Abstract

A model for the description of precipitation kinetics is presented and applied to experimental data for the evolution of the particle-size distribution in a dilute model system (Cu-Co) upon isothermal annealing at different temperatures. For coupling nucleation kinetics and growth kinetics, the model includes a recently proposed inverse evaluation method for consistent and numerically efficient evaluation of the thermodynamics of both nucleation and growth. Using the experimental data for the evolution of the particle-size distributions, obtained at least at two different temperatures, as a reference, unique and physically reasonable values for, at least, the interface energy and the activation energies for nucleation and growth can be obtained. The sensitivity of the kinetic model fitting to precise description of the thermodynamics of the particle–matrix system and the inferiority of kinetic model fitting to average data, such as data for the mean particle radius, have been highlighted.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The kinetics of heterogeneous precipitation reactions in dilute systems is frequently described in terms of nucleation and growth of solute-rich precipitates, however, often departing from different and thus inconsistent thermodynamic bases for nucleation and growth.[1] Most of these models originate from the Kampmann–Wagner numerical (KWN) approach[2]: In this approach, the evolution of the particle-size distribution (PSD) is modeled for discrete time steps and discrete particle-size classes adopting the classical theory of nucleation[3,4] and long-range solute diffusion controlled growth of (spherical) particles.[5,6] The changes in particle-number densities and particle sizes during one time step are calculated by numerical integration of the rate of nucleation and the rates of growth of the individual size classes which are functions of the (time-dependent) mean matrix composition. Such models can thus be classified as mean-field models for precipitation kinetics, constituted by two types of coupled kinetic rate equations, a nucleation rate and a growth rate, which are numerically solved on a discrete time–particle-size grid.

The inconsistent nature of the thermodynamic treatments employed for nucleation and growth originates from the thermodynamic stability consideration for the particle–matrix system being treated separately and differently for nucleation and for growth: For nucleation, the nucleation barrier for formation of a stable second-phase particle is evaluated from the release in chemical energy upon formation of the second-phase particle (the chemical driving force for nucleation) and the increase of energy due to formation of an interface between matrix and precipitate particle, and other energy contributions such as an elastic energy contribution in case of a volume misfit between precipitate and matrix. For growth, in order to describe particle coarsening in later stages of the precipitation, the Gibbs–Thomson effect is taken into account, i.e., the compositions of particle and matrix at the particle–matrix interface are taken as functions of the size of the particle, which leads to the dissolution of smaller particles once the value of the mean matrix composition falls below the size-dependent matrix composition at the particle–matrix interface. Inconsistency of the thermodynamic descriptions arises if the nucleation barrier and the Gibbs–Thomson effect are evaluated on the basis of different thermodynamic models, e.g., involving differing descriptions for the chemical Gibbs energies of the matrix phase and the precipitate phase, or an elastic energy contribution which is considered for nucleation but then neglected for growth without further reasoning. This widespread usage of inconsistent thermodynamic models for nucleation and for growth (e.g., References 2, 7, 8) can lead to unintended, pronounced biasing of the kinetic model toward artificially enhanced or attenuated nucleation or growthFootnote 1, as shown in Reference 1.

In fact, the nucleation barrier and Gibbs–Thomson effect can be retraced to the same consideration of thermodynamic equilibrium for a particle–matrix system.[1,9] This allows, as explicitly demonstrated in Reference 1, an evaluation of the thermodynamics of nucleation and growth on a consistent basis by application of an “inverse evaluation method,”[1] and provides, for typical assumptions for the interface energy and elastic misfit energy contribution, an efficacious and numerically efficient way to incorporate numerical data for the chemical driving force as derived from a thermodynamic assessment without any necessity for approximations.

The precipitation of Co-rich particles from supersaturated, dilute Cu-Co represents a model case of precipitation reactions: upon annealing, Co-rich particles of spherical shape are formed (more or less) randomly distributed within the Cu-rich matrix. For small particle sizes, the Co-rich particles are of fcc crystal structure and show full coherency with the surrounding matrix[10] owing to the small lattice mismatch of fcc-Cu and fcc-Co of about −1.7 pct. In later stages of the precipitation reaction, upon increase in particle size, loss of coherency and transition to an octahedral particle shape have been observed.[11] Due to its showcase precipitation behavior in the early stages of precipitation, the decomposition reaction of supersaturated Cu-Co alloys has been the object of numerous experimental studies in the past, e.g. References 12 through 22. The impetus of most studies was, apart from application of novel techniques for microstructural analysis, investigating the applicability of the classical theory of (homogeneous) nucleation for precipitation in the solid state by comparing experimental results and theoretical predictions for critical particle size and (the evolution of) the particle-number density (see esp. References 13, 23 through 25). Some studies also accounted for concurring nucleation and growth (e.g., References 16, 26), but experiments and modeling were restricted to a single alloy composition and a single annealing temperature. Extensive simulations of the precipitation kinetics in dilute Cu-Co alloys employing a KWN-type approach were performed in References 7, 27 through 29, mainly using as reference the experimental particle-density data of Reference 13 determined by transmission electron microscopy (TEM). However, these computations were based on approximate and (again) inherently inconsistent thermodynamic models for nucleation and growth, and moreover, the effect of elastic misfit energy was generally neglected.

In the present paper, adopting the general approach sketched in the first paragraph above, but now incorporating the recently proposed inverse evaluation method for evaluation of the thermodynamics of both nucleation and growth,[1] a kinetic model is developed and applied to detailed experimental data for the development of the size distribution of Co-rich precipitate particles in a dilute Cu-Co alloy, determined in this work by TEM, upon isothermal annealing at different temperatures for various annealing times. Thereby, a high sensitivity for testing the validity of the kinetic model used is achieved. With the experimental data for the evolution of the PSDs serving as a reference, the effect of different thermodynamic approximations on the behavior of the kinetic model, the relation between the extracted kinetic model parameters and the quantity and quality of the experimental data, and the general applicability of the mean-field approach are investigated.

2 Theoretical Background

2.1 Kinetic Model

Classical nucleation theory[3,4] yields an expression for the rate of formation of stable second-phase particles from a supersaturated parent phase. Particles are considered stable once they have reached a critical size, corresponding to an energy barrier for nucleation. Nucleation is assumed to occur homogeneously, i.e., in the present case of a solid solution, the formation of a nucleus is the result of short-range concentration fluctuations within the supersaturated matrix. The nucleation rate \(\dot{N}\) in a binary alloy can be expressed as

with the fraction \(X_1\) of solute clusters of size 1, for binary alloys equal to the atomic fraction \(x^{\upalpha }\) of non-clustered solute atoms in the matrix, the solute-capturing rate \(\beta ^*\) of a particle of critical size, the Zeldovich factor \(Z\), the Gibbs energyFootnote 2 change \(\Delta G^*\) for formation of a particle of critical size, and the time lag \(\tau \) required to establish a steady-state size distribution of solute clusters. \(k\), \(T\), and \(t\) denote Boltzmann’s constant, temperature, and time, respectively. The solute-capturing rate \(\beta ^*\) describes the probability for the addition of a solute atom of the matrix to the particle, depending on the particle–matrix interface area, the area density of solute atoms in the matrix, and the atomic jump frequency. For a spherical particle of critical size, i.e., of radius \(r^*\), \(\beta ^*\) can be expressed as

where \(a^{\upalpha }\) is the lattice parameter of the matrix phaseFootnote 3 and \(k'\) is a proportionality factor which is generally set to one. \(D_{\text{N}} = D_{\text{N,0}} \exp {\left( - \frac{Q_{\text{N}}}{RT} \right) }\) describes the temperature dependency of the jump frequency, defined by an activation energy \(Q_{\text{N}}\) and a pre-exponential factor \(D_{\text{N,0}}\). For nucleation in the solid state, \(D_{\text{N}}\) is often identified with the (self or impurity) diffusion coefficient \(D_{\text{D}}\) for volume diffusion of the solute component, although classical nucleation theory does not consider (long-range) volume diffusion of solute in the matrix, but only the addition step of a solute atom to the (sub-)critical particle as a rate-limiting step; therefore, \(Q_{\text{N}}\) and \(D_{\text{N,0}}\) can differ from the activation energy \(Q_{\text{D}}\) and the pre-exponential factor \(D_{\text{D,0}}\) pertaining to volume diffusion of the solute component. The Zeldovich factor \(Z\) is given by

where \(n^* = 4/3 \, \pi {r^*}^3 / V^{\upbeta }\) is the number of atoms within a particle of critical size. For the time lag \(\tau \), the approach of Reference 30, yielding

was used.

