Abstract

Three-dimensional hierarchical porous carbons were synthesized by direct carbonization of glucose and zinc nitrate mixtures. The effects of carbonization temperature on the formation of the microscopic pore structure were studied. When tested in 6 M KOH by three-electrode system, the carbon sample carbonized at 750 °C shows the best electrochemical performance compared to the other samples. High specific capacitance (276 F g−1) is obtained at 0.3 A g−1, and the capacitance still maintains 205 F g−1 when tested at 10 A g−1. Moreover, the sample also possesses good cycling stability with only a loss of 3.7% after 10,000 cycles at 5 A g−1. The facile preparation method and hierarchical porous structure render this carbon material a promising candidate for high-performance supercapacitors application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Electrochemical double-layer capacitors (EDLCs), one kind of supercapacitors, which store energy based on physically ion adsorption/desorption at the electrode/electrolyte interface, have been considered as promising alternative for high-power apparatuses due to their high-power density, short charge/discharge time, and long cycle life compared to batteries [1,2,3,4,5,6,7,8,9,10]. However, they usually suffer from relatively low specific capacitance. It is well known that porous carbon materials are most commonly used for EDLCs ascribed to their high specific surface area [11,12,13]. Activated carbon (AC) and various mesoporous carbon have been extensively reported as electrode material for EDLCs [14, 15]. Unfortunately, the rate performance of AC is limited because of its tortuous micropores, which is unfavorable for effective transport of electrolyte ion. Mesoporous carbon possesses favorable ion transport pathways, but they usually were prepared by template method, which involved in complicated and expensive synthesis routes [16, 17]. Moreover, the specific surface area of mesoporous carbon is always low and thus has relatively limiting specific capacitance [18].

Accordingly, carbon materials with hierarchical structure design (micro-, meso-, and macropores) are necessary to obtain good electrochemical performance. Recently, increasing attention has been concentrated for fundamental investigations on hierarchical porous carbon [19,20,21,22,23,24]. In this pore structure, micropores can provide large surface area for ion storage, while mesopores and macroporous furnish favorable ion transport pathways [25, 26]. Thus, hierarchical porous carbon would exhibit great advantages compared with other carbon materials [27, 28]. Nevertheless, the preparation process of carbon materials with hierarchical porous structure was constantly complicated and expensive [29, 30], which have severely hindered their practical application. Therefore, more facile methods should be explored to prepare hierarchical porous carbons.

Herein, we designed and synthesized three-dimensional hierarchical porous carbons through a simple method. The interaction between glucose and zinc nitrate at high temperature yielded bubble-like porous carbons with different microscopic pore structures. Interestingly, the carbonization temperature plays pivotal role in the formation of mesopores on carbon wall, neither low temperature nor high temperature can generate mesopores successfully. The carbon sample carbonized at 750 °C presents hierarchical pore structure (micro-, meso-, and macropores), leading to rapid ion transport and effective adsorption. As a result, the carbon sample exhibits good electrochemical performance when employed as electrode material for supercapacitor.

Experimental

Chemicals

In this experiment, all chemicals were used as purchased without any further processing. Deionized water was employed throughout the experiment.

Preparation of three-dimensional hierarchical porous carbon

Typically, 1 g glucose and 2 g zinc nitrate were dispersed in 5 mL deionized water, and then the solution was put into oven and heated at 120 °C for 12 h. Afterwards, the powder was annealed in tube furnace under nitrogen at desired temperature (650–850 °C) for 1 h with a heating rate of 5 °C min−1. The obtained products were then washed with 15 wt.% HCl solution. Finally, the samples were filtered, washed with abundant distilled water, and dried at 80 °C overnight. The carbon samples were labeled as HPC-x, where the x refers to the carbonization temperatures.

Material characterization

The X-ray diffraction (XRD) was measured to study the structure of as-prepared materials on a Rigaku Smart Lab X-ray diffractometer operated at 40 kV with Cu Kα radiation at a scan rate of 5° min−1. The morphologies of all the samples were analyzed by scanning electron microscopy (FESEM, Hitachi S-4800, Japan) and high-resolution transmission electron microscopy (HRTEM, JEOL-2100F). Raman spectra was recorded on a Horiva (Xplora Plus) at an excitation wavelength of 532 nm, and the Raman laser power on the sample is 0.1 mW. Nitrogen adsorption and desorption isotherms were determined by nitrogen physisorption at 77 K on a Micromeritics V-Sorb 2800P analyzer. The surface area was calculated using the Brunauer-Emmett-Teller (BET) method. Pore size distribution (PSD) in the micropore range (< 2 nm) was obtained by the Saito-Foley (SF) method, and pore size distribution in the larger range was obtained by the Barrette-Joynere-Halenda (BJH) method.

