Abstract

Appropriate nodularity in ductile iron castings is strongly associated with the presence of high enough not combined Mg dissolved in the melt to cast. However, the residual Mg which is commonly measured for production control accounts for both dissolved Mg and Mg combined as oxides and sulfides. To account for the uncertainties associated with such a control, it is quite usual to over treat the melt with the risk of porosity appearance. A new methodology based on thermal analysis has been developed in the present work so as to estimate the amount of free Mg dissolved in the melt ready for pouring. A combination of Te mixture and a new “reactive mixture” composed of sulfur plus a commercial inoculant has been prepared for this purpose. This reactive mixture is able to transform the magnesium remaining dissolved in the melt to combined forms of this element. Experiments performed both during start of production (when Mg overtreatment is usual) and during normal mass production indicate that important variations of free Mg occur without relevant changes in residual Mg content as determined by spectrometry. The method developed in the present work has shown to be highly effective to detect those melt batches where active Mg content is not high enough for guaranteeing a correct nodularity of castings. Selection of proper active Mg thresholds and a correct inoculation process are critical to avoid “false”-negative results when using this new method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Although graphite is the most common crystalline phase of solid carbon, its nucleation and growth during production of ductile cast irons (SGI) is a complex process. Processing variables as carbon equivalent, inoculation, and Mg content strongly affect the shape and distribution of graphite particles, though the amount and nature of other minor alloying elements also play an important role.[1–7] Regarding graphite nucleation, most of the small inclusions found in ductile irons are compounds related to Mg treatment and inoculation (e.g., MgS, CaS, MgO·SiO2, and 2MgO·SiO2) which may act as nucleation sites.[8] However, particles with similar composition have been found both inside and outside the nodules showing that not all of these compounds become nucleation sites for graphite particles.[9] This is possibly because some of them do not fulfill the requirements to be efficient nuclei[10] and certainly because very little of the nucleation sites are effectively activated as shown for aluminum alloys.[11] This blocking of the grain refiner action has been rationalized in the case of aluminum and magnesium alloys,[12–14] and this certainly applies to cast irons as well.

Although a definitive understanding about graphite growth is not available at present, the effective control of Mg, O, and S in cast iron alloys is well known to be critical for ensuring the formation of correct nodules. As a matter of fact, Mg is the most employed element among known nodularizers (Ca, Mg, Ce, La), and it is commonly added by means of FeSiMg master alloys. As Mg easily combines with S and O, raw materials with low S contents are required to minimize costs due to Mg consumption during nodularization treatment. Also, it is accepted that the comparative high C and Si contents usually found in cast irons drastically reduce the amount of available O dissolved in the melt.[15,16]

In foundry plants, determination of the S content in cast irons is made by optical emission spectroscopy or combustion analysis, while measurement of the O content needs techniques that are usually not available in foundries. The common technique used for determining Mg content in normal production is also optical emission spectroscopy, though control of Mg content in cast parts can also be occasionally made by induction coupled plasma technique. However, both methodologies give the so-called “residual” or total Mg content, while it is well known that only the not combined or free Mg acts for obtaining rounded graphite shape. A crude estimate of dissolved Mg can only be made by taking into account the S content of the melt, namely by considering that all S is tight by Mg as MgS and considering the remaining Mg is free. Such an evaluation can give rise to batches with similar residual Mg contents but with different nodularities under similar production conditions if S and/or Mg do form compounds with other elements. The associated uncertainty is commonly solved in foundry plants by increasing residual Mg to ensure that free Mg is high enough to match the nodularity requirement. Additional manufacturing costs and a risk of increased shrinkage result from such treatment.

Thermal analysis (TA) is a widespread technique for controlling cast iron production, mainly for determining C and Si contents and to estimate nodule count.[17–20] For C and Si analysis, the use of a standard TA cup containing Te that leads to metastable solidification[21] is preferred to stable solidification which gives less reproducible results.[22,23] The effectiveness of an inoculation treatment may be estimated using a second thermal cup in which the melt is expected to solidify in conditions close to those relevant for the casting under production. In the present work, a new method has been developed to estimate the free Mg content of a ready to pour SGI melt. This method is based on recording the cooling curve of a melt sample cast in a TA cup containing some Te and a mixture of sulfur and inoculant that will make most of the available free Mg to be reacted. This method takes advantage of the fact that cooling curves corresponding to stable and metastable solidification are easily distinguishable[24,25] and that their differences depend on the free Mg content in the sample. The present work shows that, from these differences, it can be decided if the available free Mg is above or below a critical level that would ensure a correct nodularity in castings.