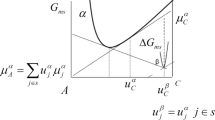

Determination of nucleation barrier \(\Delta G^*\) and critical size \(r^*\) requires evaluation of the change in energy \(\Delta G\) of the system upon formation of a precipitate particle. Typically, \(\Delta G\) is subdivided into (i) a (negative) chemical Gibbs energy contribution \(\Delta g_{\text{c}}\) (per unit volume of \(\upbeta \)) due to the decomposition of the supersaturated \(\upalpha \) matrix phase into a solute-depleted \(\upalpha \) matrix phase and a solute-rich \(\upbeta \) precipitate phase, with \(-\Delta g_{\text{c}}\) as the (positive) chemical driving force for nucleation; (ii) a (positive) interface energy contribution \(\gamma \) (per unit area of interface), and (iii) a (positive) deformation energy contribution in case of a volume misfit between nucleus and matrix. In the following, only elastic accommodation of the misfit, as pertaining to the initial stages of precipitation in the system Cu-Co (see Sections I, IV and V), will be considered. In order to simplify the thermodynamic analysis, it is usually assumed that (i) the matrix composition \(x^{\upalpha }\) remains constant upon formation of a \(\upbeta \)-phase particle (i.e., that the matrix phase is infinitely large or the precipitate particle is infinitesimally small) and that (ii) the contributions of interface energy (per unit area) and elastic energy (per unit volume) do not vary strongly within the ranges of composition assumed by the \(\upalpha \) phase and the \(\upbeta \) phase, and can therefore be treated as independent of the composition of \(\upalpha \) and \(\upbeta \). These assumptions allow to separately evaluate the change in chemical Gibbs energy upon nucleation from a thermodynamic assessment of the bulk phases (see Reference 1): By use of the so-called maximum chemical driving force method,[31] the (maximum) chemical driving force \(-\Delta g_{\text{c}} =- \Delta g_{\text{c}}(x^{\upalpha })\) and the corresponding composition \(x^{\upbeta } = x^{\upbeta }(x^{\upalpha })\) of the \(\upbeta \) phase can be derived from the chemical Gibbs energies of the \(\upalpha \) phase and the \(\upbeta \) phase as function of the composition \(x^{\upalpha }\) of the \(\upalpha \)-phase matrix, independent of the interface energy and elastic energy contributions. Determination of the nucleation barrier \(\Delta G^*\) then reduces to finding the extremum of \(\Delta G \) as function of particle size only. Adopting the sharp interface model with an isotropic interface energy \(\gamma \) per unit area and with \(\Delta g_{\text{el}}\) as the elastic energy contribution per unit volume of the particle, it follows for a spherical shape of the particle

For \(\left( \Delta g_{\text{c}} (x^{\upalpha } ) + \Delta g_{\text{el}} \right) < 0\), \( \Delta G(r) \) shows a maximum at \({\text{d}} (\Delta G(r))/ {\text{d}}r = 0\) with the critical particle radius

and the nucleation barrier

Introducing Eqs. [2] through [7] into Eq. [1], the nucleation rate can finally be expressed as

By employing the maximum chemical driving force to determine the critical radius \(r^*\), the corresponding \(\upbeta \) particle of critical size \(r^*\) and composition \(x^{\upbeta }(x^{\upalpha })\) (nucleus) is in (unstable) equilibrium with the \(\upalpha \) matrix phase of composition \(x^{\upalpha }\) (see, e.g., Reference 31).

These results allow the following generalization: For given values of \(\gamma \) and \(\Delta g_{\text{el}}\), the size relation \(r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}} )\), obtained from Eq. [6], and the composition relation \(x^{\upbeta }(x^{\upalpha })\), directly obtained from the maximum chemical driving force method, completely characterize the thermodynamic equilibrium of the particle–matrix system in terms of the variables particle size and phase compositions.[1] This result will later be used for a consistent thermodynamic treatment of both nucleation and growth.

Upon particle growth, owing to the continuous solute depletion of the matrix around the growing solute-rich precipitate particle, the particle growth rate (eventually) becomes rate-controlled by diffusion of solute atoms through the solute-depleted matrix around the particle. Assuming a linear composition gradient within the matrix phase with the composition \(x^{\upalpha }\) of the undepleted \(\upalpha \)-phase matrix remote from the particle–matrix interface and the composition \( x^{\upalpha , \text{int}}\) of the matrix at the particle–matrix interface, for small degrees of supersaturation, the growth rate of a spherical particle of size \(r\) can be described by[5,6]

with the (composition-independent) diffusion coefficient \(D_{\text{G}} = D_{\text{G,0}} \exp \left( - \frac{Q_{\text{G}}}{RT} \right) \) of solute in the matrix with activation energy \(Q_{\text{G}}\) and pre-exponential factor \(D_{\text{G},0}\). In dilute systems, for \(D_{\text{G}}\), often the value of the impurity diffusion coefficient \(D_{\text{D}}\) of the solute in the matrix phase is taken. The compositions \( x^{\upalpha , \text{int}} \) and \(x^{\upbeta ,\text{int}} \) of the \(\upalpha \) phase and the \(\upbeta \) phase at the particle–matrix interface are typically evaluated assuming local establishment of thermodynamic equilibrium at the particle–matrix interface under consideration of the Gibbs–Thomson effect, i.e., accounting for the finite size of the \(\upbeta \)-phase particle. Resorting to the same thermodynamic model as used above for the description of nucleation thermodynamics, the relations \( x^{\upalpha , \text{int}}\left( r \right) \) and \(x^{\upbeta ,\text{int}}\left( r \right) \) as function of particle size \(r\) can directlyFootnote 4 be derived from the relations \(r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}} )\) , and \(x^{\upbeta }(x^{\upalpha })\), determined for nucleation, which completely characterize the thermodynamics of the particle–matrix system (see above)[1]: by inverse evaluation of \(r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}} )\), the composition relation \( x^{\upalpha , \text{int}}\left( r \right) = x^{\upalpha }\left( r, \gamma , \Delta g_{\text{el}} \right) \) for the \(\upalpha \) phase and, via \(x^{\upbeta }(x^{\upalpha }) \), the corresponding composition relation \(x^{\upbeta ,\text{int}} (r) = x^{\upbeta }(x^{\upalpha } = x^{\upalpha ,{\text{int}}}) \) for the \(\upbeta \) phase can be obtained.Footnote 5 Using the proposed inverse evaluation method, separate evaluations of the thermodynamics of nucleation and of growth are rendered unnecessary—a single evaluation of the thermodynamics of the particle–matrix system is sufficient. In this case, the so-called no-growth radius \(r^{\text{c}}\), the radius for which \( x^{\upalpha , \text{int}}\left( r \right) = {x}^{\upalpha }\) and \( \frac{{ \text{d}} r}{ \text{d}t} = 0\) (Eq. [9]), and the critical radius for nucleation \(r^*\) at given \(x^{\upalpha }\) are truly identical, and inconsistent application of two differing thermodynamic descriptions of the particle–matrix system is thus avoided inherently (see Reference 1).

Both the rate equation for nucleation, Eq. [8], and the rate equation for growth, Eq. [9], are functions of the matrix composition \(x^{\upalpha }\). Combining the two rate equations via a mean-field approach for the matrix composition, i.e., substituting the matrix composition \(x^{\upalpha }\) by the average matrix composition \(\bar{x}^{\upalpha }\), the evolution of the particle-size distribution can be computed as function of time and temperature upon concurring particle nucleation and particle growth (Reference 2, see Section I). The incorporation of the Gibbs–Thomson effect in the model for growth implies that particle growth also comprises particle shrinkage if the mean matrix composition \(\bar{x}^{\upalpha }(t)\) falls below the size-dependent composition \( x^{\upalpha , \text{int}}\left( r \right) \) for a particle of certain size. Thus, particle coarsening is inherently included in this type of model (provided consistent thermodynamics apply to both nucleation and growth; cf. footnote in Section I).

2.2 Model Application

As for application of preceding KWN-type models, in the present work, it is assumed that the interface energy \(\gamma \) and, if present, the elastic misfit energy \(\Delta g_{\text{el}}\) contributions (as well as the atomic volumes) are independent of (varying) phase composition (see above), and that the properties of the \(\upalpha \)-matrix phase and the \(\upbeta \)-particle phase can be described adequately by the properties of the corresponding bulk phases. Thereby, an independent determination of the (maximum) chemical driving force for nucleation from a thermodynamic assessment of the bulk phases (e.g., a CALPHAD assessment) becomes possible, and the elastic misfit energy \(\Delta g_{\text{el}}\) contribution can be calculated from bulk elastic properties using an appropriate model. Values for the interface energy \(\gamma \) from independent (i.e., non-kinetic) measurements are typically not available and can only roughly be assessed from bulk properties, which is usually not sufficient for kinetic modeling owing to the high sensitivity of the nucleation rate for the value of \(\gamma \) (Eq. [8], see also Reference 2 on that aspect). The interface energy can therefore be used as an adaptable model parameter to achieve good agreement between kinetic model and experimental data.

