion couple effectively reduces the variation in the concentration. However, the use of the 124Sn sample in the self-diffusion experiments in this study was limited, due to its low abundance. Moreover, it was necessary to accurately determine the minimum amount of 124Sn for the self-diffusion experiments. The concentration profiles were therefore simulated to obtain the conditions for suitable fitting with Eq. [1]. From the simulation, the value of σ in the concentration step with self-diffusion was calculated.

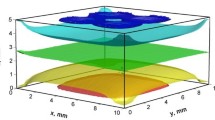

Figure B1 and Table BI present the simulation of the concentration profile and the simulation properties of the self-diffusion experiment, respectively. In the simulation, the only variable parameter was c2. First, an ideal concentration profile was created at a certain concentration step. Second, each ideal concentration was changed within the measurement error of ICP-MS used for the concentration measurement in this study, using a random function. The simulated concentration profile was obtained as shown in Figure B1. The measurement error of ICP-MS was 1.95 pct, which was obtained from the preliminary experiment.

In preliminary experiments, five solutions of 124Sn in nitric acid were prepared for each concentration level. For each solution, the measurements using ICP-MS were repeated four times. For each concentration level, a total of 20 measurements were performed, and the average and standard deviation (relative error) were calculated, as shown in Figure B2. The average of the relative error in the range of 6 at. pct to 25 at. pct of 124Sn was 1.95 pct.

Finally, the simulated concentration profile was fitted again with Eq. [1], and X2sim was obtained. From X2sim and X2meas, the standard deviation was calculated for each concentration step, and the error σ was calculated. For each concentration step, the simulation was repeated 10 times. Figure B3 presents the results of the simulation. In this study, the concentration step of 124Sn was set as 20 at. pct. Therefore, the value of σ was 3.14 pct, obtained from Figure B3.

Rights and permissions

About this article

Cite this article

Shiinoki, M., Hashimoto, N., Fukuda, H. et al. Self-diffusion Measurements of Liquid Sn Using the Shear Cell Technique and Stable Density Layering. Metall Mater Trans B 49, 3357–3366 (2018). https://doi.org/10.1007/s11663-018-1416-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1416-3