Electrochemical measurement

The electrochemical performance was tested in 6 M KOH electrolyte by the three-electrode system. Hg/HgO electrode and active carbon electrode were used as the reference electrode and the counter electrode, respectively. To prepare the working electrode, HPC-x, acetylene black and PTFE were mixed at a weight ratio of 80:15:5 to form the homogeneous slurry. Then, the slurry was continuously spread on current collectors of 1 cm2 nickel foam, and dried at 80 °C for 12 h. The mass loading of each electrode was approximately 2 mg. The fabricated electrodes were pressed at 4 MPa for 30 s, and immersed in 6 M KOH electrolyte for 24 h. The specific capacitance of the working electrodes was obtained from the galvanostatic discharge process via C = IΔt/(mΔV), where C refers the specific capacitance (F g−1), I (A) is the discharge current, Δt (s) is the discharge time, m (g) is the mass of the active material for working electrode and ΔV (V) is the potential change excluding the IR drop during the discharge process.

The galvanostatic charge-discharge measurement was recorded on a NEWARE auto-cycler. The potential window was − 1.0 to 0 V. Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) measurements were conducted on a CHI660E electrochemical workstation (Chenhua, Shanghai, China). The frequency range for the EIS measurement was from 0.01 to 105 Hz with a perturbation amplitude of 5 mV.

The complex capacitance C(ω) versus frequency can be defined as follows: C(ω) = C′(ω) − jC″(ω), the real part of the capacitance C′(ω) = (− Z″(ω))/(ω|Z(ω)|2), and imaginary part of the capacitance C″(ω) = (Z′(ω))/(ω|Z(ω)|2). Where Z(ω) is the complex impedance, Z’(ω) and Z″(ω) represent the real and imaginary parts of Z(ω), respectively. The angular frequency can be obtained by ω = 2πf.

Results and discussion

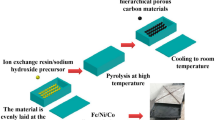

The general strategy for fabricating three-dimensional hierarchical porous carbons is illustrated in Fig. 1. In a typical synthesis, glucose as carbon source was thoroughly soaked with aqueous zinc nitrate solution at a relatively low temperature (120 °C), acquiring a uniform distribution of Zn2+ within the precursor architecture. Then, the resulting powders were followed by thermal annealing in a nitrogen atmosphere. In this process, the Zn2+ could be transformed to zinc oxide in the carbon framework at elevated temperatures [20, 31], which would serve as the pore template and etching agent. Meanwhile, the negative ions containing oxygen and nitrogen would constantly release abundant gases such as NO, NO2, and CO2, etc. [20, 32]. These gaseous phases would generate homogenous exfoliation on the intermediate product and led to the formation of bubble-like macropores. Finally, zinc oxide nanoparticles are removed after washing by HCl solution. More importantly, the micro- and mesopore structures of the carbon material could be affected by the carbonization temperature. Probably, at the other temperatures, the zinc oxide exist in the interspace of large bubbles, thus can not effectively etch the carbon wall. This result indicates that the carbonization temperature mainly influence the size of zinc oxide and the contact state of carbon and zinc oxide, and thus influence the reaction between carbon and zinc oxide. Neither low temperature nor high temperature can generate mesopores successfully, only the carbon sample carbonized at 750 °C can generate mesopores, and consequently possesses the hierarchical porous structure (micro-, meso-, and macropores).

Figure 2a–d depicts the SEM images of the carbon samples carbonized at different temperatures. We can see clearly that all of the samples exhibit a bubble-like morphology. As the carbonization temperature increases, the surface became rougher and the bubble structure is gradually destroyed. This may be due to the increased speed of gas generated from the decomposition of the precursor at higher temperature. In addition, the bubble size of all samples are approximately 2 μm, along with some small ones about 500 nm, and a greater number of smaller pores formed with the increase of the temperature.