3 Model Implementation

For modeling the evolution of the PSD, the PSD is typically divided into \(l\) discrete particle-size classes \((r_1\ldots , r_k, \ldots ,r_l )\). In the current work, a class management similar to the “Lagrange-type” approach proposed in Reference 33 was adopted: the radius \(r_k\) of a particle class \(k\) varies by positive or negative growth, while the population density \(N_k\) of the class is kept constant. By nucleation, in the \(i\)th time step \(\Delta t_{i}\) , a new particle class with particle size \(r_{{l+1,i}}= r_{{i}}^* +\Delta r_{{\text{N}}}\) and particle density \(N_{{l+1,i}} \) is generated and added to the \(l\) existing classes, where \(\Delta r_{{\text{N}}}\) is an initial growth step to render the particle super-critical (here \(\Delta r_{{\text{N}}}\) is set equivalent to the addition of one (fcc Co) atom). The radius \(r_{k,i}\) of an existing particle-size class \(k\) grows (or shrinks) by \(\Delta r_{k,i}\) during one time step. A particle class is removed from the simulation if its radius falls below a threshold \(r_{\text{cut-off}}\) to avoid numerical problems for \(r \rightarrow 0\) (see Eq. [9]; \(r_{\text{cut-off}}\) is here set equivalent to five (fcc Co) atoms). Additional class management to maintain a certain minimum number of classes upon dissolution of particles was in the present case not necessary, since experiments and model application were restricted to early stages before onset of substantial (dominant) particle coarsening and dissolution.

The particle density \(N_{{l+1,i}} \) of the newly generated class and the radius changes \(\Delta r_{k,i}\) of existing classes are calculated from the rate of nucleation \(\dot{N} = {{\text{d}}N}/{\text{d}t}\) (Eq. [8]) and the growth rate \(\dot{r} = {{\text{d}}r}/{\text{d}t}\) (Eq. [9]), respectively, by numerical integration. \(\dot{N}\) and \(\dot{r}\) are ordinary differential equations (ODEs) of first order, coupled by their dependence on the mean matrix concentration \(\bar{x}^{\upalpha }(t)\). Here, the ODEs were numerically solved using a fourth-order Runge–Kutta algorithm for coupled ODEs with an adaptive time step length \(\Delta t_{i}\) to increase numerical efficiency. Two criteria for a maximum time step length were imposed: (i) a maximum relative change in mean matrix composition of \(2 \times 10^{-4}\) during a time step and (ii) a maximum number of two classes being removed from the simulation during one time step by coarsening (i.e., dissolution of smallest particles). To speed up the computation, the length of the adaptive time step was determined in a preceding estimator step using a linear finite-difference approximation before calculation of the final values with the fourth-order Runge–Kutta algorithm.

The mean concentration of the matrix at certain time \(t_j =\left( \sum \limits _{i = 1}^{j-1} \Delta t_i \right) + \Delta t_j \), either after completion of the time step \(\Delta t_j\) or for the intermediate time steps of the Runge–Kutta algorithm, is obtained from the mass balance

where \( x^{\upalpha ,0}\) is the total solute content, with summation over all currently existing size classes \(k\), presuming a homogeneous composition within the particle (i.e., infinitely fast diffusion within the particle phase) with \(x^{\upbeta }(r_{k,j})\) equal to \( x^{\upbeta , \text{int}}\left( r_{k,j} \right) \), the composition of the \(\upbeta \)-phase particle at the particle–matrix interface.

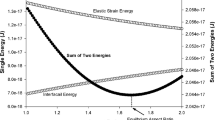

The assumption of composition-independent contributions of interface energy \(\gamma \) and elastic energy \(\Delta g_{\text{el}}\) allows to independently determine the (maximum) chemical driving force \(-\Delta g_{\text{c}} (x^{\upalpha })\) and the composition relation \(x^{\upbeta }(x^{\upalpha })\) at given temperature from a thermodynamic assessment of the chemical Gibbs energies of the phases (Section II), thus substantially reducing the computationally costly access to the thermodynamic database to its minimum. The thermodynamic input data were extracted from a recent CALPHAD assessment of the system Cu-Co[34] (Figure 1).

The chemical Gibbs energy change \(\Delta g_{\text{c}} (x^{\upalpha }) = \Delta g_{\text{c}} (x^{\text{(Cu)}}) \) and the composition relation \(x^{\upbeta }(x^{\upalpha }) = x^{\text{(Co)}}(x^{\text{(Cu)}})\) as function of the matrix composition \(x^{\upalpha } = x^{\text{(Cu)}}\), derived from a CALPHAD assessment of the system Cu-Co[34] for the experimental annealing temperatures T = 773 K, 760.5 K, and 748 K (500 °C, 487.5 °C, and 475 °C) (initial composition \(x^{\text{(Cu}),0} = 0.57\) at. pct). The dotted line represents the chemical Gibbs energy change for T = 773 K (500 °C) as determined by application of an approximate equation (Eq. [11]) based on the phase compositions for equilibrium between bulk phases

If a full thermodynamic assessment for the \(\upalpha \) phase and the \(\upbeta \) phaseFootnote 6 is not available, the change in chemical Gibbs energy upon nucleation is often derived using analytical equations based on simple thermodynamic models, e.g., ideal or regular solution models, which allow to determine \(-\Delta g_{\text{c}}(x^{\upalpha })\) as function of the matrix composition \(x^{\upalpha }\) based on the phase compositions \(x^{\upalpha ,{\text{eq}}}\) and \(x^{\upbeta ,{\text{eq}}}\) for equilibrium of the bulk phases (as given in a temperature-composition phase diagram at constant pressure). Presuming ideal or regular behavior of the \(\upalpha \) solution phase and a \(\upbeta \) phase of fixed composition, \(-\Delta g_{\text{c}}(x^{\upalpha })\) can be assessed via[35]

see Figure 1 for \(\Delta g_{\text{c}}^{\text{approx.}} (x^{\upalpha })\) at 773 K (500 °C), used in Section VI–B for investigating the influence of the thermodynamic model on the predicted kinetics.

Upon kinetic modeling, for given values of the interface energy \(\gamma \) and of the elastic energy \(\Delta g_{\text{el}}\), the relation \(r \left( \Delta g_{\text{c}} ( x^{\upalpha }), \gamma , \Delta g_{\text{el}}\right) \) (cf. Eq. [6]) can then be (re-) evaluated straightforwardly, providing a description for the critical radius \(r^*(x^{\upalpha }) =r \left( \Delta g_{\text{c}} ( x^{\upalpha }), \gamma , \Delta g_{\text{el}}\right) \) as function of the matrix composition \(x^{\upalpha }\) and, by application of the inverse evaluation method, the relations \(x^{\upalpha ,{\text{int}}} = x^{\upalpha } (r, \gamma ,\Delta g_{\text{el}})\) and \(x^{\upbeta ,{\text{int}}} = x^{\upbeta } (x^{\upalpha })\) required for calculation of the particle growth rate. During the actual numerical computation routine, the necessary data pertaining to the instantaneous mean matrix concentration \( \bar{x}^{\upalpha }(t)\) and to a certain particle radius \(r_k\) can thus be accessed rapidly via a table lookup.

The elastic energy contribution caused by a misfitting coherent spherical particle (as holds for the Co precipitates in this work) was calculated according to[36]

with the shear modulus \(\mu ^{\upalpha }\) of the \(\upalpha \)-phase matrix and the effective bulk modulus \(K^{\upbeta }\) of the \(\upbeta \)-phase particle, adopting elastic isotropy of both matrix and precipitate phase. In the present case, the elastic constants and atomic volumes of the pure bulk components were employed. Due to the small mutual solubility of Co and Cu (cf. Figure 1), the thus introduced errors can be neglected. The values used for the elastic constants of Co and Cu, the atomic volumes/lattice parameters, and the impurity diffusion coefficient of Co in fcc Cu are listed in Table I.

The above-outlined efficient usage of thermodynamic data, largely due to the usage of the proposed inverse evaluation method, allows employing an automatic optimization algorithm for fitting the kinetic model to the experimental data within reasonable computation time. Since both experimentally determined PSD and calculated PSD consist of usually differing, discrete particle-size classes, for model fitting (and visualization) of the data, the PSDs were described by kernel density estimates (KDEs)Footnote 7 employing a Gaussian kernel with a band width of \(2 \times 10^{-10}\,\rm{m}\) (cf. experimental error of the radius determination; see Section IV). As cost function for fitting, the sum of the mean squared differences of experimental KDE and calculated KDE was used, with summation over all considered experimental PSD data series obtained at different annealing times and, when applicable, at different annealing temperatures.

4 Experimental Procedure

A Cu-0.57 at. pct Co master alloy was prepared by inductive melting from pure Cu and pure Co (Cu: 99.999 at. pct purity, Co: 99.98 at. pct purity). To achieve a homogeneous distribution of Co, the alloy rod was annealed under protective Ar atmosphere for 70 hours at 1300 K (1027 °C) within the single-phase region and afterward quenched in ice water. The Co concentration of the homogenized master alloy was determined by inductively coupled plasma optical emission spectroscopy (ICP-OES) to be \(\left( 0.571 \pm 0.007\right) \) at. pct Co.

Afterward, the master alloy rod was swaged down to 3 mm diameter and cut into specimen rods of about 20 mm length. To achieve a large average grain size and a low defect density, a second homogenization treatment at 1300 K (1027 °C) for 100 hours was performed, followed by quenching in ice water to preserve a supersaturated solid solution (the presence of a homogeneous solid solution after quenching was checked by additional magnetization measurements showing only diamagnetic behavior).