Experimental Work

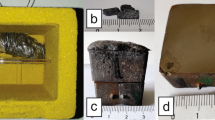

For melt characterization in the foundry workshop, standard TA cups with a K-type thermocouple (Figure 1(a)) were used. More precisely, two standard TA cups were prepared: a plain cup (denoted in the following as “thermal cup”) and a cup for active Mg determination.[26] In the first cup (left side of Figure 1(b)), 0.7 g of a commercial inoculant (grain size 0.2–0.7 mm, Si = 68–73 wt pct, Al = 3.2–4.5 wt pct, Ca = 0.3–1.5 wt pct, RE = 0.03–0.09 wt pct and balance Fe) was added before pouring it in order to record the cooling curve of the inoculated alloy. For active Mg determination, a precise amount of a reactive mixture composed of 22 pct of high-purity dust sulfur (>99.9 wt pct) and of 78 pct of dust inoculant (Si = 72.1 wt pct, Al = 0.80 wt pct, Ba = 0.98, Ca = 1.20 wt pct and Fe balance) was added to commercial TA cups that already contained about 2.50 g of a Te mixture (see the brightest stain in the central cup of Figure 1(b)). Tellurium content in this mixture stuck in the bottom of TA cups ranges from 21 to 25 wt pct. The amount of the reactive mixture to be added has been previously defined according to the expected range of active Mg in the analyzed melts. The active Mg cups were finally covered with a metallic lid (right side of Figure 1(b)) whose role is to ensure a constant filling of the cup and to avoid melt spillage. These precautions are considered as essential to properly fill the TA cups as already reported by Larrañaga et al.[18]

All melts analyzed in the present work were taken from the pouring basin of a press–pour which approximately contained 6000 kg of Mg-treated melt in a nitrogen pressurized vessel. In a previous step, nodularization was performed on 1000–1500 kg batches by means of the tundish cover method. Two different FeSiMg alloys were used for this purpose: a high Mg content ferroalloy was selected for starting production (grain size 3–10 mm, Si = 45.9 wt pct, Mg = 9.20 wt pct, Ca = 3.10 wt pct, RE = 1.04 wt pct, Al = 0.16 wt pct and Fe balance) while a ferroalloy with an intermediate Mg content was used during normal production (grain size 2–10 mm, Si = 47.0 wt pct, Mg = 6.32 wt pct, Ca = 3.15 wt pct, RE = 1.01 wt pct, Al = 0.80 wt pct and Fe balance). Thus, different amounts of FeSiMg were added in the reaction chamber of a 2000 kg capacity ladle before tapping. These additions were in the range of 1.5 to 2.0 pct of the total melt weight introduced in the ladle when starting the production while they became 1.0 to 1.5 pct during normal production.

Sampling for TA was made just before adding a new melt batch in the vessel. Each sample extracted from the pouring basin was used for pouring the TA cups described above and for obtaining a chemical composition sample. All recorded cooling curves were then analyzed using a TA software[18] so as to determine the most relevant temperatures, i.e., minimum eutectic temperature (Temin) and recalescence (Rc). On the other hand, a combustion technique (LECO CS300) was used for determining C and S contents on the chemical composition samples, while spectrometry (ARL 3460) was utilized for other elements. Table I shows the composition ranges obtained for the most important elements.

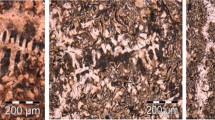

Metallographic inspections were performed in order to analyze graphite morphology on some samples poured in the thermal cups which appeared critical (see below) and on the castings manufactured using the corresponding melts. In case of the thermal cup samples, the central areas that included the thermocouple location were properly conditioned and then analyzed for inspecting graphite particles morphology on five different fields per sample. Nodularity was estimated by means of image analysis and by comparing micrographs of the selected fields with reference images in the UNE 36.118-73 and ISO-945-1 standards. A similar method was followed in case of manufactured castings where inspections were made on areas selected by the foundry customers.