The pore structure of the carbon samples were further observed by TEM (Fig. 3). Similarly, all of the samples exhibit a bubble-like morphology with different sizes, which is consist with SEM images. In addition, with the increase of carbonization temperature, the microstructure of these samples presents different results. At relatively low carbonization temperatures, the samples HPC-650 and HPC-700 are consist of abundant uniform micropores and small mesopores in the carbon wall. Probably because the large zinc oxide mostly exists in the interspace of large bubbles, it cannot effectively etch the carbon wall. Thus, it leads to the weak reaction between zinc oxide and carbon wall. With the temperature increased to 750 °C, the sample HPC-750 shows numerous uniform mesopores about 30–50 nm on the carbon wall. Finally, when continue to increase the carbonization temperature, the samples HPC-800 and HPC-850 present micropores instead of mesopores like HPC-750, this can be probably attributed to the collapse of the bubbles at high temperature, which hinders the effective contact and reaction between zinc oxide and carbon. Consequently, only the HPC-750 sample shows hierarchical pore distribution, which is advantageous for ion transport and effective energy storage [2]. The hierarchical meso−/macroporous structure with good pore connectivity provides some advantages: (i) the mesopores not only provide surface area for charge storage but also facilitate the transport of electrolyte in the carbon network, and the mesopores can decrease ion diffusion length and open pores that are closed, clogged, or obstructed [33]; (ii) the macropores can serve as ion buffering reservoirs to reduce the diffusion distance to the interior surface [34].

XRD spectrum of the carbon samples are shown in Fig. 4a. XRD patterns exhibit a typical diffraction peak at 24° and an inconspicuous peak at 43°, which represent the (002) and (100) planes of graphite, respectively, indicating the amorphous structure of the carbon samples [35]. Fig. 4b displays Raman spectra of the carbon samples. It is noted that all of them show a typical D (defect) band at around 1350 cm−1 and G (graphite) band at around 1580 cm−1. The G-band is assigned to the E2g symmetric vibration of sp2-bonded carbon atoms, while the D band can be attributed to the disordered or defective structures in carbon materials [36]. The intensity ratio of ID/IG are 1.11, 1.13, 1.21, 1.17, and 1.18 for the HPC-650, HPC-700, HPC-750, HPC-800, and HPC-850, respectively. With the increase of carbonization temperature, the graphitization degree decreases first and then increases, which may be resulted from the variation of pore characteristics. At first, as the temperature increases, the degree of zinc oxide etched to carbon gradually increases, thus resulting in more defects in the carbon matrix, so the graphitization degree of the carbon sample is reduced. As temperatures continue to rise, and the collapse of the bubbles at high temperature hinders the effective contact and reaction between zinc oxide and carbon, then the degree of etching to carbon decreases; therefore, the graphitization degree of carbon materials rise again.

Figure 4c, d presents N2 adsorption-desorption isotherm and the pore size distribution of the carbon sample HPC-750. According to IUPAC classification [37], the isotherm belong to type IV corresponding to porous carbon with mesopore size distribution. When the relative pressure is greater than 0.4, there is a significant hysteresis loop, which indicates that the material has a mesoporous structure. The increasing steep in the adsorbed volume at very low relative pressure indicates the presence of abundant micropores in the samples [24, 38]. The specific surface area of the material is 1204.6 m2 g−1 and the pore volume is 1.05 cm3 g−1. Figure 4d shows that the material has a hierarchical pore structure with micropores of less than 2 nm and mesopores with pore diameters of about 30 nm. Micropores can provide a large area of adsorption sites for the accumulation of charge, which can facilitate the formation of electric double-layer capacitance [39]. The mesoporous can provide a favorable path for the electrolyte ion diffusion, allowing the electrolyte ions to be transported quickly during the charge-discharge process at large current densities [40].