Annealing was performed in a fluidized sand bath to ensure fast heating-up of the specimens and good temperature stability during isothermal holding. Temperature during annealing was monitored using a Pt resistance thermometer. The actual temperature was within \(\pm \, 0.7\) K of the preset temperature with a standard deviation of the mean temperature of less than \(\pm \, 0.03\) K. Specimen rods were annealed at annealing temperatures of T = 773 K, 760.5 K, and 748 K (500 °C, 487.5 °C, and 475 °C) for various different times, followed by a quench in ice water.

For TEM analysis, disks were cut from the specimen rods and ground down to approx. 120-\({\upmu} \rm{m}\) thickness. Preparation of electron transparent foils was performed by electrolytic thinning using a Struers Tenupol 5 polishing unit and a phosphoric acid electrolyte (55 vol pct demineralised water, 30 vol pct 85 vol pct phosphoric acid, 15 vol pct ethylene glycol; best results were obtained for polishing at a voltage of 3 V). To reduce surface oxidation, the foils were prepared immediately before TEM investigation and were kept immersed in ethanol before insertion into the microscope. For TEM analysis, a Zeiss 912 \(\Omega \) TEM operating at 120 kV accelerating voltage was used. The instrument is equipped with an electron energy loss spectroscopy (EELS) filter which allows the determination of the foil thickness of the investigated area by application of the log-ratio method.[37,38] Digital TEM bright-field (BF) images were recorded for low-order zone-axis (ZA) beam incidence (typically \(\langle 100 \rangle \), \(\langle 110 \rangle \), or \(\langle 111 \rangle \) zone axes of Cu). Under BFZA conditions, coherent Co-rich particles are visible by a dark circular strain contrast (Reference 19, 39; for the system Cu-Co, the mass contrast caused by the local enrichment in Co atoms is negligible for small Co-rich particles). The detection of Co-rich precipitates within a Cu-rich matrix by BFZA TEM is effectively limited by its strain contrast: For particles with radius smaller than about 1 nm, the strain contrast becomes too weak to be reliably detected.[19] Upon applying the present kinetic model to the experimental data, model fitting (see Section III) was therefore restricted to particle-size regions above 1 nm.

By quantitative evaluation of the digital TEM images, the (two-dimensional) particle positions, particle radii and particle (number) density per area were determined. Introducing the thickness information obtained with the log-ratio method, the particle numbers per sampled volume were derived. According to strain-contrast simulations for coherent Co particles in a Cu matrix under BFZA conditions,[19] particle radii derived from the strain contrast are within \(\pm \, 0.1 \,\rm{nm}\) of the true particle radii; this range clearly exceeds the experimental uncertainty of the TEM BF magnification calibration. In practice, the accuracy of the particle-size measurement is determined by the analysis of the digital TEM micrograph: technically, the precision of the radius determination is limited by the digital image resolution (here typically \(0.18 \,\rm{nm} / \text{pixel}\)), with some additional arbitrariness introduced by human evaluation. The error of the radius values was thus assessed as \(0.2 \,\rm{nm}\). The accuracy of the thickness values derived with the log-ratio method is about 20 pct.[37] This has an only linear effect on the accuracy of the particle-density values (the error of the image area determination can, in comparison, be neglected). Thus, the inaccuracies of the radius measurement and of the thickness measurement have relatively small effect on the PSDs, the mean particle radii and the particle densities. However, their effect is much stronger for the volume fraction of precipitates in view of its \(r^3\)-dependency. The volume fraction determined by TEM image analysis is thus a relatively unreliable parameter to trace the progress of the precipitation reaction.

5 Experimental Results

A typical TEM BFZA image of Cu-0.57 at. pct Co after isothermal annealing of the supersaturated alloy within the two-phase region is shown in Figure 2. The formation of spherical Co-rich particles of about 3 to 7 nm in diameter is indicated by the dark strain-contrast rings. Consistent with TEM BF contrast calculations[19] particles below a lower limit of 0.8 nm to 1.0 nm were not detected.

TEM image of Cu 0.57 at. pct Co after annealing at 773 K (500 °C) for 4 h. The image is recorded under bright-field zone-axis conditions (fcc Cu \(\langle 111 \rangle \) electron beam incidence; see diffraction pattern in the inset). The coherent Co-rich particles are (indirectly) visible because of the dark strain-contrast rings resulting from the lattice misfit of fcc Cu and fcc Co

Evolution of (a) particle-number density (multiplied by factor 10 for T = 773 K (500 °C)), (b) mean particle radius, and (c) volume fraction of precipitates as function of annealing time upon isothermal annealing of Cu-0.57 at. pct Co alloys at 773 K (500 °C) (°), 760.5 K (487.5 °C) (+), and 748 K (475 °C) (×), respectively

Quantitative analysis of the TEM BFZA micrographs primarily yields the individual particle sizes and the number of particles per sampled volume. The mean particle size \(\bar{r}\), particle density \(N_{\text{V}}\) , and volume fraction \(f_{\text{V}}\) of the second-phase particles can then be derived directly from these discrete experimental data (Figure 3). The observed particle-number densities of the present study are comparable to TEM-based particle-number densities for precipitation reactions in dilute Cu-Co alloys obtain under similar experimental conditions in Reference 13.

The KDEs of the PSDs (cf. Section III) derived from the experimental data are shown in Figure 4. A comparison of the cumulative KDEs and the cumulative number of particles per volume, as derived directly from the discrete experimental data without classification of particle size, is also presented in Figure 4. It follows that the experimental data are represented adequately by the KDEs.

Evolution of the particle-size distribution for annealing of Cu 0.57 at. pct Co alloys at different isothermal annealing temperatures as derived from TEM BFZA micrographs: (a) T = 773 K (500 °C), (b) T = 760.5 K (487.5 °C), (c) T = 748 K (475 °C). Left columns: representation of the experimental data as kernel density estimate (KDE) of the PSD (cf. Section III); right columns: comparison of the cumulative KDEs (lines) and the cumulative of the discrete number densities of particles of certain size per volume (crosses) as directly derived from the experimental data

The evolution of particle size and particle-number density at different isothermal annealing temperatures clearly displays the influence of supersaturation: with decreasing annealing temperature and thus increasing degree of supersaturation (and increasing chemical driving force), the particle density strongly increases while the average particle size decreases (Figures 3(a) and (b); cf. Eqs. [6] and [8]). The effect of temperature decrease on the thermal activation of the nucleation process and the growth process, which by itself would lead to an overall retardation of the precipitation kinetics, is not directly apparent in the temperature range under investigation (cf. Figure 3, also see discussion in Section VI–D). In contrast to the evolutions of mean particle size \(\bar{r}\) and density \(N_{\text{V}}\), which strongly depends on temperature, the evolution of the volume fraction \(f_{\text{V}}\) (Figure 3(c)) seems much less dependent on temperature. This indicates that the volume fraction of precipitates is not a very sensitive experimental parameter to trace the progress of the precipitation reaction (also see remark on the accuracy of \(f_{\text{V}}\) in Section IV).

The drastic influence of supersaturation on particle size and number density leads to a confined window of annealing time and temperature (as well as composition, see[13]) in which experimental (TEM-based) investigation of the precipitation kinetics is possible: For short annealing times at high temperatures, the number of particles per sample volume is too low to allow reliable detection and thus statistically sound derivation of the PSD. This is the case for the PSD derived for \(t = 2\,\rm{hours}\) at T = 773 K (500 °C) in Figure 4(a); this dataset is therefore left out in further kinetic analysis. On the other hand, upon annealing at lower temperatures, the initially very small particle sizes inhibit a TEM-based analysis of the very early stage of the precipitation process owing to the experimental detection limit set by the strain-contrast conditions for small particles (see Section IV).

6 Modeling Results and Discussion

6.1 General Model Behavior

Using the experimental data for the evolution of the particle-size distribution as a reference, a series of exemplary cases for model application can be addressed.

Following the modeling approach as described in Sections I and II, the model is in a first step applied to the experimental data for the highest isothermal annealing temperature with the interface energy \(\gamma \) as only adaptable model parameter, i.e., setting the diffusional rate coefficients \(D_{\text{N}}\) for nucleation (Eq. [8]) and \(D_{\text{G}}\) for growth (Eq. [9]) to the value for the impurity diffusion coefficient \(D_{\text{D}}\) of Co in Cu (Reference 40, see Table I). Thus, fitting the model to the dataset for annealing at T = 773 K (500 °C) leads to an overall good agreement between simulated PSDs and experimentally determined PSDs at 773 K (500 °C) (Figure 5, case A in Table II; for discussion of the modeling results with respect to the system Cu-Co, see below): the size distributions cover similar size ranges with similar population density. For the shorter annealing times (2 to 4 hours), somewhat larger discrepancies between experimentally determined and modeled PSDs are present for small particle sizes around the detection limit equal to 1 nm, which was used as lower size limit for fitting. For the longer annealing times, i.e., upon continued particle growth, the discrepancies become smaller and very good agreement between simulation and experiment is achieved. Restricting the model fit to the experimental data for the shorter annealing times of 3 and 4 hours (the data for the shortest annealing time cannot be considered; see discussion of Figure 4(a) in Section V) leads to the same value for the interface energy and thus to no better description of the experimental data. This inability of the model to describe the experimental data more precisely might indicate that the model would principally not be capable to adequately describe the precipitation kinetics for short annealing times. However, this is incompatible with the observed good agreement for longer annealing times. Hence, it appears more plausible that the experimental data for the shorter annealing times are considerably biased by the—in practice not necessarily sharp—experimental detection limit around \(r \approx 1\) nm.