Scanning electron microscopy (SEM) was used to characterize the phases found in Te mixtures and in metallic samples that were poured in TA cups. A Zeiss Ultra Plus apparatus equipped with energy-dispersive X-ray spectroscopy (EDS) was used for these microanalyses.

Estimation of Active Mg in Melts

Common methods for determining chemical analysis of cast iron samples (spectrometry or chemical analysis procedures) provide the total or “residual” Mg content, i.e., free Mg plus Mg which is present in compounds like MgS, MgO, and silicates. However, the so-called “active Mg,” which promotes graphite nodularity and is therefore the most important chemical specie, is only the free Mg that remains unbounded and dissolved in the liquid alloy.

The use of tellurium for whitening gray cast iron samples, even if they are partially inoculated, is well known.[21] Thus, commercial TA cups used for carbon determination of gray cast irons contain an excess of Te which commonly appears as a pale gray mixture stuck to the bottom of the cup. Mg-free melt samples show an intense reaction when pouring these cups and metastable solidification is normally obtained. The resulting cooling curves are characterized by low eutectic temperature together with typical recalescence in the range of 0–4 K (thick solid line in Figure 2(a)). These features are due to carbide precipitation (Figure 2(b)), and they are quite different to those found in samples with graphite precipitated as lamellas (thin solid curves in Figure 2(a)).[24,25]

However, it has been also observed that Te effect on melt samples that were previously treated with FeSiMg alloys is quite different to the one obtained on Mg-free samples. In this case, the cooling curve typically shows an eutectic arrest at high temperature with significant recalescence (dotted curve in Figure 2(a)). Accordingly, metallographic analysis on samples treated with Mg and then with Te shows a large number of graphite particles precipitated during solidification (Figure 2(c)).

The presence of Mg in cast irons must then be the cause of the differences found between the cooling curves in Figure 2(a) obtained from the two cast irons solidified in the presence of Te. Although it has been suggested[27] that inhibition of whitening effect of Te is due to a reaction between this element and Mg to form magnesium telluride (MgTe), evidence of such compound has not been reported until now. Similar reactions can be proposed between Ce or La and Te to form the corresponding telluride compounds (Ce2Te3 and La2Te3 as the most probable compounds). Thus, one can expect that all three nodularizing elements will react with the available Te which comes from the Te mixture added at the bottom of the cups. So reaction zones are expected in both the metallic sample and in the Te mixture which should contain these compounds (schematic in Figure 3(a)). Visual evidence of intense reaction between melt samples and Te mixture appears in Figure 3(b) where a porous surface can be seen after removing the whitening product stuck to the bottom of the samples. Gas bubbles observed in Figure 3(b) are certainly due to vapors because of the low boiling temperature of Te at 1261 K (988 °C).

Metallographic and SEM characterizations have been made on the removed Te mixture and on the corresponding Mg-treated sample in the area which was in contact with this mixture. A section of the Te mixture is shown in Figure 4(a) where three different areas have been considered: the reaction area which was in contact with the melt, the internal area, and the bottom surface which was stuck to the TA cup. Notice that sand grains can be observed in this latter area. The internal area is composed of gray particles that mainly contain Si, O, and Na (Al and Mn were also detected in some zones) and bright particles where Te is the most important constituent by far. The elements found in gray particles agree with the composition of the binder that is commercially used for sticking Te to cups.

The reaction area shows a complex matrix mainly composed of coarse Te particles (white contrast in Figure 4(a)) and a mixture of two different types of gray particles (see Figures 4(b) and (c)). The darkest gray ones show a similar color and an analogous composition to gray particles found in the internal area. On the other hand, abundant pale gray particles where Mg was detected in addition to Si, O, Mn, and Na (Figure 4(d)) are also present in this area. Among all these gray particles, quite small rounded particles of Te in bright contrast were also found (see Figure 4(c)). It is worthy to say here that Mg was only detected on pale gray particles and no phase containing both Te and Mg could be detected.