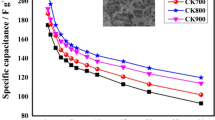

To probe the electrochemical performance of the carbon samples, cyclic voltammetry (CV), and galvanostatic charge-discharge (GCD) were measured by three-electrode system in 6 M KOH. Figure 5a presents the CV curves of the carbon samples at the scan rate of 10 mV s−1. Clearly, the samples show a rectangular-similar CV curve, suggesting its electric double-layer capacitor (EDLC) performance [41]. The GCD curves of the samples at 1 A g−1 (Fig. 5b) demonstrate that the samples show a linear characteristics, which is consistent with the CV result [42]. Obviously, the sample HPC-750 delivers the highest capacitance than other samples, which can be attributed to the favorable hierarchical porous structure consist of micro-, meso- and macropores. Moreover, CV curves of HPC-750 at different scan rates from 5 to 300 mV s−1 are presented in Fig. 5c; we can see that the slightly distorted rectangular shape has no obvious change even at high scan rate, demonstrating its good rate performance [43]. The same conclusion can be obtained from the GCD results of the HPC-750 tested at different current densities from 0.3 A g−1 to 10 A g−1 (Fig. 5d). Such a good capacitance and rate performance is derived from the considerable effect of hierarchical porous structure: the mesopores not only provide effective sites for charge storage, but also facilitate ion penetration and transport; the macropores serve as a bridge connecting the electrolyte with the internal channels of the material [2, 34]. Furthermore, the rate performance of the HPC-750 was tested from 0.3 A g−1 to 10 A g−1, as shown in Fig. 5e. High specific capacitance (276 F g−1) is obtained at 0.3 A g−1, and the capacitance still maintains 205 F g−1 when tested at 10 A g−1.The sample also shows a good cycling performance at a current density of 5 A g−1 in Fig. 5f. The specific capacitance retention after 10,000 cycles is 96.3%. The HPC-750 sample possesses appropriate pore characteristics, thus exhibiting the best electrochemical performance.

Electrochemical performance of the carbon samples tested by three-electrode system in 6 M KOH. a CV curves of the carbon samples at 10 mV s−1. b The galvanostatic charge-discharge profiles of carbon samples at 1 A g−1. c CV curves of HPC-750 from 5 mV s−1 to 300 mV s−1. d The galvanostatic charge-discharge profiles of HPC-750 from 0.3 A g−1 to 10 A g−1. e Rate performance of HPC-750. f Cycle stability of HPC-750 after 10,000 cycles at 5 A g−1

The electrochemical impedance spectroscopy (EIS) measurement was conducted to explore the resistance and capacitive property of the carbon samples (Fig. 6). The Nyquist plots (Fig. 6a) show that there is no obvious semicircle in correlation with the charge-transfer resistance [44]. The approximate vertical line at low frequency region further demonstrates the good capacitive characteristics of the carbon samples [16]. From the bode phase diagrams (Fig. 6b), it can be seen that the phase angle of all the samples are close to 90°, which is consistent with the Nyquist plots, implying that the carbon samples exhibit good capacitive characteristic. Figure 6c, d reveals the evolution of normalized real part of the capacitance C′ and imaginary part of the capacitance C′′ versus frequency, respectively. Figure 6c illustrates that the normalized C′ decreases with the increase of frequency. When C′ = 0.5, the corresponding frequency (f0) and relaxation time constant (τo = 1/2πf0) are obtained. The τo refers to the consumed time of the electrode being charged and discharged reversibly [16]. The f0 of the HPC-750 is relatively high, and the τo of the sample is 0.35 s. As shown in Fig. 6d, the normalized C′′ reaches a peak value, which represents that the component converts to purely capacitive nature [45]. Apparently, the HPC-750 are more favorable for ion diffusion than the other samples especially at higher charge-discharge rates.

Conclusions

In summary, three-dimensional hierarchical porous carbons were synthesized by direct carbonization of glucose and zinc nitrate mixtures. The effects of carbonization temperature on the formation of the microscopic pore structure were studied. The formation of a large amount of micropores provides a number of efficient adsorption site for ion storage. In addition, mesoporous structure not only provides adsorption site for ion storage but also provides fast ion transportation pathways from the solution to the inner active sites. What’s more, the bubble-like macropores serve as the electrolyte ion reservoir. Therefore, the prepared carbon sample exhibits good electrochemical performance. Also, this work opens up a facile method to produce hierarchically porous structures for unique application.