With the effect of the experimental detection limit again taken into account, i.e., omitting all particle-size classes with radius below 1 nm, the evolution of the average parameters, the particle-number density, the mean radius, and the volume fraction of precipitates, is matched very well (see Figure 5).

(a) Model fits of the experimentally determined evolution of the PSD at 773 K (500 °C). Solid lines: using the interface energy \(\gamma \) as only fit parameter and setting the rate coefficients \(D_{\text{N}}\) and \(D_{\text{G}}\) to the value \(D_{\text{D}}\) for the impurity diffusion coefficient of Co in Cu (case A in Table II). Dash-dotted lines: using the interface energy \(\gamma \) and the pre-exponential factors of \(D_{\text{N}}\) and \(D_{\text{G}}\), i.e., \(D_{\text{N,0}}\) and \(D_{\text{G,0}}\), as fit parameters (case F in Table II). Markers: experimental data. Dashed vertical lines: lower limit of the fitting range, accounting for the experimental detection limit for particle radii around 1 nm (data for \( t = 2\,\rm{h}\) were not considered upon fitting). Especially for the longer annealing times of 5 and 6 h, good agreement of model and experimental data is achieved. (b) Evolution of the average parameters particle-number density \(N_{\text{V}}\), mean radius \(\bar{r}\), volume fraction of precipitates \(f_{\text{V}}\), and of the mean matrix composition \(\bar{x}^{\upalpha }\) as follows from the one-parameter fit. Solid lines: results of the model fit in (a). Data with error bars: experimental data. Circles: calculated from fit results subject the lower limit of the fitting range at 1 nm

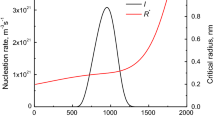

The experimentally observed bimodal shape of the PSDs can be well described by the kinetic model and thus, according to the model, is a straightforward consequence of the size dependency of the rate equation for growth, Eq. [9], in combination with nucleation (see Reference 7): it follows from Eq. [9] that the size-dependent growth rate must show a maximum at a certain particle size \(r > r^* = r^{\text{c}}\) close to \(r^*\) (see Figure 6). In the early stages of the precipitation reaction, the population density of the PSD in size regions slightly larger than \(r^*\) is continuously increased by continuous nucleation of particles. After experiencing a moderate (positive) growth rate (dominated by the Gibbs–Thomson effect), particles enter a size region associated with the maximum growth rate and thus grow rapidly until the growth rate becomes attenuated due to its inverse proportionality to particle size. This leads to a local minimum of the population density in the size region associated with the maximum growth rate and thus to a bimodal shape of the PSD.

Particle growth rate \({{\text{d}}r}/{{\text{d}}t}\) (Eq. [9]) as function of particle size \(r\) for different values of the matrix composition (for case A in Table II). For large particle size, the growth velocity is dominated by the term \(v \propto {r}^{-1}\). For a particle radius equal to the critical size \(r^* = r^{\text{c}}\), the growth rate equals zero owing to the Gibbs–Thomson effect. At intermediate particle size, the growth rate assumes a maximum; evidently, the particles quickly outgrow this size region

The development of a bimodal PSD may only be observable in the early stages of the modeled precipitation reaction: in advanced stages of precipitation, the relative contribution of recently nucleated particles to the total number of particles decreases, (also) owing to the decrease of the nucleation rate due to matrix depletion, and the bimodality disappears. In case of inconsistent thermodynamic modeling, leading to non-identity of \(r^*\) and \(r^{\text{c}}\) (cf. Section II), the particle size of a particle newly generated by nucleation may, in terms of growth, (non-physically) already be considerably larger than the no-growth radius and lie within the region of maximum growth rate, thus erroneously precluding the emergence of a bimodal size distribution (see also footnote in Section I).

6.2 Influence of the Thermodynamic Description

The nucleation rate and the growth rate are strongly dependent on the model adopted to describe the thermodynamics of the particle–matrix system, represented by the relations \(r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}})\) and \(x^{\upbeta } (x^{\upalpha })\). These relations, providing a complete characterization of the thermodynamics of the particle–matrix system (see Section II), define the critical particle size \(r^* = r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}}) \) for nucleation and the composition of the nucleus, as well as the compositions of particle and matrix at the particle–matrix interface \(x^{\upalpha ,{\text{int}}} = x^{\upalpha }(r, \gamma , \Delta g_{\text{el}})\) and \(x^{\upbeta ,{\text{int}}} = x^{\upbeta } (x^{\upalpha })\) under consideration of the Gibbs–Thomson effect. The value the interface energy \(\gamma \) assumes upon model fitting thus necessarily depends on the chemical energy contribution \(\Delta g_{\text{c}}(x^{\upalpha })\) and the elastic misfit energy contribution \(\Delta g_{\text{el}}\), as derived from literature data for the bulk system (see, e.g., References 41,42).

As can be inferred from the fair agreement between kinetic model and experiment obtained above (case A in Table II and Figure 5), the thermodynamic model used in the present study appears to be of sufficient quality to adequately describe the system properties for application in a kinetic model. To assess the consequences of the choice of a specific thermodynamic model for nucleation and growth on the kinetics of nucleation and growth, two different scenarios can be investigated:

-

(i)

Sensitivity for chemical driving force In the present case, thermodynamic data for the (maximum) chemical driving force \(-\Delta g_{\text{c}}(x^{\upalpha })\) , and the phase-composition relation \(x^{\upbeta } (x^{\upalpha })\) was extracted from a recent CALPHAD assessment of the binary system.[34] If a thermodynamic assessment of the alloy system is not available, the chemical driving force is often derived using analytical equations based on simple thermodynamic solution models (see Section III, Eq. [11]). Employing such an expression for the present case, a somewhat different dependency of \(\Delta g_{\text{c}}(x^{\upalpha })\) on the matrix composition \(x^{\upalpha }\) is obtained (see Figure 1). Upon fitting the kinetic model with this modified thermodynamic input data to the experimental data for T = 773 K (500 °C), an acceptable description of the experimental data can still be achieved (case B in Table II), however, with a considerably different value for \(\gamma \). This illustrates the sensitivity of the value assumed by \(\gamma \) in the kinetic model for the precise thermodynamics of the system.[25] The good agreement of kinetic model and experiment still obtained in case B, albeit using a less appropriate description for the chemical driving force \(-\Delta g_{\text{c}}(x^{\upalpha })\), does not hold generally and here is due to the small mutual solubility of fcc Cu and fcc Co.

-

(ii)

Sensitivity for misfit-strain energy An often made simplification of the thermodynamic model for analyzing precipitation kinetics (in the system Cu-Co) is to neglect the contribution of the elastic misfit energy \(\Delta g_{\text{el}}\) (e.g., Reference 27). In the present case, \(\Delta g_{\text{el}}\), computed with a simple Eshelby model (Reference 36, Section 3), amounts to less than 10 pct of the initial chemical driving force at \(t = 0\). Performing a model fit with \(\Delta g_{\text{el}}\) set to zero results in a drastic change of \(\gamma \) (case C in Table II): The model reacts by considerably increasing the value of the interface energy to emulate the effect of a net driving force reduced by the elastic energy contribution. Moreover, the corresponding model description is of reduced qualityFootnote 8 (see Table II).

The dependence of the interface energy values, as obtained from kinetic analysis, on the precise thermodynamics of the system renders direct, quantitative comparison of values for \(\gamma \) derived from kinetic studies based on differing thermodynamic descriptions difficult, if not impossible.

The pronounced consequences of applying inconsistent thermodynamic descriptions in kinetic models, as resulting from a combination of different approximate expressions for nucleation thermodynamics and growth thermodynamics or from consideration of an elastic strain energy contribution only for nucleation but not for growth, have been demonstrated in Reference 1.

6.3 Limitations of Kinetic Model Fitting to Averaged Experimental Data

Comparison of model and experiment has in the literature often been restricted to only the evolution of the particle-number density and/or the mean particle radius, i.e., the analysis has been restricted to average PSD parameters which do not provide a comprehensive characterization of the underlying PSD.Footnote 9 In such a case, good agreement between model and experiment can be achieved for the average parameters, but the modeled PSD parameters can be incompatible with the in reality occurring underlying particle-size distributions. Such good agreement for the average parameters then actually occurs only for the range of experimental data considered in the model fitting.