Metallographic inspection made on the cast iron shows that a layer with graphite lamellas is present in the area which was in contact with the Te mixture (Figures 5(a) and (b)). Although this layer is irregular (500–1200 µm in width), it is continuous and it also surrounds the internal surfaces of bubbles that are seen in Figure 3(b). Appearance of nonspherical graphite particles in this layer means that most Mg was combined there. SEM analyses made on this area show an important amount of inclusions among the graphite particles. Two different types of inclusions were detected (see Figures 5(c) and (d)) here: the white ones that mainly contain Te and low content of Mg, and the dark ones where peaks of Si, Mg, and Te were obtained. Detection of these compounds proves the reaction between Te and Mg which has been suggested as causing the inhibition of the whitening effect of Te in Mg-treated cast irons.

It seems of interest here to estimate the minimum free Mg content needed to avoid the whitening effect of Te. For this purpose, a group of commercial cups that contained only the Te mixture were poured using melts with different residual Mg and S contents. These two elements are expected to combine according to Eq. [1]. Thus, a rough estimate of free Mg (w Mg,free) could be made by subtracting magnesium combined with sulfur present in the alloy (w S) from residual Mg content (w Mg) by means of Eq. [2] in which M Mg and M S are the atomic weights of magnesium (24.305 g/mol) and sulfur (32.065 g/mol), respectively:

Figure 6 illustrates the evolution of Temin and Rc with the free magnesium calculated according to Eq [2]. Considering Figure 2 and the limited range of silicon content of the investigated alloys, metastable solidification takes place when Temin is lower than 1403 K (1130 °C) and Rc lower than 4 K. Figure 6 shows this occurs only when wMg,free is 0.006 wt pct or less (left side from the vertical dotted line shown in Figure 6). This result leads to think that melts with high enough active Mg content will not be whitened when solidified in the presence of Te. Accordingly, considering the characteristics of cooling curves recorded on Te-treated samples as those shown in Figure 2 can be considered as a valid method to check if active Mg is higher or lower than a minimum threshold which must be defined as the critical value for correct ductile iron production in plants.

According to Figure 6, it can be considered that 0.006 wt pct free Mg in the melt is sufficient to inhibit the whitening effect of Te. With a sample mass m sample of 300 g, this Mg content should react with 0.094 g of pure Te, which represents around 0.42 g of the Te mixture, i.e., 17 pct of the total mass of the Te mixture added in the cup. Thus, although additional Te is still available to whiten the sample, it cannot be transferred from the mixture to the sample via the reaction area within the short period of time of pouring and solidification of the TA cup.

In common manufacturing of ductile iron castings, residual Mg content is in the range of 0.023 to 0.040 wt pct when residual S ranges from 0.004 to 0.010 wt pct. Still considering the main reaction of Mg is with S for giving MgS, these values show that a significant amount of free Mg is generally present in ductile iron melts. This free Mg could be quickly reacted by adding a controlled quantity of sulfur in a dedicated TA cup to form MgS according to Eq. [1]. The required amount of sulfur (m S) can be calculated by means of the following expression:

when w Mg free is expressed in wt pct.

In a TA cup containing tellurium and the reaction mixture, Te will react with 0.006 wt pct of free Mg and the added S will react with an amount of free Mg given by Eq. [3]. Accordingly, a cooling curve showing characteristics of metastable eutectic solidification would mean that the original free Mg level is lower than a critical Mg threshold and that nodularity problems are possible in related castings. On the contrary, a cooling curve with features of stable eutectic solidification would mean that enough free Mg remains after reactions of this element with both Te and S, and correct nodularity can be obtained in castings. As nodularity in cast parts is strongly affected by the casting section size (cooling rate) and by the inoculation process, a proper selection of the critical Mg threshold must be made for each casting type which will then be used to determine the amount of S needed in the reaction mixture added in the Mg control cup.

Although of quite common use, Mg overtreatment of the melt (e.g., at the start of production) can seriously decrease graphite growth kinetics, and metastable solidification is often observed. This would provide a false result when pouring such a melt in the cup for active Mg estimation. This potential problem has been solved in the present study by adding an amount of dust inoculant in the cup together with dust sulfur. This inoculant ensures that graphite particles will always form when Te cannot lead to metastable solidification, i.e., when some active Mg still remains after reacting with the available sulfur in the cup. Dust sulfur and inoculant are the two constituents of the “reactive mixture” developed in the present work and they have to be correctly mixed before adding to TA cups.