References

Simon P, Gogotsi Y, Dunn B (2014) Where do batteries end and supercapacitors begin? Science 343(6176):1210–1211. https://doi.org/10.1126/science.1249625

Wang Y, Song Y, Xia Y (2016) Electrochemical capacitors: mechanism, materials, systems, characterization and applications. Chem Soc Rev 45(21):5925–5950. https://doi.org/10.1039/C5CS00580A

Huang P, Lethien C, Pinaud S, Brousse K, Laloo R, Turq V, Respaud M, Demortiere A, Daffos B, Taberna PL, Chaudret B, Gogotsi Y, Simon P (2016) On-chip and freestanding elastic carbon films for micro-supercapacitors. Science 351(6274):691–695. https://doi.org/10.1126/science.aad3345

Li X, Wei B (2013) Supercapacitors based on nanostructured carbon. Nano Energy 2(2):159–173. https://doi.org/10.1016/j.nanoen.2012.09.008

Yang W, Yang W, Song A, Gao L, Sun G, Shao G (2017) Pyrrole as a promising electrolyte additive to trap polysulfides for lithium-sulfur batteries. J Power Sources 348:175–182. https://doi.org/10.1016/j.jpowsour.2017.03.008

Zhang S, Yin B, Liu C, Wang Z, Gu D (2017) Self-assembling hierarchical NiCo2O4/MnO2 nanosheets and MoO3/PPy core-shell heterostructured nanobelts for supercapacitor. Chem Eng J 312:296–305. https://doi.org/10.1016/j.cej.2016.11.144

Zhang S, Yin B, Wang Z, Peter F (2016) Super long-life all solid-state asymmetric supercapacitor based on NiO nanosheets and α-Fe2O3 nanorods. Chem Eng J 306:193–203. https://doi.org/10.1016/j.cej.2016.07.057

Yang W, Yang W, Song A, Sun G, Shao G (2018) 3D interconnected porous carbon nanosheet/carbon nanotube as polysulfides reservoir for high performance lithium-sulfur batteries. Nanoscale. https://doi.org/10.1039/C7NR06805K

Yin B, Wang Z, Zhang S, Liu C, Ren Q, Ke K (2016) In situ growth of free-standing all metal oxide asymmetric supercapacitor. ACS Appl Mater Interfaces 8(39):26019–26029. https://doi.org/10.1021/acsami.6b08037

Zhang S, Yin B, Liu C, Wang Z, Gu D (2017) A low-cost wearable yarn supercapacitor constructed by a highly bended polyester fiber electrode and flexible film. J Mater Chem A 5(29):15144–15153. https://doi.org/10.1039/C7TA03697C

Hao L, Li X, Zhi L (2013) Carbonaceous electrode materials for supercapacitors. Adv Mater 25(28):3899–3904. https://doi.org/10.1002/adma.201301204

Gu W, Yushin G (2014) Review of nanostructured carbon materials for electrochemical capacitor applications: advantages and limitations of activated carbon, carbide-derived carbon, zeolite-templated carbon, carbon aerogels, carbon nanotubes, onion-like carbon, and graphene. Wiley Interdiscip Rev Energy Environ 3:424–473

Jiang H, Lee PS, Li C (2013) 3D carbon based nanostructures for advanced supercapacitors. Energy Environ Sci 6(1):41–53. https://doi.org/10.1039/C2EE23284G

Puthusseri D, Aravindan V, Madhavi S, Ogale S (2014) 3D micro-porous conducting carbon beehive by single step polymer carbonization for high performance supercapacitors: the magic of in situ porogen formation. Energy Environ Sci 7(2):728–735. https://doi.org/10.1039/C3EE42551G

Zhao Y, Liu M, Gan L, Ma X, Zhu D, Xu Z, Chen L (2014) Ultramicroporous carbon nanoparticles for the high-performance electrical double-layer capacitor electrode. Energy Fuel 28(2):1561–1568. https://doi.org/10.1021/ef402070j

Saha D, Li Y, Bi Z, Chen J, Keum JK, Hensley DK, Grappe HA, Meyer HM III, Dai S, Paranthaman MP, Naskar AK (2014) Studies on supercapacitor electrode material from activated lignin-derived mesoporous carbon. Langmuir 30(3):900–910. https://doi.org/10.1021/la404112m

Kim Y, Cho C-Y, Kang J-H, Cho Y-S, Moon JH (2012) Synthesis of porous carbon balls from spherical colloidal crystal templates. Langmuir 28(28):10543–10550. https://doi.org/10.1021/la3021468