To reveal the significance of kinetic model fitting to full PSDs, the kinetic model was fitted in the current work also to only the experimental data for the particle-number density \(N_{\text{V}}\) or those for the mean radius \(\bar{r}\) (in both cases, again only particle-size classes above 1 nm were considered in order to account for the experimental detection limit, cf. Section IV). Again using the interface energy \(\gamma \) as only fit parameter, results identical to those obtained upon fitting the full PSD were obtained for the case of taking \(N_{\text{V}}\) as reference (case D in Table II) but not for the case of taking \(\bar{r}\) as reference (case E in Table II): Although good agreement between model and experimental data is achieved for \(\bar{r}\) , the underlying calculated PSDs and the experimental PSDs differ strongly (see Figure 7). Evidently, the particle-number density and the mean particle radius show different sensitivity toward changes of the value for the interface energy: while the nucleation rate, and thus the particle-number density, depends very sensitively on the value assumed by \(\gamma \), the evolution of the mean particle radius as function of time and temperature is predominantly controlled by the diffusion coefficient and to a much lesser extent by the Gibbs–Thomson effect, and thus by the value of \(\gamma \). Hence, at least in the present case, fitting to the experimental data for the evolution of the mean particle radius does not allow to define the kinetic model parameters (here only \(\gamma \)) to correctly describe the precipitation kinetics.

Results of fitting the kinetic model to only the experimentally determined evolution of the mean radius \(\bar{r}\) at T = 773 K (500 °C) using the interface energy \(\gamma \) as fit parameter and with \(D_{\text{N}} = D_{\text{G}} = D_{\text{D}}\). While the evolution of the mean radius (a), used for model fitting, is described quite accurately with \(\gamma = 223 \,\rm{mJ\,m}^{-2} \), the evolution of the underlying PSD as then follows from the kinetic model (b), and thus also the evolution of the particle-number density \(N_{\text{V}}\) (c) strongly disagree with the experimental data

6.4 Independent Variation of Nucleation and Growth Kinetics: Utilizing the Full PSDs at Different Temperatures

Usage of only the interface energy as an adaptive parameter to achieve good agreement of model prediction and experimental data affects in a prescribed way both nucleation kinetics and growth kinetics simultaneously via the characteristic thermodynamic relation \(r(\Delta g_{\text{c}},\gamma , (x^{\upalpha }), \Delta g_{\text{el}})\) (see Section II). For a more flexible kinetic analysis, and then (again) utilizing the full PSDs, the model can be employed in a less constrained mode with independent variation of the nucleation rate and the growth rate.

A linear, temperature-independent scaling of nucleation rate and growth rate in the kinetic model can for instance be realized by allowing the pre-exponential factors \(D_{\text{N,0}}\) and \(D_{\text{G,0}}\), associated with the nucleation rate (Eq. [8])Footnote 10 and the growth rate (Eq. [9]), respectively, to vary, i.e., to deviate from the pre-exponential factor values \( D_{\text{D,0}}\) determined experimentally for the diffusion coefficient of the solute component. At constant temperature, variation of the pre-exponential factors is of course equivalent to a corresponding variation of the activation energies \(Q_{\text{N}}\) and \(Q_{\text{G}}\) associated with nucleation and growth.Footnote 11

Especially in the case of the nucleation rate, adjustment of the value assumed by the pre-exponential factor \(D_{\text{N,0}}\) appears well justified in view of the only proportional relationship derived between the solute-capturing rate \(\beta ^*\) and the rate coefficient \(D_{\text{N}} = D_{\text{N,0}} \exp (-\frac{Q_{\text{N}}}{RT})\) in Eq. [2] (cf. Section II). In any case, flexibility of the model description for the nucleation rate and for the growth rate, with \(D_{\text{N}}\) or \(D_{\text{G}}\) deviating from the (impurity) diffusion coefficient \(D_{\text{D}}\), is desired, because it appears likely that the diffusional mechanism involved in the nucleation process or in the growth process is not in general adequately represented by (impurity) solute diffusion in a homogeneous matrix. Allowing independent variation of nucleation and growth rates for example permits to account for an acceleration of the nucleation and growth kinetics caused by the presence of excess vacancies due to quenching from the homogenization temperature (cf. References 13,25), or to account, at least to some extent, for the composition dependence of the diffusion coefficient for growth which is neglected in the growth rate Eq. [9].

With the increased number of now three freely adaptable model parameters, either \(\gamma \), \(D_{\text{N,0}}\) and \(D_{\text{G,0}}\), or \(\gamma \), \(Q_{\text{N}}\) and \(Q_{\text{G}}\) (cases F and G, respectively, in Table II and Figure 5), the value assumed by the interface energy \(\gamma \), by fitting the model to the PSDs determined at T = 773 K (500 °C), is now considerably larger than the value assumed by \(\gamma \) in the single-parameter fit (Section VI–A); a change of \(\gamma \) from 229 to 240 mJ m−2 would lead to a decrease of the (initial) nucleation rate by more than factor 10. This effect is fully compensated by a strong increase of the pre-exponential factor \(D_{\text{N,0}}\) (or by a decrease of the activation energy \(Q_{\text{N}}\)) for nucleation, which now deviates significantly from \(D_{\text{D,0}}\) (or \(Q_{\text{D}}\)). By comparison, the value of the pre-exponential factor \(N_{\text{G,0}}\) (or the activation energy \(Q_{\text{G}}\)) for growth remains almost unchanged; only small changes are necessary to compensate for a larger initial particle size after particle nucleation, defined by the value of the interface energy \(\gamma \) (Eq. [6]).

Such large deviations in \(D_{\text{N,0}}\) (or \(Q_{\text{N}}\)) from \(D_{\text{D,0}}\) or \(Q_{\text{D}}\) may be considered implausible in the present case: As compared to more generally formulated models for transformation kinetics, such as obtained by the modular model approach,[43,44] the present model, as all KWN-type models, is a relatively restrictive kinetic model: The equations employed in the present model for the nucleation rate and the growth rate are derived in a very stringent way from elementary reaction steps—the movement of single solute atoms in the matrix phase (in case of nucleation, clustering of single solute atoms[3,4]; in case of growth, long-range diffusion of single solute atoms[5]). The corresponding rate equations thus both contain an Arrhenius-type expression \(D = D_0 \exp {(-\frac{Q}{RT})}\) which directly originates from the concerned elementary step, the movement of single solute atoms (see Eqs. [8] and [9]). By contrast, in the modular model, as an example for more general kinetic models, relatively abstract, (simple) rate equations for nucleation and growth can be employed, suitable to describe the kinetic problem at hand. This constitutes the high flexibility of such general models (e.g., References 45 through 47).

For model application/model fitting, this has the following consequences: model descriptions based on the modular approach, e.g., Johnson–Mehl–Avrami–Kolmogorov-like models,[43,44] have a high flexibility, but the values assumed by the kinetic parameters, such as activation energies for nucleation and growth, upon model fitting may not be interpreted straightforwardly. In the present model, by contrast, the activation energies must be somewhere close to the activation energy for diffusion of the solute component in the matrix. Largely different values for the activation energies (as in the cases F and G) therefore rather hint that the model is inapplicable or applied in a wrong way.

Indeed, in the present case, the deviations of \(D_{\text{N,0}}\) (or \(Q_{\text{N}}\)) from \(D_{\text{D,0}}\) (or \(Q_{\text{D}}\)) are caused by a (factual) direct interdependence of the parameters \(\gamma \) and \(N_{\text{N,0}}\) (or \(Q_{\text{N}}\)) at the specific temperature considered (i.e., the fit is underconstrained; cf. Eq. [8]). For the same values of \(\gamma \) and \(D_{\text{N,0}}\) (or \(Q_{\text{N}}\)), at a different temperature, no such balancing of \(\gamma \) and \(N_{\text{N,0}}\) (or \(Q_{\text{N}}\)) can occur. Consequently, usage of the model parameters, determined by fitting to the experimental data at 773 K (500 °C), to predict the evolution of the PSD at another temperature, as here the intermediate annealing temperature of T = 760.5 K (487.5 °C), yields considerable discrepancies of model prediction and experimental data (Figure 8).

Evolution of the PSD at 760.5 K (487.5 °C) predicted on the basis of the kinetic model parameters (here \(\gamma \), \(D_{\text{N,0}}\) and \(D_{\text{G,0}}\)) determined in an underconstrained model fit of the experimental data at 773 K (500 °C) (case F in Table II). Although good agreement of model and experiment was achieved for the higher temperature (cf. Fig. 5), the thus determined model parameters are inapplicable at lower temperature, leading to vast overestimation of the number of precipitate particles

Hence, to determine the kinetic parameters \(\gamma \), \(D_{\text{N,0}}\) (or \(Q_{\text{N}}\)), and \(D_{\text{G,0}}\) (or \(Q_{\text{G}}\)), fitting of the kinetic model to PSDs measured at at least two different temperatures is required. Indeed, in this way, unique values for the parameters \(\gamma \), \(D_{\text{N,0}}\) (or \(Q_{\text{N}}\)), and \(D_{\text{G,0}}\) (or \(Q_{\text{G}}\)) can be obtained (cases H and I in Table II and Figure 9), which are practically identical with the corresponding values for impurity diffusion of Co in Cu.