The results obtained are compared to the residual Mg contents determined by spectrometry and complemented with some metallographic observations. Structural characterizations have been performed on samples which have been poured in the TA cup with inoculant only and in the cup for active Mg estimation. Some metallographic observations were also performed on selected manufactured castings.

Results and Discussion

In this section is presented an extensive number of Mg-treated melts analyzed using the new method. The melt samples were collected during manufacturing processes where 2 to 4 kg calipers for automotive industry were produced. In these conditions, a residual Mg threshold of 0.025 wt pct is stated by the foundry control system in order to guarantee a correct nodularity on castings. This standard control is always made on a sample taken from the pouring basin (area close to the stopper) just before adding a new melt batch in the press–pour device. Thus, FeSiMg additions in the Mg-treated ladle are calculated according to the residual Mg content measured on the last sample analyzed.

Start of Production

At the start of production, the press–pour device and ladles usually contain important amounts of oxygen and sulfur bearing compounds. Therefore, a high FeSiMg addition is normally made for the Mg treatment of the first two batches (1700 to 1800 kg) which are then introduced in the press–pour vessel. For subsequent batches, the addition level depends on melt chemistry evolution. Experiments were made here by getting a melt sample just before adding a new batch in the press–pour and using it to pour an active Mg cup, a thermal cup, and to obtain a composition sample. Reactive mixture additions made to the active Mg cups were calculated using Eq. [3] considering an active Mg threshold of 0.023 wt pct which would ensure correct nodularity in all sections of the calipers studied in this work. For this threshold, the composition of the mixture was 0.091 g sulfur plus 0.323 g of inoculant per cup. According to Figure 6, the criterion for deciding if the Mg threshold is reached is that the minimum eutectic temperature is higher than 1408 K (1135 °C).

Table II shows the results obtained from the two sets of experiments (trials #1 and #2) made when starting production. After addition of the two first batches (batch #1+2) in the press–pour vessel, negative results were obtained from the cooling curves recorded with the active Mg cups for both trials, with minimum temperatures much lower than 1408 K (1135 °C). These negative results correspond to the lowest residual Mg contents in the melt. However, the addition of an additional Mg-treated batch (batch #3) increases the residual content of this element in both trials, with the active Mg content remaining however lower than the threshold for trial 1 while being higher for trial #2. This latter trial is a case where analytical control of the Mg content would have led to accept the melt, while the active Mg TA cup decides not to do.

To ascertain the above decision, metallographic inspections have been made on thermal cup samples of batches #(1 + 2) and #3 of trial #1 in order to check nodularity. Figure 7 shows the graphite morphology and distribution in these two samples. It is observed that both contain minor amount of vermicular particles with the sample from batch #(1 + 2) showing the highest number of them. Subsequent analyses of samples #5 and #17 have shown that only nodular graphite can be found. Similar results have been obtained from metallographic observations on thermal cup samples produced during trial #2. These metallographic results would confirm the appropriateness of the active Mg threshold at 0.023 wt pct in the thermal cups.

When checking nodularity on one caliper manufactured at the end of each batch in Table II, only some isolated vermicular particles were found in the two castings produced with the batch #(1 + 2) for both trials #1 and #2. The absence of nonspheroidal particles in calipers fabricated with batch #3 of trial #1 while they have been detected in the corresponding thermal cup sample should be assigned to the difference in cooling rate. As a matter of fact, areas of calipers used for metallographic inspections have a thermal modulus estimated to 0.45 cm, while its value is around 0.62 cm for the thermal cup. Thus, those casting sections lighter than the one of the standard cup will cool more quickly so they show a comparatively more favorable case with respect to graphite nodularity. Therefore, the active Mg threshold at 0.023 wt pct appears also adequate for producing these castings.

Normal Production

A significant number of experiments have been made to estimate the active Mg content in melts used in the pouring area under normal manufacturing conditions. Compared to the first part of this study, the noticeable difference in this second part is the use of two different active Mg cups, which leads to a threshold range instead of a single value. The low Mg threshold was defined to ensure a correct nodularity in castings, considering the adequate Mg threshold obtained for calipers analyzed in the previous chapter, their estimated modulus, and the one for castings now approached. In this part of the study, a high Mg threshold has been also adopted so as to get more information about the free Mg contents when they show to be higher than the low threshold. During this investigation, several different castings have been manufactured so that various active Mg thresholds have been adopted to achieve a correct nodularity in all cases, following the criteria already mentioned.