Tang D, Hu S, Dai F, Yi R, Gordin ML, Chen S, Song J, Wang D (2016) Self-templated synthesis of mesoporous carbon from carbon tetrachloride precursor for supercapacitor electrodes. ACS Appl Mater Interfaces 8(11):6779–6783. https://doi.org/10.1021/acsami.5b12164

Zhang H, Su H, Zhang L, Zhang B, Chun F, Chu X, He W, Yang W (2016) Flexible supercapacitors with high areal capacitance based on hierarchical carbon tubular nanostructures. J Power Sources 331:332–339. https://doi.org/10.1016/j.jpowsour.2016.09.064

Wang C, O’Connell MJ, Chan CK (2015) Facile one-pot synthesis of highly porous carbon foams for high-performance supercapacitors using template-free direct pyrolysis. ACS Appl Mater Interfaces 7(16):8952–8960. https://doi.org/10.1021/acsami.5b02453

Hasegawa G, Kanamori K, Kiyomura T, Kurata H, Abe T, Nakanishi K (2016) Hierarchically porous carbon monoliths comprising ordered mesoporous nanorod assemblies for high-voltage aqueous supercapacitors. Chem Mater 28(11):3944–3950. https://doi.org/10.1021/acs.chemmater.6b01261

Yang W, Yang W, Kong L, Song A, Qin X, Shao G (2018) Phosphorus-doped 3D hierarchical porous carbon for high-performance supercapacitors: a balanced strategy for pore structure and chemical composition. Carbon 127:557–567. https://doi.org/10.1016/j.carbon.2017.11.050

Ma X, Liu M, Gan L, Zhao Y, Chen L (2013) Synthesis of micro- and mesoporous carbon spheres for supercapacitor electrode. J Solid State Electrochem 17(8):2293–2301. https://doi.org/10.1007/s10008-013-2110-7

Miao L, Zhu D, Zhao Y, Liu M, Duan H, Xiong W, Zhu Q, Li L, Lv Y, Gan L (2017) Design of carbon materials with ultramicro-, supermicro- and mesopores using solvent- and self-template strategy for supercapacitors. Microporous Mesoporous Mater 253:1–9. https://doi.org/10.1016/j.micromeso.2017.06.032

Wang D-W, Li F, Liu M, GQ L, Cheng H-M (2008) 3D aperiodic hierarchical porous graphitic carbon material for high-rate electrochemical capacitive energy storage. Angew Chem Int Ed 47(2):373–376. https://doi.org/10.1002/anie.200702721

Yang W, Yang W, Song A, Gao L, Su L, Shao G (2017) Supercapacitance of nitrogen-sulfur-oxygen co-doped 3D hierarchical porous carbon in aqueous and organic electrolyte. J Power Sources 359:556–567. https://doi.org/10.1016/j.jpowsour.2017.05.108

You B, Jiang J, Fan S (2014) Three-dimensional hierarchically porous all-carbon foams for supercapacitor. ACS Appl Mater Interfaces 6(17):15302–15308. https://doi.org/10.1021/am503783t

Liu Z, Mi J, Yang Y, Tan X, Lv C (2014) Easy synthesis of phosphorus-incorporated three-dimensionally ordered macroporous carbons with hierarchical pores and their use as electrodes for supercapacitors. Electrochim Acta 115:206–215. https://doi.org/10.1016/j.electacta.2013.10.161

Jiang J, Bao L, Qiang Y, Xiong Y, Chen J, Guan S, Chen J (2015) Sol-gel process-derived rich nitrogen-doped porous carbon through KOH activation for supercapacitors. Electrochim Acta 158:229–236. https://doi.org/10.1016/j.electacta.2015.01.144

Zhou J, Zhang Z, Xing W, Yu J, Han G, Si W, Zhuo S (2015) Nitrogen-doped hierarchical porous carbon materials prepared from meta-aminophenol formaldehyde resin for supercapacitor with high rate performance. Electrochim Acta 153:68–75. https://doi.org/10.1016/j.electacta.2014.11.075

Liu M, Chen L, Zhu D, Duan H, Xiong W, Xu Z, Gan L, Chen L (2016) Zinc tartrate oriented hydrothermal synthesis of microporous carbons for high performance supercapacitor electrodes. Chin Chem Lett 27(3):399–404. https://doi.org/10.1016/j.cclet.2015.12.026