Results of fitting the kinetic model simultaneously to series of experimental PSDs at two temperatures: (a) isothermal annealing at T = 773 K (500 °C) and (b) isothermal annealing at T = 760.5 K (487.5 °C) , using three free model parameters, the interface energy \(\gamma \) and the activation energies \(Q_{\text{N}}\) and \(Q_{\text{G}}\) associated with nucleation and growth, respectively (Case H in Table II). Both datasets can be described reasonably well with one set of kinetic model parameters (compare Fig. 8). Employing instead of the activation energies \(Q_{\text{N}}\) and \(Q_{\text{G}}\), the pre-exponential factors \(N_{\text{N,0}}\) and \(N_{\text{G,0}}\) as fit parameters yields equivalent results (Case I in Table II)

As a matter of fact, it can be suggested that all five parameters \(\gamma \), \(D_{\text{N,0}}\), \(Q_{\text{N}}\), \(D_{\text{G,0}}\), and \(Q_{\text{G}}\) can be considered as fit parameters. Fitting the model with these five fit parameters simultaneously to the datasets at two temperatures, i.e., at T = 773 K and 760.5 K (500 °C and 487.5 °C), again provides a good description of the evolution of the PSDs at both annealing temperatures (case J in Table II). However, in the present case, a unique determination of all parameters was not possible: it was found that model descriptions of same quality but with largely different values for the pre-exponential factors and activation energies (but the same value for the interface energy) could be obtained (cf. case K and case J). This effect is ascribed to the small temperature difference of \(\Delta T = 12.5\,\rm{K}\) between the two experimental datasets, which does not allow to fully separate the effects of changes in the activation energy and the corresponding pre-exponential factor, for both the nucleation rate and the growth rate: upon lowering the annealing temperature from T = 773 K to 760.5 K (500 °C to 487.5 °C), the term \(\exp (-Q_{\text{N}}/(RT))\) associated with the diffusional step for nucleation decreases by less than a factor 2 (for \(D_{\text{N}} = D_{\text{D}}\)). The resulting modest effect on the evolution of the PSD at the different temperatures does obviously not allow determining independent values for the pre-exponential factors and corresponding activation energies. By contrast, strong variations of the precipitation kinetics (cf. Figure 3) are caused by the nucleation-barrier term \(\exp (-\Delta G^*/(kT))\) of the nucleation rate, defined by the temperature-dependent chemical driving force, which increases by a factor \(10\) upon temperature decrease from T = 773 K to 760.5 K (500 °C to 487.5 °C) (for \(\gamma = 230\,\rm{kJ\,mol}^{-1} \)).

It can be concluded that, although the present experimental data do not comprise sufficient temperature variation to determine the five potential fit parameters considered in a unique way, the present experimental data in the form of the PSD evolution at different temperatures do contain sufficient information to determine unique values for at least either the activation energies or the pre-exponential factors independently, in addition to the interface energy. The excellent agreement of the values obtained for \(Q_{\text{N}}\) and \(Q_{\text{G}}\), or \(D_{\text{N,0}}\) and \(D_{\text{G,0}}\), with literature data for impurity diffusion of Co in Cu indicates that the diffusional processes involved in nucleation and growth in the present case are indeed of a nature very similar to that of volume diffusion, in an undisturbed matrix of homogeneous composition. The value of \(\gamma \approx 230\,{\rm{mJ\,m}}^{-2}\) finally assumed by the interface energy (cases H and I) agrees well with the range of interface energy values reported in literature (e.g, Reference 26, 27, 42], cf. comments in Section VI–B).

The good agreement of experiment and model may be ascribed on the one hand to the chosen experimental conditions of low supersaturation and determination of the PSDs in coarse-grained specimens of low defect density, providing conditions as ideal as possible for homogeneous nucleation to occur in a crystalline solid solution, and on the other hand to the model properties of the Cu-Co system: the small mutual solubility of Cu and Co, allowing to investigate precipitation reactions in a very dilute system, and the formation of initially fully coherent spherical precipitates due to the relatively small lattice mismatch between fcc Cu and fcc Co.

Finally, repeating the model fit as above with \(\gamma \), \(Q_{\text{N}}\), and \(Q_{\text{G}}\) as freely adaptable parameters, but with the elastic energy contribution \(\Delta g_{\text{el}}\) set to zero (similar to case C in Section VI–B), yields considerably different values not only for the interface energy (cf. case C) but also for the activation energy \(Q_{\text{N}}\) for nucleation (case L in Table II). This cleary indicates that in order to describe the precipitation kinetics in Cu-Co in a physically reasonable way, the elastic misfit energy must be incorporated into the kinetic model, for both nucleation and growth (which contrasts with previous works; see e.g., Reference 7, 27 through 29]). This is now greatly facilitated by use of the inverse evaluation method, for the first time applied to experimental data in this study.

6.5 Predictive Capability; Limitations

Knowledge of the kinetic model parameters, obtained either from fitting the kinetic model to experimental data or from adequate literature data, should in principle allow to predict the evolution of the particle-size distribution for arbitrary annealing times and temperatures. To test the predictive capability of the kinetic model when employing the kinetic parameters determined above by fitting the model to the PSDs at two temperatures (T = 773 K and 760.5 K (500 °C and 487.5 °C), cases H and I in Table II), the thus far ignored experimental dataset for the evolution of the particle-size distribution at the lowest annealing temperature T = 748 K (475 °C), featuring the highest values of particle-number density and volume fraction of precipitates (Figures 3 and 4), can be compared against the predictions of the kinetic model: Despite the generally good agreement between model and experiment achieved upon fitting the kinetic model to the experimental data at the higher temperatures, considerable discrepancies can be observed comparing model prediction and experiment at T = 748 K (475 °C) (Figure 10): The model predicts a much higher particle-number density and a more dynamic evolution of the particle-size distribution toward larger particle size. The quality of the experimental data for 748 K (475 °C) is comparable to the two datasets employed to determine the kinetic parameters. Also, large changes in the kinetic parameters appear improbable in view of the small temperature range of 25 K covered in this study.Footnote 12

The evolution of the PSD at the lowest annealing temperature T = 748 K (475 °C). Markers: Experimental data. Solid lines: Prediction on the basis of the kinetic model parameters determined by fitting the model simultaneously to the experimental data at two higher temperatures (case J in Table II). The predicted PSDs largely overestimate the total number of particles and suggest a faster evolution of the PSD toward larger particle sizes

It can thus be suggested that the kinetic model is incapable to describe the evolution of the PSD at the high degree of solute depletion as realized at the lowest annealing temperature. Disagreement between KWN-type model prediction and experiment was observed before for later stages of the precipitation reaction within the late growth-coarsening regime (e.g., References 32,48). In these cases, better agreement was achieved by adopting an interface energy increasing with particle size. At least in the present case, this approach does not appear reasonable, since the experimental series at all three annealing temperatures feature comparable particle sizes. Recognizing that the discrepancies of the model with the experiments appear mainly for high volume fractions of particles, i.e., high degrees of solute depletion of the matrix, these discrepancies may rather be considered as an artifact owing to application of the mean-field approach for the matrix composition: the mean-field approach only considers individual interaction of a particle (class) with a matrix of average composition and cannot account for direct particle–particle interaction via their surrounding diffusion fields (note that the mean composition approach also inherently clashes with the growth rate Eq. [9] which is derived assuming a linear concentration gradient in the matrix).

In addition to particle–particle interaction via diffusion fields, in the present case of coherent Co-rich particles exhibiting a volume mismatch with the matrix, particle–particle interaction also occurs via interaction of the elastic strain fields surrounding each particle. Assessment of the effects of strain-field interaction is complex; such interaction may either (locally) promote or inhibit nucleation and growth of particles. The effect of strain-field interaction was suggested to lead to chain-like arrays of Co-rich precipitate particles along elastically soft directions of the Cu-rich matrix as observed for Cu-Co, albeit for alloys of considerably higher solute content featuring much high particle-number densities (\(10^{23}\) to \(10^{25}\,{\rm{m}}^{-3}\))[22,49]. In view of the decline of elastic strain proportional to \((r/(r+d))^3\) with distance \(d\) from the particle–matrix interface,[50] the effect of strain-field interaction may in first approximation be neglected for the relatively small volume fractions of precipitates and low particle-number densities observed in the present case.

It can be concluded that in the first stage of nucleation and growth, at low degrees of solute depletion, deficiency of the mean-field approach to describe the solute depletion has an only small effect on the kinetics of nucleation and growth, leading to good agreement between kinetic model and experiment, as indeed observed especially for the dataset determined at the highest annealing temperature of 773 K (500 °C). In late stages with higher volume fractions of precipitates, as holds for the dataset at 748 K (475 °C), the mean-field approach appears inadequate to correctly account for direct particle–particle interactions via their surrounding diffusion fields, thus demanding the spatial distribution of precipitates in the matrix and their interactions to be explicitly expressed in the kinetic model.

7 Conclusions

A kinetic model for precipitation reactions, on the basis of the recently proposed “inverse evaluation method” which allows inherently consistent, accurate, and computationally efficient evaluation of the thermodynamics for nucleation and growth, was presented and applied to experimental data for the particle-size distributions (PSDs) evolving as function of time in a dilute Cu-Co alloy at different isothermal annealing temperatures.

-

1.

Good agreement of kinetic model and experimental data was obtained for the early stages of the precipitation reaction, featuring concurring nucleation and growth at low to intermediate degrees of solute depletion. In later stages of the precipitation reaction, differences emerged as a consequence of a breakdown of the mean-field approach to describe the solute depletion of the matrix.