Figure 8 shows the results obtained from the 147 tests made. The thick and thin lines delineate the change in the low and high thresholds selected for each casting. Solid dots show the measured residual Mg content. Finally, the location of the grayed areas indicates if the active Mg predicted according to the method developed in this work was above the high threshold, in between the two thresholds or below the low threshold.

Active Mg and residual Mg evolution during normal production of castings. Thin and thick lines show the prescribed high and low active Mg thresholds, dots are measured residual Mg contents. For each test, the grayed area shows if the estimated active Mg was higher than the high threshold, in between the two thresholds or lower than the low threshold

It is observed in Figure 8 that a large number of residual Mg values are within the same domain than the predicted active Mg, most of them being higher than the high threshold. This observation applies as well when sharp changes of the active Mg thresholds were applied due to production requirements (see batches #80 to #81 and #132 to #133). However, in 14 cases, residual Mg values are higher than the top threshold though predicted active Mg lies in between the two thresholds. This fact shows again that variation of the melt chemistry (likely the sulfur content) can occur during production, leading to sharp decrease in the active Mg content at still satisfactory residual Mg contents.

Figure 8 shows also that eight batches have a residual Mg content in between the two thresholds, while active Mg predictions are below the corresponding low threshold (batches #22, #43, #55, #73, #82, #124, #125, and #138). Finally, the active Mg tests are also negative for other six cases (batches #54, #72, #103, #104, #144, and #145) where residual Mg values are below the low active Mg threshold. In these 14 cases, castings were produced even though the results obtained from the active Mg tests were negative. All these castings were extracted from the cooling line and stored until final decision. To ascertain the capabilities of this new method of estimating the active Mg content, it seemed of interest to check nodularity of thermal cup samples and of produced castings in all these “negative” cases. The results of these characterizations are presented in Table III.

All the first eight negative batches with residual Mg in between the two thresholds showed high nodularity in both the TA cup and the castings and were thus finally accepted after microstructural control. Among the six negative batches having a residual Mg content lower than the low threshold, two (#54 and #72) originated invalid castings with appearance of vermicular graphite while the other four showed high nodularity. Interestingly enough, it is seen that nodularity of batch #54 is not correct though it shows a residual Mg content which is higher than the ones in batches #103, #104, and #145 that show high nodularity. This result shows again that active Mg can change from one batch to another without relevant variations of the residual Mg content.

Conclusions

The study of cooling curves and of reactions that occur during solidification of TA samples have led to develop a new method to estimate the active Mg content in ductile cast irons before pouring the molds. This method allows detecting the potential-free Mg changes in mass production of ductile iron castings. On the other hand, this method has been successfully applied as an effective tool for controlling all melt batches during production for guaranteeing correct graphite nodularity in the parts cast. For this purpose, a preliminary selection of the proper active Mg thresholds is mandatory in order to limit as much as possible false-negative results. The most important conclusions obtained in the present work are the following:

-

A rapid estimation of different active Mg contents in melts is possible by pouring a standard TA cup that contain Te plus controlled amounts of an innovative reactive mixture composed of 22 pct high-purity sulfur and 78 pct inoculant.

-

The minimum active Mg content in the sample to stop the whitening effect of Te mixture has been determined as 0.006 wt pct. Thus, two different cooling curves can be obtained according to the amount of active Mg dissolved in the melt. Those contents higher than 0.006 wt pct can be counteracted by adding a specific amount of reactive mixture, which will be defined according to the nodularity requirements in castings.

-

The method developed in the present work allows detecting nodularity problems in mass productions as it detects uncontrolled changes of active Mg content that are rarely found when analyzing the evolution of residual Mg.

References

Y. Ueda, M. Takita, Z. Da-ben, T.Kishi, T.: Trans. Jpn. Inst. Met., 1986, vol. 27, pp. 70–79.

R.D. Bhavsar, M. Ghoreshy, R.W. Smith: Trans. Jpn. Inst. Met., 1987, vol. 28, pp 808–18.