Zhao Y, Huang S, Xia M, Rehman S, Mu S, Kou Z, Zhang Z, Chen Z, Gao F, Hou Y (2016) N-P-O co-doped high performance 3D graphene prepared through red phosphorous-assisted “cutting-thin” technique: a universal synthesis and multifunctional applications. Nano Energy 28:346–355. https://doi.org/10.1016/j.nanoen.2016.08.053

Su H, Zhang H, Liu F, Chun F, Zhang B, Chu X, Huang H, Deng W, Gu B, Zhang H, Zheng X, Zhu M, Yang W (2017) High power supercapacitors based on hierarchically porous sheet-like nanocarbons with ionic liquid electrolytes. Chem Eng J 322:73–81. https://doi.org/10.1016/j.cej.2017.04.012

Yang W, Yang W, Ding F, Sang L, Ma Z, Shao G (2017) Template-free synthesis of ultrathin porous carbon shell with excellent conductivity for high-rate supercapacitors. Carbon 111:419–427. https://doi.org/10.1016/j.carbon.2016.10.025

Su F, Poh CK, Chen JS, Xu G, Wang D, Li Q, Lin J, Lou XW (2011) Nitrogen-containing microporous carbon nanospheres with improved capacitive properties. Energy Environ Sci 4(3):717–724. https://doi.org/10.1039/C0EE00277A

Jawhari T, Roid A, Casado J (1995) Raman spectroscopic characterization of some commercially available carbon black materials. Carbon 33(11):1561–1565. https://doi.org/10.1016/0008-6223(95)00117-V

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KS (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). Pure Appl Chem 87:1051–1069

Qian J, Liu M, Gan L, Tripathi P, Zhu D, Xu Z, Hao Z, Chen L, Wright D (2013) A seeded synthetic strategy for uniform polymer and carbon nanospheres with tunable sizes for high performance electrochemical energy storage. Chem Commun 49(29):3043–3045. https://doi.org/10.1039/c3cc41113c

Vatamanu J, Bedrov D (2015) Capacitive energy storage: current and future challenges. J Phys Chem Lett 6(18):3594–3609. https://doi.org/10.1021/acs.jpclett.5b01199

Mao Y, Duan H, Xu B, Zhang L, Hu Y, Zhao C, Wang Z, Chen L, Yang Y (2012) Lithium storage in nitrogen-rich mesoporous carbon materials. Energy Environ Sci 5(7):7950–7955. https://doi.org/10.1039/c2ee21817h

Weingarth D, Cericola D, Mornaghini FCF, Hucke T, Kötz R (2014) Carbon additives for electrical double layer capacitor electrodes. J Power Sources 266:475–480. https://doi.org/10.1016/j.jpowsour.2014.05.065

Zhang L, Yang X, Zhang F, Long G, Zhang T, Leng K, Zhang Y, Huang Y, Ma Y, Zhang M, Chen Y (2013) Controlling the effective surface area and pore size distribution of sp2 carbon materials and their impact on the capacitance performance of these materials. J Am Chem Soc 135(15):5921–5929. https://doi.org/10.1021/ja402552h

Li Y, Wang G, Wei T, Fan Z, Yan P (2016) Nitrogen and sulfur co-doped porous carbon nanosheets derived from willow catkin for supercapacitors. Nano Energy 19:165–175. https://doi.org/10.1016/j.nanoen.2015.10.038

Justin P, Meher SK, Rao GR (2010) Tuning of capacitance behavior of NiO using anionic, cationic, and nonionic surfactants by hydrothermal synthesis. J Phys Chem C 114(11):5203–5210. https://doi.org/10.1021/jp9097155

Chmiola J, Yushin G, Dash R, Gogotsi Y (2006) Effect of pore size and surface area of carbide derived carbons on specific capacitance. J Power Sources 158(1):765–772. https://doi.org/10.1016/j.jpowsour.2005.09.008

Funding

We are grateful for the financial support from the National Natural Science Foundation of China (No. 51674221) and the Postgraduate Innovation Project of Hebei Province (No. CXZZBS2017058).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, W., Yang, W., Kong, L. et al. Synthesis of three-dimensional hierarchical porous carbon for high-performance supercapacitors. Ionics 24, 3133–3141 (2018). https://doi.org/10.1007/s11581-017-2432-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2432-z