-

2.

It was shown that if experimental data for the evolution of the PSDs at at least two different temperature is available, unique, physically reasonable values for the interface energy and for the activation energies of nucleation and growth, or for the corresponding pre-exponential factors (and potentially for both activation energies and both pre-exponential factors), can be determined by fitting the kinetic model simultaneously to the experimental datasets at different temperatures. Such a modeling approach is especially helpful when the diffusional mechanisms involved in the nucleation and growth process deviate from impurity diffusion of the solute component in the matrix phase.

-

3.

Incorporation of the elastic misfit energy contribution, for both nucleation and growth, was found to be mandatory to achieve good agreement of model and experiment and to obtain physically reasonable values for the kinetic model parameters.

Notes

In extreme cases, the unphysical scenario can emerge that a particle once generated by nucleation is inherently unstable with respect to growth and, in this flawed model scenario, immediately begins to dissolve.

In the present work, the Gibbs energy is used to describe the energy content change of the system considered because of experimental control of \(p\) and \(T\).

Lattice parameters \(a^{j}\) and atomic volumes \(V^{j}\) of the phases \(j = \upalpha ,\,\upbeta \) are taken as being composition-independent.

in case of a binary system; for multinary systems cf. Reference 1.

i.e., a description of the chemical Gibbs energies of \(\upalpha \) and \(\upbeta \), or of the corresponding activity coefficients, as function of alloy composition and temperature

As compared to a representation of the data as histograms, the KDE approach avoids classification of the PSD into fixed, discrete particle-size classes.

This is in particular caused by the different dependency of the size relation \(r(\Delta g_{\text{c}}(x^{\upalpha }), \gamma , \Delta g_{\text{el}})\) on \(\gamma \) and \(\Delta g_{\text{el}}\) (Eq. [6]).

This, of course, can be ascribed to the experimentally cumbersome determination of the evolution of the PSD as function of annealing time and temperature by using direct imaging techniques (as employed in the present case) or by its extraction from primary experimental data (e.g., in case of scattering experiments).[35]

In case of the nucleation rate, changes in \(D_{\text{N,0}}\) also affect the time lag \(\tau \) (with \(\exp ( - \tau / t)\) varying between 0 and 1); the nucleation rate thus does not scale exactly linearly with \(D_{\text{N,0}}\).

A variation of both activation energy and corresponding pre-factor is numerically underdetermined at constant \(T\).

Indeed, even with the full flexibility of the kinetic model provided by three fit parameters, it was not possible to achieve a model description for the experimental data at T = 748 K (475 °C) of a quality similar to that achieved at the higher temperatures. As a consequence, application of the model to different combinations of experimental datasets including the data at the lowest temperature also leads to unsatisfactory modeling results.

References

B. Rheingans and E.J. Mittemeijer: CALPHAD, 2015, DOI:10.1016/j.calphad.2015.04.013

R. Kampmann and R. Wagner: in Decomposition of Alloys: the Early Stages, P. Haasen, V. Gerold, R. Wagner, and M.F. Ashby, eds., Pergamon Press, Oxford, 1984, pp. 91–103

M. Volmer, A. Weber, Z. Phys. Chem. 119, 277–301 (1926)

R. Becker, W. Döring, Ann. Phys. 24, 719–752 (1935)

C. Zener, J. Appl. Phys. 20, 950–953 (1949)

H.B. Aaron, D. Fainstein, G.R. Kotler, J. Appl. Phys. 41, 4404–4410 (1970)

J.D. Robson, Acta Mater. 52, 4669–4676 (2004)

Z. Liu, V. Mohles, O. Engler, G. Gottstein, Comput. Mater. Sci. 81, 410–417 (2014)

J.W. Gibbs, The Collected Works of J (Green and Co., Williard Gibbs, Longmans, 1906)

V.A. Phillips, J.D. Livingston, Philos. Mag. 7, 969–980 (1962)

M. Takeda, N. Suzuki, G. Shinohara, T. Endo, J. van Landuyt, Phys. Status Solidi A 168, 27–35 (1998)

I.S. Servi, D. Turnbull, Acta Metall. Mater. 14, 161–169 (1966)

F.K. Legoues, H.I. Aaronson, Acta Metall. 32, 1855–1864 (1984)

M. Breu, W. Gust, B. Predel, Z. Metallkd. 82, 279–288 (1991)

W. Wagner, Acta Metall. Mater. 38, 2711–2719 (1990)

T. Ebel, R. Kampmann, R. Wagner, J. Phys. IV 3, 295–298 (1993)

G. Goerigk, H.G. Haubold, W. Schilling, J. Appl. Crystallogr. 30, 1041–1047 (1997)

X.D. Jiang, W. Wagner, H. Wollenberger, Z. Metallkd. 82, 192–197 (1991)

R. Hattenhauer, F. Haider, Scr. Metall. Mater. 25, 1173–1178 (1991)

R.P. Setna, J.M. Hyde, A. Cerezo, G.D.W. Smith, M.F. Chisholm, Appl. Surf. Sci. 67, 368–379 (1993)

R.P. Setna, A. Cerezo, J.M. Hyde, G.D.W. Smith, Appl. Surf. Sci. 76, 203–212 (1994)

A. Heinrich, T. Al-Kassab, R. Kirchheim, Surf. Interface Anal. 39, 240–245 (2007)

F.K. Legoues, H.I. Aaronson, Y.W. Lee, Acta Metall. 32, 1845–1853 (1984)

F.K. Legoues, Y.W. Lee, H.I. Aaronson, Acta Metall. 32, 1837–1843 (1984)

H.I. Aaronson, F.K. Legoues, Metall. Trans. A 23, 1915–1945 (1992)

R. Hattenhauer, P. Haasen, Philos. Mag. A 68, 1195–1213 (1993)

M.J. Stowell, Mater. Sci. Technol. 18, 139–144 (2002)

J.D. Robson, Mater. Sci. Technol. 20, 441–448 (2004)

J.D. Robson, M.J. Stowell, Philos. Mag. 84, 3101–3115 (2004)

J. Feder, K.C. Russell, J. Lothe, G.M. Pound, Adv. Phys. 15, 111–178 (1966)

M. Hillert: in Lectures on the Theory of Phase Transformations (1975), H.I. Aaronson, ed., 2nd ed., The Minerals, Metals and Materials Society, Warrendale, 1999, pp. 1–33

Q. Du, W.J. Poole, M.A. Wells, Acta Mater. 60, 3830–3839 (2012)

M. Perez, M. Dumont, D. Acevedo-Reyes, Acta Mater. 56, 2119–2132 (2008)

M. Palumbo, S. Curiotto, L. Battezzati, CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 30, 171–178 (2006)

R. Wagner, R. Kampmann, and P.W. Voorhees: in Phase Transformations in Materials, G. Kostorz, ed., Wiley, Berlin, 2001, pp. 309–408

J.D. Eshelby, Solid State Phys. 3, 79–144 (1956)

R. Egerton: Electron Energy-Loss Spectroscopy in the Electron Microscope, Plenum Press, 1996

T. Malis, S.C. Cheng, R.F. Egerton, J. Electron. Micr. Tech. 8, 193–200 (1988)

S. Matsumura, M. Toyohara, Y. Tomokiyo, Philos. Mag. A 62, 653–670 (1990)

R. Döhl, M.P. Macht, V. Naundorf, Phys. Status Solidi A 86, 603–612 (1984)

Y.W. Lee, K.C. Russell, H.I. Aaronson, Scr. Metall. 15, 723–726 (1981)

G.J. Shiflet, Y.W. Lee, H.I. Aaronson, K.C. Russell, Scr. Metall. 15, 719–722 (1981)

E.J. Mittemeijer, Fundamentals of Materials Science (Springer Verlag, Heidelberg, 2010)

F. Liu, F. Sommer, C. Bos, E.J. Mittemeijer, Int. Mater. Rev. 52, 193–212 (2007)

B. Rheingans, Y. Ma, F. Liu, E.J. Mittemeijer, J. Non-Cryst. Solids 362, 222–230 (2013)

Y. Ma, B. Rheingans, F. Liu, E.J. Mittemeijer, J. Mater. Sci. 48, 5596–5606 (2013)

B. Rheingans, E.J. Mittemeijer, JOM 65, 1145–1154 (2013)

J.D. Robson, M.J. Jones, P.B. Prangnell, Acta Mater. 51, 1453–1468 (2003)

A. Heinrich: Ph.D. Thesis, Georg-August-Universität zu Göttingen, 2005.

J. W. Christian: The Theory of Transformations in Metals and Alloys, Pergamon Press, 2002

X.G. Lu, M. Selleby, B. Sundman, CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 29, 68–89 (2005)

Y.A. Chang, L. Himmel, J. Appl. Phys. 37, 3567–3572 (1966)

B. Strauss, F. Frey, W. Petry, J. Trampenau, K. Nicolaus, S. Shapiro, J. Bossy, Phys. Rev. B 54, 6035–6038 (1996)

Acknowledgments