Y. Liu, S. Yang: Acta Metall. Sin. B (English Edition), 1992, vol. 5, pp. 263–67.

L. Kozlov, A. Vorobiev, S. Azzam: 62nd World Foundry Congress, April 23–26, Philadelphia, Pennsylvania, 1996, paper 27.

J. Lacaze, S. Armendariz, P. Larrañaga, I. Asenjo, J. Sertucha, R Suárez, R.: Mat. Sci. Forum, 2010, vol. 636–637, pp. 523–30.

Z. Liu, W. Chen, Y. Deng: China Foundry, 2012, vol. 9, pp. 114–18.

J. Lacaze, N. Valle, K. Theuwissen, J. Sertucha, B. El Adib, L. Laffont: Adv. Mat. Sci. Eng., 2013, paper ID 638451.

T. Skaland: Proceedings of the AFS Cast Iron Inoculation Conference, September 29–30, Schaumburg, 2005, pp. 13–30.

H.M. Muhmond: PhD thesis, Stockholm, 2014.

D.M. Stefanescu: Science and Engineering of Casting Solidification. 2nd Edition, Springerlink, New York, 2008, pp. 41–55.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, D.J. Bristow: Acta Mater., 2000, vol. 48, pp. 2823–35.

M. Qian, P. Cao, M.A. Easton, S.D. McDonald, D.H. St John: Acta Mater., 2010, vol. 58, pp. 3262–70.

D.H. StJohn, M.A. Easton, M. Qian, M., J.A. Taylor: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2935–49.

Y. Li, T. Xu, Q. Du, L. Arnberg, and R. Mathiesen: IOP Confence Series, MSE, 2015, vol. 84, paper ID 012090.

T. Elbel, J. Senberger, A. Zadera, J. Hampl, J. Arch. of Mater. Sci. Eng., 2008, vol. 33, pp. 111–116.

S. Lekakh, V. Richards, K. Peaslee: International Journal of Metalcasting, 2009, vol. 3, pp. 25–37.

R.W. Heine: AFS Trans., 1995, vol 103, pp 199–206.

P. Larrañaga, J.M. Gutiérrez, A. Loizaga, J. Sertucha, R. Suárez: AFS Trans., 2008, vol. 116, pp. 547–61.

P. Svidró, A. Diószegi: ISIJ Int., 2014, vol. 54, pp. 460–65.

D.M. Stefanescu: Int. J. Metalcasting, 2015, vol. 9, pp. 7–22.

C. Labrecque, M. Gagné, M.: AFS Trans., 1988, vol. 96, pp. 83–90.

D. Novelli, J.M. Massone, R. Boeri: Proceedings of Jornadas SAM—CONAMET, Posadas, Misiones (RA), 2001, pp. 67–74.

T. Kanno, I. Kang, T. Kikuchi, K. Hayashi, Y. Maruyama: J. Mater. Sci. Technol., 2008, vol. 24, pp. 325–26.

I.G. Chen, D.M. Stefanescu: AFS Trans., 1984, vol. 92, pp. 947–64.

E. Fras, M. Górny, H. López, H.: Metall. Foundry Eng., 2005, vol. 31, pp. 13–35.

R. Suárez, J. Garay, and P. Larrañaga: Method for controlling active magnesium in ductile cast iron, European Patent Application EP2749657A1, filed December 27, 2012, and issued July 02, 2014.

W. Van der Perre: Thermal analysis principles and applications, Heraeus Electro-Nite International, Internal report, 2000.

Acknowledgments

This paper is based on work supported by the Industry Department of the Spanish Government (PROFIT FIT-020600-2005-16). The authors would like to thank Betsaide, S.A.L. and Fuchosa, S.L. foundries for all the collaborating efforts made in the experimental work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 2, 2016.

Rights and permissions

About this article

Cite this article

Suárez, R., Sertucha, J., Larrañaga, P. et al. Active Mg Estimation Using Thermal Analysis: A Rapid Method to Control Nodularity in Ductile Cast Iron Production. Metall Mater Trans B 47, 2744–2753 (2016). https://doi.org/10.1007/s11663-016-0750-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0750-6